#3DPrintingMarket

Explore tagged Tumblr posts

Text

From Argon to Nitrogen: The Gases Powering Next-Gen 3D Printing

As 3D printing (additive manufacturing) continues to transform modern manufacturing, the role of specialty gases has become increasingly vital. These gases—used in processes like laser sintering, electron beam melting, and stereolithography—help improve print quality, material integrity, and equipment efficiency. The 3D printing gases market is growing in tandem with the global adoption of 3D printing across industries such as aerospace, healthcare, automotive, and consumer goods.

This blog provides a detailed overview of the 3D printing gases market, highlighting key applications, gas types, market players, and emerging trends shaping the industry.

Market Overview

The global 3D printing gases market is witnessing significant growth, driven by the rapid expansion of additive manufacturing and a rising demand for high-performance, precise 3D-printed components.

Key market drivers include:

Increasing adoption of metal 3D printing in aerospace and medical sectors

Advancements in 3D printing hardware and materials

Demand for inert and reactive gas environments for precision manufacturing

Growth in rapid prototyping and low-volume production

According to industry estimates, the 3D printing gases market is expected to grow at a CAGR exceeding 9% over the next five years, with North America and Europe leading the charge, and Asia-Pacific catching up due to booming industrialization and innovation.

Types of Gases Used in 3D Printing

Argon (Ar): Used in metal 3D printing for its inert properties, argon creates a stable atmosphere that prevents oxidation during printing.

Nitrogen (N₂): A cost-effective alternative to argon in selective laser sintering (SLS) and some polymer applications.

Oxygen (O₂): In small, controlled quantities, oxygen can influence the surface characteristics of certain materials, but is mostly avoided in metal printing due to oxidation risks.

Carbon Dioxide (CO₂): Used in specific SLA (stereolithography) and post-processing procedures for cleaning and finishing.

Hydrogen and Specialty Blends: Used in advanced alloys and experimental setups, particularly for aerospace and defense applications.

Applications Across Industries

1. Aerospace & Defense: High-precision metal printing of engine components, structural parts, and brackets demands ultra-pure gas environments to ensure part integrity.

2. Healthcare: 3D printing of implants, dental devices, and prosthetics using biocompatible materials requires gas atmospheres to maintain sterility and precision.

3. Automotive: From rapid prototyping to lightweight structural parts, gases play a role in ensuring consistent quality in high-performance materials.

4. Consumer Goods & Electronics: Applications include wearable tech, custom enclosures, and functional prototypes, often benefiting from controlled gas atmospheres to avoid contamination.

Benefits of Gases in 3D Printing

Oxidation Prevention: Inert gases prevent degradation of metal powders during laser-based manufacturing.

Improved Material Strength: Controlled environments lead to fewer defects and stronger, more uniform components.

Enhanced Surface Finish: Reduces porosity and improves the aesthetic and functional quality of printed parts.

Extended Equipment Life: Helps maintain laser and nozzle performance by reducing contamination.

Key Market Players

Several industrial gas suppliers and additive manufacturing companies are actively expanding into this space. Major players in the 3D printing gases market include:

Air Liquide

Linde plc

Air Products and Chemicals, Inc.

Praxair (now part of Linde)

Messer Group

Taiyo Nippon Sanso Corporation

Iwatani Corporation

These companies offer tailored gas supply solutions, cylinder management systems, and on-site generation for industrial 3D printing operations.

🔮 Future Outlook and Trends

The 3D printing gases market is set for rapid evolution, thanks to several upcoming trends:

Integration with IoT and gas monitoring systems for real-time atmosphere control

Emergence of hybrid gas blends to optimize different materials and machines

Decentralized gas generation to support distributed 3D printing facilities

Sustainability focus on recycling and reducing gas emissions

As industries move toward smart manufacturing and digital fabrication, demand for precise, efficient, and scalable gas solutions will continue to rise.

Conclusion

The 3D printing gases market is more than a support system—it’s a foundational pillar that enables the accuracy, safety, and efficiency of additive manufacturing. With innovation in materials, hardware, and printing techniques accelerating worldwide, specialty gases will play a critical role in shaping the future of industrial production.

Whether you're printing aerospace-grade titanium parts or biocompatible medical devices, having the right gas environment is essential for unlocking the full potential of 3D printing.

0 notes

Text

3D Printing Market Analysis Reveals Key Drivers Behind Increased Demand in Manufacturing Industries

The 3D Printing Market has seen a remarkable surge in demand within manufacturing industries, driven by a variety of key factors. As companies seek to improve efficiency, reduce production costs, and innovate with custom-made components, 3D printing has become a pivotal technology in reshaping industrial manufacturing. This blog explores the drivers behind this growing demand and what the future holds for 3D printing in manufacturing.

3D printing technology, also known as additive manufacturing, has revolutionized the way products are designed and produced. The 3D Printing Market is witnessing an influx of applications, from prototyping to full-scale production, in industries such as aerospace, automotive, and healthcare. As more manufacturers realize the potential of 3D printing, the market is poised for continued growth.

Key Drivers Behind the Increased Demand for 3D Printing in Manufacturing

Several factors are driving the increased adoption of 3D printing technology in manufacturing industries. From cost savings to the ability to produce complex geometries, the benefits of 3D printing are increasingly recognized by manufacturers around the world. Let’s look at some of the primary drivers behind this growing demand:

Cost Efficiency and Reduced Waste: 3D printing allows for the precise use of materials, which reduces waste and minimizes the need for expensive raw materials. Traditional manufacturing methods often involve subtracting material from a larger block, leading to material waste. In contrast, 3D printing builds objects layer by layer, reducing material wastage and lowering production costs.

Customization and Design Flexibility: One of the greatest advantages of 3D printing is its ability to create customized products. This is especially valuable in industries like aerospace, healthcare, and automotive, where unique parts or prototypes are often required. Manufacturers can quickly design and print custom components without the need for expensive molds or tooling.

Rapid Prototyping and Speed: 3D printing enables manufacturers to create prototypes quickly and efficiently, accelerating the product development cycle. The ability to iterate designs in a matter of hours, instead of weeks, helps manufacturers bring products to market faster. This speed is crucial in highly competitive industries where time-to-market can be a key differentiator.

Supply Chain Resilience: The COVID-19 pandemic highlighted the vulnerabilities in global supply chains, and manufacturers are now increasingly turning to 3D printing to mitigate these risks. With 3D printing, manufacturers can produce parts on demand, reducing reliance on distant suppliers and mitigating the impact of disruptions in supply chains. This has made localized production a more attractive option.

Sustainability: The growing emphasis on sustainability and eco-friendly manufacturing processes is another key factor contributing to the rise of 3D printing in manufacturing industries. As consumers and industries alike push for greener practices, 3D printing offers a way to reduce the environmental footprint of manufacturing. By reducing material waste and enabling more efficient use of resources, 3D printing supports sustainable production methods.

How the 3D Printing Market is Shaping the Future of Manufacturing

The 3D printing market is not just about producing parts—it's about transforming entire production processes. As more industries embrace additive manufacturing, the impact on the manufacturing landscape is profound:

Integration with Industry 4.0: The convergence of 3D printing with Industry 4.0 technologies, such as the Internet of Things (IoT) and artificial intelligence (AI), is reshaping manufacturing processes. The integration of smart technologies allows for real-time monitoring, predictive maintenance, and automated production, further enhancing the efficiency of 3D printing operations.

Expansion in End-Use Production: Initially, 3D printing was mostly used for prototyping, but now, it’s increasingly used for end-use production. Industries such as aerospace and automotive are using 3D printing to produce functional parts, not just prototypes. This shift is expected to drive the demand for 3D printing in industrial applications in the coming years.

Material Innovation: Innovations in 3D printing materials are expanding the possibilities of additive manufacturing. Today, manufacturers can print with a wide variety of materials, including metals, polymers, ceramics, and even biocompatible materials for medical applications. These advancements make 3D printing more versatile and applicable to a broader range of industries.

Challenges and Future Outlook for the 3D Printing Market

While the growth of 3D printing in manufacturing industries is impressive, it is not without its challenges. Issues such as limited material options, high upfront costs for equipment, and concerns over the scalability of production are some of the obstacles that manufacturers must overcome. However, as the technology continues to evolve and the cost of 3D printing systems decreases, these challenges are expected to diminish over time.

Looking ahead, the future of the 3D Printing Market looks promising. The continued advancements in material science, along with the growing need for sustainable and efficient manufacturing practices, will drive further adoption of 3D printing technology. Additionally, as more companies integrate 3D printing into their production lines, the ability to create complex, high-performance parts on-demand will become increasingly vital in meeting the demands of modern manufacturing.

Conclusion

The analysis of the 3D Printing Market reveals a landscape ripe for growth. With key drivers such as cost efficiency, design flexibility, rapid prototyping, and sustainability pushing demand, 3D printing is transforming the way manufacturers produce parts and products. As technology continues to improve, the future of manufacturing will increasingly rely on additive manufacturing solutions, shaping the next phase of industrial innovation.

#3DPrintingMarket#AdditiveManufacturing#SustainableManufacturing#CostEfficiency#RapidPrototyping#DesignInnovation#MaterialScience#IndustrialManufacturing#TechInnovation

0 notes

Text

#3DPrintingPlastics#AdditiveManufacturing#3DPrintingMarket#PlasticMaterials#MarketGrowth#3DPrintingIndustry#FutureOfManufacturing#MarketTrends#TechInnovation#GlobalMarket#PlasticsDemand#3DPrintingTechnology#IndustrialPrinting#SustainablePlastics#ManufacturingInnovation

0 notes

Text

Fused Deposition Modeling 3D Printing Market: Key Trends and Forecasts for 2031

InsightAce Analytic Pvt. Ltd. announces the release of a market assessment report on the "Global Fused Deposition Modeling 3D printing Market – (By Type (Stereolithography, Polyjet Printing, MultiJet Printing, Colorjet Printing, Digital Light Processing, Selective Laser Sintering), By Application (Consumer, Automotive, Aerospace & Defence, Healthcare, Fashion & Aesthetics)), Trends, Industry Competition Analysis, Revenue and Forecast To 2031."

According to the latest research by InsightAce Analytic, the Global Fused Deposition Modeling 3D printing Market is predicted to grow with a CAGR of 29.6% during the forecast period of 2024-2031.

Get Free Access to Demo Report, Excel Pivot and ToC: https://www.insightaceanalytic.com/request-sample/2540

The FDM (Fused Deposition Modeling) 3D printing market is experiencing robust growth driven by its versatility, cost-effectiveness, and broad applicability across various industries. FDM, a form of additive manufacturing, utilizes the process of melting and extruding thermoplastic materials in a layer-by-layer fashion to fabricate three-dimensional items according to digital blueprints. This technique is preferred due to its capability to create practical prototypes, personalized components, and even final products with exceptional accuracy and resilience. Key factors fueling market expansion include the increasing adoption of 3D printing for speedy prototyping and production, particularly in the automotive, aerospace, healthcare, and consumer goods sectors. The technology's capability to reduce lead times, optimize supply chains, and lower production costs further enhances its appeal. Moreover, advancements in material science have diversified the range of materials compatible with FDM printers, enhancing their suitability for a wider array of applications. Furthermore, with the ongoing advancement and increasing popularity of technology, the FDM 3D printing market is ready for further progress and acceptance in various industries that are looking for effective and flexible manufacturing solutions. Furthermore, with the ongoing advancement and increasing popularity of technology, the FDM 3D printing market is ready for further progress and acceptance in various industries that are looking for effective and flexible manufacturing solutions.

List of Prominent Players in the Fused Deposition Modeling 3D printing Market:

ExOne

EOS GmbH

Stratasys Ltd

XYZprinting, Inc.

Optomec

Voxeljet AG

Organovo Holdings, Inc.

EnvisionTEC

3D Systems

Markforged

Bambu Lab

Shenzhen Creality 3D Technology Co., Ltd.

ELEGOO

MakerBot

UltiMaker

INTAMSYS TECHNOLOGY CO., LTD.

Prusa Research a.s.

Flashforge

Expert Knowledge, Just a Click Away: https://calendly.com/insightaceanalytic/30min?month=2024-02

Market Dynamics:

Drivers-

The market is driven significantly by the rapid prototyping technique known as fused deposition modelling (FDM). This method facilitates the cost-effective and precise development of small functional components. Fused deposition modelling operates by utilizing a CAD/CAM-based design-specific blueprint, which is input into an FDM system. The system then directs design-specific instructions to the controller's head, ultimately extruding melted thermoplastic material to form the desired components. During the pandemic, there was a notable surge in demand for fused deposition modelling, particularly within the healthcare sector. This increase was primarily driven by the urgent need to prototype and produce moulds for medical equipment.

Challenges:

The restricted selection of materials that are compatible with FDM technology is a substantial obstacle. While advancements have expanded material options, FDM primarily supports thermoplastics, restricting its application in sectors requiring precise material properties such as high-temperature resistance or biocompatibility. Another challenge is the inherent limitations in printing resolution as well as surface finish compared to other 3D printing technologies like Stereolithography (SLA) or Selective Laser Sintering (SLS). This restricts FDM's suitability for applications demanding intricate details or smooth surfaces, such as in medical devices or aerospace components.

Regional Trends:

The North American fused Deposition Modeling 3D printing market is predicted to record a significant market share. North American FDM 3D printing market is characterized by continuous technological advancements, collaborations between industry players and research institutions, and increasing investments in R&D. These factors contribute to the favourable growth outlook, positioning North America as a key hub for FDM 3D printing innovation and adoption in the global market. Besides, APAC had a substantial share of the market. The expansion can be attributed to factors such as the burgeoning populations of countries such as India and China, accelerated urban development, and growing governmental support and collaborative efforts promoting technology adoption. Within the Asia-Pacific region, there is a notable rise in healthcare sector investments aimed at advancing medical equipment production, enhancing facilities, and improving infrastructure.

Unlock Your GTM Strategy: https://www.insightaceanalytic.com/customisation/2540

Recent Developments

In March 2024, Stratasys Ltd. purchased Arevo's technology portfolio, which includes its Intellectual Property (IP) estate. Stratasys will gain access to important patents related to carbon fiber printing, strategies for enhancing Z-strength, and build monitoring enabled by artificial intelligence with this acquisition. Stratasys plans to expand the variety of manufacturing applications they provide to customers by incorporating this technology into their FDM 3D printing equipment.

In Sept 2023, ExOne and BMW showcased the utilization of ExOne's binder jet 3D printing technology by BMW. BMW has collaborated with ExOne since 2002. They utilized four ExOne Exerial sand 3D printers and intend to incorporate two additional ExOne machines in the future.

Segmentation of Fused Deposition Modeling 3D printing Market-

By Type:

Stereolithography

Polyjet Printing

MultiJet Printing

Colorjet Printing

Digital Light Processing

Selective Laser Sintering

By Application:

Consumer

Automotive

Aerospace & Defence

Healthcare

Fashion & Aesthetics

By Region-

North America-

The US

Canada

Mexico

Europe-

Germany

The UK

France

Italy

Spain

Rest of Europe

Asia-Pacific-

China

Japan

India

South Korea

South East Asia

Rest of Asia Pacific

Latin America-

Brazil

Argentina

Rest of Latin America

Middle East & Africa-

GCC Countries

South Africa

Rest of Middle East and Africa

Empower Your Decision-Making with 180 Pages Full Report @ https://www.insightaceanalytic.com/buy-report/2540

About Us:

InsightAce Analytic is a market research and consulting firm that enables clients to make strategic decisions. Our qualitative and quantitative market intelligence solutions inform the need for market and competitive intelligence to expand businesses. We help clients gain competitive advantage by identifying untapped markets, exploring new and competing technologies, segmenting potential markets and repositioning products. Our expertise is in providing syndicated and custom market intelligence reports with an in-depth analysis with key market insights in a timely and cost-effective manner.

0 notes

Text

Dive into the dynamic world of 3D printing technology. Our market analysis provides insights into the latest trends, technological advancements, and transformative applications driving the 3D printing industry forward.

The 3D printing industry is comprised of several segments, including hardware, materials, software, and services. Among these segments, the hardware segment is considered to be the most significant contributor to revenue generation in 2022. This can be attributed to the fact that the hardware segment includes the actual machines that perform the additive processes to create physical objects.

0 notes

Text

The report offers 3D Printing Industry Trends and is segmented by Printer Type (Desktop and Industry-grade), Technology (Stereo Lithography, Fused Deposition Modeling, Electron Beam Melting, Digital Light Processing, and Selective Laser Sintering), Material Type (Metal, Plastic, and Ceramics), End-user Industry (Automotive, Aerospace, and Defense, Healthcare, Construction and Architecture, Energy, and Food), and by Geography.

Download Free Sample Report - 3D Printing Industry

0 notes

Text

3D Printing High-Performance Plastics Market to Reach $3.4B by 2033! 🖨️🔧

3D Printing High-Performance Plastic Market is poised for rapid growth, expanding from $1.2 billion in 2023 to $3.4 billion by 2033, reflecting a CAGR of 10.5%. This market is driven by demand for lightweight, durable, and heat-resistant materials across aerospace, automotive, and healthcare sectors.

To Request Sample Report: https://www.globalinsightservices.com/request-sample/?id=GIS21079 &utm_source=SnehaPatil&utm_medium=Article

Key Market Trends

PEEK & PAEK Leading the Market Holding a 38% market share, PEEK (Polyetheretherketone) dominates due to its high strength, heat resistance, and chemical stability, making it indispensable for aerospace and medical applications.

Polycarbonate (PC) Rising Capturing 20% of the market, PC is gaining traction in electronics and consumer goods due to its impact resistance and versatility.

North America & Europe Spearheading Growth North America leads due to technological advancements and strong R&D investments, while Europe follows closely, driven by sustainable manufacturing initiatives. Asia-Pacific is emerging as a high-growth region, fueled by industrialization and government support in China & India.

AI & Automation Reshaping the Industry The integration of AI in design and manufacturing is set to revolutionize 3D printing processes, optimizing material usage and production efficiency.

Market Segmentation

By Material: PEEK, PEI, PPSU, Nylon, PC, ABS, PLA

By Technology: SLA, FDM, SLS, MJF, EBM, DLP

By Application: Aerospace, Automotive, Healthcare, Electronics

By Key Players: Stratasys Ltd., 3D Systems Corporation, Arkema Group

Future Outlook

Despite challenges like high material costs and regulatory constraints, the market’s focus on sustainability, AI integration, and technological advancements presents lucrative growth opportunities. A 15% increase in R&D investments by 2033 underscores commitment to innovation in the sector.

🔹 #3DPrinting #AdditiveManufacturing #HighPerformancePlastics #PEEK #AerospaceTech #AutomotiveInnovation #Medical3DPrinting #PolymerScience #AdvancedMaterials #SmartManufacturing #Industrial3DPrinting #FutureOfManufacturing #SustainableTech #EngineeringExcellence #Thermoplastics #FDMPrinting #3DMaterials #MaterialInnovation #AIinManufacturing #NextGenTechnology #ManufacturingRevolution #PolymerEngineering #LightweightMaterials #R&DInnovation #3DPrintingMarket #TechTrends

0 notes

Text

Trending News: 3D Printing Market - An Insight into Current Trends, Opportunities and Future Growth Projection

Read More: https://www.forencisresearch.com/3d-printing-market-blog/

1 note

·

View note

Text

The global 3D Printing Market size valued to USD 12.96 billion in 2019; is expected a hike of USD 107.52 billion by 2030, witnessing a CAGR of 21.2% from 2020-2030.

#3DPrintingMarket#SLA#FDM#SLS#Technology#Hardware#Software#Services#Automotive#Healthcare#Industrial#Consumer Electronics#Aerospace & Defense

0 notes

Link

Automotive 3D Printing Market by Vehicle Type (ICE & Electric Vehicles), Offering (Hardware & Software), Component, Material (Metals, Plastics, Resin & Composites), Technology (SLA, SLS, EBM, FDM, LOM, 3DIP), Application, & Region

#Automotive 3D Printing Market#Automotive3DPrintingMarket#Automotive3DPrinting#3DPrintingMarket#3DPrinting#Automotive 3D Printing#Automotive3DPrintingMarketSize#Automotive3DPrintingMarketShare#Automotive3DPrintingMarketGrowth#Automotive3DPrintingMarketTrends#Automotive3DPrintingMarketAnalysis#Automotive3DPrintingMarketOutlook#Automotive3DPrintingMarketOverview#Automotive3DPrintingMarketInsight#Automotive3DPrintingMarketReport#Automotive3DPrintingMarketTechnology#Automotive3DPrintingMarketDemand

0 notes

Text

3D Printing Plastics Market Set to Reach $7.8 Billion by 2032

Meticulous Research®—a leading global market research company, published a research report titled, ‘3D Printing Plastics Market by Type (Polylactic Acid, Polycarbonate, Polyamide), Form (Filament, Pellets, Powder), Technology (FDM, SLA, SLS), End-use Industry (Manufacturing, Healthcare, Automotive), and Geography - Global Forecast to 2032.’

According to this latest publication from Meticulous Research®, the 3D printing plastics market is projected to reach $7.8 billion by 2032, at a CAGR of 23.2% from 2025 to 2032. The growth of the 3D printing plastics market is primarily driven by the rising demand for additive manufacturing across various industries, the increasing supply of 3D printing plastics, and government initiatives supporting the adoption of 3D printing technologies. However, environmental concerns related to the disposal of plastic products and regulations for the use of specific grades of plastic restrain the growth of this market.

Furthermore, advancements in 3D printing technologies and the rising demand for bio-based plastics are expected to generate growth opportunities for the players operating in this market. However, the limited availability of suitable printing materials is a major challenge in the 3D printing plastics market.

The 3D printing plastics market is segmented by type (Acrylonitrile Butadiene Styrene (ABS), Polylactic Acid (PLA), Polycarbonate (PC), Polyethylene Terephthalate (PET), Polyvinyl Alcohol (PVA), polyamide, and other 3D printing plastics), form (filament, pellets, powder, liquid), technology (Fused Deposition Modeling (FDM), Stereolithography (SLA), Selective Laser Sintering (SLS), and other technologies), end-use industry (consumer goods, automotive, aerospace & defense, manufacturing, electronics & electrical, healthcare, energy, and other end-use industries) and geography. The study also evaluates industry competitors and analyzes the market at the regional and country levels.

Based on type, the 3D printing plastics market is segmented into Acrylonitrile Butadiene Styrene (ABS), Polylactic Acid (PLA), Polycarbonate (PC), Polyethylene Terephthalate (PET), Polyvinyl Alcohol (PVA), polyamide, and other 3D printing plastics. In 2025, the polylactic acid (PLA) segment is expected to account for the largest share of over 33% of the 3D printing plastics market. The large market share of this segment is attributed to the rising demand for bioplastics, favorable government initiatives, the performance benefits of PLA, and the rising adoption of PLA in the healthcare sector. In April 2025, Filamentive Limited (U.K.) launched a PLA 3D Printing waste recycling service to combat plastic pollution caused due to FDM 3D printing.

However, the polyamide segment is projected to register the highest CAGR during the forecast period. The segment's growth is driven by the increasing use of polyamide in the automotive and aerospace sectors due to its high strength, the growing focus on eco-friendly manufacturing solutions, and the increasing use of polyamide in consumer goods manufacturing.

Based on form, the 3D printing plastics market is segmented into filament, pellets, powder, and liquid. In 2025, the filament segment is expected to account for the largest share of over 71% of the 3D printing plastics market. The large market share of this segment is attributed to the growing use of 3D printing filaments for manufacturing commercial and military aircraft and the increasing use of filament materials in prototyping applications. Moreover, several key players are focusing on the development of materials in filament form for the 3D printing of medical implants. For instance, in October 2024, Evonik Industries AG (Germany) launched the 'world's first' carbon-fiber-reinforced PEEK filament for use in 3D-printed long-term medical implants. Moreover, this segment is also projected to register the highest CAGR during the period.

Based on technology, the 3D printing plastics market is segmented into Fused Deposition Modeling (FDM), Stereolithography (SLA), Selective Laser Sintering (SLS), and other technologies. In 2025, the fused deposition modeling (FDM) segment is expected to account for the largest share of the 3D printing plastics market. The large market share of this segment is attributed to the increasing use of FDM for small-batch and customized parts production, the increasing use of FDM by educational institutes, and the better affordability and user-friendliness of FDM compared to other technologies. Moreover, this segment is also projected to register the highest CAGR during the period.

Based on end-use industry, the 3D printing plastics market is segmented into consumer goods, automotive, aerospace & defense, manufacturing, electronics & electrical, healthcare, energy, and other end-use industries. In 2025, the manufacturing segment is expected to account for the largest share of over 26% of the 3D printing plastics market. The large market share of this segment is attributed to the growing use of 3D printing for mass production in industrial manufacturing, the increasing focus of manufacturers on reducing costs and lead times, and the increasing use of 3D-printed composite materials in manufacturing applications. In November 2024, Velo3D, Inc. (U.S.) announced that Atomic Industries (U.S.) purchased a fully integrated metal additive manufacturing solution to provide its customers with 3D-printed tooling and dies.

However, the healthcare segment is projected to register the highest CAGR during the period. The segment's growth is driven by the increasing use of 3D printing plastics for creating personalized medical devices, advancements in 3D printing materials, and the increasing development of biocompatible plastics for 3D printing of implants, scaffolds for tissue regeneration, and custom-made drugs.

Based on geography, the 3D printing plastics market is segmented into North America, Europe, Asia-Pacific, Latin America, and the Middle East & Africa. In 2025, Asia-Pacific is expected to account for the largest share of over 42% of the 3D printing plastics market. Asia-Pacific’s large market share is attributed to increased R&D funding, the growing adoption of Industry 4.0, the growing utilization of 3D printing technologies in the healthcare, construction, and education sectors, and increasing government-led strategies & policies supporting the adoption of 3D printing technologies. Moreover, this region is also projected to record the highest CAGR of over 25% during the forecast period. In May 2021, Farsoon Technologies Co., Ltd (China) partnered with Japan 3D Printer Co., Ltd. (Japan) to expand its business in Japan. The company installed Farsoon’s high-temperature HT403P 3D printer at Japan 3D Printer’s Demo Center to offer industrial SLS technology.

Key Players

The key players operating in the 3D printing plastics market include 3D Systems Corporation (U.S.), Evonik Industries AG (Germany), Arkema (France), SABIC (Saudi Arabia), Stratasys Ltd. (U.S.), Materialise nv (Belgium), CRP TECHNOLOGY S.r.l. (Italy), Formlabs Inc. (U.S.), HP Development Company, L.P. (U.S.), Dassault Systemes (France), Proto Labs, Inc. (U.S.), EOS GmbH (Germany), Avient Corporation (U.S.), Henkel AG & Co. KGaA (Germany), and Huntsman International LLC (U.S.).

Download Sample Report Here @ https://www.meticulousresearch.com/download-sample-report/cp_id=5950

Key Questions Answered in the Report:

What are the high-growth market segments in terms of the type, form, technology, and end-use industry?

What is the historical market size for the 3D printing plastics market?

What are the market forecasts and estimates for 2025–2032?

What are the major drivers, restraints, opportunities, challenges, and trends in the 3D printing plastics market?

Who are the major players in the 3D printing plastics market, and what are their market shares?

What is the competitive landscape like?

What are the recent developments in the 3D printing plastics market?

What are the growth strategies adopted by major market players?

What are the key market trends, and which are the high-growth countries?

Who are the local emerging players in the 3D printing plastics market, and how do they compete with the other players?

Contact Us: Meticulous Research® Email- [email protected] Contact Sales- +1-646-781-8004 Connect with us on LinkedIn- https://www.linkedin.com/company/meticulous-research

#3DPrintingPlastics#AdditiveManufacturing#3DPrintingMarket#PlasticMaterials#MarketGrowth#3DPrintingIndustry#FutureOfManufacturing#MarketTrends#TechInnovation#GlobalMarket#PlasticsDemand#3DPrintingTechnology#IndustrialPrinting#SustainablePlastics#ManufacturingInnovation

0 notes

Link

3D Printing Market is estimated to grow from USD 11.47 Billion in 2019 to reach USD 64.95 Billion by 2027, at a CAGR of 24.2% during the forecast period from 2020-2027.

#3DPrinting#3DPrintingMarket#3DPrintingMarketSize#3DPrintingMarketShare#3DPrintingMarketTrends#3DPrintingMarketGrowth#3DPrintingMarketOpportunities#3DPrintingMarketResearch#3DPrintingMarketAnalysis#3DPrintingMarketSize2021

0 notes

Text

3D Printing Market: Healthcare Sector Expected to Have a Significant Market Share

Market Dynamics

3D printing is a process of making three dimensional solid objects from a digital file using a 3D printer. 3D printing market growth is driven by growth of the end user industries like consumer electronics, healthcare and automotive among others. The growing demand for advanced technologies that can streamline the development process and can also help in increasing the profit margin by reducing the operational cost is further propelling the growth of the 3D printing market. Increasing investments in research and development for the technological advancements and product launches are increasing the 3D printing market size is increasing by the increasing investments in research and development for the technological advancements by the key players and new product launches with innovative features.

Market Segmentation

According to market research conducted by Knowledge Sourcing Intelligence, 3D printing has been segmented by components, technology, and geography. Based on component the market has been segmented into hardware, software, services, and material. By technology, the market has been classified into vat photopolymerization, metal extrusion, material jetting, binder jetting, direct energy deposition, powder bed fusion, and sheet lamination. On the basis of end-user, the market is segmented as healthcare, automotive, aerospace and defense, construction, and others. The healthcare segment is expected to have a significant market share. 3D printing techniques are used in the healthcare sector as it helps in combining cells work a growth factor, and biomaterials by fabricating biomedical parts to enhance the characteristics of natural tissue to the maximum extent. The technology is growing in the healthcare industry due to the benefits offered by it such as efficiency, cost-effectiveness, and convenience.

Geographically, the global market has been broken down into North America, South America, Europe, Middle East, and Africa, and Asia Pacific regions. North America holds a substantial share in the global 3D printing market share. The market share is projected on account of the presence of a large number of key players and the early adoption of new technology in the region. The US holds a major share of the North America region. Europe region is also projected to hold a significantly large share in this market owing to the increasing demand for these printers from end-user industries such as healthcare, automotive, and consumer electronics among others. Asia Pacific region is expected to grow at a rapid pace in the coming years.

According to competitive intelligence done by Knowledge Sourcing Intelligence, a water-based resins market is fragmented with hundreds of manufacturers. The players are expanding globally to mirror their customers’ requirements. As a result, they are increasingly integrating with other players. The key players include Stratasys Ltd., The Exone Company, Ultimaker BV, Xjet, HP, Materialise, SLM Solutions Group, Sciaky, Mcor Technologies Ltd., Optomec, DWS, 3DCERAM SINTO, Luxexcel Group, EnvisionTEC, and Arcam EBM among others.

Key Questions Answered in This Report:

· What are the key regions having a significant market share of the global 3D printing market?

· What are the market dynamics of the 3D printing market?

· Who are the key market players in the market?

· What is the market segmentation of the 3D printing market?

· Who are the end-users of the 3D printing market?

#3Dprintingmarket#3D printing industry#3D Printing Market Size#3D printing market company by share#3d printing market trends

0 notes

Text

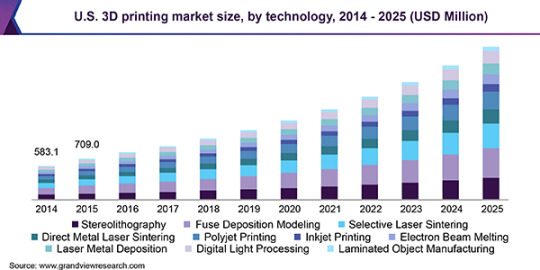

3D Printing Market Worth $23.79 Billion By 2025

The global 3D Printing market size is estimated to reach USD 23.79 billion by 2025, according to the new report by Grand View Research, Inc. It is anticipated to expand at a CAGR of 16.5% over the forecast period. 3D printing is widely adopted in the industrial sector owing to high demand for enhanced product manufacturing and a shorter time to market. The industrial vertical is anticipated to the highest market share over the forecast period.

3D Printing (3DP) is also referred to as Additive Manufacturing (AM), as it involves successive addition of layers of materials in various 2D shapes using an additive process. These layered 2D shapes build upon one another to form a three-dimensional object. The process is different from the subtractive method of production, which begins with a block of material and the unnecessary material is ground out to obtain the desired object.

3D printing continues to gain popularity among hobbyists and innovators. While individuals are using it for domestic and personal purposes; universities and educational institutes are using 3D printing for conducting technical training. The market is subject to witness a considerable economic growth in the forthcoming years. Machining shops have managed to adopt alternative business models by installing 3D printers and offering related services, such as 3D printing materials, filaments, 3D modeling, and 3D printer software, particularly in Brazil, South, Africa, and India among other developing countries.

Based on application, the 3D printing market has been segmented into prototyping, tooling, and functional parts. Apart from the industrial vertical, automotive, healthcare, and aerospace and defense verticals are among the leading adopters of the technology. Incumbents of these verticals have an emphasis on accuracy, enhanced product designing, reliability, shorter time to market, and economical production processes. Given that additive manufacturing possess can offer all these benefits, the adoption is expected to continue gaining traction over the forecast period.

The 3D printing and related technologies are evolving continuously in line with the intensive R&D activities and the aggressive investments from private and public sectors. Government funding and encouraging initiatives in developed economies are prompting manufacturers to pursue technological improvements and adoption of new technologies.

North America accounted for the largest market share of more than 35% in 2017 as a result of the extensive adoption of the technology in several industries. On the other hand, Asia Pacific has emerged as a manufacturing hub owing to an expanding consumer base and the continued Foreign Direct Investments (FDI). Hence, Asia Pacific is expected to witness a remarkable growth over the forecast period.

The 3D printing technology is a capital-intensive technology. At the same time, there is a lack of knowledge regarding the advantages associated with 3D printing. Moreover, the market lacks the standard process controls and a skilled workforce required for 3D printing. These factors are expected to hinder market growth in near future. However, government initiatives aimed at increasing awareness are expected to help counter the restraints.

To request a sample copy or view summary of this report, click the link below: https://www.grandviewresearch.com/industry-analysis/3d-printing-industry-analysis

Further key findings from the study suggest:

Demand for desktop 3D printers is expected to increase over the forecast period owing to rising popularity among hobbyists for domestic, household, and personal usage as well as for training purposes In education sector

Prototyping segment dominated the 3D printing market in 2017 and is expected to expand its market share to more than 60% by 2025

The desktop 3D printing segment is expected to witness significant rise in adoption of the technology over the forecast period

Asia Pacific is forecasted to grow significantly owing to continued urbanization and demand from automotive, consumer electronics, aerospace and defense, and healthcare verticals, particularly in China, Japan, and South Korea among other countries

The prominent market players include Stratasys Ltd.; 3D Systems, Inc.; 3D Ceram; GE Additive; HP Inc.; Tiertime; EnvisionTEC, Inc..; and Dassault Systemes.

See More Reports of This Category: https://www.grandviewresearch.com/industry/emerging-and-next-generation-technologies

About Grand View Research:

Grand View Research, Inc. is a U.S. based market research and consulting company, registered in the State of California and headquartered in San Francisco. The company provides syndicated research reports, customized research reports, and consulting services. To help clients make informed business decisions, we offer market intelligence studies ensuring relevant and fact-based research across a range of industries, from technology to chemicals, materials and healthcare.

0 notes

Text

Global 3D Printing Parts And Accessories Market Analysis

3D printing is a kind of additive manufacturing that makes things by adding layer upon layer. In the context of China-US trade war and global economic volatility and uncertainty, it will have a big influence on this market. 3D Printing Parts and Accessories Report by Material, Application, and Geography Global Forecast to 2023 is a professional and comprehensive research report on the worlds major regional market conditions, focusing on the main regions (North America, Europe and Asia-Pacific) and the main countries (United States, Germany, United Kingdom, Japan, South Korea and China).

In this report, the global 3D Printing Parts and Accessories market is valued at USD XX million in 2019 and is projected to reach USD XX million by the end of 2023, growing at a CAGR of XX% during the period 2019 to 2023. The report firstly introduced the 3D Printing Parts and Accessories basics: definitions, classifications, applications and market overview; product specifications; manufacturing processes; cost structures, raw materials and so on. Then it analyzed the worlds main region market conditions, including the product price, profit, capacity, production, supply, demand and market growth rate and forecast etc. In the end, the report introduced new project SWOT analysis, investment feasibility analysis, and investment return analysis. The major players profiled in this report include: Stratasys 3D Systems GE Additive ExOne HP EOS GmbH Materialise SLM Solutions Voxeljet EnvisionTEC Category: Chemicals Market Research Aarkstore Enterprise +91 9987295242 | [email protected] | www.aarkstore.com

#Global3DPrintingPartsAndAccessories#3DPrintingPartsAndAccessoriesMarket#3DPrintingMarket#LatestMarketResearchReports

0 notes

Link

The 3D Bioprinting Market is Segmented by Technology (Syringe/Extrusion Bioprinting, Inkjet Bioprinting, Magnetic Levitation Bioprinting, Laser-assisted Bioprinting), Component (3D Bioprinters, Biomaterials, Scaffolds), Application (Drug Testing and Development, Regenerative Medicine, Food Testing, Research), and Geography.

#3dprintingmarket#3dprintingmarketgrowth#3dprintingmarketshare#3dprintingmarketanalysis#marketresearchreports#researchreports

0 notes