#RapidPrototyping

Explore tagged Tumblr posts

Text

Sheet metal fabrication custom laser cut metal sheets aluminum housing for sheet metal cutting bending service

#gdprototyping#sheetmetal#metalsheet#lasercut metal sheets#Rapidprototyping#Manufacturingservice#fabricationservices#rapid prototyping#prototype machining

3 notes

·

View notes

Text

Maadhu Creatives offers expert industrial model services to turn your ideas into reality. Our dedicated team focuses on delivering high-quality, precise models that meet your needs. Whether you have an ongoing project or need support, we're here to help! Visit our website for more information or contact us directly for clear communication. Let us bring your vision to life with top-tier industrial model solutions.

#industrialmodelmaking#3dprinting#cadsoftware#rapidprototyping#advancedmaterials#sustainablemanufacturing#automation#industrialdesign#prototype#modelmakingservices

2 notes

·

View notes

Text

The AU project leverages the benefits of additive manufacturing , (AM), computational design and the use of composite materials to drive innovation in the medical and healthcare sector. By integrating these advanced technologies, AU aims to:

Optimize pressure distribution and comfort using personalized pressure mapping data.

Reduce weight, product size, and part count, enhancing ergonomics and usability.

Ensure more effective cooling and breathability.

Extend product longevity, performance, and customizability.

Introduce cutting-edge aesthetics to help combat stigma.

Improve sustainability by prioritizing additive over traditional subtractive manufacturing processes.

For more information, get in touch or check out our submission: 🔗 Link

#industrialdesign#product#composites#design#designer#rapidprototyping#3dprinting#additive manufacturing#cushion#computationaldesign

2 notes

·

View notes

Text

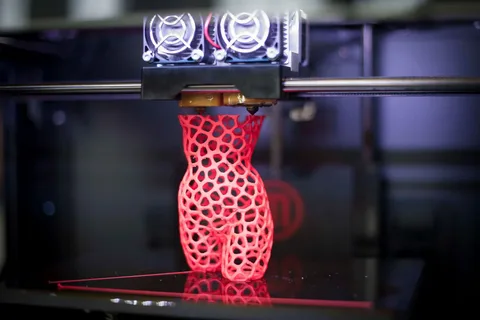

Unlocking the Potential of 3D Printing: A Guide to PrintPrizm3D

Welcome to the world of 3D printing with PrintPrizm3D! Whether you’re a hobbyist, a small business owner, or an innovator looking to turn your ideas into reality, 3D printing offers limitless possibilities. At PrintPrizm3D, we specialize in providing high-quality 3D printing services that cater to a wide range of needs. Discover how our services can help you bring your visions to life and explore the benefits of incorporating 3D printing into your projects.

What is 3D Printing?

3D printing, also known as additive manufacturing, is a process of creating three-dimensional objects from a digital file. By layering materials such as plastic, metal, or resin, 3D printers can produce complex shapes and intricate designs with precision and accuracy. This technology has revolutionized industries, including aerospace, automotive, healthcare, and fashion, by offering rapid prototyping, custom manufacturing, and cost-effective production.

Why Choose PrintPrizm3D?

At PrintPrizm3D, we pride ourselves on delivering top-notch 3D printing services. Here’s why you should choose us for your next project:

High-Quality Prints: We use advanced 3D printers and materials to ensure your prints are of the highest quality. Whether you need a prototype, a functional part, or a decorative item, we’ve got you covered.

Expertise and Experience: Our team has extensive experience in 3D printing and design, enabling us to handle a variety of projects with skill and efficiency.

Customer Satisfaction: We are committed to providing exceptional customer service. From the initial consultation to the final product, we work closely with you to meet your specific needs and expectations.

Our Services

PrintPrizm3D offers a comprehensive range of 3D printing services to cater to various requirements:

Prototyping: Quickly and accurately create prototypes to test and refine your designs.

Custom Manufacturing: Produce custom parts and products tailored to your specifications.

Design Services: Our expert designers can help you create and optimize your 3D models for printing.

Educational Workshops: Learn about 3D printing technology and its applications through our informative workshops.

Visit Our Online Stores

Explore our wide range of 3D printed products and services on our online platforms:

PrintPrizm3D Website: PrintPrizm3D Website

PrintPrizm3D eBay Store: PrintPrizm3D eBay Store

Connect with Us on Social Media

Stay updated with our latest projects, promotions, and 3D printing tips by following us on social media:

Facebook: PrintPrizm3D Facebook Page

Instagram: PrintPrizm3D Instagram

Rippin-R-Us Instagram: Rippin-R-Us Instagram

Rippin-R-Us Facebook: Rippin-R-Us Facebook

Get in Touch

Have questions or need assistance with your 3D printing project? Contact us at [email protected]. We’re here to help you every step of the way!

Conclusion

3D printing is transforming the way we create and innovate. At PrintPrizm3D, we’re dedicated to providing high-quality 3D printing services that help you turn your ideas into reality. Visit our online stores, connect with us on social media, and discover how we can assist you with your next project. Embrace the future of manufacturing with PrintPrizm3D!

For further insights and tips on 3D printing, subscribe to our blog and stay tuned for more updates. Happy printing!

#ShopNow#OrderNow#BuyNow#LimitedEdition#NewArrival#3DPrinting#AdditiveManufacturing#3DPrint#3DPrintingCommunity#3DPrintingTechnology#3DPrinted#3DPrinter#3DPrintingService#Prototyping#ProductDesign#CustomManufacturing#RapidPrototyping#Engineering#ProductDevelopment#TechInnovation#eBayStore#eBayDeals#ShopOnEbay#EbayFinds#EbaySeller#FacebookMakers#3DPrintingFB#MakerSpace#Insta3DPrinting#3DPrintingArt

2 notes

·

View notes

Text

Speed meets precision in every step of your product journey.

Createproto’s rapid prototyping and tooling services streamline the path from design to production with fast, accurate, and cost-effective solutions.

Whether you need functional prototypes, pre-production models, or quick-turn tooling using CNC, 3D printing, or injection molding, they deliver with industry-grade materials and tight tolerances. From aluminum and stainless steel to ABS, nylon, and PU—get validated parts faster, reduce risks, and bring your innovations to market with confidence.

Visit: https://createproto.com/services/rapid-prototyping-and-tooling/

#RapidPrototyping#RapidTooling#Createproto#CNCmachining#3DPrintedMolds#InjectionMolding#PrototypeToProduction

0 notes

Text

3D Printing Market future trends transforming manufacturing worldwide today

The 3D Printing Market is transforming manufacturing on a global scale through innovations that streamline production, reduce waste, and enable rapid prototyping across industries.

Introduction to the New Era of Manufacturing

The manufacturing world is undergoing a massive transformation as digitalization, automation, and new production methodologies converge. Among these, 3D printing—or additive manufacturing—stands out as a technology reshaping industrial paradigms. Unlike subtractive manufacturing, which removes material from a solid block, 3D printing builds up components layer by layer, enabling more precise, customizable, and resource-efficient production.

As global industries adapt to increasing demands for sustainability, speed, and efficiency, 3D printing offers a unique solution that meets these needs while reducing production costs and timelines. From small-scale prototyping to full-scale production runs, this technology is leading the charge into a new industrial age.

Key Future Trends Shaping the Market

The 3D printing market is evolving with technological breakthroughs that promise to enhance capabilities and widen its application. Here are some of the major trends:

1. Advanced Materials Innovation

A significant trend in 3D printing is the development of new and improved materials. High-strength polymers, biocompatible resins, metal alloys, and even concrete are expanding the possibilities of additive manufacturing. These materials enable printing of components that meet the structural and functional requirements of various industries, including aerospace, healthcare, and construction.

2. Mass Customization and On-Demand Manufacturing

One of the core advantages of 3D printing is customization. As consumer demand shifts toward personalized products, companies are leveraging additive manufacturing to create bespoke solutions—from custom footwear to personalized medical implants. This trend also supports on-demand manufacturing, which reduces the need for large inventories and shortens the supply chain.

3. Integration with AI and Machine Learning

Artificial intelligence (AI) and machine learning are increasingly being integrated with 3D printing systems. These tools optimize print paths, improve print quality, and predict equipment maintenance needs. By enabling smarter and more efficient manufacturing processes, AI is enhancing the reliability and speed of 3D printing operations.

4. Decentralized and Localized Manufacturing

3D printing supports decentralized production models, where manufacturing can occur closer to the point of demand. This localization reduces transportation costs, shortens lead times, and minimizes the carbon footprint. In the post-pandemic world, many companies are shifting to such flexible models to enhance supply chain resilience.

5. Sustainability and Waste Reduction

Environmental sustainability is a major driver for adopting 3D printing. Traditional manufacturing often generates significant waste, whereas additive manufacturing uses only the material needed to build the product. This not only conserves raw materials but also contributes to lower energy consumption.

Sector-Specific Transformations

While 3D printing is influencing every major industry, its impact is particularly profound in the following areas:

Healthcare: Custom prosthetics, dental implants, and bioprinted tissues are revolutionizing patient care.

Aerospace: Lightweight, complex components with high strength are being created with precision.

Automotive: Rapid prototyping and custom parts are reducing product development cycles.

Construction: Large-scale 3D printers are building homes and structures faster and cheaper.

Consumer Goods: Custom jewelry, eyewear, and fashion are being made with less waste and more style.

Challenges to Widespread Adoption

Despite its promising potential, the 3D printing industry faces challenges that could affect its growth:

High Initial Investment: Setting up industrial-grade 3D printers and associated software can be expensive.

Material Limitations: While material options are growing, many applications still require specialized development.

Technical Expertise Gap: A shortage of skilled professionals who can design, operate, and maintain 3D printing systems continues to be a barrier.

Standardization Issues: Inconsistencies in quality and a lack of industry-wide standards pose risks in critical sectors like aerospace and healthcare.

Outlook for the Future

Looking ahead, the global 3D printing market is expected to experience robust growth as technological improvements continue to address current challenges. Governments and private entities are investing in R&D, and collaborative efforts among manufacturers, software developers, and educational institutions are helping bridge the skill gap.

As hardware becomes more affordable and software more intuitive, the technology will likely find deeper penetration not only in large industries but also among SMEs and even individual innovators. Companies that embrace this evolution early will gain a significant competitive advantage through cost savings, enhanced customization, and faster time-to-market.

Conclusion

The future of manufacturing is being reshaped by the capabilities and flexibility offered by 3D printing technology. It enables smarter, faster, and more sustainable production models that meet the evolving demands of a global economy. While challenges remain, the pace of innovation suggests that 3D printing will soon be as essential to manufacturing as automation and robotics are today.

#3DPrinting#AdditiveManufacturing#ManufacturingInnovation#IndustrialTechnology#SmartManufacturing#SustainableManufacturing#DigitalTransformation#FutureOfWork#TechTrends#Industry40#RapidPrototyping#AIinManufacturing#3DPrintedMaterials#CustomManufacturing

0 notes

Text

#Mouser Electronics#IIoT#IndustrialAutomation#ProtoKit#EmbeddedSystems#EdgeComputing#Innovation#SmartIndustry#RapidPrototyping#Timestech#electronicsnews#technologynews

0 notes

Text

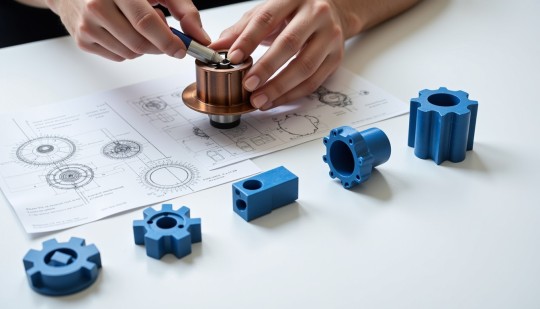

Auckam Technologies specializes in custom mechanical part design, 3D prototyping, and precision manufacturing. Using advanced CAD software and expert engineering, we turn complex technical drawings into functional components for industries like automotive, aerospace, robotics, and industrial automation. Ideal for businesses seeking rapid product development, custom gear prototyping, or CNC-ready designs. 🌐 Learn more at www.auckam.com

#CustomMechanicalParts#3DPrototyping#CADDesign#MechanicalEngineering#PrecisionManufacturing#ProductDevelopment#EngineeringServices#CNCPrototyping#RapidPrototyping#AuckamTechnologies#wwwauckamcom

0 notes

Text

Experience Design Flexibility with 3D Printing Services in India

3D printing services in India help in eliminating the setup costs and time associated with creating specialized molds or tooling. It generates less waste by adding material layer by layer, unlike subtractive manufacturing methods.Are you ready to know about our service?Know More: https://www.veetechnologies.com/industries/engineering-services-and-solutions/product-engineering-manufacturing/mechanical-testing-prototyping/3d-printing.htm

0 notes

Text

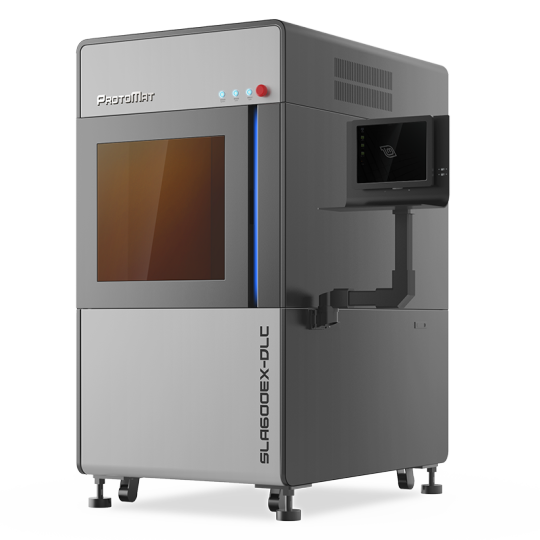

Try SLA 3D Printing for Free — Limited Time Offer

ver wanted to test SLA 3D printing before buying?

We’re offering free rental of high-resolution, industrial-grade SLA 3D printers — ideal for: ✅ Engineers ✅ Product designers ✅ Hardware startups

No cost. No commitment. Just performance.

👉 Apply here: https://www.3dprotomat.com/sla-3d-printer-free-rental/

1 note

·

View note

Link

#AIdiagnostics#cross-bordervalidation#interoperabilitysolutions#patient-centricinterfaces#PreventiveHealthcare#rapidprototyping#RegulatorySandboxes#telehealthintegration

0 notes

Text

#engineeringdesign#3Dmodelmaking#prototyping#CADmodeling#productprototype#architecturalmodel#rapidprototyping#modelmaking#prototypebuilding#industrialdesign

3 notes

·

View notes

Text

#PanasonicIndustry#IoTPrototyping#EmbeddedDevelopment#RapidPrototyping#WirelessConnectivity#powermanaement#powersemiconductor#powerelectronics

0 notes

Text

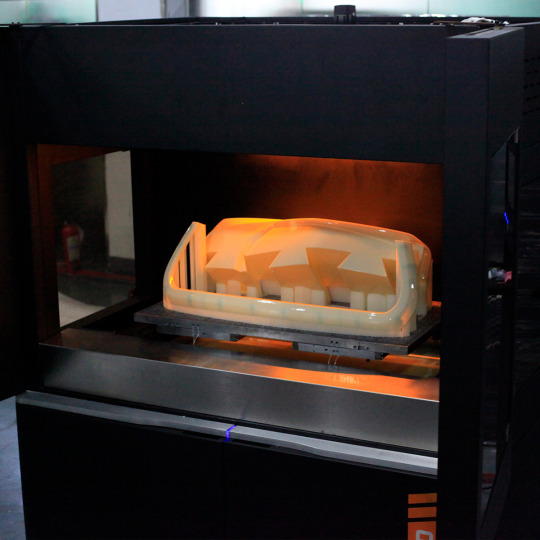

Turning ideas into reality just got faster.

Createproto’s 3D printing and rapid prototyping services empower designers and engineers to bring concepts to life with speed and precision. From quick-turn concept models to detailed, functional prototypes, their additive manufacturing solutions support a range of materials, surface finishes, and tight tolerances. Whether you’re testing form, fit, or function, get high-quality parts fast, without the cost and delay of traditional tooling.

https://createproto.com/services/3d-printing-rapid-prototyping/

#RapidPrototyping#Createproto#AdditiveManufacturing#PrototypeToProduct#IndustrialDesign#TechInnovation

1 note

·

View note

Text

3D Printing Market Analysis Reveals Key Drivers Behind Increased Demand in Manufacturing Industries

The 3D Printing Market has seen a remarkable surge in demand within manufacturing industries, driven by a variety of key factors. As companies seek to improve efficiency, reduce production costs, and innovate with custom-made components, 3D printing has become a pivotal technology in reshaping industrial manufacturing. This blog explores the drivers behind this growing demand and what the future holds for 3D printing in manufacturing.

3D printing technology, also known as additive manufacturing, has revolutionized the way products are designed and produced. The 3D Printing Market is witnessing an influx of applications, from prototyping to full-scale production, in industries such as aerospace, automotive, and healthcare. As more manufacturers realize the potential of 3D printing, the market is poised for continued growth.

Key Drivers Behind the Increased Demand for 3D Printing in Manufacturing

Several factors are driving the increased adoption of 3D printing technology in manufacturing industries. From cost savings to the ability to produce complex geometries, the benefits of 3D printing are increasingly recognized by manufacturers around the world. Let’s look at some of the primary drivers behind this growing demand:

Cost Efficiency and Reduced Waste: 3D printing allows for the precise use of materials, which reduces waste and minimizes the need for expensive raw materials. Traditional manufacturing methods often involve subtracting material from a larger block, leading to material waste. In contrast, 3D printing builds objects layer by layer, reducing material wastage and lowering production costs.

Customization and Design Flexibility: One of the greatest advantages of 3D printing is its ability to create customized products. This is especially valuable in industries like aerospace, healthcare, and automotive, where unique parts or prototypes are often required. Manufacturers can quickly design and print custom components without the need for expensive molds or tooling.

Rapid Prototyping and Speed: 3D printing enables manufacturers to create prototypes quickly and efficiently, accelerating the product development cycle. The ability to iterate designs in a matter of hours, instead of weeks, helps manufacturers bring products to market faster. This speed is crucial in highly competitive industries where time-to-market can be a key differentiator.

Supply Chain Resilience: The COVID-19 pandemic highlighted the vulnerabilities in global supply chains, and manufacturers are now increasingly turning to 3D printing to mitigate these risks. With 3D printing, manufacturers can produce parts on demand, reducing reliance on distant suppliers and mitigating the impact of disruptions in supply chains. This has made localized production a more attractive option.

Sustainability: The growing emphasis on sustainability and eco-friendly manufacturing processes is another key factor contributing to the rise of 3D printing in manufacturing industries. As consumers and industries alike push for greener practices, 3D printing offers a way to reduce the environmental footprint of manufacturing. By reducing material waste and enabling more efficient use of resources, 3D printing supports sustainable production methods.

How the 3D Printing Market is Shaping the Future of Manufacturing

The 3D printing market is not just about producing parts—it's about transforming entire production processes. As more industries embrace additive manufacturing, the impact on the manufacturing landscape is profound:

Integration with Industry 4.0: The convergence of 3D printing with Industry 4.0 technologies, such as the Internet of Things (IoT) and artificial intelligence (AI), is reshaping manufacturing processes. The integration of smart technologies allows for real-time monitoring, predictive maintenance, and automated production, further enhancing the efficiency of 3D printing operations.

Expansion in End-Use Production: Initially, 3D printing was mostly used for prototyping, but now, it’s increasingly used for end-use production. Industries such as aerospace and automotive are using 3D printing to produce functional parts, not just prototypes. This shift is expected to drive the demand for 3D printing in industrial applications in the coming years.

Material Innovation: Innovations in 3D printing materials are expanding the possibilities of additive manufacturing. Today, manufacturers can print with a wide variety of materials, including metals, polymers, ceramics, and even biocompatible materials for medical applications. These advancements make 3D printing more versatile and applicable to a broader range of industries.

Challenges and Future Outlook for the 3D Printing Market

While the growth of 3D printing in manufacturing industries is impressive, it is not without its challenges. Issues such as limited material options, high upfront costs for equipment, and concerns over the scalability of production are some of the obstacles that manufacturers must overcome. However, as the technology continues to evolve and the cost of 3D printing systems decreases, these challenges are expected to diminish over time.

Looking ahead, the future of the 3D Printing Market looks promising. The continued advancements in material science, along with the growing need for sustainable and efficient manufacturing practices, will drive further adoption of 3D printing technology. Additionally, as more companies integrate 3D printing into their production lines, the ability to create complex, high-performance parts on-demand will become increasingly vital in meeting the demands of modern manufacturing.

Conclusion

The analysis of the 3D Printing Market reveals a landscape ripe for growth. With key drivers such as cost efficiency, design flexibility, rapid prototyping, and sustainability pushing demand, 3D printing is transforming the way manufacturers produce parts and products. As technology continues to improve, the future of manufacturing will increasingly rely on additive manufacturing solutions, shaping the next phase of industrial innovation.

#3DPrintingMarket#AdditiveManufacturing#SustainableManufacturing#CostEfficiency#RapidPrototyping#DesignInnovation#MaterialScience#IndustrialManufacturing#TechInnovation

0 notes