#3DPrintingMaterials

Explore tagged Tumblr posts

Text

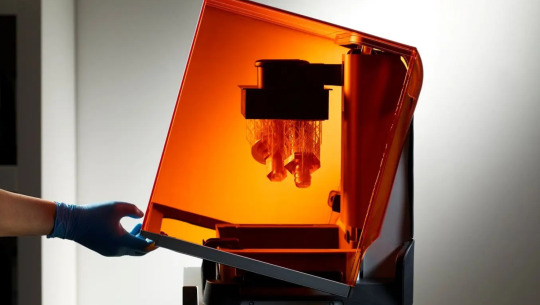

The Benefits of Using Stereolithography for Custom 3D Printing

#stereolithography#3dprinting#custom3dprinting#slaprinting#rapidprototyping#3dprintingtechnology#highprecision3dprinting#lowvolumeproduction#3dprintingmaterials#3dprintingbenefits

2 notes

·

View notes

Link

3D printing has revolutionized the world of digital art, allowing artists to transform their digital models into physical works with an unprecedented level of detail and precision. In this article, we will explore the most common technologies, available materials, and the possibilities offered by 3D printing for creating artistic figurines.

#3Dprinting#Artisticfigurines#Digitalart#3Dmodels#SLAtechnology#FDMtechnology#SLStechnology#3Dprintingmaterials#Artisticsculptures#Postproduction3Dprinting#HasbroSelfieSeries#Hasbro#Postproduction

1 note

·

View note

Text

Global Micronized Cellulose Market Expands with Demand for Sustainable Ingredients in Food, Pharma, and Cosmetics

Global Micronized Cellulose Market is witnessing significant growth due to rising demand for sustainable and high-performance materials across industries. Valued at USD 290.5 million in 2022, the market is projected to expand at a CAGR of 7.8% from 2023 to 2030, driven by increasing adoption in food, pharmaceutical, and cosmetic applications. Micronized cellulose's biodegradability, stability, and versatility make it an essential component in modern manufacturing processes.

Micronized cellulose, derived from plant-based sources, offers unique properties including high water retention, emulsification stability, and texture enhancement. Its anti-caking and thickening capabilities are particularly valuable in food processing, while pharmaceuticals leverage its binding and disintegrant properties. The material's natural origin aligns perfectly with the global push toward eco-friendly alternatives.

Download FREE Sample Report: https://www.24chemicalresearch.com/download-sample/291625/global-micronized-cellulose-market-2025-140

Market Overview & Regional Analysis

North America currently leads the micronized cellulose market, accounting for over 35% of global revenue, due to stringent food safety regulations and high R&D investments in pharmaceutical applications. The U.S. FDA's GRAS (Generally Recognized As Safe) designation for cellulose-based food additives has further accelerated adoption rates.

Europe follows closely, with Germany and France driving demand through their well-established pharmaceutical and cosmetics industries. The region's emphasis on sustainable packaging solutions presents additional growth avenues. Meanwhile, Asia-Pacific emerges as the fastest-growing market, where expanding middle-class populations and rapid industrialization in China and India are creating substantial demand across end-use sectors.

Key Market Drivers and Opportunities

The market growth stems from three primary factors: First, the food industry's need for clean-label ingredients as consumers increasingly avoid synthetic additives. Second, pharmaceutical companies require advanced excipients that enhance drug delivery efficiency. Third, the cosmetics sector's shift toward natural thickeners and stabilizers in personal care formulations.

Emerging opportunities include nanotechnology applications, where micronized cellulose's nano-fibrillated forms show promise in high-strength composites. The increasing use in biodegradable packaging films and 3D printing materials also presents untapped potential. Moreover, agricultural waste utilization for cellulose production opens new sustainable sourcing channels.

Challenges & Restraints

Despite promising growth, the market faces several hurdles. Production costs remain relatively high compared to synthetic alternatives, limiting adoption in price-sensitive markets. Variability in raw material quality, particularly from different wood pulp sources, can affect consistency. Furthermore, the lack of standardized testing methods for nanocellulose products creates regulatory uncertainties across international markets.

Tightening environmental regulations on wood pulp sourcing represent another challenge, pushing manufacturers to develop alternative agricultural feedstock. The industry must also address technical limitations in high-temperature applications where cellulose stability becomes problematic.

Market Segmentation by Type

Food Grade

Medicine Grade

Others

Download FREE Sample Report: https://www.24chemicalresearch.com/download-sample/291625/global-micronized-cellulose-market-2025-140

Market Segmentation by Application

Food products

Pharmaceutical

Cosmetic products

Others

Market Segmentation and Key Players

JRS

CFF

IFC

SWEETENER SUPPLY CORPORATION

Juku Orchem Private

JELU-WERK J. Ehrler

Ankit Pulps & Boards

NB Entrepreneurs

Nippon Paper Industries

Report Scope

This comprehensive report provides detailed analysis of the global micronized cellulose market from 2023 to 2030, including:

Market size estimates and growth projections

In-depth segmentation by type and application

Regional market analysis and country-level insights

Competitive landscape and market share analysis

Value chain and pricing analysis

Technology trends and patent analysis

Regulatory framework assessment

The study also features detailed company profiles, including business strategies, product portfolios, production capacities, and recent developments of leading market participants.

Get Full Report Here: https://www.24chemicalresearch.com/reports/291625/global-micronized-cellulose-market-2025-140

About 24chemicalresearch

Founded in 2015, 24chemicalresearch has rapidly established itself as a leader in chemical market intelligence, serving clients including over 30 Fortune 500 companies. We provide data-driven insights through rigorous research methodologies, addressing key industry factors such as government policy, emerging technologies, and competitive landscapes.

Plant-level capacity tracking

Real-time price monitoring

Techno-economic feasibility studies

With a dedicated team of researchers possessing over a decade of experience, we focus on delivering actionable, timely, and high-quality reports to help clients achieve their strategic goals. Our mission is to be the most trusted resource for market insights in the chemical and materials industries.

International: +1(332) 2424 294 | Asia: +91 9169162030

Website: https://www.24chemicalresearch.com/

Follow us on LinkedIn: https://www.linkedin.com/company/24chemicalresearch

#MicronizedCellulose#PlantBasedMaterials#SustainablePackaging#FoodAdditives#PharmaceuticalExcipients#NaturalThickeners#CleanLabelIngredients#Nanocellulose#NanoFibrillatedCellulose#BiodegradableMaterials#3DPrintingMaterials#GRASIngredient#WaterRetention#EmulsificationStability#CosmeticStabilizers#AsiaPacificGrowth#WoodPulpAlternatives

0 notes

Text

Industrial 3D Printing Materials Market, Global Outlook and Forecast 2025-2032

Industrial 3D Printing Materials Market Size,Demand & Supply, Regional and Competitive Analysis 2025-2031

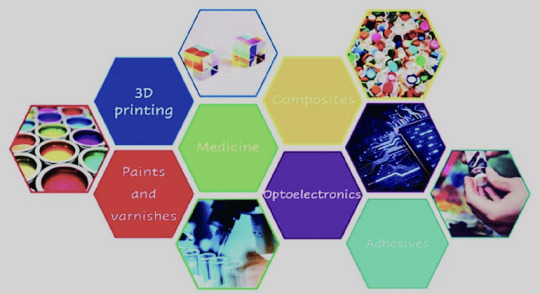

Industrial 3D Printing Materials are specialized materials used for the additive manufacturing process in various industries including automotive, aerospace, healthcare, consumer goods, and construction. These materials consist of plastics, metals, ceramics, and other advanced materials that are specifically formulated for use in 3D printing technologies.

Market Size

The global Industrial 3D Printing Materials market was valued at USD 1685 million in 2023 and is expected to reach USD 6660.90 million by 2032, with a projected CAGR of 16.50% during the forecast period. The North America Industrial 3D Printing Materials market was estimated at USD 572.04 million in 2023, showing a CAGR of 14.14% from 2025 to 2032.

Market Dynamics

Download a free Sample Report PDF

Get The Complete Report &TOC

Drivers

1. Technological Advancements: Continuous advancements in 3D printing technologies and materials are driving the demand for industrial 3D printing materials.

2. Increased Adoption Across Industries: Growing adoption of 3D printing in automotive, aerospace, and healthcare sectors is boosting the demand for industrial 3D printing materials.

3. Customization and Product Innovation: The ability of 3D printing to enable customization and innovation in product design is fueling the market growth of industrial 3D printing materials.

Restraints

1. High Initial Investment: The high initial investment required for 3D printing equipment and materials is a major barrier to market growth.

2. Regulatory Challenges: Stringent regulations and standards in industries like aerospace and healthcare can limit the adoption of industrial 3D printing materials.

3. Material Limitations: The limitations of current materials in terms of strength, durability, and performance can hinder the widespread adoption of industrial 3D printing materials.

Opportunities

1. Emerging Applications: Increasing applications of 3D printing in new industries and areas such as electronics, education, and food present untapped opportunities for industrial 3D printing materials.

2. R&D and Innovation: Continued research and development efforts to enhance material properties and develop new formulations can create opportunities for market expansion.

3. Adoption in Emerging Markets: The adoption of industrial 3D printing materials in emerging markets provides a growth opportunity due to increasing industrialization and technological advancements.

Challenges

1. Quality Control: Ensuring consistent quality and performance of 3D printed parts poses a challenge due to variations in materials and printing processes.

2. Sustainability Concerns: The environmental impact of 3D printing materials and processes, including waste generation and energy consumption, is a growing concern for sustainability.

3. Supply Chain Disruptions: Disruptions in the supply chain of raw materials and additives can impact the availability and pricing of industrial 3D printing materials.

Industrial 3D Printing Materials Market Analysis

Regional Analysis:

North America: The Industrial 3D Printing Materials market in North America has been experiencing significant growth, with key players like 3D Systems and Stratasys leading the market. The demand for industrial 3D printing materials in sectors such as aerospace, automotive, and healthcare is on the rise, driven by technological advancements and increasing adoption. Supply dynamics are robust, supported by a well-established raw material supply chain and manufacturing capabilities. Growth in this region is fueled by a strong economy, innovation, and favorable government policies.

Competitor Analysis:

Major Competitors: Leading companies in the Industrial 3D Printing Materials market include 3D Systems, Stratasys, and General Electric. These players have a significant market share and influence in the industry.

Market Share & Influence: 3D Systems and Stratasys hold a major portion of the market share, with General Electric making a strong impact as well. Their innovative technologies and product offerings contribute to their dominance in the market.

Strategies: Companies like 3D Systems and Stratasys focus on continuous innovation, strategic pricing strategies, and partnerships to enhance their market presence. General Electric emphasizes technological advancements and diversification through acquisitions to expand its market reach.

Competitive Positioning: Each company has a distinct competitive advantage. 3D Systems excels in diversified product offerings, Stratasys stands out for its strong R&D capabilities, and General Electric leads in technological advancements and global presence, positioning them uniquely in the market.

Global Industrial 3D Printing Materials Market: Market Segmentation Analysis

This report provides a deep insight into the global Industrial 3D Printing Materials market covering all its essential aspects. This ranges from a macro overview of the market to micro details of the market size, competitive landscape, development trend, niche market, key market drivers and challenges, SWOT analysis, value chain analysis, etc.

The analysis helps the reader to shape the competition within the industries and strategies for the competitive environment to enhance the potential profit. Furthermore, it provides a simple framework for evaluating and accessing the position of the business organization. The report structure also focuses on the competitive landscape of the Global Industrial 3D Printing Materials Market. This report introduces in detail the market share, market performance, product situation, operation situation, etc. of the main players, which helps the readers in the industry to identify the main competitors and deeply understand the competition pattern of the market.

In a word, this report is a must-read for industry players, investors, researchers, consultants, business strategists, and all those who have any kind of stake or are planning to foray into the Industrial 3D Printing Materials market in any manner.

Market Segmentation (by Application)

Automotive

Aerospace & defense

Healthcare

Consumer Goods

Construction

Others (Electronics, Education, Food, etc.)

Market Segmentation (by Type)

Plastic

Metal

Ceramic

Others

Key Company

3D System

Arkema

Royal DSM

ExOne Company

Stratasys

General Electric

EOS GmbH Electro

Materialise

Sandvik

Höganäs AB

FAQ

Q1.What is the current market size of Industrial 3D Printing Materials Market?

The global Industrial 3D Printing Materials market size was estimated at USD 1685 million in 2023 and is projected to reach USD 6660.90 million by 2032.

Q2.Which key companies operate in the Industrial 3D Printing Materials Market?

The major players in the market are 3D System, Arkema, Royal DSM, ExOne Company, Stratasys, General Electric, EOS GmbH Electro, Materialise, Sandvik, and Höganäs AB.

Q3.What are the key growth drivers in the Industrial 3D Printing Materials Market?

The main factors fueling market expansion include increasing demand from industries like automotive, aerospace, healthcare, and consumer goods, technological advancements, and growing adoption of 3D printing in manufacturing processes.

Q4.Which regions dominate the Industrial 3D Printing Materials Market?

The market is dominated by North America, Europe, and Asia-Pacific regions based on demand, supply, and market share contributions.

Q5.What are the emerging trends in the Industrial 3D Printing Materials Market?

Emerging trends in the market include the rise of metal 3D printing applications, advancements in ceramic materials for additive manufacturing, and the integration of 3D printing in healthcare for personalized medical devices and implants.

#Industrial3DPrinting#3DPrintingMaterials#AdditiveManufacturing#MarketForecast#GlobalMarket#AdvancedMaterials#ManufacturingTechnology#Prototyping#IndustrialInnovation#MarketTrends#Metal3DPrinting#Polymer3DPrinting#MarketGrowth#SustainableManufacturing#IndustryAnalysis#FutureOfManufacturing

0 notes

Text

#3D Printing Materials power innovation

#3D_Printing_Materials power innovation in manufacturing, healthcare, aerospace, and automotive industries. Whether for rapid prototyping, custom parts, or sustainable production, the right material ensures precision, strength, and efficiency.

Read More:

https://wemarketresearch.com/reports/3d-printing-materials-market/1338

#3DPrintingMaterials#3DPrinting#AdditiveManufacturing#Filament#ResinPrinting#SmartManufacturing#Innovation#3DPrintCommunity#RapidPrototyping

0 notes

Text

youtube

Welcome to Episode 4 of our Additive Manufacturing series! This time, we're diving deeper into advanced tools in Ansys SpaceClaim. In this session, we’ll cover essential features like creating rounded corners, using the Pull Tool to extrude sketches, and the Revolve Tool to make 3D models like spheres and pipes.

🌍 From perfecting smooth edges to designing complex geometries, this lesson will elevate your 3D modeling skills! Whether you’re creating a cylinder, a donut shape, or a complex pipe, these techniques will give you powerful control over your designs. 🎨

💡Key Highlights: 🔹 Using the Rounded Corner Tool for smooth edges. ✏️ Extruding 2D sketches with the Pull Tool. 🔄 Using the Revolve Tool to create spheres and cylinders. 📂 Saving, loading, and organizing your projects efficiently. 💡 Hands-on exercises to practice your skills!

Check out the previous episodes of this series here! https://www.youtube.com/playlist?list=PL9-f9hWLZS63LJTwIbM8vLNNKblt05aHz

#youtube#skilllync#mechanicalengineering#engineering#ansys#automotiveengineering#3dprintingmaterials#additive manufacturing

0 notes

Text

Photopolymers Market Outlook: Emerging Applications in Biomedical Engineering and Flexible Electronics

The global photopolymers market is anticipated to reach USD 5.78 billion by 2030, according to a new report by Grand View Research, Inc. The market is expected to expand at a CAGR of 10.6% from 2023 to 2030. Rising demand for prototyping across the automotive industry and designs for understanding complex surgical procedures have increased the demand for photopolymer for 3D printing. Furthermore, increasing demand for artificial jewelry and prosthetics across the global population are further propelling the market growth.

Photopolymers Market Report Highlights

The European market was valued at USD 2.60 billion in 2022 and is expected to grow at a CAGR of 10.6% from 2023 to 2030

High-performance 3D printing refers to technologies that endure exceptional capabilities in terms of high speed, precision, material options, and the highest print quality. These high-performance 3D printing technologies include selective laser melting (SLM), electron beam melting (EBM), continuous liquid interface production (CLIP), and multi-material 3D printing

Stereolithography (SLA) is the most commonly used 3D printing technology across the world. It utilizes laser light sources to carry out 3D printing of objects. The global demand for SLA-based 3D printing has rapidly increased in recent years owing to its ability to print 25–300-micron components at a high XY resolution utilizing plastic resins and photopolymers

Photopolymers in 3D printing across the dental industry have witnessed a rise in demand in the past few years on account of their benefits, such as high-quality molds, perfect & precise designs, smoother surfaces, and higher durability, in comparison to the traditional process of manufacturing molds using thermoforming

For More Details or Sample Copy please visit link @: Photopolymers Market Report

Photopolymers are imaging compositions, based on polymers, oligomers, and monomers which can be polymerized accordingly and cross-linked upon image-wise exposure to light radiation such as ultraviolet (UV) rays. Photopolymers used across VAT polymerization in the 3D printing processes are used in liquid form and when exposed to UV rays in the form of a laser (SLA 3D printing technology) or scattered light source (DLP/cDLP 3D printing technology), undergo polymerization process which hardens them into the desired shape, as per the requirement of the final 3D printed product.

Photopolymers have gained traction from VAT polymerization-based 3D printing technologies, including stereolithography (SLA), digital light processing (DLP), and continuous digital light processing (cDLP) owing to their higher conversion from the liquid state to solid state, higher aesthetic component quality, enhanced versatility, material performance, and part longevity. The manufacturing of prototypes for jewelry, dental, and automotive, among others, are the market drivers for the market across the globe.

The market space is highly competitive with the introduction of new technologies for high-quality and high-speed 3D printing by various companies. For instance, in May 2022, Merit3D set a record for printing 60,000 parts in a time period of eight hours. The record was accomplished using Magna 3D printers for high-speed polymerization technology offered by Photocentric.

#PhotopolymersMarket#3DPrintingMaterials#PhotopolymerResins#UVcuringTechnology#AdditiveManufacturing#DigitalPrintingTech#HolographicMaterials#FlexibleElectronics#SustainableMaterials#InnovationInPrinting#AdvancedManufacturing#FutureOfMaterials

0 notes

Link

#3Dprintercomponents#3Dprintermaintenance#3DPrintingHardware#3Dprintingmarkettrends#3Dprintingmaterials#3Dprintingsoftware#choosing3Dprinters#directmetallasersintering#metal3Dprinters#real-world3Dprintingapplications.

0 notes

Text

Conjure Filament Review: Testing Silk, Matte, Rainbow PLA, Other

Review by Phil Macey 3DPUK TECH Featured designs: Triple G Workshop, Kijaidesign, Stlflix

5 notes

·

View notes

Text

#fuseddepositionmodeling#3dprinting#fdmtechnology#3dprinters#rapidprototyping#3dprintingmaterials#additivemanufacturing#3dprintingindustry#advanced3dprinting#3dprintingbreakthroughs

2 notes

·

View notes

Text

"Innovations in Polylactic Acid: Market Trends and Future Outlook (2024-2033)"

Polylactic Acid (PLA) is emerging as a game-changer in the world of sustainable materials, offering a biodegradable alternative to conventional plastics. Made from renewable resources like corn starch and sugarcane, PLA is gaining traction across industries for its ability to decompose naturally and reduce environmental impact. From packaging to 3D printing, PLA is paving the way for a greener future by minimizing plastic waste and supporting a circular economy.

#PolylacticAcid #SustainableMaterials #EcoFriendlyPlastics #Biodegradable #GreenPackaging #RenewableResources #PlasticAlternatives #CircularEconomy #EnvironmentalImpact #PLA #3DPrintingMaterials #WasteReduction #GreenTech #EcoInnovation #SustainableLiving #GreenFuture #PlasticFree #NaturalDecomposition #InnovativeMaterials #EcoSolutions #FutureOfPlastics

0 notes

Text

5 Industries That Need 3D Printing Technology to Flourish in 2022

How to Build a 3D Printing BusinessEven though Chuck Hull invented 3d printing machine in the 1980s when he created and printed a little cup, the printers have just recently become more affordable to produce, allowing them to be used in a variety of innovative ways in the UK. 3D printing, also known as additive manufacturing, is the process of creating objects by depositing material in consecutive layers following the design from a digital file. Here are the top 5 most astonishing applications of 3D printing in today's world.

3D Printing That Is Edible:

Who doesn't enjoy a good chocolate bar? One of the current applications of 3D printing is the creation of edible things such as chocolate. Chocolate is the ideal material for 3d printed products in London since it hardens rapidly at room temperature, allowing chocolatiers to produce confections in any shape or form. This trend will only grow when more edible materials, such as ice cream, cookie dough, pizza, and even hamburger patties, are 3D printed. Edible 3D printing is becoming increasingly popular among professionals and individuals. 3D printing edible products is less time-consuming than traditional cooking, allows for more personalization and modification, and there is no limit to ingenuity.

Also Read: Reasons Why 3D Printing Is Gaining Rapid Popularity in UK

Manufacturing:

In a variety of industries, 3D printing is changing the way we make things. Costs have decreased as a result of advances in 3d printed consumer products technology, materials, and equipment, making it easier to adopt for general manufacturing. Short-run production and the creation of wholly new components are both possible with 3D printing, which would not be possible in a typical manufacturing environment. When 3D printing technologies are used, manufacturers can also be more nimble.

Dresses:

In the field of fashion, what role does 3D printing play? Yes, it's the next frontier in 3D printing! Nike has already used 3d printer for home use to manufacture trainers, but now designers are harnessing the technology to create incredible garments that couldn't be made any other way. Fashion and technology collide with 3D printing in the UK, and traditional fashion standards no longer apply.

Instruments of Music:

The globe witnessed the world's first live concert including entirely 3d printer for home use instruments. Instruments and instrument parts can be printed in intricate shapes that would otherwise be impossible to achieve. So far, 3D printing has produced violins, flutes, keyboards, guitars, and drums.

Body Components Can Be Printed:

The application of 3D printing in healthcare and medical is one of the most spectacular real-world instances of the technology. 3d printing machine will alter medicine and humanity's future, from bone structures that may be implanted in the human body to organs, heart, and liver tissue. These aren't just models; in many situations, these are fully functional bodily parts.

Also Read: How to Build a 3D Printing Business

1 note

·

View note

Link

The versatile range of 3D printing materials is the widest in the industry offering unparalleled aesthetic realism combined with functional performance. To ensure ultimate performance and quality, we provide a robust range of advanced materials and filament. Specifically created for concept modeling, functional prototyping and certification parts testing, they meet every exacting standard. FDM Printing Technology uses production-grade thermoplastics to ensure your 3D print material parts are built with the toughness, durability and accuracy you want, and the repeatability and stability you demand.

0 notes

Text

youtube

Welcome to Episode 3 of our Additive Manufacturing series! In this episode, we’ll explore how to refine and edit sketches in Ansys SpaceClaim. Learning how to modify geometry is essential for designing adaptable, precise models, whether you’re tweaking an existing sketch or using powerful tools like Trim and Corner.

Get ready to master the art of adjusting dimensions and trimming unwanted lines—all without starting over! 🎯 Perfect for beginners or anyone looking to polish their 3D CAD skills.

🎯 Key Highlights: ✏️ Exiting tools and selecting geometry for easy editing. 🔍 Navigating the design tree to manage individual sketch elements. 🎨 Using the Trim Tool to remove unwanted lines with precision. 🔹 Creating new corners and intersections with Create Corner Tool.

Check out the previous episodes of this series here! https://www.youtube.com/playlist?list=PL9-f9hWLZS63LJTwIbM8vLNNKblt05aHz

#youtube#skilllync#mechanicalengineering#engineering#ansys#automotiveengineering#3dprintingmaterials#additive manufacturing

0 notes

Link

J700 Dental is the first mass-produced 3D printing solution engineered for clear aligner production, and can help your dental lab take advantage of this growth market. Simplify your workflow with a fully integrated system and model accuracy that exceeds industry standards. With a streamlined plug-and-play setup and the capacity for 400 clear aligners per day, you can get to full production in just hours – meaning quicker delivery, higher patient satisfaction, and lower costs.

#3Dprintmaterial#FullColorDental3DPrinter#Dental3DPrinters#Dental3DPrintingIndustry#3dprintingmaterials

0 notes