#FlexibleElectronics

Explore tagged Tumblr posts

Text

Electrically Conductive Adhesives Market Future Trends Indicate Strong Shift Towards Miniaturized Electronics

The electrically conductive adhesives market is undergoing a transformative phase driven by the rapidly evolving demands of modern technology. With continuous developments in consumer electronics, automotive electronics, medical devices, and renewable energy systems, manufacturers are increasingly looking to conductive adhesives as reliable alternatives to traditional soldering methods. As we look ahead, several future trends are poised to shape the direction and growth of this market, making it a focal point of innovation and strategic investment.

Rise in Miniaturization and Flexible Devices

One of the most prominent trends steering the electrically conductive adhesives market is the demand for miniaturized and flexible electronic components. As wearable technology, flexible displays, foldable smartphones, and compact medical devices gain traction, traditional assembly materials struggle to keep pace with performance expectations. Electrically conductive adhesives offer mechanical flexibility, thermal stability, and excellent conductivity, making them ideal for compact, bendable devices where soldering could fail.

The move towards smaller, lighter, and more versatile electronics is not just a consumer-driven trend; it's also central to sectors like aerospace and defense, where weight savings and reliability are critical. Adhesives that provide reliable conductivity while allowing design flexibility will dominate the future, especially in smart textiles and embedded sensors.

Shift Towards Environmentally Friendly Materials

Sustainability is no longer a niche concern—it's a global mandate. The future of the electrically conductive adhesives market is increasingly influenced by environmental regulations and the push for greener electronics. Manufacturers are exploring solvent-free formulations, bio-based ingredients, and adhesives with reduced volatile organic compounds (VOCs) to meet eco-compliance without compromising performance.

With rising global awareness and government-backed regulations on hazardous substances, the market will likely see a surge in demand for products that align with green certifications. This will also extend to recyclable and biodegradable substrates that pair with conductive adhesives in packaging and flexible electronic circuits.

Expanding Role in the Automotive Sector

The automotive industry is undergoing a technological revolution led by electric vehicles (EVs), autonomous driving systems, and in-vehicle infotainment. Electrically conductive adhesives are vital in assembling batteries, sensors, and electronic control units where traditional bonding techniques are inadequate.

Future trends suggest that as vehicles become more electronically sophisticated, the reliance on conductive adhesives for EMI shielding, grounding, and thermal management will increase significantly. Their role in providing durable, vibration-resistant connections under extreme operating conditions positions them as essential in the automotive electronics ecosystem.

Advancements in Nanomaterials and Hybrid Formulations

The development of advanced materials like graphene, silver nanowires, carbon nanotubes, and hybrid nanocomposites is opening up new possibilities in conductive adhesive formulations. These innovations enhance conductivity, reduce curing time, and improve mechanical properties, enabling faster production cycles and better performance.

Future market trends will likely be shaped by the integration of these advanced materials to create adhesives that work across a broader range of substrates, temperatures, and environments. High-performance adhesives with customized functionalities—such as UV-curable, thermal conductive, or pressure-sensitive properties—are expected to grow in demand, particularly in high-reliability industries like aerospace and medical technology.

Growing Importance in Medical and Wearable Devices

Healthcare is another industry experiencing profound technological integration. Conductive adhesives are increasingly used in wearable health monitors, diagnostic devices, biosensors, and drug delivery systems. As the demand for real-time health monitoring grows, especially post-pandemic, the market is seeing a rise in bio-compatible and skin-safe adhesive technologies.

Future trends point toward the continued fusion of electronics and health tech. Conductive adhesives that enable long-term skin contact, resist sweat or moisture, and offer flexible performance in varying physiological conditions will be key to advancing the next generation of medical wearables.

Asia-Pacific Leading the Future Growth

Regionally, the Asia-Pacific market is forecasted to lead future growth due to its robust electronics manufacturing ecosystem, particularly in countries like China, Japan, South Korea, and Taiwan. With government support, increased R&D investments, and expanding EV production, the region is likely to witness the fastest adoption of advanced electrically conductive adhesives.

This regional dominance will also be bolstered by the presence of major adhesive producers, raw material suppliers, and OEMs, making Asia-Pacific the innovation hub for this market’s future.

Integration with Printed Electronics

Lastly, the growing field of printed electronics presents a promising future avenue for conductive adhesives. These adhesives are essential for connecting printed circuits, antennas, and sensors on flexible or irregular surfaces. As industries explore smart packaging, printable sensors, and IoT-enabled systems, electrically conductive adhesives will become the preferred choice for low-temperature, high-precision applications.

Conclusion

The electrically conductive adhesives market is entering an exciting phase, fueled by trends in miniaturization, sustainability, automotive evolution, wearable tech, and advanced materials. As industries across the globe embrace smarter, greener, and more compact technologies, conductive adhesives are positioned to play a pivotal role in shaping the next wave of innovation. Stakeholders who adapt to these future trends will unlock new growth opportunities and set benchmarks in performance and reliability.

#ElectricallyConductiveAdhesivesMarket#ConductiveAdhesives#ElectronicsManufacturing#FlexibleElectronics#WearableTech

0 notes

Text

#Toray Industries#PhotosensitivePolyimide#AdvancedMaterials#SemiconductorPackaging#FlexibleElectronics#Innovation#TimesTech#MaterialScience#electronicsnews#technologynews

0 notes

Text

Conductive Inks Market Growth Forecast Driven by Flexible Electronics Demand Rise

The Conductive Inks Market is undergoing substantial transformation, powered largely by the accelerating demand for flexible electronics. As industries worldwide transition from rigid circuit board architectures to bendable, stretchable, and ultra-thin designs, conductive inks have emerged as the key enabling material in this shift. Composed primarily of conductive metals such as silver and copper or carbon-based alternatives, these inks allow for seamless electronic circuit printing onto a variety of substrates, ranging from plastic and paper to fabric and glass.

With the consumer electronics industry prioritizing miniaturization and energy efficiency, the need for circuit designs that are lightweight and adaptable has become urgent. Conductive inks offer an ideal solution, particularly in applications where traditional wiring methods are no longer feasible. These include wearable technologies, foldable displays, printable batteries, and healthcare diagnostics equipment, where innovation depends heavily on the ability to embed conductivity in flexible materials.

One of the primary growth drivers is the explosive rise in flexible electronics, which has seen rapid deployment in sectors such as healthcare, automotive, consumer gadgets, and energy. The compatibility of conductive inks with low-cost, additive manufacturing techniques, including screen printing and inkjet printing, makes them particularly suitable for mass production of printed electronics. This has led to increasing commercialization of products like smartwatches, fitness bands, electronic skin patches, flexible touchscreens, and smart labels.

As the demand for flexible electronics rises, manufacturers and developers are scaling up investments in R&D to create more robust, stretchable, and printable conductive materials. The emphasis has been on improving conductivity at low curing temperatures, enhancing adhesion on polymer films, and ensuring mechanical resilience under strain. These technical advancements are supporting the expansion of conductive inks from laboratory environments to mainstream industrial manufacturing.

Silver-based conductive inks continue to dominate the market due to their high electrical conductivity, chemical stability, and proven performance in high-precision electronic applications. They are widely used in photovoltaics, RFID antennas, touchscreen panels, and printed sensors. However, the relatively high cost of silver poses a challenge for its widespread adoption in disposable and large-volume applications.

This cost constraint is prompting a shift toward alternative materials. Copper-based inks are gaining traction, especially in high-volume manufacturing, owing to their cost efficiency. Despite their susceptibility to oxidation, recent innovations in encapsulation technologies have significantly improved their stability. At the same time, carbon-based inks, including graphene and carbon nanotubes, are being explored for their flexibility, environmental benefits, and compatibility with low-temperature processing. These emerging alternatives are contributing to broader accessibility and use cases for conductive inks across industries.

The application landscape for conductive inks is rapidly diversifying. In the healthcare sector, the use of printed biosensors, medical electrodes, and wearable monitoring systems is increasing. These devices require ultra-thin, skin-conformable electronic circuits that only printed conductive inks can provide. In the automotive sector, in-mold electronics and flexible interior control panels are becoming the norm, replacing traditional wiring with lighter, integrated printed circuits. Smart packaging applications, including interactive labels and temperature-sensitive displays, are also leveraging conductive inks for enhanced functionality and brand engagement.

Another promising area of growth lies in the integration of conductive inks into energy devices such as flexible solar panels and printed batteries. These innovations are particularly appealing in off-grid and wearable energy scenarios where conventional battery formats are impractical. Furthermore, the rise of smart textiles, which embed sensors and conductive paths directly into garments, is creating new commercial avenues for ink manufacturers targeting the fashion and healthcare industries.

Regionally, Asia-Pacific dominates the global conductive inks market, primarily due to its massive electronics manufacturing base and early adoption of flexible electronics technologies. Countries such as China, Japan, South Korea, and Taiwan are at the forefront of both production and innovation. China’s rapid expansion in OLED displays and smartphone components has made it a central player, while Japan continues to lead in research and development of novel ink formulations. South Korea’s dominance in display manufacturing also positions it as a critical region for conductive ink consumption.

North America is emerging as a high-potential growth market, supported by rising R&D investments, especially in healthcare wearables and aerospace applications. The region is also witnessing growth in 3D printing and smart packaging solutions that depend on printable electronics. Europe, meanwhile, is focusing on sustainable ink formulations and regulatory frameworks, encouraging eco-friendly innovation in the market.

Looking ahead, the global conductive inks market is expected to experience robust expansion through 2030. Increasing industrial automation, the Internet of Things (IoT), and energy storage innovation are projected to amplify demand further. Companies are strategically aligning their portfolios to cater to both premium applications requiring high-performance inks and mass-market segments demanding cost-effective alternatives. Key players are also forming partnerships with material science firms, electronics OEMs, and research institutions to maintain technological leadership and secure long-term growth.

The future of the conductive inks market is inextricably tied to the evolution of flexible electronics. As industries push the boundaries of design, functionality, and form factor, the role of conductive inks will only deepen, unlocking new product classes and redefining the way circuits are integrated into the world around us.

#ConductiveInks#FlexibleElectronics#PrintedElectronics#MaterialScience#WearableTech#SmartDevices#GrapheneInks#SilverInks#MarketResearch#ElectronicsInnovation

0 notes

Text

Global Flexible Display Market Growth Analysis: Innovations, Key Players & Projections (2025-2032)

#FlexibleDisplay#OLED#AMOLED#FoldableScreen#DisplayTech#ConsumerElectronics#Smartphones#Wearables#TechInnovation#MarketTrends#NextGenDisplays#FlexibleElectronics#DigitalDisplays#FutureTech#MarketGrowth#Touchscreen#BendableScreens#DisplayMarket#EmergingTech#ThinFilm

0 notes

Text

#TransparentConductiveCoating#TCO#SmartDisplays#FlexibleElectronics#TouchscreenTechnology#Optoelectronics#ConductiveFilms#TransparentElectronics#DisplayTechnology#ThinFilmCoating#SolarCellMaterials#Nanotechnology#ElectronicMaterials

0 notes

Text

The Future is Transparent: Exploring the Growth of the Colorless Polyimide Films Market

In today’s fast-evolving landscape of advanced electronics and flexible displays, colorless polyimide (CPI) films are making headlines—and for good reason. Known for their exceptional combination of transparency, thermal stability, mechanical strength, and flexibility, these next-gen materials are poised to reshape several high-tech industries.

The global Colorless Polyimide Films Market is on a steady upward trajectory, fueled by surging demand across consumer electronics, aerospace, solar energy, and automotive sectors. The global colorless polyimide films market was valued at USD 96 million in 2022 and is projected to reach USD 1,102 million by 2027, growing at a cagr 60.0% from 2022 to 2027

But what’s driving this growth, and why now?

Why Colorless Polyimide Films?

Unlike traditional amber polyimide films, colorless variants offer optical clarity while retaining the core benefits of polyimides: high heat resistance, chemical stability, and lightweight strength. This makes them an ideal fit for foldable smartphones, wearable devices, transparent flexible circuits, and OLED displays.

As innovation in electronics leans toward flexibility and compactness, CPI films are proving to be the go-to substrate and cover film solution—especially in 5G-enabled and IoT-powered devices.

Key Growth Drivers

Rise of Foldable & Flexible Electronics

With tech giants investing heavily in foldable smartphones, e-paper, and next-gen wearable gadgets, CPI films are in high demand as protective cover layers and substrates that can bend without compromising functionality.

Renewable Energy Integration

CPI films are also gaining traction in flexible solar panels and photovoltaic cells, where transparency and durability under extreme conditions are essential. Their lightweight nature makes them suitable for aerospace and off-grid applications.

Aerospace & Defense Demand

The aerospace sector is exploring CPI films for lightweight insulation materials, sensors, and antenna components—a move that aligns with the growing need for energy efficiency and space optimization in modern aircraft.

Push for Lightweight & Sustainable Materials

Colorless polyimides support the global sustainability trend by replacing heavier materials and contributing to more efficient, environmentally friendly product designs.

Regional Trends & Market Dynamics

Asia Pacific is currently leading the charge, driven by a strong electronics manufacturing base in South Korea, China, and Japan. Meanwhile, North America and Europe are focusing on aerospace, defense, and R&D in advanced materials, fostering innovation and adoption.

While the growth outlook is positive, the market does face challenges—primarily related to high production costs and limited large-scale availability. However, with major players investing in production capacity and R&D, these barriers are expected to diminish over time.

What Lies Ahead?

As we move into an era where devices are expected to be smarter, thinner, and more flexible, colorless polyimide films will be key enablers of innovation. From enabling next-gen electronics to enhancing the durability of aerospace systems, CPI films are laying the foundation for a more transparent and connected future.

Download PDF Brochure To Know More :

For businesses operating in electronics, clean energy, or advanced manufacturing, now is the time to explore how these materials can unlock new design possibilities and market opportunities.

#ColorlessPolyimide#FlexibleElectronics#AdvancedMaterials#FoldableDevices#OLEDDisplays#Wearables#5GTechnology#RenewableEnergy#MaterialsInnovation#TechTrends#SmartManufacturing

0 notes

Text

Electroactive Polymers Market — By Type , By Application , By Geography — Global Opportunity Analysis & Industry Forecast, 2024–2030

Electroactive Polymers Market Overview

Request Sample :

Electroactive Polymers Market COVID-19 Pandemic

The outbreak of Covid-19 is having a huge impact on the economy of electronic devices. The COVID-19 pandemic caused an unprecedented increased demand for some medical devices, as well as significant disruptions in the manufacturing and supply chain operations of global medical devices. The FDA monitors the supply chain of medical products and works closely with producers and other stakeholders to assess the risk of disruption and to prevent or reduce its impact on patients, health care providers, and the general public’s health. In addition, there is a delay in imports and exports of medical devices due to the import-export restriction by the governments in various regions. All these factors are having a major impact on the Electroactive Polymers Market during the pandemic.

Report Coverage

The report: “Electroactive Polymers Market — Forecast (2024–2030)”, by IndustryARC, covers an in-depth analysis of the following segments of the electroactive polymers Industry.

By Type: Ionic Electroactive Polymers (Ionic Polymer Gels (IPG), Ionic Polymer Metal Composites (IPMC), Conductive Polymers (CP), and Carbon Nanotubes (CNT)), Electronic Electroactive Polymers (Ferroelectric Polymers, Electrostrictive Graft Elastomers, Dielectric Elastomers, Electro VIscoelastic Elastomers, Liquid Crystal Elastomer (LCE), and Others), and Others.

By Application: Actuators, Sensors, Plastic, Aviation Technology, Energy Generation, Automotive Devices, Prosthetics, Robotics, and Others.

By Geography: North America (U.S., Canada, and Mexico), Europe (U.K, Germany, France, Italy, Netherland, Spain, Russia, Belgium, and Rest of Europe), Asia-Pacific (China, Japan, India, South Korea, Australia and New Zealand, Indonesia, Taiwan, Malaysia, and Rest of APAC), South America (Brazil, Argentina, Colombia, Chile, and Rest of South America), Rest of the World (Middle East, and Africa).

Inquiry Before Buying :

Key Takeaways

Asia-Pacific dominates the Electroactive Polymers Market owing to the increasing demand for the electroactive polymers industry in the region. The increasing urbanization coupled with the rising population in APAC is the major factor driving the demand for electroactive polymers.

Electroactive polymers are extensively used for corrosion-preventing coatings in ferrous and non-ferrous alloys, actuators, damped harmonic oscillator, metamorphic biomaterials, and protective fabrics points. These properties of electroactive polymers are projected to increase market growth.

Electroactive polymers due to its unique properties find application in different end-use industries. These are lighter in weight, more durable, and have better conductive properties, unlike conventional materials (metals). During the forecast period, this factor is anticipated to drive the market.

Due to the Covid-19 pandemic, most of the countries have gone under lockdown, due to which the projects and operations of various industries such as energy generation and automotive are disruptively stopped, which is hampering the Electroactive Polymers Market growth.

Electroactive Polymers Market Segment Analysis — By Type

The conductive polymers segment held the largest share in the Electroactive Polymers Market in 2020 and is growing at a CAGR 8.10% over 2024–2030. The significant class of functional materials that have certain useful properties of both organic polymers (such as strength, plasticity, flexibility, strength, elasticity) and semiconductors (such as electric conductivity) are conducting polymers (CPs). The conductive polymers are often used in miniature boxes that have the ability to open and close, micro-robots, surgical tools, surgical robots that assemble other micro-devices. In addition, conductive polymers (CPs) are extensively used as an alternative to metallic interfaces within biomedical devices as a way of imparting electroactivity to normally passive devices such as tissue scaffolds. Thus, all these extensive characteristics of conductive polymers are the key factor anticipated to boost the demand for conductive polymers in various regions during the forecast period.

Schedule A Call :

Electroactive Polymers Market Segment Analysis — By Application

The actuator segment held the largest share in the Electroactive Polymers Market in 2020 and is expected to grow with a CAGR of 7.2% for forecast period. To maximize the actuation capability and durability, effective fabrication, shaping, and electrode techniques are being developed. Many engineers and scientists from many different disciplines are attracting attention with the impressive advances in improving their actuation strain. Due to their inherent piezoelectric effect, ferroelectric polymers, such as polyvinylidene fluoride (PVDF), are largely used in manufacturing electromechanical actuators. For biomimetic applications, these materials are especially attractive, as they can be used to make intelligent robots and other biologically inspired mechanisms. To form part of mass-produced products, many EAP actuators are still emerging and need further advancements. This requires the use of models of computational chemistry, comprehensive science of materials, electro-mechanical analytical tools, and research into material processing. Which will eventually drive is the Electroactive Polymers Market during the forecast period.

Electroactive Polymers Market Segment Analysis — By Geography

Asia-Pacific region held the largest share in the Electroactive Polymers Market in 2020 up to 38%, owing to the escalating medical device industry in the region. A key factor behind the growth of the region’s electroactive polymer market is the large demand for electroactive polymers for the manufacture of advanced implant devices for medical conditions. According to Invest India, the Indian medical device sector is projected to register a CAGR of 14.8% and is expected to reach $11.9 billion in 2021–22, and the sector is projected to reach $ 65 bn industry by 2024. According to the most recent official figures from the Ministry of Health, Labour and Welfare (MHLW), the Japanese medical devices market in 2018 was roughly $29.3 billion, up about 6.9 percent from 2017 in yen terms. And from 2018 to 2023, the medical device market in Japan is estimated to show an increment of 4.5% CAGR in yen terms. Furthermore, North America also holds a prominent market share of the Electroactive Polymers Market due to the escalating medical device industry. According to the Select USA, the United States medical device market is anticipated to rise to $208 billion by the year 2023. Thus, with the expanding medical device industry, the demand for electroactive polymers will also subsequently increase, which is anticipated to drive the Electroactive Polymers Market in the Asia Pacific and North America during the forecast period.

Electroactive Polymers Market Drivers

Increasing Automotive Production

In the automotive industry, electroactive polymers are used as actuators and sensors. For materials that are light in weight but strong and durable such as an electroactive polymer, there is high demand. By using modern electroactive polymers in numerous automotive electronic components, such as multiple sensors, accelerometers, and accelerator pedal modules, car manufacturers are attempting to achieve lightweight properties. China is the world’s largest vehicle market, according to the International Trade Administration (ITA), and the Chinese government expects the production of cars to reach 35 million by 2025. According to the International Trade Administration (ITA), in 2019 the Mexican market for electric, plug-in vehicles, and hybrid vehicles reached 25,608 units, representing a 43.8% growth over 2018. Thus, increasing automation production will require more electroactive polymers for manufacturing various automotive components, which will act as a driver for the Electroactive Polymers Market during the forecast period.

Increasing Application of Electroactive Polymers

Textiles called sensing and actuating microfibers can be directly woven into electromechanical systems such as sensors, actuators, electronics, and power sources. They can be used as smart fabrics because of the flexibility and low cost of electroactive polymers. In developing intelligent fabrics, polypyrrole and polyaniline are used. In addition, using electroactive polymers in robotics for muscle development is better, as it is more cost-effective than the semiconductor and metal materials. And robotics is widely used; hence the demand for electroactive polymers will also positively affect the market growth. Furthermore, Electroactive Polymers Market growth is increasing owing to its wide usage in areas such as medical devices, damped harmonic oscillator, electric displacement field, electrostatic discharge/electromagnetic interference, high-strain sensors, and biomimetic. Hence, the increasing application of electroactive polymers acts as a driver for the Electroactive Polymers Market.

Buy Now :

Electroactive Polymers Market Challenges

Environmental Hazards Related to the Electroactive Polymers

Raw materials which are used to produce electroactive polymers (EAPs) are difficult to extract and often harmful to the environment. The disposal of waste generated by electroactive polymers is one of the major concerns (EAPs). Improper disposal of EAP products could harm the environment and ultimately impact the food chain. Manufacturers of EAPs may experience increased costs associated with the disposal of certain electroactive polymers (EAPs) that cannot be disposed of by biodegradation. The government has, therefore, enforced strict regulations on the use of such polymers. Besides, the environmental regulations on the use of petroleum products restrict the growth of the EAPs market. These factors are hampering the electroactive polymer market growth.

Electroactive Polymers Market Landscape

Technology launches, acquisitions, and R&D activities are key strategies adopted by players in the Electroactive Polymers Market. Major players in the Electroactive Polymers Market are Solvay, Parker Hannifin, Agfa-Gevaert, 3M, Merck, Lubrizol, Novasentis, Premix, PolyOne Corporation, Celanese Corporation, and KEMET Corporation.

Key Market Players:

The Top 5 companies in the Electroactive Polymers Market are:

Merck

3M

Solvay

Parker Hannifin

Agfa-Gevaert

For more Chemicals and Materials Market reports, Please click here

#ElectroactivePolymers#SmartMaterials#ConductivePolymers#FlexibleElectronics#ShapeMemoryAlloys#PolymersInElectronics#SoftRobotics

0 notes

Text

Colorless Polyimide Films Market worth $1,102 million by 2027

The report "Colorless Polyimide Films Market by Application (Flexible Displays, Flexible Solar Cells, Flexible Printed Circuit Boards, Lighting Equipment), End-Use Industry (Electronics, Solar, Medical), and Region - Global Forecast to 2027", is expected to grow from USD 96 million in 2022 to USD 1,102 million by 2027, at a CAGR of 60.0% during the forecast period. The key factor driving the colorless polyimide market include increasing demand from applications such as flexible displays, flexible solar cells, and flexible printed circuit boards owing to its excellent heat resistance and light transmittance properties.

Download pdf-https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=16252223

Excellent light transmittance of colorless polyimide films leading to its application in flexible displays

The colorless polyimide market has been segmented into flexible displays, flexible solar cells, flexible printed circuit boards, lighting equipment, and others, on the basis of application. Amongst these, the flexible displays segment accounted for the largest share of the market in 2021. With digitalization, a significant amount of information is being consumed through electronic media such as mobiles and laptops and hence, consumers have presented demand for high-quality, convenient, and portable digital devices with advanced display designs. Designers are also looking for greater freedom in developing them and are moving away from traditional display designs to next-generation displays that are larger, thinner, lightweight, and flexible or foldable. As colorless polyimide combines the thermal resistance properties of polyimide resin with the optical performance of polymer products, it is a the forefront for making of flexible display cover windows.

Product innovation in the electronics industry presenting growth opportunities for the colorless polyimide films market

The colorless polyimide films market is segmented on the basis of end-use industry into electronics, solar, medical, and others. Out of them, the electronics segment is projected to dominate the demand for these films through the forecast period. Colorless polyimides provide excellent thermo-mechanical properties, have high chemical resistance, and are also optically transparent. These properties are suitable for manufacturing electronic components such as flexible displays and flexible printed circuit boards. With electronics companies constantly developing new products to attract potential customers, including the likes of foldable smartphones, flexible screen for laptops, and curved displays in televisions, the demand for colorless polyimides films is expected to grow during the forecast period.

Sample Request- https://www.marketsandmarkets.com/requestsampleNew.asp?id=16252223

Asia Pacific is projected to register the fastest growth between 2022 to 2027

Asia Pacific is the dominant market for colorless polyimide films. Innovation, price deflation, and rising household incomes, especially in emerging markets in Asia Pacific, have resulted in high demand for consumer electronics products in the region. Electronics companies including Oneplus, Xiaomi, Samsung, and LG, present in Asia Pacific, are well-positioned in the field of flexible electronics and dominate their commercial applications. These companies have been at the forefront in the development of electronics with flexible design using colorless polyimide films in their components. With the demand for flexible electronics gaining traction, these companies are expected to boost the production of such devices. For instance, according to OMDIA, the shipment of flexible OLED panels is expected to grow by 10 times between 2022 and 2028. Owing to these factors, the market of these films is expected to be concentrated in the Asia Pacific region through the forecast period.

DuPont (US), Kaneka Corporation (Japan), Kolon Industries Inc. (South Korea), SK Innovation Co., Ltd. (South Korea), and Sumitomo Chemical Company Ltd. (Japan) are the key players in this market. These players have adopted strategies such as expansions and new product development to enhance their position in the market.

#ColorlessPolyimideFilms#PolyimideFilms#FlexibleElectronics#TransparentPolymers#HighPerformanceMaterials#FlexibleDisplays#Optoelectronics#PolymerScience#AdvancedMaterials#ElectronicMaterials#InnovativeMaterials#PolyimideTechnology#HighTemperaturePolymers#EngineeringPlastics#FlexibleCircuits

0 notes

Text

Embracing the Future: The Cutting-Edge of Electronics Manufacturing with Avalontec

In today's fast-paced technological landscape, the electronics manufacturing industry is undergoing a remarkable transformation. Companies like Avalontec are at the forefront, shaping the future of Electronic Manufacturing Services (EMS) with innovative solutions that cater to diverse sector's

The Evolution of Electronics Manufacturing

From the early days of vacuum tubes to the revolutionary impact of transistors and integrated circuits, electronics manufacturing has seen significant milestones. Avalontec embodies this evolution, leveraging advanced technologies to deliver high-quality manufacturing solutions that meet the demands of modern consumers.

Key Trends Driving the EMS Industry

Automation and Industry 4.0: Automation is reshaping manufacturing processes, enabling real-time monitoring and optimization. The integration of IoT, AI, and machine learning enhances efficiency and reduces downtime.

Sustainability: As environmental concerns grow, manufacturers are prioritizing eco-friendly practices. Avalontec is committed to utilizing recyclable materials and energy-efficient processes to minimize its environmental impact.

Flexible and Printed Electronics: The rise of flexible electronics opens new avenues for innovative product designs, allowing for lightweight, bendable devices that cater to diverse applications, including healthcare and wearables.

Advanced Materials: The exploration of materials like graphene and nanomaterials pushes the boundaries of electronic device capabilities, enabling the creation of smaller, more efficient devices.

The Role of Collaboration

In this rapidly evolving landscape, collaboration is key. Avalontec emphasizes partnerships with suppliers, technology providers, and research institutions to drive innovation and tackle common challenges. By fostering a collaborative ecosystem, the company enhances its competitive advantage and accelerates technological advancement's

Looking Ahead

The future of electronics manufacturing is bright, characterized by endless possibilities. As consumer preferences evolve, manufacturers must remain agile and responsive, focusing on customization and sustainability. Avalontec is well-positioned to navigate these changes, ensuring it meets the demands of a dynamic market while driving innovation forwards

Leading Clean Energy & EMS industry India | Avalon (avalontec.com)

Conclusions

As we embrace the future of electronics manufacturing, companies like Avalontec lead the way with cutting-edge solutions and a commitment to excellence. By staying informed about industry trends and fostering collaboration, we can all contribute to a more innovative and sustainable future in electronics manufacturing.

#ElectronicsManufacturing#Avalontec#Innovation#Sustainability#Automation#Industry4_0#FlexibleElectronics#AdvancedMaterials#TechTrends#FutureOfManufacturing#EcoFriendly#Collaboration#SmartManufacturing#ConsumerTrends#ManufacturingExcellence#electronics manufacturing service#electronic manufacturing company#manufacturing services company#ems manufacturing services#aerospace metal fabrication#todaynews#USA#Blog#Post#wednesday#Trendynew#Trendy blog

1 note

·

View note

Text

1 note

·

View note

Text

#usa#europe#SemiFlex#RigidFlexPCB#PCBDesign#FlexibleCircuits#ElectronicEngineering#PCBManufacturing#TechInnovation#PCBTechnology#RigidFlexTechnology#ElectronicsDesign#CircuitBoard#AdvancedElectronics#EngineeringSolutions#PCBAssembly#ElectronicComponents#TechTrends#FlexibleElectronics#HighTechPCBs#PCBPrototyping

0 notes

Text

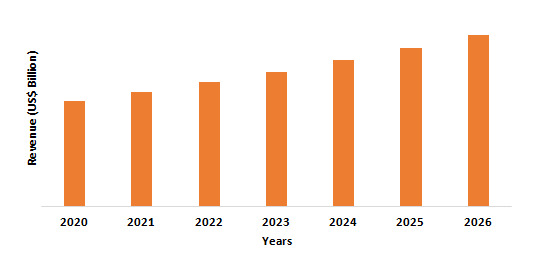

Photopolymers Market Outlook: Emerging Applications in Biomedical Engineering and Flexible Electronics

The global photopolymers market is anticipated to reach USD 5.78 billion by 2030, according to a new report by Grand View Research, Inc. The market is expected to expand at a CAGR of 10.6% from 2023 to 2030. Rising demand for prototyping across the automotive industry and designs for understanding complex surgical procedures have increased the demand for photopolymer for 3D printing. Furthermore, increasing demand for artificial jewelry and prosthetics across the global population are further propelling the market growth.

Photopolymers Market Report Highlights

The European market was valued at USD 2.60 billion in 2022 and is expected to grow at a CAGR of 10.6% from 2023 to 2030

High-performance 3D printing refers to technologies that endure exceptional capabilities in terms of high speed, precision, material options, and the highest print quality. These high-performance 3D printing technologies include selective laser melting (SLM), electron beam melting (EBM), continuous liquid interface production (CLIP), and multi-material 3D printing

Stereolithography (SLA) is the most commonly used 3D printing technology across the world. It utilizes laser light sources to carry out 3D printing of objects. The global demand for SLA-based 3D printing has rapidly increased in recent years owing to its ability to print 25–300-micron components at a high XY resolution utilizing plastic resins and photopolymers

Photopolymers in 3D printing across the dental industry have witnessed a rise in demand in the past few years on account of their benefits, such as high-quality molds, perfect & precise designs, smoother surfaces, and higher durability, in comparison to the traditional process of manufacturing molds using thermoforming

For More Details or Sample Copy please visit link @: Photopolymers Market Report

Photopolymers are imaging compositions, based on polymers, oligomers, and monomers which can be polymerized accordingly and cross-linked upon image-wise exposure to light radiation such as ultraviolet (UV) rays. Photopolymers used across VAT polymerization in the 3D printing processes are used in liquid form and when exposed to UV rays in the form of a laser (SLA 3D printing technology) or scattered light source (DLP/cDLP 3D printing technology), undergo polymerization process which hardens them into the desired shape, as per the requirement of the final 3D printed product.

Photopolymers have gained traction from VAT polymerization-based 3D printing technologies, including stereolithography (SLA), digital light processing (DLP), and continuous digital light processing (cDLP) owing to their higher conversion from the liquid state to solid state, higher aesthetic component quality, enhanced versatility, material performance, and part longevity. The manufacturing of prototypes for jewelry, dental, and automotive, among others, are the market drivers for the market across the globe.

The market space is highly competitive with the introduction of new technologies for high-quality and high-speed 3D printing by various companies. For instance, in May 2022, Merit3D set a record for printing 60,000 parts in a time period of eight hours. The record was accomplished using Magna 3D printers for high-speed polymerization technology offered by Photocentric.

#PhotopolymersMarket#3DPrintingMaterials#PhotopolymerResins#UVcuringTechnology#AdditiveManufacturing#DigitalPrintingTech#HolographicMaterials#FlexibleElectronics#SustainableMaterials#InnovationInPrinting#AdvancedManufacturing#FutureOfMaterials

0 notes

Text

Organic Electronics Research

Organic Electronics Research refers to the scientific study and development of electronic devices and systems using organic (carbon-based) materials as the active components. Unlike traditional silicon-based electronics, which rely on inorganic semiconductors like silicon and gallium arsenide, organic electronics utilize organic molecules or polymers with semiconducting properties.

Nomination Link :https://x-i.me/emcnom Get Connected Here: ================== Facebook : https://www.facebook.com/profile.php?id=61556074815651 Twitter : https://twitter.com/PencisE28647 Pinterest : https://in.pinterest.com/electronicconference/

#OrganicElectronicsResearch#OrganicElectronics#OrganicSemiconductors#OLEDResearch#OPVResearch#OTFTResearch#FlexibleElectronics#PrintedElectronics#OrganicMaterials#ConductivePolymers

0 notes

Text

Global Flexible Display Market Industry Report: Growth Insights, Challenges & Forecast (2025)

The Flexible Display Market Is Revolutionizing Modern Technology

Technology is getting a flexible upgrade—literally. With foldable smartphones, rollable televisions, and next-gen medical devices entering the mainstream, the flexible display market is experiencing unprecedented growth. Valued at USD 27.2 billion in 2023, it’s projected to skyrocket to USD 385.8 billion by 2032, growing at a CAGR of 34.3%.

What’s Powering the Growth?

📱 Demand for Foldable and Rollable Devices

Consumers are embracing devices that offer larger screens without compromising portability. Flexible OLED and AMOLED panels are leading this charge, backed by major tech investments.

⚙️ Cutting-Edge Innovations

Advancements in OLED, Micro-LED, and E-paper technologies are making displays thinner, more efficient, and more durable—perfect for folding and bending without losing performance.

📈 Expanding Use in Electronics

Flexible displays are now integral to:

Foldable smartphones

Smartwatches and fitness trackers

Curved and rollable TVs

These devices are redefining convenience, style, and user experience.

Industry Applications Beyond Gadgets

🚗 Automotive Evolution

Cars are becoming smarter with flexible displays integrated into dashboards, control systems, and infotainment interfaces.

🏥 Health Tech Revolution

Flexible screens are making wearable medical devices more lightweight, comfortable, and interactive for better real-time monitoring.

📄 Request your free report sample here: https://dimensionmarketresearch.com/report/flexible-display-market/request-sample/

Regional Market Insights

🌏 Asia Pacific Leads with 35% Market Share

Asia Pacific is driving innovation with:

High mobile usage

Manufacturing dominance (China, Japan, South Korea)

Early adoption of immersive tech

🌍 Strong Momentum in North America & Europe

North America continues to invest in innovation and consumer electronics, while Europe focuses on automotive and industrial applications.

Market Challenges

Despite rapid progress, several issues persist:

High production costs

Longevity concerns with frequent folding

Material supply chain limitations

What’s Next?

⌚ Rise of Smart Wearables

Expect more flexible displays in:

AR glasses

Foldable e-readers

Health-tracking smart bands

🖼️ Transparent & Ultra-Thin Displays

New applications include:

Smart retail signage

Interactive architecture

Museum and showroom exhibits

🌍 Growth in Emerging Markets

India, Brazil, and Southeast Asia are poised to drive future demand as digital technology adoption accelerates.

Final Thoughts

Flexible displays are no longer experimental—they’re defining the next era of tech. From phones and cars to hospitals and storefronts, screens are becoming more versatile, immersive, and integrated into daily life.

📘 Explore the full market analysis here: https://dimensionmarketresearch.com/report/flexible-display-market/

📥 Download your free sample report: https://dimensionmarketresearch.com/report/flexible-display-market/request-sample/

#FlexibleDisplay#OLED#AMOLED#FoldableScreen#DisplayTech#ConsumerElectronics#Smartphones#Wearables#TechInnovation#MarketTrends#NextGenDisplays#FlexibleElectronics#DigitalDisplays#FutureTech#MarketGrowth#Touchscreen#BendableScreens#DisplayMarket#EmergingTech#ThinFilm

0 notes

Text

Wifi energy harvesting with flexible 2D rectenna!

Mit researchers develop a flexible rectenna that converts wifi signals into electricity, enabling battery-free electronic devices.

#2dmaterials #flexibleelectronics #wifienergy #4TechViews

Read more: https://4techviews.net/converting-wifi-signals-to-electricity-with-new-2d-materials/?lang=en

1 note

·

View note

Text

The Transparent Polyimide Films Market: Pioneering Next-Generation Applications

The Transparent Polyimide Films Market is rapidly transforming industries by offering materials that combine optical clarity, thermal stability, and unmatched flexibility. These advanced films are now essential in cutting-edge sectors such as electronics, aerospace, and renewable energy. What sets transparent polyimide films apart is their ability to maintain functionality under extreme conditions while meeting the high-performance requirements of modern technology.

Shaping the Clear Polyimide Films Industry

In today’s innovation-driven world, the Clear Polyimide Films Industry has witnessed a surge in demand. These materials are vital in foldable smartphones, touchscreens, and advanced flexible circuits, providing optical transparency without compromising durability. Similarly, the Optical Polyimide Films Market is gaining traction for applications in optoelectronics, where precise light transmission and clarity are crucial.

Raising the Bar with High-Performance Polyimide Films

Industries like aerospace and automotive demand materials that can withstand intense heat, stress, and wear. Enter High-Performance Polyimide Films, which have become the material of choice for engineers and designers. These films excel in applications requiring heat resistance, making them indispensable in the Heat-Resistant Polyimide Films Market and the Transparent High-Temperature Films Industry, where performance under extreme conditions is critical.

The Growing Need for Lightweight and Ultra-Thin Films

As global industries move toward lighter, more efficient materials, the Lightweight Polyimide Films Market is seeing unprecedented interest. These films reduce weight in applications like aviation and wearable technology, improving energy efficiency. Meanwhile, the Ultra-Thin Polyimide Films Market is opening new doors in advanced electronics. Their ultra-slim profile is ideal for foldable and flexible devices, where compactness and adaptability are key.

Flexible Transparent Films: Revolutionizing Display Technology

One of the most exciting developments in this field is the advent of flexible electronics. The Flexible Transparent Films Market plays a pivotal role in enabling bendable, rollable, and foldable designs. Applications in the Flexible Display Films Market include foldable screens and flexible circuit boards that can seamlessly integrate into compact, portable devices. These films are not only redefining device design but are also paving the way for futuristic concepts like rollable televisions and dynamic wearables.

The Future of Transparent Polyimide Films

The versatility and advanced properties of transparent polyimide films ensure their relevance across a broad spectrum of industries. Whether it’s improving the durability of flexible displays or enhancing the heat resistance of industrial components, the market is positioned for sustained growth. The ongoing push for sustainable and recyclable materials will only add to the appeal of these films, as manufacturers respond to increasing environmental consciousness.

To know more Download PDF Brochure :

With continued investment in innovation, the Transparent Polyimide Films Market is on track to deliver revolutionary solutions that address the ever-evolving demands of technology and design. As industries adopt these materials to create lighter, stronger, and more efficient products, the role of transparent polyimide films will remain vital in shaping the future.

#TransparentPolyimideFilms#FlexibleElectronics#FoldableDisplays#WearableTechnology#Sustainability#MaterialInnovation#EmergingMarkets

0 notes