#Advanced Coating Solutions

Explore tagged Tumblr posts

Text

Nano Coating Supplier: Your Strategic Partner for High-Performance Surface Solutions

As nanotechnology continues to revolutionize surface treatment, nano coatings have become essential in industries ranging from automotive and electronics to construction and medical devices. Finding a reliable nano coating supplier is now a crucial step for companies seeking advanced protection and performance. 1. What Is Nano Coating? Nano coatings are ultra-thin layers applied at the…

#advanced coating solutions#industrial nano coating provider#nano protective film manufacturer#nano-coating-supplier#nanotechnology coatings

0 notes

Text

Leading the Way in Surface Protection: Rust Bullet's Advanced Coating Solutions

[Reno, Nevada, 2024] RustBullet.com, a distinguished name in the realm of surface protection, continues to set the standard with its advanced coating solutions. With a proven track record of excellence, Rust Bullet stands at the forefront of innovation in rust prevention and surface preservation.

Boasting a comprehensive range of products tailored to automotive, industrial, and residential needs, Rust Bullet has become synonymous with durability and reliability. The company's commitment to quality and performance shines through in every application, providing customers with peace of mind and long-lasting protection.

"At RustBullet.com, we take pride in offering our customers unmatched surface protection solutions that go beyond expectations. Our dedication to excellence drives us to continually push the boundaries of what is possible in surface coating technology."

RustBullet.com's coatings are renowned for their ease of application, superior adhesion, and resilience in the face of challenging environmental conditions. From automotive surfaces to concrete floors, Rust Bullet's products ensure optimal protection and longevity, making them a trusted choice for professionals and DIY enthusiasts alike.

In addition to their performance benefits, Rust Bullet's coatings are formulated with a focus on environmental sustainability, aligning with the company's commitment to eco-conscious practices.

For further details on Rust Bullet's advanced coating solutions and to discover the full range of products available, please visit RustBullet.com.

Contact:

Rust Bullet

Phone No. (800) 245-1600

300 Brinkby Ave.,

Suite 200 Reno, NV 89509 USA

Website: www.rustbullet.com

About Rust Bullet: Rust Bullet is a renowned provider of cutting-edge coating solutions specializing in rust prevention and surface protection. With a dedication to quality, innovation, and sustainability, Rust Bullet offers a diverse range of products suitable for various applications, from automotive to industrial settings. Learn more about Rust Bullet's industry-leading solutions at RustBullet.com.

Follow Us:

Follow Us:

Facebook : https://www.facebook.com/rustbulletkillsrust

Twitter :https://twitter.com/rustbullet

0 notes

Text

Zero Friction Coatings Market: Charting the Course for Enhanced Performance and Sustainable Solutions

The global zero friction coatings market size is estimated to reach USD 1,346.00 million by 2030 according to a new report by Grand View Research, Inc. The market is expected to expand at a CAGR of 5.6% from 2022 to 2030. Growth can be attributed to the fact that these coatings reduce friction and wear resulting in low fuel consumption and less heat generation. According to the European Automobile Manufacturers' Association, 79.1 million motor vehicles were produced across the globe in 2021 which was up by 1.3% as compared to 2020. Zero friction coatings can extend the time between component maintenance and replacement, especially for machine parts that are expensive to manufacture.

Zero Friction Coatings Market Report Highlights

In 2021, molybdenum disulfide emerged as the dominant type segment by contributing around 50% of the revenue share. This is attributed to its properties such as low coefficient of friction at high loads, electrical insulation, and wide temperature range

The automobile & transportation was the dominating end-use segment accounting for a revenue share of more than 35% in 2021 due to the rapid growth of the automotive industry across the globe

The energy end-use segment is anticipated to grow at a CAGR of 5.7% in terms of revenue by 2030, owing to the excessive wear on the drill stem assembly and the well casing during the drilling operations in the oil and gas sector

In Asia Pacific, the market is projected to witness the highest CAGR of 5.8% over the predicted years owing to the presence of car manufacturing industries in the countries such as Japan, South Korea, and China

For More Details or Sample Copy please visit link @: Zero Friction Coatings Market Report

Several applications in the automobile industry use wear-resistant plastic seals that require zero tolerance for failure and lifetime service confidence. Increasing demand for the product from the automotive industry across the globe for various applications including fuel pumps, automatic transmissions, oil pumps, braking systems, and others is expected to drive its demand over the forecast period.

Low friction coatings can be used in extreme environments comprising high pressure, temperatures, and vacuums. These coatings can provide improved service life and performance thereby eliminating the need for wet lubricants in environments that require chemicals, heat, or clean room conditions. The product containing molybdenum disulfide (MoS2) are suitable for reinforced plastics while those free from MoS2 are suitable for non-reinforced plastics.

Zero friction coatings are paint-like products containing submicron-sized particles of solid lubricants dispersed through resin blends and solvents. The product can be applied using conventional painting techniques such as dipping, spraying, or brushing. The thickness of the film has a considerable influence on the anti-corrosion properties, coefficient of friction, and service life of the product. Its thickness should be greater than the surface roughness of the mating surfaces.

ZeroFrictionCoatingsMarket #FrictionlessTechnology #CoatingInnovations #IndustrialEfficiency #ZeroFrictionSolutions #AdvancedMaterials #SurfaceCoatings #ManufacturingAdvancements #GlobalIndustryTrends #InnovativeCoatings #PerformanceOptimization #MechanicalSystems #SustainableTechnology #IndustrialApplications #FutureTech #InnovationInMaterials #EfficiencySolutions #ZeroFrictionMarket #TechnologyInnovation #EngineeringMaterials

#Zero Friction Coatings Market#Frictionless Technology#Coating Innovations#Industrial Efficiency#Zero Friction Solutions#Advanced Materials#Surface Coatings#Manufacturing Advancements#Global Industry Trends#Innovative Coatings#Performance Optimization#Mechanical Systems#Sustainable Technology#Industrial Applications#Future Tech#Innovation In Materials#Efficiency Solutions#Zero Friction Market#Technology Innovation#Engineering Materials

2 notes

·

View notes

Text

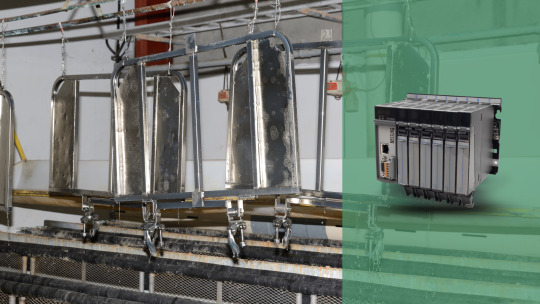

Smarter Surface Protection – PLC Automation in Autophoretic Coating Plants

In modern manufacturing, surface coating is not just cosmetic—it’s essential for durability, corrosion resistance, and performance. Autophoretic coating (also known as A-coating) has emerged as a water-based, eco-friendly alternative to electro-coating. When combined with PLC-based automation, it becomes a powerful, scalable solution for high-quality, uniform metal finishing.

Because let’s face it—metal without proper protection is like a knight without armour. In today’s industrial world, that armour comes in the form of surface coating. And when it comes to smart, sustainable, and scalable coating, autophoretic coating is the unsung hero.

But wait, here’s where it gets exciting. Pair this eco-warrior coating with PLC automation, and what you get is nothing short of magic. At Messung Industrial Automation, we believe that the perfect coat is not just about shine—it's about smarts, speed, and sustainability.Let’s dive into the world where chemistry meets code, and surface protection meets the future.

What is Autophoretic Coating?

Autophoretic coating, also known as A-coating, is a process where metal parts are dipped in a reactive water-based solution. The result? A self-depositing layer forms on the surface, without any electric current. Unlike traditional methods that zap the surface with electricity, A-coating lets chemistry take the wheel.

Why Are Industries Making the Switch?

Industries are coating their bets on it because it avoids the need for heavy electric setups and provides uniform coverage even in complex geometries. Since it is water-based, it is also very environmentally friendly.

Where Is It Being Used?

From under-the-hood car parts to refrigerator frames, autophoretic coating is making waves in:

Automotive parts

Appliance components

Agricultural and construction machinery

General industrial structures

In an age where efficiency, sustainability, and performance go hand in hand, autophoretic coating emerges as a transformative solution. Its simplicity belies its power, ushering in a cleaner, smarter way to protect surfaces without compromising on quality or cost. As industries across the board continue to embrace greener practices, A-coating, powered by automation and intelligence, is painting the future—one seamless coat at a time.

Role of PLC in the Coating Plant

In the realm of autophoretic coating, precision isn't a luxury—it's a necessity, and that precision begins with the silent genius of automation: the Programmable Logic Controller (PLC). Think of the PLC as the central nervous system of your coating plant—connecting, communicating, and commanding every mechanical muscle with machines. Here is how PLCs turn a basic coating line into a harmonious dance of efficiency and intelligence.

Precision Process Automation

A modern autophoretic coating plant runs smoothly like a well-coordinated team, and the PLC (Programmable Logic Controller) is in charge. It doesn’t just control the machines—it helps everything work perfectly together. From:

Tank temperature

Solution pressure & pH levels

Cycle timing for each dip and rise

...every step is monitored and controlled by PLC automation.

Material Handling Magic

Using intelligent material handling controllers, our PLC guides parts through multiple stages:

Degreasing

Surface conditioning

Coating dip

Rinsing & curing

Like a choreographer directing a ballet of metal.

Circulation & Filtration Mastery

Good coating = Consistent flow. Our process controllers and PLC control systems manage:

Fluid circulation

Filtration cycles

Solution replacement timing

Synchronisation with Process Controllers

Through seamless synchronisation with motion control systems, everything moves with precision. No drips, no downtime.

In an industry where milliseconds matter and uniformity is sacred, PLC automation elevates the autophoretic coating plant from functional to phenomenal. It enables not just control, but clarity—ensuring that every part, every dip, and every process flows with intelligent intent.

NX-ERA JET PLC System Architecture

Our flagship—NX-ERA JET PLC—is a robust, real-time, and rugged automation genius. It’s compact, reliable, and battle-tested in industrial heat.

Talk the Talk: MODBUS & TCP/IP

Built-in PLC communication protocols like:

MODBUS TCP/IP

MODBUS RTU

Make it plug-and-play with SCADA and automation systems. Yes, it speaks fluent-machine.

Ethernet-Based Controllers for High-Speed Sync

Using Ethernet-based controllers, data flows like molten metal. Zero lag, maximum productivity.

HMI with PLC Controllers

With user-friendly HMIs with PLC controllers, even a non-techie can operate complex coating sequences. Tap, drag, drop—and coat!

From seamless communication to intuitive control, the NX-ERA JET PLC is more than just a controller—it's the central nervous system of your autophoretic coating plant. With its advanced architecture, lightning-fast data sync, and plug-and-play compatibility, it transforms complexity into clarity. Whether you're scaling up or starting smart, this system offers the flexibility, durability, and intelligence your operations demand.In a world where precision meets pressure, the NX-ERA JET PLC ensures your plant doesn’t just perform—it excels.

Advanced PLC Automation for Smart Manufacturing

In the age of Industry 4.0, surface coating is no longer just about chemistry—it's about intelligence, precision, and adaptability. That’s where advanced PLC automation steps in as the invisible powerhouse behind your plant’s performance. Whether you're scaling up operations or streamlining a compact facility, smart automation is the lever that elevates your process from ordinary to outstanding.

Let’s uncover how Messung’s cutting-edge PLC technology is revolutionising autophoretic coating plants with flexible, responsive, and future-ready control systems.

Modular, Compact & Ready to Go - Whether it’s a big plant or a small-scale setup, our Modular PLC, Compact PLC, and Smart PLC configurations give you tailor-made flexibility.

Motion Control with Millisecond Precision - Our motion control systems enable synchronised movement, avoiding delays or overlaps in the coating sequence.

Material Handling - Our embedded material handling controllers do the heavy lifting—literally—without breaking a sweat.

This isn't just automation. This is smart automation that thinks ahead, moves with purpose, and adapts to demand. With Messung’s PLC-powered intelligence, your coating plant doesn’t just run—it evolves.

Because in the world of advanced manufacturing, it’s not just about staying ahead—it's about setting the pace.

Smart. Sustainable. Secure: The Evolution of PLC Automation in Coating Plants

In the era of Industry 4.0, coating plants need more than just control—they need intelligence, integration, and intention. Here’s how Messung’s PLC automation is redefining autophoretic coating systems:

Built for Harsh Industrial Realities – Our Industrial PLCs endure dust, moisture, heat, and vibration. Conformal-coated PLCs protect against corrosive chemicals in A-coating zones and provide long-lasting performance in extreme environments.

Safety Meets Smarts - PLCs are integrated for emergency stops, controlled shutdowns, and real-time fault alerts with logs, making them smart, secure, and always in control.

Welcome to Industry 4.0-Based Controllers

PLC with IoT for remote monitoring and real-time plant access.

MQTT-based PLCs for cloud-friendly, lightweight data communication.

Full PLC system integration with BMS, SCADA & more—ensuring a harmonious automation ecosystem.

Green Gains: Eco-Friendly A-Coating Automation

Water-based chemistry reduces VOCs and emissions.

Smart PLCs optimize dosing & disposal—minimising waste, maximising results.

Cleaner air, cleaner conscience, smarter coatings.

With Messung’s intelligent PLC, you don’t just automate—you evolve. Sustainable, scalable, and secure—this is the new face of PLC-based automation solutions in A-coating.

Business Benefits of PLC-Based Automation Solutions

In today’s hyper-competitive manufacturing world, success isn’t just about innovation—it’s about consistency, efficiency, and scalability. This is where PLC-based automation doesn’t just support your coating process—it transforms it. Let’s explore how Messung’s smart automation systems turn operational goals into tangible business advantages.

Uniformity Every Time - When every product must meet the same high standard, there’s no room for guesswork. Thanks to PLC control systems, your coating process is even, repeatable, and of high quality.

Never any Downtime - Time is money, and downtime is a thief. With real-time monitoring and intelligent automation controllers, potential issues are detected and resolved before they affect production. Fewer breakdowns. More uptime. Happier bottom line.

Easy to Maintain & Scale - Growth shouldn’t be a gamble. With built-in PLC maintenance alerts, you get proactive notifications that prevent surprises. Want to expand operations? Simply plug and play with modular I/O modules. You’re ready for tomorrow—today.

In essence, PLC automation is not just a control system—it’s a business strategy. It safeguards quality, boosts efficiency, and equips your coating plant with the agility to evolve. Because when your process is smart, your performance is unstoppable.

Conclusion: The Final Coat

A surface is only as strong as the system behind it. In the era of smart manufacturing, Messung’s PLC automation solutions empower autophoretic coating plants with unmatched precision, efficiency, and sustainability. From real-time monitoring and advanced PLC control systems to seamless IoT integration and predictive maintenance, our technology ensures optimal surface protection with minimal waste. Whether it’s modular PLCs, industrial automation controllers, or motion control systems, Messung delivers the complete package. So why let inefficiencies corrode your bottom line? Upgrade your coat. Upgrade your process. Upgrade with Messung PLCs—where intelligent automation meets perfect protection.

FAQs

How does PLC contribute to energy efficiency in coating plants?

By optimizing process timings, reducing idle machine hours, and enabling intelligent power management, PLCs help cut down energy consumption and operational costs.

Can PLC automation reduce coating defects?

Absolutely. With real-time monitoring, precision control, and error alerts, PLC automation ensures consistent quality.

How easy is it to integrate Messung PLCs in existing lines?

Very! Our modular PLC systems and versatile PLC communication protocols like MODBUS and TCP/IP allow seamless integration.

Are conformal-coated PLCs necessary?

Yes, especially in chemically aggressive environments like coating plants. They extend the life and reliability of your Programmable Logic Controller.

What industries benefit most from PLC with IoT?

Automotive, general manufacturing, and any industry embracing Industry 4.0-based controllers and smart factory setups.

#Autophoretic coating#Messung Industrial Automation#PLC automation#Programmable Logic Controller (PLC)#material handling controllers#motion control systems#NX-ERA JET PLC#HMI with PLC Controllers#advanced PLC automation#Modular PLC#Compact PLC#Smart PLC#Industrial PLCs#Smart PLCs#PLC-based automation solutions#PLC control systems#PLC automation solutions#IoT integration#industrial automation controllers#Industry 4.0-based controllers

0 notes

Text

Enhancing Coil Reliability with Trickle Impregnation Technique and Varnishing Machines from Omsai PS Enterprises

In the electrical manufacturing and motor repair industry, insulation is everything. Proper insulation ensures long-lasting performance, minimizes electrical losses, and reduces maintenance costs. At Omsai PS Enterprises, we offer advanced Varnishing Machines based on the Trickle Impregnation Technique – a proven method for high-quality insulation of stator windings and coils.

What Is the Trickle Impregnation Technique?

The Trickle Impregnation Technique is a modern varnishing process that involves the slow and controlled application of varnish onto rotating windings, typically under heat and vacuum. This ensures deep penetration, minimal waste, and even coating across the coil surface. It is widely used in manufacturing motors, alternators, and transformers due to its excellent electrical, mechanical, and thermal properties.

Our Expertise in Trickle Impregnation

At Omsai PS Enterprises, we specialize in the design and manufacturing of high-performance Varnishing Machines based on the Trickle Impregnation Technique in Pune and Trickle Impregnation Technique in Satara. Our machines are engineered for precision and durability, ensuring superior insulation and reduced production times.

Key Features of Our Varnishing Machines

✅ Precision varnish application with minimal spillage

✅ High thermal efficiency for better curing

✅ Customizable to suit various motor sizes and coil types

✅ Easy operation and low maintenance

✅ Suitable for low-voltage and high-voltage motor windings

Applications of Trickle Impregnation Technique

Electrical motor windings

Generator stators

Alternator coils

Transformer coils

Compact motors in automotive and appliance industries

Serving Satara, Pune, and All Across India

Our Trickle Impregnation Technique in Satara and Trickle Impregnation Technique in Pune has gained recognition for its high-quality results and cost-effective performance. With a wide customer base across Maharashtra and India, we are one of the leading manufacturers and suppliers of Varnishing Machines in Satara, Varnishing Machines in Pune, and Varnishing Machines in India.

Why Choose Omsai PS Enterprises?

🛠 Decades of industrial experience

🧪 Precision-engineered equipment

🌍 Wide distribution network across India

💡 Custom-built solutions for unique requirements

📞 Prompt support and expert guidance

#Trickle Impregnation Technique#Trickle Impregnation Technique in satara#Trickle Impregnation Technique in pune#Varnishing Machines#Varnishing Machines in Satara#Varnishing Machines in India#Varnishing Machines in Pune#Batch Type Trickle Impregnating Machine in Satara#Batch Type Trickle Impregnating Machine in India#Trickle Varnishing Machine#Trickle Impregnation Machine#Varnishing Equipment#Industrial Varnishing Machines#Trickle Varnishing System#Coil Varnishing Machine#Omsai Enterprises#AR Engineering#Advanced Varnishing Machines#Industrial Coating Solutions"

0 notes

Text

Unlocking Growth in the Battery Coating Market: A Path to Innovation and Sustainability

The Rapid Evolution of Battery Coatings

As the global demand for cleaner energy and sustainable technologies escalates, the battery coating market has emerged as a pivotal enabler of next-generation energy solutions. Battery coatings, essential for enhancing the performance, longevity, and safety of energy storage systems, are increasingly in demand across industries such as electric vehicles (EVs), consumer electronics, and renewable energy.

From ensuring the durability of lithium-ion batteries to improving thermal management and conductivity, advanced coatings are revolutionizing the way energy storage systems function. These coatings help mitigate key challenges such as overheating, degradation, and electrolyte leakage, making them critical in scaling up battery applications in modern industries.

The surge in electric vehicle (EV) adoption has further catalyzed innovation in the battery coating space. Governments and corporations globally are setting ambitious goals for net-zero emissions, driving demand for innovative, efficient, and safe battery technologies. In this context, the battery coating market is not just evolving; it is transforming industries.

Opportunities and Challenges in the Battery Coating Market

The global battery coating market is poised for exponential growth. According to MarketsandMarkets, the market is projected to expand from USD 604.7 million in 2024 to USD 1,613.6 million by 2030, registering a CAGR of 17.8% during the forecast period. Let’s explore the key factors driving this growth and the challenges the industry faces.

Market Drivers

Surge in EV and Hybrid Vehicle ProductionThe proliferation of Battery Electric Vehicles (BEVs), Plug-in Hybrid Electric Vehicles (PHEVs), Hybrid Electric Vehicles (HEVs), and Fuel Cell Electric Vehicles (FCEVs) has created a robust demand for advanced battery technologies. As the EV market continues to flourish, the need for high-performance coatings that ensure safety and enhance energy efficiency is skyrocketing.

Expanding Consumer Electronics and Renewable Energy StorageThe rapid growth of consumer electronics and renewable energy projects has increased the emphasis on battery reliability and efficiency. Coatings that enhance conductivity, reduce resistance, and prevent degradation are key to meeting the demands of these industries.

Market Restraints

High Costs of Advanced TechnologiesThe implementation of cutting-edge battery coating solutions comes with a steep price tag, often making it a barrier for companies aiming to adopt these technologies. This challenge calls for cost-effective innovations without compromising quality and performance.

Opportunities

Innovations in Battery MaterialsTechnological advancements in materials science are creating unprecedented opportunities for the battery coating market. From nanotechnology-based coatings to solid-state innovations, these breakthroughs promise safer, longer-lasting, and more efficient batteries. Companies investing in R&D have the potential to redefine industry standards.

Challenges

Preference for Solid ElectrolytesAs the industry increasingly transitions to solid-state batteries, which rely on solid electrolytes, the demand for traditional liquid-electrolyte-based coatings is facing competition. Adapting coating technologies to suit solid-state systems is critical for sustained growth.

Industry Players Shaping the Market

Several key players are at the forefront of innovation in the battery coating market, driving growth and shaping industry trends. These include:

Arkema (France)

Solvay (Belgium)

Asahi Kasei Corporation (Japan)

PPG Industries, Inc. (US)

SK Innovation Co. Ltd. (South Korea)

Mitsubishi Paper Mills, Ltd. (Japan)

Tanaka Chemical Corporation (Japan)

Targray (Canada)

These companies are investing heavily in research and development to create cutting-edge coating technologies that address industry challenges while capitalizing on opportunities.

For More Insights Download PDF Brochure :

The battery coating market is a dynamic space where innovation meets necessity. As industries pivot toward sustainability, battery coatings will continue to play a critical role in enabling high-performance energy storage systems. Companies and decision-makers investing in advanced coating solutions today are poised to lead the energy transition tomorrow. Whether you are an executive exploring sustainable solutions or a professional seeking cutting-edge technologies, now is the time to align your strategies with the evolving trends of the battery coating market.

#Battery Coating Market#Advanced Battery Technology#Electric Vehicles#Energy Storage Solutions#Sustainable Innovation#Battery Materials#EV Industry Trends

0 notes

Text

Explore RCMPL’s advanced liquid construction chemical plants designed for optimal efficiency and superior quality. Our cutting-edge facilities produce a wide range of construction chemicals, including waterproofing solutions, concrete additives, and industrial coatings.

#Liquid construction chemicals#Advanced construction chemical plants#Concrete additives production#Waterproofing solutions plant#Industrial coatings manufacturing#State-of-the-art construction chemical facilities#High-performance construction chemicals#Chemical plants for construction industry#RCMPL construction chemical production#Durable construction solutions.

0 notes

Text

Experience the best in class with Chemteach.com, your trusted chemical manufacturing company in India.

#Die Cast#Foundry Solutions#Composites#Polyurethane#Rubber Molding#Tire Manufacturing#Rotational Molding#Thermoplastics#Advanced Composites#Automotive Solutions#Industrial Manufacturing#Casting Release#Composite Molding#Process Aids#Surface Coatings#Manufacturing Efficiency#Performance Materials

1 note

·

View note

Text

Unraveling the Mystery of Corrosion Control Treatments

Corrosion – the silent enemy of metal structures and equipment. It sneaks in unnoticed, gradually eating away at surfaces, compromising structural integrity, and causing costly damage. But fear not! With the right Corrosion Control Treatments, you can wage war against this formidable foe and protect your assets from its destructive grasp. Let's delve into the world of corrosion control treatments, exploring their importance, strategies, and the transformative impact they have on industries across the United States.

Understanding the Significance of Corrosion Control Treatments

Why are corrosion control treatments crucial for industrial assets? Imagine your metal equipment as knights in shining armor, vulnerable to the relentless assault of rust – corrosion control treatments act as their protective shield, preserving their strength and resilience against the ravages of time and the elements.

Preventing Structural Deterioration

Corrosion control treatments are not just about aesthetics; they're about preserving the structural integrity of metal assets. How do these treatments prevent deterioration? By forming a barrier that shields surfaces from moisture, oxygen, and corrosive agents, corrosion control treatments prevent the electrochemical reactions that lead to corrosion, ensuring that structures remain sound and functional for years to come.

Extending Service Life

Just as a well-maintained suit of armor can withstand the test of time, corrosion control treatments extend the service life of metal assets. How do they achieve this? By proactively addressing corrosion and preventing its spread, these treatments reduce the need for costly repairs and replacements, saving both time and money in the long run.

Strategies for Corrosion Control Treatments

Protective Coatings

Protective coatings are the frontline defense against corrosion, forming a durable barrier that shields metal surfaces from environmental exposure. What types of coatings are commonly used?

Epoxy Coatings: Known for their excellent adhesion and chemical resistance, epoxy coatings are ideal for protecting metal structures in harsh industrial environments.

Zinc-rich Primers: Zinc-rich primers provide sacrificial protection by corroding in place of the underlying metal, delaying the onset of corrosion and extending the lifespan of the coating system.

Polyurethane Coatings: Polyurethane coatings offer superior UV resistance and weatherability, making them suitable for outdoor applications where exposure to sunlight and moisture is a concern.

Cathodic Protection

Cathodic protection is another effective strategy for combating corrosion, particularly in buried or submerged metal structures. How does cathodic protection work? By introducing a sacrificial anode or impressed current system, cathodic protection creates a cathodic environment that inhibits corrosion, preserving the integrity of underground pipelines, storage tanks, and marine structures.

Benefits of Corrosion Control Treatments

Cost Savings

One of the primary benefits of corrosion control treatments is cost savings. How do these treatments save money? By preventing corrosion-related damage and the need for extensive repairs or replacements, corrosion control treatments help organizations minimize downtime, reduce maintenance costs, and prolong the lifespan of their assets.

Safety and Reliability

In addition to cost savings, corrosion control treatments enhance safety and reliability. How do they achieve this? By ensuring that metal structures and equipment remain structurally sound and free from corrosion-induced failures, these treatments minimize the risk of accidents, environmental contamination, and costly shutdowns, promoting a safer and more reliable operating environment.

youtube

Conclusion: Embracing the Power of Corrosion Control Treatments

Corrosion may be a formidable adversary, but with the right corrosion control treatments in place, you can protect your metal assets and ensure their longevity and performance. Whether it's applying protective coatings, implementing cathodic protection systems, or adopting other corrosion mitigation strategies, investing in corrosion control is an investment in the future resilience and reliability of your industrial infrastructure. So, don't wait for corrosion to strike – take proactive steps to safeguard your assets and keep them shining bright for years to come.

#Corrosion Resistant Industrial Paints#Professional Warehouse Painting Services#Advanced Surface Preparation Techniques#Durable Industrial Painting Solutions#Bespoke Industrial Coating Applications#Safety Line Marking Services#Industrial Tank Coating Specialists#Environmentally Friendly Painting Options#Heavy-Duty Industrial Paint Systems#Youtube

1 note

·

View note

Text

Advantages of PZSSS Nano Coating

#advanced surface protection#benefits of nano coating#durable nano coating solution#PZSSS nano coating#smart nano coating technology

0 notes

Text

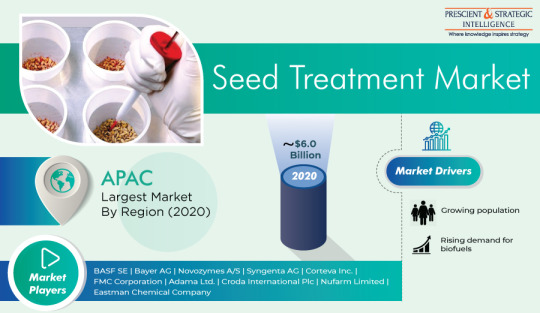

How Does Seed Treatment Help in Improving Yield?

Seed treatment can be defined as the application of insecticide, fungicide, or both to seeds to disinfect them from soil-borne or seed-borne pathogenic organisms or storage insects. It refers to seeds subjected to immersion in conditioned water, solar energy exposure, or others.

The seed treatment helps in preventing the spread of plant diseases. It protects seeds from seedling blights and seed rot. In addition, seed treatment improves germination, ensures protection from storage insects, and controls soil insects.

Methods for Seed Treatment

Seed Dressing: Seed dressing is the most common method for seed protection. In this way, the seed is dressed with either a dry formulation or wet treatment with a liquid formulation or slurry. Dressings need to be applied in both industries, and farms. This process involves, spreading the sheet on a polyethylene sheet, and needs several chemicals for sprinkling on surface seeds.

Seed Coating: The seed coating method is primarily utilized in industries. It involves advanced treatment technology.

Seed Pelleting: It is a method utilized for transforming the physical shape of the seed to improve palatability. This process involves sophisticated seed treatment technology.

The seed treatment industry is projected to rise in the coming years. It is ascribed to surging government initiatives, and efforts of private organizations to enhance the crop yield, with increasing application of technologically advanced seed treatment solutions for improving the seed quality, and growing requirement for basic grains and vegetables, led by increasing population.

Under the crop type, cereals and grains capture the largest industry share, in terms of both value, and volume. It is ascribed to the massive-volume production of cereals and grains, including wheat, rice, corn, ragi, barley, and sorghum, led by increasing consumption and surging per capita income.

Under the application method segment, the dressing category holds the largest volume and revenue shares. It is ascribed to the rising usage of dressings as dry formulations, wet-treated slurry, and liquid formulation applications.

Under the application time segment, the pre-treatment category captures the largest industry share, in terms of both revenue and volume. It is ascribed to the rising adoption by the manufacturer for the protection of seeds from soil-borne, and seed-borne diseases.

APAC captures the largest industry share, and it is projected to follow the same trend in the coming future. It is ascribed to the high-volume crop production in countries, such as Vietnam, South Korea, India, China, and Australia. Furthermore, these countries employ more seed protection products to improve yield.

#seed treatment#agriculture industry#market analysis#seed treatment technology#agricultural innovations#market trends#crop protection#seed coating#pest control#agricultural advancements#market dynamics#seed treatment solutions#sustainable agriculture#crop enhancement#seed treatment market outlook

0 notes

Text

Bruce looking past the fact that (recently adopted) Danny is a powerhouse and recognizing that he has other skills also. <3

Danny is a STEM kid and just as brilliant as his sister, you cannot convince me otherwise

Danny gave Bruce the handwritten list of powers in the morning. Bruce stared at it over his cup of coffee, then gave Danny a flat, somewhat disbelieving look. Danny shrugged sheepishly, rubbing the back of his neck.

“Sorry,” he said, perching on one of the stools. “I can point out the ones I don’t use if you just want to work on the ones I do. At least I have an idea of what needs improving with those.” Alfred gave him a cup of coffee and a plate of bacon and French toast, and Danny smiled at him. “Thanks, Alfred.”

“We’ll have to prioritize your training,” Bruce allowed after a moment, frowning down at the paper. Dick leaned over to look and whistled. “But all of these will be addressed eventually. You should have at least a moderate grasp of every tool at your disposal.” He looked up. “You intended to work in the lab today, correct?”

Danny nodded, playing with a strip of bacon. “I’ll probably spend most of today making a big batch of phaseproof coating,” he said. “Then I can experiment with mixing it with paint and maybe coat some of your spare weapons in it? That should work for the bo staff and escrima sticks, maybe a set of brass knuckles. But I’ll need to make a different solution for the edged weapons.” His mind wandered, thinking of how he could adapt what he knew of the Bats’ gear to work against ghosts.

“Who’re the brass knuckles for?” Dick asked, raising an eyebrow at Danny. Danny flushed and shrugged.

“Batman,” he said. “You don’t really use a weapon, right?” Bruce grunted. “But phaseproof cloth isn’t something my parents ever really figured out. I can work on it, maybe, but I thought brass knuckles would be an okay compromise for now.”

“Hn.”

“Good thinking,” Dick praised with a smile. “It’ll be easy to add to the utility belt too. Should we ghostproof my main set or a spare?”

“The main, I think, if you’re okay with it,” Danny said, tilting his head thoughtfully. “You probably won’t even notice. But the edged weapons should all be spares. Ecto-treated metal tends to glow.”

“Not great for stealth,” Dick nodded. “Whatever you think is best, baby spook. We have the resources.”

“You’re hyper-specialized,” Bruce noted without inflection, sipping from his coffee. Danny winced.

“Sorry,” he muttered. It was easy to forget that all this was pretty useless outside of Amity Park. Bruce shook his head.

“It’s not a problem. But we’ll need to diversify your skillset. Your talent for chemistry and engineering should expand beyond ectoscience alone.” He studied Danny contemplatively. “Higher education might be beneficial, perhaps a PhD.”

Danny’s eyes went wide. “What? I’m barely passing high school!”

“I had Casper High send over your transcripts,” Bruce said. Danny flinched. “You had a B+ average in middle school, with a particular bent for math and science. You also participated in several advanced extracurriculars, including a junior astronaut program, space camp, and competitive robotics. Further, you clearly have a comprehensive understanding of your parents’ work, which eludes both the Justice League engineers and JL Dark. You had these talents prior to acquiring your powers, and it would be a waste to discard them in favor of your raw combat ability.”

Danny stared at Bruce, open-mouthed and speechless. He couldn’t remember the last time he’d considered even the possibility that he could have a future outside of his hero career.

“…Do you think I could do that and be a superhero?” he managed after a minute, quieter than he’d meant to.

Bruce nodded sharply. “Most Justice League heroes maintain a career outside of heroics,” he reminded Danny, without even sounding like he thought Danny was an idiot for asking. “Aside from myself, there is also a Pulitzer prize-winning journalist, a museum curator, a forensic scientist, and a fighter pilot.”

Danny had known that on some level, but it had always seemed unreal. Practically a myth. “When am I going back to school?” he asked, hardly able to believe that he was suddenly looking forward to it.

“At the beginning of next semester,” Bruce said. “Your parents’ trial should be completed by then. I assume you don’t want to be announced publicly until that happens.” Danny shook his head fervently. “You may need to complete some make-up classes online, but we can discuss that next week.”

“Thanks,” Danny said sincerely. He was talking about a lot more than his re-enrollment.

1K notes

·

View notes

Text

ALRIGHT EVERYONE!

Nobody asked - but I broke down the construction of Epel’s cardigan from the sleepwear card as best I was able (aka. Me zooming in on him and staring very intensely).

This is the pattern idea I’ve come up with and a few grid charts. This is not finished, but what I’m going forward with to make his coat this month. My goal is to be done by the end of June.

So. Looking close at his sleeves - the closest resemblance we’ll get in the crochet world is the honeycomb stitch for the argyle diamonds. My plan is to break his sleeve into fourths. Three large panels of honey comb for the diamonds, and two smaller panels of a curved half-double-crochet to create dividers. The cardigan is clearly oversized on him, and even if it’s because of his smaller stature - I want to be SWAMPED in this thing. So the cuffs need to be CHUNKY. I’ll be going in with either a ribbed stitch, or a back stitch of double crochet. When the time comes I’ll test both to see which looks better.

Now - we’ve got the granny squares.

Looking at my little dude - we can see that they’re not just the front panel. They’re going on the back as well. Since I can’t see behind him, I’m going to take creative liberty and make one large panel of honeycomb stitch to be a central strip on the back. The front panels and side panels are going to be made of jumbo cranny squares.

For those of y’all who don’t crochet - the average granny square is about 25x25 stitches. Except oversized cardis use 8 of these bad boys per front panel. So since Epel has only four on each side, that means those squares gotta be JUMBO.

Zooming in - we see that the patterns are more embroidered. They’ve got texture. Since we’re crocheting, the best way to achieve this is to do pixel crochet for the squares and then go over the designs with a basic embroider stitch. This can be any of your choosing - I’ve yet to pick but will note what I want when the time comes.

There are THREE types of squares on Epel’s coat. I’m just calling them blossom, diamond, and apple. Since there are only three, it would have been difficult to make an entire back with them without having two of a kind touching or diagonal from each other (this is personal preference. I hate how this looks) which is why I’ve decided to go for that middle panel of honeycomb stitch.

The rest of the cardigan seems simple enough. The collar and trim is likely a simple ribbing, and those look like classic farmhouse wooden buttons if I’ve ever seen them.

EDIT (5/6/25): So. Complete change of plan for the sleeves now that I’ve gotten some sleep and thought on it. There’s a cable-knit stitch in the crochet world that closely resembles knit cables. Also lattice stitch or Tunisian crochet can be used for the diamond pattern. So if you want simple/beginner then do the honeycomb with a twisted hdc. If you want advanced then mix the cable-stitch with lattice.

Now - let’s talk materials.

I’m going with acrylic for this. Would it be absolutely divine as wool or a nice, dense alpaca blend? Definitely. I bet that’s what Epel has since his family runs a farm.

I am broke so I’ll be going in with a medium - weight acrylic, hook size 6, and all the granny squares will be done with basic hdc. Although acrylic is a bit itchy - id any of y’all choose to do this? Soak that finished product in a fabric softener solution. It’s a few dollars and your project will lose that scratchy texture. Just don’t let it hang out in the bath too long or the fibers will loosen more than you’d like.

^^^^ This is my general eyeball for how I’ll be constructing this piece. There aren’t any measurements since I’ve get to get my yarn and do a gauge…also, I’m not too sure how oversized I want this. I want to be swamped but not weighed down so hmm…

-

I don’t know how many of y’all like to crochet or do fibre arts - but I fell in love with this coat the moment I saw it and knew it had to be mine. I’m the impatient sort, and already ordered my supplies despite telling myself to wait. Pixel crochet does take a hot minute, so I’m hoping for June but the finished product will likely be more around late-july or august. Just in time for fall and market living where I live!

I could go quicker - but uh, I work as a bridal tailor and Run my own small shop off this app. I spend most of my day sewing lol. It’s been a hot minute since I made something for me, but dang it Epel made it look so cute. I just have to.

No one’s asking, but I’ll be updating. I’m literally so excited and my package of supplies can’t get here quick enough

393 notes

·

View notes

Note

If you were a sci-fi writer, how would you solve the Fermi paradox? That being the discrepancy between evidence for alien life, versus the likelihood of their existence? (basically. If alien so likely, why we not see?) The Dead Space series has an amazing cosmic horror solution, but i'm curious what you're brain could come up with!

There's a lot of possibilities, some more interesting than others.

The speed of light and the distance between inhabited stars makes it prohibitively slow to detect, make contact with, or reach any star with alien life. It doesn't matter if we're not alone, our corner of Space Reachable Within A Human Lifetime is so comparatively small that we may as well be. We're all blindly wandering through an infinite desert, calling into the void. Space exploration is a long game, and on that timescale, even whole civilizations blink out very quickly. If we manage to catch a signal and follow it, we might find nothing on the other end but ruins - or an asteroid field where a planet's orbit used to be.

The universe is too young for us to find anyone else out there. We're the first. How will we shape the galaxy to make life better for those who come after us?

The life that formed on Earth is terrifyingly invasive. The atmosphere and ocean is choked with monocellular life, and its surface is coated with a mass of multicellular organisms finding new ways to devour one another. Even extinction events don't keep down the biomass for long. If life on other planets looks anything like us, the problem isn't going to be detecting it. It'll have gotten everywhere. The problem is going to be not immediately getting colonized and eaten alive by it. And if life on other planets DOESN'T look like us, our whole planet is probably a class 1 biohazard and contamination risk. Multicellular earth organisms contain microcosmic ecosystems that proliferate explosively when they die. If anything inside them can find ANYTHING to eat, it's over.

Life evolves frequently, but always in oceans. It is extremely rare for any alien life to leave that ocean and adapt to life on land. Without this step, the jump to space exploration - even space contemplation - becomes infinitely more unlikely.

Monocellular life is seeded on planets from an outside source and allowed to self-cultivate and grow until the biomass reaches a certain volume. Then the farmers return to harvest it.

There is not a single other species on our entire planet that humans can actually reliably communicate with. It takes tremendous amounts of training to make an animal capable of recognizing even a handful of words, and very few of them can use them. Humans can't even communicate with other humans with 100% clarity, even if they're using the same language. When we find alien life, if we even recognize it as anything resembling life as we know it, we have absolutely no way of communicating.

Space colonialism has been disallowed by the space geneva conventions due to massive past tragedies, parasitic exploitation of worlds and senseless loss of life. Human expeditionary efforts are being watched warily through targeting sights.

We've known about radio communication for less than 200 years. We haven't yet figured out the medium through which all advanced civilizations communicate.

Alien life exists in abundance, but the vast majority of it is extremely tiny. We wouldn't spot an anthill on a satellite photo, and none of their ships are large enough to survive passage through our atmosphere.

Earth's oxygen atmosphere is an anomaly, and our first and most enduring extinction event. The explosive proloferation of cyanobacteria and their oxygen photosynthesis irreparably altered the planet's prebiotic atmosphere and wiped out everything that couldn't handle the sudden massive increase in a highly reactive and flammable gas. Earth is considered highly toxic and unstable, though recently detected increases in methane and CO2 might signal that nature is finally beginning to heal.

941 notes

·

View notes

Text

Time to draw the stronk, grumpy, science man:

I had a predicament: I wanted to draw more of my technologically advanced troll AU “Furtherance,” but I also wanted to practice drawing my muscle anatomy. My solution? To draw “Furtherance” Branch without his lab coat. With Poppy as a witness. You can expect more of him.

Listen: Branch is a survivalist. He’s very active. He has his own gym, and he definitely uses it, otherwise it would be a waste of space and effort. He is strong, there is no question. With strength comes muscles. Not LEAN muscles, no no no, he is a THIC BOI; my man has BULK muscle. BULK.

#trolls#trolls fanart#trolls au#trolls branch#trolls poppy#dreamworks trolls#trolls meme#poppy#branch#trolls broppy#broppy#THEM#trolls art#lmao#your welcome#trolls with tails#Furtherance Au#new designs#I have so much planned for this#smexy science man go burrrrrrr#popcorn never stood a chance#girly fell HARD#Fallin for ya🎶#OH NO HE’S HOTTT#she said calmly#i regret nothing#Branch with muscle definition is Peak#what have i gotten myself into#yolo

116 notes

·

View notes

Note

God I love this au, it's feeding me so good today. The last one with the part about only one bedroom has me thinking about a sick reader, the gross kind of sick where you're sweaty and wheezy and snotty, and the fact that if it were anyone else Simon would be quarantining them. But because it's his spouse, he wakes up to you nasally wheezing and mouth breathing while sprawled across him, and all he can think about is when you're due for your next round of medicine and if he needs to buy more tissues.

Sometimes love comes coated in mucus, and is reciprocated with an artificial cherry taste. Also do the guinea pigs have names and what do they look like?

I'm dying. This is the first ever ask I've ever gotten (that I recall) and I'm going to pass away. Also "sometimes love comes coated in mucus, and is reciprocated with an artificial cherry taste" that is such a good line, I'm apologizing in advance if I steal it.

Also warning for content of being sick, this is based off my last bout of plague.

Also Also Here's the Simon & Thimble playlist

Also Also Also Here's the Military Program Spouse AU masterlist

Bedsharing in general does not happen at first. (Now I want to percolate an idea about sharing the bed for the first time). You're way to use to having your own bed that sharing with someone means you're not sleeping easily and I think Simon would rather sleep with the guinea pigs in their cage than have another human being that close to him when he sleeps. (This was also not something he initially thought about when being told a spouse was to be picked)

So what's the solution? Obviously bunk beds! Kind of, sorta...okay not really but the look on Simon's face when you had suggested getting bunk beds had been entertaining. Who knew so much indignation could come through a medical mask. Really his eyebrows did so much talking.

With the dream of bunkbeds dashed, the next best solution was either two twin beds crammed into the bedroom with a bedside's worth of space between them, or a pull out couch. You managed to find a couch same day that didn't terribly clash with the artwork you have yet to hang up.

You two actually manage to come up with a schedule for who slept where. Obviously you'd get the bed when Simon was deployed, made no sense for you not to. And when he was home the bed was all his unless he was having a night that he knew he wasn't going to trust a deadbolt to keep monsters at bay. Then he made himself comfortable, TV playing low until he managed a few hours in the early morning before you try to leave a silently as you can for work.

(Funny thing, even if you aren't sharing a bed traditionally, you both most certainly have your own sides, along with bed stands that told two different stories)

The first time you get sick is when Simon is technically deployed. Well actually, the day he returns is the day you spike a 101.8 fever and work forces you to go home so you don't become a walking petri dish and expose the college kids that come into your office.

Once you're home you appease the little beasts demanding some sort of vegetal boon, change into the rattiest clothes you have, and then huddle under a staggering amount of blankets that have made their home on your bed. (Simon may have side eyed them when you first set them out, but you've seen the mountain he creates under them, you knew the magic of weighted blankets)

Sleep isn't peaceful, you hadn't broken out the Nyquil quite yet, but you do manage to drift off for a few hours. And then the coughing starts. It's the kind that's a bitch to deal with, dry and pushing your ribs to the limit with how often they can expand and contract. By the time Simon comes home you've steamed yourself twice, taken only a smidge over the recommended amount of cough suppressant, and slathered yourself with Vic's Vaporub. All in all, you were properly miserable.

You're in the kitchen, staring into the abyss of your over-steeping tea as if it will magically make you feel better if you only sell your soul to it, really a tempting offer, when the wheeks of the pigs announce that another person they know has arrived.

If Simon wasn't clued in that something was off at seeing you home before the end of your work day, the pungent smell of menthol would have been a dead give away. You're still communing with your tea when he knocks against the wall, pulling you out of the deal for your soul to meet him with bleary eyes and a flushed face.

You croak out a greeting that makes Simon wince in sympathy, though that's about all he really does. Simon doesn't really do pleasantries and doting probably wouldn't be the first word people use to describe him, so with your brain function reduced by an overflow of mucus and fever, the kitchen was rather silent.

Until you started coughing, face buried into the crook of your elbow to try to keep your contagion to a minimum and back bowing to nearly double you over. That drives Simon to action, coming to try to keep you up incase you collapse, grabbing your free arm.

When you feel him touch you, you try to pull away, shaking your head and finally finishing your bout, gasping a little as you try to daunting task of breathing and speaking to dissuade him from getting close lest he catches what you have. He clearly wasn't persuaded, hands clenching and unclenching like he simply wanted to pick you up and put you...somewhere.

How exactly Simon Riley would take care of you, he didn't know but he'd be damned sure to at least try. He'd been left to fend for himself while sick before and he didn't like the idea of you going through that. When it was clear that he wasn't going to just leave you to your suffering you relented enough to try to reach a compromise; if he'd be alright watching the pigs while you were sick that would be more useful than a nursemaid while you camped out on the couch.

That...that was something Simon could do. He'd watched how you took care of the boys, surely this was something he could do. And then his brain caught up to the rest of what you had said. There was no way he was going to let you sleep on some pull out couch, as nice as it was. Being Sick meant sleeping in a proper bed, on a mattress that didn't spend it's days folded up.

You tried to insist it was alright but he wouldn't listen to a word of it. Instead he practically herded you back to the bedroom, ignoring your murmurs of your abandoned hot beverage. He didn't lift you to plop you onto the bed itself but it was a near thing. He had to bribe you with the promise of a proper cup of tea for you to even lay your head on your pillow, eyes already heavy with the need for sleep. By the time he had actually made a cup you were out for the count, nasally mucus filled snores letting him know you hadn't perished in the time it took him.

The next few days were filled with mucus, the attempted escape of your lungs via coughing fits, and more Vics than the human body should be exposed to. And the entire time you insisted that you could fend for yourself. Simon didn't push to play nurse, but your tissues never ran out, a dose of medication was always ready on your bedside, and a warm cup of tea stood waiting for you after each nap, like a solider committed to his guard.

Edit;

I'm going to make a separate post for the guinea pigs, because honestly I'm torn on if they're based on my guinea pigs I used to have, or guinea pigs I'd want to have in the future

#military program spouse#cod#simon riley x reader#simon x reader#simon ghost riley#Simon x Thimble#ghost x reader

271 notes

·

View notes