#AerospaceAdditive

Explore tagged Tumblr posts

Text

3D Printing Powder Market analysis reveals 2025 industry trends and forecasts

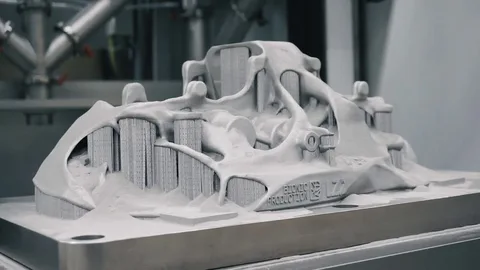

The 3D Printing Powder Market is entering a transformative phase as 2025 approaches, driven by innovation, adoption across sectors, and increasing demand for precision manufacturing. This market, crucial to additive manufacturing, is evolving rapidly due to advancements in powder materials and their varied applications in industries such as aerospace, medical, automotive, and consumer goods.

Rising Demand Across Key Industries

The increasing integration of 3D printing technologies in critical sectors is accelerating the demand for specialized powders. Aerospace remains a leading consumer, benefiting from lightweight components and complex part geometries that 3D printing enables. Medical applications are also surging, as biocompatible powders are used for implants and prosthetics. Automotive companies are leveraging powder-based printing for rapid prototyping and lightweight parts that meet sustainability goals.

As industrial adoption scales, so does the need for consistent powder quality, better flowability, and reduced contamination—trends that are shaping powder development strategies globally.

Dominance of Metal Powders

Metal powders dominate the market, with titanium, stainless steel, aluminum, and nickel-based powders seeing high demand. Titanium, in particular, is favored in aerospace and medical due to its high strength-to-weight ratio and biocompatibility. However, the high cost of production and the need for controlled particle sizes continue to challenge suppliers.

Powder manufacturers are investing in atomization technologies to improve particle uniformity. Gas atomization and plasma atomization are becoming standard for premium-grade powders, particularly in high-stakes applications.

Polymer and Ceramic Powder Trends

Polymer powders, especially nylon-based variants, are popular in consumer goods and healthcare due to their flexibility and affordability. Meanwhile, ceramic powders are gaining traction in dental and aerospace applications for their thermal and structural properties.

Research into hybrid powders and composite formulations is ongoing, with the goal of achieving new material properties and expanding the scope of end-use applications.

Regional Market Insights

North America and Europe currently lead the market, with significant investment from aerospace and healthcare industries. The U.S. continues to be a hub for powder innovation, supported by strong R&D initiatives and partnerships between academia and industry.

In contrast, the Asia-Pacific region is emerging rapidly, driven by China, Japan, and South Korea’s investments in manufacturing infrastructure and localized powder production. Government support in these regions is accelerating domestic innovation, making APAC a critical growth driver through 2025.

Forecasting 2025 Growth

By 2025, the 3D printing powder market is expected to exceed previous estimates, thanks to the continued expansion of additive manufacturing ecosystems globally. Market analysts forecast a steady CAGR, with metal powders maintaining the largest revenue share, followed by polymers.

Key factors driving this growth include:

Decreasing costs of powder production

Greater customization in manufacturing

Increasing regulatory acceptance in medical applications

Adoption of digital manufacturing in developing economies

Sustainability and Circular Economy Influence

Sustainability is now a strategic priority. Manufacturers are exploring powder recycling and reuse strategies to reduce waste. Closed-loop systems are being developed to ensure powders can be collected, reprocessed, and reused, especially in high-volume production environments.

Moreover, sustainable sourcing of raw materials is influencing buyer behavior. Companies that demonstrate reduced carbon footprints in powder production are being favored in competitive bidding scenarios, especially by OEMs seeking greener supply chains.

Challenges Ahead

Despite promising growth, the market faces challenges. These include:

High cost of advanced metal powders

Quality control across batch productions

Regulatory hurdles in medical and aerospace sectors

Intellectual property issues in powder formulations

Addressing these concerns will require collaboration between powder manufacturers, printer OEMs, regulatory bodies, and end-use industries.

Innovations and Future Outlook

Nanostructured powders and smart materials are on the horizon. These advancements could bring entirely new capabilities to additive manufacturing, including materials that change properties based on external stimuli. Furthermore, AI-powered quality assurance and real-time powder monitoring systems are expected to become integral to maintaining powder consistency and performance.

The future of the 3D printing powder market lies not just in scale, but in precision and adaptability. As additive manufacturing becomes central to digital production strategies, powder producers must evolve from suppliers to strategic partners in innovation.

#3DPrintingPowder#AdditiveManufacturing#MarketForecast2025#MetalPowders#3DPrintingTrends#PowderMaterials#DigitalManufacturing#AerospaceAdditive#Medical3DPrinting#SustainableManufacturing#APACManufacturing#AdvancedMaterials#3DPrintingIndustry#ManufacturingInnovation

0 notes