#Automated Packaging Solutions

Explore tagged Tumblr posts

Text

How Automated Pharmaceutical Packaging Machines Are Revolutionizing Drug Production in India

The pharma industry in India is now building a global success story. Ranked third in volume and 14th in value, India is a pharmaceutical powerhouse that is currently supplying over 50% of the global demand for vaccines and another significant share of generic drugs worldwide. As this sector accelerates, so does the demand for speed, safety, precision, and smarter medicine packaging.

This has, in turn, created a higher demand for the pharmaceutical packaging machines. These machines are the unsung heroes that work quietly behind the scenes to protect drugs, extend shelf life, prevent contamination, and meet compliance standards.

In today’s fiercely moderated and regulated, export-driven Indian pharma market, packaging isn’t just a final step; it is a frontline warrior ensuring brand credibility and patient safety.

To maintain this demand, manual packaging has become passé. Now, automated packaging solutions are continuously transforming how medicines are being prepared for the market, with benefits spanning across hygiene, output, traceability, and efficiency. At the heart of this shift is Nichrome, a trusted packaging machine manufacturer and supplier, known for engineering innovation and providing consistent support to the pharmaceutical sector.

From tablets and capsules to ointments and sachets, Nichrome machines offer precision, speed, and smart packaging technology that meets today’s needs and foresees tomorrow’s challenges.

Pharmaceutical Packaging – The Protective Layer of Trust

It’s not just about putting pills in a box when it comes to pharmaceutical packaging. It is about protecting lives, as it plays a crucial role in ensuring the safety, stability, and usability of medicines across their lifecycle, from manufacturing to consumption.

Why is Pharmaceutical Packaging so important?

Contamination Prevention – Safeguards from moisture, air, light, and microbial exposure that can degrade the product.

Accurate Dosage – Maintains the exact amount of dosage per unit, especially vital in tablet packaging, capsule packaging, and sachet packaging.

Enhances Tamper Evidence – Helps in building consumer trust by offering easily visible signs if a product has been previously opened or altered.

Patient Compliance – Allows for clear instructions, proper labelling and smart packaging that can help patients/medical professionals follow the correct dosages schedules.

Extends Shelf Life – Preserves product efficacy and safety over time, especially for sensitive formulations like suspensions and creams.

Traceability Support – Helps trace products through the supply chain, vital for recalls, audits, and regulatory approvals.

Global Compliance – Supports adherence to multiple medical norms like Good Manufacturing Practices (GMP), WHO, and FDA guidelines that are necessary for domestic and export markets.

What products need specialised packaging?

Tablets and capsules

Powders (e.g., ORS, nutritional supplements)

Liquids and suspensions

Ointments and gels

Single-use doses via sachets, stick packs, or tubes

What are the hidden risks of poor packaging?

Inaccurate labelling can cause wrong dosages

Damaged packs can result in contaminated products

Leaky containers cause reduced efficacy

Regulatory penalties or market bans can occur from even a single non-compliance

Robust medicine packaging isn’t just good practice; it is a critical business strategy in today’s competitive market. When done right, it not only protects the product but also your brand and, most importantly, your patients.

Manual Drug Packaging Challenges: Why can’t it keep up?

At first glance, manual drug packaging can appear to be a very cost-effective and simple option, especially for startups and small-scale pharma units. It offers a low initial investment and doesn’t require any complex machinery or specialised training, but beneath the surface, the limitations of manual processes have revealed themselves quickly. Let’s tally up the pros with the cons:

Pros:

Low upfront investments make manual drug packaging suitable for businesses with tight budgets

With Simple operations, it is ideal for small-scale, low-volume production runs

Cons:

Prone to human errors, in dosage, labelling and sealing accuracy

Time-consuming and inefficient, causing slower output per batch

Labour-intensive, as it requires more manpower, increasing operational costs

Inconsistent results with higher rejection rates due to non-uniform packaging

Since it is difficult to maintain hygiene standards manually, there are greater contamination risks

Non-compliance issues, since it is harder to align with GMP, WHO, and FDA regulations

No traceability to support serialization or batch tracking for exports

Not feasible for growing production needs with limited scalability options

In the highly competitive and regulated pharma industry, manual methods often fall short. As global markets demand faster turnarounds and tighter compliance, manual packaging becomes a bottleneck rather than a solution.

Therefore, today, upgrading to automated pharmaceutical packaging machines isn’t just about improving productivity; it is about staying relevant, reliable, and ready for the future.

Rise of Automated Pharmaceutical Packaging Machines: Making precision meet progress

The days of packaging being manual, repetitive, and slow-moving are long gone. Today, automated pharmaceutical packaging machines have vastly redefined the landscape by ushering in an era where speed meets precision and compliance meets convenience.

These are more than your average machines; they are almost like intelligent packaging companions, outfitted with robotics, vision sensors, servo-driven controls, and data-enabled diagnostics. These machines don’t just pack; they inspect, adjust, align, and ensure that every pack meets the gold standards of pharma packaging.

Why is automation winning the race?

High-speed packaging - thousands of units are sealed, sorted, and labelled in minutes, without a dip in quality.

Precision dispensing - minimal deviation guarantees uniformity in dosage and weight

Reduction of manual contact - improves hygiene and eliminates the risk of contamination—crucial in GMP-compliant environments.

Integration with vision systems, serialisation, and barcoding ensures traceability, anti-counterfeiting, and regulatory compliance.

From WHO to FDA norms, automated systems make it easier to tick every compliance checkbox.

What about the challenges?

Automation does require a higher initial investment, along with skilled personnel for operating and maintaining these machines. However, these are quickly outweighed by the benefits like reduced wastage, higher output, minimal rejections, and audit-readiness.

Whether you are looking at the blister packaging machine, a capsule counting and filling machine, or a sachet packaging machine, automation has now become essential. And with our advanced packaging technology, India’s pharma industry is stepping confidently into the future.

Nichrome’s Pharma Packaging Machines: Making innovation meet implementation

At Nichrome, we believe that pharmaceutical packaging is more than just a process; it is a promise. For over 4 decades, we’ve led the charge in India packaging innovation, delivering custom pharmaceutical packaging machines that combine speed, accuracy, and hygiene with unmatched reliability.

Our deep domain expertise in the pharmaceutical sector allows us to offer machines that can easily cater to every stage of medicine packaging, be it powders, liquids, tablets, or ointments. Each of our machines is thoughtfully engineered, keeping the industry standards and guidelines in mind.

Let’s take a closer look at our specialised lineup:

Blister Packaging Machine: This high-speed machine delivers precision cavity filling, robust sealing, and minimal material wastage, making it ideal for tablet packaging and capsule packaging. Features include servo-based indexing, inline coding, and an easy-to-clean structure, making it perfect for both large-scale and contract manufacturing units.

Sachet Packaging Machines (Multilane Stick Pack Machine): A go-to solution for ORS powders, rehydration salts, protein supplements, and liquid suspensions. It is available in 3-side seal, 4-side seal, and stick pack formats. These machines offer flexibility with high output, making them ideal for single-dose sachets that demand accuracy and hygiene.

Tube Filling Machine: Built for creams, gels, and ointments, this machine ensures air-tight fills without leaks or dosage variation. Its precise fill control, minimal changeover time, and robust build make it a favourite for pharma and personal care applications.

Capsule Counting and Filling Machine: It features smart rejection systems, sensor-based counting, and dust-free operation, with its high-speed operations. Excellent for packaging and compliance with serialization norms.

Powder & Liquid Filling Machines: Our servo-based auger fillers and volumetric liquid fillers offer high-precision fills with reduced wastage. They are designed for consistent fill weight and tamper-proof packaging of syrups, suspensions, and dry powders.

Each machine is compact, operator-friendly, and equipped with smart diagnostics. Plus, with our strong post-sales support, remote monitoring capabilities, and nationwide service network, seamless operations for you are always assured. When it comes to drug packaging India, relies on Nichrome packaging machines that are the prescription for performance, precision, and peace of mind.

Time to Consider Automatic Packaging Machines: The right fit for you

Now you may still wonder whether or not our state-of-the-art automatic packaging machines are the right fit for you or not. Well, let’s quickly break it down for you:

Startups & SMEs: Manual machines may be working fine for you now, but they will limit your scale. A good auto packaging machine with modular upgrades can easily give the head start that your business needs.

Mid to Large Pharma Units: To meet the export norms, improve travelability, reduce manual dependency, automating with pharmaceutical packaging machines is essential.

Key Decision Factors:

Projected production volumes

Regulatory compliance needs

Quality control requirements

Skilled manpower availability

With pharma automation, even niche manufacturers can achieve big-league efficiency.

Nichrome Advantage: Powering Smart Packaging with Real-time Intelligence

As pharmaceutical packaging embraces the digital shift, Nichrome Data Over Internet (NDOIT) emerges as a game-changer, fusing IoT capabilities with cloud-based intelligence to power smarter operations. Here's how NDOIT is revolutionising the landscape:

Real-time Data Logging - Enables instant data collection from packaging lines—monitor performance, uptime, and quality metrics in real-time.

Cloud-based Connectivity - Uses public, private, or hybrid cloud models to store and analyse data—accessible from anywhere, anytime.

Remote Monitoring & Predictive Maintenance - Helps detect issues before they become breakdowns—boosting uptime, reducing rejections, and enhancing machine longevity.

With NDOIT, Nichrome transforms every packaging machine into a smart, self-aware unit, equipping pharmaceutical companies with the tools to scale securely, operate efficiently, and lead confidently in a data-driven world.

Conclusion: Wrapping the future right with automation

The future of pharma is fast, smart, and safe; therefore, if you are in pharma production, your packaging line should be the strongest link and not the weakest.

As automated pharmaceutical packaging machines are powering this revolution, robust drug packaging machines have become a strategic investment. So, are you ready to upgrade your pharmaceutical packaging?

Contact us today to explore our cutting-edge automated packaging machines because with Nichrome machines, you don’t just automate—you elevate.Let’s take your packaging from manual to magnificent—because at Nichrome, we don’t just pack, we package the future.

#pharmaceutical packaging machines#automated packaging solutions#packaging machine manufacturer#automated pharmaceutical packaging machines#blister packaging machine#capsule counting and filling machine#sachet packaging machine#Tube Filling Machine#Powder & Liquid Filling Machines#automatic packaging machines#Nichrome Data Over Internet (NDOIT)

0 notes

Text

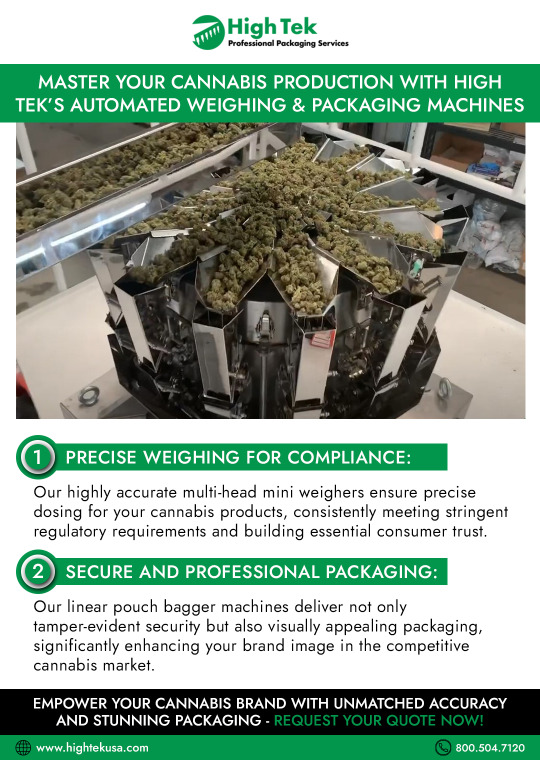

Master Your Cannabis Production with High Tek's Automated Cannabis Weighing & Packaging Machines

Elevate your cannabis brand with unmatched accuracy and stunning packaging! High Tek's automated weighing and packaging machines are designed to meet stringent regulations while giving your products a premium look. Secure, professional, and precise – that's the High Tek difference.

Ready to boost your brand? Request your quote today!

#AutomatedCannabisPackagingMachine#AutomatedPackaging#AutomatedCannabisPackagingEquipment#AutomatedCannabisWeighingMachine#AutomatedCannabisWeighingEquipment#CannabisBusiness#PackagingSolutions#HighTekUSA#Automated packaging solutions

0 notes

Text

Automatic Food Wrapping and Packaging Machines Market Set to Hit $6.2 Billion by 2035

The global market for Automatic Food Wrapping and Packaging Machines is expected to grow significantly, with industry revenue projected to reach $6.2 billion by 2035, up from $2.3 billion in 2024. This represents a compound annual growth rate (CAGR) of 9.4% during the forecast period from 2024 to 2035.

Detailed Analysis - https://datastringconsulting.com/industry-analysis/automatic-food-wrapping-and-packaging-machines-market-research-report

These machines play a pivotal role across various industries including food production, bakery and confectionery, pharmaceuticals, and electronics. The growing demand for packaged food, advancements in automation technology, and the increasing importance of food safety are key drivers of this market expansion.

Competitive Landscape and Industry Leadership

The Automatic Food Wrapping and Packaging Machines market is characterized by intense competition, with several leading players vying for market share. Major companies in the market include:

ABB Ltd

Bosch Packaging Technology

Coesia SpA

Fuji Machinery Co Ltd

Illinois Tool Works Inc

Krones AG

Multivac Sepp Haggenmuller SE & Co KG

Nichrome India Ltd

Oystar Holding GmbH

Sealed Air Corp

SIG Combibloc Group AG

Tetra Laval International SA

These companies are continuously innovating to enhance automation, increase packaging efficiency, and meet stringent food safety regulations, all of which are helping them secure leadership positions in the market.

Key Growth Drivers and Emerging Opportunities

The market’s growth is fueled by several key factors:

Demand for Packaged Food: The increasing consumer preference for ready-to-eat and convenient food products is driving the demand for efficient and cost-effective packaging solutions.

Advancements in Automation: Automation in food packaging is enhancing operational efficiency, reducing human intervention, and improving packaging consistency.

Stringent Food Safety Regulations: The rising focus on food safety is pushing manufacturers to adopt advanced packaging solutions that extend shelf life and ensure hygiene.

Smart and Sustainable Packaging: The shift towards smart, eco-friendly, and sustainable packaging solutions is creating new opportunities in the market.

Strategic Collaborations: Partnerships between equipment manufacturers and packaging material providers are driving innovation and expanding market reach.

Regional Dynamics and Supply Chain Evolution

North America and Europe are the most active and leading regions in the Automatic Food Wrapping and Packaging Machines market. Both regions benefit from advanced manufacturing capabilities, strong regulatory frameworks, and high consumer demand for packaged food. However, emerging markets such as Vietnam, Nigeria, and Indonesia are becoming increasingly important as new growth hubs. Companies are expanding their operations into these regions to diversify revenue streams and capitalize on growing demand.

Despite challenges such as high equipment costs, maintenance expenses, and the need for skilled labor, the supply chain from raw material acquisition to machine manufacturing and end-user distribution is expected to evolve. Strategic advancements in emerging markets will further contribute to the expansion of the industry.

About DataString Consulting

DataString Consulting is a trusted market research and business intelligence provider, offering a comprehensive range of solutions for both B2C and B2B markets. With over 30 years of combined industry experience, DataString delivers actionable insights that help businesses make informed, strategic decisions.

The firm specializes in opportunity assessment, competitive intelligence, and market forecasting, ensuring that clients are equipped with the tools and knowledge to navigate high-growth industries. DataString’s customized research services are tailored to meet specific business objectives and support long-term strategic success.

#Automatic Food Wrapping Machines#Food Packaging Machines#Packaging Industry#Food Processing Equipment#Automated Packaging Solutions#CAGR#Packaging Market Growth#Food Safety Regulations#Sustainable Packaging#Automation in Food Packaging#Global Packaging Market#Smart Packaging Technology#Food Industry Automation#Food Packaging Innovation#Market Expansion#Packaging Equipment Market#Food Production Packaging#Bakery Packaging#Confectionery Packaging#Emerging Markets in Packaging#Packaging Industry Trends#Food Packaging Solutions#Tetra Laval#Krones AG#Multivac Packaging

0 notes

Text

Agrochemical Packaging Materials: What You Need to Know

#Agrochemical Packaging Machines#automated packaging solutions#filling and packaging mach#VFFS machine#pesticide packaging#fertilizer packaging

0 notes

Text

Automatic Double Positioning Rigid Box Making Machine PC-8040A

The Automatic Double Positioning Rigid Box Making Machine is setting new standards in the packaging industry, particularly for businesses that require efficiency and precision in box production. This innovative machine is designed to create two boxes simultaneously, streamlining the manufacturing process and significantly enhancing productivity.

Key Features

The PC-8040A model exemplifies the latest advancements in rigid box making technology. Here are some of its standout features:

Dual Production Capability: The machine can produce two different box types at the same time, which is a game-changer for businesses that need versatility in their packaging solutions.

High-Speed Operation: With the ability to handle double paper feeding, corner pasting, and box forming concurrently, the PC-8040A can produce up to 15-25 pairs of boxes per minute. This high-speed operation is crucial for meeting large orders and tight deadlines.

Precision Engineering: Equipped with a Yamaha robotic arm, the machine ensures high precision in positioning, with an accuracy of ±0.1mm. This level of precision is essential for maintaining quality in packaging, especially for luxury items.

User-Friendly Control System: The machine features a PLC control system that allows for easy adjustments and monitoring of the production process. This digital interface enhances operational efficiency and reduces the likelihood of errors.

#Rigid Box Manufacturing#Automated Packaging Solutions#Double Positioning Technology#High-Speed Box Production#Precision Packaging Machinery

1 note

·

View note

Text

🎯 Want to future-proof your SharePoint projects? Learn how to build SPFx components & publish them to NPM for ultimate reusability. 🚀 Master modular, maintainable SharePoint dev today! #SharePoint #JavaScript #WebDev

#build sharepoint ui#build spfx solution#component based sharepoint#enterprise sharepoint#es6 module sharepoint#gulp sharepoint#hello world web part#javascript module#lerna monorepo#maintainable sharepoint code#microsoft 365 developer#microsoft spfx#modern sharepoint#modular javascript#npm publish#npm sharepoint#nx workspace#publish npm package#publish sharepoint solution#react components sharepoint#react spfx#reusable javascript#reusable spfx#scalable sharepoint development#semantic versioning#sharepoint automation#SharePoint customization#SharePoint customization tutorial#sharepoint developer guide#SharePoint Framework

0 notes

Text

The Palletizer Basic is the latest addition to the popular palletizing series from EasyRobotics. Designed with simplicity, reliability, and efficiency in mind, this collaborative robot palletizer is a compact and robust unit that offers an ideal solution for businesses prioritizing straightforward automation. Its durable steel construction ensures long-lasting performance, while its mobility allows for seamless integration into dynamic production environments.

#automated palletizing system#cobot palletizing solution#end-of-line palletizing system#compact cobot palletizer system#packaging automation palletizer

0 notes

Text

Packaging Machinery Specialist Greif-Velox Celebrates 80 Years at Its Site in Lübeck, Germany

Packaging machinery manufacturer Greif-Velox is celebrating 80 years of company history at its Lübeck location in Germany and invites guests to the in-house trade show Greif-Velox Connect on May 13, 2025. Reflecting on a rich tradition while keeping a firm eye on future innovations, the company underscores its role as a technology leader in the packaging industry.

From the “Greifenmühle” to High-Tech Manufacturing

The roots of Greif-Velox trace back to the year 1100, with the founding of the Greifenmühle (“Griffin Mill”) by monks in Pomerania, in what is now Poland. A key turning point came in 1936 when Ernst Mahlkuch founded the Greif-Werke in Klützow, Pomerania, after inventing and patenting the automatic bagging scale “Velox.” Following the company’s relocation from Pomerania, a new chapter began in Lübeck in 1945. “The past eight decades have been shaped by challenges—but above all, by the development of outstanding innovations for the industry,” says Sebastian Pohl, Managing Director of Greif-Velox.

Milestones of Industrial Progress

From manufacturing certified Velox scales to developing fully automated packaging systems, Greif-Velox has continuously advanced filling technology over the past decades. Key technological milestones include the introduction of valve bag filling machines in 1957, sealing machines in 1966, and the establishment of a strong research partnership with the Lübeck University of Applied Sciences beginning in the 1980s. One major leap was the development of the VeloVac vacuum technology, which enabled dust-free packaging of ultra-light powders such as carbon black and silica—securing the company’s position as a global market leader in this segment.

Structural Change and Strategic Turning Points

Following the insolvency of Greif-Werke in 1997, a new beginning was marked by the founding of Greif-Velox Maschinenfabrik GmbH. The acquisition of filling and dosing specialist LogDos in 1999 significantly expanded the company’s portfolio, including the addition of automated liquid filling systems. In the years that followed, Greif-Velox continued to drive its internationalization. With the founding of Greif-Velox America in 2020—now based in Houston, Texas—the company currently operates in more than 90 countries worldwide.

Lübeck Remains a Strategic Hub

By extending the lease for its premises for another ten years, the company has once again reaffirmed its commitment to the city of Lübeck as a strategic location. “The combination of innovation, entrepreneurial vision, and a strong connection to the Lübeck site will continue to drive our success in the future,” says Managing Director Sebastian Pohl.

Greif-Velox Connect: Where Innovation Meets Networking

As part of its anniversary celebrations, Greif-Velox will host Greif-Velox Connect at its Lübeck headquarters on May 13, 2025. Under the motto “Explore. Innovate. Network.” the event will feature expert talks, live machinery demonstrations, discussions with industry specialists, and exclusive insights into the company’s in-house InnovationHub. “Greif-Velox Connect is a key meeting point for our partners, customers, and employees,” says Managing Director Thorsten Köll. “Our aim is not only to reflect on the past but to actively engage in conversations about the future of packaging technology and to spark new ideas together.”

For more information, please visit: https://www.greif-velox.com

#pharmaceutical packaging#sustainable packaging solutions#automated packaging systems#packaging innovation#industrial packaging equipment#packaging trade show#packaging trends 2025#80 years celebration#packaging tests

1 note

·

View note

Text

The Best Time to Setup Your Spice Business with Right Packing Machines

Monsoon is the best season to start your own spice business — the demand is high, and so are the margins! But packaging issues like moist pouches, unclear batch codes, and sealing failures can ruin your product quality.

Common Spice Packaging Problems Faced by Business Owners:

Moisture trapped inside spice pouches Smudged or unclear MRP/date printing Spillage during filling Low-speed packaging affecting bulk orders Inconsistent batch codes Weak sealing causing product damage

In this blog, you’ll discover what machines are essential to start a spice brand and how Avant Garde Industries supports you with packaging, printing, and sealing solutions. We offer demo videos, EMI plans, free consultations, and Pan India delivery. Read now to build a strong foundation for your spice business!

👉 Read Full blog: Setup to start a Spice Business in India with the Right Packaging Equipment

#setup to start spice business#masala packing machine#powder filling#TIJ printer#spice packaging solutions#industrial equipment#batch coding#packing machine#industrial automation

0 notes

Text

#Truck loading conveyor system manufacturer#Vertical lift for material handling manufacturer#Flow wrap machine for FMCG packaging manufacturer#Vertical reciprocating conveyor (VRC) manufacturer#Goods lift manufacturer India#Industrial conveyors for packaging lines manufacturer#End-of-line packaging solutions manufacturer#Smart packaging and conveyor integration manufacturer#Heavy-duty goods lifts manufacturer#Automated truck loading and unloading system manufacturer#Conveyor belt manufacturer#Horizontal flow wrap machine India manufacturer#Horizontal packaging machine for high-speed wrapping manufacturer#Industrial palletizing and packaging line manufacturer#Intralogistics solutions manufacturer#Telescopic boom conveyor manufacturer#Telescopic conveyor for truck loading manufacturer#Warehouse automation manufacturer#FMCG packaging machinery manufacturer

0 notes

Text

How Automated Pharmaceutical Packaging Machines Are Revolutionizing Drug Production in India

The pharma industry in India is now building a global success story. Ranked third in volume and 14th in value, India is a pharmaceutical powerhouse that is currently supplying over 50% of the global demand for vaccines and another significant share of generic drugs worldwide. As this sector accelerates, so does the demand for speed, safety, precision, and smarter medicine packaging. This has, in…

#automated packaging solutions#automated pharmaceutical packaging machines#automatic packaging machines#blister packaging machine#capsule counting and filling machine#Nichrome Data Over Internet (NDOIT)#packaging machine manufacturer#pharmaceutical packaging machines#Powder & Liquid Filling Machines#Sachet packaging machine#Tube Filling Machine

0 notes

Text

Reliable Semi-Auto Crimping Machine | NPM Machinery

Looking for a high-performance Crimping Machine? NPM Machinery offers a reliable Semi-Auto Crimper for precise cap sealing. Ideal for pharma & cosmetics.

Explore now at NPM Machinery.

#Crimping Machine#Semi Auto Crimper#Cap Sealing Machine#Pharma Packaging Machine#Cosmetic Packaging Equipment#NPM Machinery#Bottle Capping Machine#Packaging Automation#Industrial Crimping Equipment#Semi Automatic Capping Machine#Pharmaceutical Machinery#Cosmetic Machinery#Sealing Solutions#Crimping Solutions#Reliable Crimping Machine

0 notes

Video

youtube

Customized Packaging Line with 8 sets of vertical packing machines & Car...

Customized Packaging Line with 8 sets of vertical packing machines & Cartoning & Automatic Labeling This fully integrated packaging system combines 8 vertical form-fill-seal machines with manual cartoning and automatic labeling for complete end-to-end production. Line Configuration: • 8 independent VFFS units for continuous product packaging • Manual cartoning station for operator-assisted box loading • 90° belt turn modules (x2) for compact floorplan adaptation • Automatic labeling system for sticking at side of carton Design Advantages: ✓ Space-optimized layout designed around your facility ✓ Natural workflow between automated and manual processes ✓ Gentle product handling throughout all stages ✓ Adaptable components for various packaging formats

#youtube#packing machine#packaging line#manufacturing packaging#customized packaging#packaging solution#cartoning#labeling#automation#bestar packaging#bestar rachel

0 notes

Text

MicroScan by MicroDynamics enhances automation and scanning, aligning with sustainability of packaging, recyclable packaging, sustainable packaging solutions

#sustainability of packaging#recyclable packaging#sustainable packaging solutions#MicroScan 3.7#software automation#packaging technology update

1 note

·

View note

Text

Automatic Labeling Machine Market Drivers: Key Forces Fueling Global Industry Growth

The automatic labeling machine market is gaining momentum globally, driven by rapid industrial automation and the need for accurate, efficient, and high-speed labeling solutions. These machines, essential in industries such as food and beverage, pharmaceuticals, cosmetics, and logistics, are evolving in design and function to meet growing demands. With the global market expected to reach over USD 3.4 billion by 2030, understanding the key drivers behind this growth is crucial for businesses, investors, and industry professionals.

1. Rising Demand for Packaging Automation

One of the most influential drivers of the automatic labeling machine market is the increasing demand for automation in packaging processes. As manufacturers aim to enhance productivity and minimize human error, automated labeling systems offer an ideal solution. These machines streamline the labeling process, reduce labor costs, and improve overall operational efficiency. In industries with high-volume production, such as food and beverages or pharmaceuticals, automation has become a necessity rather than an option.

2. Expanding E-Commerce Sector

The explosive growth of e-commerce globally has significantly contributed to the demand for efficient labeling systems. Accurate product labeling ensures smooth logistics, helps in inventory management, and improves the customer experience. Automatic labeling machines facilitate the handling of large volumes of products by applying barcodes, shipping labels, and QR codes with high precision. As e-commerce continues to expand, especially in emerging markets, so does the need for reliable labeling solutions.

3. Stringent Labeling Regulations

Governments and regulatory bodies worldwide are enforcing stricter guidelines on product labeling, particularly in sensitive sectors like healthcare, pharmaceuticals, and food. These regulations aim to ensure consumer safety, product authenticity, and traceability. Automatic labeling machines help businesses comply with these requirements by producing consistent and tamper-proof labels. Their ability to integrate with traceability systems, such as serialization and anti-counterfeiting features, adds further value in regulated environments.

4. Technological Advancements and Smart Labeling

The adoption of smart technologies such as RFID (Radio Frequency Identification), IoT (Internet of Things), and AI (Artificial Intelligence) has transformed the labeling industry. Modern automatic labeling machines are now equipped with intelligent systems that offer real-time tracking, error detection, and remote operation capabilities. These advancements not only improve efficiency but also enable better decision-making and inventory control. Companies investing in smart labeling are gaining a competitive edge in terms of quality assurance and data analytics.

5. Growth in the Food and Beverage Industry

The food and beverage industry holds a significant share of the automatic labeling machine market. This sector demands fast, accurate, and hygienic labeling solutions to ensure compliance with food safety standards and consumer expectations. With the increasing consumption of packaged foods and beverages globally, manufacturers are upgrading to automatic labeling systems that support diverse packaging formats and label types. Product traceability, nutritional labeling, and expiration date accuracy are critical aspects driving this trend.

6. Pharmaceutical and Healthcare Applications

Pharmaceutical companies are among the early adopters of automatic labeling machines due to their need for precision and compliance. Labels on medicine bottles, vials, and cartons must contain critical information such as dosage, manufacturing date, batch number, and warnings. Given the strict regulations in the pharmaceutical industry, labeling errors can have serious consequences. Automatic machines ensure consistent and error-free application, making them indispensable in healthcare manufacturing units.

7. Sustainability and Eco-Friendly Labeling

Sustainability trends are shaping the automatic labeling machine market as companies aim to reduce their environmental impact. Eco-friendly label materials, recyclable packaging, and reduced waste in the labeling process are becoming standard expectations. Automatic labeling machines that support water-based adhesives, linerless labels, and energy-efficient operations are gaining popularity among environmentally conscious manufacturers. This shift is particularly strong in Europe and North America, where green initiatives are heavily promoted.

8. Regional Market Expansion

The Asia-Pacific region is currently leading the automatic labeling machine market, accounting for over 38% of the global share. Rapid industrialization, growing consumer markets, and government support for automation in countries like China, India, and Thailand are fueling this growth. Meanwhile, North America and Europe are experiencing steady demand due to their mature industrial infrastructure and focus on technological upgrades. Latin America and the Middle East are emerging markets with increasing investments in automation technologies.

Conclusion

The automatic labeling machine market is on a robust growth path, driven by a combination of industry needs, technological innovations, and regulatory frameworks. As businesses prioritize efficiency, accuracy, and compliance, the demand for automated labeling solutions will continue to rise. Understanding these key drivers allows companies to strategically invest in labeling technologies that not only enhance productivity but also support long-term growth and sustainability goals.

#Automatic Labeling Machine Market#Packaging Automation#Labeling Technology#Smart Labeling Solutions#Industrial Automation

0 notes

Text

Greif-Velox marks 80 years at Lübeck site with a trade show invite. Latest trends in packaging, packaging tests, pharmaceutical packaging news featured.

#pharmaceutical packaging#sustainable packaging solutions#automated packaging systems#packaging innovation#industrial packaging equipment#packaging trade show#packaging trends 2025#80 years celebration#packaging tests

1 note

·

View note