#Automatic Vial Filling and Rubber Stoppering Machine

Explore tagged Tumblr posts

Text

High Speed Automatic Vial Filling & Rubber Stoppering Machine

High Speed Automatic Vial Filling & Rubber Stoppering Machine suitable for the filling & rubber stoppering of glass vials. Our Automatic Eight Head Vial Filling & Rubber Stoppering Machine is widely uses in large volume injectable preparations. Machine consist automatic feeding, filling, bunging & ejection system all complies as per cGMP requirements. Automatic Vial Filling & Rubber Stoppering Machine can be attached to Vial Washing Machine and Vial Cap Sealing Machine in order to complete online Sterile Vial Filling Line. Machine complies as per GMP requirements. Our standard machine equipped with stainless steel piston pump for the liquid filing, further we can also provide peristaltic pump for higher filling accuracy upon specific customer request.

#Automatic Vial Filling & Rubber Stoppering Machine#Automatic Eight Head Vial Filling & Rubber Stoppering Machine

0 notes

Text

In need of a solution for sterile vial filling? The Automatic Injectable Powder Filling & Rubber Stoppering Machine provides accurate, high-speed vial filling at 120/240 vials per minute. This compact and GMP-compliant machine guarantees clean filling and precise rubber bunging, making it the perfect choice for pharmaceutical production.

visit https://www.parthec.com/product/automatic-servo-base-injectable-powder-filling-rubber-stoppering-machine

0 notes

Text

Leading Manufacturer of Pharmaceutical Machinery in China: Comprehensive Solutions for Vial and Ampoules Packaging Line

As a trusted manufacturer of pharmaceutical machinery and equipment, we specialize in delivering complete solutions designed for the production of tablets, liquids, capsules, powders, granules, and especially Vial and Ampoules Packaging Line. Our robust manufacturing capabilities, advanced R&D, and unwavering commitment to quality position us at the forefront of the pharmaceutical equipment industry in China and globally.

Why Choose Our Pharmaceutical Machinery Solutions

Unmatched Expertise in Pharmaceutical Engineering

We bring decades of experience in pharmaceutical engineering, offering high-precision machinery tailored for all production stages. Our pharmaceutical equipment is designed to comply with international standards such as GMP, CE, and ISO, ensuring safe, efficient, and compliant pharmaceutical production.

End-to-End Production Capabilities

From tablet compression machines to granule processing units, our product lineup covers every essential stage of pharmaceutical manufacturing:

Tablet Press Machines

Capsule Filling Machines

Liquid Filling and Sealing Machines

Powder Mixing & Blending Systems

Granulation Lines

Vial and Ampoules Packaging Line

Our integrated solutions streamline production processes, reduce downtime, and increase yield, which directly translates into higher profitability for pharmaceutical manufacturers.

Vial and Ampoules Packaging Line – Precision and Performance

Fully-Automated Packaging Line for Sterile Injectables

Our Vial and Ampoules Packaging Line offers high-speed, fully automated systems suitable for sterile environments. These lines are designed to handle delicate ampoules and glass vials with pinpoint precision, ensuring integrity, sterility, and consistent quality across batches.

Key features of our vial and ampoule packaging lines include:

Washing, Sterilizing & Drying Units

Liquid Filling Systems (Peristaltic or Piston Pump Based)

Rubber Stoppering and Capping Machines

Ampoule Sealing & Vial Crimping

Visual Inspection Systems

Labeling & Serialization Modules

Integrated PLC and SCADA Control Systems

Each component is designed to maintain aseptic conditions, protect product integrity, and deliver consistent performance.

Core Components of Vial and Ampoules Packaging Line

1. Automatic Vial and Ampoule Washing Machines

These machines are engineered to remove particulates and contaminants from containers using multi-stage ultrasonic and pressure-based washing with WFI (Water for Injection) and clean compressed air. Features include:

In-feed and out-feed automation

Multiple needle spray systems

Customizable formats for different vial sizes

2. High-Temperature Sterilization Tunnels

Utilizing dry heat sterilization, our tunnels eliminate microbial contamination and maintain the sterility of containers post-wash. They feature:

HEPA filtration

Conveyor system with variable speed

Temperature monitoring and validation systems

3. Liquid Filling and Stoppering Machines

These are precision filling machines with servo-driven pistons or peristaltic pumps, ensuring accurate filling volumes for even the smallest doses.

Filling range flexibility (0.1 ml to 100 ml)

In-line or rotary stoppering mechanisms

Laminar airflow units integrated for Class 100 environments

4. Sealing and Capping Units

For ampoules, flame-sealing systems provide hermetic closures, while for vials, aluminum caps are crimped tightly for maximum security.

Flame annealing systems for ampoules

Rotary or linear vial crimping systems

Cap feeding and sorting automation

5. Visual Inspection Systems

High-speed cameras and AI-powered software ensure every ampoule or vial is visually inspected for foreign particles, fill volume, seal integrity, and cosmetic defects.

360-degree inspection

Rejection systems for non-conforming units

Batch reporting and traceability

6. Labeling, Serialization, and Track & Trace

Incorporating advanced serialization technology, our labeling systems help comply with global traceability regulations including 21 CFR Part 11, EU FMD, and DSCSA.

Inkjet and thermal transfer printing

Tamper-evident labels

QR code and barcode support

Made in China, Trusted Worldwide

Our pharmaceutical machinery, proudly made in China, is exported to over 70 countries, including markets in Europe, the Americas, Middle East, Southeast Asia, and Africa. We offer turnkey projects and full support, from design consultation to post-installation training and after-sales service.

Custom-engineered solutions are our specialty. Whether you need a small-scale line for clinical trials or a full commercial production system, we provide flexible configurations tailored to your needs.

Innovation and Compliance – Our Manufacturing Promise

Research-Driven Development

Our dedicated R&D center is continuously innovating to enhance performance, reduce footprint, and integrate AI, IoT, and smart automation into our systems.

Digital twin modeling

Predictive maintenance systems

Cloud-connected data analytics

Regulatory Compliance

Our equipment complies with international regulatory frameworks, including:

GMP (Good Manufacturing Practices)

FDA 21 CFR Part 11

EU Annex 1 Guidelines

WHO and PIC/S Recommendations

Each machine undergoes rigorous FAT (Factory Acceptance Testing) and SAT (Site Acceptance Testing) to ensure seamless compliance during audits.

Unparalleled Customer Support and Global Services

Our team of multilingual engineers and service professionals provides 24/7 remote and on-site support to ensure uptime, training, and continuous improvement. Our global network of distributors and service hubs ensures fast delivery of spare parts and preventive maintenance services.

Industries We Serve

Our solutions are ideal for:

Pharmaceutical manufacturers

Biotech companies

Veterinary drug producers

Clinical research facilities

Contract manufacturing organizations (CMOs)

Partner with Us for Advanced Pharmaceutical Machinery Solutions

As a manufacturer of pharmaceutical machinery, we are proud to set benchmarks in precision engineering, sterile manufacturing, and packaging automation. Our specialized Vial and Ampoules Packaging Line is one of the most trusted solutions for injectable drug manufacturers worldwide.

Contact us today to discuss your production needs and discover how our China-based manufacturing facility can support your end-to-end pharmaceutical production goals.

Contact us:

GRAND INTELLIGENT EQUIPMENT (GUANGZHOU) CO.,Ltd

301A, Building 5, No.333, Juhuashi Ave, Huadu District, Guangzhou City, Guangdong, China.

+86-15361285728 ; +86-020-86886090

Email [email protected]

Wenzhou Grand Machinery Technology Co.,Ltd

Floor 4, Building 2, No.116, Xinglong Road, Wanquan Town, Pingyang County, Wenzhou City, Zhejiang Province, China

+86-15323319612 ; +86-577-65565288

Also available on

On Whatsapp

On Facebook

On Twitter

On Pinterest

On Youtube

On Tumblr

0 notes

Link

We have wide range of Products Including Automatic Liquid Bottle Filling Machine, Automatic Digital (Electronic) Liquid Filling Machine, Automatic Vial Filling and Rubber Stoppering Machine, Injectable Liquid Filling and Rubber Stoppering Machine, Automatic Two Head Volumetric Liquid Filling Machine, Automatic Four Head Volumetric Liquid Filling Machine, Automatic Six Head Volumetric Liquid Filling Machine, Automatic Eight Head Volumetric Liquid Filling Machine, High Speed Vial Filling and Rubber Stoppering Machine, Aseptic Liquid Filling Machine, Monoblock Bottle Filling & Capping Machine, Semi Automatic Liquid Filling Machine.

#Automatic Liquid Bottle Filling Machine#Automatic Digital (Electronic) Liquid Filling Machine#Automatic Vial Filling and Rubber Stoppering Machine#Injectable Liquid Filling and Rubber Stoppering Machine#Semi Automatic Liquid Filling Machine

0 notes

Text

How Are Colored Contact Lenses Made?

The contact lens is a device worn in the eye to correct vision, although some people wear colored contact lenses to enhance or change their eye color. The thin plastic lens floats on a film of tears directly over the cornea. For some forms of eye disease, contact lenses correct vision better than conventional spectacles. Many people prefer contact lenses over glasses for cosmetic reasons, and active sports enthusiasts prefer contact lens because of the freedom it provides them. There are basically three types of lenses: soft, hard, and gas-permeable. Soft contact lenses are usually more comfortable to wear, but they also tear more easily than hard contact lenses. Hard lenses also tend to "pop" out more frequently. Gas-permeable lenses are a compromise between the hard and soft, allowing greater comfort than hard lenses but less chance of tearing than soft lenses. Contacts are usually worn during the day and taken out every night for cleaning. Extended-wear lenses allow users to leave in their contacts for longer periods of time, even when they're sleeping. More recently, one-a-day contact lenses are gaining popularity among lens wearers. These contacts are worn for only one day and thrown away, eliminating the hassle of cleaning them every night.

Raw Materials

The raw material for contact lenses is a plastic polymer. (A polymer is a blend of materials created by linking the molecules of different chemical substances.) Hard contact lenses are made of some variant of polymethyl methacrylate (PMMA). Soft contact lenses are made of a polymer such as poly hydroxyethyl methacrylate (pHEMA) that has hydrophilic qualities, that is, it can soak up water and still retain its shape and optic functions. The science of lens material is always being updated by lens manufacturers, and the specific material of any contact lens may differ depending on the maker.

The Manufacturing Process

Contact lenses may be produced by cutting a blank on a lathe, or by a molding process. The forming of the lens involves shaping the plastic into specified curvatures. The major curves of the lens are named the central anterior curve (CAC) and the central posterior curve (CPC). The CAC refers to the overall curve of the side of the lens that faces out. This outer contour produces the correct refractive change to fit the patient's visual needs. The CPC is the concave inner side of the lens. This conforms to the measurements of the patient's eye. Usually these two curves are formed first, and the lens is then called semi-finished. The lens is deemed finished when peripheral and intermediate curves are formed, and the edge is shaped.

Molding method

1 Molding the lens can be carried out in several different ways. The lenses first developed in Prague were spin-cast. Three different fluids were poured into open rotating molds. The outside curvature of the lens was shaped by the mold, and the inside curvature was formed according to the speed of the rotation of the mold. The centrifugal force of the spinning mold led to the polymerization of the fluids so that the molecular chains linked to form the required hydrophilic plastic. A more reliable mass-production Contact Lens method is injection molding. In injection molding, the molten plastic is injected into the mold under pressure. Then the lens is removed from the mold and cooled. The lens is then finished on a lathe. It is also possible to produce lenses entirely through molding, that is, they need no lathe cutting. This is a recent development, made possible through highly automated, computer controlled mold production.

Lathe process

2 The initial forming of the lens can also be done by cutting on a lathe. First a blank is made. The blank is a circle only slightly larger than the size of the finished lens. This can be cut from a plastic rod, or stamped from a plastic sheet. Next the blank is fastened to a steel button with a drop of molten wax. The button is then centered on a lathe, which begins to spin at high speed. A cutting tool, which may be a diamond or a laser, makes concave cuts in the blank to form the CPC. Indicators on the lathe measure the depth of the cuts to guide the lens operator.

The button holding the blank is next moved to a lapping machine. The lapping machine holds the blank against a lapper, which is a revolving disk coated with an abrasive compound. The shape of the lapper matches the CPC of the lens. The lapping machine spins the blank in one direction, and the lapper in the other. It also moves the blank in a small figure eight motion. The abrasion polishes the lens surface.

The polished lens is then mounted on a steel shaft called an arbor. The end of the arbor has been ground to match the CPC so the lens will fit on the shaft. The arbor is installed in a lathe, and the operator makes convex cuts in the lens to form the other major curve, the CAC. Now this side of the lens is polished, and the lapper is modified to fit the convex CAC. When this second side of the lens is polished, the lens is considered semi-finished.

Finishing

3 The contact lens requires several more curves to be ground before the lens will fit exactly on the patient's eye. The final curves are the peripheral anterior and posterior curves and the intermediate anterior and posterior curves, which govern the shape of the lens nearest and next-nearest the edge. The lens is mounted on an arbor again by suction or with double-sided tape. The arbor is installed in the lathe or grinding machine. These shallower cuts may be ground with emery paper or cut with a razor blade. The diameter of the lens may also be trimmed at this time.

Quality control

4 Quality control is very important for contact lenses, since they are medical devices and they must be custom fit. The lenses are inspected after each stage of the manufacturing process. The lenses are examined under magnification for anomalies. They are also measured by means of a shadow graph. A magnified shadow of the lens is cast on a screen imprinted with a graph for measuring diameter and curvature. Any errors in the lens shape show up in the shadow. This process may be automatically performed by computer.

Packaging

5 After the lens has passed inspection, it is sterilized. Lens are boiled in a mixture of water and salt for several hours to soften the lens. Next, the lens are packaged. Standard packaging for lenses is a glass vial, filled with a saline solution and stoppered with rubber or metal. The hydrophilic material of soft contact lenses soaks up the saline solution, which is similar to human tears, and becomes soft and pliable. The lenses in this state are ready to wear.

The Future

The material for contact lenses is the subject of much research. Scientists are investigating different chemical recipes that may give plastic more desirable characteristics. One polymer currently being researched is a silicon-oxygen compound called siloxane. Siloxane forms a thin, flexible film and admits oxygen through to the eye 25 times better than current standard soft lenses. There are disadvantages to this compound, however: siloxane does not wet easily and it attracts lipids (fats) to its surface, causing it to cloud. Researchers have found a way to add flourine molecules to the siloxane compound, causing the material to resist lipids. Then they chemically attach a wetting agent, which changes its molecular shape when boiled in a saline solution, so that the material can soak up water like traditional soft lens. This material may ultimately lead to extended-wear contacts that can be worn for weeks at a time.

Researchers are also investigating new polymers that can be used for sclera lenses. For most people, comeal lenses are the norm, but the large sclera lenses are useful for patients with severely damaged corneas. Depending on the eye problem, some patients cannot regain their sight without a corneal transplant, but sclera lenses may help patients avoid eye surgery. Sclera lenses rest on the white part of the eye and form a vault over the cornea itself. This space over the cornea is filled with artificial tears, which serve to smooth out the cornea's damaged surface. In the past, sclera lenses have been uncomfortable because they do not allow enough oxygen to the eye, but investigations into new materials are focusing on more oxygen-permeable lenses.

Material for oxygen-permeable lenses has also been experimented on the space shuttle Endeavour. The designers of the experiment believe that micro-gravity conditions would promote a lens material that repels debris better and processes oxygen more effectively than polymers made in traditional labs. If commercially feasible, a new generation of contact lenses may be manufactured in space.

3 notes

·

View notes

Text

Vial Filling Machine come with salient features such as very high fill accuracy, diving nozzle for foam-free filling, automatic infeed and exit of vials, built-in a.c. variable freq. drive system, etc.

For more details, visit at https://www.lodhapharma.com/automatic-vial-filling-and-rubber-stoppering-machine.php

0 notes

Photo

Automatic High Speed Multi Axis Servo Driven Injectable Dry Powder Filling with Pick and Place Type Rubber Stoppering Machines

https://www.ambica.co.in/products/vials/injectable-dry-powder-filling-machines/automatic-high-speed-multi-axis-servo-driven-injectable-dry-powder-filling-with-pick-and-place/15

0 notes

Text

POINTS TO CONSIDER WHEN BUYING PHARMA PACKAGING MACHINERY

In the pharma industry, there's no margin for error. Whether it be the research, product development, product manufacturing or packaging process, the highest levels of precision, hygiene and quality are mandatory. Stringent GMP, FDA and other compliances have to be met.

Choosing new pharmaceutical packaging machines can be a confusing, stressful experience. There are so many manufacturers, suppliers and equipment models to choose from, and the cost implications can be huge. Here are some points to keep in mind when selecting your pharma packaging machinery.

1. Output capacity

Output capacity depends on the speed of your machine. Depending on your output requirement, choose a packaging machine that can deliver as per specifications. A machine that runs too fast or too slow can be problematic for your operators.

2. Digital capabilities

The pharma industry runs on the power of information technology and automation. A machine with advanced digital capabilities increases efficiency and enhances ease of use. From touch screens and all-access control to IoT compatible systems - pharma equipment with these capabilities will make your processes more productive, accurate and manageable.

3. Cleaning ease

Cleaning is an essential component of any manufacturing process but it shouldn't be complicated or involve huge amounts of downtime. Look for a machine that offers easy disconnect features. It will make cleaning faster, easier, and less stressful for your operators.

4. Production scale

Research industry requirements will naturally differ from those of industrial scale production lines. Machines can be of lab-scale and commercial-scale, so being clear about what type of equipment you need will make your selection easier and more effective.

5. Ease of operation

While modern machines are fully automatic, human intervention cannot be completely ruled out. Man-machine interaction still prevails, so you need a machine or pharma packaging line that is easy to understand and operate. Your equipment shouldn't be so simple as to miss out the latest innovations or technical features, nor should it be too complex to handle. With proper training, your operators should be able to efficiently manage day-to-day operations of the system.

6. Helpful, reliable supplier

Pharmaceutical machinery is a substantial investment, so find a supplier who deals in reputed brands and proven models. Your supplier should also have the knowhow, skills and experience to deliver and service high quality automatic packaging machines. Above all, your supplier should understand your industry needs and criteria, and patiently guide you through the best options.

PHARMACEUTICAL PACKAGING MACHINES FROM NICHROME

Nichrome is the pioneer and leading provider of integrated packaging solutions in India. It has joined hands with global players to bring to India a comprehensive, state-of-the-art range of cost-effective, high-quality filling lines and primary packaging systems for pharmaceutical products.

Strengthened by its own wealth of diversified knowhow and expertise in packaging, Nichrome offers the advantage of pooled expertise, delivering top-quality, technologically advanced solutions spanning the entire value chain of filling and packaging lines for pharmaceutical products.

Pharmaceutical powder packing machines, liquid filling machines, sachet filling machines – Nichrome offers a wide range of automatic packaging machines for the pharma industry. It also offers blister packaging lines capsules, tablets, pills and other pharma/cosmetic products besides solutions for processes such as Granulation, Tablet Compression, Coating, Counting and Filling, Printing, Inspection, Bulk packaging, Labelling and Cartoning.

Integrated solutions include:

· Counting and Feeding systems for tablets/capsules that cover bottle filling & capping, labelling, dessicant & leaflet insertion.

· Injection Automation line for ampoules/vials that cover washing, drying & sterilising, filling and rubber stoppering, and AL-cap sealing.

If you’re considering pharma packaging machine India, contact Nichrome. For 4 broad categories of pharmaceutical products, namely Oral Solid Dosage, Oral Liquid Dosage, Ophthalmic & ENT, and Injectibles (Vials/Ampoules and Pre-filled Syringes) - Nichrome offers advanced technology from international majors, backed by their own expertise, industry knowledge and strong nation-wide sales and service network. Can you ask for anything more?

#pharmaceutical packaging machines#pharma packaging machinery#pharma packaging#automatic packaging machines#powder packing machines#liquid filling machines-#sachet filling machines#blister packaging#pharmaceutical blister packaging machines#blister packaging machine pharmaceutical industry#pharmaceutical packaging machine#pharmaceutical sachet packaging machine#packaging machines in pharmaceutical#pharmaceutical blister packaging machines manufacturers

0 notes

Text

Injectable Liquid Filling and Rubber Stoppering Machine

Automatic Four Head Volumetric Liquid Vial Filling with Rubber Stoppering Machine Model ALVF 4 is suitable for Round Vials with maximum speed up to 120 Vials per minute. The Machine can give Maximum speed up to 120 Vials per minute depending on nature of Liquids, Vial Neck Size, Fill Volume and Rubber Stopper size. Machine construction in fully Stainless Steel finish including machine frame structure. Machine with built-in Turn Tables at In-feed and Out-feed with individual drives to match the speed of incoming and outgoing vials for smoother operation. All parts coming in contact with Liquids and Rubber Stoppers are made from SS 316 Materials. Machine also available with Vaccumetric type Rubber Stoppering System.

#Liquid Filling and Rubber Stoppering Machine#Automatic Four Head Volumetric Liquid Vial Filling with Rubber Stoppering Machine#Liquids and Rubber Stoppers

0 notes

Text

Experience unmatched precision with our Automatic Servo-Based Vial Filling & Stoppering Machine — featuring a 12-head servo-driven syringe system for accurate liquid dosing and a vacuum stoppering unit for flawless rubber stopper placement, supporting both full and half stoppering.

For more details, visit- https://www.parthec.com/product/automatic-servo-base-vial-filling-stoppering-machine-motion-filing

#parthengineersandconsultant#VialFillingMachine#ServoFillingMachine#AutomaticFillingMachine#LiquidFillingMachine#PharmaFillingMachine#StopperingMachine#VialStoppering#HighPrecisionFilling

0 notes

Photo

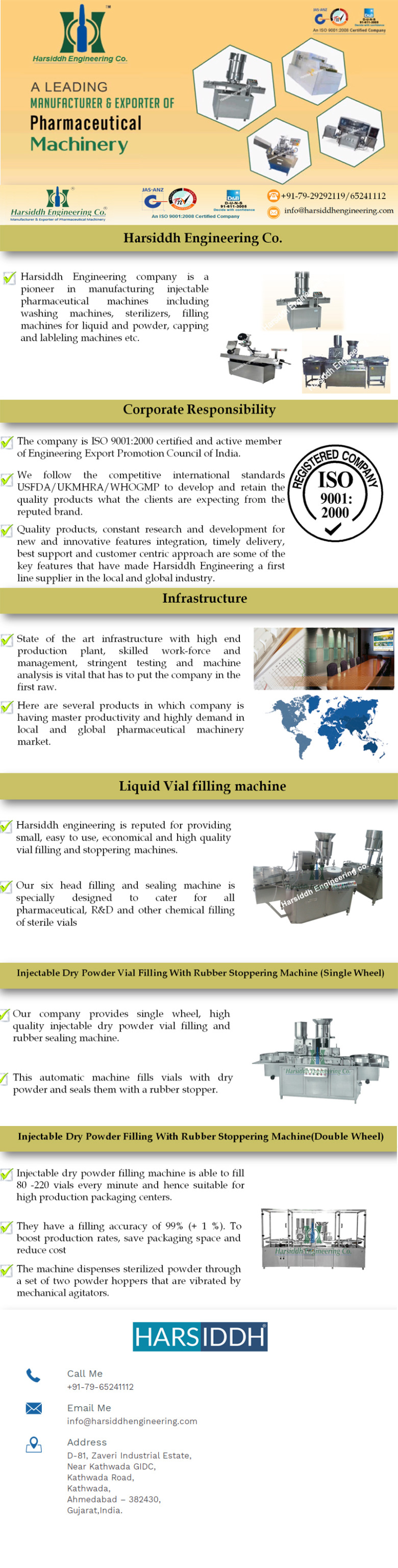

Our company provides single wheel, high quality injectable dry powder vial filling and rubber sealing machine. This automatic machine fills vials with dry powder and seals them with a rubber stopper.

The machine operates by first agitating the sterile powder stored in a hopper using a mechanical system. The system is fitted with a rotating powder wheel that has eight ports. Each of the port has vacuum plate and a piston to adjust the amount of powder depending on piston length. During operation, a fixed powder amount is sucked into the powder wheel port while excess materials are scrapped off using a doctor blade. The powder is moved to the vial and any excess powder is removed using compressed nitrogen. Our machine bears CE certification.

For more information about Vial filling machine, Liquid vial filling machine Visit our website https://www.harsiddhengineering.com/

For more information about Injectable vial filling machine & Dry powder vial filling machine visit our website https://www.harsiddhengineering.com/injectable-dry-powder-filling-with-rubber-stoppering-machine-double-wheel/

0 notes

Text

Dig into filling and closing

Fillingand Closing Machines it offers a variety of semi-automatic and automatic solutions for nested syringes, vials, cartridges, tablet filling, liquid filling, and Capsule filling. This solution is designed for products that are counted by pieces instead of weight.

This filling system is convenient for the operation taking place in the conventional Laminar Flow hoods in the laboratories.

The engineer puts in a syringe nest into the nest carrier and then begins the filling process via the touch screen HMI. The FSV will naturally locate the syringe beneath the filling needle and lower the needle in the container. The FSV flushes the syringe with nitrogen before it begins the filling action automatically. Synchronously to the filling process a rubber stopper is kept into the syringe that was previously filled using vacuum stoppering system. Post the process once the syringe is properly filled, the needle will retract and the FSV will indicate the syringe nest again to the next filling position. The FSV is also available for vials and cartridges.

Filling and Closing machines is a very important part of the whole process it has its own benefits majorly for perfection purposes and its functioning is quite simple.

For more information visit us @ Inos.in

Source: https://inostechnologies.blogspot.com/2019/07/dig-into-filling-and-closing.html

0 notes

Text

Various types of #PowderFillingMachine available are Auger Powder Filler, Dry Syrup Powder Filling, Injectable Powder Filling with Rubber Stoppering Machine, Automatic Vial Powder Filling Machine, etc.

For more details, visit us at https://www.lodhapharma.com/powder-filling-machine.php

0 notes

Link

0 notes

Text

Different Packaging Machinery for Pharmaceutical Industries & their Applications

Packaging machinery enjoys extensive application in pharmaceutical companies as it performs all the necessary operations, starting all the way from washing to packaging of vials. The machines must perform their functions effectively as even the slightest of error can have huge repercussions. As pharmacy machine manufacturers, NKP Pharma has a wide array of packaging machines to offer, namely- Washing Machine, Liquid Filling Machine, Inspection Machine, Dry Powder Filling Machine, Sealing Machine, Labeling Machine, Dry Syrup Powder Filling Machine, External Vial Washing & Drying Machine, and Carton Coding Machine.

Packaging Machines & their Applications

Dry Powder Filling Machine: Dry Powder filling machine is used to fill up the vials with the contents that are in the form of powder. It also has a mechanism for placing rubber stopper on top of the vials so that there is no leakage. Injectable dry powder filling machine uses vacuum/pressure dosing system in order to achieve greater precision levels even for the micronized powders. It is a highly compact and durable machine and is capable to perform long hour operations.

Sealing Machine: Vial sealing machine seals the vial after it gets filled with the content in liquid or powdered form. It provides hermetic seals, apart from capping vials, which protects the integrity of the drug inside the container. These drugs are used as a cure to treat patients suffering from diseases and hence care must be taken to maintain the sterility of the vial. Automatic high-speed vial sealing machine is also provided with compression pressure indication & rejection system.

Labeling Machine: Labeling of vials is very important as it helps to display the necessary information of the product, like- composition, company name, etc. To serve this purpose, labelling machines are used. The automatic self-adhesive vertical labeling machine is a very effective machine as it possesses the capability of having production rate of up to 240 vials/min. For ampoule labeling, Automatic high speed self adhesive vertical ampoule labelling machine is used whose production rate can be as high as 400 ampoules/min.

Dry Syrup Powder Filling Machine: Dry syrup powder filling machine is used for filling up containers or bottles with large volume powder. The production rate of the machine can differ from 100 bottles/min to 120 bottles/min. The machine has a robust structure and hence it can be used for a prolonged period. The dry syrup filling machine also consists of ROPP cap sealing machine that operates on the bottles and seals them. It is a versatile machine and is capable of attending up to 120 bottles/min.

External Vial Washing & Drying Machine: The automatic external vial washing machine is a multifaceted machine that performs the dual operation of washing and drying. The vial surface is washed thoroughly with the help of this machine and then later tried so that it gets filled with the suitable content. External Ampoule Washing Machine performs the same operation on ampoules instead of vials.

Carton Coding Machine: Carton coding machine is an advanced machinery developed to keep a track of all the products. There are two types of carton coding machine- Online carton coding machine and Offline Carton Coding Machine with Inspection and Rejection System. The machines have the capability of attending 250 carton/min.

Summary: Packaging machinery provides a complete solution to pharmaceutical companies. Dry powder filling machine is used to fill powder in vials. The sealing machine provides a hermetic seal to the container in order to protect it. Labeling machine puts label around the container in order to display specific information. For filling large volume powder in containers, Dry syrup powder filling machine is used. To ensure complete cleansing of vial and ampoule surfaces, external vial/ampoule washing & drying machine is employed. Carton coding machine keeps track of all the products after being packed.

The Bottom Line: NKP Pharma, with over 25 years of experience, has advanced manufacturing facilities and R&D unit at its disposal. These facilities ensure production of superior grade pharmaceutical packaging machinery that has a plethora of applications. The packaging machines produced by our company performs all the operation required to produce pharmaceutical products and hence are the most sought-after units by several companies.

0 notes

Link

· Vialwash-120, Dryfill-120i, Capseal-120 · Automatic Injectable Vial Line consisting of Vial Washing Machine, Injectable Powder Filling with Rubber Stoppering Machine, and Vial Cap Sealing Machine · Suitable for Automatic Vial Filling with Rubber Stoppering and Cap Sealing Machine · Used in Pharmaceutical, Veterinary, FMCG, Packaging, and Other Allied Industries For More Details, Visit:- www.brothers.in Contact us:- +917940213213

0 notes