#Cold Chain Monitoring Market Report

Explore tagged Tumblr posts

Text

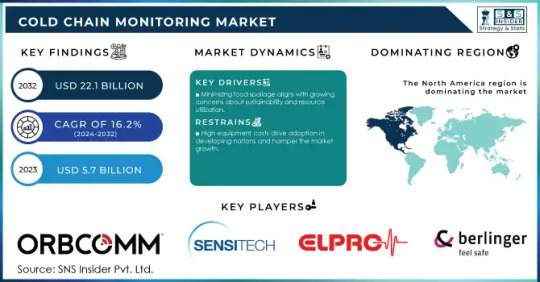

Cold Chain Monitoring Market Analysis: Key Players and Competitive Landscape

Rising Demand for Temperature-Sensitive Logistics Drives Growth in the Cold Chain Monitoring Market.

The Cold Chain Monitoring Market Size was USD 5.7 Billion in 2023 and is expected to reach USD 22.1 Billion by 2032 and grow at a CAGR of 16.2% over the forecast period of 2024-2032.

The Cold Chain Monitoring Market is driven by the increasing need for temperature-sensitive logistics solutions across industries such as pharmaceuticals, food & beverages, and chemicals. Cold chain monitoring systems ensure that perishable goods and temperature-sensitive products maintain their required storage conditions throughout the supply chain. The rising demand for biopharmaceuticals, vaccines, and fresh food products, coupled with stringent regulations on storage and transportation, is fueling the adoption of advanced cold chain monitoring solutions.

Key Players

ORBCOMM (US) – (IoT-based cold chain monitoring solutions, Fleet Management Systems)

Sensitech (US) – (TempTale Data Loggers, Cold Chain Monitoring Software)

Elpro-buchs (Switzerland) – (ELPRO Monitoring Solutions, e-Transcript System)

Berlinger & Co. (Switzerland) – (ThermoTrack Temperature Monitoring, ActiveSense Monitoring System)

Monnit (US) – (Monnit Wireless Sensors, Monnit Cloud Platform)

Controlant (Iceland) – (Controlant Smart Cold Chain, Real-time Monitoring Solutions)

Lineage Logistics Holding – (Cold Storage Solutions, Lineage Link Digital Platform)

Tagbox – (Cold Chain IoT Sensors, Tagbox Data Analytics Platform)

DAIKIN Industries – (Refrigeration Solutions, Remote Monitoring Systems)

Savi Technology – (SaviTrack RFID Solutions, SaviSense Sensor Platform)

Future Scope

The Cold Chain Monitoring Market is set for substantial expansion as supply chain digitization, IoT-based tracking systems, and AI-driven predictive analytics enhance real-time monitoring capabilities. Government regulations and quality control mandates for pharmaceutical and food safety are pushing businesses to integrate automated and cloud-based monitoring systems. Innovations in blockchain technology for supply chain transparency and the integration of smart sensors with predictive maintenance capabilities are expected to revolutionize cold chain management, reducing spoilage and ensuring compliance.

Emerging Trends

The industry is shifting toward real-time and AI-powered cold chain monitoring solutions, ensuring greater accuracy and efficiency in tracking temperature-sensitive shipments. The demand for wireless and cloud-based monitoring systems is rising, offering 24/7 remote access to temperature data and ensuring compliance with regulatory standards. Additionally, blockchain technology is being explored to enhance supply chain transparency and prevent counterfeiting in pharmaceuticals. The rise of automated alert systems, GPS tracking, and energy-efficient refrigeration technologies is also contributing to market growth.

Key Points

Rising demand for temperature-sensitive logistics in pharmaceuticals and food industries.

Increased adoption of IoT, AI, and blockchain for real-time supply chain monitoring.

Stringent regulatory requirements driving investments in advanced cold chain technologies.

Growing use of cloud-based and wireless temperature monitoring systems.

Expansion of automated alert systems and GPS tracking for improved shipment security.

Conclusion

The Cold Chain Monitoring Market is poised for significant growth, fueled by technological advancements, regulatory compliance requirements, and increasing demand for perishable goods logistics. As smart monitoring solutions, blockchain integration, and predictive analytics continue to evolve, the industry is set to enhance supply chain efficiency, reduce product wastage, and ensure the safe delivery of temperature-sensitive goods worldwide.

Read Full Report: https://www.snsinsider.com/reports/cold-chain-monitoring-market-1974

Contact Us:

Jagney Dave — Vice President of Client Engagement

Phone: +1–315 636 4242 (US) | +44- 20 3290 5010 (UK)

#Cold Chain Monitoring Market#Cold Chain Monitoring Market Size#Cold Chain Monitoring Market Share#Cold Chain Monitoring Market Report#Cold Chain Monitoring Market Forecast

0 notes

Text

A Sick Day

It’s not a cold. It’s not. It’s just… allergies or something. Y/N definitely does not need to stay home. Bruce disagrees.

B (24) & Y/N (22)

A/N: recently got a puppy and he has taken all of my free time <3 Also, this fic is unedited and proud.

“Get your coats and turn on your radiators, Gotham. An ice front is coming in and it’s coming in hot. Or should I say cold? No, this isn’t the work of Mr.Freeze, he’s still in Arkham and we hope he stays there. This is the work of a winter storm. While the snow will be beautiful, it will also be dangerous.”

Y/N scoffed at her computer. The newscasters always made such a big deal about winter storms. Nothing can be worse than what they had to deal with when Mr.Freeze escaped a year ago. She was stuck in her apartment for three days with no groceries, splitting a box of stale Triscuits with Carrie three meals a day. If anything, cold weather is more an inconvenience than a danger. Plus, it’s been teetering on 45 degrees out the past week. How much colder would it get?

-

So… It got fucking cold.

Gotham had hit record-low temperatures. So low it hadn’t been a natural occurrence since the 60s. Lucky for Carrie, she had chemo this week and the hospital had gotten spooked by the recent weather reports so they asked her to stay overnight. While the hospital bill wouldn’t be nice, it’s way better than what Y/N is dealing with.

Her radiator is shitting out on her. The whole building's radiator system actually. Normally when the weather is this bad she would opt to work at home, like everyone else, except she can’t take the cold. Her body in particular can’t take the cold. It could be from the shitty surroundings in her apartment building or from sniffly Nathan who works in Wayne Enterprise’s marketing department, but she thinks she’s coming down with something. What’s worse is that the cold weather is making it worse.

Her whole chest felt like it was burning, which is a real contrast to how cold she was walking to work. She couldn’t get her car past the snow and she needs warmth and warmth is at Wayne Enterprises. So, she trudges into the empty building, up the elevator, and sits at her desk with a groan.

Breathing heavily, she shrugged her coat off her shoulders and pressed her freezing fingertips underneath her armpits. She looked at her reflection in her desktop monitor. Her cheeks were bright red and she had dark circles under her eyes. At least no one else was here to see her. No one else was here to see her…

Would it hurt to take a nap? No one would know. No one would see.

Y/N stood and stepped out into the hallway. Not. A. Single. Soul. Oh, she is so napping.

-

Bruce had chained up his tires this morning and headed to Wayne Enterprise. It was too bright for The Tumbler and he needed to gather a few equipment items from Lucious Fox’s bunker. It’s not like anyone was here anyway. There was not a single car in the garage, not even Y/N’s, which is really saying something.

He perused the bunker, grabbing a few small but powerful heaters, fleece-lined leather for his suit, and a couple of other items, stuffing them into his duffle bag. He was used to the cold, training in it, even living in it on one occasion, and the people of Gotham needed him so he’d be there.

Pulling the duffle bag over his shoulder with ease, he headed out of the bunker and towards the elevator. He left a particular file that wasn’t meant for Wayne Enterprise in his office, while no one was here, you can never be too careful. Except… There was someone here.

He could only assume the head poking out from her coat was Y/N and she was sleeping? In the office? Stepping closer to her, he noticed, even under all her layers, she was trembling. Pulling her coat collar from her face, he finally got a good look at her. She was flushed and had broken out into a sweat, even her ears were bright red. He held onto her shoulder and shook her lightly.

“Y/N,” Bruce spoke softly. She ground turning away from him. He slapped a hand to her forehead trying to gauge her temperature. She definitely had a fever, it couldn’t be lower than a 100. Slowly her eyes opened at the disruption, then became wide at who was standing over her.

“What are you doing here?”

“I’m not the one sleeping in the office.”

“Sorry,” she mumbled embarrassed, “I don’t know how that happened-”

“Y/N you’re burning up. What are you even doing here?”

“Why does someone come to work, Bruce?”

“You’re not working. You’re sleeping.”

“I had the intent to work-”

“Y/N.”

“I just felt like coming in,” she snapped. In truth, she was embarrassed. Here was her billionaire boss. If he didn’t feel like sleeping in his mansion, he could stay the night at his penthouse. She was sure he had other properties as well, meanwhile her radiator couldn’t even stay on when it gets chilly outside.

Bruce held her stare with a firm gaze and narrowed his eyes.

“You’re going home.” It wasn’t a question and he definitely didn’t ask as he lifted her under her armpits from the couch and stood her up on the floor. He took her coat roughly from the couch and threw it over her shoulders. Bruce turned to pack the rest of her things up. Y/N was so tired, but she was also so frustrated. She had just gotten here. It had taken her so long to walk here. “Let’s go. Where’d you park?”

She remained silent and looked away from him.

“Y/N. Where did you park?”

“I’m not going home. I just got here.”

“You’re sick you’re going home,” before she could speak he added, “and don’t say your car is in the garage because I know it’s not in there.”

“...I parked on the street.”

He tilted his head examining her, “No you didn’t. The snow us up to the stairs. Where’s your car?”

His question came out as more of a statement, demanding of an answer. She wouldn’t look at him and he grew both frustrated and disappointed. “For the love of god, please tell me you did not walk here.”

“My car couldn’t get past the snow!” she loudly admitted, “Is that what you wanted to hear-”

“Y/N. When your car can’t get past the snow, it means you stay home!”

He held his hand to his brow, trying to sooth the tension in his head. Throwing his duffle bag and her work bag easily over his shoulder, he didn’t give her much of a chance to say anything as he grabbed her by the hand to pull her toward the elevator. Even in his frustrated state, shaking his head and rolling his eyes, his grip on her was still gentle.

Stubborn as ever, she would let him pull her to the car. She would let him buckle her in. She would let him drive her to her broken, cold home, but she wouldn’t say a damn thing about the radiator. None. Of. His. Business.

[She’s even more stubborn when she’s sick.]

And she did just that. She let Bruce Wayne take her hand, blaming the warmth in her face on her high fever. She let him tug her to his expensive McLaren 650s Spider with a new shiny set of winter tires. She enjoyed seeing it too and part of her enjoyed annoying him. And she let him plop her into his expensive shiny car, buckle her in, and drive her home. What she didn’t expect was him wanting to walk her inside…

“I can get inside just fine, thank you.” Y/N attempted to push him back towards his car. Her hand held to his chest and pushed firmly. He didn’t even budge. Not even a sway.

“You’re not walking up three flights of stairs alone in your condition.”

“My condition?” she paused. “How do you know I live on the third floor?”

“You put your address on your resume,” he lied smoothly.

“I didn’t know you read my resume-”

“Stop stalling.”

She tried to keep him out, she really did, but he was so persistent. They made it to the front door, thank you Mr.Wayne I can take it from here. Nope, he needed to help her up the stairs, so they made it up the stairs. Thank you, Mr.Wayne I think I can make it inside by myself. Nope, he had already made it up the stairs; he might as well finish the journey. They made it to her front door. Thank you, Mr.Wayne you can go now. Nope, there’s no reason he can’t sit her things down for her.

In her heart, she knew there was no way he didn’t notice the cool, crisp air in the hallway. The way not a single apartment radiated heat and she knew he had to be suspicious. Her hand shook in shame as she unlocked her apartment and opened the door up, head down.

Letting himself in, she heard a deep sigh, radiating from his chest, “Y/N, you can’t stay here-”

“Stop-”

“It’s freezing in here-”

“You don’t think I know that?” Once again, he grabbed her hand pulling her into the hallway, shaking her head. He took the keys straight out of her hand, locking the apartment door. “What are you doing? We just got here?”

“You’re staying with me this weekend.”

“Are you insane?”

“I have a house with over fifteen bedrooms. I think you can find somewhere to sleep.”

“This is so unprofessional.”

“I don’t care.” With her apartment keys he walked back toward the stairs at an alarming pace. She had no choice but to follow.

“Bruce, I swear to God I am not staying at the manor.”

-

“Welcome to Wayne Manor Miss.Y/N.”

@pank0w @moejoeflow @padsfirewhisky @maxinehufflepuffprincess @pastelsweaters-and-bubble-t @mariadvorak @100520s @st0rmyt @stxrsberkshire

#batfam#bruce wayne x reader#batman#batmom#bruce wayne#batboys x reader#slow burn#sick!reader#sickfic

247 notes

·

View notes

Text

The Billion-Dollar Secret: How Styrofoam Shipping Boxes Dominate the Cold Storage Market

Insulated Styrofoam Shipping Boxes Market Outlook and Projected Expansion

The GlobalInsulated Styrofoam Shipping Boxes Market is undergoing a transformative evolution, expected to grow from USD 5.8 billion in 2024 to over USD 9.8 billion by 2035, marking a 5.1% CAGR. This expansion is underpinned by surging demand for temperature-controlled logistics, particularly in pharmaceuticals, biotechnology, food & beverage, and chemical sectors. As global trade intensifies and e-commerce logistics demand highly effective cold chain packaging, insulated Styrofoam shipping boxes are becoming indispensable in ensuring thermal stability and minimizing spoilage.

Request Sample Report PDF (including TOC, Graphs & Tables): https://www.statsandresearch.com/request-sample/40651-global-insulated-styrofoam-shipping-boxes-market

Drivers of Insulated Styrofoam Shipping Boxes Market Momentum:

Cold Chain Logistics: Fueling Demand

Accelerated by global vaccine distribution and increasing biologics shipments, cold chain infrastructure investment is expanding rapidly. Logistics providers are integrating EPS-based shipping boxes due to their light weight, thermal resistance, and low cost. Emerging economies across Asia-Pacific and Latin America are establishing cold storage nodes, elevating regional adoption of EPS and its alternatives.

Thermally Sensitive E-Commerce Fulfillment

With the explosion of direct-to-consumer delivery models, including meal kits, frozen groceries, and pharmaceutical subscription services, packaging solutions must now perform at a higher thermal standard. Styrofoam boxes excel in preserving contents during last-mile delivery, particularly in high-temperature regions or extended transit windows.

Get up to 30%-40% Discount: https://www.statsandresearch.com/check-discount/40651-global-insulated-styrofoam-shipping-boxes-market

Industry Trends Reshaping the Insulated Styrofoam Shipping Boxes Market Landscape:

Eco-Friendly Insulation Innovation

Environmental scrutiny around traditional Expanded Polystyrene (EPS) has prompted industry leaders to introduce biodegradable EPS, Expanded Polypropylene (EPP), and Expanded Polyurethane (EPU). These innovations aim to balance thermal efficiency with recyclability and biodegradability, addressing both regulatory pressure and consumer sustainability demands.

Integration of IoT and Smart Packaging

Innovations such as IoT-based sensors, real-time temperature tracking, RFID chips, and blockchain-enabled traceability are redefining product integrity. Advanced boxes now feature embedded condition-monitoring solutions, allowing logistics providers to react in real-time to temperature breaches, critical in pharmaceuticals and biologics.

Rise of Vacuum Insulated Panels (VIPs) and Phase Change Materials (PCMs)

Next-gen thermal packaging increasingly utilizes VIPs and PCMs to ensure temperature stability in extreme conditions. These materials enhance insulation with minimal volume, optimizing space efficiency in shipping containers and reducing fuel consumption in transport.

Product Segmentation and Performance:

Hinged vs. Un-Hinged Boxes

Hinged boxes dominate the product landscape, capturing 68.5% market share in 2024. Their popularity stems from ease of use, secure sealing, and durability. Un-hinged variants, while less prevalent, continue to grow steadily due to their customization potential and lower unit cost, catering to niche applications.

Material Performance

EPS (55.3% share) remains the workhorse due to its cost-effectiveness and thermal balance.

EPP, growing at 6.3% CAGR, offers superior mechanical resilience and reusability, ideal for pharmaceutical supply chains.

EPU, though costlier, provides unmatched insulative performance, suited for ultra-cold shipments and perishable biotech products.

Insulated Styrofoam Shipping Boxes Market by End-Use Applications:

Food & Beverage

Holding a 50.4% share, the food industry leverages insulated boxes for frozen meal kits, seafood, dairy, and fresh produce. The rise of online grocery and farm-to-table delivery models is spurring demand for custom-sized, recyclable packaging.

Pharmaceuticals & Healthcare

With a projected 6.6% CAGR, this sector is the fastest-growing, driven by vaccine distribution, clinical trials, and the rise in biologic and personalized medicines. EPS and EPU boxes are the backbone of cold chain assurance in these high-stakes deliveries.

Electronics and Specialty Chemicals

Thermally sensitive semiconductors, batteries, and temperature-reactive chemicals require rigid, vibration-absorbing packaging. EPP's impact resistance and insulation are pivotal in ensuring transit safety.

Sales Channel Dynamics

Distributors lead at 59.8%, leveraging bulk procurement networks and established B2B logistics relationships.

Online retailers, fueled by D2C models, are the fastest growing, benefiting from the scalability of e-commerce fulfillment.

Specialty stores, though niche, serve high-margin segments like biotech R&D and small-batch gourmet shipping.

Insulated Styrofoam Shipping Boxes Market Regional Insights:

North America

Dominates at 38% insulated styrofoam shipping boxes market share, underpinned by mature cold chains, stringent FDA and EPA compliance norms, and leading e-commerce networks.

Asia-Pacific

Experiencing 6.8% CAGR, propelled by urbanization, rising disposable income, and massive investments in infrastructure modernization across China, India, and Southeast Asia.

Europe

With a 29.2% share, Europe is pushing the envelope in green packaging mandates, accelerating the transition to biodegradable EPS alternatives and reusable systems in the EU market.

Competitive Landscape and Innovation Leadership

Key Insulated Styrofoam Shipping Boxes Market Players and Strategic Movements

Sonoco Products Company: Launched a biodegradable EPS line, targeting regulated markets and reducing landfill contributions.

Cryopak: Acquired a PCM technology firm, expanding its thermal innovation pipeline.

Topa Thermal: Introduced IoT-enabled boxes through a logistics partnership, merging smart technology with cold chain essentials.

These firms are doubling down on research, mergers, and IP acquisition to maintain a competitive edge, particularly in high-growth verticals like personalized medicine and frozen food delivery.

Future Insulated Styrofoam Shipping Boxes Market Pathways and Strategic Recommendations

Invest in Material R&D: Prioritize hybrid packaging that combines VIPs, biodegradable EPS, and PCM layers.

Adopt Smart Packaging: Enable supply chain visibility through IoT and blockchain integrations.

Target Emerging Markets: Capitalize on growth corridors in Asia-Pacific and Latin America, focusing on urban logistics hubs.

Align with ESG Goals: Offer certified carbon-neutral packaging solutions, appealing to conscious B2B buyers and regulators alike.

Modularize Offerings: Provide scalable and custom-fit designs for cross-sector applicability, from biopharma to gourmet.

Purchase Exclusive Report: https://www.statsandresearch.com/enquire-before/40651-global-insulated-styrofoam-shipping-boxes-market

Conclusion

The Global Insulated Styrofoam Shipping Boxes Market is entering an era defined by thermal innovation, sustainability, and digital integration. As industries escalate their demand for high-performance cold chain packaging, the market's future hinges on material advancements, real-time monitoring capabilities, and responsible manufacturing. Businesses that integrate eco-conscious design with smart logistics compatibility will lead the next wave of global cold chain excellence.

Our Services:

On-Demand Reports: https://www.statsandresearch.com/on-demand-reports

Subscription Plans: https://www.statsandresearch.com/subscription-plans

Consulting Services: https://www.statsandresearch.com/consulting-services

ESG Solutions: https://www.statsandresearch.com/esg-solutions

Contact Us:

Stats and Research

Email: [email protected]

Phone: +91 8530698844

Website: https://www.statsandresearch.com

1 note

·

View note

Note

[ VISITING HOURS ]

interesting prompts || accepting always

[ VISITING HOURS ]: upon waking in a hospital bed, one of the muses turns their head, and finds the other sleeping in an uncomfortable chair by their bedside.

To get in had been the hardest part. He was armored with his ceremonial attire and the excuse of the right to practice one's faith being a widely acknowledged human right. But in truth what had helped him the most was the fact nursing was apparently yet another female-dominated line of work. And so he strolled the hallways to her appointed floor and there mistakenly entered another female patient's room and profusely apologized to the nurse there and thanked her for her directions — though not before snatching that patient's vital sign report from the pocket at the edge of the hospital bed.

And with the same tranquility he had walked a few rooms further down the hallway, until his heart skipped a beat upon closing the distance with the one and only being that mattered in this world. A nurse was fumbling with the heart monitor inside. Its rhythmic beeping welcomed them in the room; but there was something off with the machine, apparently.

God herself on a hospital bed.

Did mundane hybris truly have no limit?

❝ Konbanwa, sister. ❞ He begins; and the nurse turns - only to fall right into the trap of diamond eyes. After a brief chat on how the marvels of science can be disappointing because humans are not meant to control the whims of Gods and other jibber-jabber like that, she's walking out of the room and leaving the two alone, as is required for one to practice their spiritual needs with a confidant in the form of a priest. He has a legit visitor's card, after all. He was allowed in through security and he's taking out a chain of prayer beads that looks pretty antique and original, so it's fine. The guy looks safe.

Soon after he's assuming his rightful place by her bedside, looming over her pale visage as she rests peacefully. He pouts. There's a bullet hole the size of his thumb between her eyes. Michikatsu was not kidding when he spoke of special bullets. Fingers idly trace over the wound, applying the slightest pressure, if only to harvest some blood. He makes sure no one is passing by the room's window when he brings it to his lips for a taste of communion.

❝ Mm... how I've missed that, you have no idea. ❞ He breathes under a hum of delight. Blessing comes in the form of a forehead kiss. He presses his lips over the wound a moment longer; and cups her face with hands cold enough to jolt the dead back into life. ❝ I'm sure my lesser brethren has failed to accomodate your hospitalization already; but don't you worry, my blood. ❞ The smile he wears is shared between affection and sinisterness whilst gazing down on her resting features. He parts with her then, to drag the visitor's chair a little closer to the bed. It makes no sound, as he makes sure to single-handedly lift it off of the floor ever so slightly.

His eyes stalk the entrance when he discreetly reaches for her patient's report card. There's more papers than the other folder had. Digging into his cloak, he unearths the stolen report and briefly browses over both documents. Things highlighted in red; so much red. He's lucky; he got here on time and the doctors have yet to check on her vital stats. Things that are way above average; and others that are way below. He can't quite figure out what all those terms are - but he won't need to. He will only need to change the names on those cards.

And after that he will take the TV remote and put on stock market news, which is one of the Lord's favorite things to watch. And then he will settle there beside her, and take her palm to wrap both their hands together with the prayer beads and press her cold fingers to his forehead whilst mumbling a prayer or two — from those in his recollection.

Dōma would have an easy rest tonight. Knowing, that when sunlight finds him dozing off in that uncomfortable armchair on her bedside, his immunity will have been returned. And as for the miraculous recovery that would follow?

Well, with a pious man by her side day and night, surely some humans would be more... willing to believe their explanation.

#𝚅 𝟶𝟼. ⟅ i have been here as i am a thousand times ⟆#(( i dug all the way back in my inbox to find this it's SO good for this setting ))#fallesto#♥ ʜᴇᴀʀᴛ ꜱʜᴀᴘᴇᴅ ʙᴏx ᶠᵗ. ᴸᵒʳᵈ ᴹᵘᶻᵃⁿ | fallesto ♥

2 notes

·

View notes

Text

Real-Time Monitoring in U.S. Pharma Cold Chain Logistics

The pharmaceutical cold chain packaging industry in the United States is poised for significant expansion, with its market value projected to grow from USD 4.9 billion in 2025 to USD 13.8 billion by 2035. This represents a robust Compound Annual Growth Rate (CAGR) of 10.9% over the forecast period, driven by the critical need for temperature-controlled solutions to transport sensitive drugs, biologics, and vaccines.

Browse the Complete Report: https://www.futuremarketinsights.com/reports/pharmaceutical-cold-chain-packaging-industry-analysis-in-united-states

This growth is a direct response to the increasing development of high-value, temperature-sensitive pharmaceuticals and the need for validated logistics. The market, which accounts for a 4-6% share of the pharmaceutical packaging space, is a vital link in the drug supply chain. Recent strategic moves, such as Knipper Health’s acquisition of Thermo Fisher Scientific’s commercial sample management operations in Memphis, Tennessee, underscore the industry's focus on expanding cold chain infrastructure and leveraging strategic logistics hubs to meet rising demand.

Active Packaging and Biologics Drive Market Evolution

The market is not only expanding in size but also in technological sophistication. Active packaging is projected to be the leading segment, capturing a massive 79.8% share by 2035. These systems, with their integrated sensors and real-time monitoring capabilities, are essential for maintaining the efficacy of high-value biopharmaceuticals. The demand for these advanced solutions is primarily from biopharmaceutical companies, which are expected to account for a 50% market share in 2025 due to their heavy reliance on specialized cold chain packaging for transporting monoclonal antibodies, vaccines, and cell & gene therapies.

The most common temperature requirement is the refrigerated range (2°C - 8°C), which will hold a 45% market share in 2025. This temperature range is crucial for a wide array of biologics, vaccines, and injectables, necessitating packaging that can ensure precise thermal stability throughout the distribution network.

Dominant Products and Materials

In terms of product type, boxes are anticipated to hold a commanding 60% market share in 2025, valued for their versatility, affordability, and suitability for small- to medium-sized shipments. These designs are increasingly integrating advanced insulation materials and tamper-proof closures to meet stringent cold chain regulations.

The preferred material for insulation is Expanded Polystyrene (EPS), which is projected to dominate the substrate segment with a 35% market share in 2025. EPS is favored for its superior insulation capabilities, lightweight nature, and cost-effectiveness. Meanwhile, coolants, a critical component for maintaining temperature stability, are expected to lead their segment with a 65% share in 2025, driven by the use of gel packs, phase change materials (PCMs), and dry ice solutions.

Key Market Dynamics: Drivers and Restraints

The market is primarily driven by the expanding pipeline of advanced therapies and the increasingly strict regulatory standards from the FDA. These factors are compelling pharmaceutical companies to invest in validated cold chain systems that ensure drug safety and efficacy.

However, challenges remain. High costs associated with advanced packaging solutions, especially active systems, can be a barrier for smaller players. Environmental concerns are also a growing restraint, with regulations targeting polystyrene and plastic waste, which raises compliance costs. This dual pressure of cost and sustainability is pushing manufacturers to innovate in reusable and eco-friendly solutions.Request Pharmaceutical Cold Chain Packaging Industry Analysis in United States Draft Report: https://www.futuremarketinsights.com/reports/sample/rep-gb-22371

0 notes

Text

Clinical Trial Supplies Market projected to grow at ~8% CAGR with cold chain expansion by 2026

The clinical trial supplies market is projected to grow at a CAGR of ~8% over the forecast period. Key factors driving this growth include the rising number of clinical trials, increasing complexity in trial designs, and the globalization of research activities. However, market expansion faces challenges such as regulatory hurdles, logistical complexities, and high costs associated with supply chain management.

Clinical trial supplies encompass the procurement, distribution, and management of materials necessary for conducting clinical studies. These supplies include investigational drugs, comparator medications, placebos, kits, and ancillary materials required to ensure trial integrity. The process involves packaging, labeling, blinding, and distribution logistics to maintain compliance with regulatory standards and good manufacturing practices (GMP). Effective management of clinical trial supplies is crucial to ensuring patient safety, study validity, and timely completion of trials.

Download a free sample report for in-depth market insights https://meditechinsights.com/clinical-trial-supplies-market/request-sample/

Increasing complexity of clinical trials driving market growth

The growing complexity of clinical trials is a primary factor propelling the clinical trial supplies market. Modern trials involve decentralized models, adaptive designs, and precision medicine approaches, all of which demand sophisticated supply chain solutions. The rise of multinational trials has increased the logistical burden, requiring seamless coordination across diverse regulatory frameworks and distribution networks. Additionally, the demand for biologics and personalized therapies has led to stringent temperature-controlled supply chains and real-time monitoring solutions. Sponsors and contract research organizations (CROs) are increasingly investing in just-in-time (JIT) manufacturing, demand forecasting, and advanced packaging to reduce wastage and ensure efficient trial execution. These complexities necessitate robust supply chain strategies, making the role of clinical trial supplies indispensable for the success of pharmaceutical and biotech research initiatives.

Impact of direct-to-patient (DTP) supply models on market efficiency

A significant advancement shaping the clinical trial supplies market is the adoption of direct-to-patient (DTP) supply models. This approach enables investigational drugs and trial materials to be shipped directly to participants, reducing site visits and improving patient retention. The DTP model is particularly beneficial for rare disease trials, decentralized studies, and elderly or mobility-challenged patients. It minimizes logistical bottlenecks, lowers dropout rates, and enhances trial adherence, ultimately accelerating research timelines. Additionally, DTP distribution requires robust packaging solutions, temperature-controlled logistics, and regulatory compliance to ensure product integrity. The integration of real-time tracking, remote patient monitoring, and secure delivery channels has further streamlined this model. As trials continue to globalize and decentralize, DTP supply models are expected to gain widespread adoption, optimizing clinical research efficiency and broadening patient access to innovative therapies.

Competitive Landscape Analysis

The clinical trial supplies market is marked by the presence of established and emerging market players such as Almac Group; Biocair; Catalent Inc.; Eurofins Scientific; KLIFO; Movianto; PCI Pharma Services; Sharp Services, LLC; Thermo Fischer Scientific Inc.; UPS Healthcare; PAREXEL International Corporation among others. Some key strategies market players adopt include strategic partnerships & collaborations, and geographic expansion.

Unlock key data with a sample report for competitive analysis: https://meditechinsights.com/clinical-trial-supplies-market/request-sample/

Global Clinical Trial Supplies Market Segmentation

This report by Medi-Tech Insights provides the size of the global clinical trial supplies market at the regional- and country-level from 2023 to 2030. The report further segments the market based on phase, product & service, therapeutic area and end-user.

Market Size & Forecast (2023-2030), By Phase, USD Million

Phase I

Phase II

Phase III

Others

Market Size & Forecast (2023-2030), By Product & Service, USD Million

Manufacturing

Storage & Retention

Logistics & Distribution

Others

Market Size & Forecast (2023-2030), By Therapeutic Area, USD Million

Neurology

Oncology

Infectious Diseases

Cardiovascular Diseases

Metabolic Disorders

Others

Market Size & Forecast (2023-2030), By End-user, USD Million

Pharmaceutical & Biotechnology Companies

Contract Research Organizations (CROs)

Academic & Research Institutions

Others

Market Size & Forecast (2023-2030), By Region, USD Million

North America

US

Canada

Europe

UK

Germany

France

Italy

Spain

Rest of Europe

Asia Pacific

China

India

Japan

Rest of Asia Pacific

Latin America

Middle East & Africa

About Medi-Tech Insights

Medi-Tech Insights is a healthcare-focused business research & insights firm. Our clients include Fortune 500 companies, blue-chip investors & hyper-growth start-ups. We have completed 100+ projects in Digital Health, Healthcare IT, Medical Technology, Medical Devices & Pharma Services in the areas of market assessments, due diligence, competitive intelligence, market sizing and forecasting, pricing analysis & go-to-market strategy. Our methodology includes rigorous secondary research combined with deep-dive interviews with industry-leading CXO, VPs, and key demand/supply side decision-makers.

Contact:

Ruta Halde Associate, Medi-Tech Insights +32 498 86 80 79 [email protected]

0 notes

Text

Why Choosing the Right Fresh Brown Chikoo Exporter Isn’t Just Smart—it’s Business-smart.

If you've ever sourced fresh produce internationally, you already know the game isn’t just about finding good fruit—it’s about finding good people behind the fruit. Fresh Brown Chikoo, or sapodilla as some call it, isn’t your average export. It bruises easily, has a short post-harvest life, and if mishandled? You'll get a shipment that looks more like compost than commodity.

That’s where a trusted exporter comes in. Not just any supplier with a pretty website and glossy photos, but one who understands timing, temperature control, and real market demands—and honestly, one who picks up the phone when your shipment hits a snag.

Consistency Isn’t Just Nice. It’s Critical.

When you're sourcing for supermarkets, juice processors, or even regional distributors, you’re not just buying fruit—you’re buying predictability.

Trusted Fresh Brown Chikoo exporters don’t just throw products into crates and call it a day. They track Brix levels. They monitor maturity windows. Some even time their harvests with lunar cycles—no joke.

The goal? Fruit that’s not only sweet and creamy but also ships like a dream. Imagine your brand's reputation riding on a single pallet of spoiled chikoo. Now imagine not having to worry about that ever. That’s the difference.

Trust Means Transparency—and Real Numbers, Too

Let’s be blunt: anyone can promise "Grade A quality." But a serious exporter will show you the numbers—pre-shipment inspections, cold chain data logs, and even photos of packed consignments. Some go further and provide real-time shipping updates, including location pings from temperature-monitored containers.

And it’s not about micromanaging. It’s about trust through transparency. When your importer in Berlin or your client in Dubai wants a QA report, you don’t want to stall. You want answers—fast, clean, and backed by actual data.

Your Margins Are Tied to Their Integrity

You know what really hurts margins? Rejected loads, unpredictable ripening, or worse, a seller ghosting you mid-season when they get a better price elsewhere.

The thing with chikoo is, it’s seasonal—but relationships aren’t. A reliable exporter values long-term business over short-term wins. They won’t suddenly inflate rates mid-contract or play games with sizing. They understand that a slightly smaller fruit that arrives perfectly ripe beats a large one that arrives mushy and overripe.

And guess what? That kind of reliability doesn’t just protect your margins—it builds your credibility in the supply chain. People remember who delivers, season after season.

Real Exporters Know the Market Inside-Out

Some chikoo exporters just ship. The good ones advise. They’ll tell you when demand is spiking in the Gulf or when Indian monsoons might hit harvests early. They’ve got ears in the orchards and eyes on shipping lanes.

Dealing with them is more like having an adviser on call than it is like purchasing vegetables. They are aware of which fruit consumers like with a harder peel and which boxes are ideal for air freight, as well as how to quickly change course if a cargo is delayed by customs. It's similar to having a field crew that you didn't have to employ.

Logistics That Don’t Feel Like a Gamble

If you’ve dealt with perishables, you already know the freight struggle. Delays kill. Literally.

That’s why a serious chikoo exporter doesn’t just pack and pray. Before the first crate leaves the warehouse, they choose the appropriate ports, work with cold chain experts, and account for transit hazards.

You risk spoiling if you miss even one window. However, a trustworthy exporter has previously planned for contingencies. It may be an alternate reefer route, a quicker ship, or even a partner in port clearance. It's the difference between being prepared before the first whistle sounds and playing defensively.

Bottom Line: Purchase from a Seller Who Is Concerned About the After-Sale Situation

You want your company to expand. That means less firefighting and more forward planning. And it starts with picking the right people.

A trusted chikoo exporter isn’t just a vendor—they’re a silent partner in your success. They help you deliver not just fruit, but reliability. And in this business, that’s the real currency.

So, ask yourself: next time you shake hands on a shipment, are you buying chikoo—or are you buying peace of mind?

0 notes

Text

Industry-Backed Cold Chain Logistics in Singapore You Can Trust

At Pan Ocean Group, we deliver high quality, customisable and safe Singapore cold room storage space and comprehensive end-to-end cold chain solutions that adhere to the strictest food safety, pharma integrity and global logistics requirements. Backed by decades of operational excellence and customer trust, we are experienced leaders in Singapore’s logistics and warehousing space, delivering innovative, professional, and dependable services.

We steadfastly adhere to these values in regards to the proper management, warehousing, and transportation of temperature sensitive goods from the point of origin to the end user through an uninterrupted cold chain.

Singapore Cold Room Storage Professional Facility Services

Key to our services in the cold chain logistics in Singapore cold room storage, specifically tailored for a growing list of perishable products. Created with operational flexibility in mind, our temperature-controlled storage zones can accommodate products requiring ambient, chilled, or frozen temperatures.

Using 24/7 monitoring and real-time temperature monitoring and rigorous quality checks, from temperature fluctuations and external environmental risks such as humidity, contamination or spoilage. Our facilities are certified in compliance with Singapore’s regulatory requirements and also comply with the global standards for food safety and pharmaceutical warehousing.

Whether you’re dealing with fresh fruit and vegetables, dairy products, meats, seafood, vaccines, or specialized chemicals, our cold storage solutions are designed with the preservation of freshness, safety, and compliance in mind at every stage of the cold chain.

Complete End-to-End Cold Chain Solutions, First Mile to Last

Pan Ocean Group provides a full cold chain solution that integrates all parts of the logistics process – from production to the last mile of delivery. We leverage cutting-edge technology, optimized routing, and full visibility to offer unparalleled control and visibility.

Our cold chain logistics cover:

Storage temperature and inventory monitoring in cold storages.

Customs clearance and regulatory documentation

Temperature-controlled container haulage across Singapore

For urban delivery and crossing-border refrigerated transport

Live tracking, temperature control, and reporting

Our expertly trained team oversees every touchpoint, maintaining an uninterrupted cold chain while making your process more efficient, cost-effective, and environmentally friendly.

Established in Trust, Driven by Expertise

With extensive experience in logistics, freight forwarding and warehousing, Pan Ocean Group has become one of Singapore’s most reliable service providers in cold chain management. Our staff consists of logistics veterans, supply chain experts and operations managers that bring decades of experience to each and every client engagement.

We are a solutions provider, offering consultation and coverage customized to your industry-needs – whatever your business (F&B, pharmaceuticals, biotech, or retail). We work to become more than just a “shipping supplier”; an active partner helping extend shelf life, preserve product quality, and ensure market reliability.

Intelligent solution for smart cold chain management

Use smart automation and IOT technology to gain real-time visibility and pro-active control of your cold-chain operations with Pan Ocean. Using sensor-driven monitoring and AI-based logistics solutions, our predictive maintenance, shipment tracking and accurate temperature logging are designed within a single platform.

These advances allow companies to minimize waste, improve compliancy and respond more quickly and accurately to consumer needs.

Comprehensive one-stop end-to-end cold chain solutions based on your specific requirements

An expert logistics team composed of industry veterans

Regulatory compliance and food-grade certifications

Internet of Things technologies for real time monitoring and management

Trusted by the brands you know in F&B, healthcare and FMCG

Quality, Safety, and Sustainability Promise

Our processes are all about quality assurance and sustainability. We use ecologically friendly methods for storage, packaging, and transport to save energy and reduce carbon emissions. Our practices in waste management, refrigerant use, and responsible sourcing model reflect our commitment to environmental stewardship.

With enhanced shelf life and public health protection through secure, efficient cold chain systems, from waste prevention, to protecting the health of the public, Pan Ocean Group’s cold chain infrastructure is a valuable resource for both commercial performance and sustainability.

Collaborate with Us for Dependable Singapore Cold Room Storage and Cold Chain Services

At Pan Ocean Group, we know that every degree is important. Combined with our complete service, state-of-the-art facilities, and unparalleled service quality, we are the #1 cold room storage and total cold chain solution partner for you in Singapore.

Contact us today to discover what our dedicated cold logistics can do for your business, protecting your perishables and ensuring your goods are delivered with care and confidence.

0 notes

Text

The Froyo Revolution: Why Frozen Yogurt is Sweeping the Health-Conscious Nation

United States of America – Date – 22/07/2025 - The Insight Partners is proud to announce its newest market report, "Frozen Yogurt Market: An In-depth Analysis of the Frozen Yogurt Market " The report provides a holistic view of the Frozen Yogurt market and describes the current scenario as well as growth estimates for Frozen Yogurt during the forecast period.

Overview of Frozen Yogurt Market

There has been some development in the Frozen Yogurt market, such as growth and decline, shifting dynamics, etc. This report provides insight into the driving forces behind this change: technological advancements, regulatory changes, and changes in consumer preference.

Get the Sample of The Report: - https://www.theinsightpartners.com/sample/frozen-yogurt-market

Key findings and insights

Market Size and Growth

Historical Data: The Frozen Yogurt market is estimated to reach US$ XX million by 2031, with a CAGR of 5% during 2023–2031.These estimates provide valuable insights into the market's dynamics and can inform future projections.

Key Factors Affecting the Frozen Yogurt Market:

The Frozen Yogurt market is dynamic, influenced by evolving consumer health trends, lifestyle changes, and innovation in the food and beverage industry. Key factors include:

Growing Health Consciousness and Demand for Healthier Desserts: This is a primary driver. Consumers are increasingly seeking desserts that offer a balance of indulgence and health benefits. Frozen yogurt, often positioned as a lower-calorie, lower-fat, and probiotic-rich alternative to traditional ice cream, directly caters to this trend.

Rising Popularity of Probiotic-Rich Foods: Awareness of gut health and its impact on overall well-being is increasing. Frozen yogurt, containing live and active probiotic cultures, benefits from this trend, as consumers actively seek foods that support digestive health and immunity.

Increasing Demand for Plant-Based and Non-Dairy Options: A significant segment of consumers is adopting flexitarian, vegetarian, vegan, or lactose-intolerant diets. This drives demand for frozen yogurt made from alternative milk sources like almond, coconut, oat, and soy milk.

Spotting Emerging Trends:

Technological Advancements:

While not as heavily impacted by "hard tech" as other markets, the Frozen Yogurt market is seeing disruption through:

Advanced Freezing Technologies: Innovations in freezing processes aim to improve the texture and mouthfeel of frozen yogurt, making it smoother, creamier, and less icy. Technologies like "isochoric freezing" (though still nascent for mass production) could potentially offer superior quality and shelf life.

Precision Ingredient Blending and Formulation: Automated systems and data analytics are being used to precisely control ingredient ratios, especially for dairy-free bases, sweeteners, and functional additives (like specific probiotic strains or protein sources). This ensures consistency, optimizes texture, and allows for rapid development of new product variations.

IoT and AI in Supply Chain and Retail:

Smart Cold Chain Monitoring: IoT sensors and real-time monitoring systems are being deployed to track temperature and humidity throughout the frozen yogurt supply chain, from production to retail. This minimizes spoilage, ensures product quality, and extends shelf life.

AI-Driven Demand Forecasting: AI and machine learning algorithms are being used to analyze sales data, seasonal trends, and even local weather patterns to accurately predict demand for specific flavors and product types. This helps optimize inventory, reduce waste, and manage the challenges of seasonal fluctuations.

Changing Consumer Preferences:

Consumer preferences in the Frozen Yogurt market have significantly shifted towards health-conscious, customizable, and ethically driven choices:

Prioritizing "Better-for-You" Indulgence: Consumers are increasingly seeking desserts that align with their health goals without sacrificing taste. This means a strong preference for:

Lower Sugar & Calorie Options: Driven by concerns about obesity and diabetes.

Probiotic Powerhouses: A high demand for products explicitly promoting gut health and immunity benefits.

Clean Label & Natural Ingredients: A desire for products with simple, recognizable ingredients and no artificial flavors, colors, or preservatives.

High Protein Content: Appealing to fitness enthusiasts and those looking for more satiating snacks.

Regulatory Changes:

Regulatory changes, while not as frequent or dramatic as in some other food sectors, primarily impact the Frozen Yogurt market in areas of labeling, health claims, and food safety:

Nutritional Labeling Requirements: Stricter mandates regarding clear and accurate nutritional information (calories, fat, sugar, protein, etc.) on packaging are a key regulatory impact. This enables consumers to make more informed choices, especially given the emphasis on "healthy" desserts.

Health Claims and Functional Ingredients: Regulations around making specific health claims (e.g., "good source of probiotics," "supports gut health," "sugar-free") are becoming more stringent. Manufacturers must provide scientific substantiation for such claims, preventing misleading advertising. This directly impacts how frozen yogurt products are marketed.

Ingredient Sourcing and Allergen Labeling: Regulations require clear labeling of common allergens (e.g., dairy, nuts, soy, gluten). For plant-based and "lactose-free" products, accurate labeling is crucial to avoid cross-contamination and ensure consumer safety.

Growth Opportunities of the Frozen Yogurt Market:

The Frozen Yogurt market, despite its competitive landscape, offers several detailed growth opportunities by leveraging current trends and addressing consumer demands:

Innovation in "Better-for-You" Formulations:

Expanded Plant-Based Portfolio: Continuously innovating and expanding the range of non-dairy frozen yogurts using diverse plant milks (e.g., new oat milk varieties, less common nut milks) to cater to diverse tastes and dietary needs. Focusing on superior taste and texture that rivals dairy-based options.

Ultra-Low/No Sugar Options: Developing and promoting frozen yogurts with natural, innovative sweeteners (like allulose or fruit-based sweeteners) that significantly reduce sugar content without compromising flavor, appealing to health-conscious and diabetic consumers.

Enhanced Functional Benefits: Fortifying frozen yogurt with specific probiotic strains for targeted gut health benefits, added protein, vitamins, or fibers, and clearly communicating these benefits to consumers.

Get The Infographics of Report: - https://in.pinterest.com/pin/952863233668435991

Conclusion

The Frozen Yogurt Market: Global Industry Trends, Share, Size, Growth, Opportunity, and Forecast Frozen Yogurt 2023-2031 report provides much-needed insight for a company willing to set up its operations in the Frozen Yogurt market. Since an in-depth analysis of competitive dynamics, the environment, and probable growth path are given in the report, a stakeholder can move ahead with fact-based decision-making in favor of market achievements and enhancement of business opportunities.

About The Insight Partners

The Insight Partners is among the leading market research and consulting firms in the world. We take pride in delivering exclusive reports along with sophisticated strategic and tactical insights into the industry. Reports are generated through a combination of primary and secondary research, solely aimed at giving our clientele a knowledge-based insight into the market and domain. This is done to assist clients in making wiser business decisions. A holistic perspective in every study undertaken forms an integral part of our research methodology and makes the report unique and reliable.

0 notes

Text

Cost Insights on Transglutaminase Production

The demand for Transglutaminase, an enzyme widely used in the food, cosmetic, and pharmaceutical industries, is experiencing rapid growth. Understanding the Transglutaminase Production Cost is essential for manufacturers, investors, procurement teams, and stakeholders aiming to optimize their sourcing strategies and stay ahead of market fluctuations. This article provides a detailed overview of the production process, cost components, supply chain dynamics, and industry trends shaping the transglutaminase market.

Transglutaminase Production Cost Analysis Report

The Transglutaminase Production Cost Analysis Report is a vital resource for evaluating the various factors that contribute to the overall cost of manufacturing this enzyme. It includes a breakdown of cost modeling, raw material pricing, labor expenses, utility consumption, logistics, and capital investment required for setting up and running the production process.

The report provides a pre-feasibility assessment for new entrants and current industry players looking to expand operations. This includes understanding the scalability of the process, market accessibility, capital needs, and supply chain readiness.

From fermentation and enzyme extraction to downstream purification, every stage in the transglutaminase production process contributes to the final product cost. The selection of microbial strains, the efficiency of the fermentation process, and the purification yield significantly influence cost-efficiency and product quality.

Manufacturing Process Overview and Cost Components

The industrial production of transglutaminase generally follows a biotechnological process involving microbial fermentation using strains like Streptoverticillium mobaraense. The steps include:

Fermentation: Cultivation of microbial cultures under optimized conditions

Extraction: Separation of the enzyme from the biomass

Purification: Chromatographic or filtration techniques to isolate the active enzyme

Stabilization and Packaging: Conversion into usable forms like powder or liquid for industrial use

The Transglutaminase Production Cost consists of the following main components:

Raw Materials: Glucose, yeast extract, peptone, salts, and microbial strains used for fermentation

Utilities: Electricity, steam, water, and temperature regulation during fermentation and purification

Labor Charges: Skilled labor for fermentation monitoring, purification, and quality control

Machinery and Equipment: Fermenters, filtration systems, dryers, and packaging machines

Logistics: Cost of storage, cold-chain handling (if needed), and delivery to end users

Regulatory Compliance: Costs associated with meeting food-grade and pharmaceutical safety standards

The cost model helps businesses identify cost-saving opportunities across these components and plan procurement accordingly.

Product Details and Applications

Transglutaminase, commonly referred to as “meat glue,” is used in the food industry to enhance texture, appearance, and binding of proteins. It finds application in:

Meat processing: Improving structure and reducing waste

Dairy products: Enhancing the texture of cheese and yogurt

Bakery: Improving dough elasticity and product consistency

Pharmaceuticals: In research for drug delivery and biomedical applications

Cosmetics: As a stabilizer in certain formulations

With the expanding use of clean-label and functional food products, demand for transglutaminase is expected to surge, further driving production and sourcing interest.

Industrial Trends and Supply Chain Insights

Current industrial trends in transglutaminase production reflect a shift towards sustainable, high-yield microbial strains and advanced bioprocess optimization. Biotechnology firms are exploring enzyme variants with higher thermostability and broader substrate specificity to cater to multiple industries.

On the supply chain front, manufacturers are focusing on:

Securing raw material supplies from verified sources

Upgrading utility systems to improve energy efficiency

Reducing process downtime through automation and advanced monitoring

Regional diversification to reduce logistics costs and supply risks

Supply chain analysis also considers external factors such as raw material pricing volatility, international trade policies, and environmental regulations that can impact the Transglutaminase Production Cost.

Labor Charges and Utility Consumption

Labor costs vary significantly depending on regional labor markets, plant size, and automation levels. Countries in the Asia-Pacific region generally benefit from lower labor costs, while North America and Europe see higher operational expenses due to skilled labor and compliance standards.

Utilities such as electricity, water, and compressed air are major contributors to overall production costs. For fermentation-based enzymes like transglutaminase, utility optimization is key to reducing batch costs and maintaining profit margins.

Monitoring and reducing utility costs through energy-efficient fermenters and heat recovery systems is becoming a common practice among manufacturers looking to improve competitiveness.

Logistics and Distribution Costs

Efficient logistics management is essential for maintaining the shelf life and activity of transglutaminase, especially in its liquid or sensitive formulations. Distribution strategies must account for:

Cold chain requirements (if needed)

Global reach for serving multinational food and pharma companies

Regional warehousing to reduce lead times

Packaging innovations for bulk and retail formats

With global demand rising, logistics partners are collaborating with enzyme manufacturers to offer specialized solutions that preserve enzyme stability and reduce supply chain costs.

Procurement Resource plays a critical role in helping businesses analyze and optimize their production costs. With a global network of researchers and consultants, the company provides:

Tailored production cost reports

Strategic procurement advisory

Raw material sourcing intelligence

Supplier benchmarking and feasibility studies

Market forecasting and pricing analytics

Whether you're planning to enter the enzyme production space or seeking to lower your operational costs, Procurement Resource delivers actionable intelligence that supports procurement and business development goals.

Request a Free Sample – Gain Cost and Market Insights

To understand the comprehensive cost structure and industrial applications of this enzyme, you can request a free sample report that includes data-driven insights into the Transglutaminase Production Cost, market trends, and sourcing strategies.

Request a Free Sample-https://www.procurementresource.com/production-cost-report-store/transglutaminase

The free sample offers a preview of the detailed cost breakdown, procurement challenges, process economics, and industrial benchmarks provided in the full report. It is designed for procurement heads, R&D teams, project investors, and sourcing managers.

Role of Procurement Resource in Strategic Cost Planning

Contact Information

Company Name: Procurement Resource Contact Person: Ashish Sharma (Sales Representative) Email: [email protected] Location: 30 North Gould Street, Sheridan, WY 82801, USA

Phone Numbers: UK: +44 7537171117 USA: +1 307 363 1045 Asia-Pacific (APAC): +91 1203185500

Connect With Us Online: Twitter (X) LinkedIn Pinterest YouTube Website

#Transglutaminase Production Cost#TransglutaminaseProductionCost#TGaseFermentationCost#MicrobialTGaseManufacturing#CarbonNitrogenSourceExpense#TGasePurificationCost#FermentationMediaCost#TGaseCapEx#TGaseOpEx#ROIinTGaseProduction#TGasePlantInvestment#EnzymePurificationExpenditure

0 notes

Text

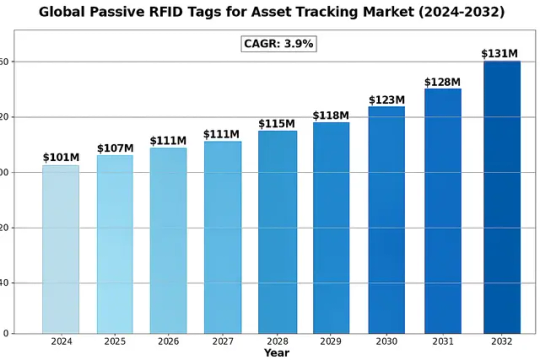

WiFi Data Logger Market : Analysis by Product Types, Application, Region and Country, Trends and Forecast

WiFi Data Logger Market, Trends, Business Strategies 2025-2032

The global WiFi Data Logger Market was valued at 3349 million in 2024 and is projected to reach US$ 4349 million by 2032, at a CAGR of 3.9% during the forecast period.

WiFi Data Loggers are wireless monitoring devices designed to capture, store, and transmit environmental and industrial data through WiFi connectivity. These devices measure critical parameters such as temperature, humidity, pressure, and voltage, enabling real-time remote monitoring across industries like healthcare, logistics, and food safety. Unlike traditional loggers, WiFi-enabled models eliminate manual data retrieval, providing seamless integration with cloud platforms for analytics.

Market growth is driven by the rapid adoption of IoT technologies and stringent regulatory requirements for data traceability in sectors like pharmaceuticals and cold chain logistics. For instance, the FDA’s 21 CFR Part 11 compliance mandates electronic record-keeping, accelerating demand in life sciences. While connectivity limitations in industrial settings pose challenges, advancements in mesh networking and edge computing are expanding application potential. Key players including Testo, Vaisala, and Emerson dominate the competitive landscape, collectively holding over 40% market share as of 2024.

Our comprehensive Market report is ready with the latest trends, growth opportunities, and strategic analysis. https://semiconductorinsight.com/download-sample-report/?product_id=103290

Segment Analysis:

By Type

Single Probe Loggers Dominate the Market Due to Compact Design and Ease of Deployment

The market is segmented based on type into:

Single Probe

Dual Probe

Multi-parameter Loggers

Others

By Application

Healthcare Segment Leads Due to Critical Need for Temperature-Sensitive Asset Monitoring

The market is segmented based on application into:

Healthcare

Life Sciences

Foodservice

Vaccine Monitoring

Industrial Monitoring

By Connectivity

Cloud-Enabled Loggers Show Strong Growth Due to Remote Monitoring Capabilities

The market is segmented based on connectivity into:

Standalone WiFi Loggers

Cloud-Connected Loggers

Hybrid Connectivity Solutions

By End-User

Pharmaceutical Companies Emerge as Key Adopters for Compliance Monitoring

The market is segmented based on end-user into:

Pharmaceutical Companies

Hospital & Healthcare Facilities

Food & Beverage Manufacturers

Research Institutions

Logistics Providers

Regional Analysis: WiFi Data Logger Market

North America North America leads the WiFi Data Logger market, driven by strict regulatory requirements in healthcare (FDA compliance for vaccine storage) and food safety (USDA monitoring standards). The region’s advanced IoT infrastructure and substantial investments in pharmaceutical cold chain logistics – valued at over $16.5 billion annually – accelerate adoption. Key applications include temperature monitoring for biotech facilities and restaurant refrigeration systems. However, cybersecurity concerns regarding wireless data transmission slightly hinder market penetration. Major players like Emerson and Dickson leverage local manufacturing capabilities to serve this high-value market.

Europe Europe’s market growth is propelled by EU Directive 2001/83/EC for pharmaceutical storage and the widespread Industry 4.0 adoption in Germany’s manufacturing sector. The region shows strong demand for multi-parameter loggers combining humidity and temperature tracking, particularly in Scandinavian countries with stringent food export regulations. GDPR compliance for data handling creates additional complexity for manufacturers, though it drives innovation in secure cloud-based solutions. Market leaders like Testo and Vaisala dominate through precision instruments meeting EU’s exacting calibration standards.

Asia-Pacific This fastest-growing region benefits from expanding pharmaceutical production in India (projected to reach $130 billion by 2030) and China’s smart factory initiatives. While cost sensitivity favors basic single-probe loggers, rising awareness about vaccine cold chain integrity is driving premium product demand. Japanese manufacturers like Hioki lead in high-accuracy industrial applications, while Southeast Asia sees growth in agriculture monitoring. Infrastructure limitations in rural areas create opportunities for hybrid cellular-WiFi solutions to ensure connectivity.

South America Market development here focuses on food export compliance and emerging pharmaceutical hubs in Brazil. The lack of universal WiFi coverage pushes demand for loggers with extended local storage (up to 1 million readings). Economic constraints limit adoption to essential applications like vaccine distribution, though Argentina shows growth in wine storage monitoring. Regional players compete through ruggedized designs for tropical climates, while global brands face challenges adapting to local calibration standards.

Middle East & Africa This developing market centers on pharmaceutical imports and oil/gas applications, with UAE leading in high-tech adoption. Temperature extremes drive demand for wide-range loggers (-40°C to 85°C capability). Infrastructure gaps favor battery-efficient models with 5+ year lifespans. While South Africa shows mature adoption in healthcare, other nations face slower uptake due to limited technical expertise. The market shows potential for solar-powered WiFi loggers in remote monitoring applications.

List of Key WiFi Data Logger Companies Profiled

T&D Corporation (Japan)

Testo SE & Co. KGaA (Germany)

Eupry (Denmark)

NOVUS Automation (Brazil)

Lascar Electronics (UK)

Dwyer Instruments (U.S.)

Comark Instruments (UK)

Vaisala (Finland)

SensoScientific (U.S.)

OMEGA Engineering (U.S.)

Hioki E.E. Corporation (Japan)

Emerson Electric Co. (U.S.)

Dickson (U.S.)

PCE Instruments (Germany)

The global Internet of Things (IoT) market is experiencing unprecedented growth, with connected devices projected to exceed 29 billion by 2030, creating a robust ecosystem for WiFi data loggers. These devices serve as critical nodes in IoT networks, enabling seamless data collection and transmission across industrial and commercial applications. The pharmaceutical sector alone has seen a 28% increase in adoption of wireless monitoring solutions since 2022, driven by stringent regulatory requirements for temperature-sensitive products. Furthermore, advancements in edge computing have enhanced the processing capabilities of WiFi data loggers, allowing real-time analytics at the device level while reducing cloud dependency.

Heightened regulatory scrutiny in food safety, healthcare, and logistics sectors is compelling organizations to transition from manual monitoring to automated WiFi data logging solutions. The FDA’s increased emphasis on electronic temperature monitoring for vaccine distribution during the pandemic established new industry benchmarks that continue to drive adoption. In cold chain logistics, where temperature deviations can result in product losses exceeding $35 billion annually, WiFi data loggers provide auditable documentation that meets GDP and GMP requirements. Similarly, ISO 13485 certifications for medical devices now frequently mandate continuous environmental monitoring, creating sustained demand in healthcare verticals.

Another significant driver is the growing emphasis on sustainability and energy efficiency. WiFi-enabled building automation systems integrate data loggers to optimize HVAC performance, contributing to LEED certification goals while reducing operational costs by an average of 18-22%.

Urban infrastructure modernization programs worldwide are creating substantial opportunities for WiFi data logger deployment. Municipalities investing in smart grid technologies require distributed environmental monitoring for substations and transmission equipment, with pilot programs demonstrating 27% improvements in maintenance efficiency. Similarly, intelligent transportation systems leverage WiFi-enabled sensors for road condition monitoring and bridge structural health assessment, representing a potential $2.3 billion addressable market by 2027.

The healthcare sector presents another high-growth avenue as hospitals transition to continuous equipment monitoring. Wireless data loggers now track parameters ranging from sterilization autoclave performance to pharmaceutical fridge temperatures, with integrated AI analytics flagging anomalies before they impact patient safety. Leading medical centers report 90% reductions in compliance documentation time after implementing comprehensive WiFi monitoring solutions.

Emerging industrial applications in precision agriculture and renewable energy further expand the market potential. Solar farm operators increasingly deploy weather-resistant WiFi loggers to monitor panel temperatures and inverter performance, correlating environmental data with energy output to optimize maintenance schedules.

The market is highly fragmented, with a mix of global and regional players competing for market share. To Learn More About the Global Trends Impacting the Future of Top 10 Companies https://semiconductorinsight.com/download-sample-report/?product_id=103290

Key Questions Answered by the WiFi Data Logger Market Report:

What is the current market size of Global WiFi Data Logger Market?

Which key companies operate in Global WiFi Data Logger Market?

What are the key growth drivers?

Which region dominates the market?

What are the emerging trends?

Browse More Reports:

CONTACT US:

City vista, 203A, Fountain Road, Ashoka Nagar, Kharadi, Pune, Maharashtra 411014

[+91 8087992013]

0 notes

Text

Enhance Efficiency with Warehouse Control Tools from Mantis Advanced WMS

In today's fast-paced logistics landscape, the pressure to manage warehouse operations with maximum efficiency is stronger than ever. Companies must deal with rising customer expectations, complex supply chains, and increasing operational costs. That’s where warehouse control tools play a vital role—streamlining processes, reducing errors, and driving productivity.

At Rubicon Logistics Solution, we partner with Mantis, a global leader in warehouse management software, to bring the Mantis Advanced WMS (Logistics Vision Suite) to businesses across the region. Our goal is simple: help businesses gain better visibility, control, and optimization of their warehouse operations.

What Are Warehouse Control Tools?

Warehouse control tools are integrated software features designed to manage and automate the physical processes in a warehouse. These tools act as the bridge between a warehouse management system (WMS) and the physical handling equipment like conveyors, sorters, carousels, and robotics. The result is real-time coordination, reduced downtime, and improved order accuracy.

Whether you run a single warehouse or a multi-site distribution network, effective warehouse control tools are essential for maintaining a competitive edge.

Why Choose Mantis Advanced WMS?

Mantis’s Logistics Vision Suite (LVS) is a next-generation WMS platform that offers modularity, scalability, and powerful warehouse control tools tailored to diverse logistics needs. Through Rubicon’s expertise and localized support, businesses gain access to this industry-leading system with full implementation and training support.

Here’s what makes the Mantis Advanced WMS a game-changer:

1. Intelligent Automation Integration

LVS integrates seamlessly with a wide range of automation technologies—such as AS/RS, pick-to-light, put-to-light, voice picking, and mobile robotics. Its warehouse control tools ensure real-time communication between software and equipment, enabling faster throughput and lower labor costs.

2. Real-Time Visibility and Control

From receiving to shipping, Mantis Advanced WMS offers real-time dashboards and reports to monitor warehouse operations. Managers can track inventory levels, order statuses, and worker performance with precision—making it easier to adjust workflows and optimize resources.

3. Advanced Slotting and Task Management

Using built-in algorithms, the system suggests optimal product placement and task assignments to maximize picking efficiency and reduce travel time. These smart control tools boost overall productivity while minimizing errors.

4. Flexibility and Scalability

Whether your operations are growing or evolving, Mantis WMS is built to scale. It supports multi-client, multi-warehouse environments and can be tailored to suit unique industry needs—from e-commerce and retail to pharmaceuticals and cold storage.

Rubicon Logistics Solution brings years of logistics expertise to every implementation. We don’t just provide software—we provide end-to-end solutions that deliver measurable results. Our team handles system configuration, staff training, integration with existing infrastructure, and ongoing support.

Partnering with Rubicon gives your business access to:

Certified WMS consultants

Localized support and training

Custom implementation plans

Scalable solutions for any warehouse size

Unlock the Power of Warehouse Control Tools

The right warehouse control tools can transform your warehouse into a high-performing, data-driven operation. With Rubicon Logistics Solution and Mantis Advanced WMS, your business can improve order fulfillment speed, inventory accuracy, labor efficiency, and customer satisfaction.

Whether you're managing distribution for retail, 3PL, or manufacturing, the advanced features of Mantis WMS—combined with Rubicon’s expertise—give you the edge you need to stay ahead in an increasingly competitive market.

0 notes

Text

Master Inventory Management for Food Manufacturers in 2025