#Cold Formed Steel Design Software

Explore tagged Tumblr posts

Text

Steel Smart System provides cutting-edge solutions for the steel construction industry. Our offerings include Structural Framing Software, Metal Stud Design Software, Cold Formed Steel Smart Software, and Cold Formed Steel Design Software. Enhance your design efficiency and accuracy. Discover more at Steel Smart System.

#Structural Framing Software#Metal Stud Design Software#Cold Formed Steel Smart Software#Cold Formed Steel Design Software

0 notes

Text

Why Cold-Formed Steel Design Software is a Game Changer for Structural Engineering

Cold-Formed Steel (CFS) Design Software is transforming structural engineering by enhancing accuracy, efficiency, and compliance with building codes. This software automates complex calculations, reducing the risk of human error, and allowing engineers to focus on creating more efficient designs. Tools like Cold-Formed Steel Smart Software streamline the design process for engineers working with cold-formed steel structures, while CFS Design capabilities help model complex structures and visualize different load scenarios, ensuring safety and cost-efficiency.

Read the Complete Blog here: https://steelsmartsystem0.wordpress.com/2024/09/17/why-cold-formed-steel-design-software-is-a-game-changer-for-structural-engineering/

0 notes

Text

The Power of Advanced Software Solutions in Structural Engineering

The power of advanced software solutions lies in their ability to streamline processes, enhance precision, and accelerate decision-making in structural engineering. To learn about structural engineering, go through Applied Science. Regarding structural design and analysis, ASI’s team of veteran engineers and scientists provides a collective wealth of over 200 years of hands-on experience in engineering research, analysis, and design. Read the full blog for more information - https://sites.google.com/view/applied-science-int/home

#forensic structural engineering#structural analysis engineering software#demolition engineering#structural design software#performance based design#cold formed steel software#structural forensic engineering

0 notes

Text

It's not quite accurate to say I have 60,000 consecutive words on Akatsuki's Big Adventure now, given various vagueries of word-counts in different pieces of software, but it's close enough and I'm 10 chapters from the end now, so hey, milestone.

This is despite being hit out of nowhere with a nasty cold/flu thing this week that has left me quite shattered.

I do hope this is going to be fun to read when I'm done. I'm currently entering the 'shock reveal cavalcade' stretch of proceedings, which should be quite enjoyable to get sorted out (start a chapter with one reveal, end it on the left-field twist, then continue in this vein for a couple more). I do however need to solve the problem of how to have somebody stow away aboard a mobile suit in a relatively believable fashion. Such is life.

Here are some character descriptions by way of teasers, and the fact I have yet to find the will to do costume design sketches like I want.

------

They're too far to make out the details of their faces. She notes how they tense up, though, Lab Coat stepping forward and nodding to whoever's approaching, who she can't see from this angle until they've nearly reached the welcoming committee. Three more men, two in business sits, the sharper of the pair at the front, going to shake Lab Coat's hand, and someone in a more military-looking jacket, dark maroon, with black pants and heavy boots. He – or, actually, it's just the impression of the build that makes her think that – has a helmet that covers more of their head, leaving only the clean-shaven jaw and a hint of hair visible above the jacket's collar. A soldier's helmet, definitely. Surplus Gjallarhorn equipment? Steel silver, a cluster of sensor apertures on the front, otherwise smooth and blank.

------

I don't know how much of an idea I'd formed of what she looked like under [her helmet]. Enough to be surprised. She's taller than me and with the harsh voice, I think I expected her to be older. Her black hair is cut close, although not so much she doesn't have to smooth it down. She has narrow, elegant eyebrows and a pointy nose, and her skin is a rich bronze tone that does nothing to hide the acne scars on her cheeks.

A perfectly normal-looking girl, maybe my age, maybe a year or two more.

“Got something on my face?” she asks, not quite smiling, not quite sneering.

------

Number Seven, meanwhile, looks like he's somebody's grandpa. Half-moon spectacles perched on his long nose, a neat black waistcoat, thin eyebrows under a lank grey fringe. Except, you can see the corded muscle exposed by his rolled-up shirtsleeves and the tattoos stretching down to the backs of his broad hands, and also the cable stretched from the roof to his spine, disappearing through custom-made gaps in his clothes. An Alaya-Vijnana system. Got to be. You can't help staring for a few seconds, unsure what to think. Have you ever seen one used outside of a cockpit? Why would anyone need to?

“Is that mask recording?” the man asks, snapping you out of it.

The woman asked the same thing. The bar-fly didn't. “Yeah.”

------

From one angle, everything about Jove is made up. His name, the inky black of his hair, his bright suits and neatly-pointed goatee, each as deliberately crafted as the Tournament itself. The fighters pretend, putting on an act in the ring, and Jove at the top puts on the biggest of all, selling them body and soul. He'll say whatever he needs to, do whatever he has to, to draw in the crowd's money.

But there's the trick. He makes himself up to chase a single goal, and that isn't hidden in the slightest. It's as naked as a wad of meria bills.

------

We spend a few more minutes searching the supermarket for the makings of a decent meal. It's not badly stocked, overall. Everything you could hope for, far as nutrition goes. Oh, I am definitely being a snob. Mom'd be telling me off and Kudelia would be seriously disappointed. The people shopping here aren't going to have a say in what's on offer, are they? They'll be able to make the best of it, just the same as I hopefully can. Even those living off Mr Sunshine's Spectacular Savoury Sensations don't deserve some Martian punk looking down on them.

Also a smart man, looking up at his host and sole protector when he's astronomical units from home, wouldn't want to insult her by being a huge dick over her living conditions.

------

You clocked them the moment they rose from their seats. Three people in military uniforms – in Gjallarhorn uniforms, or the remains of them. The sleeves have been cut off the men's olive green tunics and the badges on the front are gone, a blank space where the shield and seven stars was once displayed. The woman standing between them wears her officer's coat unbuttoned and without the belt, showing off the ruffled white blouse underneath and the big silver medallion hung around her neck. She's easily as tall as Jove and has a tumbling mass of curly brown hair, contrasting sharply with a complexion almost as pale as her shirt.

“Good morning.” Natural authority rings through her voice. “A pleasure to make your acquaintance.”

------

Should she stay locked inside Räum? Sit here, safely armoured, ready to go if everything nosedives.

Yeah. She knows that's a dumb idea even before Pinky's pilot floats over to beckon her out. So she pulls her jacket from the right-side storage compartment and digs in the left for mag-strips to fasten on the bottom of her boots.

“Jaén, was it?” The woman waiting outside is averagely tall, built broad and curvy enough for it to show from under her rose-coloured normal-suit. She's got a pile of dark, frizzy hair tied up on her head – and a smile pretty as a razor. “I'm Gabriela Turbine.”

Grunted acknowledgement is the safest response when Jaén's head is suddenly full of several competing kinds of warning bells.

------

(*points* Do you see the structural conceit this time around? Isn't it shiny??)

#fanfic#my fic#WIP#akatsuki's big adventure#I lied#one of these excerpts is just Akatsuki having Opinions about food

6 notes

·

View notes

Text

Cold Formed Steel Drawing and Drafting Services in Bloomington

Steel Construction Detailing is leading the top-notch quality of Cold Formed Steel Detailing Services. Our Cold Formed Steel Detailing Services cover a wide spectrum of solutions, ranging from initial concept development to the creation of intricate and accurate steel detailing plans. Our Outsource Cold Formed Steel Detailing team ensures that each detail is meticulously accounted for, ensuring precision and compliance with industry standards. Leverage the power of Computer-Aided Design (CAD) through our Cold Formed Steel Detailing CAD Services. If you are looking for your next Cold Formed Steel Detailing Consultants Services than Connected with US.

Why Choose Us ?

- 15+ years of experience - 70+ Design and Drafting Engineering Team - Use Advanced tools and Updated Software - 11100+ completed project - Use international standards and unique codes

Website : https://www.steelconstructiondetailing.com/shop-drawing-detailing/bloomington-shop-drawing-detailing.html

#coldformedsteelwallframing#coldframesteelstructure#lightgaugesteelframingdesign#lightgaugesteelframingdetailing#lightgaugesteelstructuredesign#prefabfabricationdrawing#prefabpaneldetailing#prefabshopdrawing#lightgaugesteelframedstructuresdetailing#lightgaugesteelworkfabricationdrawing#CADServices#SteelCAD

1 note

·

View note

Text

Techno-Nationalism and Global Power Plays: A Deep Dive by Sayyed Farhan Naqvi

In today’s world, the levers of global influence have shifted dramatically from traditional resources like oil and steel to advanced technologies such as semiconductors, cloud computing, artificial intelligence (AI), and algorithms. These technologies now form the backbone of economic strength, military power, and geopolitical influence. Sayyed Farhan Naqvi explores the rising significance of techno-nationalism and its impact on global power dynamics.

The Digital Battleground: Semiconductors, AI, and Cloud Dominance Semiconductors, cloud infrastructure, and AI have become the cornerstone of modern geopolitical strategy. Semiconductors power critical sectors, from AI models to precision weaponry, making them vital for both national security and global competitiveness. As a result, countries across the world, including the United States, China, and Europe, have introduced policies like the U.S. CHIPS Act, investing billions into semiconductor development and production.

Cloud computing, once exclusive to tech startups, is now central to the concept of national sovereignty. Policies focused on "digital sovereignty" are reshaping data storage and processing to serve as tools for geopolitical influence. From Taiwan’s TSMC to major American players like AWS and Google Cloud, the global digital infrastructure has become a high-stakes arena in international relations.

The U.S.-China Tech Rivalry: A New Cold War for Digital Dominance The escalating technological rivalry between the U.S. and China has transformed from a trade conflict to a battle for dominance in AI, quantum computing, and 5G networks. Issues like Huawei’s 5G rollout, TikTok’s data handling, and U.S. chip export controls are not just trade disputes but indicators of a broader technological cold war.

This rivalry is about setting the rules for the digital world. The U.S. promotes a market-driven approach, while China pushes for a state-controlled model. As Sayyed Farhan Naqvi points out, AI is a key battleground, with both nations racing to secure not only hardware and software but also the talent necessary for technological supremacy.

Sovereign AI: Governments’ Quest for Control Sovereign AI refers to nations’ attempts to control the development and deployment of artificial intelligence. Countries like France, the UAE, and China have launched their own AI initiatives to reduce dependence on Western technologies. However, Sayyed Farhan Naqvi argues that true AI sovereignty is complicated. Global talent mobility, open-source models, and supply chain dependencies create significant interdependencies. Nations without local chip production or large-scale cloud providers face substantial challenges.

A fragmented AI landscape could lead to divergent standards and security risks, making global cooperation essential. Countries must balance national ambitions with global collaboration to prevent vulnerabilities in the AI ecosystem.

Weaponized Interdependence: Strategic Leverage through Supply Chains Once symbols of efficiency, global supply chains have now become tools for coercion, with nations using their control over technology and materials as leverage. This concept, known as "weaponized interdependence," is evident in actions like the U.S. imposing chip export restrictions and China threatening to limit rare earth minerals.

In response, countries are forming defensive tech alliances, such as the U.S.-led Chip 4 group (comprising Japan, South Korea, and Taiwan), India’s expanding tech partnerships, and the EU’s push for digital autonomy. These new alliances are redefining global tech relationships as vital national security compacts.

Digital Mercantilism: Rethinking Global Tech Trade Global trade policies, designed for physical goods, are ill-suited for the challenges of managing data and algorithms. This mismatch has given rise to digital mercantilism, where governments impose data localization rules and limit foreign tech companies’ reach. Examples include India’s data protection laws, China’s Great Firewall, and Europe’s Digital Markets Act. While these measures aim to protect national interests, they risk fragmenting the global internet and stifling innovation.

The Stakes of Techno-Geopolitics: The Future of Global Power The growing dominance of digital technologies in shaping global power dynamics reflects the rise of techno-geopolitics, where control over chips, cloud infrastructure, and algorithms is now as important as military might. The decisions made today, regarding cooperation or confrontation in the tech sphere, will influence the global geopolitical landscape for generations to come.

In an era governed by data, AI, and algorithms, the crucial question is: who will set the rules? Nations must navigate the balance between national interests and global collaboration to secure their place in the future of global power.

#Sayyed Farhan Naqvi#GlobalPower#DigitalSovereignty#Sayyed Farhan Naqvi iLearningEngines#Sayyed Farhan

0 notes

Text

Elmalo, let’s dive deeper into the hardware specifications that will form the foundation of Iron Spine’s sensor fusion capabilities. This detailed look will cover sensor choices, ruggedization strategies for extreme environments, and considerations for optimizing edge computing performance.

1. Sensor Choices

A diverse sensor suite is crucial for a system designed to operate across space, deep sea, underground, and more. Here are some categories and specific choices to consider:

Environmental Sensors:

Radiation Detectors:

Example: Semiconductor-based sensors (e.g., Silicon PIN diode detectors) or Geiger-Müller tubes.

Key Considerations: Sensitivity range, calibration for cosmic or deep-sea radiation, and response time.

Pressure Sensors:

Example: Piezoresistive or capacitive sensors like those used in underwater applications.

Key Considerations: Depth ratings, response time, and temperature compensation.

Temperature & Humidity Sensors:

Example: Bosch BME280 or Sensirion SHT series.

Key Considerations: Accuracy under varying environmental conditions, low power consumption, and integration ease.

Motion & Optical Sensors:

Insect-Inspired Motion Sensors:

Example: MEMS-based inertial measurement units (e.g., InvenSense MPU-9250 or similar) that capture acceleration, angular velocity, and magnetic field data with high resolution.

Key Considerations: Minimal latency, low drift, and high sensitivity for subtle movements.

High-Resolution Cameras:

Example: Industrial-grade camera modules (such as those designed for robotics or autonomous vehicles) that can perform in varied lighting.

Key Considerations: Frame rate, resolution, and the ability to operate in low-light or high-contrast conditions.

LIDAR/Optical Ranging:

Example: Compact, time-of-flight sensors or structured light systems.

Key Considerations: Range, environmental adaptability, and integration with visual feeds.

Acoustic & RF Sensors:

Acoustic Sensors:

Example: MEMS microphone arrays or specialized underwater hydrophones for sonar applications.

Key Considerations: Frequency sensitivity (audible versus ultrasonic), noise cancellation, and dynamic range.

RF Sensors:

Example: Software-defined radio (SDR) modules or narrow-band receivers capable of picking up anomalous electromagnetic signals.

Key Considerations: Frequency range, sensitivity, and resistance to interference.

2. Device Ruggedization

Operating in extreme environments demands that each edge device and sensor module be hardened for durability and reliability. Consider these strategies:

Enclosures & Packaging:

IP-Rated Cases: Use industrial enclosures rated at least IP67 or higher to protect against dust, water ingress, and contaminants.

Shock & Vibration Dampening: Implement mounting solutions with shock-absorbing materials (such as silicone inserts or rubber gaskets) to reduce the effects of mechanical impacts and vibrations common in harsh environments.

Temperature Control:

Thermal Management: Integrate active cooling (mini fans or heat sinks) or passive solutions (thermal conductive materials) to maintain optimal operating temperatures across extreme conditions.

Heaters or Insulation: In cold or high-altitude settings, built-in heaters or insulation can prevent sensor malfunctions and maintain performance.

Material Selection:

Robust Circuitry: Use components rated for wide temperature ranges and shock tests. Consider industrial-grade microcontrollers (like those used in aerospace) along with robust soldering and PCB design techniques.

Corrosion Resistance: For deep-sea or subterranean applications, use corrosion-resistant materials (e.g., conformal coatings, stainless steel housings) to extend the lifetime of the sensors and board-level components.

3. Edge Computing Performance

At the edge, the processing unit must handle a high throughput of sensor data in real time. Consider these platforms and configurations:

Primary Edge Devices:

NVIDIA Jetson Series:

AGX Xavier: Offers high computational power with an 8-core ARM CPU, 512-core GPU, and accelerated deep learning inference capabilities. Ideal for implementing sophisticated preprocessing and fusion algorithms.

Jetson Nano: A cost-effective alternative when power is limited, capable of running streamlined models and basic sensor fusion tasks.

Key Advantages:

Real-Time Processing: GPU acceleration and support for frameworks like TensorRT enable fast, in-situ data analysis and decision-making.

Modular Scalability: Easily integrated with additional sensor inputs and can run multiple fusion algorithms concurrently.

Supplementary Controllers:

Raspberry Pi Compute Modules & Arduino Boards:

Roles: Act as microcontroller units (MCUs) for simpler sensor tasks such as data acquisition, local filtering, or secondary processing.

Interfacing: Use standardized communication protocols (SPI, I2C, UART) to easily integrate with primary edge devices.

Communication & Connectivity:

Protocols for Inter-Device Communication: Consider MQTT for lightweight messaging and LoRaWAN for long-range, low-power communication in areas with intermittent connectivity.

Latency & Bandwidth Considerations: Properly balance between local processing (minimizing transmission delays) and cloud synchronization for historical data analysis.

Power Considerations:

Energy Efficient Design: Optimize both hardware and software to balance high performance with reasonable power consumption, especially critical in remote field deployments.

Battery Solutions: Explore rugged, high-capacity battery units or renewable energy options (solar panels) for prolonged, autonomous operation.

Summarized Blueprint Table

This comprehensive hardware specification not only outlines your sensor choices but also integrates strategies for device ruggedization and robust edge computing performance—ensuring Iron Spine’s sensor network is resilient, precise, and ready for extreme, real-world applications.

Would you like to further explore specific sensor integration techniques, or do you have additional requirements or constraints—perhaps environmental limits or power consumption targets—we should account for in the current blueprint?

0 notes

Text

Light Gauge Steel Machine: A Game-Changer in Modern Construction

In the dynamic world of construction, speed, precision, and sustainability are no longer optional—they’re essential. As the industry shifts toward modular construction and prefabricated solutions, the Light Gauge Steel Machine has emerged as one of the most impactful tools for builders and manufacturers alike.

Whether you’re building residential homes, commercial complexes, or prefabricated units, a Light Gauge Steel Machine can dramatically enhance your workflow, reduce costs, and deliver exceptional quality with structural integrity. In this blog, we’ll explore everything you need to know about light gauge steel machines—from how they work to why they matter.

What is a Light Gauge Steel Machine? A Light Gauge Steel Machine is a high-precision roll forming system designed to produce cold-formed steel framing components. These machines transform galvanized steel coils into structural elements such as studs, tracks, joists, and trusses, which are used for framing walls, ceilings, and floors in light steel construction systems.

These machines are fully automated and programmable, making them ideal for high-volume production of framing systems with minimal human intervention.

Why Light Gauge Steel is Gaining Popularity Before diving deeper into the machine, let’s understand why light gauge steel (LGS) is becoming a top choice in construction:

Lightweight yet Strong: LGS offers excellent strength-to-weight ratio.

Non-Combustible: Steel does not burn, making it a safer alternative to timber in fire-prone areas.

Sustainable: Steel is 100% recyclable and leaves minimal waste during production.

Dimensionally Stable: No warping, shrinking, or rotting—ensuring long-lasting structures.

Faster Construction: LGS buildings can be assembled quickly with prefabricated parts.

All these advantages are maximized when produced using a Light Gauge Steel Machine.

How Does a Light Gauge Steel Machine Work? The machine process is designed for speed and accuracy. Here’s how it works step-by-step:

Coil Loading A galvanized steel coil is placed onto a hydraulic decoiler which unwinds the coil and feeds it into the machine.

Leveling and Straightening The steel passes through straighteners that remove coil memory and flatten the material.

Punching & Notching Precision punches create service holes for electrical wiring, plumbing, and HVAC installations based on the design.

Roll Forming The core of the machine features multiple stations of roll forming dies that shape the steel into C, U, or custom profiles.

Cutting An automated flying shear or saw cuts the profiles to exact lengths as specified in the building plan.

Labeling & Stacking Optional modules label the parts for easy assembly and stack them for delivery or on-site use.

The entire process is controlled via CNC or PLC systems and can integrate with BIM or CAD software.

Key Features of a Modern Light Gauge Steel Machine ✅ Automated Operation – Reduces human error and labor cost.

✅ CAD/BIM Compatibility – Import architectural designs directly into the machine.

✅ Multiple Profile Options – Easily switch between stud, track, joist, and truss production.

✅ High-Speed Production – Capable of producing 10–25 meters per minute or more.

✅ Precision Punching – Custom hole placement for MEP systems.

✅ Material Efficiency – Minimizes scrap and maximizes yield.

Applications of Light Gauge Steel Machines These machines have a wide range of applications across multiple sectors:

🏠 Residential Construction From single-family homes to multi-story buildings, light gauge steel frames provide structural components for walls, floors, and roofs.

🏢 Commercial Interiors LGS is widely used in office buildings, malls, and hospitals for partitions, suspended ceilings, and support walls.

🛠️ Modular and Prefab Buildings Light gauge steel machines are the cornerstone of prefab housing factories that require fast and repeatable production.

🏭 Industrial Buildings Warehouses, cold storage units, and logistics centers rely on light steel framing for flexible design and durability.

🌍 Disaster Relief and Remote Housing Due to their lightweight and easy assembly, LGS structures are perfect for rapid deployment in disaster zones or remote areas.

Benefits of Using a Light Gauge Steel Machine

Faster Construction Timelines Manufacture and pre-assemble framing systems off-site and reduce on-site work significantly.

Consistent Quality Eliminate variability and errors common in manual fabrication.

Reduced Labor Dependency One machine operator can manage production for large-scale projects.

Flexible Design Options Easily switch between different steel thicknesses and profiles.

Sustainability Precise cuts and digital control minimize waste, contributing to eco-friendly building practices.

Integration with BIM & CAD Software One of the standout features of the Light Gauge Steel Machine is its seamless integration with BIM (Building Information Modeling) and CAD platforms. This allows designers and architects to:

Upload building models directly to the machine

Reduce design-to-production time

Ensure accurate part labeling and coordination

Detect and correct clashes before construction

This digital-to-physical workflow significantly improves project coordination and efficiency.

What to Look for When Buying a Light Gauge Steel Machine If you're considering investing in a Light Gauge Steel Machine, here are a few things to keep in mind:

Feature Why It Matters Profile Range Can the machine produce all the profiles you need (C, U, Sigma, etc.)? Software Integration Supports your existing CAD/BIM ecosystem? Punching Flexibility Are the punching dies easily adjustable or replaceable? Speed and Output Does it meet your volume demands? After-Sales Support Is training, maintenance, and troubleshooting support available? The Future of Light Gauge Steel Machines As the construction industry continues to embrace digitalization and prefabrication, we can expect even smarter and more versatile LGS machines:

AI and Machine Learning for predictive maintenance and adaptive production

IoT-Connected Machines for real-time performance monitoring

3D Framing Capabilities for more complex structural systems

On-Site Compact Machines for localized production in remote projects

Conclusion: Build Smart with a Light Gauge Steel Machine In an era where time is money and quality is non-negotiable, the Light Gauge Steel Machine is more than just a piece of equipment—it’s a strategic investment. From reducing costs to enhancing precision and accelerating construction timelines, this machine plays a vital role in modernizing the building industry.

Whether you’re a contractor, prefab builder, or steel product manufacturer, adopting a Light Gauge Steel Machine can help you deliver superior results while staying ahead of the competition.

Looking to upgrade your production line? Explore our high-performance Light Gauge Steel Machines designed for builders who demand the best in speed, accuracy, and flexibility. Contact us now for a free consultation and quote. roll forming machine in india purlin machine light steel frame machine

0 notes

Text

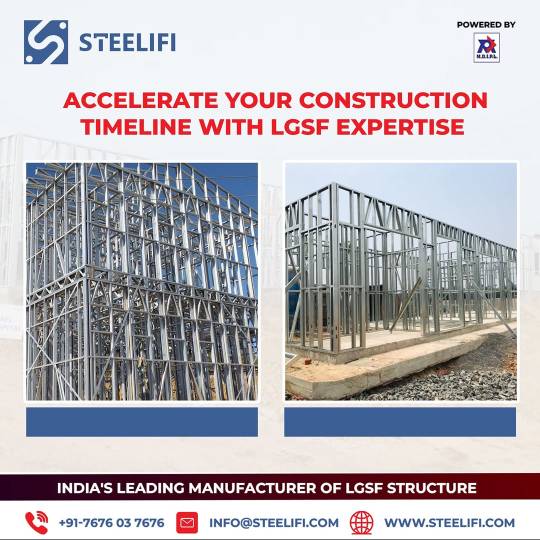

Building the Future: The Power of LGSF Construction

In the fast-paced world of construction, innovation is key. Light Gauge Steel Framing (LGSF) is revolutionizing the industry, offering a smarter, faster, and more sustainable way to build. At Steelifi, we specialize in cutting-edge LGSF technology, bringing strength, efficiency, and versatility to modern construction.

What is LGSF Construction?

LGSF is a construction method that uses cold-formed steel sections to create durable and lightweight structures. Unlike traditional building techniques, LGSF construction offers precision engineering, rapid assembly, and enhanced durability, making it ideal for residential, commercial, and industrial projects.

Why LGSF is the Future of Construction

Speed Like Never Before Time is money, and LGSF construction significantly reduces project timelines. Prefabricated components mean faster on-site assembly, helping developers meet deadlines without compromising quality.

Strength Without the Bulk Steel is known for its durability, and with Light Gauge Steel Framing, buildings gain superior strength while remaining lightweight. This makes LGSF perfect for high-rise structures and seismic-prone regions.

Sustainability at Its Core The future of construction is green, and Steelifi's LGSF solutions are leading the way. Steel is 100% recyclable, and our precision-driven manufacturing process ensures minimal waste, making it an eco-friendly choice.

Precision & Design Flexibility With advanced design software like Vertex BD and StadPro, Steelifi delivers LGSF structures with unmatched accuracy. Whether you need sleek commercial spaces or robust industrial buildings, our solutions adapt to any architectural vision.

Fire & Weather Resistance Safety is paramount, and LGSF buildings offer excellent fire resistance and protection against extreme weather conditions, ensuring long-term security and reliability.

Where is LGSF Used?

Residential Projects: Modern homes, apartments, and villas.

Commercial Buildings: Offices, hotels, and retail spaces.

Industrial Infrastructure: Warehouses, factories, and logistics hubs.

Institutional Buildings: Schools, hospitals, and research centers.

Why Choose Steelifi?

At Steelifi, we don’t just build—we innovate. As a leading LGSF manufacturer in India, we provide state-of-the-art solutions tailored to your needs. With years of expertise, cutting-edge technology, and a commitment to excellence, we ensure that your project stands tall—both in strength and sustainability.

Ready to transform your next construction project? Contact us today and take the first step towards a smarter, stronger future with LGSF construction.

0 notes

Text

STAAD Pro is the most powerful software that can design almost any kind of civil engineering structure such as steel, concrete, timber, aluminum, and cold-formed steel designs. The newly released or complete package of analysis from Bentley is STAAD Pro Course in Jaipur. With the most experienced trainers, CAD DESK delivers many software training in the fields of CAD, CAM & CAE that are the best in the industry. While learning from the best software courses, students get an option to do an Internship and can also go for Industrial visits assisted by the trainers; so that it helps the students to escalate their career and let them have in-hand knowledge of the software.

0 notes

Text

Tooling for Cold Heading and Thread Rolling Machines: The Backbone of Fastener Manufacturing

In the fast-paced world of manufacturing, precision and efficiency are paramount. Among the many industrial processes, cold heading and thread rolling are critical for producing high-quality fasteners like screws, bolts, and nuts. At Taiwan Metiz Alliance (TMA), we specialize in designing and producing tooling solutions that cater to these essential processes. With over 25 years of expertise and innovation, TMA has established itself as a trusted global partner for manufacturers seeking reliable, efficient, and high-performing tooling for cold-heading and thread-rolling machines.

Understanding Cold Heading and Thread Rolling

Cold heading is a process where metal wire or rods are shaped into fasteners without heating, utilizing high pressure and advanced dies. This method produces parts with exceptional strength due to the preservation of the material's grain structure. On the other hand, thread rolling involves forming threads onto fasteners by pressing them between hardened dies, ensuring consistent thread profiles with minimal material waste.

Both processes rely heavily on the quality of the tooling used. Accurate tooling not only enhances the product's durability and functionality but also optimizes manufacturing efficiency by reducing downtime and material costs.

TMA’s Expertise in Cold Heading Tooling

At TMA, we offer a comprehensive range of cold-heading tooling designed to meet diverse manufacturing needs. Our products include:

Header Punches and Pins: Manufactured using premium Japanese and European steels, our punches are precision-engineered for creating complex slots such as marking, piercing, and forging. Available in standard formats like JIS (Japan), ANSI (US), and DIN (Germany), we also offer custom punches tailored to specific customer requirements.

Heading and Cutting Dies: These are crafted with advanced coatings like titanium nitrides and carbides, enhancing wear resistance and extending tool life.

Specialized Tools: From slugger punches to first-pass punches, we provide solutions for cold heading tasks involving intricate geometries and high tolerances.

Each TMA tool undergoes rigorous quality control and testing on high-precision European measuring equipment to ensure flawless performance in high-volume production environments.

Thread Rolling Tooling by TMA

Thread rolling tooling is another cornerstone of TMA’s product portfolio. We design and manufacture flat and profiled thread-rolling dies tailored to rolling metric and inch threads on fasteners, including self-tapping screws, bolts, and specialty products. Key highlights of our thread rolling tooling include:

Material Excellence: Made from high-speed steel (HSS) and high-alloy tool steels sourced from Japan and Germany, our dies are heat-treated for exceptional hardness and strength.

Precision Engineering: Our thread rolling dies are manufactured using state-of-the-art CNC machinery, ensuring dimensional accuracy and superior thread quality.

Durable Coatings: To enhance tool longevity, we apply advanced coatings like titanium carbides and nitrides, reducing wear and maintaining sharpness even in high-speed operations.

Custom Designs: TMA provides bespoke thread rolling dies to accommodate unique fastener designs, meeting the needs of industries like automotive, aerospace, and construction.

Why Choose TMA for Tooling Needs?

Quality Assurance: Our ISO 9001:2015 certification reflects our commitment to producing tooling solutions that meet the highest industry standards. Each product is subjected to strict quality inspections and testing to ensure flawless performance.

Advanced Technology: Equipped with modern EDM machines, vacuum furnaces, and CNC metalworking systems, TMA stays at the forefront of manufacturing innovation. We also utilize advanced computer-aided design software to develop precise tooling solutions.

Expertise and Customization: With over 25 years of experience, our team excels in creating custom tooling solutions tailored to specific production needs. Whether it’s a unique thread design or a specialized heading die, TMA can deliver.

Competitive Pricing: Thanks to Taiwan’s robust manufacturing ecosystem and competition among suppliers, we provide premium-quality tooling at affordable prices, ensuring excellent value for our clients.

Applications and Industries

The tooling solutions from TMA are widely used in industries such as:

Automotive: For high-strength bolts, screws, and specialty fasteners used in vehicle assembly.

Construction: For durable self-tapping screws and bolts in building projects.

Aerospace: For precision fasteners requiring tight tolerances and high durability.

Electronics: For small, intricately designed screws used in gadgets and appliances.

Our tools are trusted by manufacturers around the globe, and known for their durability, functionality, and cost-efficiency.

Partner with TMA for Superior Tooling Solutions

Cold heading and thread rolling are indispensable processes in fastener production, and the quality of tooling significantly influences their outcomes. At Taiwan Metiz Alliance, we take pride in delivering world-class tooling solutions that empower manufacturers to achieve excellence. From header punches and cutting dies to thread rolling dies, every TMA product reflects our unwavering commitment to quality, innovation, and customer satisfaction.Let TMA be your trusted partner for all your tooling needs. Contact us today at [email protected] or call +886-2-278-45675 to discuss how we can support your business.

0 notes

Text

Revolutionizing Construction with CFS Software and Cold Formed Steel

Cold Formed Steel (CFS) is quickly becoming the preferred material in modern construction due to its high strength-to-weight ratio, resistance to corrosion, and design flexibility. Unlike traditional materials, CFS is manufactured through a cold-forming process at room temperature, resulting in precise, lightweight components that are ideal for both commercial and residential structures. Its ability to reduce structural weight without sacrificing integrity makes it an excellent choice for cost-effective and sustainable building projects.

As CFS continues to grow in popularity, the complexity of designing and detailing these structures also increases. That’s where CFS Software plays a crucial role. Tailored specifically for engineers, architects, and fabricators working with Cold Formed Steel, this software provides advanced tools for structural analysis, member sizing, and automatic code checks. It not only speeds up the design process but also enhances accuracy and ensures compliance with building standards—something that manual calculations or general-purpose tools often struggle to achieve.

Incorporating CFS Software into your design workflow means you can confidently deliver precise drawings, optimize material usage, and collaborate more effectively with your team. Whether you're working on light-gauge steel framing, modular buildings, or steel trusses, this software simplifies complex tasks and reduces the risk of costly errors. As construction moves toward greater efficiency and digital integration, CFS Software has become an essential resource for anyone working with Cold Formed Steel.

Discover more on the topic by visiting our blog - https://steelsmart.blogspot.com/2025/06/revolutionizing-construction-with-cfs.html

0 notes

Text

Find how Cold-Formed Steel Design Programs Can be a Game-Changer for Steel Framing Projects

In the world of construction, precision and efficiency are essential. Utilizing advanced Structural Framing Software can significantly enhance the design and implementation process of steel framing projects. By utilizing this software, construction professionals can create detailed and accurate designs for their steel framing projects. The software can also help streamline the implementation process, reducing the time and resources required to complete a project.

Maximizing Efficiency with Cold-Formed Steel

Cold-formed steel (CFS) is increasingly popular in the construction industry due to its strength, versatility, and cost-effectiveness. The adoption of CFS Software allows engineers and architects to fully harness these benefits. These programs facilitate detailed analysis and design, enabling users to create highly accurate models and simulations. This precision not only reduces material waste but also enhances the overall structural integrity of the building.

One of the leading tools in this domain is developed by a company renowned for its innovation in steel design technology. Their software solutions are designed to support complex calculations and provide intuitive interfaces that simplify the user experience. Investing in advanced Cold-Formed Steel Design Software can transform your steel framing projects, providing a robust foundation for success. Embracing this technology ensures that you deliver top-notch results efficiently and effectively, reinforcing your reputation for excellence in the industry. For more read the full blog here-https://steelsmartsystem.blogspot.com/2024/07/blog-post_23.html

0 notes

Text

Pioneering Innovations with Cold-Formed Steel Software Solutions

Applied Science drives the integration of scientific principles into practical applications, revolutionizing industries with cutting-edge solutions. A key focus is the development and application of Cold Formed Steel Software, enabling precise design, analysis, and optimization of steel structures. This specialized technology enhances efficiency, accuracy, and sustainability in construction and engineering projects. By merging advanced computational tools with material science, Applied Science empowers professionals to create resilient, cost-effective, and innovative structural designs.

0 notes

Text

Discover Steel Smart System’s CFS software for efficient and accurate CFS design. Our tools streamline cold-formed steel design and detailing, enhancing your projects. Call us now - (919) 645-4090

1 note

·

View note