#Compost machine

Explore tagged Tumblr posts

Text

From Trash to Treasure: Unlocking the Power of On-Site Composting with COMPOSTO VEER

📞 Call DSC Engineering at +91 9958858881 📧 Email: [email protected] 🌐 Website: www.compostmachinemanufacturers.com

Introduction: The Urgency of a Sustainable Waste Revolution

India generates over 62 million tonnes of waste annually—and nearly 50-60% of this is organic waste from food scraps, kitchen leftovers, canteens, and wet markets. Unfortunately, a large portion ends up in landfills, producing harmful methane gases and leachates, contributing to urban pollution and climate change.

For bulk waste generators such as housing societies, hotels, hospitals, and corporate campuses, the issue is especially critical. Compliance with Solid Waste Management (SWM) Rules 2016 is no longer optional—it is legally and ethically imperative. But with increasing urbanization and tightening environmental norms, how can institutions manage organic waste efficiently, hygienically, and cost-effectively?

Enter COMPOSTO VEER: A Smart, Sustainable, and Compliant Solution

Manufactured by DSC Engineering, the COMPOSTO VEER range of Organic Waste Converter (OWC) machines is transforming the way bulk organic waste is managed across India. Using cutting-edge aerobic bio-mechanical technology, COMPOSTO VEER converts food waste into nutrient-rich compost on-site within 24 hours—efficiently, safely, and odorlessly.

Whether you're managing a gated community, running a large hotel chain, or overseeing waste operations in an educational or corporate campus—COMPOSTO VEER offers a complete, customizable solution that aligns with sustainability goals and government compliance.

What is an OWC Machine? Why Is It a Game-Changer?

An Organic Waste Converter (OWC) is a mechanical system designed to process organic or biodegradable waste into compost. Traditional waste management relies heavily on collection, transportation, and landfilling, which is not only unsustainable but also costly and environmentally damaging.

An OWC machine, like COMPOSTO VEER, decentralizes the process—allowing for on-site conversion of waste to compost through aerobic digestion. This reduces dependency on centralized systems, cuts down transport costs, eliminates odor and pest problems, and produces valuable compost for gardens, landscapes, or commercial sale.

In essence, it’s a compact, eco-friendly factory that transforms "trash into treasure" right where waste is generated.

Introducing COMPOSTO VEER: The Future of On-Site Organic Waste Management

COMPOSTO VEER OWC Machines are the result of DSC Engineering’s decade-long innovation in sustainable waste technology. With models ranging from 150 kg/day to 2000 kg/day, these machines are built to serve the needs of both mid-sized establishments and large-scale campuses or municipalities.

What Makes COMPOSTO VEER Different?

COMPOSTO VEER is not just another composting unit. It’s a robust, intelligent, and reliable system—engineered for real-world Indian conditions. Each machine is designed for:

High efficiency: Converts waste to compost within 24 hours.

Volume reduction: Up to 85-90% of waste volume reduced.

Odor control: Through advanced aeration and filtration systems.

Durability: Constructed using SS304 stainless steel and high-torque motors.

Ease of use: Fully automated with minimal manual intervention.

Compliance: Aligned with SWM Rules 2016 and FCO standards.

Beyond the Basics: COMPOSTO VEER's Advanced Technological Features

Let’s dive deeper into what makes COMPOSTO VEER stand out in the competitive composting landscape.

1. Superior Construction for Longevity

SS 304 Inner Chamber & Outer Shell: Corrosion-resistant, food-grade stainless steel ensures long life and hygiene.

Thermo-Block Insulation: Advanced insulation maintains temperature stability while conserving energy.

Durable MS Structural Frame: Designed to endure high loads and daily operation stresses.

2. Intelligent Mixing & Shredding System

Dual-Helical Shaft Design: Equipped with variable pitch paddles for optimized mixing and aeration.

Kinetic-Cut Shredder Blades: Tungsten carbide-tipped in-chamber shredding ensures consistent particle size and faster decomposition.

3. Smart Power & Drive Mechanism

Smart-Torque Dynamic Drive System: Adapts torque and speed in real-time, enhancing power efficiency.

IP66 Rated Geared Motors: Dust-proof, water-resistant motors offer consistent, reliable performance.

4. Precision Heating for Optimal Composting

Segmented PID-Controlled Heating Array: Delivers targeted heating zones for stable microbial activity.

Inconel 800 Heating Elements: Heat-resistant and long-lasting components for temperature control.

5. Odor Control & Ventilation

‘Odor-Lock’ Air Management System: Combines centrifugal blowers and activated carbon filters to neutralize odors.

Continuous Aeration: Maintains aerobic environment to prevent foul smells and anaerobic build-up.

6. Smart Sensor Suite

Temperature, Load, and Moisture Sensors: Real-time monitoring ensures ideal composting conditions.

Auto Alerts: Notifies operator in case of system anomalies or maintenance requirements.

7. Advanced Safety Protocols

Guardian Safety Protocol: Emergency stop, door interlocks, overload protection, and jam detection for safe operation.

8. Intelligent Control & User Interface

7” Industrial-Grade HMI Touchscreen: Offers real-time process visualization and intuitive control.

Dual Operation Modes: ‘Eco-Cycle’ for daily processing and ‘Boost-Cycle’ for rapid turnaround.

Automated Diagnostics: System self-checks ensure optimal performance and quick troubleshooting.

The Tangible Benefits: Why Choose COMPOSTO VEER?

Environmental Impact

Diverts thousands of kilograms of organic waste from landfills.

Reduces methane and CO2 emissions.

Helps close the organic loop with compost output.

Supports zero waste and green campus initiatives.

Operational Ease

Plug-and-play design with low setup time.

Odor-free and pest-free environment.

Requires minimal labor and supervision.

Compact footprint, suitable for space-constrained areas.

Financial & Compliance Benefits

Saves on waste transport and disposal costs.

Potential revenue from compost sales or internal reuse.

100% compliant with SWM Rules 2016.

Qualifies for CSR, ESG, and Green Building credits.

SWM Rule Compliance Made Easy

The Solid Waste Management Rules, 2016, mandate that all bulk waste generators process their biodegradable waste at source. Non-compliance can lead to legal penalties, cancellation of environmental clearances, or financial liabilities.

How COMPOSTO VEER Helps:

Enables on-site processing with 24-hour cycle.

Produces FCO-compliant compost.

Ensures traceable and auditable operations.

Helps fulfill green reporting and audit requirements.

In short, COMPOSTO VEER is not just a machine—it’s your compliance partner.

Finding Your Perfect Fit: Flexible Capacities for Diverse Needs

COMPOSTO VEER offers a range of models to match every scale:ModelDaily CapacityIdeal ForCV-150150 kg/daySmall societies, guest housesCV-300300 kg/dayMid-size hotels, campusesCV-500500 kg/dayLarge apartments, institutionsCV-10001000 kg/dayCorporates, hospitals, clustersCV-1500 & CV-20001500–2000 kg/dayMunicipalities, industrial zones

No matter your volume, COMPOSTO VEER has a smart, scalable solution to meet your goals.

Partnering with Excellence: The DSC Engineering Advantage

DSC Engineering isn’t just a manufacturer—it’s a trusted partner in sustainable waste management.

Why Clients Trust DSC Engineering:

In-house R&D and manufacturing—Made in India, made for India.

Complete support ecosystem—Installation, training, and operational guidance.

Responsive after-sales service—AMC, spare parts, repairs, and remote diagnostics.

Proven field performance—Hundreds of machines installed across North India.

We understand the operational challenges faced by facilities teams. That’s why we offer hands-on support, backed by years of industry insight and engineering excellence.

Client Success Snapshot

1. Green Living in Noida: A 500-apartment housing society installed a COMPOSTO VEER 300 kg/day unit. Within weeks, their waste collection costs dropped by 40%, and residents began using the compost in terrace gardens.

2. Corporate Campus in Gurugram: A 1000-employee IT park implemented a 500 kg/day model. Their green building certification was upgraded, and their waste disposal bill dropped significantly.

3. Hospitality Chain in Mussoorie: An eco-luxury resort chain adopted decentralized composting using two 150 kg/day units. Tourists loved the sustainability story, and the hotel began selling compost to nearby farms.

Conclusion: Toward a Cleaner, Greener India

The question isn’t “Can we afford to compost?” The real question is: “Can we afford not to?”

With rising environmental concerns, growing regulatory pressure, and increasing public awareness, waste generators can no longer rely on outdated, unsustainable disposal systems.

COMPOSTO VEER by DSC Engineering empowers you to take charge of your waste—efficiently, hygienically, and responsibly. Whether you manage a campus, a residential tower, a hospital, or an industrial kitchen—there’s a COMPOSTO VEER machine built just for you.

Together, let’s turn waste into wealth. Let’s compost with purpose. Let’s build a sustainable tomorrow.

Call to Action: Transform Your Organic Waste Management Today

🌱 Ready to compost smartly, safely, and sustainably?

📞 Call DSC Engineering at +91 9958858881 📧 Email: [email protected] 🌐 Website: www.compostmachinemanufacturers.com

We’re happy to offer a personalized consultation, site assessment, or product demo to help you find the best-fit COMPOSTO VEER solution for your facility.

Let me know if you'd like this in downloadable DOCX or PDF format for your website or if you’d like a shorter version for newsletters or LinkedIn articles.

You said:

in 3900 charecters

ChatGPT said:

Here is a blog post for COMPOSTO VEER OWC Machines written within 3900 characters (approx. 600–650 words), structured as per your detailed brief and SEO-optimized:

From Trash to Treasure: Unlocking the Power of On-Site Composting with COMPOSTO VEER

India generates thousands of tonnes of organic waste every day — from food leftovers in homes to large volumes from hotels, canteens, societies, and institutions. Improper disposal leads to overflowing landfills, foul odors, pest issues, and regulatory non-compliance. But what if this “waste” could become an asset?

That’s where COMPOSTO VEER OWC Machines step in — your smart, sustainable, and compliant solution to transform food waste into rich, usable compost right at the source.

What is an OWC Machine?

An Organic Waste Converter (OWC) machine processes biodegradable waste using controlled aerobic digestion. It reduces waste volume by up to 90%, producing nutrient-rich compost. On-site composting cuts transportation, reduces emissions, and helps comply with SWM Rules 2016.

Introducing COMPOSTO VEER: The Future of Organic Waste Management

Manufactured by DSC Engineering, COMPOSTO VEER machines are designed for modern sustainability needs. From 150 kg/day for small communities to 2000 kg/day for municipalities or industrial campuses, there’s a solution for every scale.

These fully automatic machines convert organic waste into stable compost in approximately 24 hours using high-temperature aerobic bio-mechanical digestion.

Beyond the Basics: COMPOSTO VEER’s Smart Features

1. Build Quality & Insulation: Inner & outer body made from SS 304 stainless steel, mounted on a robust MS frame. Advanced Thermo-Block insulation minimizes heat loss and energy use.

2. Smart Mixing & Shredding: Dual-Helical Shaft with Variable Pitch Paddles ensures uniform mixing. Integrated ‘Kinetic-Cut’ Shredder Blades (tungsten-carbide tipped) allow efficient in-chamber shredding.

3. Power Efficiency: Driven by an IP66-rated Geared Motor with the Smart-Torque Dynamic Drive System, it dynamically adjusts power based on load.

4. Precise Heating & Odor Control: Uses PID-controlled Inconel 800 heaters for efficient temperature regulation. The Odor-Lock Air System with activated carbon filters ensures odorless operation.

5. Full Automation & Safety: Features include 7” HMI touchscreen, Industrial PLC, real-time diagnostics, emergency stop, door interlocks, and Eco-Cycle / Boost-Cycle modes for flexibility.

Real Benefits to You

✅ Environmental: Up to 90% waste reduction, minimal landfill burden, and reduction in greenhouse emissions. Produces FCO-compliant compost. ✅ Operational: Silent, odorless, user-friendly, and compact. Needs minimal labor and manual input. ✅ Financial: Cost savings on waste disposal, compliance with SWM Rules, and potential compost resale income.

SWM Rule Compliance Made Easy

COMPOSTO VEER helps bulk waste generators meet the Solid Waste Management Rules, 2016 by enabling decentralized waste treatment and reducing load on civic systems. It aligns with sustainability goals and ESG targets of corporates and institutions.

Find Your Perfect Fit

Whether you manage a medium-sized housing society, hotel, school, industrial unit, or an entire municipal ward, DSC Engineering offers machines from 150 kg/day to 2000 kg/day. Each model is designed to handle specific volumes efficiently.

Why Choose DSC Engineering?

DSC Engineering is an Indian pioneer in sustainable waste management, known for precision manufacturing, timely support, AMC & repair services, and a client-first approach. Each COMPOSTO VEER machine comes with full installation, training, and after-sales care.

A Cleaner Future Begins with You

Don’t let your waste go to waste. Choose COMPOSTO VEER for a cleaner, greener tomorrow. Whether it’s a residential complex or a corporate canteen, turn your organic waste into wealth.

Call to Action

Ready to transform your organic waste management? Contact DSC Engineering today for a personalized consultation or demo of COMPOSTO VEER OWC Machines.

🌐 Visit: www.owcmachine.co.in 📞 Call: +91 9958858881 📧 Email: [email protected]

#biocomposter#composting equipment#compost machine#food waste composting machine#on-site composting machine#mini owc machine#commercial compost machine#automatic composter#bio-digester machine#organic waste composter

0 notes

Text

New and returning looks in the ShopShifty store!

I Like Machines | Future Compost | Metal Autism

#machines#autism#mushrooms#compost#our shirts#otter's art#thank you for supporting indie disabled queer weird shit

77 notes

·

View notes

Text

This is not an original observation, but “war crimes” truly is such a dystopian phrase.

Not that there’s no value in being able to describe (and prosecute) violence that’s especially beyond the pale, but the conceptual framework that implies there’s such a thing as good legal “civilized” war, that those acts of extreme violence are the exception to the rule as opposed to the logical outcome.

#CLEARLY this is not a shrug at the seriousness of war crimes but a condemnation of war#saying this is a great way to get a whole range of people really angry at you but imo we can acknowledge#that there have been regimes/armies/individuals with a particular penchant for brutality#AND acknowledge that when you build a violence machine what you get from it is violence.#it’s a Few Bad Apples vs this is a literal compost pile designed expressly to be an environment in which apples rot kinda problem.#no more war#my posts

16 notes

·

View notes

Text

me immediately after finishing lord of the rings

#it broke my heart shoved it in a blender on high then poured it into a compost machine to be remade into a block#tears are flowing like Niagara Falls#lotr#I just love Frodo and Sam and Aragorn and the fellowship so much

5 notes

·

View notes

Text

How to adjust a windrow compost turning machine for different materials?

Windrow compost turning machines are core equipment in modern composting. Knowing how to adjust them correctly can significantly improve compost quality and production efficiency.

1.Adjusting Turning Depth

For dense materials like livestock manure, set the turning depth between 1.2 and 1.5 meters.For lighter materials like garden waste, a depth of 0.8 to 1.2 meters works better.Adjust the rotor height using the hydraulic system. This ensures thorough mixing without overloading the machine.

2.Controlling Travel Speed and Turning Frequency

For high-moisture materials (like fresh food waste), slow the travel speed down to 2-3 meters per minute and turn more often, about every two days.For drier materials (like straw), you can increase the speed to 4-5 meters per minute and turn less often, every 3-4 days.

3.Handling Special Materials

When processing high-fiber materials, consider adding a special shredding attachment.For materials that clump easily, you can add a crushing roller behind the windrow compost turning machine.Check the blades regularly for wear. Worn blades mix poorly and waste energy.

4.Seasonal Adjustments

During hot summers, turn more frequently. Use temperature sensors to monitor the pile.In the rainy season, turn less often to avoid losing too much moisture.In winter, slightly reduce the turning height to help the pile retain heat.

By scientifically adjusting your windrow compost turning machine's settings, you can meet the needs of different materials. This improves compost quality while saving energy. Regular maintenance and fine-tuning are key to keeping it running efficiently long-term.

0 notes

Text

#Mushroom Composting Unit Machinery#Mushroom Machinery#Mushroom Machines#Compost Turner#Mushroom Air Handling Unit

0 notes

Text

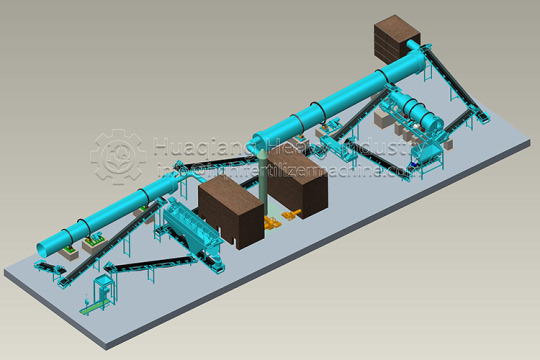

Organic fertilizer equipment solves the problems left over from breeding

Organic fertilizer equipment has played an important role in solving the problems left over from breeding. The following is a specific analysis:

1. Manure treatment and resource utilization: Farms need to build supporting manure storage, treatment and pollution prevention facilities. For example, composting technology requires the construction of storage and fermentation sites, equipped with organic fertilizer fermentation turning machines and closed storage facilities. Automated high-temperature closed organic fertilizer fermentation equipment and thermophilic composite microbial agents are used to accelerate the degradation of waste organic matter and the formation of humus, and produce stabilized, mature and harmless organic fertilizer products.

2. Improve the level of resource utilization of livestock and poultry manure: Support livestock and poultry farms to improve manure treatment facilities, and improve the equipment rate and treatment process level of manure treatment facilities of farms.

3. Innovate livestock and poultry manure treatment: Use models to support social third-party investment in livestock and poultry manure treatment, form a full industrial chain of livestock and poultry manure collection, storage, transportation, treatment and comprehensive utilization, and promote the combination of breeding and farming, and the agricultural and animal husbandry cycle model.

4. Policy support and technology promotion: Increase financial support and credit support, cultivate new entities, new formats, and new industries, and guide social capital to participate in the development of organic fertilizers, new energy and other industries. Research and develop new technologies and equipment, and increase the development and popularization of technologies and equipment such as mixed raw material fermentation, biogas purification and canning, and manure and biogas application.

Through the above measures, organic fertilizer equipment can not only effectively solve the manure treatment problem in the aquaculture industry and reduce environmental pollution, but also convert waste into valuable resources and achieve sustainable development of the aquaculture industry.

0 notes

Text

An organic waste composter is a system or machine that converts biodegradable waste—such as food scraps, vegetable peels, garden waste, and other organic materials—into compost, a nutrient-rich substance that enhances soil health.

0 notes

Text

How to prevent blockages in windrow compost turning machines for smooth production?

Windrow compost turning machines are central to organic fertilizer production. Their stable operation directly affects fermentation efficiency and product quality. Blockages are a common problem in actual production, reducing efficiency and potentially damaging the equipment.

1.Pre-treating Raw Materials

Keep moisture content between 50-65% (material should form a ball when squeezed but break apart when dropped).Shred long-fiber materials (like straw or branches) to under 5cm.Keep out large foreign objects (hard impurities like stones or metal).

2.Set Operating Parameters Smartly

Keep the windrow compost turning machine's travel speed between 2-5 meters per minute.Set the turning drum speed between 25-35 RPM.Adjust the turning depth (recommended 30-50cm) based on the material's characteristics.

3.Regular Maintenance

Clean residue off the drum and tracks after each shift.Check blade wear weekly (replace if worn over 20%).Lubricate drive components (key parts like bearings and chains) monthly.

4.Emergency Response Plan

If a blockage occurs, stop the machine and cut power immediately.Clear the blockage using proper tools in reverse rotation (never use your hands).Find and remove the cause of the blockage.Test run the machine empty before resuming work.

Following these steps can reduce blockage chances by over 80%. Choosing a high-quality windrow compost turning machine with built-in anti-blocking features.This ensures the machine runs reliably and efficiently, providing solid support for your organic fertilizer production.

0 notes

Text

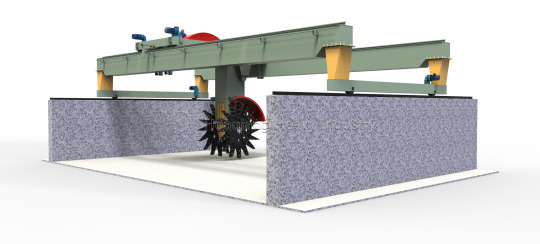

How to use the large wheel compost turning machine correctly

The correct use of the large wheel compost turning machine can improve work efficiency and extend the service life of the equipment. The following are the operation steps and precautions:

1. Preparations before operation: Before use, check whether all components of the organic fertilizer equipment are complete, whether the connections are firm, and whether there is any looseness or damage. Check if there is oil in the reducer and clean the dirt on the equipment in time, especially the dirt on the chassis. If there is any peeling of protective paint, it should be repainted.

2. Startup and Operation: Start the turning equipment and observe whether the rotation direction is correct. If the rotation direction is reverse, stop immediately and change the three-phase circuit joints to change the rotation direction. When the equipment is running, listen for any abnormal sounds from the reducer and touch the temperature of each bearing to see if it is within the temperature range.

3. Load test run: During the load test run, the transmission parts of the flipping equipment should operate smoothly without any abnormal sounds. If there are any abnormal sounds, they should be inspected. The electronic control system should operate stably, start and stop sensitively, and act accurately.

4. Shutdown and Maintenance: Before shutting down the equipment, check if there is any accumulated material in front of the turning roller, and then lift the turning roller above the highest accumulation point of the material in the trough. The tightness of the transmission chain should be frequently checked and adjusted in time. If it is found that the links of the transmission chain do not rotate smoothly, they should be lubricated with grease or engine oil in time.

5. Daily maintenance: The walking support bearings on the chassis, the rotating support of the stirring shaft, and the lifting support bearings should be regularly lubricated with grease.

Through the above steps, it can be ensured that the large wheel disk turning machine operates safely and efficiently during use, and at the same time, the service life of the equipment can be prolonged.

0 notes

Text

What raw materials can be turned by windrow compost turning machines?

The windrow compost turning machine is key equipment in modern compost production. Its strong power, flexible steering, and deep turning ability have completely changed traditional composting methods.

1.Livestock Manure

Chicken Manure: Nitrogen-rich material; needs frequent turning to speed up fermentation.

Pig Manure: Thick and sticky; crawlers effectively break up clumps.

Cow Manure: High in fiber; requires strong turning for mixing.

Duck/Goose Manure: High water content; crawlers handle wet conditions well.

Key Point: Aim for 60% initial moisture. Add straw to adjust the C/N ratio.

2.Agricultural Waste

Crop stalks (corn, wheat), fruit/vegetable scraps (leaves, peels), spent mushroom substrate (mushroom bags, lingzhi blocks), etc.

Advantage: The windrow’s crushing action speeds up breaking down fibrous materials.

3.Organic Waste

Pre-treated food waste, garden waste (branches, leaves, grass clippings), sludge (from wastewater plants, moisture needs adjusting).

Special Handling: Adding bulking agents improves the mix structure.

4.Mixed Compost Ingredients

Organic-inorganic blends, biochar compost mixes, compost with added functional microbial agents.

Materials not suitable for windrow compost turning machines:

Lots of hard impurities (stones, metal, etc.).Very long, unshredded fibers (like whole sugarcane stalks).Extremely sticky materials (moisture >75% without adjustment).

The windrow compost turning machine works with almost all common organic wastes for composting. Matching the material’s properties to the machine’s settings can boost composting efficiency by over 30% and noticeably cut production costs.

0 notes

Text

The Science of Sustainability: An Inside Look at COMPOSTO VEER OWC Technology

In a nation striving towards a cleaner and greener future, the efficient management of organic waste stands as a monumental challenge and a profound opportunity. With the swelling burden on landfills, the escalating costs of waste disposal, and the urgent environmental mandates of the Solid Waste Management (SWM) Rules 2016, a paradigm shift from traditional waste handling to innovative, on-site solutions has become non-negotiable for bulk waste generators across India. At the forefront of this transformative movement is COMPOSTO VEER OWC Machines, an indigenously manufactured marvel that embodies the fusion of advanced engineering and ecological responsibility, ushering in an era of decentralized, sustainable waste transformation.

The Imperative of On-Site Organic Waste Management

The sheer scale of organic waste generated by urban centers, housing societies, hospitality sectors, and industrial canteens presents an environmental and logistical quagmire. Traditional waste disposal methods, predominantly landfilling, contribute significantly to environmental degradation through methane emissions (a potent greenhouse gas), soil and water contamination, and the perpetual demand for more land. The economic strain of collecting and transporting this waste over long distances further exacerbates the problem. Recognizing these critical issues, the SWM Rules 2016 specifically mandate bulk waste generators to manage and process their organic waste within their own premises. This legislative push underscores the vital role of decentralized composting as a pragmatic and eco-friendly solution, mitigating environmental damage and fostering local resource recovery.

Introducing COMPOSTO VEER: An Advanced OWC Solution

An Organic Waste Converter (OWC) machine is a sophisticated bio-mechanical system designed to accelerate the natural decomposition of organic waste, transforming it into valuable compost right at the source of generation. This technology bypasses the inefficiencies and environmental detriments of centralized waste collection.

COMPOSTO VEER, the flagship OWC machine brand from DSC Engineering, represents the pinnacle of this technology in India. As a distinguished Original Equipment Manufacturer (OEM), DSC Engineering is committed to delivering robust, reliable, and technologically superior solutions. The fundamental promise of COMPOSTO VEER is its capability to efficiently convert a diverse array of segregated organic waste—including daily food waste, fruit and vegetable peels, cooked food, meat and fish scraps, garden waste, and biodegradable cutlery—into stabilized, high-quality compost within an impressive 24-hour processing cycle. This rapid and effective transformation is underpinned by our innovative High-Temperature Aerobic Bio-Mechanical Digestion technology, which expertly controls the environment to foster thermophilic microbial activity, ensuring accelerated and thorough decomposition.

Engineering Excellence: Key Technological Differentiators of COMPOSTO VEER

COMPOSTO VEER OWC Machines are a testament to meticulous engineering and innovative design, built for consistent performance, exceptional durability, and intelligent operation. They integrate several proprietary features that set them apart in the realm of organic waste management technology:

Uncompromising Construction & Material Integrity:

Proprietary Multi-layer SS 304 Composite Wall Construction: The machine's inner chamber and outer shell are constructed from high-grade SS 304 (Low Carbon) stainless steel. This multi-layer design ensures superior corrosion resistance, paramount hygiene, and extended operational life, especially vital in the acidic and moist environment of organic waste processing.

Patented 'Thermo-Block' Ceramic Wool Insulation: Integrated within this composite wall structure, our patented 'Thermo-Block' ceramic wool insulation, augmented with reflective foil, drastically minimizes heat loss. This translates directly into substantial energy efficiency, yielding up to 25% savings in operational heating costs and significantly reducing the overall energy footprint.

Robust Anti-Vibration MS Structural Frame: The entire COMPOSTO VEER unit is supported by a heavy-duty, IS Grade MS (Mild Steel) Anti-Vibration Structural Frame, fabricated from reinforced square pipes. This robust foundation, equipped with pre-drilled foundation bolt holes and anti-vibration damping pads, ensures exceptional stability, significantly minimizes operational noise (keeping it below 65 dB), and reduces mechanical stress on the installation surface, guaranteeing long-term durability.

Advanced Processing Dynamics:

Dual-Helical Shaft with Variable Pitch Paddles: At the core of the processing chamber is a solid SS 304 Dual-Helical Shaft, featuring uniquely designed variable pitch paddles. This innovative design ensures dynamic, multi-directional shredding and thorough mixing of the organic waste. This process promotes uniform temperature distribution throughout the biomass, critical for effective microbial action, and results in a consistent output particle size of less than 10mm, preventing clumping.

Integrated 'Kinetic-Cut' Blade Array: Directly integrated onto the mixing shafts, the 'Kinetic-Cut' Blade Array features high-wear-resistant Tungsten Carbide-tipped blades. This advanced system enables self-cleaning and energy-efficient in-chamber shredding, eliminating the need for separate shredders and the associated material transfer losses, thereby optimizing processing flow and efficiency.

Intelligent Control & Dynamic Power System:

Smart-Torque Dynamic Drive System: Powering the robust mixing and shredding operations is a Smart-Torque Dynamic Drive System, composed of independent IP66 rated High-Torque Geared Motors with direct coupling. This intelligent system provides real-time torque and speed modulation based on the waste load, ensuring optimized power consumption and effectively preventing motor overload, guaranteeing uninterrupted and reliable performance.

Segmented PID-Controlled Heating Array: Precision temperature control is vital for successful thermophilic digestion. Our Segmented PID-Controlled Heating Array utilizes multi-zoned, high-efficiency Inconel 800 heating elements with a distributed load. Each zone is precisely controlled by a dedicated PID (Proportional-Integral-Derivative) controller, maintaining accurate temperature regulation within an impressive ±2°C, which is crucial for sustaining optimal microbial activity and ensuring consistent decomposition.

Superior Hygiene & Odor Management:

Intelligent 'Odor-Lock' Air Management System: To ensure a clean and pleasant operating environment, COMPOSTO VEER incorporates a multi-stage 'Odor-Lock' Air Management System. This includes a powerful Centrifugal Blower for uniform airflow and a high-capacity Activated Carbon Filter Bank (with a pre-filter stage). Differential pressure sensors continuously monitor airflow, automatically adjusting blower speed to maintain optimal oxygen levels for aerobic decomposition while effectively trapping and neutralizing any potential odors.

‘Zero-Leak’ Cam-Lock Sealing System: Heavy-duty SS 304 access doors are equipped with our patented Silicone-Polymer blend gasket and ergonomic, multi-point cam-lock handles. This robust system ensures a hermetic, odor-proof seal, rated up to an impressive 200°C, preventing any leakage and maintaining pristine operating conditions.

Advanced Automation, Real-time Monitoring & Comprehensive Safety:

Industrial-Grade PLC with 7" color HMI Touchscreen: The sophisticated operations of COMPOSTO VEER are managed by an Industrial-Grade PLC (Programmable Logic Controller) with Edge Computing Capability, running proprietary firmware. This advanced system allows for sophisticated control logic and seamless integration with future IoT systems. The intuitive 7" color HMI (Human-Machine Interface) Touchscreen offers user-friendly Visual Recipe Management (allowing selection of pre-set programs for various waste types) and Real-time Process Visualization (graphical representation of machine status, internal temperature, mixing cycle, and blower activity).

Intelligent Operational Modes: For optimized performance, COMPOSTO VEER features ‘Eco-Cycle’ for energy-efficient processing of routine loads and ‘Boost-Cycle’ for accelerated processing during peak periods, ensuring the 24-hour cycle is consistently maintained even with slight overloads.

Automated Diagnostic Reporting: The PLC diligently maintains a comprehensive event log of all errors and shutdowns, facilitating rapid remote or on-site troubleshooting. It also generates invaluable daily and weekly operational reports on waste processed, energy consumed, and runtime, providing critical data for efficient facility management.

Integrated Multi-Parameter Sensor Array: A suite of high-precision sensors, including Triple-point RTD (Resistance Temperature Detector) sensors for accurate internal temperature, a Capacitive Moisture Sensor for real-time humidity tracking, and an Optical Load Sensor on the input chute, collectively ensure optimized operation and prevent overfilling.

‘Guardian’ Safety Protocol: For ultimate operational safety, COMPOSTO VEER integrates a comprehensive 'Guardian' Safety Protocol. This includes a redundant Emergency Stop (E-Stop) system, Door Interlock Sensors (which automatically halt operations when any door is opened), intelligent Motor Overload Protection with auto-reset logic, and Smart Jam Detection, ensuring maximum safety for both personnel and the machine.

Unlocking Multi-Faceted Benefits: Why COMPOSTO VEER is the Smart Choice

Implementing a COMPOSTO VEER OWC machine offers a holistic array of advantages, making it an indispensable asset for any bulk organic waste generator committed to sustainable practices:

Profound Environmental Impact: With an impressive 85-90% waste volume reduction (in Reduction Mode), COMPOSTO VEER drastically lessens the burden on landfills, contributing significantly to a cleaner environment. This directly translates to reduced greenhouse gas (GHG) emissions, particularly methane, and the creation of valuable organic fertilizer, fully compliant with FCO standards. The on-site processing model also minimizes the ecological footprint associated with waste transportation logistics.

Unparalleled Operational Efficiency: Designed for odor-free and hygienic operation, COMPOSTO VEER machines enhance the quality of life within your premises. Their compact footprint allows for seamless integration into various existing spaces. The intuitive controls and advanced automation translate into minimal manual intervention, streamlining waste management processes and freeing up valuable human resources. The swift 24-hour processing cycle ensures continuous and efficient waste conversion.

Significant Economic & Regulatory Compliance: Beyond environmental gains, COMPOSTO VEER offers tangible economic benefits. Users can realize substantial cost savings on waste collection and disposal fees, which are often a major operational expenditure. The high-quality compost generated can be utilized internally for landscaping or gardening, reducing procurement costs, or even sold, creating a new potential revenue stream. Crucially, the system ensures seamless adherence to the SWM Rules 2016, mitigating regulatory risks and enhancing an organization's sustainability profile.

Scalability for Every Need: Understanding the diverse organic waste generation profiles across India, COMPOSTO VEER offers an extensive range of capacities. From compact 10 kg/day and 15 kg/day models perfect for smaller communities and eateries, to robust solutions for 150 kg/day suitable for medium-sized societies and hotels, and large-scale units up to 2000 kg/day (2 Tonnes) for sprawling corporate campuses, municipal projects, and military cantonments—we have a tailored COMPOSTO VEER solution for every requirement.

The DSC Engineering & DS Consultancy Services Advantage: Your Trusted Partner

Choosing COMPOSTO VEER means aligning with DSC Engineering, an OEM synonymous with quality, reliability, and unwavering customer support in India. Our direct manufacturing capabilities ensure superior product knowledge and stringent quality control at every stage.

Our commitment extends beyond just providing world-class machines. Through DSC Engineering and our dedicated consulting arm, DS Consultancy Services, we offer a comprehensive ecosystem of waste management solutions:

Complete Service Spectrum: From expert manufacturing, we provide full support for installation, commissioning, and on-site operator training. Our robust after-sales support includes a 1-Year Standard Warranty against manufacturing defects, ready availability of genuine spare parts, and flexible Annual Maintenance Contracts (AMCs) for sustained, worry-free operation. Uniquely, our expertise extends to providing prompt and efficient repair services for all OWC machine brands, solidifying our position as a complete lifecycle partner for organic waste converters.

Strategic Consulting & Project Implementation: Through DS Consultancy Services, we leverage the invaluable strategic partnership with Dr. Sanjay K Gupta to offer holistic waste management consulting. This includes conducting meticulous Physical Site Surveys to assess waste streams and needs, developing detailed Detailed Project Reports (DPRs) and Feasibility Studies that outline optimized, SWM Rules 2016 compliant solutions. We specialize in conceptualizing and implementing "Zero Waste" and "Sustainable Eco-Waste Management" strategies for bulk generators, encompassing waste segregation, collection, and even strategies for selling recyclables to authorized partners. Our involvement in large-scale initiatives, such as the ambitious "Zero Waste Cantonment Proposal" for the Belgaum Military Cantonment and potential projects in Dehradun, underscores our capacity for impactful change.

Government Procurement Facilitation: Recognizing the importance of public sector engagement, DS Consultancy Services is fully authorized to facilitate government procurements via the GeM (Government e-Marketplace) portal, streamlining the acquisition process for public entities nationwide.

Proven Impact: Our Track Record

Our commitment to sustainable waste management is reflected in our robust track record of successful implementations across diverse sectors:

Municipal Transformation: We are proud to have spearheaded a significant 20-tonne per day (TPD) waste management plant for Ghaziabad Nagar Nigam, demonstrating our capability in executing large-scale municipal projects for effective solid waste management in India.

Industrial Leadership: Leading corporate entities such as Mahle Ltd. and Samkwang India have entrusted their organic waste management needs to our solutions, a testament to our reliability and efficiency in demanding industrial environments.

Institutional Excellence: Prominent educational institutions like Mangalmay Greater Noida benefit from our efficient OWC solutions, fostering greener campuses.

Visionary Projects: Our proactive engagement in strategic initiatives, including the "Zero Waste Cantonment Proposal" for the Belgaum Military Cantonment, highlights our commitment to pioneering and implementing truly sustainable, decentralized waste management models for the future.

Conclusion: Paving the Way for a Sustainable Future

The challenge of organic waste management in India is immense, but with innovations like COMPOSTO VEER OWC Machines, it transforms into an immense opportunity for sustainable development and resource recovery. DSC Engineering, through its cutting-edge manufacturing and comprehensive consulting services, stands as a beacon of reliability and expertise. We are not just selling machines; we are offering a complete ecosystem of solutions, built on the principles of efficiency, environmental responsibility, and compliance.

By integrating COMPOSTO VEER into their operations, organizations and communities can take a decisive step towards a decentralized, zero-waste future, actively contributing to the vision of the Swachh Bharat Mission and cultivating a cleaner, greener, and healthier India for generations to come.

For a detailed consultation, site assessment, or to explore how COMPOSTO VEER can transform your organic waste management, please visit www.compostmachinemanufacturers.com or contact Mr. Vikram Sharma at +91 9958858881.

#Compost machine#OWC machine#Organic waste converter#Organic waste composter#Food waste composting machine#Waste composting machine#Biocomposter#Automatic composter#Composting equipment#Bio-digester machine#On-site composting machine#Small compost machine#Mini OWC machine#Home compost machine (for very small if applicable)#Residential OWC#Commercial compost machine

0 notes

Text

Chain Compost Turning Machine: A Revolutionary Solution for Organic Waste

In the field of organic solid waste treatment, efficiency and quality have long been difficult to achieve simultaneously—until the advent of the chain compost turning machine! This innovative equipment has revolutionized traditional composting methods, providing the perfect solution for deep-trough composting of organic wastes including livestock manure, sludge, and municipal solid waste.

A chain compost turning machine plays a crucial role in the organic solid waste treatment sector by efficiently aerating and mixing compost piles, accelerating decomposition. In the organic fertilizer production process, it ensures proper fermentation, breaking down waste into nutrient-rich compost, which is then processed into high-quality organic fertilizer, enhancing sustainability and soil health.

Imagine: An intelligent device that automatically moves along fermentation trough rails, through efficient turning operations, not only accelerating the fermentation process but also significantly reducing moisture content and improving compost quality. This is exactly the value our chain compost turning machine brings to you!

Why Choose the chain compost turning machine?

Efficient Fermentation: Unique turning design promotes oxygen circulation, increasing microbial activity by over 40%, significantly shortening fermentation cycles

Moisture Control: Through uniform turning, moisture evaporation efficiency improves by 35%, solving traditional compost moisture problems

Quality Assurance: Thorough material mixing eliminates fermentation dead zones, ensuring every batch meets highest standards

Flexible Adaptation: Multiple specifications available to perfectly match fermentation troughs of different widths

Easy Operation: Automated operation reduces manual intervention, lowering labor intensity by 60%

Working Principle Revealed

The core of the chain compost turning machine lies in its precise transmission system and unique chain plate design. As the equipment moves smoothly along the rails, high-speed rotating chain plates lift and throw materials from the bottom, creating perfect parabolic movement. This process not only achieves thorough material mixing but also creates ideal aeration conditions, providing the best growth environment for beneficial microorganisms.

Compared with traditional turning equipment, our chain design reduces power consumption by 30% while increasing processing capacity by 25%. This means you can obtain higher quality compost products with less energy input!

"From farms to cities, from livestock manure to food waste, chain compost turning machines are changing the game of organic waste treatment worldwide. Join this green revolution and turn your waste into real 'black gold'!"

0 notes

Text

Organic Fertilizer Equipment: The Golden Triangle of Perfect Synergy

The Symbiotic Relationship Between Turner and Fermentation Tank

Imagine the compost turning machine as a diligent gardener, while the horizontal fermentation tank is the garden it carefully tends. This golden duo forms the heart of organic fertilizer production process.

The turner shuttles back and forth in the fermentation tank like a precise chef stirring ingredients in a pot, ensuring every inch of material receives even oxygen and temperature. This dynamic balance creates an ideal fermentation environment, allowing organic waste to complete its magnificent transformation in just 7-15 days.

Perfect Integration with Organic Fertilizer Production Process

In the entire symphony of organic fertilizer production, the fermentation stage is undoubtedly the most spectacular movement. From raw material pretreatment to fermentation conversion, then to subsequent crushing, granulation, and packaging, the combination of turner and fermentation tank ensures the efficient completion of the core fermentation phase.

This is like the most crucial baton in a relay race—without quality fermentation, all subsequent processes would be meaningless. In modern production lines, this combination can process over 85% of organic waste with conversion rates reaching 90%.

The Innovative Mission of Equipment Manufacturers

Excellent fertilizer machine manufacturers act like technical directors, continuously optimizing this "organic-to-gold" performance. Each generation of turners and fermentation tanks they develop pursues three ultimate goals: lower energy consumption, higher efficiency, and smarter control.

Leading manufacturers provide not just individual equipment but complete solutions including technical support, process guidance, and after-sales service. When you choose reputable brands, you're essentially purchasing a "quality insurance" for the entire production process.

0 notes

Text

Ventilation quality control for composting in bio-organic fertilizer production lines

In bio-organic fertilizer production lines, the quality of compost ventilation directly affects fermentation efficiency and the final product. A good ventilation system supplies enough oxygen for microbial activity, promotes organic matter breakdown, and effectively regulates compost pile temperature and moisture.

1.Key Points of Ventilation Systems

Pipeline Layout: Use cross-shaped or well-shaped pipe designs to ensure even airflow. Space pipes 1-1.5 meters apart. Pipe diameter should be 20-30 cm, chosen based on pile size.

Airflow Control: Recommended airflow is 0.05-0.2 cubic meters per minute per cubic meter of compost. Adjust based on raw material properties. For example, manure composting needs higher airflow.

2.Smart Ventilation Control

Temperature Feedback: Install multiple temperature sensors. Start forced ventilation automatically when compost temperature exceeds 65°C. Reduce airflow when it drops below 45°C.

Oxygen Monitoring: Use online oxygen sensors to maintain oxygen levels within the ideal range of 10-18%.

3.Ventilation Management Practices

Turnover-Assisted Ventilation: Turn the pile with a compost turning machine every 2-3 days. Increase turning frequency during the initial fermentation phase (first 7 days).

Pile Height Control: Maintain a height of 1.5-2 meters. Piles that are too high increase ventilation resistance; piles that are too low have poor heat retention.

Raw Material Prep: Crush raw materials to 3-5 cm particle size and adjust moisture content to 50-60% to ensure smooth ventilation.

In summary, scientific system design, smart control, and careful management in bio-organic fertilizer production lines can significantly boost composting efficiency and lower costs.

0 notes

Text

Windrow Compost Turning Machine: The Efficiency Engine for Fertilizer Production Lines

In the field of organic fertilizer production process, the windrow compost turning machine is becoming an indispensable core equipment for modern composting processes with its outstanding performance and flexible adaptability. This professional machine, specially designed for ground windrow fermentation technology, integrates turning, crushing, oxygen supply and stacking functions, injecting new vitality into fertilizer production lines.

1. Intelligent Control, Double Harvest of Yield and Quality

One of the most praised features of the windrow compost turning machine is its intelligent adjustment capability. Operators can precisely set the running speed of wheels and turning shafts according to material characteristics, just like a chef adjusting heat for different ingredients, ensuring each batch of raw materials obtains optimal fermentation conditions. This fine control not only guarantees stable output but also significantly improves the quality consistency of finished organic fertilizer.

Production data shows that windrow turners with adjustable speed design can improve fermentation efficiency by over 35% while reducing raw material loss by 15%, truly achieving the production goal of "more, faster, better and cheaper".

2. Powerful Yet Energy-saving

The windrow compost turning machine equipped with a vertical water-cooled diesel engine can be called the "muscle man" of organic fertilizer production lines. This power configuration not only provides ample torque, ensuring the equipment works effortlessly in heavy materials, but also significantly reduces production costs with its high efficiency and low fuel consumption. Compared with traditional equipment, fuel consumption can be reduced by 20% while work efficiency can be improved by 30%.

3. Flexible Operation, Maximizing Space Efficiency

The design philosophy of modern windrow turners is "flexibility first". Its steering system is consistent with the pull bar direction, operating as lightly as driving a luxury car, with small turning radius and strong site adaptability. In today's land-scarce environment, this compact design means you can process more materials in smaller spaces, improving space utilization by up to 40%.

Electric button switch, one-click start/stop, intuitive operation

Joystick control, precise adjustment, sensitive response

Hydraulic adjustment of axle distance, adapting to different pile height requirements

4. Customized Service for Individual Needs

Truly professional equipment never sticks to conventions. The windrow compost turning machine can adjust the distance between the axle and the ground through hydraulic system according to customers' special requirements, effectively preventing shaft jamming. This thoughtful customized design allows the equipment to perfectly adapt to various special materials and site conditions, becoming the "Transformer" on production lines.

Choosing a windrow compost turning machine is not just choosing a piece of equipment, but also choosing a 24/7 fermentation expert. It works tirelessly around the clock to ensure your organic fertilizer production line always maintains optimal condition, producing high-quality organic fertilizer.

From precise control to powerful performance, from flexible operation to customized services, windrow compost turning machines are redefining efficiency standards for organic fertilizer production with their comprehensive advantages. In the context of pursuing sustainable development, this green and efficient equipment is undoubtedly the wisest investment choice for modern fertilizer production lines.

0 notes