#Automatic composter

Explore tagged Tumblr posts

Text

The Science of Sustainability: An Inside Look at COMPOSTO VEER OWC Technology

In a nation striving towards a cleaner and greener future, the efficient management of organic waste stands as a monumental challenge and a profound opportunity. With the swelling burden on landfills, the escalating costs of waste disposal, and the urgent environmental mandates of the Solid Waste Management (SWM) Rules 2016, a paradigm shift from traditional waste handling to innovative, on-site solutions has become non-negotiable for bulk waste generators across India. At the forefront of this transformative movement is COMPOSTO VEER OWC Machines, an indigenously manufactured marvel that embodies the fusion of advanced engineering and ecological responsibility, ushering in an era of decentralized, sustainable waste transformation.

The Imperative of On-Site Organic Waste Management

The sheer scale of organic waste generated by urban centers, housing societies, hospitality sectors, and industrial canteens presents an environmental and logistical quagmire. Traditional waste disposal methods, predominantly landfilling, contribute significantly to environmental degradation through methane emissions (a potent greenhouse gas), soil and water contamination, and the perpetual demand for more land. The economic strain of collecting and transporting this waste over long distances further exacerbates the problem. Recognizing these critical issues, the SWM Rules 2016 specifically mandate bulk waste generators to manage and process their organic waste within their own premises. This legislative push underscores the vital role of decentralized composting as a pragmatic and eco-friendly solution, mitigating environmental damage and fostering local resource recovery.

Introducing COMPOSTO VEER: An Advanced OWC Solution

An Organic Waste Converter (OWC) machine is a sophisticated bio-mechanical system designed to accelerate the natural decomposition of organic waste, transforming it into valuable compost right at the source of generation. This technology bypasses the inefficiencies and environmental detriments of centralized waste collection.

COMPOSTO VEER, the flagship OWC machine brand from DSC Engineering, represents the pinnacle of this technology in India. As a distinguished Original Equipment Manufacturer (OEM), DSC Engineering is committed to delivering robust, reliable, and technologically superior solutions. The fundamental promise of COMPOSTO VEER is its capability to efficiently convert a diverse array of segregated organic waste—including daily food waste, fruit and vegetable peels, cooked food, meat and fish scraps, garden waste, and biodegradable cutlery—into stabilized, high-quality compost within an impressive 24-hour processing cycle. This rapid and effective transformation is underpinned by our innovative High-Temperature Aerobic Bio-Mechanical Digestion technology, which expertly controls the environment to foster thermophilic microbial activity, ensuring accelerated and thorough decomposition.

Engineering Excellence: Key Technological Differentiators of COMPOSTO VEER

COMPOSTO VEER OWC Machines are a testament to meticulous engineering and innovative design, built for consistent performance, exceptional durability, and intelligent operation. They integrate several proprietary features that set them apart in the realm of organic waste management technology:

Uncompromising Construction & Material Integrity:

Proprietary Multi-layer SS 304 Composite Wall Construction: The machine's inner chamber and outer shell are constructed from high-grade SS 304 (Low Carbon) stainless steel. This multi-layer design ensures superior corrosion resistance, paramount hygiene, and extended operational life, especially vital in the acidic and moist environment of organic waste processing.

Patented 'Thermo-Block' Ceramic Wool Insulation: Integrated within this composite wall structure, our patented 'Thermo-Block' ceramic wool insulation, augmented with reflective foil, drastically minimizes heat loss. This translates directly into substantial energy efficiency, yielding up to 25% savings in operational heating costs and significantly reducing the overall energy footprint.

Robust Anti-Vibration MS Structural Frame: The entire COMPOSTO VEER unit is supported by a heavy-duty, IS Grade MS (Mild Steel) Anti-Vibration Structural Frame, fabricated from reinforced square pipes. This robust foundation, equipped with pre-drilled foundation bolt holes and anti-vibration damping pads, ensures exceptional stability, significantly minimizes operational noise (keeping it below 65 dB), and reduces mechanical stress on the installation surface, guaranteeing long-term durability.

Advanced Processing Dynamics:

Dual-Helical Shaft with Variable Pitch Paddles: At the core of the processing chamber is a solid SS 304 Dual-Helical Shaft, featuring uniquely designed variable pitch paddles. This innovative design ensures dynamic, multi-directional shredding and thorough mixing of the organic waste. This process promotes uniform temperature distribution throughout the biomass, critical for effective microbial action, and results in a consistent output particle size of less than 10mm, preventing clumping.

Integrated 'Kinetic-Cut' Blade Array: Directly integrated onto the mixing shafts, the 'Kinetic-Cut' Blade Array features high-wear-resistant Tungsten Carbide-tipped blades. This advanced system enables self-cleaning and energy-efficient in-chamber shredding, eliminating the need for separate shredders and the associated material transfer losses, thereby optimizing processing flow and efficiency.

Intelligent Control & Dynamic Power System:

Smart-Torque Dynamic Drive System: Powering the robust mixing and shredding operations is a Smart-Torque Dynamic Drive System, composed of independent IP66 rated High-Torque Geared Motors with direct coupling. This intelligent system provides real-time torque and speed modulation based on the waste load, ensuring optimized power consumption and effectively preventing motor overload, guaranteeing uninterrupted and reliable performance.

Segmented PID-Controlled Heating Array: Precision temperature control is vital for successful thermophilic digestion. Our Segmented PID-Controlled Heating Array utilizes multi-zoned, high-efficiency Inconel 800 heating elements with a distributed load. Each zone is precisely controlled by a dedicated PID (Proportional-Integral-Derivative) controller, maintaining accurate temperature regulation within an impressive ±2°C, which is crucial for sustaining optimal microbial activity and ensuring consistent decomposition.

Superior Hygiene & Odor Management:

Intelligent 'Odor-Lock' Air Management System: To ensure a clean and pleasant operating environment, COMPOSTO VEER incorporates a multi-stage 'Odor-Lock' Air Management System. This includes a powerful Centrifugal Blower for uniform airflow and a high-capacity Activated Carbon Filter Bank (with a pre-filter stage). Differential pressure sensors continuously monitor airflow, automatically adjusting blower speed to maintain optimal oxygen levels for aerobic decomposition while effectively trapping and neutralizing any potential odors.

‘Zero-Leak’ Cam-Lock Sealing System: Heavy-duty SS 304 access doors are equipped with our patented Silicone-Polymer blend gasket and ergonomic, multi-point cam-lock handles. This robust system ensures a hermetic, odor-proof seal, rated up to an impressive 200°C, preventing any leakage and maintaining pristine operating conditions.

Advanced Automation, Real-time Monitoring & Comprehensive Safety:

Industrial-Grade PLC with 7" color HMI Touchscreen: The sophisticated operations of COMPOSTO VEER are managed by an Industrial-Grade PLC (Programmable Logic Controller) with Edge Computing Capability, running proprietary firmware. This advanced system allows for sophisticated control logic and seamless integration with future IoT systems. The intuitive 7" color HMI (Human-Machine Interface) Touchscreen offers user-friendly Visual Recipe Management (allowing selection of pre-set programs for various waste types) and Real-time Process Visualization (graphical representation of machine status, internal temperature, mixing cycle, and blower activity).

Intelligent Operational Modes: For optimized performance, COMPOSTO VEER features ‘Eco-Cycle’ for energy-efficient processing of routine loads and ‘Boost-Cycle’ for accelerated processing during peak periods, ensuring the 24-hour cycle is consistently maintained even with slight overloads.

Automated Diagnostic Reporting: The PLC diligently maintains a comprehensive event log of all errors and shutdowns, facilitating rapid remote or on-site troubleshooting. It also generates invaluable daily and weekly operational reports on waste processed, energy consumed, and runtime, providing critical data for efficient facility management.

Integrated Multi-Parameter Sensor Array: A suite of high-precision sensors, including Triple-point RTD (Resistance Temperature Detector) sensors for accurate internal temperature, a Capacitive Moisture Sensor for real-time humidity tracking, and an Optical Load Sensor on the input chute, collectively ensure optimized operation and prevent overfilling.

‘Guardian’ Safety Protocol: For ultimate operational safety, COMPOSTO VEER integrates a comprehensive 'Guardian' Safety Protocol. This includes a redundant Emergency Stop (E-Stop) system, Door Interlock Sensors (which automatically halt operations when any door is opened), intelligent Motor Overload Protection with auto-reset logic, and Smart Jam Detection, ensuring maximum safety for both personnel and the machine.

Unlocking Multi-Faceted Benefits: Why COMPOSTO VEER is the Smart Choice

Implementing a COMPOSTO VEER OWC machine offers a holistic array of advantages, making it an indispensable asset for any bulk organic waste generator committed to sustainable practices:

Profound Environmental Impact: With an impressive 85-90% waste volume reduction (in Reduction Mode), COMPOSTO VEER drastically lessens the burden on landfills, contributing significantly to a cleaner environment. This directly translates to reduced greenhouse gas (GHG) emissions, particularly methane, and the creation of valuable organic fertilizer, fully compliant with FCO standards. The on-site processing model also minimizes the ecological footprint associated with waste transportation logistics.

Unparalleled Operational Efficiency: Designed for odor-free and hygienic operation, COMPOSTO VEER machines enhance the quality of life within your premises. Their compact footprint allows for seamless integration into various existing spaces. The intuitive controls and advanced automation translate into minimal manual intervention, streamlining waste management processes and freeing up valuable human resources. The swift 24-hour processing cycle ensures continuous and efficient waste conversion.

Significant Economic & Regulatory Compliance: Beyond environmental gains, COMPOSTO VEER offers tangible economic benefits. Users can realize substantial cost savings on waste collection and disposal fees, which are often a major operational expenditure. The high-quality compost generated can be utilized internally for landscaping or gardening, reducing procurement costs, or even sold, creating a new potential revenue stream. Crucially, the system ensures seamless adherence to the SWM Rules 2016, mitigating regulatory risks and enhancing an organization's sustainability profile.

Scalability for Every Need: Understanding the diverse organic waste generation profiles across India, COMPOSTO VEER offers an extensive range of capacities. From compact 10 kg/day and 15 kg/day models perfect for smaller communities and eateries, to robust solutions for 150 kg/day suitable for medium-sized societies and hotels, and large-scale units up to 2000 kg/day (2 Tonnes) for sprawling corporate campuses, municipal projects, and military cantonments—we have a tailored COMPOSTO VEER solution for every requirement.

The DSC Engineering & DS Consultancy Services Advantage: Your Trusted Partner

Choosing COMPOSTO VEER means aligning with DSC Engineering, an OEM synonymous with quality, reliability, and unwavering customer support in India. Our direct manufacturing capabilities ensure superior product knowledge and stringent quality control at every stage.

Our commitment extends beyond just providing world-class machines. Through DSC Engineering and our dedicated consulting arm, DS Consultancy Services, we offer a comprehensive ecosystem of waste management solutions:

Complete Service Spectrum: From expert manufacturing, we provide full support for installation, commissioning, and on-site operator training. Our robust after-sales support includes a 1-Year Standard Warranty against manufacturing defects, ready availability of genuine spare parts, and flexible Annual Maintenance Contracts (AMCs) for sustained, worry-free operation. Uniquely, our expertise extends to providing prompt and efficient repair services for all OWC machine brands, solidifying our position as a complete lifecycle partner for organic waste converters.

Strategic Consulting & Project Implementation: Through DS Consultancy Services, we leverage the invaluable strategic partnership with Dr. Sanjay K Gupta to offer holistic waste management consulting. This includes conducting meticulous Physical Site Surveys to assess waste streams and needs, developing detailed Detailed Project Reports (DPRs) and Feasibility Studies that outline optimized, SWM Rules 2016 compliant solutions. We specialize in conceptualizing and implementing "Zero Waste" and "Sustainable Eco-Waste Management" strategies for bulk generators, encompassing waste segregation, collection, and even strategies for selling recyclables to authorized partners. Our involvement in large-scale initiatives, such as the ambitious "Zero Waste Cantonment Proposal" for the Belgaum Military Cantonment and potential projects in Dehradun, underscores our capacity for impactful change.

Government Procurement Facilitation: Recognizing the importance of public sector engagement, DS Consultancy Services is fully authorized to facilitate government procurements via the GeM (Government e-Marketplace) portal, streamlining the acquisition process for public entities nationwide.

Proven Impact: Our Track Record

Our commitment to sustainable waste management is reflected in our robust track record of successful implementations across diverse sectors:

Municipal Transformation: We are proud to have spearheaded a significant 20-tonne per day (TPD) waste management plant for Ghaziabad Nagar Nigam, demonstrating our capability in executing large-scale municipal projects for effective solid waste management in India.

Industrial Leadership: Leading corporate entities such as Mahle Ltd. and Samkwang India have entrusted their organic waste management needs to our solutions, a testament to our reliability and efficiency in demanding industrial environments.

Institutional Excellence: Prominent educational institutions like Mangalmay Greater Noida benefit from our efficient OWC solutions, fostering greener campuses.

Visionary Projects: Our proactive engagement in strategic initiatives, including the "Zero Waste Cantonment Proposal" for the Belgaum Military Cantonment, highlights our commitment to pioneering and implementing truly sustainable, decentralized waste management models for the future.

Conclusion: Paving the Way for a Sustainable Future

The challenge of organic waste management in India is immense, but with innovations like COMPOSTO VEER OWC Machines, it transforms into an immense opportunity for sustainable development and resource recovery. DSC Engineering, through its cutting-edge manufacturing and comprehensive consulting services, stands as a beacon of reliability and expertise. We are not just selling machines; we are offering a complete ecosystem of solutions, built on the principles of efficiency, environmental responsibility, and compliance.

By integrating COMPOSTO VEER into their operations, organizations and communities can take a decisive step towards a decentralized, zero-waste future, actively contributing to the vision of the Swachh Bharat Mission and cultivating a cleaner, greener, and healthier India for generations to come.

For a detailed consultation, site assessment, or to explore how COMPOSTO VEER can transform your organic waste management, please visit www.compostmachinemanufacturers.com or contact Mr. Vikram Sharma at +91 9958858881.

#Compost machine#OWC machine#Organic waste converter#Organic waste composter#Food waste composting machine#Waste composting machine#Biocomposter#Automatic composter#Composting equipment#Bio-digester machine#On-site composting machine#Small compost machine#Mini OWC machine#Home compost machine (for very small if applicable)#Residential OWC#Commercial compost machine

0 notes

Text

subconscious on substack

cyanotypestrings the landscape of social media and the internet is constantly in flux. trying to stay nimble. you can follow me on substack where i’ll be posting more frequently about art makings and process stuff. there’s some good humans over on that platform. my impulse is to keep sharing and to continue learning using art as a portal into more presence and connection. “art is all over” is a…

View On WordPress

1 note

·

View note

Text

Kelvin's Organic Waste Compost Machines

हर जगह मिलेगी आपको यह मशीन Big Malls, Hospitals, Canteens, Army, Industries , Temples & Restaurants

Compost Machine supplying globally Pan India & exporting to Nepal, Bangladesh, UAE, Chile, Bhutan, Sri Lanka, Philippines,

Mfr & Supplied by Kelvin Water Technologies Pvt. Ltd. Delhi, India +91-9812241001, [email protected]

#organic waste composter#owc machine#organic waste converter#waste management#waste converter machine#natural composter#food waste converter#food waste composter#fully automatic composter

0 notes

Video

youtube

Organic Waste Composter Machine for hotels, canteens, mess, temples, ind...

#organic waste composter#owc waste management#waste management#organic waste composter machine#organic waste converter#owc machine manufacturer#Natural Composter#Owc Machine manufacturers#Composter manufacturers#Fully Automatic Composting Machine#composting for waste disposal#organic waste for composting#food waste converter machine#OWC Machine Price#semi automatic organic waste composter#Fully Automatic Composting Machine in India

1 note

·

View note

Text

10 Benefits Of Semi Automatic Organic Waste Converter

A Semi Automatic Organic Waste Converter offers a range of compelling benefits. Firstly, it diverts organic waste from landfills, lessening their environmental impact. By transforming waste into nutrient-rich compost, it bolsters soil health and fertility. This process also reduces waste volume, easing the strain on disposal sites and curbing transportation costs. Financially, it delivers savings by producing cost-effective compost and diminishing the need for external fertilizers.

Environmentally, it mitigates greenhouse gas emissions, particularly methane, contributing to climate change mitigation. Additionally, community engagement is fostered through educational opportunities and localized compost production, while the reduction of foul odors and pests ensures a healthier living environment. By closing the nutrient loop, it supports sustainable agriculture. Moreover, compliance with Waste Management regulations is facilitated. Overall, a semi organic waste converter aligns economic, environmental, and community interests, making it an indispensable asset in modern waste facilities strategies.

Efficient Waste Management: One of the primary benefits of a semi-automatic organic waste converter is its ability to efficiently manage organic waste. This technology accelerates the decomposition process, converting organic waste into nutrient-rich compost in a relatively short time frame. This reduces the reliance on conventional landfill disposal methods, minimizing the environmental impact of waste.

Reduced Landfilling: Organic waste is a major contributor to landfills. Using a semi automatic OWC helps divert organic waste from landfills, reducing landfill space requirements and associated environmental impacts.

Compost Production: The OWC converts organic waste into nutrient-rich compost, which can be used to improve soil fertility, retain moisture, and enhance plant growth in gardens, farms, and landscapes.

Waste Volume Reduction: Organic waste, particularly food scraps and yard waste, can take up significant space in landfills. The converter significantly reduces the volume of organic waste through the composting process, thereby reducing the need for additional landfill space and curbing transportation costs.

Can handle tonnes of scrap : This robust system efficiently handles tons of scrap material, streamlining waste management and recycling processes for enhanced sustainability and resource recovery.

Comfortable to use : Designed for user comfort, this intuitive system ensures ease of operation, making it a user-friendly choice for efficient waste processing and management.

Financial Savings: Producing compost locally through a semi-automatic converter can lead to substantial financial savings. The compost generated can be used on-site or sold, reducing the need for commercial fertilizers and other soil amendments. This cost-saving aspect is particularly attractive for businesses, farms, and municipalities.

Improved Soil Health: The compost produced from the OWC enriches soil with essential nutrients, improves soil structure, and enhances microbial activity, leading to healthier and more productive soils.

Saves the environment : Semi Automatic Organic Waste Composter plays a vital role in environmental conservation by diverting organic waste from landfills, minimizing methane emissions, and producing valuable compost. This eco-friendly solution reduces pollution, conserves resources, and promotes sustainable waste management, contributing significantly to the overall well-being and health of our planet.

Resource Recovery: The automatic waste converter facilitates the efficient recovery of valuable resources from organic waste. It closes the nutrient loop by recycling organic matter back into the soil, reducing the need for external inputs and promoting a circular economy approach.

Conclusion:

A Semi Automatic Composter is a remarkable innovation that offers numerous benefits for waste management, resource optimization, and environmental well-being. By accelerating the decomposition process, reducing manual labor, and producing nutrient-rich compost, this technology not only saves time and resources but also contributes to the reduction of landfill waste and greenhouse gas emissions. Its role in promoting sustainable practices, conserving resources, and mitigating climate change highlights its importance in creating a greener and more sustainable future for generations to come.

0 notes

Text

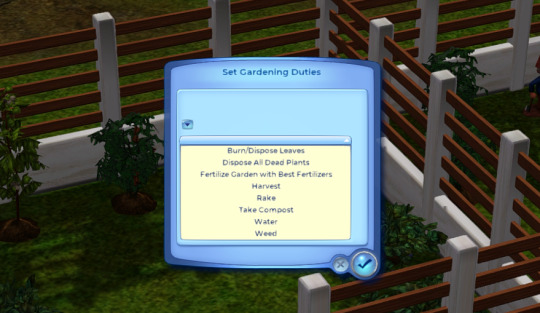

Allotments Mod - Download

I made this mod for @desiree-uk! It's being shared as per her suggestion. A big thank you to her and I hope you all enjoy!

Put your community (or residential) gardens to use! Create and rent allotments, push gardening interactions and make a nice profit while you're at it.

Place the allotment marker in a gated enclosure, set the sim who will be renting the allotment, and they'll take care of all the plants within their enclosure, plus partake in other specified duties.

Available Duties - Toggle on/off - [visibility subject to lot-type]

Water,

Weed,

Harvest,

Get Fertiliser**,

Fertilise Plants,

Dispose of Dead Plants,

Rake Leaves,

Burn or Dispose Leaves.

Gardening Push

As the allotment marker is a meta object, the sim renting the marker may autonomously be pushed to the lot to garden their allotment while inactive.

The marker is also a broadcaster object, so while within the vicinity, the renter will be pushed to complete any outstanding garden activities while in range.

You can also set up dedicated gardening days to push your sim to the lot and prevent your sim from coming to garden during certain seasons.

Payment

Set an owner for the allotment or attach a Bronzo* bank to the marker and make your sim pay to use the space! You can even set up automatic rent payments.

Harvesting

Link a harvest box to the allotment marker and all harvested produce will go straight into the box instead of clogging up your sims inventory. You can also sell produce straight from the box!

Requirements:

*My social clubs mod and **Ani's compost mod. Without these, the mod will at worst, crash, and at best, not work as intended.

Please read the included documentation for a more comprehensible feature breakdown.

Objects:

A collection file is included for easy access to the objects.

Otherwise: the harvest box is in storage/misc. for $190 and the allotment marker is in outdoors/lawn ornaments for $35.

Thanks:

To @aroundthesims for generously allowing me to use her objects for my mods.

To @anitmb for her composting mod which has helped to enhance this mod.

To douglasveiga from MTS for the gardener service mod which I looked at when my interactions weren't working as intended.

Download: Simblr.cc - Allotment Mod - Create and Manage Garden Allotments

Please enjoy!

If you would like to donate to say thanks, please feel free to do so at: my kofi :)

#ts3#phoebejaysims#phoebejaysims allotment mod#sims 3 mod#s3cc functional#sims 3 download#ts3 download#simblr

364 notes

·

View notes

Text

SiliNOT! Testing and Review

Since I run a lot of casting workshops, I've had several people in the costuming/maker community ask me my opinion on SiliNOT!, a relatively new product advertised as a budget- and eco-friendly moldmaking alternative to silicone, urethane, and other single-use materials.

I finally bought a couple of bottles to play with, so I did a test project. My experience and findings are below! (It's not a recipe blog, but if you want to skip the play-by-play and get to the TL;DR, it's under the big "In Summary" header near the bottom.)

First, if you aren't familiar with this material, SiliNOT! is a remeltable, reusable medium for making molds. Though its exact ingredients are not disclosed, it purports to nontoxic, food-safe, and compostable. It melts in a household microwave or double boiler and solidifies at room temperature (or in a refrigerator/freezer for faster results). The website is https://silinot.com/.

(I am not an affiliate, and have no connection to this company apart from having made one retail purchase from them. I just have a lot of casting experience and like trying out new products.)

The Positive Original

I’m still in the middle of a Vincent Valentine build, so I decided to test the SiliNOT! on his custom buttons. My original is a stack of various nonporous materials: an antique (probably Bakelite) coat button, an epoxy resin dome I cast using a mold I already had in my library, and some engraved Worbla’s Pearly Art for the raised detail. The button shanks won’t be added until the final casting, so the original can be mounted flat for the moldmaking process.

Sample Worbla on the left; completed button stack on the right:

The Mold

I built the mold container the same way I do for silicone pours, with the flat back of the button fixed to a styrene plate and a cylinder (actually a small paper cup with the bottom cut off) surrounding it for the walls. The lip of the cup is sealed all the way around with Monster Clay to prevent leaks.

Heating and Pouring

The SiliNOT! didn’t take long at all to heat up; I did maybe four or five 20-second bursts before it was completely fluid. The bottle does get rather warm, so hand protection isn’t a bad idea. If you have heat-resistant gloves, you can use those; I was working in my kitchen (yay for nontoxic stuff!), so I just grabbed an oven mitt with a silicone grip.

The melted SiliNOT! looks a bit like Luke Skywalker’s blue milk. It’s about the consistency of a yogurt smoothie and likes to pour in a thicker stream compared to silicone. While silicone can be stretched into a thin ribbon for delicate pours or chemically thinned with solvent for really tricky jobs, SiliNOT!'s viscosity is dependent on temperature and never seems to get quite as thin as silicone.

I’d automatically made my mold compact to conserve material (not really a concern with a reusable moldmaking material like SiliNOT!, but after using silicone for more than a decade, I’ve trained myself to be as efficient as possible), so the walls of my mold container were only about half or three quarters of an inch from my object. Because the target was so narrow, I found it difficult to accurately fill from the lowest area of the mold with the SiliNOT! The heavier pour also means more air can get trapped in or under the material.

Bubbles are one of the areas in which SiliNOT! is decidedly inferior to silicone. SiliNOT! has higher viscosity, so bubbles don’t want to rise to the surface without vigorous tapping, which can distort the mold edges or affect leveling depending on your mold container. The bubbles that do make their way to the surface are difficult to pop, even when poked with a sharp implement. Heat gun degassing doesn’t have much effect.

Since the bubble surface cools and skins over quickly, I actually had to use a tool and scoop some large bubbles completely out of the mold to allow the surface to level. Critically, the SiliNOT! is opaque, so you can’t spot bubbles clinging to the surface of your original. (This is why my first mold was a reject, and I had to repour. More on that below.)

Hardening

Once the surface had set, I carefully moved the mold into the refrigerator to cool faster. Here’s another area where some types of silicone can have an advantage: I typically use fast-curing Smooth-On products (because I always have random quantities left to use up after our casting workshops), so I rarely have to wait more than half an hour for a silicone mold to cure, regardless of its size or mass.

The SiliNOT! has to chill completely before handling, though, and discharging that amount of heat requires a fair amount of time even in a cool environment. My mold was pretty small, maybe 2 1/2” wide by 1” deep, and it still took around 40 minutes to cool completely. A larger, deeper mold could hold considerably more energy in the center, and might have to be left in the freezer for a couple of hours before use.

Demolding the Original

When the mold was completely chilled, I removed it from the refrigerator and popped it off the plastic plate I’d used for the base of the mold. The texture was very different from what I’d expected: Unlike other meltable materials (Monster Clay, et al.) that have a firm surface when cool, the SiliNOT! remains tacky, which means it promptly collects any debris that crosses its path. In my case, this meant I had to pick dog hair off the surface throughout the casting process (and I don’t want to think about what would happen if glitter had contaminated the work space).

I’d used a paper cup for my mold walls, which usually works fine with fast-curing silicone. But the SiliNOT! must have a high oil content, because the cup absorbed some of it:

Lesson learned; use only nonporous containers with this stuff.

The SiliNOT!! really wanted to cling to the edges of my original, so I had to go slow at first to avoid tearing the thin flanges of the mold off. However, it did demold nicely from the smooth surfaces, and preserved texture very well. You can see the Worbla pebbling and the engraving channels clearly in the mold (as well as some dust and dog hair, because I made the mistake of setting it down briefly):

Unfortunately, as you can see, a large bubble had stuck to my original and created a pit in the mold, so I decided to do a second mold pour. I figured I’d tear up the failed mold and put the pieces back in the bottle to remelt… and discovered I couldn’t. The mold would stretch and twist, but not tear. It also seemed to return to its original shape relatively faithfully. Here’s a video of me manhandling the mold:

As you can see, the SiliNOT! has much better stretch and recovery than many silicone products (there are silicones that stretch well -- some of the Dragon Skin products come to mind -- but they’re not typically marketed for moldmaking). This means it’s likely well suited to casting objects with moderate undercuts or oddly-shaped bits that need the mold to stretch during demolding.

You can cut the SiliNOT! easily with scissors, which is the recommended method for getting it back in the bottle when you’re ready to remelt.

Take Two

Using what I’d learned from the first pour, I did the second one inside a hard plastic ramekin. This gave me a bit more room to pour into the floor of the mold, reducing the bubble risk, and also eliminated the porous paper cup that had absorbed oil. I still had the issue with bubbles that didn’t want to pop, but there were fewer of them this time.

The ramekin made for a much cleaner mold, buuuuut there was ANOTHER BUBBLE right in the middle of the design. >.<

Take Three

Lather, rinse, repeat. Or in this case, melt, pour, chill.

This time I heated the SiliNOT! as much as I dared and did the absolute slowest, narrowest pour I could manage, giving the air extra time to escape as the mold was filled from the bottom. The risk with stringing out the pour like this is that in a thinner stream, the heat escapes faster, leading to uneven viscosity as the liquid fills the mold. I don’t think that’s a major problem for this particular piece, but it’s something to pay attention to as regards leveling and degassing, especially for larger molds that will take longer to fill.

The result of pour three:

/siiiiigh/ Well, at least the bubbles are smaller, this time. They may not show up enough to matter in the final cast. I’ll give it a try.

Casting

I had leftover workshop resin that was getting on toward the end of its shelf life, so I used Smooth-On Smooth-Cast 300 for my initial resin trial. It’s an opaque white resin with about a 10-minute cure time (the fast turnaround is why we use it for workshops).

Before pouring, I had to do a little mold cleanup where the SiliNOT! had managed to sneak under the edge of the Worbla (I think I’d loosened the corner of the star from prying it out of so many molds), but since the SiliNOT! stretches so well, it was pretty easy to invert it to get little scissors down into the bottom of the depression.

For the first cast, I didn’t use anything but the resin in order to get a baseline. Ideally I’d like to cold cast or dye the resin so I don’t have to worry about paint chipping, but since I’m doing a trial here (and need multiple buttons anyway) I figured some plain white extras wouldn’t hurt.

So, my first cast…

…smacked into a big problem, which I probably should have seen coming: The resin I’m using is a fast cure formula, which means it discharges a fair amount of heat as it's going through that rapid chemical reaction -- enough heat to melt the SiliNOT!, as it turned out. When I tried to demold it (after giving it a few extra minutes beyond label time to be sure it was done), the surface of the mold had melted to the resin and even embedded itself in a few places. It’s difficult to see the resin detail in the photos (my camera went into white balance panic mode with all the shades of white and blue), but you can see how pitted the formerly-smooth mold surface is.

In fairness to the SiliNOT!, the bottle does say that you should put the mold in the freezer for half an hour before casting high-temperature materials. But I assumed high-temperature material was something like candle wax or melted chocolate, rather than ordinary resin. (And the mold had just come out of the refrigerator.)

So, on to pour FOUR of the SiliNOT! mold…

Take Four

NGL, this is getting a little old. >.<

Fourth mold definitely needed some cleanup around the edges, and there are still a couple of tiny bubbles I can’t seem to get rid of, but it’s good enough for a test. (I’m starting to despair of using these for actual production, given how many times I’ve had to redo the molds because of bubbles...)

Deep in the recesses of my basement, I found some transparent epoxy resin with a 24-hour cure time -- much slower and lower-temperature than the Smooth-Cast. Since it cures clear, I went ahead and mixed in some metallic powder pigment on the off chance that I get a usable button out of this one. I had excess resin after mixing, so I poured that into my first mold, which has a bubble in the design but is otherwise fine. Two test pieces are better than one, right?

Results

Here are the results of the slow-curing resin out of mold #4:

Finally, a (mostly) clean cast!

As you can see, the detail reproduction is excellent -- certainly on par with the pulls from the silicone mold I ended up making while waiting on this set to cure (purely for time reasons; I couldn’t afford five days to cast the buttons using slow-curing resin, and with a silicone mold and fast-curing resin I could get them all done within a couple of hours).

However, you can also see a few spots where bits of the SiliNOT! embedded themselves in the final cast. Part of that may be due to design flaw in the original; I didn’t want to glue anything permanently to the antique button, and that resulted in a tiny gap between the button and the resin hemisphere. Silicone has enough strength to resist tearing out in that kind of area, but apparently the SiliNOT! doesn’t. The bits of mold around the outer edge seem to have stuck just to be difficult, as there was no structural reason for those to have become embedded in the resin. This means the mold could be damaged by successive casts, reducing its usable life and accuracy.

Still, the mold definitely produced decent results for a first cast, and a different shape might not have had as much of a problem with tearing off mold parts. The slow-curing resin is a bit of a limitation, but not a unique one (I use this same epoxy resin for any glass-clear casts I do, and only use the Smooth-Cast 300 for opaque items or things I need very quickly). I don’t personally use UV resin, but I’d be curious to learn how it performs with the SiliNOT!

IN SUMMARY:

Here’s the TL;DR on SiliNOT!

Pros

Cost effectiveness. This is the most obvious advantage of SiliNOT! over silicone; it’s (theoretically) infinitely reusable, and even with natural attrition/inevitable contamination from use, you can likely get over a hundred pours out of a bottle. That's a lot cheaper per use than silicone.

Non-toxicity. SiliNOT! is touted as food contact-safe, so you don’t have to panic if you get it on your skin or kitchen counters. While platinum-cure silicone is also relatively harmless (some varieties are labeled for food or life casting), other common moldmaking materials such as tin-cure silicone or urethane are not. (NOTE: Since the company is very hush-hush about what actually makes up the SiliNOT! secret formula, I do not know if it might release any vapors or fumes that would be irritating or harmful to pet birds. In general, I advise not doing any kind of casting around birds.)

Eco-friendliness. This is the biggest draw for me personally: Given the number of casting workshops I run and all the things I sell commercially, I have constant guilt about the amount of waste I generate for creative projects. In most areas of life I’m an aggressive reduce/reuse/recycler and try to use organic materials instead of synthetics whenever possible, so a mold that’s reusable and compostable is very appealing.

Ease of use. It’s honestly pretty hard to mess this up -- just microwave according to the directions and pour. No measuring, no A/B mixture, no concerns about chemical contamination from latex or sulfur, etc.

Shelf life. Unlike silicones, which have a shelf life of anywhere from six months to three years depending on storage conditions, the SiliNOT! purports to be shelf-stable. It's compostable, so don’t bury it in your yard, but otherwise it appears that it could be kept on hand for years.

Cons

Bubbles. Honestly the most irritating thing about this stuff for me. I’m used to being able to see bubbles forming as I pour, tap them to the surface, and remove them. The fact that I poured four molds of the same object and never once got one without bubbles is super irritating.

Stickiness. I’m not a big fan of the tacky surface texture, and while I haven’t done any cold casting yet, I can imagine that it would be very difficult to clean out any pigment or mica powder that got where you didn’t want it. I probably wouldn’t use this for any kind of cold casting that required isolated colored areas or changing colors between casts.

Set time. The SiliNOT! may take longer to cool than a fast silicone would to cure when dealing with larger molds, so it’s not ideal for projects with a really tight turnaround. (But cosplayers would never be casting something the night before a con, right? We always plan ahead and never, ever procrastinate!)

Library life. The SiliNOT! may or may not structurally degrade over time the way urethane, latex, and tin cure silicones do, but I noticed even in my very limited casts that it was prone to having tiny bits of the mold (particularly at edges) stick and pull off. While I keep most of my platinum silicone molds for years and reuse them, I don’t feel that the SiliNOT! molds would hold up to repeated casting, and they’re far more sensitive to ambient temperature, so they’re probably best used for short term only. (I also wonder about the possibility of oil leaching out in long-term storage.)

Comparative Ranking

Ranking it against other mold-making materials, I’d place SiliNOT! below platinum-cure silicone in terms of performance, but maybe somewhere in the neighborhood of urethane and tin-cure silicone. It's definitely superior to latex. (Though to be honest, I'd rank Play-Doh above latex. I hate working with that stuff.)

Factoring in cost and environmental impact, it beats out urethane and tin-cure silicone. I'm still not sure if I'd rank it above platinum-cure silicone, though... Silicone costs much more and isn't eco-friendly, but the performance and lifespan is significantly better, so it still makes more sense for some projects.

Alginate is another type of material entirely, but in some ways SiliNOT! is comparable to it -- both are more cost-effective than silicone, both are biodegradable, both are skin safe, and both have long shelf lives. But SiliNOT! is easier to use for beginners than alginate, which has to be mixed to the right consistency and has an extremely short lifespan once poured.

Overall, I would recommend SiliNOT! for:

People who want accurate, non-shrinking molds but don’t have the budget for platinum-cure silicone

People who are committed to eliminating waste from single-use materials, and are willing to trade off a little performance for a more eco-friendly material

Projects with smooth surfaces and no indentations/sharp edges/undercuts where bubbles might stick (e.g. cabochons; simple geometric forms)

Projects where you need only one or two casts of something, rather than many casts from the same mold

Casting oddly-shaped pieces around which the mold needs to stretch in order to demold

Use with slow-curing resins that do not generate much heat

I would NOT recommend SiliNOT! for:

Extremely complex or detailed pieces, or pieces with a lot of surface texture that bubbles might stick to

Two-part molds

Projects requiring many identical casts out of the same mold

Molds that you intend to add to your library for future or repeat casting

Use with fast-curing resins, melted wax, melted Monster Clay, or any other material that emits heat

Cold casting with precise color application

My Overall Opinion

It's... okay? I will almost certainly keep SiliNOT! in my toolkit for certain specific applications. It's MUCH cheaper over the long term, I love the idea of recycling mold material, and there are some projects for which it will likely perform very well (those listed in the above bullet points). I will also admit that three days of working with it does not constitute a comprehensive familiarity with the product, and it might be the sort of thing that you get better at working with after more practice. (Just learning how to eliminate bubbles would go a long way toward making me adopt this for more projects!)

However, I don't quite buy the "better than silicone" tagline. It's definitely more difficult to get a perfect result, and there are some projects for which platinum-cure silicone is always going to be more reliable (e.g. high-temperature casting, mass production, large-scale life casting).

For those looking for a recommendation of whether or not to buy, I'd say look at your project budget and the applications for which you're going to be making molds, and let those factors guide which mold material you go with. People doing some kinds of projects are likely going to find this a godsend, while those doing different projects would probably hate working with it.

39 notes

·

View notes

Note

where do you stand with living in the moment, feeling grateful, and how do you personally approach it?

It's interesting, I actually struggle a lot with staying in the moment even though I also tend to notice small things so easily--I could be having the worst day of my life but I will always notice the veins on a leaf, for example, or how light falls into the train carriage, or a patchy section of grass erupting between the footpath and the street.

More than anything I think that, even if I struggle with staying centered, the thing for me is making sure I find these individual pockets to slip into and you really can find them everywhere: watching steam rise from a cup of warm milk, a slant of afternoon sunlight in mid-winter, tree roots buckling the tarmac along a footpath, overgrown patches of ivy, a flower stall in the middle of the high street etc. They don't even need to be traditionally "romantic" or pleasant or picturesque things, either: there's something in a moment of sympathy for a pigeon hobbling across the tram tracks with an injured foot, or the patterns made by paint peeling off a dilapidated door, or even the geometric cross-sections of electricity wires against the sky (whether blue, or pink, or grey).

It's not necessarily that I actively root myself deeply in these moments (as I said, actively quieting my mind is hard for me to do), but more that, because I always notice them, and because I always take note of myself noticing them, because I feel something for them, even just fleetingly, they create a kind of interruption to whatever was going on before. The interruption might last a second and no more, but I've noted it for that second. It doesn't automatically make a bad day go away, but it's a nice reminder that a bad day doesn't have to be all consuming. There's always going to be something new to see, even if you have seen it before because each time you see it is it's own unique event. I'll be going through it and see a pigeon huddled by a window as the bus passes and when it's out of sight I'll still be going through it, but I'll be going through it having just seen a pigeon and there is a kind of momentary lull in that for me. The easiest way I can describe it is like a dark and empty room where all you've done is lift a single blind. The room is still empty, but also it's not--does that make sense?

In any case when I am trying to stay present my favourite thing is to try and find some kind of immersive activity--this could be a small craft like origami or braiding bracelets, but my favourite is to just go on walks along the beach or through a park and pay as much attention to things as I can: the smell of vegetation when I pass the wild compost heap, or if the grass has been cut, or the gulls picking their way along the sand, or the faraway voices of people and dogs. Sometimes, if I really, really need to calm my mind I'll narrate everything I do: now I am walking up this hill, now I am crossing the grass, now I can feel the mud because it's rained, now the hill is steeper and my legs are pushing harder and I feel it in my thighs etc.

Gratitude, I think, is maybe partly tied in with the whole noticing every little thing--it's not a conscious decision, but I think it does open space for it in a way even if I'm not thinking "I'm so grateful I saw that toddler dressed as Sonic the Hedgehog". It's like the open blind in the dark and empty room again: there's space for something, even if the room itself doesn't change.

But like the rest, there are a lot of things I struggle with where I do need to train myself to be actively conscious of gratitude: I have a series of cue cards tacked over my bed and one of them is, literally, "choose gratitude, bitch ❤️" (heart included). The rest involves me not letting my inner voice doom-monger my life as much which is difficult, but I try. By far the most important to me, though, is trying not to counter the compliments people close to me give by going "actually, I'm really not" or something along those lines. It's not about whether or not I can see these things in myself (some days I can, a lot of days I can't) but about acknowleding that I can't dictate what others see or feel: rejecting their kind words is, in essence, the same as rejecting them, and I don't want to do that.

None of this is to say they have all been failsafes for me or that I don't struggle with things because I do--but they're the scaffolds I have and use the most and that make the world what it is for me. Granted, I think I've always been like this, even as a childhood (I was the very opposite of an apathetic teenager)--so maybe I'm always tuned up this way already and that makes it a little easier; but, again, it doesn't make you immune to the world or to your own troubles so while it isn't necessarily a conscious thing, the older I get the more aware of it I become, and the more intentional I try to make my approach to things, if that makes sense 🤍

79 notes

·

View notes

Text

Why Investing in a Paper Bag Machine is a Smart Move in 2025

As the world moves toward sustainability and eco-conscious living, businesses across the globe are rapidly shifting from plastic to paper packaging. One of the most significant outcomes of this transition is the growing demand for paper bags — and with that, a rising interest in high-performance paper bag making machines.

At Prakash Machineries , we specialize in manufacturing fully automatic paper bag machines that are helping businesses make the smart switch. Here’s why investing in a paper bag machine is not only good for the planet but also great for your business.

🌿 1. Environmentally Friendly Solution

Plastic bags have become one of the biggest environmental threats in recent decades. They take hundreds of years to decompose and often pollute landfills, rivers, and oceans. In contrast, paper bags are 100% biodegradable, recyclable, and compostable. Paper bag machines enable businesses to produce eco-friendly packaging on a large scale — reducing carbon footprint and aligning with global sustainability goals.

⚙️ 2. High-Speed, Automated Production

Modern paper bag machines, like those offered by Prakash, are equipped with fully automatic systems that can produce a wide range of paper bags with minimal manual labor. Whether it’s grocery bags, shopping bags, or food delivery pouches, these machines can handle various sizes and specifications with precision and efficiency.

With outputs ranging from 100 to 400 bags per minute, these machines significantly boost productivity and help meet large-scale commercial demands.

💼 3. Business Opportunity & Market Demand

The ban on single-use plastics in many states and countries has opened up a huge market for paper bag manufacturers. From retail stores and supermarkets to restaurants and e-commerce companies — the demand is only increasing.

Starting a paper bag manufacturing unit is now seen as a profitable and future-ready business, especially with support from government initiatives promoting sustainable alternatives.

🧠 4. Easy to Operate and Maintain

Our paper bag machines are designed to be user-friendly, even for first-time entrepreneurs. With touchscreen controls, automatic counting systems, and durable build quality, they require minimal maintenance and training. Plus, our dedicated service team ensures smooth installation and after-sales support.

��️ 5. Customization & Branding Benefits

Paper bags are not just about functionality; they are also a powerful branding tool. Our machines allow for in-line printing and handle attachments, giving businesses the freedom to create custom, brand-enhancing packaging.

🔧 Why Choose Prakash Machineries ?

With decades of engineering experience, Prakash Machineries is a trusted name in the packaging machinery industry. Our paper bag making machines are built for performance, reliability, and long-term ROI.

We help entrepreneurs, SMEs, and large enterprises shift toward sustainable packaging with confidence and efficiency.

📞 Get in Touch

If you're ready to start or scale your paper bag manufacturing business, we’re here to help. Visit www.prakashoffset.com to explore our range of machines or request a free quote.

Join the green revolution — with Prakash.

2 notes

·

View notes

Text

Angel Message:

My dear friends, we love you so very much,

As you look at life and sort things into categories of good and bad, consider that even what you consider bad can be turned to good. The compost feeds your garden. The fertilizer helps make the roses sweet.🌹 And while the dark and difficult times in your life are not necessary for growth, they can be used as turning points or launching pads that inspire you to create and calibrate even more deliberately.

Often you don’t even know there are challenging vibrations active within you until life presents something to mirror them back to you. You may be giving more than you authentically want to give and not even realize it. Perhaps you didn’t notice that you were tired of one-sided relationships, tired of being the one everyone runs to, or tired of being interrupted when you sit down to do something you enjoy. Your kind and loving nature is beautiful, but you may have been pushing yourself to give more than you automatically felt inspired to give.

When someone leaves your life, asks for more than is reasonable, or becomes ungrateful, suddenly you realize that the overgiving doesn’t feel so good after all. You send tidal waves of desire for more balanced relationships into the universe. You recalibrate, give only when truly a joy, and begin to attract people who love you for who you are, not what you do.

Likewise, suppose you didn’t realize a lot of little things were upsetting you (galling you or pissing you off) and suddenly you experience gallbladder or kidney issues. Now you know that you have been pinching yourself off from love and you can authentically process these feelings, stop stuffing them, and allow your body to heal as well. The seeming suddenness of the problem is not so sudden after all. Sickness takes a lot of little pinches to brew, wheras healing can happen more quickly as you truly open to love. Sit. Breathe, Receive. The subtle slide into pinching off the love is why taking a few minutes in silence regularly can be useful. You will voluntarily feel what you have stuffed. You will notice the emotions masked by activity. You will hear your heart and know its needs. What is revealed can be healed and before you inch toward an injury or drift into a undesirable situation, you can see, feel, and recalibrate your energy.

If you find yourself in a difficult situation, there’s no need to beat yourself up. You can instead use the moment as a launch pad for the future. When difficulties arise, the desire for solutions becomes acute. When you get sick, you feel a strong desire to be well. When you don’t have enough your desire for abundance becomes a loud signal emanating form within.

Many of you have learned to settle for feeling less until a situation becomes intolerable. You do not have to settle. You do not have to tell yourself it is God’s will that you suffer. It is not. God is love. You simply have to acknowledge your desire and open to the love that is offered in the here and now. Sit. Breathe. Receive.

You can always accept the present moment and desire more. You can acknowledge the challenges today while looking forward to the solutions tomorrow. You can feel the pain today while anticipating the relief.

Dear ones, you were not put on earth to suffer. You were not meant to endure the behaviors of others while being at their mercy. You eagerly dover into this world of contrast with a desire to view the buffet of life, select what you wanted, and create more.

You are not at the mercy of the world, your bodies or your bank accounts. You are loved beyond what you can imagine. Your will shift quickly and beautifullly as you begin to allow this love into your lives in even the smallest of ways.

God Bless You. We love you so very much.

— The Angels

3 notes

·

View notes

Text

behold, my massive fucking moonshine factory (in minecraft for legal reasons)

so basically, i've been goofing around with the create mod the last few weeks and i installed quite a few addons to add way more content. one of these addons, "destroy", adds chemistry and stuff. but that's not important, all that matters is that it adds ILLEGAL LIQOUR BREWING

knowing me, i'd of course spend almost a week or two building a 100% fully automatic moonshine brewery and distillery.

the only thing that isn't completely automated is the heat from the blaze burners of the steam engine that powers this behemoth, which have been fed with creative blaze cakes so i don't have to build a blaze fuel farm too (i'll do it at some point)

here's some screenshots

and here's a top-down view, with and without legend

Steam Engine (absolute beast, provides power to the entire factory)

Emergency Waterwheels (in case the steam engine overstresses, i can disconnect it from the main mechanism and start it up using these, no need to restart it up manually)

Ingredient Sorter, Left Wing

Ingredient Sorter, Right Wing

Aging Barrels, Left Wing

Aging Barrels, Right Wing

Water Pumps (collect water for the moonshine)

Distillation Bubble Cap Mechanisms (three of them for maximum liquor potence)

Final Fluid Tank (stores fully-distilled moonshine before it is bottled)

Automatic Cobblestone Generator

Cobblestone Crushers (two sets of crushing wheels per belt, one crushing cycle turns cobble into gravel, the second turns gravel into sand)

Bulk Blaster (create mod's equivalent of a super-smelter. smelts all of the sand into glass)

Mechanical Crafters (craft glass into glass bottles)

Bottling Station (spouts sploosh moonshine into the freshly crafted bottles)

Final Storage Vault (where the bottled moonshine finally ends up. has a storage space so massive it'll basically never stop growing)

Automatic Wheat Farm (wheat is one of two ingredients for moonshine, uses a gantry carriage contraption to sweep the mature crops and then deposits them into the vault sorting system)

Seed Composters (uses the leftover seeds from the wheat farm to make bone meal for the mushroom farm)

Semi-Automatic Mushroom Farm (relies on the wheat farm for bone meal, but besides that, is fully automatic. repeatedly plants a mushroom, bone meals it into a giant shroom, then cuts it down with a mechanical saw to get more shrooms in return)

Mushroom Crusher (grinds mushrooms into bricks of yeast, the other ingredient in moonshine, then flings it into the yeast vault)

Wheat Vault (stores wheat until it's time for another brewing cycle)

Yeast Vault (stores yeast until it's time for another brewing cycle)

Wheat Farm Sorting System (wheat is deposited into the wheat vault, seeds are flung into the mushroom farm's composters, and any other items that might've ended up there by mistake are incinerated)

Distilled Water Disposal Pipe (transports any leftover water from the moonshine distillation into the steam engine, thus getting rid of it)

Catwalk Elevator (thought it'd be cool to have a lift bring you up to some catwalks above the whole factory, so i made it)

#shitpost#shitposting#minecraft#minecraft build#minecraft builds#minecraft building#minecraft factory#minecraft farm#minecraft farms#minecraft farming#minecraft create#minecraft create mod#create#create mod

17 notes

·

View notes

Text

From Trash to Treasure: Unlocking the Power of On-Site Composting with COMPOSTO VEER

The Growing Waste Challenge

India generates 65 million tonnes of municipal solid waste annually, of which nearly 50–55% is organic waste. When left unmanaged, this waste ends up in landfills, producing harmful greenhouse gases, foul odors, and leachate that contaminates soil and water. For bulk waste generators such as housing societies, hotels, hospitals, and corporate campuses, this is not only an environmental challenge but also a compliance issue under Solid Waste Management (SWM) Rules 2016.

So, what’s the solution? On-site organic waste management—and that’s where COMPOSTO VEER OWC Machines step in.

What is an OWC Machine?

An Organic Waste Converter (OWC) is a smart, automated system that transforms segregated organic waste—like kitchen scraps, food waste, and garden clippings—into high-quality compost in a hygienic, odor-free, and compliant manner. It’s an essential component for zero waste solutions in residential and commercial facilities.

Introducing COMPOSTO VEER: The Future of Waste Management

COMPOSTO VEER is the flagship range of Organic Waste Converter Machines by DSC Engineering, designed to provide efficient, sustainable, and fully compliant solutions for bulk waste generators. Whether you manage a 150 kg/day requirement for a medium housing society or 2,000 kg/day for a large industrial canteen, COMPOSTO VEER offers customized capacities to fit every need.

Beyond the Basics: COMPOSTO VEER’s Advanced Features

What makes COMPOSTO VEER a preferred choice for professionals? It’s the engineering excellence and smart automation packed into every machine:

✔ Robust Construction: Made with SS 304 inner & outer chambers for corrosion resistance, a ‘Thermo-Block’ insulation layer for energy efficiency, and a durable MS structural frame for longevity.

✔ Intelligent Shredding & Mixing: Equipped with Dual-Helical Shafts, variable pitch paddles, and Tungsten Carbide-tipped ‘Kinetic-Cut’ shredder blades for superior shredding and mixing.

✔ Smart Power & Heating: IP66-rated geared motors, Smart-Torque Dynamic Drive, and PID-controlled heating arrays with Inconel 800 elements for precise temperature regulation.

✔ Odor-Free Operation: Advanced ‘Odor-Lock’ Air Management System, centrifugal blowers, and Activated Carbon Filters ensure a clean, odorless environment.

✔ Automation & Safety: Industrial-grade PLC with 7" HMI touchscreen, Eco-Cycle & Boost-Cycle modes, real-time process visualization, and safety features like door interlocks, E-stop, overload protection, and jam detection.

✔ Compliance Ready: Every output meets SWM Rules 2016 and FCO standards, ensuring legal compliance.

The Tangible Benefits: Why Choose COMPOSTO VEER?

✔ Environmental Impact: Divert organic waste from landfills, reduce methane emissions, and produce nutrient-rich compost for landscaping or sale.

✔ Operational Efficiency: Compact design, low noise (<65 dB), odor-free, and minimal manual intervention.

✔ Financial Advantage: Reduce waste hauling costs, comply with SWM norms (avoid penalties), and generate revenue through compost sales.

SWM Rule Compliance Made Easy

Under SWM Rules 2016, all bulk waste generators must process organic waste at the source. COMPOSTO VEER simplifies compliance with automated processing, documentation-ready reports, and fully regulated output quality.

Finding Your Perfect Fit

We offer models ranging from 150 kg/day for mid-sized societies or hotels to 2,000 kg/day for large facilities and municipal projects. For small-scale needs, we even provide 10 kg/day and 15 kg/day units—ideal for small canteens or boutique hotels.

Partnering with Excellence: The DSC Engineering Advantage

When you choose COMPOSTO VEER, you don’t just buy a machine—you gain a technology partner. DSC Engineering offers: ✔ 6-month warranty & extended AMCs ✔ Expert installation & commissioning ✔ On-site training & 24/7 support ✔ Repair & maintenance for all OWC brands

Conclusion: Building a Cleaner, Greener Future Together

Decentralized organic waste management is no longer an option—it’s a necessity for sustainability and compliance. COMPOSTO VEER OWC Machines make this journey simple, reliable, and future-ready.

Ready to Take the First Step?

📞 Call us now at 9958858881 🌐 Visit:www.compostmachinemanufacturers.com ✅ Request a demo today and transform your waste into wealth with COMPOSTO VEER!

#Compost machine#OWC machine#Organic waste converter#Organic waste composter#Food waste composting machine#Waste composting machine#Biocomposter#Automatic composter#Composting equipment#Bio-digester machine#On-site composting machine#Small compost machine#Mini OWC machine#Home compost machine (for very small if applicable)#Residential OWC#Commercial compost machine#Industrial OWC machine#Large capacity OWC#100 kg OWC machine#200 kg OWC machine#500 kg compost machine#1 ton OWC machine#2 ton compost plant#Hotel waste composting machine#Housing society compost machine#Apartment complex OWC#Corporate office waste composter#Canteen waste composting solution#Restaurant food waste machine#Hospital waste composting (excluding biomedical)

0 notes

Text

Men don't get tied up and fed to the automatic composting machine anymore. Because of woke

4 notes

·

View notes

Text

Food Waste Composter: The Future of Waste Management

As environmental concerns continue to rise globally, the issue of food waste has become a critical focus. Roughly one-third of the food produced for human consumption is wasted annually, contributing to significant environmental degradation, including greenhouse gas emissions, land degradation, and water wastage. To address this growing problem, food waste composters have emerged as a sustainable solution that not only reduces waste but also converts it into valuable resources like nutrient-rich compost. As cities, businesses, and households seek greener waste management practices, food waste composters are positioning themselves as the future of sustainable waste management.

What is a Food Waste Composter?

A food waste composter is a machine or system designed to decompose organic waste—primarily food scraps—through natural processes. Composters use microorganisms, heat, moisture, and aeration to break down food waste and convert it into compost, a nutrient-dense soil additive. This process helps divert food waste from landfills, reducing methane emissions while creating an eco-friendly byproduct that enhances soil fertility.

Composting can take place in various settings, from household kitchens to large-scale commercial and municipal operations, with food waste composters ranging in size and complexity depending on the intended use.

Why Food Waste Composters Are Crucial for the Future of Waste Management

The future of waste management must address the environmental impact of food waste, which contributes significantly to climate change. Traditional methods of waste disposal—particularly sending food waste to landfills—are unsustainable and environmentally damaging. Food waste composters offer an innovative solution with several key benefits:

1. Reduction of Landfill Waste

Food waste accounts for a large portion of municipal solid waste sent to landfills. When food waste decomposes anaerobically in landfills, it releases methane, a potent greenhouse gas that contributes to global warming. Composting food waste reduces the volume of organic matter that ends up in landfills, directly reducing methane emissions.

2. Creation of Nutrient-Rich Compost

One of the primary benefits of food waste composting is the production of compost. It improves soil health by increasing moisture retention, enhancing soil structure, and supporting the growth of beneficial microorganisms. The resulting compost can be used in gardening, agriculture, landscaping, and land rehabilitation, reducing the need for chemical fertilizers and promoting sustainable farming practices.

3. Support for Circular Economy

Food waste composters promote the concept of a circular economy, where waste is not simply discarded but repurposed into something valuable. Instead of contributing to a linear economy where resources are extracted, used, and then wasted, food waste is transformed into compost, which reenters the ecosystem, supporting new plant growth. This closed-loop system reduces resource depletion and helps build a more sustainable future.

4. Cost Savings for Municipalities and Businesses

Managing food waste can be expensive, especially when factoring in landfill fees, transportation costs, and environmental damage. For municipalities, implementing food waste composting programs can lower waste management costs by reducing the need for landfill space and transportation. Similarly, businesses like restaurants, hotels, and food processing industries can reduce their waste disposal costs by composting on-site or participating in composting programs.

5. Energy-Efficient and Time-Saving Solutions

Advanced food waste composters, particularly electric models, offer rapid composting solutions. These machines can process food waste in as little as 24 hours, converting it into usable compost much faster than traditional composting methods, which can take weeks or months. By using heat, oxygen, and mechanical agitation, these composters accelerate the decomposition process, making them efficient for high-waste environments like commercial kitchens or urban areas.

6. Odor and Pest Control

Modern food waste composters are designed with features like carbon filters and airtight seals that minimize odors and keep pests at bay. These features are particularly beneficial for households and businesses where unpleasant smells and the attraction of insects or rodents can be a concern. The ability to compost food waste without these nuisances makes it easier for more people to adopt the practice.

Types of Food Waste Composters

There are various types of food waste composters available, each suited to different needs, from home use to large-scale industrial operations:

1. Household Composters

Electric Composters: Compact, efficient, and designed for indoor use, these composters use heat and agitation to break down food waste rapidly. Many models can process waste in under a day, making them convenient for homes and small businesses.

Traditional Compost Bins: Typically used outdoors, these bins rely on natural decomposition processes and require periodic turning of the compost material. While slower than electric models, they are a cost-effective and eco-friendly option for home gardeners.

2. Commercial and Industrial Composters

In-Vessel Composting Systems: These systems are enclosed, automated composters designed for larger volumes of food waste. They can handle food waste from restaurants, schools, and other institutions, producing high-quality compost in a short time frame.

Windrow Composting: This method involves piling organic waste into long rows (windrows) that are aerated and turned periodically. It is commonly used in large-scale operations, such as municipal composting facilities or agricultural settings.

3. Vermicomposting Systems

Worm Composters: This system uses worms to break down organic waste. Worms digest food waste and excrete nutrient-rich castings, which can be used as a natural fertilizer. Vermicomposting is a popular choice for indoor composting, particularly in small spaces, because it produces minimal odor and is highly efficient for processing smaller quantities of food waste.

The Role of Technology in the Future of Composting

As technology continues to advance, the efficiency and accessibility of food waste composters are improving. Many modern composters come equipped with smart technology that monitors temperature, moisture, and oxygen levels to optimize the composting process automatically. These systems require minimal user input and can even be connected to apps or other digital platforms for easy monitoring.

Additionally, decentralized composting models are gaining popularity. Instead of relying solely on large, centralized facilities, decentralized systems allow for composting at the community level, in homes, businesses, or local composting centers. This reduces the need for transporting waste and creates a more sustainable, localized approach to waste management.

Challenges and Solutions

While food waste composters are gaining traction, challenges remain in ensuring widespread adoption. One issue is the initial cost of some composting machines, particularly for households or small businesses. However, as technology advances and demand grows, prices are expected to decrease, making composters more accessible.

Another challenge is public awareness and education. Many people are unaware of the environmental impact of food waste or the benefits of composting. Governments, NGOs, and environmental organizations must continue to promote composting through educational campaigns, incentives, and policies that encourage individuals and businesses to adopt composting practices.

Conclusion: The Future is Green with Food Waste Composters

As we move toward a more sustainable future, food waste converter represents a pivotal shift in waste management. These systems offer an eco-friendly solution to the growing food waste problem, transforming organic waste into valuable compost while reducing the environmental burden of landfills.

With the right technological advancements, public education, and policy support, food waste composters are poised to become an integral part of the global waste management infrastructure. They not only divert waste from landfills but also contribute to healthier soils, a circular economy, and a more sustainable planet.

As the future of waste management evolves, composting food waste will undoubtedly play a significant role in reducing our environmental footprint and building a greener, more sustainable world.

#organic waste composter#owc machine#food waste composter#waste management#fully automatic composter#food waste converter

0 notes

Text

highlights from my adventures in Area X, totally blind the whole time until i finished Acceptance. Spoilers for all of it.

me being neurotic about spoilers (this is a common theme)

obsessed with how this is my first instance of theorizing. the last two sentences are eerily accurate and i can't believe i said "alien planet" that's hilarious

this is good analysis too bad i was missing a key piece of information that makes my inadequate conclusion actually make sense

middle of Annihilation, first attempt at analyzing Where lies...this is actually pretty close to what I think about the tower text Now except missing the parts that would have never occurred to me without reading further (that the Crawler is Saul and that Area X is not on earth).

aw this is so cute. They don't even know about the first expedition footage with the sky leviathan POV (i have a pet theory that SR used that clip specifically to brainwash the husband. this is supported by his anecdote of falsely attributing memory to lived experience when its origin was television, as a young child)

i was so right

this is so funny. you are like a little baby

this is still Based

The Antics

this theory is so fucking funny considering how much grace hates lowry

this was like the least brutal of my Control roasts. they ramped up considerably in Acceptance

then i stopped reading the trilogy for eight months and had to start over Authority. but i still thought about it. this is me thinking about it.

This was me like a third of the way into Authority. What the fuck. It's not that creepy when you consider the information dispensed by that point but it's still kind of creepy how accurate my actual predictions were when my ideas were still wrong

then i went to sleep and

so true, me. So righteously true. magic IS real and it's coming to fuck up your town

Future me here: Yea it was a red herring

More Control roasts:

CALL ME IMPORTANT THAT'S MY NAME

Fragment of my "Area X clones are agents of germination" theory. I felt so smart at the end of Authority. So in Control if you will. And then

it was fucking life changing. the homosexuals that they were

first drama in the gc...

This is when the amount of Divine Knowledge brought to me by Accemptance started to get to my consciousness. Once i start saying phrases like "the virgin control and the chad ghost bird" and "the Caroline to his GlaDOS" and "everyone is a clone of a clone of a clone of a clone" that's when you know i've lost the thread

more disjointed quotes because i ran out of images:

"the BASED control vs. the CRINGE everyone else is no longer the dynamic because he's not narrating. i feel like i just broke up with him" "so does ghost bird probably"