#Concrete Tech

Explore tagged Tumblr posts

Text

Super Rings Revolutionizing Concrete Durability and Structural Integrity

Construction professionals know that the real strength of a structure does not lie in its original design but in how well it can resist time, stress, and environmental conditions. Super Rings are an innovative technology that answers the fundamental weaknesses of traditional concrete reinforcement, promising unprecedented durability and structural performance.

The Hidden Challenges of Concrete Structures

Concrete, although highly prevalent in construction, suffers from critical durability issues:

Microcracking leading to loss of structural integrity

Loss of load-carrying capacity over time

Susceptibility to environmental stress

Weakness against thermal expansion and contraction

Risk of early degradation of the structure

Now Comes Super Rings: The Technology Revolution

Super Rings is a technological leap forward in concrete reinforcement. The specially designed circular elements are a solution to all those issues that have been persisting for centuries in construction. These revolutionize how engineers and architects approach structural design.

Technical Benefits of Super Rings

The Super Ring design offers multilayered structural protection as follows:

Better Stress Distribution

Circular geometry allows for even distribution of stress

Reduces localized stress concentrations

Averts potential failure points in concrete structures

Superior Mechanical Properties

Excellent tensile strength

High ductility and flexibility

Dynamic loading resistance is improved

Fatigue resistance is highly remarkable

Comparative Advantages: Super Rings versus Traditional Reinforcement

Traditional reinforcement techniques fail to deliver comprehensive structural protection. Super Rings excel in the following ways:

Advanced Load Transmission

Better load transfer mechanism

Decreased risk of structural failure

Increased overall structural toughness

Corrosion Resistance

Better material makeup

Minimum degradation by environmental factors

Increased service life of concrete structures

Thermal Performance

Better control of thermal expansion

Reduced chances of cracking due to temperature fluctuations

Consistent performance throughout temperature ranges

Super Rings in Practical Life

Architects and engineers have found numerous applications of Super Rings in construction works:

High-rise buildings

Bridge constructions

Earthquake-resistant buildings

Industrial facility construction

Massive civil engineering projects

Concrete Quantifiable Benefits for Construction Professionals

Super Rings provide measurable benefits:

30% more structural life

Lower maintenance costs

Wider safety margins

Better overall structural performance

Meets strict building codes

Economic and Safety Consequences

Super Rings investment goes beyond mere cost savings:

Long-term cost savings due to reduced maintenance

Reduced risk of structural failures

Improved safety for occupants

Sustainable construction practices

Future-proofing infrastructure investments

Certification and Quality Assurance

Stringent testing confirms the performance of Super Rings:

Comprehensive laboratory tests

International construction standards compliance

Consistent performance in various environmental conditions

Independently verified structural strengthening capacity

Making the Smart Choice in Concrete Reinforcement

Selecting Super Rings represents a smart approach to construction. Durability, safety, and long-term performance are top priorities for construction professionals to:

Reduce possible structural risk

Ensure a better-quality project

Keep up with the increasing standard of buildings

Offer clients a more dependable, sustainable structure

Conclusion: The Future of Structural Engineering

Super Rings are not just a product—they're a paradigm shift in construction technology. For professionals committed to excellence, these innovative reinforcement solutions offer a compelling path to more durable, reliable, and resilient structures.

Embrace the future of construction. Choose Super Rings.

#Super Rings#Concrete Tech#Durability#Structural Strength#Reinforcement#Advanced Design#Load Bearing#Crack Resistant#Longevity#Modern Construction

0 notes

Text

Ending of frontiers got me thinkin, you know what that means

FOREVER WIP HELL (Ref. Amy design)

#imagie kid draws#told ya sonic would be back#sonic the hedgehog#sonic#I want a small time jump#small#something fun#these are not concrete. but pretty close#we agree knuckles with the hat right#knuckles the echidna#knuckles#amy#amy rose#tails#miles tails prower#tails the fox#I want the early 2000’s tech we though we would have sonic sonic#ref his canon human design bc it’s PEAK#so much cool gadgets that def do NOTHIN#brb I’ll finish this after my dbd fixation#sonic au#au#sure why not it’s just designs#wip#work in progress#doodles#sonic frontiers#sureeeee

119 notes

·

View notes

Text

Travelator, Sainsbury's, Camden, 1988. From the Sainsbury Archive.

34 notes

·

View notes

Text

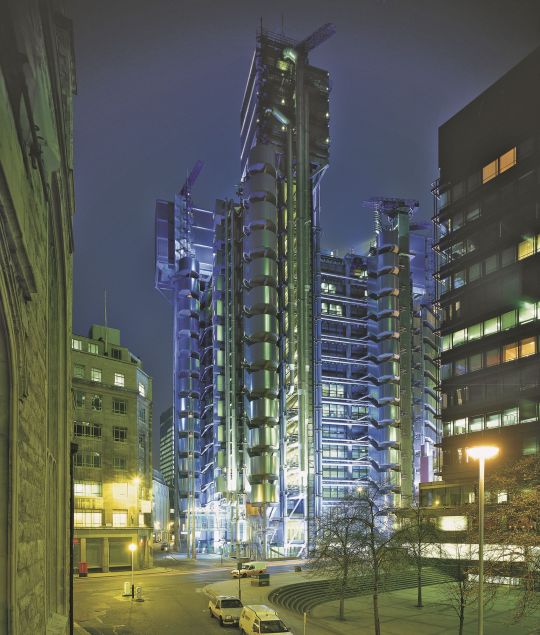

Lloyd's Building, London - Richard Rogers

#Richard Rogers#architecture#design#building#modern architecture#interiors#concrete#steel#structure#high tech#modern#iconic#services#city of london#banks#commercial#tower#skyscraper#cool architecture#english architecture

133 notes

·

View notes

Text

now u see it!! ⇨ 💚

#print(char)#print(reference)#im actually happy with this design. going fully dark for the head was inspired by wizard with a gun#since hes. well. a ''tech wizard''#with magician aspects. of course#he specializes in illusions <3 real ones of course#print(doodle)#not hazbin#((technically))#hes my voxsona and hes LOVELY!!#i have lore for him. still writing it properly but i have CONCRETE LORE THIS TIME

10 notes

·

View notes

Text

I think the battleship movie was absolutely peak and nobody enjoyed it as much as it should have been enjoyed.

#yes the one with the drifting ships#yes the one with giant deathballs that could bulldoze through concrete and rebar and helicopters#yes the one with Rihanna and Liam Neeson#yes the one that bullshitted bullets being able to go through forcefields and ships having even a remote chance against alien tech#yes the pro-anti-anti-pro war film that you'd think was produced by Michael Bay but isn't

2 notes

·

View notes

Text

Power plants 🏭

#aesthetic#cyberpunk#tech#tech aesthetic#electricity#engineering#technology#electricity aesthetic#industrial#electricity is beautiful#power plant#industrial landscape#dark pale#dark grunge#elektrostantsiyapost#electrical engineer#electrical engineering#power engineering#cooling towers#clouds#techwave#grunge#grungecore#engineer#engineers#dark#landscape#trees#smoke stack#concrete

2 notes

·

View notes

Text

i didnt puke tofay eveeyone clap

#usually i js puke uo spit bc i don’t eat#a lot#i have like some grapes or likr a salad#i don’t eat meat and bread and carby thibgs make me sick#but i ate this weird thing my friend made in food tech#it was like cucumber#and some type of noodle i think#idk i don’t eat noodles a lot#my mum only makes either traditional food or like pasta every night#i didnt eat ALL of it but i had like a quarter#snd i didnt throw up so thats a firsy#i felt so sick though#i cant even chew gum withoit gagging#i used to have the toughest stomach too#lile i licked the school concrete twice#fuck#the concequences of my own actions

4 notes

·

View notes

Text

#viagra boys#youtube#shrimp tech#sebastian murphy#post punk#shrimp shack#live#shrimp#live music#live show#tour#tours#the eras tour#tourism#dominate tour#tournament poll#tourist#presale#tickets#ticket#concert tickets#live concert#concert photos#concert#concept art#nsft concept#character concept#concrete#concerts#concerto

5 notes

·

View notes

Text

booted up the ten year old ipod that my dad let us play with in middle school & that when i was eleven i was obsessed with bc my parents were SUPER stringent re: screen time but they let me go nuts with this bc it was just full of my dad’s favorite music (and also some games that i suspect they didn’t know about + that i would play in bed as my Secret Silly Tweenage Rebellion), and immediately it hit me with this

#i think the tech is saying Hi Celia I Love You Too <3#life and stuff#im so emotional over finally having a charger thing to charge it up!!!#the clock on it said it was FEBRUARY 2013#this little guy has been taking a ten year long nap!!!!#was not even HERE for my jenny phase#INSANE#also i vividly remember repeatedly badly failing this quiz bc i was in middle school and also lived under a rock#i am somehow now passably better at this 2007 era pop culture quiz#which is weirdly very gratifying 2 me#btw the little dinged up part is from when i dropped it off a deck and down an entire story straight onto concrete#(really just having a whole EVERYONE LOOK AT MY BABY moment…)

34 notes

·

View notes

Text

you would not believe the Ideas in my brain right now. you would also not believe how i cannot draw any of them

#GOOD IDEAS!!! CANT EXECUTE#AAAGAUAAGAGAHAHDHAGG#COMBUSTS AND EXPLODES VIOLENTLY#not necessarily a negative thing though im jsut. auushfh#i wish. i could character design well. i mean sj is probably the best character design ive done but i wanna like#design actual outfits. and armor. and tech. theres a reaaon why my brain has a reason#blowing myself up rn im mentally ill about Characters#im.mentally ill abt Games (youll never guess which one its definitely not possible to guess based on one glance at our blogs or anything)#bites direcrly into concrete with my teeth

5 notes

·

View notes

Text

yknow if the stills from the initial side order teaser really were just concept art then i have a feeling that they’re going to leave something like this out and that makes me sad /lh

#idk SO seems very tech themed and this isn’t really tech#itz just concrete yk#i still think its really cool though </3#barkin kiiro#splatoon#side order#ask to tag

19 notes

·

View notes

Text

3 notes

·

View notes

Text

Smart Structures Start with Super Rings: Engineering Precision by SRJ Steel

The strength of a structure begins at its very foundation — and Super Rings are increasingly proving themselves as indispensable components in high-performance construction.

These seemingly simple circular reinforcements offer far more than just support; they engineer precision into every build, especially when paired with essential materials like binding wires and dowel bars in rigid pavement.

Why Structural Precision Matters

In heavy-obligation construction and infrastructure, precision isn't non-compulsory — it's fundamental. Any variance in alignment or structural bonding can bring about long-term weaknesses. This is where Super Rings play a crucial role. Their design ensures uniform spacing and circular reinforcement, allowing concrete structures to maintain form and function under various stress conditions.

What Are Super Rings?

Super Rings are specialized circular ties used to reinforce concrete columns and piers. Unlike conventional rings, they’re manufactured with higher dimensional accuracy and consistent strength. This translates to:

Enhanced load distribution

Reduced risk of deformation

Improved seismic resistance

Their integration with binding wires creates a tightly wound reinforcement cage that can handle dynamic loads without displacement.

Binding Wires: The Silent Strength

Often underestimated, binding wires are the unsung heroes of steel reinforcement. These wires tie the rebars, Super Rings, and other steel components securely in place before concrete pouring. They:

Prevent movement during concrete setting

Maintain geometric alignment

Distribute internal stress evenly

In practice, binding wires work synergistically with Super Rings to ensure stability. Without proper tying, even the most advanced Super Rings can’t fulfill their potential.

Dowel Bars in Rigid Pavement: Supporting the Horizontal Load

Horizontal alignment in pavements demands a different kind of reinforcement — dowel bars in rigid pavement. These cylindrical bars are embedded at slab joints to:

Transfer load between concrete panels

Prevent differential settlement

Enhance longevity of roads and airport runways

In infrastructure projects involving both vertical and horizontal elements, dowel bars and Super Rings complement each other. While dowel bars handle the shear force and slab movement, Super Rings ensure columnar integrity, especially at intersections.

How Super Rings Enhance Performance

Super Rings are engineered for precision, which offers several tangible benefits:

Consistent Spacing: Ensures even stress distribution across the rebar cage.

Improved Safety Margins: Reduces failure risks in earthquake-prone zones.

Faster Installation: Minimizes alignment errors, saving time on-site.

These benefits become especially valuable in projects where binding wires and dowel bars in rigid pavement are already being used, creating a cohesive and durable system.

Material Compatibility and Engineering Efficiency

Super Rings, binding wires, and dowel bars in rigid pavement are not standalone solutions. Their efficiency comes from how well they integrate:

Binding wires secure Super Rings and longitudinal bars, reinforcing vertical integrity.

Dowel bars maintain horizontal integrity across pavement slabs.

Super Rings ensure concrete holds shape and structural load across the column height.

Using materials from a single, quality-controlled source like SRJ Steel ensures uniformity, avoiding mismatches in tensile strength or diameter that could compromise performance.

Smart Structures Demand Smart Components

As infrastructure moves towards smarter, more sustainable practices, engineering elements like Super Rings aren’t just add-ons — they’re integral. Today’s flyovers, metro stations, and industrial buildings demand a level of mechanical discipline that only precision-engineered components can deliver. Super Rings provide the stability and alignment that traditional rings often fail to achieve, especially under long-term stress.

Conclusion: Built to Last with Engineering Foresight

Structures of the future are not only taller and stronger — they’re also smarter. Behind the scenes, precision components like Super Rings are making that possible. Alongside binding wires and dowel bars in rigid pavement, these elements ensure every beam, column, and slab is reinforced with integrity. SRJ Steel’s commitment to manufacturing excellence stands as a testament to what's achievable when engineering precision becomes non-negotiable.

#Super Rings#SRJ Steel#Smart Structures#Steel Rings#Rebar Rings#Construction Rings#Precision Steel#Steel Support#Concrete Frames#Reinforced Steel#Building Rings#Smart Steel#Steel Innovation#Super Ring Tech#Structural Steel#Steel Solutions#Modern Rebar#Ring Reinforcement#Steel Strength#Advanced Rings

0 notes

Text

Smart Infrastructure Demands Smart Steel: The Evolving Role of Dowel Bars in Smart Cities

As cities evolve into interconnected, tech-driven ecosystems, the materials that support them must evolve too.

Dowel bars are a critical, often overlooked component that supports the very roads and pavements on which smart cities thrive. Right after them, bar dowel systems and the innovations introduced by TMT bar manufacturers are redefining urban durability and strength like never before.

Why Smart Cities Need Smarter Foundations

With urban populations exploding and infrastructure becoming increasingly high-tech, traditional materials can no longer keep up. Smart infrastructure demands steel components that aren’t just strong, but also intelligent — materials that can bear heavier loads, resist time, and adapt to their environment.

Dowel Bars: The Load-Bearing Links That Make It Work

Dowel bars quietly serve as joints in concrete pavements, transferring loads from one slab to another and minimizing stress buildup. In heavy-use areas like metro roads, airports, or smart transportation systems, their role becomes critical in ensuring smooth, long-lasting surfaces.

Unlike simple rods, bar dowel systems ensure precise load transfer and reduce pavement cracking. Combined with steel made by leading TMT bar manufacturers, these components bring together tensile strength and flexibility, ideal for demanding smart city conditions.

The Real Science Behind Bar Dowel Strength

How does it all work? When vehicles pass over a joint, stress is dispersed across dowel bars embedded into the slabs. This balanced distribution approach fewer cracks, longer pavement life, and minimal need for restore — all essential in a 24/7 city environment wherein downtime isn’t an alternative.

Modern bar dowel technology has developed, providing corrosion-resistant coatings, better alignment tools, and better-grade metallic alloys. Leading TMT bar manufacturers are pioneering these advancements, ensuring not just physical performance but also economic efficiency.

TMT Bar Manufacturers Are Setting New Industry Standards

Smart cities demand consistency and reliability. That’s why trusted TMT bar manufacturers have become partners in innovation — offering high-strength products tested for extreme conditions. From robotic testing to AI-based quality assurance, these manufacturers are reshaping how urban foundations are built.

Their steel isn’t just strong — it’s smart. Paired with efficient bar dowel systems, it’s transforming how roads, bridges, and public infrastructure stand the test of time.

Sustainability and Strength Go Hand-in-Hand

Long-lasting roads reduce the need for frequent repairs, which in turn cuts carbon emissions from construction machinery. Dowel bars contribute significantly to sustainability by enhancing pavement life and supporting smart waste reduction strategies.

More and more smart cities are now mandating the use of high-performance bar dowel systems in green-certified construction.

Making the Right Choice for Long-Term Success

Whether you’re planning a city-scale project or upgrading existing infrastructure, selecting the right bar dowel system and sourcing from reliable TMT bar manufacturers ensures performance that matches your vision for urban excellence.

Certifications, proven track records, and innovative product lines should guide your selection — because smart infrastructure deserves nothing less.

Conclusion: Build Smart, Stay Smart

The cities of tomorrow depend on decisions made today. When it comes to foundations, dowel bars are more than just a detail — they’re a design necessity. And when paired with precision-engineered bar dowel systems and the expertise of leading TMT bar manufacturers, they form the invisible yet critical layer of strength every smart city needs.

FAQs

1. How do dowel bars improve pavement durability? They transfer loads between concrete slabs, reducing joint stress and preventing cracks.

2. Are bar dowels different from regular steel rods? Yes, bar dowels are engineered for specific load-bearing roles with better alignment and corrosion resistance.

3. Why are TMT bar manufacturers important in infrastructure? They ensure high-quality, durable steel suitable for complex, high-performance urban environments.

#Smart steel#Dowel bars#Smart roads#Urban growth#Steel joints#Road tech#Pavement bars#City upgrade#Load transfer#Road safety#Urban steel#Joint support#Durable roads#Steel bars#Smart cities#Concrete links#Bar strength#Steel dowels#Road joints#Smart builds

0 notes

Text

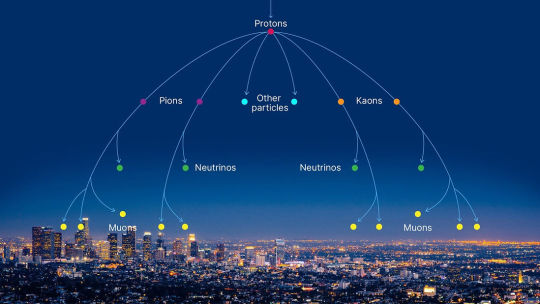

Okay so a guy in my solid state physics class was telling us about this muon scanning startup he worked at, GScan, and I'm going insane. I don't work there and I have no stake in the company, financial or otherwise, I just need to tell you about it.

Muons are short-lived subatomic particles, same charge as an electron but ~200 times more massive. On Earth, they're produced by cosmic rays colliding with the upper atmosphere, and they hit the ground at a rate of about ten thousand per minute per square meter.

They're moving extremely fast at ground level, like 0.99 c. So they careen right through matter, deflecting only very slightly around heavy atomic nuclei – they'll penetrate like a hundred meters into solid rock.

What do you do with this continuous shower of deep-penetrating charged particles, constantly blanketing every square inch of the Earth's surface?

(source)

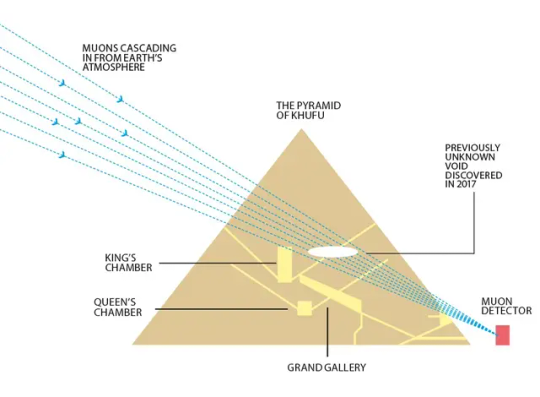

The classic thing is use them to image the inside of massive structures, like we use x-rays to look inside living tissue – except instead of generating them yourself, you just use atmospheric muons. Muon archeology is a whole thing, they've used it to find hidden chambers in pyramids and stuff. Neat!

But this one Estonian company is doing some crazy bullshit and I love it.

Sandwich anything between a pair of portable muon detectors and get full 3D imaging of the interior, with sub-millimeter accuracy, by tracking the minute deflection of muons between them. Samples that are WAY too thick for x-rays, made of literally anything. Just put some muon detectors on some two by fours in a warehouse and call it a day.

You can just. Image anything??? Anything you want?? Completely passively!! Just detectors! No particle source! Put them anywhere. The detectors themselves are a mature technology, the company's tech is in the algorithms they use to get this level of spatial and elemental resolution.

You can detect failures inside cable-reinforced concrete bridges without cutting open the bridges.

Decommissioned Soviet nuclear submarine filled with concrete, with no drawings or documentation, that may or may not have spent fuel canisters in it? And you need to cut it up for storage? Just look at the muons.

One of the wackiest ideas is to put one detector under your bed and one on the ceiling, so you get a full 3D scan of your body every night, passively. I want one.

7K notes

·

View notes