#Core–Shell Nanoparticle Uses

Explore tagged Tumblr posts

Text

High-Purity Nanomaterials & Graphene Nanoplatelets Powder Supplier

Nanochemazone is a global leader in advanced nanomaterials, offering high-purity Graphene Nanoplatelets Powder, MXenes, metal oxides, and custom nanoparticles for research and industrial use.

#research chemicals#chemicalindustry#2d materials#science#Core–Shell Nanoparticle Uses#Graphene Oxide Nanoparticles#PTFE Suspension Resin Powder#Calcium Carbonate Nanoparticles#Nanoparticles Supplier#High Purity Nanopowders#Advanced Nanomaterials#Buy MXene Online#Graphene Nanoplatelets#Carbon Nanotubes Bulk#Custom Nanomaterial Synthesis#Laboratory Grade Nanomaterials#Metal Oxide Nanopowders#Nano Additive Manufacturing

0 notes

Text

Researchers reveal ways to fine-tune nanoparticles and outline future areas of study

The demand for renewable energy sources is constantly growing fueling the development of catalytic-based technologies. By separating and forming chemical bonds, these technologies can be used to produce environmentally friendly energy. In recent decades, researchers have been actively studying how core-shell nanoparticles can improve the performance of catalytic systems, which mainly use metal catalysts that accelerate chemical reactions. Researchers from Skoltech analyzed the latest achievements in synthesizing core-shell particles, research methods, techniques for adjusting their properties, and also identified the most promising areas for future research. A large review has been published in Nanoscale.

Read more.

8 notes

·

View notes

Text

if i wasn’t Girlblogging as much yesterday it was because i was preoccupied with the chaotic state of our senior design program, another undergraduate who HAD to use the centrifuge mass balancing scale to measure out a shit ton of NaOH and prevented me from cleaning my first silica shell coated nanoparticles of the year to the point where the reaction pushed too far and the ammonium etched the core, and then having to deal with a polyacrylic acid modification reaction that wouldn’t give me a stable pH reading until i LITERALLY started praying for the reading to stabilize so i could neutralize it with 0.1 M NaOH.

#i feel like i don’t Girlblog as much about my research as i do about orchestra but. i do both.#iskul bukol

5 notes

·

View notes

Text

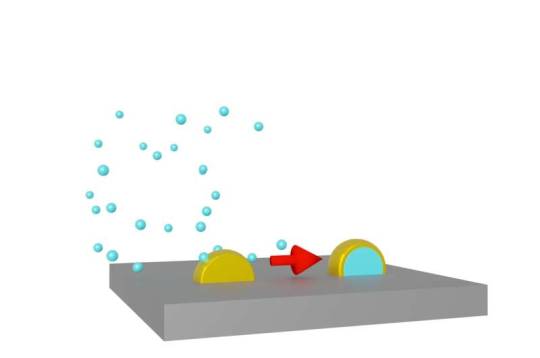

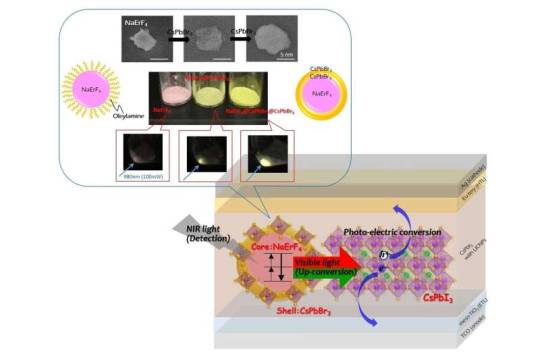

Industry trend|"Nano ink" batch printing wearable sensors

Personalized healthcare can tailor the ratio of nutrients, metabolites and drugs according to the unique needs of individuals. The realization of this process is inseparable from the continuous monitoring of certain biomarkers. Recently, the California Institute of Technology announced on its official website that its research team has successfully developed a new "nano-ink" printing technology that can mass-produce durable wearable sweat sensors. These sensors have the function of real-time tracking of multiple biomarkers such as vitamins, hormones, metabolites and drugs, allowing patients and doctors to continuously observe the dynamic changes at the molecular level.

The nanoparticles generated by this printing technology are named core-shell cubic nanoparticles. Their operating mechanism relies on the recognition ability of the molecularly imprinted polymer shell to specific molecules (such as vitamin C). Once the target molecules exist, they will contact the polymer shell and penetrate into the internal pores, causing the electrical signal to weaken. By monitoring this signal change, the content of the target molecule can be accurately determined. In addition, the team also introduced nickel hexacyanoferrate as a core material to enhance the stability of the sensor in biological fluids and ensure the accuracy of long-term measurements.

It is worth noting that this technology is not limited to the detection of a single biomarker, but can also build sensor arrays by using different types of nanoparticle "ink" to achieve simultaneous measurement of multiple amino acids, metabolites, hormones or drug levels. In the study, the team has successfully printed sensors for vitamin C, tryptophan and creatinine, and has been applied in actual cases.

The advent of this technology provides new possibilities for the realization of personalized drug dosage, especially in the field of cancer treatment. It can remotely monitor the dosage of anti-cancer drugs in the body in real time, opening up new avenues for disease treatment. In addition, the study also explored the feasibility of implanting nanoparticle sensors subcutaneously to accurately monitor drug levels in the body. This breakthrough marks a key step towards more precise and efficient personalized medicine.

This paper is from Ulink Media, Shenzhen, China, the organizer of IOTE EXPO (IoT Expo in China)

0 notes

Text

Tiny magnetic discs offer remote brain stimulation without transgenes

New Post has been published on https://thedigitalinsider.com/tiny-magnetic-discs-offer-remote-brain-stimulation-without-transgenes/

Tiny magnetic discs offer remote brain stimulation without transgenes

Novel magnetic nanodiscs could provide a much less invasive way of stimulating parts of the brain, paving the way for stimulation therapies without implants or genetic modification, MIT researchers report.

The scientists envision that the tiny discs, which are about 250 nanometers across (about 1/500 the width of a human hair), would be injected directly into the desired location in the brain. From there, they could be activated at any time simply by applying a magnetic field outside the body. The new particles could quickly find applications in biomedical research, and eventually, after sufficient testing, might be applied to clinical uses.

The development of these nanoparticles is described in the journal Nature Nanotechnology, in a paper by Polina Anikeeva, a professor in MIT’s departments of Materials Science and Engineering and Brain and Cognitive Sciences, graduate student Ye Ji Kim, and 17 others at MIT and in Germany.

Deep brain stimulation (DBS) is a common clinical procedure that uses electrodes implanted in the target brain regions to treat symptoms of neurological and psychiatric conditions such as Parkinson’s disease and obsessive-compulsive disorder. Despite its efficacy, the surgical difficulty and clinical complications associated with DBS limit the number of cases where such an invasive procedure is warranted. The new nanodiscs could provide a much more benign way of achieving the same results.

Over the past decade other implant-free methods of producing brain stimulation have been developed. However, these approaches were often limited by their spatial resolution or ability to target deep regions. For the past decade, Anikeeva’s Bioelectronics group as well as others in the field used magnetic nanomaterials to transduce remote magnetic signals into brain stimulation. However, these magnetic methods relied on genetic modifications and can’t be used in humans.

Since all nerve cells are sensitive to electrical signals, Kim, a graduate student in Anikeeva’s group, hypothesized that a magnetoelectric nanomaterial that can efficiently convert magnetization into electrical potential could offer a path toward remote magnetic brain stimulation. Creating a nanoscale magnetoelectric material was, however, a formidable challenge.

Kim synthesized novel magnetoelectric nanodiscs and collaborated with Noah Kent, a postdoc in Anikeeva’s lab with a background in physics who is a second author of the study, to understand the properties of these particles.

The structure of the new nanodiscs consists of a two-layer magnetic core and a piezoelectric shell. The magnetic core is magnetostrictive, which means it changes shape when magnetized. This deformation then induces strain in the piezoelectric shell which produces a varying electrical polarization. Through the combination of the two effects, these composite particles can deliver electrical pulses to neurons when exposed to magnetic fields.

One key to the discs’ effectiveness is their disc shape. Previous attempts to use magnetic nanoparticles had used spherical particles, but the magnetoelectric effect was very weak, says Kim. This anisotropy enhances magnetostriction by over a 1000-fold, adds Kent.

The team first added their nanodiscs to cultured neurons, which allowed then to activate these cells on demand with short pulses of magnetic field. This stimulation did not require any genetic modification.

They then injected small droplets of magnetoelectric nanodiscs solution into specific regions of the brains of mice. Then, simply turning on a relatively weak electromagnet nearby triggered the particles to release a tiny jolt of electricity in that brain region. The stimulation could be switched on and off remotely by the switching of the electromagnet. That electrical stimulation “had an impact on neuron activity and on behavior,” Kim says.

The team found that the magnetoelectric nanodiscs could stimulate a deep brain region, the ventral tegmental area, that is associated with feelings of reward.

The team also stimulated another brain area, the subthalamic nucleus, associated with motor control. “This is the region where electrodes typically get implanted to manage Parkinson’s disease,” Kim explains. The researchers were able to successfully demonstrate the modulation of motor control through the particles. Specifically, by injecting nanodiscs only in one hemisphere, the researchers could induce rotations in healthy mice by applying magnetic field.

The nanodiscs could trigger the neuronal activity comparable with conventional implanted electrodes delivering mild electrical stimulation. The authors achieved subsecond temporal precision for neural stimulation with their method yet observed significantly reduced foreign body responses as compared to the electrodes, potentially allowing for even safer deep brain stimulation.

The multilayered chemical composition and physical shape and size of the new multilayered nanodiscs is what made precise stimulation possible.

While the researchers successfully increased the magnetostrictive effect, the second part of the process, converting the magnetic effect into an electrical output, still needs more work, Anikeeva says. While the magnetic response was a thousand times greater, the conversion to an electric impulse was only four times greater than with conventional spherical particles.

“This massive enhancement of a thousand times didn’t completely translate into the magnetoelectric enhancement,” says Kim. “That’s where a lot of the future work will be focused, on making sure that the thousand times amplification in magnetostriction can be converted into a thousand times amplification in the magnetoelectric coupling.”

What the team found, in terms of the way the particles’ shapes affects their magnetostriction, was quite unexpected. “It’s kind of a new thing that just appeared when we tried to figure out why these particles worked so well,” says Kent.

Anikeeva adds: “Yes, it’s a record-breaking particle, but it’s not as record-breaking as it could be.” That remains a topic for further work, but the team has ideas about how to make further progress.

While these nanodiscs could in principle already be applied to basic research using animal models, to translate them to clinical use in humans would require several more steps, including large-scale safety studies, “which is something academic researchers are not necessarily most well-positioned to do,” Anikeeva says. “When we find that these particles are really useful in a particular clinical context, then we imagine that there will be a pathway for them to undergo more rigorous large animal safety studies.”

The team included researchers affiliated with MIT’s departments of Materials Science and Engineering, Electrical Engineering and Computer Science, Chemistry, and Brain and Cognitive Sciences; the Research Laboratory of Electronics; the McGovern Institute for Brain Research; and the Koch Institute for Integrative Cancer Research; and from the Friedrich-Alexander University of Erlangen, Germany. The work was supported, in part, by the National Institutes of Health, the National Center for Complementary and Integrative Health, the National Institute for Neurological Disorders and Stroke, the McGovern Institute for Brain Research, and the K. Lisa Yang and Hock E. Tan Center for Molecular Therapeutics in Neuroscience.

#250#applications#author#background#Behavior#bioelectronics#Brain#Brain and cognitive sciences#brain research#brain stimulation#brains#Cancer#Cells#challenge#chemical#chemistry#Composition#computer#Computer Science#development#devices#Disease#disorders#DMSE#droplets#effects#electrical stimulation#electricity#electrodes#Electronics

0 notes

Text

They say their technology, using iron-based nanoparticles, could supply a large share of the lithium needed for batteries as America transitions to electric vehicles and displace the environmentally harmful methods currently used to mine and process lithium.

Great!

The technique devised by the U.S. Department of Energy lab uses magnetic nano-particles to trap the lithium dissolved in many underground aquifers. The tiny particles have iron oxide at their core and a synthetic outer shell designed to attract and hold lithium ions.

The plan is to harvest lithium from the hot, briny groundwater used by geothermal power plants and the salty water that comes to the surface as a byproduct of oil and gas drilling.

Thallapally said lithium could become an additional revenue stream for energy producers and help to lower the cost of the energy they produce.

While improving the economics of a clean energy source like geothermal power could help the transition to a climate-friendly economy, doing so for oil and gas production could have the opposite effect.

The Pacific Northwest National Laboratory has licensed the technology to Texas startup Moselle Technologies and is collaborating with other companies including energy giant Conoco Phillips on further testing of it.

Less great!

5 notes

·

View notes

Photo

Celebrate International Women’s Day by reading a book by a woman scientist!

Our recommendation: Assistant Professor of Physics Jillian Scudder’s “curious journal through our cosmic family tree,” Astroquizzical; a “quirky guide to how things work in the universe.”

Scientists are more likely to publish research articles than monographs, of course. As indexed in the Web of Science, there are nearly 35 articles published in the past three years by Oberlin College scientists who identify as female. This is not an exhaustive list by any means, and it’s impressive to see the breadth of research.

Articles are listed after the break, arranged alphabetically by the last name of the first author; faculty names are show in bold font.

------ Publications by Oberlin College Women in Science 2018-2020: limited to current faculty/recent emerita in the departments of biology, chemistry and biochemistry, geology, neuroscience, physics and astronomy.

Bailey, H.D., A.B. Mullaney, K.D. Gibney, and Leslie D. Kwakye. 2018. Audiovisual integration varies with target and environment richness in immersive virtual reality. Multisensory Research 31:689-713.

Barald, K.F., Y.C. Shen, Lynne M. Bianchi. 2018. Chemokines and cytokines on the neuroimmunoaxis: Inner ear neurotrophic cytokines in development and disease. Prospects for repair? Experimental Neurology 301:92-99.

Bell, E.W., E.J. Zheng, Lisa M. Ryno. 2018. Identification of inhibitors of the E. coli chaperone SurA using in silico and in vitro techniques. Bioorganic and Medicinal Chemistry Letters 28: 3540-3548.

Bianchi, Lynne. 2018. Developmental Neurobiology. Garland Science, Taylor and Francis Group. 345p.

Bohm-Levine, N., A. R. Goldberg, Monica Mariani, M. Frankfurt, and Janice Thornton. 2020. Reducing luteinizing hormone levels after ovariectomy improves spatial memory: Possible role of brain-derived neurotrophic factor. Hormones and Behavior 118:104590.

Ceperley, Elizabeth G., et al. 2020. Widespread early Holocene deglaciation, Washington Land, northwest Greenland. Quaternary Science Reviews 231:106181.

Drabeck, D. H., A. Rucavado, E. Hingst-Zaher, Yolanda P. Cruz, A. M. Dean, and S. A. Jansa. 2020. Resistance of South American opossums to vWF-binding venom C-type lectins. Toxicon 178:92-99.

Edwards, J., Marta Laskowski, T. I. Baskin, N. Mitchell, and B. DeMeo. 2019. The role of water in fast plant movements. Integrative and Comparative Biology 59:1525-1534.

Ellison, S. L., M. D. Thorp, L. Lin, H. Pan, A. F. L. Bluck, Jillian M. Scudder, H. Teimoorinia, S. F. Sanchez, and M. Sargent. 2020. The ALMaQUEST survey - III. Scatter in the resolved star-forming main sequence is primarily due to variations in star formation efficiency. Monthly Notices of the Royal Astronomical Society 493:L39-L43.

Ellison, S. L., M. D. Thorp, H. Pan, L. Lin, Jillian M. Scudder, A. F. L. Bluck, S. F. Sanchez, and M. Sargent. 2020. The ALMaQUEST Survey II. What drives central starbursts at z ti 0? Monthly Notices of the Royal Astronomical Society 492:6027-6041.

Garvin, Mary C., et al. 2020. A survey of trace metal burdens in increment cores from eastern cottonwood (Populus deltoides) across a childhood cancer cluster, Sandusky County, OH, USA. Chemosphere 238:124528.

Garvin, Mary C., et al. 2018. Attraction of Culex pipiens to house sparrows Is influenced by host age but not uropygial gland secretions. Insects 9: article 127.

Garvin, Mary C., et al. 2018. Attraction of Culex pipiens to uropygial gland secretions does not explain feeding preference for American robins. Journal of Vector Ecology 43:110-116.

Hammer, A. C., X. Jia, M. Zeller, E. J. Coughlin, W. Zhang, and Catherine M. Oertel. 2020. Ligand geometry directs the packing and symmetry of one-dimensional helical motifs in lead oxide naphthoates and biphenylcarboxylates. Crystengcomm 22:6465-6477.

Hillis, D.M., M.V. Price, R.W. Hill, D.W. Hall, Marta J. Laskowski. 2019. Principles of Life, 3rd ed. Sinauer Associates; Macmillan. 1050p.

Ijiri, Yumi, et al. 2019. Correlated spin canting in ordered core-shell Fe3O4/MnxFe3-xO4 nanoparticle assemblies. Physical Review B 99:094421.

Kamhi, J. Frances, A.B. Barron, A. Narendra. 2020. Vertical lobes of the mushroom bodies are essential for view-based navigation in Australian Myrmecia ants. Current Biology 30:3432+

Krycka, K.L. ...Yumi Ijiri, et al. 2018. Spin waves across three-dimensional, close-packed nanoparticles. New Journal of Physics 20: article 123020.

Mariani, Monica M., K. Mojziszek, E. Curley, and Janice E. Thornton. 2020. Lowering luteinizing hormone (LH) reverses spatial memory deficits associated with neurotoxin infusion into the hippocampus of ovx rats. Hormones and behavior 119:article 104631.

McCormick, Catherine A. 2019. Immunocytochemical evidence for electrical synapses in the dorsal descending and dorsal snterior octaval nuclei in the Goldfish, Carassius auratus. Brain Behavior and Evolution 93:34-39

Oberdick, S.D., ...Yumi Ijiri, et al. 2018. Spin canting across core/shell Fe3O4/MnxFe3-xO4 nanoparticles. Scientific Reports 8:3425

Paine, Tracie A., S. Chang, and R. Poyle. 2020. Contribution of GABA(A) receptor subunits to attention and social behavior. Behavioural brain research 378:112261.

Pan, H., L. Lin, B. Hsieh, T. Xiao, Y. Gao, S. L. Ellison, Jillian M. Scudder, et al. 2018. The effect of galaxy interactions on molecular gas properties. Astrophysical Journal 868:132.

Riordan, A.J. ... Tracie A. Paine, Janice E. Thornton. 2018. Estradiol and luteinizing hormone regulate recognition memory following subchronic phencyclidine: Evidence for hippocampal GABA action. Psychoneuroendocrinology 91:86-94.

Rutter, M.T., Angela J. Roles, C.B. Fenster. 2018. Quantifying natural seasonal variation in mutation parameters with mutation accumulation lines. Ecology and Evolution 8:5575-5585.

Ryno, Lisa M. and C. Cottine. 2018. Biological impact and ethical implications of pesticide use: A short module for upper-division-undergraduate biochemistry courses. Journal of Chemical Education 95:1771-1777

Saintonge, A., … Jillian M. Scudder, et al. 2018. JINGLE, a JCMT legacy survey of dust and gas for galaxy evolution studies - I. Survey overview and first results. Monthly Notices of the Royal Astronomical Society 481:3497-3519.

Schijf, J., Mary C. Garvin. 2018. Validation and application of a new microwave-digestion/ICP-MS method for the analysis of trace metals in tree increment cores. Geochemical Journal 52:347-358

Schmidt, Amanda H., S. Ludtke, C. Andermann. 2020. Multiple measures of monsoon-controlled water storage in Asia. Earth and Planetary Science Letters 546: article 116415

Schmidt, Amanda H., A.R. Denn, A.J. Hidy, P.R. Bierman, Y. Tang. 2019. Human and natural controls on erosion in the Lower Jinsha River, China. Journal of Asian Earth Sciences 170:351-359.

Schmidt, Amanda H., et al. 2018. Agricultural land use doubled sediment loads in western China's rivers. Anthropocene 21:95-106.

Scudder, Jillian M., et al. 2018. Cosmic happenstance: 24-mu m selected, multicomponent Herschel sources are line-of-sight projections. Monthly Notices of the Royal Astronomical Society 480:4124-4137

Smith, Christina L., et al. 2020. The line-of-sight extinction record at Gale Crater as observed by MSL's Mastcam and Navcam through similar to 2,500 Sols. Journal of Geophysical Research-Planets 125:e2020JE006465.

Violino, G., S. L. Ellison, M. Sargent, K. E. K. Coppin, Jillian M. Scudder, T. J. Mender, and A. Saintonge. 2018. Galaxy pairs in the SDSS - XIII. The connection between enhanced star formation and molecular gas properties in galaxy mergers. Monthly Notices of the Royal Astronomical Society 476:2591-2604.

Yang, B. ...Rachel Eveleth, et al. 2020. Phytoplankton phenology in the North Atlantic: insights from profiling float measurements. Frontiers in Marine Science 7:article 139.

2 notes

·

View notes

Text

Hydrogen made from seawater

University of Houston Texas Center for Superconductivity Director, Zhifeng Ren. Image credit: University of Houston.

By Anthony Caggiano

A new catalyst has enabled hydrogen to be made from seawater.

University of Houston, USA, researchers found combining an oxygen and a hydrogen evolution reaction catalyst together achieved current densities capable of supporting industrial demands while requiring relatively low voltage to start seawater electrolysis.

The researchers said the device, made with non-noble metal nitrides, avoids obstacles that have made it difficult to make hydrogen or safe drinking water from seawater.

University of Houston Texas Center for Superconductivity Director, Zhifeng Ren, said a major issue had been that there wasn’t a catalyst that could split seawater to produce hydrogen without also setting free ions of sodium, chlorine, calcium and other components of seawater, which once freed can settle on the catalyst and render it inactive. Chlorine ions are especially challenging, in part because chlorine requires only a slightly higher voltage to free than is needed to free hydrogen.

The researchers designed and synthesised a 3D core-shell oxygen evolution reaction catalyst using transition metal-nitride, with nanoparticles made of a nickle-iron-nitride compound and nickle-molybdenum-nitride nanorods on porous nickle foam.

University of Houston Postdoctoral Researcher and first paper author, Luo Yu, said the new oxygen evolution reaction catalyst was paired with a hydrogen one of nickle-molybdenum-nitride nanorods.

The catalysts were integrated into a two-electrode alkaline electrolyser, which can be powered by waste heat via a thermoelectric device or by an AA battery.

Cell voltages required to produce a current density of 100 milliamperes per square centimetre (a measure of current density, or mA cm-2) ranged from 1.564V to 1.581V.

The voltage is significant, Yu said, because while a voltage of at least 1.23V is required to produce hydrogen, chlorine is produced at a voltage of 1.73V, meaning the device had to be able to produce meaningful levels of current density with a voltage between the two levels.

The researchers tested the catalysts with seawater drawn from Galveston Bay, off the Texas coast. Ren said it also would work with wastewater.

The work is described in Nature Communications.

90 notes

·

View notes

Photo

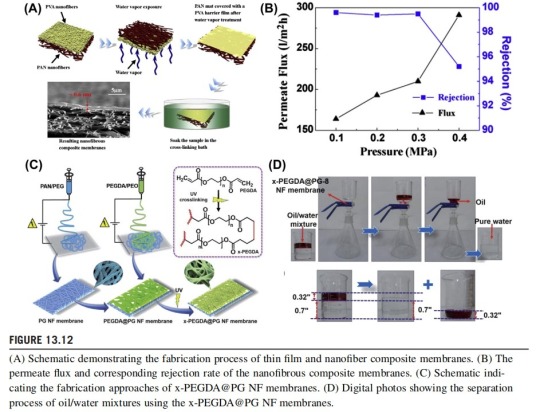

How To Separate Oil From Water By Electrospinning Nanofiber Technology?

#separate #oil #water #electrospinning #nanofiber #technology #composite #polymeric #nanofibrous #mats #carbonbased #porous #electrospun #filter #membranes #oilwater #separation #hydrophobicoleophilic #instinctive #modified #superhydrophobicoleophilic #hydrophilicoleophobic #singlelayer #superhydrophilicoleophobic #multilayer #structured

1. COMPOSITE POLYMERIC NANOFIBROUS MATS

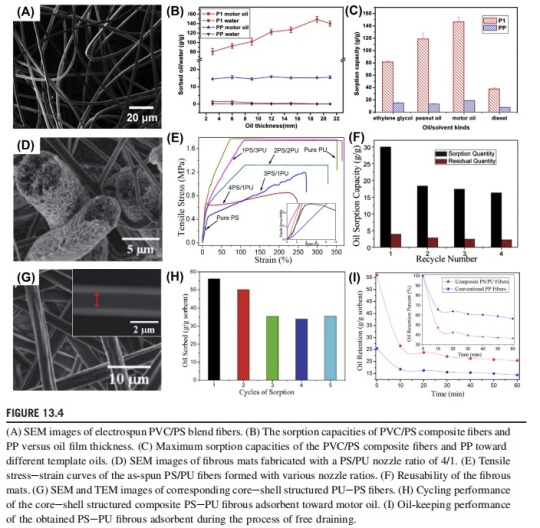

Due to the relatively weak mechanical strength of PS fibers and the unstable networks of the mats, the practical application performance (e.g., retention over time, oil recovery rate) of pure electrospun PS fibrous absorbents was seriously limited. To overcome this challenging problem, mechanical enhancers with high strength were introduced into the PS fibrous mats to improve their mechanical property. Various criteria must be fulfilled by the reinforcing components: they should be mechanically robust to withstand the tensile or compressive stresses during adsorption and recovery processes of sorbents; and hydrophobic-oleophilic wettability is required to ensure the mats have selective wetting ability. Accordingly, a series of additives such as polyvinyl chloride (PVC), polyurethane (PU), polyvinylidene fluoride (PVDF), and carbon nanotubes (CNTs) were employed to modify the PS fibers via different methods based on electrospinning technology.

To incorporate the reinforcing component into PS fibrous mats, various approaches involving blend electrospinning, multinozzle electrospinning, and coaxial electrospinning have been developed. As shown in Fig. 13.4A-C, PVC/PS composite fibers was first fabricated via directly adding an appropriate amount of PVC to PS solutions, and then made by blend electrospinning. The obtained oil absorbents performed well for motor oil, peanut oil, diesel, and ethylene glycol, with high sorption capacities of 146, 119, 38, and 81 g/g, respectively; these capacities are about five to nine times that of commercial PP melt-blown nonwoven sorbent. The PVC/PS oil adsorbent also possessed excellent oil-water selectivity and good buoyancy, which are important in oil-slick cleanup. Multinozzle electrospinning, a powerful technology in fabricating composite nanofibrous materials, has also been used to make porous PU/PS fibrous mats for oil absorption (Fig. 13.4D-F). The robust elasticity of the PU fibers greatly improves the mechanical strength of the obtained PU/PS fibrous mats, even with low PU contents. As a result the oil absorption performance, especially the reusability of the PU/PS fibrous absorbents, was significantly enhanced. Moreover, core-shell structured fibers were considered as an effective approach to enhance the mechanical property of single fibers. The SEM and the corresponding Transmission Electron Microscopy (TEM) images shown in Fig. 13.4G show that the core-shell structured PU-PS fibers have been prepared with a coaxial electrospinning technique by taking PU and PS solutions as the core and shell, respectively. The obtained PU-PS fibrous sorbent has sorption capacities of 64.40 and 47.48 g/g for motor oil and sunflower seed oil, respectively, which are two to three times that of traditional nonwoven PP fibrous mats with the same template oils (Fig. 13.4H and I). Moreover, the oil adsorption capacity comparable with melt-blown nonwoven sorbent was maintained even after five sorption cycles, giving excellent reusability.

2. CARBON-BASED POROUS NANOFIBROUS MATS

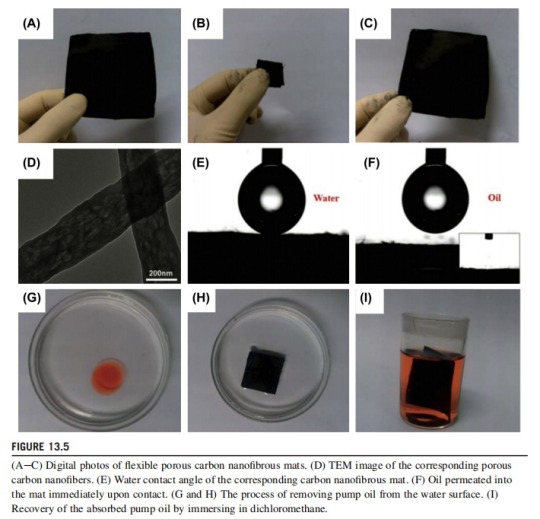

Carbon-based materials have been widely developed to absorb oils due to their instinctive hydrophobic-oleophilic wettability, excellent chemical stability, and thermal stability; this avoids several limitations of organic absorbents, which can be swollen or even dissolved when recycled by rinsing with organic solvents. Recently, electrospun macroporous carbon nanofibrous mats were fabricated through a sublimation method (Fig. 13.5), with terephthalic acid (PTA) used as the pore former to create macropores. During the carbonization of the PTA/polyacrylonitrile (PAN) composite NFs, PTA was sublimed and the macropores were formed, producing flexible and self-sustained macroporous carbon nanofibrous mats. These mats possessed special superhydrophobic and superoleophilic wettability, as well as relatively large porosity of up to 89.2%, attributed to the porous structure of the electrospun fibrous mats. The carbon-based membrane shown a high silicone oil sorption quantity of up to 138.4 g/g, and the absorbed silicone oil could be removed from the membrane by using organic solvents, exhibiting excellent recyclability. Furthermore, a spongelike carbonesilica nanofibrous absorbent with an interconnected three-dimensional structure was also synthesized using the electrospinning technique. The resulting composite fibrous sponge possessed a high porosity of more than 99% and displayed the specific wettability of ultrahydrophobicity and superoleophilicity. With its integral properties of high porosity, low density, and selective wettability, the sponge could adsorb oil up to 140 times of its own weight. Furthermore, oil recovery and sponge regeneration could be easily carried out through circular distilling or mechanical squeezing.

3. ELECTROSPUN NANOFIBROUS FILTER MEMBRANES FOR OIL-WATER SEPARATION

Filtration is another powerful technology for oil-water separation. Unlike the common filtration process for removing solid particulates, achieving efficient separation of oil/water mixtures, especially for emulsions, is quite difficult due to their complex composition, the tiny droplet size in the dispersed phase, and the ease of secondary emulsification. Nowadays, membrane separation technology with the advantages of high separation efficiency and simple operation is considered one of the most promising approaches for the treatment of oily wastewater and purification of oils. For effective separation of oil/water emulsions, a membrane needs to fulfill three criteria: selective wetting ability for the oil or water; appropriate pore size according to the droplet size of emulsions; and high porosity to ensure an acceptable permeation flux under a certain operational pressure. Recently, electrospun nanofibrous separation membranes have attracted considerable attentions with their thinner fiber diameter, high porosity, high surface area, and ease of use.

4. HYDROPHOBIC-OLEOPHILIC MEMBRANES FOR OIL-WATER SEPARATION

To separate the water contaminant from oil, an effective and simple method is to use a hydrophobic-oleophilic membrane with appropriate pore size to filter the tiny water droplets while allowing the oil to permeate through (oil-removing type). In general, there are two approaches to fabricate a nanofibrous oil-water separation membrane: one-step electrospinning of the hydrophobic-oleophilic polymers, and incorporation of modification processes.

4.1 Instinctive Hydrophobic-Oleophilic Polymeric Membranes

Direct electrospinning of hydrophobic-oleophilic polymers is a simple and effective way to fabricate a filter membrane for oil filtration. As shown in Fig. 13.6, a hydrophobic-superoleophilic membrane was successfully prepared by directly depositing the PS NFs on to a substrate (a stainless steel mesh) via one-step electrospinning. The fabrication process is quite simple, and the raw materials are easy to obtain and inexpensive. With the merits of low free energy of PS and the network-like structures of the membrane, the hydrophobicity of the membranes was significantly enhanced while keeping the intrinsic oleophilic property. As a result, the obtained PS fiber membrane could effectively separate oil/water mixtures in a single step. Other hydrophobic-oleophilic polymers (e.g., PP, PVDF, and PVB) were also directly used to create oil-water separation membranes via one-step electrospinning. For example, a hydrophobic fiber mat made of syndiotactic PP was fabricated for the removing of dispersed water droplets from diesel. Solutions of different weight concentrations of the PP were electrospun to produce submicron-sized fibers of different diameters. These fibrous membranes showed good selective wettability for oil and water, and could effectively remove water from fuel with efficiencies reaching 99%.

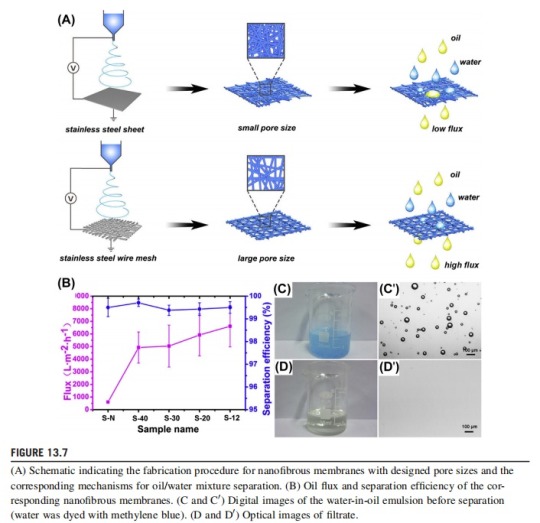

Furthermore, electrospun hydrophobic-oleophilic polyvinyl butyral (PVB) NFs were directly deposited on stainless steel wire meshes with different mesh numbers to obtain nanofibrous membranes with different pore sizes (Fig. 13.7). With synergistic effects of selective wettability and tunable porous structure, the obtained PVB nanofibrous membranes had an impressive capability to separate immiscible oil/water mixtures and stable water-in-oil emulsion. In addition, the oil flux of the separation membrane was greatly improved by controlling the pore size, which was about 10 times that of commercial nonwoven filters.

4.2 Modified Superhydrophobic-Oleophilic Composite Membranes

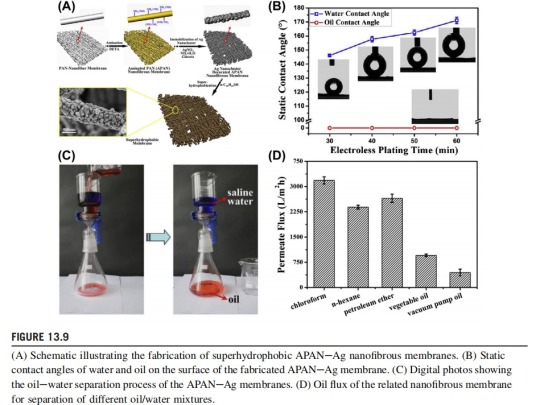

A variety of biomimetic superwettable nanofibrous materials for oil-water separation have been developed based on the synergistic effects of multiscale roughness and low surface energy. According to the principle of the Wenzel and Cassie-Baxter model, the construction of appropriate nano/microscaled roughness can transform a surface from hydrophobic to superhydrophobic, and an oleophilic surface becomes superoleophilic. In general, construction of a multiscale rough surface with low energy requires modifications to the as-spun NFs, including their physical morphology and chemical composition. Based on this theory, a superhydrophobic and superoleophilic nanofibrous membrane was developed using a novel in situ polymerization method to construct a functional layer of silica nanoparticles (SiO2 NPs)/fluorinated polybenzoxazine (F-PBZ) on the surface of electrospun cellulose acetate (CA) NFs (Fig. 13.8A). Benefiting from the low surface energy and excellent oleophilicity of F-PBZ and the hierarchical rough structures, the pristine CA nanofibrous membranes were transformed from instinct hydrophilic to superhydrophobic and superoleophilic, with a water contact angle (WCA) of 161 degrees and oil contact angle (OCA) of 3 degrees. More importantly, the modified nanofibrous membranes were capable of fast, efficient, and stable separation of oil/water mixtures at different pH conditions. Furthermore, the SiO2 NPs/F-PBZ/modified poly(m-phenylene isophthalamide) (PMIA) nanofibrous membrane exhibited promising superhydrophobicity, high thermal stability (350C), and excellent mechanical strength of 40.8 MPa. As a result, the SiO2 NPs/F-PBZ/modified PMIA nanofibrous membranes gave a fast and efficient separation performance for oil/water mixtures. Furthermore, a core/shell structured polyimide/cellulose acetate electrospun fibrous membrane was fabricated by electrospinning and then modified by SiO2 NPs and F-PBZ; the obtained membranes showed much higher critical tensile stress (130 MPa) and superhydrophobic-superoleophilic wettability, and could effectively separate various oil/water mixtures solely driven by gravity, with high flux (3106.2 100 L/m2 h) and high separation efficiency (>99%). As shown in Fig. 13.8B, ceramic nanofibrous membranes, such as the F-PBZ/Aluminium oxide nanoparticles (Al2O3 NPs) modified SiO2 nanofibrous membranes, were also fabricated by the in situ polymerization method, and the obtained membranes gave effective gravity-driven separation performance for water-in-oil emulsions with a relative high flux of 892 L/m2 h, and had good antifouling property, thermal stability, and durability. Apart from in situ polymerization of F-PBZ, other chemicals (e.g., Nafion, beeswax, and n-hexadecyl mercaptan) have successfully been employed to create superhydrophobic and superoleophilic nanofibrous membranes for effective oil-water separation. As shown in Fig. 13.9, a uniform and hierarchical rough layer can be constructed on the surface of single electrospun NF via a simple combination of the amination of PAN NFs (APAN) and immobilization of Ag nanoclusters on the surface of fibers (APAN-Ag) using an electroless plating technique. This APAN-Ag nanofibrous membrane was modified with alkyl thiols: the modified nanofibrous membrane was superhydrophobic and superoleophilic, and had an excellent capability for oil-water separation in a hypersaline environment and a broad range of pH conditions.

5. HYDROPHILIC-OLEOPHOBIC MEMBRANES FOR OIL-WATER SEPARATION

Membrane separation is the most promising technology to treat oily wastewater, and ultrafiltration and nanofiltration membranes have been used in many industrial oil-water separation processes. Conventional ultrafiltration and nanofiltration membranes have fairly high separation efficiency for oil/water emulsions, but suffer from low flux, which is attributed to their limited permeability and serious surface fouling. To overcome these problems two aspects should be considered: constructing a hydrophilic surface to avoid oil fouling of the membranes, and increasing the porosity and decreasing the thickness of the separation layer.

5.1 Single-Layer Superhydrophilic-Oleophobic Nanofibrous Membranes

Inspired by the oil-repellent abilities of creatures in nature (such as fish scales), a superhydrophilic and underwater superoleophobic surface could be constructed by combining a hydrophilic chemical surface and appropriate roughness into polylactide NFs using the blending electrospinning method. The obtained composite nanofibrous membrane had good hydrophilicity and high water permeability, endowing it with the superior separation performance of oil-in-water emulsion under gravity. Besides blending electrospinning, dip coating is also an effect approach to modify nanofibrous membranes. Ahmed et al. employed cellulose regenerated from its ionic liquid solution to coat electrospun PVDF-co-hexafluoropropylene (PVDF-HFP). After modification with cellulose, the membrane had smaller pores with narrower pore size distribution: it exhibited superhydrophilicity and underwater superoleophobicity, and was successfully used for oil-water separation with quite high efficiency. Recently, a composite membrane made from graphene oxide coating aminated polyacrylonitrile (GO/APAN) fibers was fabricated by controlled assembly of GO sheets on the surface of electrospun APAN fibers and in the gaps between fibers. This membrane was superhydrophilic, had low oil adhesion, and exhibited ultrahigh flux, a preferable rejection ratio, and remarkable antifouling performance for the separation of oil/water emulsions. Furthermore, as shown in Fig. 13.10, a PAN/GO composite fibrous membrane with spindle-knot structured NFs was fabricated by electrospinning and then hydrolyzed (H-PAN/GO) to tailor its chemical features. With the combination of chemical features of hydrolyzed PAN and a spindle-knotted structure, the antifouling performance of the composite membrane was enhanced and it performed well in separating oil/water emulsions.

Compared to polymers, ceramic nanofibrous membranes have potential advantages in terms of relatively high surface energy, relatively stable chemical properties, and good antifouling ability. As shown in Fig. 13.11, Yang et al. used electrospun SiO2 NFs (SNFs) as the template, and anchored the SiO2 NPs uniformly on the surface of SNFs through a novel in situ synthesis method to fabricate flexible, thermally stable, and hierarchically porous structured composite membranes with highly selective wettability of superhydrophilicity and underwater superoleophobicity. With prominent selective wettability and high porosity, the obtained SiO2 NP/SNF composite membranes exhibited an extremely high separation flux up to 2237 L/m2h and high separation efficiency for a surfactantstabilized oil-in-water emulsion. In further studies, NiFe2O4 NPs were incorporated in SNFs to fabricate hierarchical magnetic nanofibrous membranes: these membranes were able to separate surfactant-stabilized oil-in-water emulsions effectively in a relatively high separation flux.

5.2 Multilayer Structured Superhydrophilic-Oleophobic Nanofibrous Membranes

Constructing a separation layer with high selective wettability and small pore size on the surface of electrospun nanofibrous membranes is an effective way to enhance oil-water separation efficiency. Various composite nanofibrous membranes have been developed for high flux and high efficiency separation of oil-in-water emulsions. The main idea is to deposit a very thin hydrophilic polymeric layer of poly(vinylalcohol) (PVA), chitosan, polyamide, or even ultrafine polysaccharide NFs on to electrospun nanofibrous membranes via physical absorption or interfacial polymerization. As shown in Fig. 13.12, a double-layer separation membrane was fabricated by depositing the PVA NFs on electrospun PAN nanofibrous membranes, and then remelting and cross-linking the PVA nanofibrous layer to construct a nonporous PVA film with a thickness of several micrometers. Using this hydrophilic PVA layer, the composite membrane could effectively separate oil-in-water emulsions with excellent antifouling properties. In general, when a microporous or nonporous coating layer is constructed on the surface of a nanofibrous membrane, the water-permeate flux of the obtained composite membrane will be significantly reduced, which is attributed to the hydraulic resistance of the coating layer. To address this problem, Raza et al. fabricated superhydrophilic and oleophobic nanofibrous membranes by incorporating a composite layer of polyethylene glycol (PEG) diacrylate NFs on PAN/PEG nanofibrous membranes (x-PEGDA@PG NF) using the in situ cross-linked method. The obtained x-PEGDA@PG NF membranes could be completely wetted by water within a very short time and the superhydrophilic layer could trap a layer of water on the surface of membrane; this blocked the contact of oil with the membrane, thus making the membrane oleophobic. Benefiting from the high selective wettability and high porous structures, the membranes were capable of effectively separating immiscible oil/water mixtures and oil-in-water emulsions with high capacity and robust antifouling property. Most recently, a novel superhydrophilic and underwater superoleophobic nanofibrous membrane with a hierarchical structured skin for the separation of oil-in-water emulsions was prepared via electrospinning and electrospraying methods. Unlike the conventional nonporous polymeric film or submicro fibrous layer, the hierarchical structured SiO2/PAN microspheres bonded with monofilament significantly enhanced the wetting selectivity and antifouling properties of the composite membranes. With the combination of a superwettable hierarchical structured skin layer and a high-porosity nanofibrous substrate, the membranes performed well in separating microscaled oil-in-water emulsions solely under the driving force of gravity with excellent separation efficiency and high fluxes.

#separate#oil#water#electrospinning#nanofiber#technology#composite#polymeric#nanofibrous#mats#carbonbased#porous#electrospun#filter#membranes#oilwater#separation#hydrophobicoleophilic#instinctive#modified#superhydrophobicoleophilic#hydrophilicoleophobic#singlelayer#superhydrophilicoleophobic#multilayer#structured

1 note

·

View note

Text

What Are Core–Shell Nanoparticles? Uses, Benefits & Why They’re Transforming Modern Materials

1. Welcome to the Core–Shell Revolution

Imagine materials so small they're invisible to the naked eye—yet powerful enough to revolutionize everything from clean energy to medical diagnostics. These are core–shell nanoparticles, and they’re quietly powering the next wave of innovation across industries.

At Nanochemazone, we work with a wide range of advanced nanomaterials like PTFE Suspension Resin Powder, Graphene Oxide Powder, and Calcium Carbonate (CaCO₃) Nanoparticles—all of which play a role in composite and hybrid structures like core–shells. In this post, we’ll unpack what core–shell nanoparticles are, how they’re made, where they’re used, and why they’re becoming essential to everything from electronics to biotech.

2. What Are Core–Shell Nanoparticles?

At their core (literally), these nanoparticles are a two-part system: a central core made of one material (metal, ceramic, or polymer), surrounded by a protective or functional shell made of another.

This core–shell structure provides several advantages compared to traditional single-material nanoparticles, including enhanced stability, improved functionality, and the ability to fine-tune surface properties for targeted applications. The shell can enhance properties such as stability, functionality, or reactivity—without changing the identity of the core.

At Nanochemazone, we offer several high-purity, lab-ready core–shell combinations including:

Gold–Palladium (Au/Pd) – for catalysis and biomedical uses

Aluminium/Silica (Al/SiO₂) – for thermal insulation and composite materials

Lanthanum Fluoride doped with Europium (LaF₃/Eu) – for medical imaging and fluorescence applications

3. How Are They Made?

Though they may sound complex, core–shell nanoparticles are synthesized through well-established processes such as:

Sol–gel techniques

Microemulsion synthesis

Chemical precipitation

Each method allows control over particle size, composition, and core-to-shell ratio. For example, with products like Graphene Nanoplatelets Powder or PTFE Suspension Resin Powder, we can fine-tune the shell thickness or disperse them in resins or solvents for enhanced compatibility.

4. Real-World Uses & Applications

4.1 Catalysis & Chemical Industry

Core–shell nanoparticles like Gold–Palladium (Au/Pd) and Gold–Platinum are prized for their high catalytic activity. They’re widely used in:

Catalytic converters

Green hydrogen production

Organic synthesis

Powders such as Calcium Oxide Nanoparticles and Barium Sulfate Nanoparticles are also used in tandem with core–shell structures to enhance catalytic surface area and reusability.

4.2 Electronics & Conductive Inks

In modern electronics, core–shells enable better conductivity, durability, and miniaturization. CdSe/ZnS core–shells are widely utilized in quantum dots and sensor technologies.

Materials like Graphene Powder (Industrial Grade), Reduced Graphene Oxide Powder, Polyetheretherketone (PEEK), and Polyamide 66 (PA66) are frequently embedded in circuits, inks, or casings to boost strength and conductivity.

4.3 Medicine, Biotech & Imaging

Thanks to their biocompatibility and controlled surface properties, core–shells such as Au/Pd and LaF₃/Eu are increasingly used in:

Bioimaging and diagnostics

Drug delivery systems

Photodynamic therapy

Other materials like Cellulose Nanofiber Powder and Calcium Carbonate Nanoparticles are used to develop bioresorbable carriers or as drug-loading matrices.

4.4 Coatings, Composites & Advanced Materials

For engineers, PTFE Suspension Resin Powder and Carbon Fiber Powder are go-to choices for high-performance coatings and composites.

Core–shells incorporated into polymers like PVC, PET, POM, and PS—along with fillers like CaCO₃ or BaSO₄—create materials with superior strength, thermal resistance, and surface finish.

5. Top Benefits of Core–Shell Structures

✅ Tunable Properties – Adjust thermal, optical, and catalytic behavior without changing the core material ✅ Improved Stability – Shells protect against oxidation, moisture, and chemical degradation ✅ Cost Efficiency – Use expensive materials (e.g., palladium) only on the shell, reducing overall material cost ✅ Hybrid Functionality – Combine magnetic + fluorescent or conductive + barrier features in one particle

6. Emerging Trends & Future Potentials

The future of core–shell nanotechnology lies in multifunctional hybrid structures:

Nanowires, MXenes, and graphdiyne are rapidly emerging as promising materials in electronics and energy storage.

Researchers are exploring ZnO–TiO₂ and ZnO–MgO core–shells for dye-sensitized solar cells.

Sustainability is driving demand for green nanomaterials, including biodegradable or plant-based nanoparticle systems.

7. Nanochemazone’s Edge: Why Partner With Us

At Nanochemazone, we offer:

ISO and GMP-certified nanomaterials for industrial and research-grade use

A wide selection of powders and dispersions: PTFE, Graphene Oxide, CaCO₃, BaSO₄, CaO, Cellulose Nanofiber

Global shipping, 24/7 support, and custom synthesis services

Every product is customizable by purity, particle size, solvent type, and more—so you always get exactly what you need.

8. Practical Tips: Choosing the Right Core–Shell

🧪 Match by function:

Catalysis → Au/Pd

Imaging → LaF₃/Eu

Electronics → CdSe/ZnS

📏 Choose the right size: Most core–shell particles are 50–100 nm, but we can scale up/down to your requirements.

🧴 Decide on the form: Choose between dry powder or liquid dispersion depending on your process.

9. FAQ Section

Q: What’s the difference between PTFE Suspension Resin Powder and Graphene Oxide Powder? A: PTFE offers non-stick, thermal resistance ideal for coatings. Graphene Oxide brings conductivity and flexibility, great for electronics or inks.

Q: How do I store core–shell nanoparticles safely? A: Store in airtight containers at room temperature, away from light and moisture. Store dispersions in the refrigerator and shake well before use.

Q: Are core–shells scalable for mass production? A: Absolutely. Our synthesis processes are scalable from grams to kilos while maintaining particle integrity.

Q: Can they be used with polymers like PET, PA66, or PEEK? A: Yes—core–shells are often blended into thermoplastics for high-strength, functional composites.

10. Conclusion

Core–shell nanoparticles aren’t just lab curiosities—they’re real-world game changers. Whether you're creating next-gen electronics, developing smart drug delivery systems, or formulating high-performance coatings, these engineered nanomaterials are unlocking new frontiers.

👉 Explore Nanochemazone’s full catalog today, or contact us for a custom quote tailored to your formulation needs. We’re here to help you innovate—one nanoparticle at a time.

#Core–Shell Nanoparticles#Nanoparticle Applications#Advanced Nanomaterials#Nanomaterial Powder Suppliers#Core–Shell Nanoparticle Uses#Graphene Oxide Nanoparticles#PTFE Suspension Resin Powder#Calcium Carbonate Nanoparticles#Bulk nanomaterials delivery#Nanoparticles Supplier#High Purity Nanopowders#Metal Oxide Nanopowders#Laboratory Grade Nanomaterials#Custom Nanomaterial Synthesis#Carbon Nanotubes Bulk#Graphene Nanoplatelets#Buy MXene Online

1 note

·

View note

Text

New results to help fine-tune catalytic properties of bimetallic nanoparticles

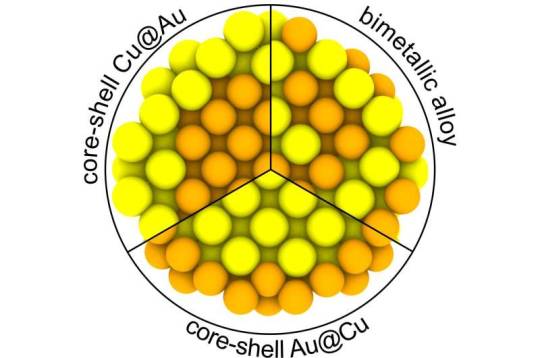

Nanoparticles range in size from 1 to 100 nanometers, and compared with usual particles, they are known to have unique features that are increasingly used for diagnosing cancer, developing small electronic devices and solar batteries, as well as in many other spheres. In their new paper published in Physical Review B, researchers from Skoltech revealed that catalytic properties of bimetallic nanoparticles—when a material accelerates or delays a chemical reaction without being consumed by the reaction—can be fine-tuned while changing the structure of the nanoparticle. As of now, of greatest interest are bimetallic core-shell particles, in which the core and the shell consist of different metals. Researchers studied three types of nanoparticles: Cu-core/Au-shell, Au-core/Cu-shell, and homogeneous bimetallic AuCu alloy particles. Unlike core-shell particles, the structure of usual bimetallic particles is not ordered.

Read more.

#Materials Science#Science#Nanoparticles#Nanotechnology#Catalysts#Gold#Copper#Skoltech#Core shell structures

12 notes

·

View notes

Text

Toenail Fungus Natural Remedies

Yeast cells have a protective shell made up of a number of layers. This powerful outer shell known as a biofilm and it’s what makes yeast powerful to kill. Once this protecting biofilm is stripped off, the yeast is no longer protected against immune cells and other useful micro organism. Redness and swelling are the first signs of a yeast infection, but a dog’s symptoms can progress to swelling, warmth, and pain in the infected space. The best approach to knock out pneumonia or bronchitis fast is to breathe in colloidal silver into the lungs.

I continued for about 5 weeks and the sore has completely healed with no signal of any scar. My husband has just left hospital with serious pneumonia, and was struggling to recuperate correctly. Since ingesting your colloidal silver, he has turn out to be a lot stronger and his recovery has been outstanding. I recommend colloidal silver for everybody with a critical illness. I even have had Athlete’s Foot for sixteen years and have tried nearly every powder and cream out there in the marketplace with limited success.

An inflammatory type of the illness, generally identified as kerion, results from infection by zoophillic organisms corresponding to Trichophyton verrucosum or Trichophyton mentagrophytes. Favus is a very severe form of kerion, normally attributable to T. Dermoscopic findings in tinea capitis embody comma-shaped hairs with black dots. Huang Lian Su Tablets to forestall colloidal silver for fungal infection vacationers from diarrheaIf you've a pure drugs in your journey apothecary that works for you when traveling? Eating foods which are excessive in pure digestive enzymes can tremendously enhance digestion. These digestive superfoods are pineapples, papaya, mangos, bananas, sauerkraut, avocados, honey, kefir, kimchi, miso, kiwis, and the powerhouse, almighty ginger.

Like many pure therapies, we are seeing a much-welcomed resurgence in using silver, not just within the integrative community however in the mainstream as nicely. This blog has not been permitted by your local health division and is not supposed to provide analysis, remedy, or medical recommendation. The content material provided on this weblog is for informational purposes solely.

My name is Ken Roth and that is a part of my story as a 7 year head and neck most cancers individual. My cancer treatment involved base of tongue surgical procedure, radiation and chemo. I have been training utilizing this system for the last 5 years and felt I ought to share with others what labored for me to resolve the issue of thrush that fashionable medicines could not.

While employed at UCLA Medical School in the Eighties, Larry C. Ford, MD, documented over 650 different disease-causing pathogens that were destroyed in minutes when uncovered to small quantities of silver. 10) There has been some success utilizing colloidal silver with AIDS sufferers. It provides a layer of wanted additional immunity while destroying current pathogens. 8) It may be taken early with the onset of a chilly, flu, or bronchitis to recover from it rapidly without harming helpful micro organism. 4) Small quantities taken every day as a tonic will give what some name a second immune system to guard towards flues and colds. Easy and cheap if you make should you make your personal.

The color of the reaction resolution changed to darkish reddish brown. Formation of the color arises because of the excitation of surface plasmon vibrations the place the metabolites within the algal extract act because the capping agent. The color of the solution gradually intensified on heating which clearly signifies and confirms the formation of silver nanoparticles.

Add three drops of Echinacea Anti Cold and Core Phyto Lavage to the answer. Use this to carry out the nasal wash as directed by the Neti Pot directions on the bottle. With antiviral and immune modulating effects, including licorice, skullcap, dandelion, and rosemary. Sweet wormwood this has been utilized in conventional drugs for some colloidal silver for athlete foot time and has been employed in medicines to deal with malaria. There are some indications that the plant can also be used to treat some coronavirus signs, notably the SARS related coronavirus. Also generally known as dandelion, this can be used as an anti-inflammatory complement.

At the same time, there are many well-known health sites or regulatory bodies that warn about safety issues . Colloidal silver may be great for treating ear infections. The liquid can be dropped instantly into the ears (3-4 drops into each contaminated ear) to help struggle off micro organism and yeast whereas being fed orally as well. Even worse, antibiotics won’t kill fungal infections, which are left to multiply. Furthermore, antibiotics are taken systemically, which suggests they course throughout the complete body even when they're only needed within the sinuses.

Spores of that fungal organism have been recovered from avian excreta, soil, and mud. The “deep” mycoses are secondary cutaneous manifestations of fungal infections of the viscera. Many but colloidal silver for athlete's foot not all use the lungs as the portal of entry.

0 notes

Text

100-48-1 In situ immobilized palladium nanoparticles on surface of poly-methyldopa coated-magnetic nanoparticles (Fe<sub>3</sub>O<sub>4</sub>@PMDA/Pd): A magnetically recyclable nanocatalyst for cyanation of aryl halides with K<sub>4</sub>[Fe(CN)<sub>6</sub>]

Poly-methyldopa (PMDP)-coated Fe<sub>3</sub>O<sub>4</sub> nanoparticles (Fe<sub>3</sub>O<sub>4</sub>@PMDP) have been synthesized through a simple and green procedure. In the present study, for the first time, Pd nanoparticles were successfully deposited using Fe<sub>3</sub>O<sub>4</sub>@PMDP as a core-shell magnetic coordinator and stabilizer agent. In this protocol, Pd ions were adsorbed on surfaces of Fe<sub>3</sub>O<sub>4</sub>@PMDP through immersion of the PMDP-coated Fe<sub>3</sub>O<sub>4</sub> nanoparticles into a palladium plating bath. Next, they were reduced in situ to palladium nanoparticles using PMDP's N-containing groups and reducing ability. The structure, morphology and physicochemical properties of the synthesized nanoparticles were characterized by different analytical techniques such as energy-dispersive X-ray spectroscopy (EDS), field emission scanning electron microscope (FESEM), Fourier-transform infrared spectroscopy (FT-IR) spectroscopy, high resolution transmission electron microscopy (HR-TEM), inductively coupled plasma (ICP), thermo gravimetric analysis (TGA), vibrating sample magnetometer (VSM), and X-ray photoelectron spectroscopy (XPS). Core-shell Fe<sub>3</sub>O<sub>4</sub>@PMDP/Pd(0) nanoparticles showed excellent catalytic performance as a reusable nanocatalyst for cyanation of aryl iodides and bromides with K<sub>4</sub>[Fe(CN)<sub>6</sub>] as the cyanating agent. The nitriles were obtained in good to excellent yield and the catalyst can be recycled and reapplied up to seven times with only very slight decrease in its catalytic performance.

0 notes

Link

How To Separate Oil From Water By Electrospinning Nanofiber Technology?

1. COMPOSITE POLYMERIC NANOFIBROUS MATS

Due to the relatively weak mechanical strength of PS fibers and the unstable networks of the mats, the practical application performance (e.g., retention over time, oil recovery rate) of pure electrospun PS fibrous absorbents was seriously limited. To overcome this challenging problem, mechanical enhancers with high strength were introduced into the PS fibrous mats to improve their mechanical property. Various criteria must be fulfilled by the reinforcing components: they should be mechanically robust to withstand the tensile or compressive stresses during adsorption and recovery processes of sorbents; and hydrophobic-oleophilic wettability is required to ensure the mats have selective wetting ability. Accordingly, a series of additives such as polyvinyl chloride (PVC), polyurethane (PU), polyvinylidene fluoride (PVDF), and carbon nanotubes (CNTs) were employed to modify the PS fibers via different methods based on electrospinning technology.

To incorporate the reinforcing component into PS fibrous mats, various approaches involving blend electrospinning, multinozzle electrospinning, and coaxial electrospinning have been developed. As shown in Fig. 13.4A-C, PVC/PS composite fibers was first fabricated via directly adding an appropriate amount of PVC to PS solutions, and then made by blend electrospinning. The obtained oil absorbents performed well for motor oil, peanut oil, diesel, and ethylene glycol, with high sorption capacities of 146, 119, 38, and 81 g/g, respectively; these capacities are about five to nine times that of commercial PP melt-blown nonwoven sorbent. The PVC/PS oil adsorbent also possessed excellent oil-water selectivity and good buoyancy, which are important in oil-slick cleanup. Multinozzle electrospinning, a powerful technology in fabricating composite nanofibrous materials, has also been used to make porous PU/PS fibrous mats for oil absorption (Fig. 13.4D-F). The robust elasticity of the PU fibers greatly improves the mechanical strength of the obtained PU/PS fibrous mats, even with low PU contents. As a result the oil absorption performance, especially the reusability of the PU/PS fibrous absorbents, was significantly enhanced. Moreover, core-shell structured fibers were considered as an effective approach to enhance the mechanical property of single fibers. The SEM and the corresponding Transmission Electron Microscopy (TEM) images shown in Fig. 13.4G show that the core-shell structured PU-PS fibers have been prepared with a coaxial electrospinning technique by taking PU and PS solutions as the core and shell, respectively. The obtained PU-PS fibrous sorbent has sorption capacities of 64.40 and 47.48 g/g for motor oil and sunflower seed oil, respectively, which are two to three times that of traditional nonwoven PP fibrous mats with the same template oils (Fig. 13.4H and I). Moreover, the oil adsorption capacity comparable with melt-blown nonwoven sorbent was maintained even after five sorption cycles, giving excellent reusability.

1. CARBON-BASED POROUS NANOFIBROUS MATS

Carbon-based materials have been widely developed to absorb oils due to their instinctive hydrophobic-oleophilic wettability, excellent chemical stability, and thermal stability; this avoids several limitations of organic absorbents, which can be swollen or even dissolved when recycled by rinsing with organic solvents. Recently, electrospun macroporous carbon nanofibrous mats were fabricated through a sublimation method (Fig. 13.5), with terephthalic acid (PTA) used as the pore former to create macropores. During the carbonization of the PTA/polyacrylonitrile (PAN) composite NFs, PTA was sublimed and the macropores were formed, producing flexible and self-sustained macroporous carbon nanofibrous mats. These mats possessed special superhydrophobic and superoleophilic wettability, as well as relatively large porosity of up to 89.2%, attributed to the porous structure of the electrospun fibrous mats. The carbon-based membrane shown a high silicone oil sorption quantity of up to 138.4 g/g, and the absorbed silicone oil could be removed from the membrane by using organic solvents, exhibiting excellent recyclability. Furthermore, a spongelike carbonesilica nanofibrous absorbent with an interconnected three-dimensional structure was also synthesized using the electrospinning technique. The resulting composite fibrous sponge possessed a high porosity of more than 99% and displayed the specific wettability of ultrahydrophobicity and superoleophilicity. With its integral properties of high porosity, low density, and selective wettability, the sponge could adsorb oil up to 140 times of its own weight. Furthermore, oil recovery and sponge regeneration could be easily carried out through circular distilling or mechanical squeezing.

2. ELECTROSPUN NANOFIBROUS FILTER MEMBRANES FOR OIL-WATER SEPARATION

Filtration is another powerful technology for oil-water separation. Unlike the common filtration process for removing solid particulates, achieving efficient separation of oil/water mixtures, especially for emulsions, is quite difficult due to their complex composition, the tiny droplet size in the dispersed phase, and the ease of secondary emulsification. Nowadays, membrane separation technology with the advantages of high separation efficiency and simple operation is considered one of the most promising approaches for the treatment of oily wastewater and purification of oils. For effective separation of oil/water emulsions, a membrane needs to fulfill three criteria: selective wetting ability for the oil or water; appropriate pore size according to the droplet size of emulsions; and high porosity to ensure an acceptable permeation flux under a certain operational pressure. Recently, electrospun nanofibrous separation membranes have attracted considerable attentions with their thinner fiber diameter, high porosity, high surface area, and ease of use.

3. HYDROPHOBIC-OLEOPHILIC MEMBRANES FOR OIL-WATER SEPARATION

To separate the water contaminant from oil, an effective and simple method is to use a hydrophobic-oleophilic membrane with appropriate pore size to filter the tiny water droplets while allowing the oil to permeate through (oil-removing type). In general, there are two approaches to fabricate a nanofibrous oil-water separation membrane: one-step electrospinning of the hydrophobic-oleophilic polymers, and incorporation of modification processes.

4.1 Instinctive Hydrophobic-Oleophilic Polymeric Membranes

Direct electrospinning of hydrophobic-oleophilic polymers is a simple and effective way to fabricate a filter membrane for oil filtration. As shown in Fig. 13.6, a hydrophobic-superoleophilic membrane was successfully prepared by directly depositing the PS NFs on to a substrate (a stainless steel mesh) via one-step electrospinning. The fabrication process is quite simple, and the raw materials are easy to obtain and inexpensive. With the merits of low free energy of PS and the network-like structures of the membrane, the hydrophobicity of the membranes was significantly enhanced while keeping the intrinsic oleophilic property. As a result, the obtained PS fiber membrane could effectively separate oil/water mixtures in a single step. Other hydrophobic-oleophilic polymers (e.g., PP, PVDF, and PVB) were also directly used to create oil-water separation membranes via one-step electrospinning. For example, a hydrophobic fiber mat made of syndiotactic PP was fabricated for the removing of dispersed water droplets from diesel. Solutions of different weight concentrations of the PP were electrospun to produce submicron-sized fibers of different diameters. These fibrous membranes showed good selective wettability for oil and water, and could effectively remove water from fuel with efficiencies reaching 99%.

Furthermore, electrospun hydrophobic-oleophilic polyvinyl butyral (PVB) NFs were directly deposited on stainless steel wire meshes with different mesh numbers to obtain nanofibrous membranes with different pore sizes (Fig. 13.7). With synergistic effects of selective wettability and tunable porous structure, the obtained PVB nanofibrous membranes had an impressive capability to separate immiscible oil/water mixtures and stable water-in-oil emulsion. In addition, the oil flux of the separation membrane was greatly improved by controlling the pore size, which was about 10 times that of commercial nonwoven filters.

4.2 Modified Superhydrophobic-Oleophilic Composite Membranes

A variety of biomimetic superwettable nanofibrous materials for oil-water separation have been developed based on the synergistic effects of multiscale roughness and low surface energy. According to the principle of the Wenzel and Cassie-Baxter model, the construction of appropriate nano/microscaled roughness can transform a surface from hydrophobic to superhydrophobic, and an oleophilic surface becomes superoleophilic. In general, construction of a multiscale rough surface with low energy requires modifications to the as-spun NFs, including their physical morphology and chemical composition. Based on this theory, a superhydrophobic and superoleophilic nanofibrous membrane was developed using a novel in situ polymerization method to construct a functional layer of silica nanoparticles (SiO2 NPs)/fluorinated polybenzoxazine (F-PBZ) on the surface of electrospun cellulose acetate (CA) NFs (Fig. 13.8A). Benefiting from the low surface energy and excellent oleophilicity of F-PBZ and the hierarchical rough structures, the pristine CA nanofibrous membranes were transformed from instinct hydrophilic to superhydrophobic and superoleophilic, with a water contact angle (WCA) of 161 degrees and oil contact angle (OCA) of 3 degrees. More importantly, the modified nanofibrous membranes were capable of fast, efficient, and stable separation of oil/water mixtures at different pH conditions. Furthermore, the SiO2 NPs/F-PBZ/modified poly(m-phenylene isophthalamide) (PMIA) nanofibrous membrane exhibited promising superhydrophobicity, high thermal stability (350C), and excellent mechanical strength of 40.8 MPa. As a result, the SiO2 NPs/F-PBZ/modified PMIA nanofibrous membranes gave a fast and efficient separation performance for oil/water mixtures. Furthermore, a core/shell structured polyimide/cellulose acetate electrospun fibrous membrane was fabricated by electrospinning and then modified by SiO2 NPs and F-PBZ; the obtained membranes showed much higher critical tensile stress (130 MPa) and superhydrophobic-superoleophilic wettability, and could effectively separate various oil/water mixtures solely driven by gravity, with high flux (3106.2 100 L/m2 h) and high separation efficiency (>99%). As shown in Fig. 13.8B, ceramic nanofibrous membranes, such as the F-PBZ/Aluminium oxide nanoparticles (Al2O3 NPs) modified SiO2 nanofibrous membranes, were also fabricated by the in situ polymerization method, and the obtained membranes gave effective gravity-driven separation performance for water-in-oil emulsions with a relative high flux of 892 L/m2 h, and had good antifouling property, thermal stability, and durability. Apart from in situ polymerization of F-PBZ, other chemicals (e.g., Nafion, beeswax, and n-hexadecyl mercaptan) have successfully been employed to create superhydrophobic and superoleophilic nanofibrous membranes for effective oil-water separation. As shown in Fig. 13.9, a uniform and hierarchical rough layer can be constructed on the surface of single electrospun NF via a simple combination of the amination of PAN NFs (APAN) and immobilization of Ag nanoclusters on the surface of fibers (APAN-Ag) using an electroless plating technique. This APAN-Ag nanofibrous membrane was modified with alkyl thiols: the modified nanofibrous membrane was superhydrophobic and superoleophilic, and had an excellent capability for oil-water separation in a hypersaline environment and a broad range of pH conditions.

4. HYDROPHILIC-OLEOPHOBIC MEMBRANES FOR OIL-WATER SEPARATION

Membrane separation is the most promising technology to treat oily wastewater, and ultrafiltration and nanofiltration membranes have been used in many industrial oil-water separation processes. Conventional ultrafiltration and nanofiltration membranes have fairly high separation efficiency for oil/water emulsions, but suffer from low flux, which is attributed to their limited permeability and serious surface fouling. To overcome these problems two aspects should be considered: constructing a hydrophilic surface to avoid oil fouling of the membranes, and increasing the porosity and decreasing the thickness of the separation layer.

4.1 Single-Layer Superhydrophilic-Oleophobic Nanofibrous Membranes

Inspired by the oil-repellent abilities of creatures in nature (such as fish scales), a superhydrophilic and underwater superoleophobic surface could be constructed by combining a hydrophilic chemical surface and appropriate roughness into polylactide NFs using the blending electrospinning method. The obtained composite nanofibrous membrane had good hydrophilicity and high water permeability, endowing it with the superior separation performance of oil-in-water emulsion under gravity. Besides blending electrospinning, dip coating is also an effect approach to modify nanofibrous membranes. Ahmed et al. employed cellulose regenerated from its ionic liquid solution to coat electrospun PVDF-co-hexafluoropropylene (PVDF-HFP). After modification with cellulose, the membrane had smaller pores with narrower pore size distribution: it exhibited superhydrophilicity and underwater superoleophobicity, and was successfully used for oil-water separation with quite high efficiency. Recently, a composite membrane made from graphene oxide coating aminated polyacrylonitrile (GO/APAN) fibers was fabricated by controlled assembly of GO sheets on the surface of electrospun APAN fibers and in the gaps between fibers. This membrane was superhydrophilic, had low oil adhesion, and exhibited ultrahigh flux, a preferable rejection ratio, and remarkable antifouling performance for the separation of oil/water emulsions. Furthermore, as shown in Fig. 13.10, a PAN/GO composite fibrous membrane with spindle-knot structured NFs was fabricated by electrospinning and then hydrolyzed (H-PAN/GO) to tailor its chemical features. With the combination of chemical features of hydrolyzed PAN and a spindle-knotted structure, the antifouling performance of the composite membrane was enhanced and it performed well in separating oil/water emulsions.

Compared to polymers, ceramic nanofibrous membranes have potential advantages in terms of relatively high surface energy, relatively stable chemical properties, and good antifouling ability. As shown in Fig. 13.11, Yang et al. used electrospun SiO2 NFs (SNFs) as the template, and anchored the SiO2 NPs uniformly on the surface of SNFs through a novel in situ synthesis method to fabricate flexible, thermally stable, and hierarchically porous structured composite membranes with highly selective wettability of superhydrophilicity and underwater superoleophobicity. With prominent selective wettability and high porosity, the obtained SiO2 NP/SNF composite membranes exhibited an extremely high separation flux up to 2237 L/m2h and high separation efficiency for a surfactantstabilized oil-in-water emulsion. In further studies, NiFe2O4 NPs were incorporated in SNFs to fabricate hierarchical magnetic nanofibrous membranes: these membranes were able to separate surfactant-stabilized oil-in-water emulsions effectively in a relatively high separation flux.

4.2 Multilayer Structured Superhydrophilic-Oleophobic Nanofibrous Membranes

Constructing a separation layer with high selective wettability and small pore size on the surface of electrospun nanofibrous membranes is an effective way to enhance oil-water separation efficiency. Various composite nanofibrous membranes have been developed for high flux and high efficiency separation of oil-in-water emulsions. The main idea is to deposit a very thin hydrophilic polymeric layer of poly(vinylalcohol) (PVA), chitosan, polyamide, or even ultrafine polysaccharide NFs on to electrospun nanofibrous membranes via physical absorption or interfacial polymerization. As shown in Fig. 13.12, a double-layer separation membrane was fabricated by depositing the PVA NFs on electrospun PAN nanofibrous membranes, and then remelting and cross-linking the PVA nanofibrous layer to construct a nonporous PVA film with a thickness of several micrometers. Using this hydrophilic PVA layer, the composite membrane could effectively separate oil-in-water emulsions with excellent antifouling properties. In general, when a microporous or nonporous coating layer is constructed on the surface of a nanofibrous membrane, the water-permeate flux of the obtained composite membrane will be significantly reduced, which is attributed to the hydraulic resistance of the coating layer. To address this problem, Raza et al. fabricated superhydrophilic and oleophobic nanofibrous membranes by incorporating a composite layer of polyethylene glycol (PEG) diacrylate NFs on PAN/PEG nanofibrous membranes (x-PEGDA@PG NF) using the in situ cross-linked method. The obtained x-PEGDA@PG NF membranes could be completely wetted by water within a very short time and the superhydrophilic layer could trap a layer of water on the surface of membrane; this blocked the contact of oil with the membrane, thus making the membrane oleophobic. Benefiting from the high selective wettability and high porous structures, the membranes were capable of effectively separating immiscible oil/water mixtures and oil-in-water emulsions with high capacity and robust antifouling property. Most recently, a novel superhydrophilic and underwater superoleophobic nanofibrous membrane with a hierarchical structured skin for the separation of oil-in-water emulsions was prepared via electrospinning and electrospraying methods. Unlike the conventional nonporous polymeric film or submicro fibrous layer, the hierarchical structured SiO2/PAN microspheres bonded with monofilament significantly enhanced the wetting selectivity and antifouling properties of the composite membranes. With the combination of a superwettable hierarchical structured skin layer and a high-porosity nanofibrous substrate, the membranes performed well in separating microscaled oil-in-water emulsions solely under the driving force of gravity with excellent separation efficiency and high fluxes.

��_��m��|

#separate#oil#water#electrospinning#nanofiber#technology#composite#polymeric#nanofibrous#mats#carbonbased#porous#electrospun#filter#membranes#oilwater#separation#hydrophobicoleophilic#instinctive#modified#superhydrophobicoleophilic#hydrophilicoleophobic#singlelayer#superhydrophilicoleophobic#multilayer#structured

1 note

·

View note

Text

Science and Chemistry Classes

Seeing below the surface of bimetallic nanoparticles