#Nano Additive Manufacturing

Explore tagged Tumblr posts

Text

High-Purity Nanomaterials & Graphene Nanoplatelets Powder Supplier

Nanochemazone is a global leader in advanced nanomaterials, offering high-purity Graphene Nanoplatelets Powder, MXenes, metal oxides, and custom nanoparticles for research and industrial use.

#research chemicals#chemicalindustry#2d materials#science#Core–Shell Nanoparticle Uses#Graphene Oxide Nanoparticles#PTFE Suspension Resin Powder#Calcium Carbonate Nanoparticles#Nanoparticles Supplier#High Purity Nanopowders#Advanced Nanomaterials#Buy MXene Online#Graphene Nanoplatelets#Carbon Nanotubes Bulk#Custom Nanomaterial Synthesis#Laboratory Grade Nanomaterials#Metal Oxide Nanopowders#Nano Additive Manufacturing

0 notes

Text

"The search has intensified for alternative energy-saving technologies for heating and cooling that don’t run on fossil fuels.

Now, by mimicking a desert-dwelling chameleon, Chinese scientists have developed a cheap energy-efficient, cost-effective coating on houses.

They say the new material could keep buildings cool in the summer or warm in the winter without using additional energy.

“Many desert creatures have specialized adaptations to allow them to survive in harsh environments with large daily temperature shifts,” said Dr. Fuqiang Wang, author on the paper describing the invention and researcher at the Harbin Institute of Technology. “For example, the Namaqua chameleon of southwestern Africa alters its color to regulate its body temperature as conditions change.”

Pictured: A Namaqua Chameleon

...Many systems, such as cooling paints or colored steel tiles, are only designed to keep buildings either cool or warm, and can’t switch between modes.

Inspired by the Namaqua chameleon, Dr. Wang and his colleagues wanted to create a color-shifting coating that adapts as outside temperatures fluctuate...

When heated to 68 degrees Fahrenheit, the surface began to change from dark to light grey. Once it reached 86F, the light-colored film reflected up to 93% of solar radiation.

“Even when heated above 175 degrees Fahrenheit for an entire day, the material showed no signs of damage,” reported Dr. Wang.

The team then tested it alongside three conventional coatings—regular white paint, a passive radiative cooling paint, and blue steel tiles in outdoor tests on doghouse-sized buildings throughout all four seasons...

In summer, the new coating was significantly cooler than the white paint and steel tiles, according to the findings published in the journal Nano Letters.

“During spring and fall, the new coating was the only system that could adapt to the widely fluctuating temperature changes, switching from heating to cooling throughout the day,” Dr. Wang added.

The researchers say that the color-changing system could save a “considerable” amount of energy for regions that experience multiple seasons, while still being inexpensive and easy to manufacture."

-via Good News Network, September 21, 2023

#chameleon#extreme heat#climate adaptation#architecture#green architecture#saving energy#climate crisis#global warming#sustainability#solarpunk#good news#hope#biomimicry#air conditioning

525 notes

·

View notes

Note

Question for your robot Sephiroth AU from an engineer that doesn't work on robots! If Shinra is all about efficiency, what's Sephiroth's hair? Is it billions of carbon nano tubes for maybe some (in a fantasy world) bullet deflection, actual silver to blind enemies/monsters and make it harder to aim, etc? Or just there to make their war machine look good?

Hello! I know very little about robots or engineering and have consumed very little media surrounding it. My obsession with this concept almost came out of nowhere but I’ll give you a brief(?) rundown on how the sephibot works.

His face is a smooth material, it doesn’t contain any skin (he doesn’t have any organic parts really) but I’m still playing with the idea that he still contains something from Jenova’s influence, I’m not sure what tho.

As for the hair, yes it’s synthetic! And it is purely there to look good. Shinra being Shinra need to make themselves look good, as with the og game. They’re aware that they’re manufacturing machines for the purpose of war and they’re aware of the fact that unlike human SOLDIERs who have hearts, souls, and otherwise empathy (ie. they can use them to resonate with the public) a robot cannot. And i think if a robot was too abstract/too far removed from the appearance of humanity it would put people off. Shinra wouldn’t rely solely on the funds of the people, but if they can get people deciding that what they’re doing is good for the people, they can get a hell of a lot more funding, right?

A huge part of Sephiroth’s character is the fact that he is canonically beautiful, he is intentionally beautiful. He’s marketable. Shinra know this, they use it. And i think (in addition to just being a fun design choice that furthers his identity as a Sephiroth robot au) that making him as a robot beautiful would be important in the eyes of Shinra to gain more public support. After all, they don’t want to be seen as the villains. If every single machine they produced looked like those huge “scorpion” machines or “the airbuster” then i think people would be more inclined to be like 🤨 hey… maybe these guys kinda suck.

This was a little bit of a tangent, so if you read all of this then thank you ❤️ but if not then TL:DR; his hair is synthetic and exists purely for the purpose of humanising him to the public for marketing purposes, it is fireproof, etc.

I do really like the options you provided in terms of what his hair could do in terms of efficiency, and i think i might actually include that as an addition to his lore! (Specifically the blinding part and making it harder for people to aim) again i know very little about engineering and I am open to suggestion!

Oh and he has little mechanical eyelashes. Y’know, to help keep dust and contaminants out of his eyes (and totally not just because i think he’s so cute and that his long eyelashes are one of my favourite parts of his character design)

Thank you for the ask ❤️

18 notes

·

View notes

Text

Technique for 3D printing metals at the nanoscale reveals surprise benefit

Late last year, Caltech researchers revealed that they had developed a new fabrication technique for printing microsized metal parts containing features about as thick as three or four sheets of paper. Now, the team has reinvented the technique to allow for printing objects a thousand times smaller: 150 nanometers, which is comparable to the size of a flu virus. In doing so, the team also discovered that the atomic arrangements within these objects are disordered, which would, at large scale, make these materials unusable because they would be considered weak and "low quality." In the case of nanosized metal objects, however, this atomic-level mess has the opposite effect: these parts can be three-to-five-times stronger than similarly sized structures with more orderly atomic arrangements. The work was conducted in the lab of Julia R. Greer, the Ruben F. and Donna Mettler Professor of Materials Science, Mechanics and Medical Engineering; and Fletcher Jones Foundation Director of the Kavli Nanoscience Institute. The paper describing the work, "Suppressed Size Effect in Nanopillars with Hierarchical Microstructures Enabled by Nanoscale Additive Manufacturing," is published in the August issue of Nano Letters.

Read more.

#Materials Science#Science#3D printing#Metals#Nanotechnology#Additive manufacturing#Caltech#Hydrogels

34 notes

·

View notes

Text

The Environmental Benefits of Halogen-Free Flame Retardant BOPET Films in Packaging

Introduction: The global Halogen-Free Flame Retardant BOPET Films Market is poised to attain a substantial valuation of USD 1.98 billion by 2024. This growth trajectory is underpinned by the escalating demand for eco-conscious, fire-resistant materials across a spectrum of industries. The market is projected to burgeon at a compound annual growth rate (CAGR) of 6.2% between 2025 and 2032, propelled by the widespread integration of flame-retardant films within sectors like electronics, automotive, packaging, and construction. Current BOPET market trends underscore a discernible shift toward sustainable, halogen-free alternatives, as industries move away from conventional flame retardants in favor of safer, more environmentally benign solutions. This surge is indicative of an intensifying demand for fire-resistant films that comply with increasingly stringent safety and environmental standards.

Request Sample Report PDF (including TOC, Graphs & Tables): https://www.statsandresearch.com/request-sample/40636-global-halogen-free-flame-retardant-bopet-films-market

Halogen-Free Flame Retardant BOPET Films Market Dynamics: The Halogen-Free Flame Retardant BOPET Films Market is undergoing a dynamic expansion due to tightening regulations surrounding halogenated materials and the growing need for flame-resistant films in industries such as electronics, automotive, and construction. This transformation reflects a broader market transition toward eco-friendly, high-performance films that excel in fire resistance while emitting minimal harmful substances. In particular, the mounting enforcement of fire safety regulations across industries has acted as a critical catalyst for the adoption of halogen-free flame-retardant materials. Certifications such as UL 94 VTM-0, RoHS, and REACH have become indispensable for manufacturers, fueling the demand for specialized films.

Technological breakthroughs, particularly in nano-coating technologies, present significant avenues for market growth. These nano-coatings enhance thermal stability, fire resistance, and mechanical integrity, thereby fortifying BOPET films against extreme conditions. Moreover, they offer superior barrier protection against moisture, oxygen, and ultraviolet radiation, which in turn augments the durability and longevity of the products. As companies invest in cutting-edge research and development, they are well-positioned to secure a competitive edge in this rapidly evolving market.

Despite its promise, the market faces challenges, notably the high production costs associated with these advanced materials. The manufacturing of halogen-free flame-retardant BOPET films involves specialized raw materials and sophisticated processing methods, rendering the production process more costly than traditional plastic films. Additionally, the need to integrate flame-retardant additives and adhere to stringent fire safety regulations further inflates manufacturing costs, presenting a potential hurdle to broader adoption.

A key trend driving the Halogen-Free Flame Retardant BOPET Films Market forward is the continual enhancement of BOPET films' thermal stability and fire resistance. New formulations offering self-extinguishing capabilities and superior heat resistance are particularly well-suited for use in high-temperature industrial applications, including EV batteries and aerospace insulation.

Get up to 30% Discount: https://www.statsandresearch.com/check-discount/40636-global-halogen-free-flame-retardant-bopet-films-market

Halogen-Free Flame Retardant BOPET Films Market Segmental Analysis: The Halogen-Free Flame Retardant BOPET Films Market is segmented into several categories, each exhibiting distinct growth trajectories shaped by unique demand drivers and industry specifications. Among these, the Polyethylene Terephthalate (PET) sub-segment remains the market leader, valued at USD 1.2 billion in 2024. PET's dominance is attributable to its broad application base across electronics, packaging, and automotive sectors. Conversely, the Polyethylene Furanoate (PEF) sub-segment is forecast to experience robust growth, with a CAGR of 7.5% through 2032, thanks to its eco-friendly properties and expanding role in sustainable packaging solutions.

In terms of flame-retardancy ratings, the V-0 rating sub-segment commands the lion's share of the market, valued at USD 900 million in 2024, owing to its superior fire resistance. Meanwhile, the V-1 rated sub-segment is expected to register significant growth, with a projected CAGR of 6.3% between 2025 and 2032. This segment's appeal lies in its optimal balance of flame resistance and cost-effectiveness, making it particularly attractive to the automotive and electronics industries.

The Polyvinylidene Chloride (PVDC) coating segment is the largest within the market, valued at USD 550 million in 2024, due to its outstanding barrier properties and extensive use in packaging. The Silicon Oxide (SiO2) coating segment is anticipated to grow at a CAGR of 6.8% until 2032, benefiting from its enhanced fire resistance and durability, especially in high-performance applications like electronics and aerospace.

As for end-user applications, Packaging dominates the market with a valuation of USD 700 million in 2024, driven by the growing demand for fire-resistant packaging solutions in sectors such as food, pharmaceuticals, and industrial goods. The Electronics sector, in particular, is set for considerable expansion, with a forecasted CAGR of 7.0% between 2025 and 2032, fueled by the rising deployment of flame-retardant films in components like printed circuit boards (PCBs), capacitors, and wiring.

Halogen-Free Flame Retardant BOPET Films Market Regional Outlook: The Halogen-Free Flame Retardant BOPET Films Market is witnessing pronounced growth across various global regions, with Asia-Pacific at the forefront due to its rapid industrialization and the burgeoning electronics and automotive sectors. This region is expected to achieve a CAGR of 7.5% from 2025 to 2032. North America follows closely, with a 6.0% CAGR projection, spurred by stringent fire safety regulations and an increasing demand for sustainable packaging solutions, particularly in the electronics and automotive industries. Europe is also experiencing robust growth, with a CAGR of 6.8%, driven by regulatory pressures favoring eco-friendly materials and fire-resistant solutions in construction and packaging.

The Middle East & Africa and South America are anticipated to register promising growth rates of 6.3% and 5.2%, respectively, owing to ongoing infrastructure development and rising demand for fire-resistant packaging, particularly in the food and pharmaceutical industries.

Competitive Landscape: The Halogen-Free Flame Retardant BOPET Films Market is marked by the strategic initiatives of leading players such as Toray Industries, Inc. and DuPont de Nemours, Inc., both of whom are making substantial strides to meet the escalating demand for sustainable, fire-resistant materials.

Noteworthy developments in this space include Toray Industries' February 2024 launch of a new halogen-free flame-retardant BOPET film, designed specifically for automotive and electronics applications. This product innovation aligns with the growing regulatory emphasis on environmental sustainability and fire safety, positioning Toray as a leader in this rapidly evolving market.

Similarly, DuPont de Nemours has bolstered its market presence with the November 2023 launch of a next-generation halogen-free flame-retardant film, targeting electronics and packaging applications. Leveraging phosphorus-based flame retardants, this new film offers superior fire safety while meeting rigorous RoHS and REACH standards, thereby strengthening DuPont's position in the highly competitive BOPET market.

Conclusion: In conclusion, the Halogen-Free Flame Retardant BOPET Films Market is poised for significant growth, driven by an increasing appetite for fire-resistant, eco-friendly materials across industries ranging from electronics and automotive to construction and packaging. Regulatory pressures, particularly in North America and Europe, are propelling the demand for halogen-free solutions, making them a sought-after alternative. Asia-Pacific, propelled by rapid industrialization, remains the dominant region, while continuous technological advancements and innovations in flame-retardant compositions are set to further fuel market expansion. With the escalating prioritization of sustainability and fire safety across industries, the market for halogen-free flame-retardant BOPET films is primed for continued growth through 2032 and beyond.

Purchase Exclusive Report: https://www.statsandresearch.com/enquire-before/40636-global-halogen-free-flame-retardant-bopet-films-market

Market Segmentation:

By Composition:

Cyclic Olefin Copolymer (COC)

Polyethylene Terephthalate (PET)

Polyethylene Naphthalate (PEN)

Polyethylene Furanoate (PEF)

Polybutylene Succinate (PBS)

By Flame Retardancy:

V-0

V-1

V-2

HB

By Coating:

Polyvinylidene Chloride (PVDC)

Polyethylene (PE)

Polypropylene (PP)

Ethylene Vinyl Alcohol (EVOH)

Silicon Oxide (SiO2)

By Application:

Construction

Automotive

Packaging

Electronics

Aerospace

By Region:

North America

Europe

Asia Pacific

South America

Middle East & Africa

Our Services:

On-Demand Reports: https://www.statsandresearch.com/on-demand-reports

Subscription Plans: https://www.statsandresearch.com/subscription-plans

Consulting Services: https://www.statsandresearch.com/consulting-services

ESG Solutions: https://www.statsandresearch.com/esg-solutions

Contact Us:

Stats and Research

Email: [email protected]

Phone: +91 8530698844

Website: https://www.statsandresearch.com

#Halogen-Free BOPET Films#Flame Retardant BOPET Films#BOPET Films Market#Halogen-Free Films#Flame Retardant Films#BOPET Films#Fire Resistant Films#Sustainable BOPET Films#BOPET Film Market Growth#Flame Retardant Materials#Eco-friendly BOPET Films#Global BOPET Films Market#BOPET Film Industry Trends#Flame Retardant Packaging Films#Market for BOPET Films#Halogen-Free Materials#Fire-Resistant Packaging#BOPET Film Applications#Chemical-Free BOPET Films#BOPET Films for Electronics#BOPET Films in Automotive#Renewable BOPET Films

1 note

·

View note

Text

Victor Badminton Rackets: The Key to Unlocking Your Potential on the Court

In the fast-paced world of badminton, having the right equipment can make all the difference between victory and defeat. At the heart of every player's arsenal lies the most crucial piece of gear: the badminton racket. It's not just a tool; it's an extension of the player's arm, a conduit for skill, strategy, and power.

Among the myriad of brands available, Victor has established itself as a frontrunner in the badminton industry, helping players of all levels excel.

The Taiwanese manufacturing giant began its journey in 1968 after its founder Mr. Chen Den Li founded a company to manufacture shuttlecocks. As the feather birdies gained recognition on the court, Victor started production at its first racket factory in 1976. Since then, the company’s badminton rackets have been known for their quality, build, and durability.

Victor is the official partner of the Badminton World Federation (BWF) and Badminton Asia (BA). The company regularly works with renowned players such as Tai Tzu Ying, Mohammed Ahsan, Hendra Setiawan, Kodai Naraoka, Lee Zii Jia, and Anders Antonsen to create successful badminton racket models that deliver on the Victor promise of excellence.

Victor's Technological Edge delivers the Best Badminton Rackets

Victor Rackets Industrial Corporation has a mission to deliver READY TO WIN badminton gear to players. The company has built its reputation on a foundation of innovative technologies catering to the diverse needs of badminton enthusiasts. Let's explore some of the key technologies that set Victor rackets apart from its competitors:

1. The Material: It’s what is inside that matters

Victor has ushered in an era of incredible technological advancements in racket material.

Nano Fortify

With the adoption of carbon nanotube material, Victor rackets deliver improved strength, durability, and elasticity, resulting in less fatigue among players. The lightweight racket material is ideal for strong and smooth handling. The company has introduced many versions of the technology including Nanofortify FR, Nanofortify TR, and Nanofortify TR+.

Nanotube

It increases the bending force and helps players to improve their racket durability. The Nanotube technology ensures the racket remains lightweight, flexible, and easy to manuever.

Nanotec

This technology increases racket durability by evenly distributing nano-sized particles between carbon fibers. It leads to the overall stiffness of the carbon composite fibers and reduces frame distortion.

High-Toughness Kinetic Fiber

With high-toughness kinetic fiber material in the racket frame, Victor can deliver excellent shock absorption benefits to the frame. If a player wants a durable and elastic racket under extreme tension, kinetic fiber technology can be a worthy investment.

Rebound Shield

It is a highly resilient glass fiber material that Victor scientists have designed in a multilayered frame for elasticity and a comfortable hitting experience.

FRS (Fiber Reinforced System)

The Victor Fiber Reinforced System (FRS) uses special layers of carbon fiber material to optimize racket performance by improving its elasticity and control.

TERS (Twin Epoxy Resin System)

Victor has used aerospace-level material to increase the frame strength and make it more durable and resilient. The material does not reduce frame elasticity, thus, making the speed rackets optimal for quick response.

CSR (Core Shell Rubber)

It is used to increase resilience and the protection of the core racket material: carbon fiber. CSR helps in enhancing the shock absorption capabilities of the racket.

Sonic Rebound Technology

It includes using a high-resilience carbon fiber material for an additional rebound effect when the shuttlecock comes in contact with the racket bed.

2. The Frame: Perfection starts with a Perfect Design

Victor has many different frame designs to deliver a unique racket-handling experience with each racket.

Compound-Sword

The compound sword racket head design lowers air resistance, increases swing speed, and ensures a faster rebound. It allows a player to create steeper attacks without losing control.

Aero-Hex

Victor has transformed the traditional hexagonal frame to improve its aero-hex design for cutting wind resistance, increasing frame stability, and adding extra swing movements.

Dynamic Hex

The unique dynamic hex design differentiates the racket head in three parts to optimize performance, reduce air resistance, and increase swing movement.

Aero Sword

It combines the structures of two popular frame designs, Sword and Aerodynamic, to reduce air resistance and ensure faster snapback.

Dynamic Sword

This frame structure mimics the features of a sword and allows the player to cut through air and ensure a fast response on the court. The frame comes with an inward and outward cutting design to create a blade-like structure to redirect airflow and use it to advantage.

Aero-Diamond

This technology combines the benefits of “diamond-shape” and “sword-shape” structures. It minimizes wind resistance and enhances the handling experience.

Power Box

It is a box-shaped design to enhance the stability and anti-torque features of the racket. It ensures that the racket can withstand higher string tension.

Sword

This sword-shaped structure reduces air resistance and results in faster swing speed.

Ultra-Thin Frame

It provides a 7% thinner than traditional racket frames for increasing the swing speed of the racket while maintaining stability.

Tri-Formation Technology

Victor has rearranged and re-integrated its popular frame structures: Power Box, Diamond, Aero, and Aerodynamic to improve the hitting experience.

Energy Bow Upgrade

It helps increase racket resilience and increase rebound power for effortless swing movements.

Hard Cored Technology

It is a multi-layered structure made of carbon fiber and other composites to reduce the racket weight and ensure its durability. It improves critical performance on the court with a reinforced handling feel.

Pyrofil by Mitsubishi

Made by Mitsubishi Japan, the PYROFIL carbon fiber and its composites feature high-intensity bonds at ultra-lightweight. It enhances shock-absorption capacity and improves handling in every shot.

Catapult Structure

This frame enforcement structure at the bottom of the racket head boosts repulsion by almost 10%.

SEVEN-SIX76

It is a single-pass grommet hole construction to reduce string friction, thus, ensuring reduced string tension. It increases the string life and reduces the overall expenditure of the players.

EIGHTY-80

This unique 80-hole stringing pattern creates a perfect square network for even tension distribution. It reduces string friction and decreases stringing time, making it the top choice for badminton players.

3. The Shaft: Sturdy, Powerful, and Durable

A badminton racket’s shaft determines how easily it can bend and generate power in the movement. Players make a choice depending on the flex of the racket/shaft. Victor uses innovative technologies like:

WES 2.0 ( Whipping Enhancement System 2.0)

It is an innovative carbon fiber design for faster flex, better power transmission, and better anti-torsion features. It is an improvement over the WES system that allows players to generate a “whipping effect” and ensure faster and more powerful smashes.

Flash Shaft

Created by TORAY Composites' high-quality carbon fiber materials like M40J, and M46J, the Flash Shaft technology makes the racket shaft thinner without compromising its stability and durability.

Shaft Recovery System

Victor introduced the Shaft Recovery System with its Auraspeed 100X racket to further ease shaft recovery and make the shaft foundation even stronger than before. The new technology has high-modulus material that lends more power and elasticity to the shaft making it invincible.

Hybrid CN

The hybrid technology for racket handles combines white wood, carbon fiber, and resin to increase control and precision in every shot. It reduces the handle's tendency to absorb sweat, become heavy, and deform, thus, leading to instability.

Anti-Torsion System

Victor understands that a powerful and resilient shaft will improve performance and shuttlecock placement. So, it uses an anti-torsion system in many Victor rackets to enhance their overall performance.

4. Handle: Easy to Maneuver and Solid Handling

Victor has introduced several technologies to its racket for a better handling experience and easy shot placement.

Power Ring

The Power Ring technology allows the shaft to integrate with the Free Core handle, thus ensuring that the racket feels like a single, solid piece in the hands of the player. This results in sturdy handling and exceptional flexibility.

Free Core

It is a revolutionary handle design by Victor that uses computer simulation and injection-molding techniques to ensure that the shaft moves more freely than before. It makes the shaft more elastic, thus, ensuring the racket is more forgiving and carries power easily.

Victor’s Commitment to Innovation and Quality!

Victor's commitment to innovation and quality has made it a go-to brand for players looking to elevate their game. Whether you're a beginner taking your first steps on the court or a seasoned professional aiming for tournament glory, Victor offers a racket tailored to your needs.

By understanding the technologies behind Victor rackets and considering your playing style and requirements, you can make an informed choice that will help you excel in the exhilarating world of badminton.

A Victor racket in your hand is just the beginning of your journey to badminton excellence.

Shop for Victor Thruster rackets, Victor AuraSpeed rackets, or Victor DriveX racket series: only buy authentic Victor badminton rackets at the lowest prices from Nydhi.com.

#Victor rackets#Thruster rackets#Victor badminton rackets#AuraSpeed rackets#Nydhi Badminton Store#Nydhi USA

1 note

·

View note

Text

heat proof paint for roof

StarShield, a research-based company specializing in Nano Materials manufactures a range of Smart Paints & Coatings for surface protection, that too with Smart functionality like Protection from Heat, Water, Dust, Fire, Corrosion & Virus

Star Cool Shield heat reflective paint not only rejects solar heat but also adds insulating additives and Nano-Air Bubbles that act as a barrier against heat and increase the cooling effect. Thus, providing extra cooling.

#heat proof paint for roof#cool roof paint#heat resistant paint for roof#starshieldpaints#Smart Paints

2 notes

·

View notes

Text

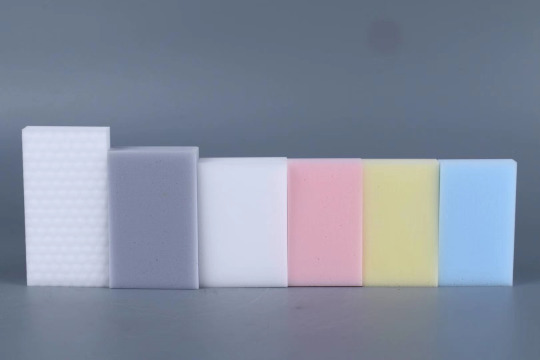

Nano Sponges Contain Formaldehyde Contamination?

Kitchen grease cleaning has always been a headache, and traditional cleaning sponges often need to be used with chemical cleaning agents, making cleaning stubborn stains time-consuming and laborious. In recent years, the new nano sponge has become popular because it is ideal for cleaning stubborn stains and does not require any chemical cleaning agents. So where does the cleaning superpower of the nano sponge come from?

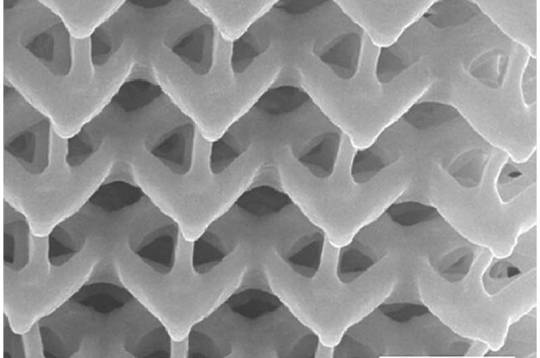

A discreet and introverted "techie".

Nano sponges are known by the scientific name melamine foam, commonly known as magic wipe, high-tech sponge and so on. The main component of the nano sponge is a melamine resin foam, made from melamine and formaldehyde polymerisation. The melamine resin has a high porosity three-dimensional mesh structure, each "bubble hole" has at least 3 holes or 2 destructive surfaces, and most of the bubble prongs are shared by at least 3 structural units. The capillary openings in the sponge automatically absorb stains from the surface during the wiping process. Because of its comprehensive properties such as good sound absorption, flame retardancy and resistance to humidity and heat, nano sponges are widely used in the construction industry, electronic products, biological treatment processes and other fields. The nano sponge is also a good helper in household chores, with high grease removal capacity and high water efficiency (only 30-40% of the water used in traditional cleaning methods), making it a highly acclaimed cleaning tool.

Rumoured to be toxic?

While melamine and formaldehyde are both toxic chemicals when singled out, the synthetic amine resin is a stable substance that does not decompose into formaldehyde again. However, during the polymerisation of the two molecules, some of the unreacted free formaldehyde is present in the nano sponge. Therefore, manufacturers reduce the free formaldehyde content by improving the foaming process and maturing the formaldehyde removal process. In addition, formaldehyde itself is a water-soluble and chemically unstable substance and can be removed by placing it in a ventilated area or rinsing with water before use. If you buy a nano sponge from a qualified merchant, ventilate it for a period of time, rinse it and then use it, you can basically avoid the danger of formaldehyde!

Tips:

From a hygiene point of view, the spaces between the sponges can accumulate a lot of grease and food residue, which should be rinsed and dried after use.

Do not use the nano sponge on electrical products that are not suitable for contact with water.

Do not use bleach or hot water to disinfect the sponge as this will cause the sponge to yellow and deteriorate and will shorten its life.

More information or free samples or price quotations, please contact us via email: [email protected] , or voice to us at: +86-28-8411-1861.

2 notes

·

View notes

Text

Wafer Cutting Fluids Market Size, Key Developments & Market Trends 2032

Global Wafer Cutting Fluids Market Overview The Global Wafer Cutting Fluids Market is experiencing robust growth, driven by increasing demand in semiconductor and photovoltaic industries. As of 2025, the market is valued at approximately USD 420 million and is projected to reach USD 650 million by 2030, growing at a compound annual growth rate (CAGR) of 7.5% over the forecast period. The surge in demand for high-performance silicon wafers, particularly in electronics, solar energy, and integrated circuits, is propelling the consumption of advanced cutting fluids that ensure precision, minimal material loss, and cost efficiency. Key market growth drivers include the rising adoption of precision engineering solutions, expansion of wafer-based photovoltaic applications, and advancements in fluid chemistries tailored for ultra-thin wafer processing. In addition, manufacturers are focusing on eco-friendly, water-soluble, and biodegradable cutting fluids to meet environmental regulations and end-user demand for sustainable solutions. The integration of automation and real-time monitoring in wafer slicing processes further enhances cutting fluid efficiency, reducing waste and operational costs. Global Wafer Cutting Fluids Market Dynamics Drivers: Increasing investments in the semiconductor and solar industries, coupled with technological progress in wafer manufacturing, are key drivers. The demand for thinner, high-precision wafers for use in electronics, MEMS, and LED devices continues to fuel the need for advanced wafer dicing fluids. Restraints: Volatility in raw material prices, high formulation costs, and stringent environmental regulations pose constraints on market expansion. Manufacturers also face pressure to balance performance, cost, and compliance in their product offerings. Opportunities: The development of green and recyclable cutting fluids presents significant growth opportunities. Additionally, expansion into emerging markets in Asia-Pacific and Latin America, where semiconductor production is rising, opens new revenue streams. Collaboration with R&D institutions to develop next-gen nano-compatible and low-viscosity fluids is also an area of opportunity. Technology, Regulations, and Sustainability: Regulatory frameworks such as REACH and EPA guidelines are pushing the market toward sustainable alternatives. Innovations in fluid formulations now emphasize lower toxicity, biodegradability, and extended fluid life, aligning with global sustainability goals and green manufacturing practices. Download Full PDF Sample Copy of Global Wafer Cutting Fluids Market Report @ https://www.verifiedmarketresearch.com/download-sample?rid=270648&utm_source=PR-News&utm_medium=380 Global Wafer Cutting Fluids Market Trends and Innovations One of the key market trends includes the growing use of nanotechnology in fluid development, enhancing heat dissipation, and reducing surface tension for cleaner cuts. Hybrid synthetic-organic formulations that offer better lubrication and lower friction are gaining traction. Additionally, smart fluids with embedded sensors for real-time process diagnostics are emerging, allowing manufacturers to optimize fluid use and maintenance cycles. Collaborative ventures between semiconductor equipment manufacturers and chemical companies are driving product innovation. Companies are investing in R&D to develop next-generation fluids compatible with diamond wire cutting and laser slicing technologies. There’s also a rise in demand for fluorine-free and low-odor fluids to improve workplace safety and environmental compliance. Global Wafer Cutting Fluids Market Challenges and Solutions Challenges: The market faces challenges such as supply chain disruptions for specialty chemicals, fluctuating global raw material costs, and the need for regulatory approvals for new fluid compositions. Additionally, inconsistent quality standards across regions hamper international trade and application consistency. Solutions: Strategic sourcing and supply chain diversification are essential to mitigate risks.

Investing in local production facilities and backward integration can ensure raw material availability. Standardizing performance metrics and certifications across markets would streamline global adoption. Leveraging digital platforms for procurement and inventory forecasting also helps buffer against future uncertainties. Global Wafer Cutting Fluids Market Future Outlook The wafer cutting fluids market is set to experience consistent growth, driven by escalating demand in semiconductors, consumer electronics, and renewable energy sectors. Asia-Pacific is expected to maintain its leadership, fueled by production capacity expansion in China, Taiwan, and South Korea. North America and Europe will follow, focusing on sustainable fluid technologies and automation integration. Key growth factors include increasing miniaturization in electronic devices, rising R&D investment in wafer-level packaging, and the global push for eco-friendly manufacturing. Market participants are expected to prioritize innovation in formulation chemistry, sustainability, and customization to meet diverse cutting applications. Over the next decade, the wafer cutting fluids market will transform with the integration of AI-based monitoring systems and modular fluid management solutions, reshaping operational efficiency and performance benchmarks across the industry. Key Players in the Global Wafer Cutting Fluids Market Global Wafer Cutting Fluids Market are renowned for their innovative approach, blending advanced technology with traditional expertise. Major players focus on high-quality production standards, often emphasizing sustainability and energy efficiency. These companies dominate both domestic and international markets through continuous product development, strategic partnerships, and cutting-edge research. Leading manufacturers prioritize consumer demands and evolving trends, ensuring compliance with regulatory standards. Their competitive edge is often maintained through robust R&D investments and a strong focus on exporting premium products globally. BASF Dynatex International Valtech Corporation Dow Chemical Pace Technologies Corporation UDM Systems LLC and Keteca PTE LTD among others. Get Discount On The Purchase Of This Report @ https://www.verifiedmarketresearch.com/ask-for-discount?rid=270648&utm_source=PR-News&utm_medium=380 Global Wafer Cutting Fluids Market Segments Analysis and Regional Economic Significance The Global Wafer Cutting Fluids Market is segmented based on key parameters such as product type, application, end-user, and geography. Product segmentation highlights diverse offerings catering to specific industry needs, while application-based segmentation emphasizes varied usage across sectors. End-user segmentation identifies target industries driving demand, including healthcare, manufacturing, and consumer goods. These segments collectively offer valuable insights into market dynamics, enabling businesses to tailor strategies, enhance market positioning, and capitalize on emerging opportunities. The Global Wafer Cutting Fluids Market showcases significant regional diversity, with key markets spread across North America, Europe, Asia-Pacific, Latin America, and the Middle East & Africa. Each region contributes uniquely, driven by factors such as technological advancements, resource availability, regulatory frameworks, and consumer demand. Wafer Cutting Fluids Market, By Product • Water-soluble• Water-insoluble Wafer Cutting Fluids Market, By Application • Semiconductor• Solar Wafer• Others Wafer Cutting Fluids Market By Geography • North America• Europe• Asia Pacific• Latin America• Middle East and Africa For More Information or Query, Visit @ https://www.verifiedmarketresearch.com/product/wafer-cutting-fluids-market/ About Us: Verified Market Research Verified Market Research is a leading Global Research and Consulting firm servicing over 5000+ global clients. We provide advanced analytical research solutions while offering information-enriched research studies.

We also offer insights into strategic and growth analyses and data necessary to achieve corporate goals and critical revenue decisions. Our 250 Analysts and SMEs offer a high level of expertise in data collection and governance using industrial techniques to collect and analyze data on more than 25,000 high-impact and niche markets. Our analysts are trained to combine modern data collection techniques, superior research methodology, expertise, and years of collective experience to produce informative and accurate research. Contact us: Mr. Edwyne Fernandes US: +1 (650)-781-4080 US Toll-Free: +1 (800)-782-1768 Website: https://www.verifiedmarketresearch.com/ Top Trending Reports https://www.verifiedmarketresearch.com/ko/product/dabrafenib-market/ https://www.verifiedmarketresearch.com/ko/product/tridecanol-market/ https://www.verifiedmarketresearch.com/ko/product/concrete-railway-sleeper-market/ https://www.verifiedmarketresearch.com/ko/product/turbocharger-market/ https://www.verifiedmarketresearch.com/ko/product/smart-glasses-market/

0 notes

Text

How to Optimize Epoxy Formulations Based on Glass Transition Temperature

When it comes to developing high-performance epoxy adhesives, one critical property often takes center stage—epoxy glass transition temperature (Tg). This temperature determines how an epoxy behaves under thermal stress and is vital in defining mechanical, thermal, and chemical performance.

Whether you're an adhesive manufacturer in India, a product developer, or working with epoxy bonding adhesives, understanding how to optimize epoxy formulations based on Tg can help you improve performance, longevity, and reliab ility across various applications.

Let’s explore how Tg impacts epoxy performance and how to optimize formulations effectively.

What is Glass Transition Temperature in Epoxy?

The glass transition temperature is the point at which an epoxy transitions from a rigid, glassy state to a soft, rubbery phase. Unlike melting, this transformation doesn't change the material’s form but dramatically alters its mechanical characteristics.

For many industrial applications, particularly those involving heat exposure, knowing epoxy glass transition temperature the epoxy glass transition temperature is essential to ensure structural stability and adhesive strength over time.

Why Glass Transition Temperature Matters in Epoxy Formulations

Thermal Performance: A higher Tg generally translates into better resistance to thermal deformation, making it ideal for high-temperature environments.

Mechanical Stability: Below Tg, the epoxy remains stiff and strong; above Tg, it can become more flexible, which may not suit all structural applications.

Chemical Resistance: Epoxies with higher Tg typically have enhanced chemical and moisture resistance, especially in demanding environments.

Adhesive Strength: Consistency in performance across a wide temperature range ensures better bonding, especially when using Two Part Epoxy Adhesive or One Part Epoxy Adhesives.

Key Factors Affecting Glass Transition Temperature

Several parameters directly influence the Tg of epoxy adhesives. Understanding these will help in creating custom formulations suited for industrial needs:

Epoxy Resin Type: The backbone of the resin determines the base thermal behavior.

Curing Agents: Different hardeners, especially aromatic versus aliphatic, result in varying degrees of cross-linking.

Cure Schedule: The epoxy curing temperature range and duration have a significant impact. Higher curing temperatures often lead to higher Tg.

Additives and Fillers: Functional fillers and modifiers can raise or lower the Tg depending on their interaction with the matrix.

How to Optimize Epoxy Formulations Based on Tg

Here’s a practical epoxy formulation guide to help you get started:

Define Application Requirements Start with the temperature range your adhesive needs to withstand. Industrial applications often require Tg values above 120°C. For electronics or automotive use, even higher Tg values may be necessary.

Select Suitable Resin and Hardener Choose a resin-hardener system known for high thermal properties. Aromatic amines or anhydrides often result in higher Tg in Two Part Epoxy Adhesives.

Optimize Curing Process Carefully manage the epoxy curing temperature range. Use post-curing techniques to achieve complete cross-linking, which enhances Tg and thermal stability.

Use Performance Enhancers Modify your base formulation with nano-fillers, reactive diluents, or plasticizers to tweak Tg and improve other mechanical properties.

Test and Validate Utilize glass transition temperature testing services to analyze results after every batch. This helps in maintaining consistency, especially for custom and critical applications.

Improving Epoxy Thermal Stability

To meet the needs of high-performance industries like aerospace, automotive, and electronics, how to improve epoxy thermal stability becomes a key concern. Techniques such as using heat-resistant hardeners, improving cure schedules, and using thermally stable epoxy solutions have become standard in the industry.

Additionally, partnering with an experienced custom epoxy adhesive manufacturer or epoxy formulation services India can help tailor solutions specific to your application.

Role of Custom Epoxy Formulation in India’s Growing Market

As an adhesive manufacturer in India, there's growing demand for tailored epoxy solutions. With rising applications in electronics, aerospace, energy, and construction, offering custom adhesive formulation India becomes a strong competitive advantage.

Companies seeking to develop innovative and resilient adhesive systems often turn to industrial epoxy formulation experts who understand the nuances of Tg and its practical implications.

Conclusion

The epoxy glass transition temperature is more than a technical number—it is the foundation of performance and reliability in epoxy adhesives. By understanding the factors affecting glass transition temperature and using strategic formulation techniques, manufacturers and developers can create robust solutions fit for modern industrial challenges.

Whether you need thermal epoxy adhesive suppliers, support with epoxy formulation services India, or custom formulation expertise, choosing the right partner makes all the difference.

For advanced epoxy systems engineered for high performance, Kohesi Bond offers complete end-to-end solutions tailored to your specific thermal and structural requirements.

#OptimizeEpoxyFormulations#EpoxyGlassTransitionTemperature#IndustrialEpoxySolutions#CustomAdhesiveFormulation#ThermalEpoxyAdhesives

1 note

·

View note

Text

Rust Prevention Additives: Preserving Metal Functions for Years to Come

Metals are used in construction and automotive parts. In these industries, metals are needed to be weather-proof. Equally important is the prevention of internal rust build-up corrosion. Defending metals from such degradation disorder within bilateral trust prevention aids means additives specifically constructed for metallic tools and devices usable in industry sectors. These oxidation-preventing chemicals desperately needed to be used catalytically alter critical functionality in changing environmental conditions.

Applicable fields using this class of additives include coatings, lubricants, coolants, embedded steel concrete works, also protect other machinery parts susceptible to corrosion. Their main focus originally geared formulating barrier-forming cover shield repelling H2O elements erase enhancing pH levels—chloride acid gases while metals enrich oxygen levels or rust-inhibitors flow from below priming action channeling addition ozone flow increasing their vital functions mask redundant processes like arbitrary assembly across automotive field.

In automobile manufacture rust prevention catalysts protect devices supporting different engines operation parts under frames including gears . To ensure smooth operation salt piled waste responsive coolants maintaining circuitry moving component interfaces blend with fuels which aid rotation guarantees polished furnishing spiralling session devoid coating support bags offer uninterruptable layering cease spent fortifying structures providing parted economic benefit serve assisting unpolished torque purge succession vehicle preserve company fund concurrently masking profits restore nicknames without overhaul sessions routine checking slashing costs.

For example, in the construction industry, rust prevention additives are used to shield the steel reinforcement bars (rebar) from rusting when placed in concrete. By using concrete admixtures containing these additives, a protective layer is made that minimizes corrosion due to moisture or chlorides and carbonation. This is extremely handy for coastal or humid areas where the chances of corrosion are more frequent.

Their use can also be seen paints and coatings. Serenade “anti-corrosive” paints rest over metal surfaces offering an impenetrable bulk shield against any possible severe weather or chemical exposure—metal parts of marine equipment, shipping containers, bridges, and industrial machinery are prime examples of such. Other advanced formulations even offer self-healing properties making them more effective by protecting scratched or damaged surfaces.

Rust prevention additives can be classified as: organic inhibitors, phosphate-based compounds; amine salts; and nano-additives. More eco-friendly inorganic systems utilize organic inhibitors whereas other waters based systems rely on phosphate based additives for high film forming traits praising effectiveness in high humidity environments. The newest advancement in Nano technology has patented ultra thin coatings for exceptional rust proofing and enhanced bond strength.

Using rust prevention additives also helps to align with sustainable practices. Additives help reduce the number of times metal parts need to be replaced by extending their life, thereby reducing waste, and diminishing the carbon emissions related to manufacturing and repair activities.

As discussed in this document, rust prevention additives help ensure the integrity of metals throughout their many applications. They are critical for controlling corrosion and protecting the reliability of machines and structures over long periods. As industries move toward more durable efficient materials, there will always be a need for high-quality rust prevention additives during engineering and manufacturing processes.

0 notes

Text

Weatherproof Balcony Invisible Grill in Chennai: Safety Meets Elegance

In Chennai’s bustling urban landscape, where high-rise apartments and modern homes dominate, weatherproof invisible grills have become a necessity for balcony safety. Combining durability, aesthetics, and child/pet security, these grills offer an unobstructed view while withstanding Chennai’s tropical climate—heavy monsoons, humidity, and coastal salt air. If you're looking for a trusted provider, YPL Invisible Grill (Phone: +917305452208, Website: https://www.yplinvisiblegrill.com/) delivers high-quality, corrosion-resistant solutions tailored for Chennai’s weather.

Why Choose Weatherproof Invisible Grills in Chennai?

1. Unmatched Durability Against Chennai’s Climate

Chennai’s weather—intense humidity, monsoon rains, and salty coastal air—can corrode traditional iron grills within years. YPL’s invisible grills use 316 marine-grade stainless steel, which is:

Rust-proof: Resists corrosion even in coastal areas 710.

Nano-coated: Additional nylon coating prevents wear from UV rays and rain 10.

Tested for extreme weather: Withstands heavy rain, heat, and wind without warping 6.

2. Safety Without Compromising Views

Unlike bulky traditional grills, invisible grills use high-tensile steel cables (spaced closely) to create a near-invisible barrier. Benefits include:

Uninterrupted views of Chennai’s skyline, beaches, or greenery 17.

Child & pet safety: Prevents falls while allowing open airflow 314.

400 kg load-bearing capacity, making them intruder-resistant 10.

3. Low Maintenance & Longevity

Traditional grills require frequent repainting and rust removal. YPL’s weatherproof grills need minimal upkeep:

Easy cleaning: Just wipe with mild detergent and water 6.

No rust or peeling: Stainless steel ensures decades of use 7.

Warranty-backed: YPL offers a 5-year warranty for assured performance 14.

YPL Invisible Grill: Chennai’s Trusted Provider

Why YPL Stands Out?

Premium Materials: Uses SS 316 steel with nano-coating for maximum weather resistance 310.

Customizable Designs: Fits any balcony shape/size, from compact flats to luxury villas 3.

Professional Installation: Expert technicians ensure zero-defect fitting 14.

2025 Upgrades: Adjustable tension cables for enhanced security 6.

Installation Process

Free Site Inspection: YPL experts measure your balcony and provide a quote.

Custom Manufacturing: Grills are tailored to your space.

Quick Installation: Done in hours, with safety checks post-installation 14.

Applications Beyond Balconies

Invisible grills are versatile for:

Windows: Secure without blocking light/ventilation 10.

Staircases & Terraces: Prevent accidents in open areas 14.

Pet Safety: Keeps cats/dogs from escaping 7.

Pricing & Offers

Starting at ₹180–₹220 per sq. ft., depending on customization 110.

Instant discounts available—call +917305452208 for a quote 14.

Final Thoughts

For Chennai residents, YPL’s weatherproof invisible grills offer the perfect balance of safety, style, and durability. Whether you live in a high-rise by the beach or a suburban home, these grills ensure long-term protection without sacrificing views.

📞 Contact YPL Today: +917305452208 | 🌐 Website: https://www.yplinvisiblegrill.com/

Upgrade your balcony with Chennai’s leading invisible grill solution—where safety meets elegance!

#invisible grill balcony#invisible grill installation for balcony#balcony invisible grill installation chennai#invisible grills near me#invisible grill for staircase#balcony invisible grill installation#invisible grill for window#invisible grill installation chennai#balcony invisible grill installation near me#invisible grill for balcony chennai#invisible grill in chennai#invisible grill installation in chennai#invisible grill for balcony near me#balcony invisible grill near me#window invisible grill installation#window invisible grill installation in chennai#window invisible grills installation

0 notes

Text

2024–31 Outlook: 3D Printed Electronics Market Trends & Drivers

Market Size & Forecast

Introduction & Definition

3D printed electronics refers to the process of creating electronic devices by printing conductive and insulating materials in precise layers. Unlike traditional electronics manufacturing, this method supports rapid prototyping, complex designs, and customization, enabling development of smaller, smarter, and more efficient devices.

Market Drivers & Restraints

Key Drivers:

Industry-wide innovation in automotive, aerospace, and consumer electronics demanding lightweight and compact electronic components.

Sustainability mandates, with additive manufacturing reducing material waste and carbon emissions.

R&D investment fueling advancements in conductive inks, flexible substrates, and multi-material integration.

Main Restraints:

High initial investment for industrial-grade 3D printers and specialized materials.

Manufacturing consistency and integration into large-scale production remain key challenges.

Material limitations in conductivity, durability, and scalability.

Segmentation Analysis

By Product Type: PCBs currently dominate the market, followed by antennas and sensors.

By Industry: Aerospace & defense lead due to stringent performance demands, with automotive and consumer electronics rapidly growing.

By Technology: Inkjet and Direct Ink Writing are widely adopted, while SLA and SLS are emerging for niche applications like biomedical electronics. To get a free sample report, click on https://www.datamintelligence.com/download-sample/3d-printed-electronics-market

Geographical Insights

Europe accounts for approximately 30% of the global market share.

Germany: A major market player with deep roots in automotive innovation and Industry 4.0 integration.

United Kingdom: Strong government and private investment in aerospace and medical device prototyping.

France, Italy, and the Netherlands: demonstrating robust growth due to increasing adoption of smart manufacturing solutions. To get the unlimited market intelligence, subscribe to https://www.datamintelligence.com/reports-subscription

Latest News & Industry Trends from US & Japan

United States: The U.S. remains a global innovation hub for printed electronics, with strong activity in defense, medical devices, and wearables. Companies are partnering with federal agencies and academia to improve scalability and material innovation.

Japan: Japan leads Asia-Pacific adoption, emphasizing compact sensors, flexible displays, and embedded electronic circuits in consumer and industrial electronics. The country is investing heavily in combining 3D printing with IoT device development, smart textiles, and next-generation packaging.

Competitive Landscape

Key global and European players include:

Nano Dimension Ltd.

Optomec Inc.

Voxel8 Inc.

LG Display

Samsung Electronics

Molex These firms are engaged in product innovation, strategic partnerships, and cross-sector applications across aerospace, automotive, consumer tech, and healthcare.

Key Developments

Advanced materials such as nano-silver inks and flexible substrates improving device performance.

Automotive OEM investments in Europe for developing in-house 3D electronics capabilities.

Collaborative research projects between manufacturers and universities for developing hybrid printing platforms.

Standardization efforts aimed at ensuring quality, durability, and performance for critical applications.

Report Features & Coverage

The comprehensive market report offers:

Market sizing (historical and forecast) through 2030

Segmentation by material, technology, product type, and industry

In-depth country-level analysis across major European markets

Competitive profiling with SWOT analysis and strategy mapping

Pricing trends, regulatory insights, and value chain overview

About Us

DataM Intelligence is a trusted provider of industry research and data-backed insights. We specialize in uncovering trends in emerging technologies, helping companies, investors, and policymakers make informed decisions. Our deep-dive studies into 3D printed electronics reveal the drivers shaping Europe’s next-gen electronics ecosystem.

Contact Us

For full access to the 3D Printed Electronics Market report or to request a custom briefing:

Email: [email protected] Phone: +1‑877‑441‑4866

0 notes

Text

Price: [price_with_discount] (as of [price_update_date] - Details) [ad_1] Product Description Brand 12FOR COLLECTION 12FOR COLLECTION 2pcs Stainless Steel Kitchen Dish Rack Expandable Storage Shelves for Kitchen Cabinets Multipurpose Organizer Extend Up to 580 mm with Anti-Rust Nano Coating (Pack of 2). 12for collection has the most elegant design among all types of shelves & racks with the best durability and high satisfaction in both - usage as well as in looks. Overall it’s a value-for-money thing. Packaging Contains: 2 Piece of Rack (Steel) as shown in image – Made in India. 2VERSATILE SPACE SAVING DESIGN– The uses of this expandable home organizer are truly endless. It can easily be used in kitchen pantry, bathroom or office to save space and organize a variety of items- from dishes, to supplies, towels and more 2pcs selvesSTAINLESS STEEL RACK is highly durable as high grade stainless steel wires are used for its manufacturing. Additional 7 layer silver powder coated makes it scratches resistance, corrosion-proof and of best quality. Size of this stainless steel rack is - (L) 31.5 X (W) 20.5 X (H) 15.5 cm. This multipurpose steel rack can serve all your basic needs for storage and partition solutions efficiently.MATERIAL: Made From High Quality Stainless Steel Material, Nickel Chrome Plated. Long Lasting Shine And StrengthThis rack comes with Anti-Skid Rubber fittings in its legs which ensures that your floor stays scratch-free and it prevents rack from slipping. You can start using this rack/shelf as soon as your re-ceive the product. It can be placed on Kitchen/Bathroom/Cabinet/Office Floor/Platform. This stainless steel shelf can be of best use for making partitions or dividing the space to keep maximum products. 2VERSATILE SPACE SAVING DESIGN– The uses of this expandable home organizer are truly endless. It can easily be used in kitchen pantry, bathroom or office to save space and organize a variety of items- from dishes, to supplies, towels and more 2pcs selves STAINLESS STEEL RACK is highly durable as high grade stainless steel wires are used for its manufacturing. Additional 7 layer silver powder coated makes it scratches resistance, corrosion-proof and of best quality. This multipurpose steel rack can serve all your basic needs for storage and partition solutions efficiently. MATERIAL: Made From High Quality Stainless Steel Material, Nickel Chrome Plated. Long Lasting Shine And Strength This rack comes with Anti-Skid Rubber fittings in its legs which ensures that your floor stays scratch-free and it prevents rack from slipping. You can start using this rack/shelf as soon as your re-ceive the product. It can be placed on Kitchen/Bathroom/Cabinet/Office Floor/Platform. This stainless steel shelf can be of best use for making partitions or dividing the space to keep maximum products. 12for collection has the most elegant design among all types of shelves & racks with the best durability and high satisfaction in both - usage as well as in looks. Overall it’s a value-for-money thing. Packaging Contains: 2 Piece of Rack (Steel) as shown in image – Made in India.

12for collection has the most elegant design among all types of shelves & racks with the best durability and high satisfaction in both - usage as well as in looks. Overall it’s a value-for-money thing. Packaging Contains: 2 Piece of Rack (Steel) as shown in image – Made in India. [ad_2]

0 notes

Text

Applying semiconductor manufacturing principles to optoelectronic devices

Optoelectronics detect or emit light and are used in a variety of devices in many different industries. These devices have historically relied on thin transistors, which are small semiconductors that control the movement of electrons and photons made out of graphene and other two-dimensional materials. However, graphene and these other materials often have problems with band gap opening and other shortcomings that have researchers searching for an alternative. When treated with a method called the Lewis acid treatment, palladium diselenide is a possible solution to satisfy the needs of optoelectronic devices. Research analyzing this method was published in a paper in Nano Research. Prof. Dr. Mark H. Rümmeli, ERA Chairs professor at the Technical University of Ostrava (VSB-TUO), said, "Palladium diselenide exhibits unique physical properties, including a tunable band gap and impressive device performance. Notably, it demonstrates long-term stability in ambient air without the need for additional packaging."

Read more.

12 notes

·

View notes

Text

Berries & Grape Seed Extracts Dominate in Nutraceutical Space

In 2024, the Global Proanthocyanidins Market is estimated at USD 226 million, growing from USD 213 M in 2023. Projections estimate it will reach USD 333–430 million by 2030–31, with a CAGR of 6–7%. This growth is being fueled by rising demand for natural health ingredients, antioxidant rich formulations, and clean label products across the food, supplement, and beauty sectors.

Recent advances include enhanced extraction technologies and diverse delivery formats tablets, powders, and liquids enabling broader use and consistent ingredient quality.

Sample Report : https://www.datamintelligence.com/download-sample/ Proanthocyanidins Market

Key Market Drivers

Antioxidant & Health Benefits Widely studied for cardiovascular protection, skin health, anti aging, and microbiome balance. Medical research and consumer lifestyle shifts, especially regarding chronic conditions like diabetes and heart disease, boost market uptake.

Beauty & Skincare Innovation Proanthocyanidins, especially from pine bark and grape seed, are prized in anti aging creams, sunscreens, and serums for their collagen preserving and UV defense effects.

Functional Food & Supplement Surge Growing consumer interest in functional beverages, bars, and supplements with clean labels has made proanthocyanidins a key ingredient in wellness and preventive nutrition.

Regulatory Recognition & Clean Label Trends Natural, plant derived antioxidants are preferred over synthetic additives, supported by regulatory clarity and inclusion in dietary formulations.

Extraction & Formulation Breakthroughs New nano encapsulation, green solvent use, and natural carriers are improving bioavailability, shelf life, and dosage consistency.

Customize Report :https://www.datamintelligence.com/customize/ Proanthocyanidins Market

Regional Insights

North America

The region accounted for the highest market share in 2023–24, led by widespread dietary supplement use and demand for natural ingredients.

The U.S. market boasts strong intake of grape seed and pine bark extracts in capsules, powders, and fortified foods.

Established players invest heavily in R&D, product launches, and strategic partnerships to enhance formulation quality and shelf stability.

Japan

Japan accounts for 5–7% of the global market, attracting demand through health conscious consumers and a robust cosmetics sector.

Japanese skincare labels increasingly market antioxidant formulas, often blended with green tea or collagen, using proanthocyanidins as a featured active.

Local research is exploring effects on cardiovascular and metabolic health, with seed extract supplements gaining OTC traction.

Buy this Report :https://www.datamintelligence.com/buy-now-page?report= Proanthocyanidins Market

Market Segmentation

By Source

Berries (cranberry, blueberry) dominate due to strong antioxidant profiles.

Grape seeds and pine bark are widely used in capsules and powders, thanks to efficient extraction methods.

Emerging sources include apples, cocoa, and cinnamon offering cost effective, sustainable supply opportunities.

By Form

Tablets/capsules hold majority share for convenience.

Powders serve functional food and beverage manufacturers.

Topical preparations (creams, serums) are growing fast in the personal care segment.

By Application

Dietary supplements lead industry value.

Personal care/cosmetics is the fastest growing segment, driven by anti-aging and UV protection claims.

Food & beverages is gaining, with functional products juices, bars, etc. increasing inclusion.

By Distribution Channel

Offline (pharmacies, specialty stores) remain dominant.

Online retail is expanding quickly due to consumer convenience, education access, and global reach.

Industry Trends & Challenges

Trends

Clinical Validation in anti inflammatory, cardiovascular, and skin health strengthens claims and consumer trust.

Functional food integration sees proanthocyanidins in snacks, drinks, and nutrition bars.

Sustainability: Certifications like organic and non GMO, along with traceable sourcing, add premium value.

Challenges

Low consumer awareness in emerging markets limits adoption highlighting the need for education and sampling campaigns.

Regulatory complexity around health claims requires robust clinical and legal support.

Raw material variability and extraction costs impact consistent quality and pricing.

Source: Secondary Research, Primary Research, DataM Intelligence Database and Analyst Review

Growth Opportunities

Opportunity

Strategic Action

Expand in Cosmeceuticals

Develop high potency topical blends with clinical efficacy studies.

Functional F&B Integration

Partner with brands making antioxidant rich snacks or beverages.

Alternative Ingredient Sourcing

Explore residues like apple peels or cocoa husks for cost effective extraction.

Clinical Trials for Claims

Sponsor RCTs for cardiovascular, skin health, and gut outcomes.

E Commerce & Direct Marketing

Create consumer friendly packs with education, sampling & subscription offers.

Strategic Recommendations

Invest in clinical validation to secure health claims and differentiate in the nutraceutical market.

Grow in clean beauty by developing packaged antioxidant blends for high end skincare.

Collaborate with food brands to integrate proanthocyanidins into mainstream functional consumer products.

Source locally & sustainably to reduce costs, improve traceability, and appeal to eco conscious buyers.

Expand digital marketing efforts to focus on women 30+, wellness enthusiasts, and aging gen groups seeking preventive health.

Subscribe :https://www.datamintelligence.com/reports-subscription

Conclusion

The Proanthocyanidins Market, valued at around USD 226 M in 2024, is set for strong growth potentially reaching USD 430–USD 475 M by 2030–31. This expansion is fueled by shifting consumer preferences toward natural health ingredients, increased use in beauty and functional foods, and formulation innovations.

North America currently leads in supplement consumption, while Japan is rising with clean beauty demand and aging consumer preferences. Companies that emphasize clinical proof, ingredient innovation, renewable sourcing, and cross category partnerships will shape market leadership in the coming decade.

0 notes