#Cored Wire Injection

Explore tagged Tumblr posts

Text

Why Foundries Prefer Cored Wire Injection for Consistent Nodularizer Results!

In today’s competitive metal casting industry, foundries are under increasing pressure to deliver products that meet exact specifications while keeping production efficient and cost-effective. One of the most significant advancements in this space has been the adoption of automated alloy feeding systems that enhance the consistency and quality of molten metal treatments.

Among these innovations, Cored Wire Injection stands out as a smart choice—particularly when it comes to improving the use of Nodularizing agents during ductile iron production. The consistent and controlled introduction of additives through this technique has significantly improved the way foundries operate

The Need for Consistency in Ductile Iron Casting

Due to its exceptional strength and durability, ductile iron finds extensive application in a variety of sectors, such as heavy machinery, infrastructure, automotive, and energy. Achieving the right graphite structure in cast iron is essential to obtain the desired mechanical properties.

To do this, Nodularisers are added to the molten metal to promote the formation of spheroidal graphite. This process is highly sensitive—affected by timing, temperature, and the method of alloy delivery. Even slight deviations can lead to poor nodularity, resulting in casting defects or reduced performance.

Controlled Feeding: A Smarter Way Forward

The key advantage of using Cored Wire Injection lies in its precision. With this method, foundries can introduce treatment materials deep into the molten bath, exactly where and when they are needed. This reduces exposure to air, minimizes reaction losses, and provides a more stable metallurgical outcome.

By doing so, foundries gain better control over the entire treatment process, resulting in more predictable casting properties and fewer batch rejections. This not only saves time and resources but also improves customer satisfaction with consistently high-quality products.

Enhancing Nodularizing Efficiency

The use of Nodularizers in iron casting plays a crucial role in shaping the microstructure of the final product. Magnesium and rare earth elements are commonly abundant in these agents, which promote the production of nodular graphite during solidification. However, their effectiveness can be compromised when not applied properly.

With wire feeding, the Nodularizing material is enclosed and delivered below the slag line, reducing oxidation and improving the absorption rate of magnesium. This improves the efficiency of the process while maintaining operator safety—especially compared to traditional ladle treatment methods.

A Reliable Way to Introduce Key Alloys

One of the most common additives used in ductile iron treatment is Ferro Silicon Magnesium. It provides both silicon and magnesium—two essential elements that enhance graphite nodulization and castability. However, magnesium is highly reactive and prone to rapid fading, making controlled delivery critical.

By incorporating Ferro Silicon Magnesium into wire form, foundries can inject it with greater accuracy and reduce the loss of active elements. This leads to higher recovery rates and a more stable chemical composition, which translates to better quality castings.

Benefits Beyond Metallurgy

The adoption of Cored Wire Injection systems also brings broader operational advantages:

Increased Safety: The enclosed design minimizes exposure to volatile materials and reduces the risk of violent reactions.

Cleaner Operations: With less slag formation and fewer surface disturbances, castings are cleaner, requiring less finishing.

Process Automation: The feeding process can be easily integrated into automated production lines, increasing efficiency and throughput.

Environmental Benefits: Less fume generation and material wastage contribute to cleaner and greener operations.

Applications Across Industries

The advantages of controlled alloy feeding aren’t limited to a particular sector. Manufacturers of automotive components, pipes, machinery parts, and structural castings all benefit from the consistent metallurgical quality it offers. As demand for durable and high-performance iron components grows, so does the need for reliable and repeatable production methods.

Conclusion

In a foundry setting where consistency, safety, and quality control are paramount, the shift to precision alloy delivery systems has been a game changer. For ductile iron production, this approach offers a reliable way to manage the addition of treatment agents—especially when handling reactive materials.

With better control over Nodularizing elements and key alloys like Ferro Silicon Magnesium, foundries can achieve superior graphite structure, reduce defects, and improve casting performance. As industries continue to demand higher standards and leaner operations, Cored Wire Injection will remain a cornerstone of modern metallurgical processes.Looking to upgrade your iron treatment process? Choosing the right delivery method for your alloying materials can significantly enhance your casting results and reduce operational costs. Connect with experienced suppliers and metallurgical experts to find the most effective solutions for your foundry.

Check out one of India’s most reliable manufacturers and suppliers for all your Ferro Silicon Magnesium needs: https://www.ferrosiliconmagnesium.com #CoredWireInjection, #Nodularisers, #FerroSiliconMagnesium

#nodularisers#ferro silicon magnesium#cored wire injection#high recovery for ferro silicon magnesium#inoculants#ferrosiliconmagnesium#ferro silicon magnesium cored wire#ferro silicon magnesium in india

0 notes

Text

Unlocking Efficiency: Cored Wire Injection by Bansal Brothers

Discover how Cored Wire Injection enhances metal quality effortlessly. Dive into our user-friendly guide to grasp its benefits in 60 seconds. Elevate your metallurgical prowess with Bansal Brothers, pioneers in innovative solutions for your industry.

For more Info: https://www.ferrosiliconmagnesium.com/products.php

Address: Plot No 7 & 12, Borai Industrial Growth Centre, Rasmada, Durg, Chhattisgarh, 491001

Contact Us: 7610125164

Cored Wire Injection

0 notes

Text

super soldiers!141 x new to the unit!reader | this is dumb and poorly written, i'm sorry, just needed to get it out my mind

thinking about a sci-fi, future-ish au where human soldiers became sort of a social experiment on a large scale after machine soldiers have proven to be inefficient against certain “threats” because of their lack of motivation, incentives. purpose. machines needed things to make sense, they couldn’t be encouraged to do some tasks. they would follow orders, of course, but they – for themselves – were not ethical at all.

machines didn’t care if it was a child, a man, a woman or an animal, if it was their target they were going to put it down at any cost and that caused problems. a lot of different problems throughout their years of usage. especially if a mission needed fast changing of target. but they were a single mind distributed in countless bodies of wires and hard plastic, and that was their biggest strength. if one knew, they all knew. if one was given an order, all the others knew what it was and what should be done to reach it. it was visceral, a core knowledge that no human was capable of achieving by natural means – of course.

so the government started to support the return of human soldiers on field, with the exception that they required new training, one to make them more united, more like one living force. they also had to work within a task force – the fewer people in a group, the better. in the first two years of this change of scenario, higher ranked soldiers started making their own task forces in order to choose the people that they worked more in sync with, and proceed through training to get them all to feel in synch as well – until the whole group felt like there was no doubt ever, just pure certain and mutual understanding.

after a sufficient number of task forces were completed and started to act on the field again, it became clear that intense training wasn’t enough. they kept running tests to understand exactly what these soldiers were lacking to improve their performance. after a few months scientists developed a new device, one that should answer their remaining questions. it was an extremely small piece of technology that was injected into the soldiers and that allowed them to communicate better – they needed fewer and fewer words to understand one another. of course, that didn’t really last long until they became obsolete and were replaced by new ones.

that technology kept on evolving until, a few years after, a special type of “device” was achieved. it half worked like a hormone in the human body – heightened senses mostly, that allowed an insane capacity to deeply understand things in a visceral matter. some people suspected it was made from specific DNA traits of animals highly skilled in things that mattered in the military – like hunting –, but in reality no one really questioned what it was. the results were all very natural – as far as they could possibly be in human terms. it worked, and that was all that mattered. it was almost totally customized, the injectable liquid had a different composition depending on what it was that the task force needed to improve as a whole. everyone in the same group received the same sample, they weren't repeated because it changed accordingly with the task force.

the truth is that task force 141 never really needed any of this shit, since day one they were a highly effective unit in all matters. with a total of five years in and out of test devices, they one hundred percent relied on their personal interaction – as any other unit should do. to say that they had each other's back was a total understatement, they completely trusted each other in an extremely vulnerable way. of course it required a deep amount of reliance to reach that, but they had come a long way anyway – with all the training plus the training with the previous test devices. but as time passed and it became law that “all working units shall have a dose to optimize their performance on field”, they had no other choice but to accept. which they were silently glad for, but they were never going to admit it. 141 was the best unit since new training began and human soldiers were a thing again, they were the very proof that human connections were necessary to certain tasks. but after they took their dose? oh boy, they were the best of the best. no questions asked, they all became more sensitive to nature itself. gaz started knowing all significant changes on the weather two day before it happened even if he was in blindfolds, soap somehow managed to always calm stray animals with his mere presence on the empty concrete forests that they had to visit every once in a while, ghost could tell how many people were inside of a room even several floors apart and captain price stopped needing to bark orders, he simply acknowledged them and then the boys seemed to simply know what to do.

they slowly morphed into one consciousness, not like the artificial intelligence prior to them, but like a new evolved version of themselves. suddenly ghost understood every sensation gaz ever talked about, gaz just knew what went through soap's mind, soap didn't even need to touch price to feel his tense shoulders anymore because everytime their captain got worried, they felt it. not like they felt their own feelings, but it was there. like they understood the very idea of their emotions.

eventually, they grew used to their new form, an emotionally charged bond that held them together. if they felt something hard enough they made the others feel it too. it wasn't always nice. one time kyle and johnny fought and that created an atmosphere where they all kept feeding off their anger, until captain told them to knock it off already and then he was mad at them like he felt both their ire – he did feel it, and it sucked. but then sometimes it was outstanding, like when ghost was so horny on a random ass tuesday and he kept horny for the rest of the week and the week after. when he finally managed to get his sweet, sweet relief, he dragged all his boys with him – even though he was alone in his room and they were all doing their respective chores. they all felt that knot loose in their lower half and just knew exactly what it was – who it was. after that they all tried to rile each other up with only their weird telepathic bond.

things were fun and enigmatic, they didn't need scientific explanations to things they simply knew. and understood. it wasn’t a problem to be solved by any means, they all simply embraced this new scenario and tried to make the most of it. and it worked, they got to a level that some things didn’t even have to be said because they would know from the moment that the others acknowledged it as well.

until one day they were chilling in the living room of their house, watching tv when a small pang of anxiety sparked somewhere low in their chest. cap furrowed his brows looking at johnny for an answer but he was just as confused. he turned to simon to see his visible discomfort at the foreign sensation. simon turned to kyle, the only one who seemed rather unbothered by it, although just as confused, and asked “what is it?”, even though he knew it wasn't kyle, and he knew kyle didn't know either.

kyle simply shrugged, “dunno, but it's weird as fuck.” it was his way to cope with the strange feeling, trying to not let it consume him. he wondered where it was coming from, since it wasn't from any of the others.

“we will know soon enough,” john said, the soothing tone a bit unusual in the captain's voice, but it was welcome nonetheless. it managed to work the boys' nerves, and soon enough none of them felt the small, irritating poke of anxiety.

it wasn't four days later that realization washed over them. it was price who received the news – of course, like always – but they all immediately knew that something was up. they wordlessly gathered at john's office door exchanging glances until his voice cut through the silence. they didn't knock but he knew that they were standing there, “come in already, will you?”

johnny opened the door, simon and kyle stepped in first as he held it open for them. he closed the door behind him, watching john's expression. they all knew they needn't worry, but they also knew it wasn't easy news. no one said a word, simply watching silently as price lit up a cigar and rubbed a hand down his face, then his hand scratched his beard. he sighed, taking a few seconds to find the right words, he took one final drag and settled his cigar down.

he wasn't stressed, just tired – and that said a lot, it also soothed the boys. they could help him relax in their own way if he was tired, but if he was stressed he never really allowed them close – that required a great deal of work, he never wanted them to feel stressed too. john took a breath, opened his mouth to say something more elaborate, but he couldn’t, he was just as surprised as the boys would be. so he just spilled the words out.

“we are getting an addition to the unit.”

a/n: i have no idea what to think of this. | series masterlist

#cod x reader#poly!141 x reader#poly 141 x reader#john soap mactavish x reader#kyle gaz garrick x reader#simon ghost riley x reader#john price x reader#call of duty x you#cod fanfiction#cod fanfic#cod fic#task force 141 x reader#tf 141 x you#tf 141 x reader#cod 141#john price#kyle gaz garrick#simon ghost riley#john soap mactavish#call of duty#cod#poly 141#task force 141#tf 141#bel's works

809 notes

·

View notes

Note

jdhfgasjkdhgf Poor Megsy lol (hive queen optimus)

Man he would think that the Insecticons were following Arcee huh. Airachnid's grudge is with Arcee and Arcee is the only female Autobot he knows of. But nope it's Optimus Prime and Megatron has to take a second to process that because what do you mean the Insecticons follow Optimus Prime specifically???

The healer Insecticon injecting the healing agent into Oppy as it spreads through the hivemind that their queen gave birth to the sparkling and to get Ratchet here asap. Ratchet notices the few Insecticons with him acting off and he's like "wtf is wrong now?" and the Insecticons are like "our queen gave birth" and Ratchet goes "WHAT" and demands to go to them immediately. The Insecticons go with it because they don't know what to do once a sparkling is live-birthed, they're used to egg-births.

They all start getting to the old hive one by one and everybody say hi to Ultra Magnus! He almost shot a member of the Hive and caused all of them to freak out, but they all calmed down when Optimus recognized him and guess what? Ultra gets pulled into the strict bedtime and fueling and cleaning of the hive! Wheeljack also has to stick around thanks to the destruction of his ship.

Well, there's the issue of the fucking Predacon, but I'm sure the Hive will swarm him like a pack of scraplets and chase him off while ripping off plating and destroying wiring. No one messes with the hive('s queen and friends)!

Shockwave does not believe the Insecticons follow Optimus until the Predacon comes limping back to Darkmount missing half of its wing, a leg, seven fingers, and a whole bunch of wiring destroyed.

And wouldn't it be great if at the same time the Autobots decide to storm Darkmount and nearly the entire hive plus almost the entire team exit through a GroundBridge :)

And wouldn't if he swell if the Insecticons were the ones to destroy the core at their queen's behest :)

And get all the relics back the Decepticons took from the destroyed base and Omega Lock battles :)

Sorry these keep getting longer and longer -Oppy breeding anon

Megatron is getting blue balled by Insects and not even knowing it. Of course he'd think Arcee is the new queen, because of how they huddled around her. They huddled around everyone, until Op walked in and they all stood at attention. Op scratching a nearby insecticon under its chin, making it purr, before they all glared daggers at Megatron.

And once the baby is born and it gets to Ratchet, he would first ask them to bring him to the hive, and once Op was alright, did he yell at them to have told him sooner.

Also Yippee Ultra Magnus is here, and he is weirded the fuck out. Of course he almost killed a member of the hive, last he knows about them they are mindless, and Smokescreen just brings him in. He's probually the one to yell "DON'T HURT THEM." causing the mech to pause.

All the insecticons are on edge, until they hear Optimus's voice telling them that it was a mistake and won't happen again.

"Right Ultra Magnus?" He looks up, and immediately turns his helm sideways upon seeing Optimus's titties out, the sparkling suckling away.

Ultra immedetly gets pulled into the hive's schedual, and would you look at that, nap time. He's getting piled on by them, keeping him warm in the cold of their old hive. Most of the hive is with Optimus, vibrating (Like Bees) to heat up their plating and keep Op and new baby warm.

Oh Predacon would of been a problem. If it wasn't for the insecticons though they'd be in bigger trouble with him and Shockwave. Shockwave did not foresee this in his plans, and it takes time to counteract this, but by that point its too late.

But ohoh The autobots get scary dog privileges with the insecticons. They would 100% destroy anything their queen asks for them to do as well. as well as be very successful getting everything that the decepticons stole.

Also do not say sorry. I'm obsessed with this au, please keep going, and giving me ideas I do not know the TFP episodes so I am very much at a lost lmao.

46 notes

·

View notes

Text

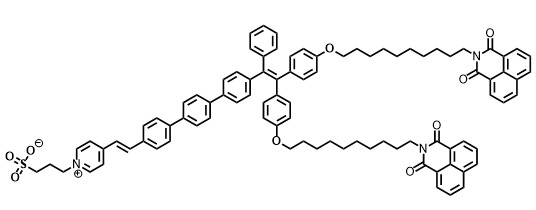

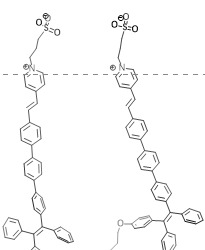

day dreaming about designing a better AIE voltage sensing dye (at the worst time, which is after I successfully made the original structure passed down to me and should be focusing on characterizing it rather than redoing the design)

This is the dye design I was handed four years ago and told to make and characterize in cell culture, which I just finished making...

but... I just think.... a) the naphthalimides on my dye aren't gonna do what the post doc who designed this said they would (inject current, bro its going to electroporate the membrane) b) it would be so much easier to solubilize in aqueous without bulky ass naphthalimide at the ends, we could even shorten the chains if we're not worried about cross talk between the naphthalimide fluorophores and the tetraphenylethylene core c) easier to characterize without competing cross talk from having TWO fucking fluorophores if I redesigned her without the naphthalimides.... and if I can shorten the chains too that would help with b). and if I reduce it to one chain, I think she'd ALSO be a better voltage sensor because d) the donor/spacer/acceptor structure (PeT wire, photoinduced electron transfer, i.e. the tetraphenylethylene donor/phenyl bridge/pyridinium acceptor structure) would be more parallel to the membrane potential and probably e) get uptaken into membranes EVEN MORE with a more favorable packing parameter (ratio of area of polar head to volume of hydrophobic body/tails) and f) have more noticeable AIE upon insertion into membrane/restriction of intramolecular rotation, which would reduce the necessity of wash steps afterwards to remove bg unbound dye

actually it'd be pretty easy to make the two chains version with one of the precursor molecules I have leftover............. maybe i could get some 1-bromo-octane or something for cheap and just make some anyway...............................................................................................

#one chain version would be more exciting to me but i'd have to go back and remake the TPE core and ugh fuck suzuki couplings#and fuck the reaction for being in DMF too#and needing acidification before extraction#and having a horrid horrid emulsion form every time its extracted#blog#stem#chemistry#voltage sensing dyes#lol#fluorophores#LOL#i wonder if anyone actually looks at those tags ever

11 notes

·

View notes

Text

FROSTTALE: Master Post

Frosttale is an au I made over two years ago now, and quite a few things have changed since i made the original concept on discord. At this point nearly every character has a finalized design and the story is complete, so i think its time i made it more mainstream!!!

Opening Cutscene:

Long ago, two races ruled over earth: humans and monsters

One day tragedy struck, a blizzard worse than any before it struck the human village and the humans believed the monsters to be the cause.

The humans fought the monsters, and sealed them into a cave, using magic to curse them with eternal cold

Many monsters suffered, and more died.

PRESENT DAY:

Legend has it that a furnace powered by seven human souls could stop the winter and break the ice barrier that seals them underground

MT. EVEREST, 202X

They say those who climb this mountain may never return.

(Thingy of chara falling into the underground blah blah blah game starts)

Ok so time for the changes!!!

this au centers around everything being cold, duh.

The most major change is that undyne is dead due to the extreme temperatures, and that drives nearly every other change in the au.

Alphys found her goop stuff after she died, scooped it up and saved it. Since then has been secretly using the royal scientist funds not for technological development but in an attempt to revive undyne.

One day, papyrus is walking around in waterfall, looking for undyne in a hope that somehow, he could find her (he doesn’t know that she’s dead, sans told him she’s just missing). Alphys sees him, and sees an opportunity (he has a similar body shape to undyne), she persuades him to come to the lab, then she knocks him out cold (see what I did there)

Papyrus wakes up a few hours later tied to a table and has a couple of wires and containers hooked up to him, most notably two labeled “remains” and “DT”

Due to the fact that he’s tied down papyrus is stuck there.

A few minutes later Alphys walks into the room and tells him that he will be ok, and tells him that if the procedure works, papyrus can be part of the royal guard, when papyrus asks what the procedure is, Alphys doesn’t answer.

Slowly, papyrus goes back to sleep, and the vials are all injected into him.

Once he wakes up again, he is now in a bed in a room that is similar to undynes, and is wearing a suit of armor also similar to undynes clothing.

Alphys walks in and tells papyrus that she cannot tell him where he is, and that he will stay here for the next few months.

Over the next few months papyrus is nurtured by Alphys, but notices something, Alphys is getting increasingly more stressed, and is now preforming daily checkups on him, and soon papyrus starts to notice something else.

Flesh.

Papyrus is growing flesh on his bones.

Flesh with scales.

And something else, papyrus feels much more determined and stronger in general, along with the sudden ability to be able to summon and throw spears as well as bones now.

However, the flesh doesn’t completely cover him, only parts of his limbs and face. He also loses vision in his left eye and needs an eyepatch, soon the changes stop.

Alphys realizes that her attempt at bringing undyne has failed and slowly realizes what she has put this innocent monster through. she leaves the lab and takes after her mentor, jumping into the core and killing herself.

Alphys has created Papyryne (name is a wip lmao).

Papyryne never found the key to leave the true lab, and has turned to be the caretaker of the other amalgamates, He has a lot of physical traits of undyne, while keeping most of the personality of papyrus, meaning he is now actually able to do the good deeds he once wanted to do. He makes the true lab look nicer, and treats the amalgamates like family

During all those shenanigans Sans has become very very lonely and quite depressed. He looks for papyrus everyday and can’t find him. He spends most of his time in his house or the judgement hall, or at least, he did.

Sans does end up meeting toriel, and in fact is at the door when you fight her, However sans never made his promise to not kill a human to toriel, as he feels that if there is an opportunity to melt the ice, he should take it.

After you leave the ruins, sans will have run away and back to his house. As you go through Snowdin, all of papyrus’ puzzles are completely frozen over and easily passable, and there are no monster encounters.

When you reach snowdin, no one is there either, they all either left or died, sans and papyrus, being skeletons, are the only ones who were able to survive the cold.

The river is completely frozen solid, and the ice cube machine is backed up with ice. When you reach the area where you would normally fight papyrus, sans will sneak up on you and start a battle.

The battle is different depending on weather you killed toriel or not. If you haven’t, sans is simply fighting you out of obligation, and the fight is very easy. After a few turns of acting and sparing, sans starts to cry a little. He doesn’t want to kill anyone, stating the underground has lost enough, and spares you. If you attack, the screen turns black and then you go back to the overworld. no sans in sight. If you do not attack, sans will not say anything, and go back to his house.

If you did kill toriel, the fight is a bit harder, but after a few turns, sans will run away regardless of what you do to him.

Entering waterfall, everything is frozen over, and again there is no life to be seen. There are two places of intrest, the old tem village (the new one will be mentioned later) where you can grab some nice items, and the village.

Upon entering the main area (the one with the save point and houses) you will encounter all three ghost characters, alphys was too obessed with reviving undyne to build mettaton, and undyne wasnt alive to need a training dummy (mad mew mew still happens post game btw).

Mad dummy forces the other two to attack you, napstablook being shy and mettaton being generally depressed (due to lack of body) dont really care too much, but fight you for their cousin anyways.

At the end of waterfall, they fight you one at a time (mirroring the multiple undyne fight segments). You can spare them by promising MTT and Mad Dummy that youll get them bodies (witch then becomes a pacifist quest), and letting blooky show you dapper blook.

Entering hotland youll notice everything is mostly ashen and gray, most of the lava having been turned to stone. You begin by passing through alphys's lab (nothing happens there... yet) and making your way to where MTT resort would have been, youll notice that as you enter hotland (now called "The Refuge" by most monsters) you can encounter monsters from anywhere in the previous areas.

Approaching the MTT resort location, youll instead find a bustling town called "New Snowdin", featuring Grillbys 2, a closed down nice cream stand, a royal guard sign up center, and... a massive cemetary.

In the cemetary youll find graves for muffet and lesser dog, as well as memorials for alphys, sans, and papyrus (the latter two being presumed dead by the public)

When attempting to enter the core, the door will be locked and have a sign saying "ROYAL GUARD ONLY", promting you to visit the sign up center.

You can sign up to the royal guard and enter the core, eventually getting on the elevator to the castle.

When you reach the top, youll be met by a hill, climbing on top of it youll find sans, he will explain that youre standing on top of the judgment hall, its been covered in snow

He says that for a long time, monsters have hated the king for his "wait out the humans" idea, and activley tried to revolt, promting the closing of the core to the public. He says that you are the final human needed, and sadly, you must die.

He then sends you off to asgore.

When you arrive, asgore brings you in for tea, sitting down with you in front of a large unpowered furnace with seven heart shaped slots, and explaining youre the first person willing to do so in quite some time.

He then escorts you to the barrier, and the fight begins. During the fight, your hp will drain very slowly due to the proximity of the barrier, being that it is what emmits the cold.

At the end, he reaches his final bit of hp, and then does something drastic.

You may have noticed a lack of flowey while reading this and thats because, well, he doesnt exist. flowers dont grow in these temperatures, and even if they could, alphys wouldnt have made him.

Asgore turns his back, and swings his trident, destroying the containers of souls, destroying them.

A second phase begins, he is now much powerful and has much more health, but eventually soul segments similar to those omega flowey has occur, and you can eventually defeat him.

You are then given the option to kill or spare him, if you kill, you recive the six souls and can break the barrier, if you spare, he takes you in as his own, and the game ends with you going to sleep in his castle.

This means that yes, there is no true pacifist run (but there is something similar...)

(Almost) PACIFIST EXCLUSIVE EVENTS:

If you have spared everyone, the elevator to the hill will collapse, bringing you to the true lab, where you can meet papyryne, he will treat you with kindness... at first.

He eagarly shows you around the lab, introducing you the amalgamates who he has lovingly named Puppy, Birdy, Snowy, Goopy, and Whispy.

However, as he shows you around youll begin to notice times where the font he is speaking in changes, and he becomes more agressive.

You can see the following entries on the walls:

Entry 1:

I found what I believe to be undynes remains today, something’s off though, it isn’t dust… it’s goop

Entry 2:

I’ve stored her remains down here, I plan to begin doing tests on it, seeing how she could have possibly gained DETERMINATION

Entry 3:

The DT extractor broke today, it will be a while untill it is fixed

Entry 4:

The memory heads keep looking around my shelf, spouting nonsense like “still there” or “don’t forget”

Entry 5:

The DT extractor is up and running again, I’m preforming some diagnostics, then tests begin tomorrow

Entry 6:

This is impossible

Entry 7:

I’ve made a discovery, in undynes remains, although there is only a fragment… her SOUL… is still there.

Entry 8:

The tests have been stopped, I’m attempting to recover some old files about the amalgamates

Entry 9:

Just as I thought, the records show that monster souls, when in their weakened state, can fuze, the most dominant soul taking the consciousness

Entry 10:

I took a small portion on undynes remains today and gave it to one of the amalgamates in their food, so far, nothing has happened

Entry 11:

It’s no problem, I simply need a bigger sample size, and perhaps a more stable monster with a complete soul, unlike the amalgamates

Entry 12:

I found a shyren today, I’ve lured it here and and captured it, I will be preforming the same experiment I did with the amalgamate

Entry 13:

…

Nothing is happening

Entry 14:

The shyren lost Vision in one eye today, though I am not sure if this is related to the experiment

Entry 15:

The shyren has been knocked out for 3 days now, I’ve hidden her body in the bathroom

Entry 16: I beleive I have found a new candidate for an experiment, this next experiment could be very very interesting.

As you are about to leave with him, freeing him from the lab, undyne takes over and he fights you. the fight is difficult by interchanging blue and green soul mechanics, the final attack using a combination of both.

You are forced to spare, as you cant damage him, and his fit of rage will end, he then will leave the lab with you and youll fast travel back to snowdin, reuniting him with sans.

You can then go back to the elevator and everything else will play out the same, with some additional sans dialouge at the end.

GENO EXCLUSIVE EVENTS:

You have to do like. a shit ton of grinding in hotland. You also have to do the ghost quests so you can kill them.

You reach level 14 and thats the highest you can get, you then take the elevator.

Once you reach the hill, you meet sans. He doesnt say anything, and a fight begins.

"it was a nice day today"

"can you see the snow sparkling in the light?"

"..."

"of course not"

"no one like you would stop to appreciate that"

"it was already bad down here, why did you have to make it worse"

"..."

"not much of a talker..?"

"me neither"

"but..."

"heres the thing"

"you see... king asgore needs one more soul"

"and youve got a nice one ripe for the taking"

"so... heres what im going to do"

"i am going to fight you"

"and i wont stop..."

"...UNTIL HELL FREEZES OVER"

then you fight, and at the end a similar cutscene to the one in UT will play, exept he doesnt ask papyrus if he wants anything.

you then go to asgore, and everything will play out as normal, exept you arent allowed to spare him.

EPILOUGE:

Holy fuck, that took so long to write. pleasepleaseplease if you have any questions feel free to ask, and i dont usually ask but if you liked it please reblog, i spent a lot of time on this.

ill be posting designs soon, and fanart would be much appreciated!!

sans design

#oc#undertale#undertale au#Toriel#Sans#Papyrus#Asgore#Alphys#Amalgamates#Undyne#Lore#Au Lore#undertale fandom

19 notes

·

View notes

Text

💳Integrated Payments with Stripe and Paddle: Inside EasyLaunchpad’s Payment Module

When building a SaaS app, one of the first questions you’ll face is:

How will we charge users?

From recurring subscriptions to one-time payments and license plans, payment infrastructure is mission-critical. But implementing a secure, production-grade system can be time-consuming, tricky, and expensive.

That’s why EasyLaunchpad includes a fully integrated payment module with support for Stripe and Paddle — out of the box.

In this article, we’ll walk you through how EasyLaunchpad handles payments, how it simplifies integration with major processors, and how it helps you monetize your product from day one.

💡 The Problem: Payment Integration Is Hard

On paper, adding Stripe or Paddle looks easy. In reality, it involves:

API authentication

Checkout flows

Webhook validation

Error handling

Subscription plan logic

Admin-side controls

Syncing with your front-end or product logic

That’s a lot to build before you ever collect your first dollar.

EasyLaunchpad solves this by offering a turnkey payment solution that integrates Stripe and Paddle seamlessly into backend logic and your admin panel.

⚙️ What’s Included in the Payment Module?

The EasyLaunchpad payment module covers everything a SaaS app needs to start selling:

Feature and Description:

✅ Stripe & Paddle APIs- Integrated SDKs with secure API keys managed via config

✅ Plan Management- Define your product plans via admin panel

✅ License/Package Linking- Link Stripe/Paddle plans to system logic (e.g., access control)

✅ Webhook Support- Process events like successful payments, cancellations, renewals

✅ Email Triggers- Send receipts and billing notifications automatically

✅ Logging & Retry Logic- Serilog + Hangfire for reliability and transparency

💳 Stripe Integration in .NET Core (Prebuilt)

Stripe is the most popular payment solution for modern SaaS businesses. EasyLaunchpad comes with:

Stripe.NET SDK is configured and ready to use

Test & production API key support via appsettings.json

Built-in handlers for:

Checkout Session Creation

Payment Success

Subscription Renewal

Customer Cancellations

No need to write custom middleware or webhook processors. It’s all wired up.

🔁 How the Flow Works (Stripe)

The user selects a plan on your website

The checkout session is created via Stripe API

Stripe redirects the user to a secure payment page

Upon success, EasyLaunchpad receives a webhook event

User’s plan is activated + confirmation email is sent

Logs are stored for reporting and debugging

🧾 Paddle Integration for Global Sellers

Paddle is often a better fit than Stripe for developers targeting international customers or needing EU/GST compliance.

EasyLaunchpad supports Paddle’s:

Inline Checkout and Overlay Widgets

Subscription Plans and One-Time Payments

Webhook Events (license provisioning, payment success, cancellations)

VAT/GST compliance without custom work

All integration is handled via modular service classes. You can switch or run both providers side-by-side.

🔧 Configuration Example

In appsettings.json, you simply configure:

“Payments”: {

“Provider”: “Stripe”, // or “Paddle”

“Stripe”: {

“SecretKey”: “sk_test_…”,

“PublishableKey”: “pk_test_…”

},

“Paddle”: {

“VendorId”: “123456”,

“APIKey”: “your-api-key”

}

}

The correct payment provider is loaded automatically using dependency injection via Autofac.

🧩 Admin Panel: Manage Plans Without Touching Code

EasyLaunchpad’s admin panel includes:

A visual interface to create/edit plans

Fields for price, duration, description, external plan ID (Stripe/Paddle)

Activation/deactivation toggle

Access scope definition (used to unlock features via roles or usage limits)

You can:

Add a Pro Plan for $29/month

Add a Lifetime Deal with a one-time Paddle payment

Deactivate free trial access — all without writing new logic

🧪 Webhook Events Handled Securely

Stripe and Paddle send webhook events for:

New subscriptions

Payment failures

Plan cancellations

Upgrades/downgrades

EasyLaunchpad includes secure webhook controllers to:

Verify authenticity

Parse payloads

Trigger internal actions (e.g., assign new role, update access rights)

Log and retry failed handlers using Hangfire

You get reliable, observable payment handling with no guesswork.

📬 Email Notifications

After a successful payment, EasyLaunchpad:

Sends a confirmation email using DotLiquid templates

Updates user records

Logs the transaction with Serilog

The email system can be extended to send:

Trial expiration reminders

Invoice summaries

Cancellation win-back campaigns

📈 Logging & Monitoring

Every payment-related action is logged with Serilog:

{

“Timestamp”: “2024–07–15T12:45:23Z”,

“Level”: “Information”,

“Message”: “User subscribed to Pro Plan via Stripe”,

“UserId”: “abc123”,

“Amount”: “29.00”

}

Hangfire queues and retries any failed webhook calls, so you never miss a critical event.

🔌 Use Cases You Can Launch Today

EasyLaunchpad’s payment module supports a variety of business models:

Model and the Example:

SaaS Subscriptions- $9/mo, $29/mo, custom plans

Lifetime Licenses- One-time Paddle payments

Usage-Based Billing — Extend by customizing webhook logic

Freemium to Paid Upgrades — Upgrade plan from admin or front-end

Multi-tier Plans- Feature gating via linked roles/packages

🧠 Why It’s Better Than DIY

With EasyLaunchpad and Without EasyLaunchpad

Stripe & Paddle already integrated- Spend weeks wiring up APIs

Admin interface to manage plans- Hardcode JSON or use raw SQL

Background jobs for webhooks- Risk of losing data on failed calls

Modular services — Spaghetti logic in controller actions

Email receipts & logs- Manually build custom mailers

🧠 Final Thoughts

If you’re building a SaaS product, monetization can’t wait. You need a secure, scalable, and flexible payment system on day one.

EasyLaunchpad gives you exactly that:

✅ Pre-integrated Stripe & Paddle

✅ Admin-side plan management

✅ Real-time email & logging

✅ Full webhook support

✅ Ready to grow with your product

👉 Start charging your users — not building billing logic. Get EasyLaunchpad today at: https://easylaunchpad.com

#.net boilerplate#.net development#easylaunchpad#Stripe .NET Core integration#Paddle in .NET#payment module SaaS

2 notes

·

View notes

Text

This week in listening 02/23/24

Okay, wow. Today was a massive day for new releases, so let's get a few of those out of the way first. Starting with...

Job For A Cowboy was like... not on my radar AT ALL this year. I listened to this band a bit around 2010, but they were always a little too extreme for me. I'll be honest, the album cover is what sold me on this. The art is giving me huge Born of Osiris vibes, which is another band I used to listen to in the 2010s and have actually been getting back into lately (The Discovery is a fucking incredible record). So, inspired by amazing psychedelic alien artwork, vague nostalgia, and a healthy dose of morbid curiosity, I decided to jump in to this as soon as I woke up. I am actually blown away by how good this is. I'm not a huge metalhead, so I struggle to describe the intricacies of this type of music, but I know for certain it's activating some disgusting primal neurons in my brain. It's heavy, technical, colourful, thoughtful. The guitars whip around with the sharpness of wire torture devices as the bass paints terrifying rhythms into the background of every song. The drums don't just keep up, they hold the leash to maintain control over the chaos and do so flawlessly. The vocals? They add a nice flavouring to the sound but I'm honestly so intrigued by what's going on underneath the surface of these songs that I keep forgetting to listen to him. It's not really a bad thing.

When I was just starting to get back into metalcore a few years ago, I spent a night swapping the aux and drinking beers with my best friend, and he threw on Darkest Hour's song DEMON(S). I was blown away by their ability to inject melody into their sound in a very subtle and nuanced way. They had a much heavier melodeath influence and didn't rely on huge soaring pop choruses like every other -core band of the 2000s. A lot of the melody in their songs comes from the riffs themselves and I love that about them. Even when clean vocals are present, they are mellow in pitch and are used almost more like a texture to enrich the riffing instead of being the main show. When Darkest Hour started dropping singles for this new album my ears perked up right away. Societal Bile showcased a more straight forward thrash influence and I was a little worried that this album would be lacking in melody, but I'm relieved to find that isn't the case. This song in particular is a perfect showcase of the band ability to be heavy and also execute insanely beautiful choruses without being corny about it. Another absolute standout track from this album is Mausoleum, which sounds almost like if Elliot Smith wrote a melodeath song. Trust me, check it out and you’ll know what I mean. I also want to take a second to appreciate that the artwork for this is clearly a nod to The Black Dahlia Murder (rest in peace Trevor Strnad).

Okay, massive diversion away from metal for a second. MGMT is a band that I have always reserved a spot in my heart for despite not being interested in... well... anything they've put out since their debut. Like many other people my age, Electric Feel is more than just a song, it's a core memory. I've listened to few tracks here and there from their other albums out of curiosity but nothing clicked. Not because they weren't good, but because I just wasn't at a place in my life where I was willing to let the magic of MGMT back into my heart. Loss Of Life may very well be the album to change that. When Bubblegum Dog dropped in 2023 I was immediately captivated by the strange, off kilter folkiness of it. Weird, and catchy? Wait a minute, that's the same reason I fell in love with Oracular Spectacular! I haven't listened to this full album yet so we'll see how much of it delivers on those qualities, but I have been jamming this single a lot over the past few days so I had to include it in the list.

I posted a full review for this album here, but I'll do a quick summary. I've racked up about 270 scrobbles out of this album over the past week since it was released, that's like listening to it about 24 times in full (or 3.4 times a day). I absolutely adore this album because it brings back to life everything I loved about music growing up. It's passionate, catchy, emotional, and heavy. Seriously, if you are a fan of My Chemical Romance, early Escape the Fate, AFI, The Used etc etc.. I can not beg you enough to give this album a chance. It's a very well written love letter to that era of 2000s post hardcore and emo bands and you will find it immediately familiar and comforting.

Okay, we are moving away from new releases now. I mentioned in a previous post how I was getting back into prog by listening to bands like TesseracT, Aviations and Artificial Language. The Contortionist is the newest addition to that roster and they bring something very unique to the table. Their instrumentals are heavy but methodical and hypnotic, much like the image on the album art. The thing that stuck out to about this band the most is their singer. I can't get over how much I love his mellow, folky approach to singing on a metal album. I've never heard anything like it. Seriously, take out the metal instrumentation and replace them with Nick Drake's Pink Moon and his voice wouldn't feel out of place at all. The result is a progressive metal album that feels extremely down to earth. If this album had a scent it would be of bark and dirt. Again, somehow the album art has done an immaculate job at representing the sound of the record. I'm obsessed. This is their last album (released in 2017) and is far from their most popular, but I'm curious to go backward and see how their sound progressed to this point.

Thursday is probably going to keep popping up on these roundups because they are my favourite fucking band right now and I never want to stop listening to them. I initially glossed over WATT as a “good but stagnant” entry to their discog, but after hearing lots of people say this is their favourite Thursday album, I knew there had to be something about it that I was missing. Don’t get me wrong, I always enjoyed it, but I felt it lacked the hooks and the gut wrenching punches of Full Collapse, and it also did nothing to push their sound forward like ACBTLD did. Well, I’ve spent the last two weeks listening to it non stop in honour of their WATT tour, and I have to say it’s grown on me so much to the point where it’s become my go to choice when I need a kick in the teeth. I think this album has some of Thursday's heaviest material both sonically and thematically, and it's also a bit more nuanced in the way it shows it's colours. It has a tough shell that takes multiple listens to crack, but it's so worth the time. “Signals Over the Air” was always my fav song from this, but recently “Steps Ascending” and the closer “Tomorrow I’ll Be You” have started to stand out as serious highlights to me. The ending of this song when Geoff yells “I’M CALLING FROM YOUR HOUSE, IN YOUR ROOM, IN YOUR NAME. LAYING IN YOUR BED, FOLLOWING YOUR DREAMS” sends chills up my spine.

Last but not least, I’ve been jamming this album again for pure nostalgia purposes. This album came out when I was 11 and was one of the first/most life changing CD's I ever owned. I was actually inspired to spin this again because of The Requiem’s song “Less Than Zero” has riffs that remind me soo much of some of the songs here. This album just never gets old though, despite it turning 20 next years (I want to cry thinking about that). In fact, I think the older I get, the better these songs sound. I was listening to this while on a long walk the other day and kept finding myself being wildly impressed by the songwriting and guitar riffing. There are so many subtle switch ups happening underneath the surface, and the way the two guitars play around each other is just incredible. The closer you listen the more depth there seems to be. "Under The Knife" and "Injection" are straight up two of the best melodic punk songs ever written. Pure genius.

#Spotify#rise against#thursday#the contortionist#the requiem#mgmt#darkest hour#job for a cowboy#progressive metal#death metal#post hardcore#hardcore punk#alternative music#melodeath#music

6 notes

·

View notes

Text

Yamaha Celebrates 25th Anniversary of the Revolutionary R1

Yamaha Motor Europe is proud to celebrate the 25th anniversary of the ground-breaking R1 with dedicated activities planned at the Yamaha Racing Experience (YRE). This year the YRE will be held at the legendary Mugello Circuit in Italy on the 21st and 22nd of July and will bring together some of Yamaha's biggest stars and enthusiasts to honour the remarkable legacy of the iconic machine. Since its launch, the Yamaha R1 has redefined standards of performance and innovation in the industry. Its 25-year journey of evolution is a testament to Yamaha's dedication to engineering excellence, which cemented the R1 as an icon of speed, power, and cutting-edge technology that revolutionised the sports bike market. Making its grand entrance in 1998, at the core of the R1 was an innovative, compact, and lightweight 998cc, liquid-cooled, 20-valve, double overhead camshaft, four-cylinder engine which featured a five-valve-per-cylinder head with redesigned valve sizes to boost torque and improved porting. However, the real game-changer came from Project Leader Kunihiko Miwa's ingenious decision to create the world's first vertically stacked gearbox in a production motorcycle, which resulted in a lighter, shorter engine that allowed for a longer swing arm, enhancing traction while maintaining a conventional sports bike wheelbase. In addition to its innovative powertrain, the 1998 R1 introduced an all-new aluminium Deltabox II chassis, a heavily braced alloy swingarm, a Yamaha Monoshock shock absorber, and upside-down 41mm fully adjustable front forks developed in collaboration with Öhlins. This Grand Prix-inspired compact chassis and suspension setup offered unrivalled handling and manoeuvrability, setting a new benchmark for modern sports bikes, with the R1 producing an astonishing 150PS while weighing only 177 kg. The R1's racing success was equally remarkable. At the prestigious Isle of Man TT, the bike made history in 1999 when David Jefferies stormed to the TT Formula One victory, in the process setting a record 121,235 mph lap, before going on to win the Senior race and the Production TT, confirming the R1’s racing pedigree to the world. As Yamaha continued to refine and improve the R1, the 2000 model was launched with revisions to over 250 parts, including engine and chassis enhancements, more aerodynamic bodywork, and a new titanium muffler. Two years later, in 2002, Yamaha introduced the next generation of R1, led by Project Leader Yoshikazu Koike, which showcased a groundbreaking vacuum-controlled fuel injection system that provided refined power output and a new Deltabox III frame which was lighter and yet 30% stronger in torsional rigidity. The year 2004 marked the arrival of the fourth generation R1 featuring new engine with larger bore and shorter stroke and closed-deck cylinder design, as well as fracture-split (FS) connecting rods, RAM-air intake, new under-seat exhausts, revised chassis geometry and a sharpened body design. For the first time a production motorcycle was achieving the 1:1 power to weight ratio, thanks to the 180PS delivered by the completely new power train. The R1 that was unveiled in 2007 boasted Yamaha's innovative YCC-T ride-by-wire throttle system and electronically controlled variable air intake funnels (YCC-I). Project Leader Makato Shimamoto also introduced a new four-valve design motor, slipper clutch, an improved Deltabox frame as well as improved brakes and suspension. Building on its legacy, Yamaha launched the next generation R1 in 2009, featuring a ground-breaking crossplane crankshaft engine, directly derived from Yamaha’s MotoGP M1. This unique design reduced inertia forces and delivered a more linear throttle connection. Next to that, Development Leader Toyoshi Nishida introduced twin fuel injectors, a new lightweight aluminium Deltabox frame, cast magnesium subframe and cutting-edge electronics. This model set the standard for handling and performance in the world of racing in 2009, highlighted by the incredible performance of American Ben Spies in WorldSBK, with the rookie recording 14 wins in 28 races to claim the 2009 title. Reinforcing the competitiveness of the R1 that year, the YART Yamaha EWC team was crowned Endurance World Champions, while Leon Camier won 19 out of 26 races on his way to lifting the British Superbike Championship, and Katsuyuki Nakasuga clinched his first Japanese Superbike Championship title. Constantly looking to innovate, the 2012 R1 incorporated a traction control system that adjusted ignition timing, fuel delivery, and throttle opening to maintain optimal traction, enhancing drivability and fuel consumption. To mark another ground-breaking step, the 2015 R1 was launched with a powerful 200PS engine and was the first production motorcycle equipped with a six-axis Inertial Measurement Unit (IMU) and electronic support systems – developed and proven in MotoGP. With a dry weight of 179 kg and a host of racing features the 2015 R1 has been a sensation. Project Chief Hideki Fujiwara also introduced the top-of-the-line, limited edition R1M which featured electronically controlled suspension, a lightweight carbon-fibre cowl, and an onboard data logger to cater to the needs of serious racing and track day devotees. The 2018 R1 model offered riders an even more extensive array of sophisticated electronics, and the addition of a Quick Shift System (QSS) with a blipper function for clutchless up and downshifting took the R1 and R1M’s performance on the street and track to the next level. The R1’s handling performance was refined with more progressive mapping on the Lift Control System as well as revised suspension settings – and the Öhlins Electronic Racing Suspension on the R1M featured a revised interface for a more intuitive set-up. For 2020, the R1 featured a CP4 engine with new cylinder head, camshafts and injection system – while the extensive electronic rider aids were refined to ensure even higher levels of controllability. A new EBM (Engine Brake Management) enabled the rider to select one of three different engine braking forces to match riding conditions – and the new Brake Control (BC) system gave added confidence and control when cornering. With revised damping valves and a reduced spring rate, the R1’s 43mm KYB forks provided increased feedback for a more natural handling feeling. And for improved chassis performance and reduced lap times the R1M was equipped with a new rear shock and uprated Öhlins ERS NPX gas pressurised forks. Over recent years, the R1 and R1M have continued to evolve and remain a dominant force on the racing scene, with Pata Yamaha Prometeon Official WorldSBK Team’s Toprak Razgatlıoğlu and Andrea Locatelli leading the charge in the FIM Superbike World Championship. The highlight of which was Razgatlıoğlu’s 2021 WorldSBK Championship winning season that saw the Turkish rider rack up 13 race wins and 16 further podiums on his way to the title, while Italian Locatelli has grown from strength-to-strength on the R1 and has 11 podiums to his name so far. On top of this, the R1 has demonstrated its prowess all over the world, with the Yamaha Factory Racing Team winning the historic Suzuka 8 Hours endurance race four times in a row between 2015-2018, plus Cameron Beaubier (2015, 2016, 2018, 2019, 2020) and Jake Gagne (2021, 2022) securing seven of the last eight AMA Superbike titles. In 2021, Nakasuga would lift an incredible tenth Japanese Superbike Championship, with Tommy Hill (2011), Josh Brookes (2015), Tarran Mackenzie (2021), and Bradley Ray (2022) all being crowned British Superbike Champions on the R1. As the legacy of the R1 continues to grow, Yamaha remains committed to pushing the boundaries of innovation with the introduction of the R1 GYTR. GYTR (Genuine Yamaha Technology Racing) is Yamaha’s in-house specialist racing component division that has been developing performance enhancing technology for over 40 years. Designed specifically for track-day riders and racers who recognise Yamaha’s winning performance and premium quality, the 2023 R1 GYTR is faster and more precise than ever. Manufactured to comply with FIM Stock 1000 regulations, this high-specification machine provides individuals and teams with the ultimate canvas to create their own unique superbike. The R1 GYTR is equipped with over 25 GYTR race specification components including an Akrapovic race exhaust system, racing ECU, wiring harness, GYTR chassis parts, drive system and complete race cowling in primer white – plus much more. The R1 GYTR is available exclusively from GYTR PRO SHOPS. To mark such a momentous anniversary, the Yamaha Racing Experience at Mugello will host the celebration activities for the R1, with the Tuscany circuit, renowned for its fast and challenging track layout that makes it a favourite among riders and fans alike, providing the perfect setting to honour such an incredible machine. Usually the event is exclusive to R1M customers, however the 2023 YRE will be open for the first time to R1 owners to mark this momentous occasion, with two different options available to them to attend. There are 25 spots available to R1 owners for the whole two days program, where they can enjoy the full Yamaha Racing Experience along with the R1M customers – which includes track sessions on both days, the ability to get advises from Yamaha racing technicians to give their bikes the optimum setup, exclusive tours of the Pata Yamaha Prometeon WorldSBK pit box, and much more. Click here to learn more and register for the two-day whole YRE experience. There is also an option for R1 owners to attend just on Saturday, where they can register for up to two track sessions for free and still enjoy the event atmosphere, and go behind the scenes in the Pata Yamaha Prometeon garage. For more information on this option and to register to attend just on Saturday, click here. The track sessions at the YRE will see owners get the chance to meet and ride alongside some of Yamaha’s biggest stars from WorldSBK, including Pata Yamaha Prometon WorldSBK riders Toprak Razgatlıoğlu and Andrea Locatelli, the GYTR GRT Yamaha WorldSBK Team duo of Remy Gardner and Dominique Aegerter, GMT94 Yamaha WorldSBK Team’s Lorenzo Baldassari, Yamaha Motoxracing WorldSBK Team’s Bradley Ray, plus YART Yamaha Official EWC Team’s Niccolò Canepa. The 25th-anniversary celebration at the YRE promises to be an exclusive experience for all R1 and R1M owners to come together and celebrate these iconic machines, with a special exhibition of R1s from across the years and including a collection of some of the most memorable race bikes, with the event showcasing the R1’s enduring legacy in the world of motorcycling. Paolo Pavesio Marketing and Motorsport Director, Yamaha Motor Europe “We are proud to honour the 25th anniversary of the Yamaha R1 in 2023. The R1 has been a game-changer in the world of motorcycles, pushing the boundaries of performance and innovation and constantly evolving to be at the pinnacle of the racing world. It is a bike that has redefined what is possible during the last 25 years with technology and innovations derived directly from MotoGP and WSBK. The Yamaha Racing Experience at Mugello will be something special this year, the perfect opportunity to salute such an iconic machine together with our customers and some of Yamaha's biggest stars.” For more Yamaha Motorcycles UK news check out our dedicated page Yamaha Motorcycles UK or head to the official Yamaha Motorcycles UK website yamaha-motor.eu/gb/en/ Read the full article

2 notes

·

View notes

Text

How Magnesium 6-8 Alloy Improves the Nodularization Process in SG Iron Treatment!

Strong, flexible, and dependable materials are becoming more and more in demand in the foundry sector. SG Iron, sometimes referred to as Spheroidal Graphite Iron or Ductile Iron, is one substance that continuously satisfies these requirements. The technique that gives SG Iron its special qualities is equally as remarkable as its strength. The Magnesium 6-8 Alloy, a crucial component for efficient nodularization, is at the center of this procedure.

What is SG Iron?

Instead of the flake-like graphite present in grey cast iron, SG Iron is a type of cast iron that has spherical (nodular) graphite in its microstructure. Because of these spherical nodules, SG Iron is able to retain its strength and ductility, which makes it appropriate for uses where stress and impact resistance are necessary.

It is extensively utilized in: Automobile parts (suspension parts, crankshafts)

Pipe and valve fittings

Agricultural equipment

Heavy machinery

Wind turbine parts

But how does graphite take this spherical form? That’s where the nodularization process comes into play.

The Purpose of Magnesium in Nodularization

Magnesium is responsible for modifying the structure of graphite during solidification. When added to molten iron, it suppresses flake formation and encourages the development of spherical nodules. This not only improves strength but also enhances elongation and fatigue resistance.

However, handling pure magnesium is highly reactive and hazardous. For this reason, foundries use controlled magnesium alloys—specifically those with 6-8% content—which act as Nodularisers, allowing for safer, more efficient, and consistent processing during S G Iron Treatment.

What is Magnesium 6-8 Alloy?

These alloys have typically contains:

6-8% Magnesium

Silicon

Iron (Fe) base

This composition allows for a controlled and gradual reaction with molten iron, delivering consistent magnesium recovery rates and ensuring proper nodularization.

Key Benefits of Using Magnesium Alloy

1. Regular Nodularization

The optimal magnesium concentration for different grades of ductile iron is between 6 and 8%. It leaves enough magnesium behind to generate graphite nodules while supplying enough magnesium to react with sulfur and oxygen in the melt.

2. Better Microstructure

Graphite nodules that are uniformly shaped are encouraged to develop by magnesium alloy. Increased tensile strength results from this.

Better elongation properties

Enhanced fatigue resistance

3. Reduced Carbide Formation

Carbides may occur in the matrix as a result of too much or unequal magnesium. When utilized properly, magnesium reduces this risk and guarantees a ductile, clean construction.

4. Stable Metallurgical Process

The use of alloyed magnesium helps maintain consistency across melts. This stability is essential for large-scale production, where quality control is critical.

5. Safe Handling and Application

Magnesium alloy is available in various forms such as ingots, cored wire, and crushed granules. Each form is designed for specific treatment practices, offering better control and safety compared to pure magnesium.

6. Cost Efficiency

Due to its high reactivity, pure magnesium results in more wastage. The alloyed form, on the other hand, ensures higher magnesium recovery, better usage efficiency, and less material loss—resulting in overall cost savings.

Application Methods in Foundries

There are various methods of introducing Mg 6-8 into molten iron:

1. Tundish Cover Method: Placing the alloy in a covered ladle and pouring molten metal over it. Simple but can result in some magnesium loss.

2. Cored Wire Injection Method: Using a wire feeder, magnesium is injected into the molten metal as wires. This enables little reaction loss and accurate control.

3. Converter or Sandwich Method: Magnesium alloy is buried under a cover material at the bottom of the ladle to control the reaction rate.

Each foundry selects the method based on its production setup, melt size, and casting requirements.

Example: Real-World Impact

A mid-sized auto parts foundry reported the following improvements after switching to Magnesium alloy:

Reduction in reject rate by 25% due to fewer casting defects

Increased magnesium recovery from 30% to over 45%

Improved nodule count and nodularity in final castings

These outcomes resulted in reduced production costs as well as improved customer satisfaction and product quality.

Conclusion

The success of S G Iron Treatment relies heavily on precise and controlled nodularization. Using magnesium alloys with a balanced composition ensures not only better mechanical performance but also consistency across production batches.

By enhancing graphite morphology and minimizing process-related risks, these alloys are instrumental in producing high-quality ductile iron castings for a wide range of industries. #Magnesium6-8Alloy#SGIronTreatment#CoredWireInjection#Nodularisers

0 notes

Text

India’s Top Inoculant Wire Feeder Producer | Superior Manufacturing

India’s metallurgical and foundry industries have experienced tremendous growth, particularly in the production of essential materials like inoculant wire feeders. These feeders play a crucial role in enhancing the quality of metal casting, especially in industries like automotive, aerospace, and heavy machinery.

Indian producers have earned a reputation for delivering top-notch products with a focus on precision, innovation, and reliability. In this article, we’ll explore why these feeders are important for industries reliant on metal casting, how Indian manufacturers have emerged as global leaders, and the unique qualities that set them apart in terms of production excellence.

Importance of Inoculants in Metal Casting

Inoculants play a vital role in the casting of metals such as cast iron and steel. They are added in small quantities to molten metal to modify its microstructure, which enhances its mechanical properties and reduces defects. In particular, inoculants help to control the solidification process, resulting in finer grain structures and improved overall performance of the cast product.

One of the most efficient ways to introduce inoculants into molten metal is through feeder systems, which ensure controlled and accurate dosing. This precise addition improves the quality of the metal, minimizes waste, and increases the efficiency of the casting process. The result is a more cost-effective production method and a higher-quality end product.

Key Benefits of Using These Systems:

Enhanced Material Strength: Inoculants help refine the grain structure of the metal, leading to stronger and more durable castings.

Reduction in Defects: By preventing the formation of carbides and other unwanted phases, inoculants help reduce common casting defects such as porosity and shrinkage.

Process Optimization: The accurate delivery of inoculants ensures uniformity in the final product, reducing the need for rework and lowering production costs.

Improved Surface Finish: Better solidification control leads to a smoother and more consistent surface on cast components.

Leading Indian Producers Inoculant Wire Feeders

Several Indian companies have become prominent producers in this field, gaining recognition for their advanced production processes and commitment to quality. These companies supply domestic and international markets with feeders that meet stringent industry requirements, contributing to the high performance of critical cast components in various industries.

1. Elkem India Pvt. Ltd.

A subsidiary of the global industry leader Elkem, Elkem India has built a strong presence in the Indian market by providing reliable and advanced solutions. The company’s commitment to research and development enables it to stay ahead of technological trends, offering efficient systems that improve the quality of castings in automotive, construction, and other industries.

2. Ferroglobe India

Ferroglobe India is known for producing a wide range of silicon-based products, including inoculants that enhance the quality of steel and iron castings. The company’s high-performance feeders are designed to meet the demands of industries requiring precision and consistency. With cutting-edge technology and a focus on sustainability, Ferroglobe India is a leader in this field.

3. IFGL Refractories Ltd.

IFGL Refractories Ltd. has established itself as a trusted name in India’s metallurgical industry. The company produces a variety of products for the foundry sector, with its feeders recognized for their role in optimizing casting processes. By focusing on customer satisfaction and consistent product quality, IFGL has earned a strong reputation both in India and abroad.

4. Simco Group

Simco Group is a prominent Indian manufacturer and exporter of advanced casting systems. Their products are widely used in industries that require high-performance materials, such as automotive and heavy machinery. Simco’s dedication to technological advancement and rigorous quality control ensures that its solutions meet the highest international standards.

5. Tata Steel Advanced Materials

Tata Steel, one of India’s largest and most respected companies, has expanded into producing advanced materials, including feeder systems. Known for its innovation and sustainability practices, Tata Steel’s products are designed to enhance the efficiency of casting operations, ensuring high-quality output with minimal environmental impact.

Why Indian Manufacturers Stand Out

Indian producers have gained a competitive edge in the global market for several reasons, positioning themselves as top suppliers in the casting industry for both feeder systems and alloys ferro silicon magnesium in India:

1. Advanced Manufacturing Technology

India’s leading manufacturers have invested in modern production facilities that allow for high-precision manufacturing. By incorporating automation and cutting-edge technologies into their processes, these companies ensure that their products meet the strict quality standards required by industries worldwide.

2. Innovation and R&D

Innovation is a key driver for success in the Indian alloy industry. Leading producers are continually developing new solutions that improve casting efficiency and product quality. By focusing on research and development, these companies stay ahead of industry trends, offering customized solutions that meet the unique needs of their customers.

3. Customization and Flexibility

Indian manufacturers are known for their ability to provide tailored solutions. Industries that require specific compositions or designs can rely on Indian companies to meet their exact requirements. This flexibility, combined with a strong focus on customer satisfaction, has helped Indian producers build long-term relationships with clients around the world.

4. Cost-Effectiveness

One of the key advantages Indian producers offer is the ability to provide high-quality products at competitive prices. By streamlining production processes and leveraging economies of scale, Indian manufacturers can offer cost-effective solutions without sacrificing quality. This makes them attractive suppliers for industries looking to optimize their production costs.

5. Sustainability Initiatives

Environmental responsibility is becoming increasingly important in the manufacturing industry, and Indian producers are leading the way in adopting sustainable practices. Many companies have implemented measures to reduce energy consumption, minimize waste, and use renewable resources, ensuring that their products are not only high-quality but also eco-friendly.

Global Reach and Future Prospects

The success of India’s leading manufacturers has extended far beyond the domestic market. These companies have established strong export networks, supplying high-quality products to industries around the world. As global demand for efficient and precise casting systems continues to rise, Indian producers are well-positioned to meet these needs, ensuring consistent growth and further expansion in the future.

Conclusion

India’s top inoculant wire feeder producers have earned their place in the global metallurgical industry through superior manufacturing practices, innovation, and a commitment to quality. By investing in advanced technologies and focusing on customer satisfaction, Indian manufacturers continue to meet the growing demand for high-performance inoculant wire feeders in industries worldwide. Their ability to provide cost-effective and sustainable solutions makes them the go-to choice for businesses seeking reliable and high-quality products.

#inoculant wire feeder#ferro silicon magnesium in india#ferro silicon magnesium#magnesium cored wire injection system#cored wire#manufacturers

0 notes

Text

How Indian Ferro Titanium Producers Are Meeting Global Demand for Cored Wire and Lumps!

In a rapidly evolving global metals industry, Ferro Titanium has become an essential alloying element, especially in the production of steel and other specialty alloys. With its ability to enhance strength, reduce grain size, and remove oxygen and nitrogen during production, ferro titanium is in growing demand across sectors such as Automotive, Aerospace, Shipbuilding, and Heavy Engineering.

As the market expands, India has Emerged as a Leading Player, especially in the supply of Ferro Titanium Cored Wire and Lumps. But how exactly are Indian Producers Meeting the Global Demand? Let’s explore the innovations, infrastructure, and strategies that are helping Indian manufacturers rise to the occasion.

The Rising Global Demand for Ferro Titanium

In the global steel and alloy industry, efficiency, purity, and cost-effectiveness are more important than ever. Ferro titanium is widely used as:

A Deoxidizing Agent in steel production

A Grain Refiner in aerospace-grade alloys

A Stabilizer in stainless steel manufacturing

The demand for Ferro Titanium Cored Wire—used in steel refining processes—and Lumps—used as alloying additions—is growing steadily due to increased global steel output and stricter quality standards in finished metals.

Countries across Europe, the Middle East, East Asia, and North America are importing large volumes of ferro titanium in various forms. This demand surge has opened the door for India’s producers to play a more central role.

India's Strategic Advantage in Ferro Titanium Production

India offers several Competitive Advantages in the ferro alloys industry:

Abundant access to titanium scrap from domestic and regional sources

Advanced processing technology to produce high-purity alloys

Skilled metallurgical workforce and trained engineers

Favorable trade policies and competitive export pricing

These factors have enabled Indian companies to scale operations and develop a strong export network.

Vertical Integration for Quality Control

One of the key strategies employed by Indian producers is Vertical Integration. Many leading manufacturers control the full supply chain—from Titanium Scrap Sourcing to Refining, Melting, and Packaging.

This level of control allows them to:

Maintain consistent Chemical Composition

Achieve Customized Sizing for cored wire and Ferro Titanium Lumps

Deliver High-Purity Alloys with precise specifications

Ensure Fast Turnaround Times for international orders