#Dowel Bar Code

Explore tagged Tumblr posts

Text

Engineering Best Practices for Dowel Bars in Rigid Slabs

Dowel bars in rigid pavement are the unseen heroes of structural durability. Found across expressways, airfields, industrial yards, and bus lanes, they’re vital for smooth load transfer between concrete slabs. But their success isn’t based on guesswork—precision is everything. Coupled with innovations like construction rings and Super Rings, dowel bars have evolved from simple cylindrical inserts to engineered components in rigid pavement systems.

From the very beginning of slab installation, construction rings play a foundational role. These elements help maintain proper spacing, alignment, and position during placement, preventing misalignment that could otherwise lead to joint failure. Meanwhile, Super Rings—known for their high tolerance and performance in extreme loads—deliver unmatched holding power, particularly in high-traffic zones. These two elements, when integrated properly, elevate the lifespan and integrity of rigid pavement structures.

Why Proper Load Transfer Can’t Be Overlooked

Concrete expands and contracts. It cracks. It shifts. That’s inevitable. Without an effective load transfer system, these natural changes cause differential settlement—making one slab sink while the next holds. The result? A bumpy ride, early cracking, and costly maintenance. Dowel bars in rigid pavement solve this problem by linking adjacent slabs, distributing the wheel load evenly, and reducing stress concentration on the joint.

But even the best dowel bar won’t work if placed incorrectly or without adequate alignment support. This is where construction rings step in. These devices ensure precise positioning during installation, especially in repetitive paving operations. Super Rings, on the other hand, are engineered to keep the dowel in optimal alignment even when subjected to heavy vibration or shifting during the pour. Together, these components form a fail-proof trio.

Installation Techniques That Define Performance

Surface Preparation and Alignment

The foundation of rigid pavement success starts with a clean, compacted sub-base. Once formwork is in place, construction rings are used to hold dowel bars exactly perpendicular to the joint face. Misalignment by even a few degrees can compromise load transfer and cause binding.

Joint Width and Embedment Length

The spacing of dowel bars typically ranges from 300 mm to 400 mm, depending on load class. Embedment length is equally critical—ideally half the length of the dowel sits in each slab. The role of Super Rings becomes evident here, locking the bar into perfect position during curing, preventing any shift due to weight or concrete flow.

Benefits That Go Beyond Basics

Long-Term Pavement Performance Proper dowel installations drastically reduce faulting at joints, leading to smoother surfaces and fewer maintenance disruptions.

Cost Efficiency Fewer repairs mean less downtime and resource allocation. Integrating Super Rings early on may seem like a minor added cost, but they pay off in lifecycle extension.

Sustainability and Resource Optimization With longer service life, pavements need fewer reconstructions. Fewer reconstructions mean reduced use of concrete, fuel, labor, and logistics—a win for both budgets and the environment.

Common Pitfalls and How to Avoid Them

1. Misaligned Bars

A slightly tilted dowel may create restraint instead of freedom of movement. Using construction rings during placement eliminates such misalignments.

2. Floating During Concrete Pour

The buoyancy of steel in fluid concrete is often underestimated. This is why Super Rings—with their strong anchoring capability—are essential.

3. Inadequate Bar Length or Diameter

Cutting corners on dowel specs often leads to cracked slabs. Always consult pavement design loads and use recommended diameters.

Final Thoughts: Engineering That Lasts

Dowel bars in rigid pavement aren’t just optional accessories—they are a critical design element. When paired with construction rings for alignment and Super Rings for stability, they offer unparalleled longevity and performance in rigid slab systems. These practices aren’t just “best”; they’re essential. Long-lasting roads, safer industrial platforms, and stronger airport runways all begin with what lies beneath—precise, engineered connection.

#Dowel Bar Basics#Rigid Slab Tips#Concrete Dowels#Slab Joint Guide#Load Transfer Bars#Dowel Bar Size#Dowel Bar Use#Rigid Pavement#Slab Crack Fix#Pavement Joints#Dowel Bar Code#Slab Strength Bar#Tied vs Dowel#Bar Alignment#Bar Placement#Dowel Spacing#Rebar vs Dowel#Road Joint Bars#Slab Load Guide#Dowel Design Tips

0 notes

Text

How Kapila Steel’s Dowel Bar Standards Align with Global Construction Codes

Dowel bars have left a vital detail in civil engineering, mainly for pavements and urban slabs. These unassuming metal rods silently deliver the responsibility of transferring hundreds between adjoining slabs, minimizing joint deflection and stopping cracking. Their performance plays an instantaneous role in determining the energy, durability, and lifespan of a concrete structure. As construction standards tighten globally, so does the scrutiny over bar dowel satisfactory and compliance. This is where the role of reliable TMT bar manufacturers, like Kapila Steel, becomes critically important.

The moment any infrastructure project begins to scale, consistency in material strength and code alignment becomes non-negotiable. Dowel bars aren't just metal pieces—they’re precision-engineered elements that must meet exact tolerances. The early-stage selection of bar dowel products can influence the long-term success of pavements, industrial floors, and airport runways. In this scenario, engineers seek not just suppliers, but dependable allies.

Raising the Bar in Dowel Precision

Kapila Steel manufactures dowel bars with consistent diameter, length, and finish, ensuring seamless load transfer and preventing pavement distress. These bars are fabricated with exacting standards that reflect internationally recognized norms. Whether it's ASTM A615/A615M or BS 4449, Kapila’s production process mirrors the rigorous checks and balances that top global construction codes demand.

A Focus on Metallurgical Integrity

Material science lies at the heart of performance. Kapila Steel’s dowel bars are manufactured using advanced metallurgical techniques that ensure high tensile strength and ductility. Through controlled heat treatment and chemical balancing, the bars can endure cyclic loading, impact pressure, and even harsh weathering without fatigue.

Such attributes are crucial when aligning with Eurocode 2 or Indian IRC specifications. These standards emphasize not only physical dimensions but also fatigue resistance, corrosion tolerance, and load-sharing effectiveness. Kapila’s production plant adheres to these principles without compromise.

TMT Bar Manufacturers Who Think Globally, Deliver Locally

While the spotlight is on dowel bars, it’s important to understand that TMT bar manufacturers who get the details right here tend to apply the same ethos across all products. This is evident in how Kapila Steel handles their entire TMT lineup—built for resilience, earthquake resistance, and superior bonding with concrete. The global codes they follow for dowel bar production echo across their TMT bar solutions, creating a consistent reliability engineers can count on.

When Standards Meet Supply Chain Reliability

It's one thing to manufacture dowel bars that meet global standards. It's another to deliver them reliably, on time, and at scale. Kapila Steel operates with supply chain agility, enabling project managers to meet their construction timelines without compromising on material compliance.

The availability of bar dowel products, backed by thorough documentation and certificates of compliance, brings peace of mind to stakeholders who cannot afford risks in large-scale construction projects. It’s this harmony between engineering discipline and logistic efficiency that gives Kapila its industry edge.

A Smarter Choice for Builders and Engineers

In the end, aligning with global construction codes isn’t about ticking boxes—it’s about instilling confidence. Whether it's highway expansion, industrial floors, or mass housing projects, the quality of dowel bars can define the success or failure of the structure over time.

Kapila Steel stands as a quiet partner in this journey—through dowel bars that meet international standards and through a commitment to precision that’s visible in every delivery.

Conclusion

Global construction codes exist to ensure durability, safety, and structural integrity. Kapila Steel’s dowel bars don’t just comply—they contribute. Through manufacturing excellence, rigorous quality checks, and a mindset aligned with international engineering demands, Kapila Steel offers much more than metal rods. It delivers the foundation for lasting trust and construction that endures.

#Dowel Bar Specs#Global Codes Fit#Kapila Steel Bars#Bar Strength Test#Concrete Dowels#Code-Ready Steel#Global Bar Norms#Bar Quality Check#Steel Bar Grade#Kapila Bar Tech#Dowel Fit Guide#Bar Code Match#ISO Steel Bars#Bar Design Code#Durable Dowels#Code Safe Bars#Global Build Fit#Bar Spec Sheet#Dowel Compliance#Steel Code Align

0 notes

Text

Concrete Coring Company

Concrete Coring Company: The Backbone of Precision in Construction and Renovation

Concrete is the foundation—both literally and figuratively—of modern infrastructure. From highways to high-rises, this durable material is everywhere. But when it comes to making precise openings or performing modifications within these solid structures, brute force isn’t the answer. That’s where a concrete coring company becomes invaluable. These specialists bring expertise, precision tools, and safety protocols that make it possible to alter concrete without compromising its integrity.

Whether for new installations, retrofitting, plumbing, or electrical access, the work of a concrete coring company is critical. Understanding what they do, how they operate, and the value they provide can help developers, engineers, and facility managers appreciate their indispensable role in the construction world.

What Is a Concrete Coring Company?

A concrete coring company focuses on drilling precise circular holes through concrete, asphalt, stone, and other tough materials. These holes range from small to large diameters and can be created in walls, floors, ceilings, and structural components. Core drilling is not the same as traditional hammer drilling; it utilizes diamond-tipped drill bits and high-powered equipment to ensure smooth, accurate cuts with minimal disruption.

These companies provide services across multiple industries, including commercial construction, infrastructure development, residential renovations, industrial plant maintenance, and more. A reliable concrete coring company ensures the job is done safely, efficiently, and in compliance with engineering and regulatory standards.

Core Applications of Concrete Coring

Plumbing and Electrical Installations One of the most common reasons to hire a concrete coring company is for plumbing or electrical routing. Coring allows contractors to create access points for pipes, conduits, and wiring without damaging existing structures. Whether it’s for a new bathroom in a commercial building or adding fire protection systems to a warehouse, coring creates the path forward.

HVAC and Mechanical Systems Modern mechanical systems often need to pass through concrete floors and walls. A concrete coring company makes these modifications possible without introducing structural weaknesses. This is crucial in maintaining energy efficiency and mechanical performance in both residential and commercial facilities.

Retrofitting and Renovation Projects Older buildings often require updates that involve coring through existing materials. A concrete coring company plays an essential role in retrofitting buildings for new technology, updated safety systems, or compliance with revised building codes. This work often needs to be performed with great care to avoid damaging aging infrastructure.

Bridge and Highway Projects On highways, bridges, and tunnels, core drilling is used for sampling materials, installing sensors, or enabling the placement of new infrastructure. Core samples help engineers analyze the condition and composition of the concrete to inform maintenance or construction decisions.

Anchoring and Structural Reinforcement Concrete coring is often required before installing anchor bolts, dowels, or reinforcement bars. These installations are vital for structural upgrades or additions such as canopies, signage, or mezzanines.

The Technology Behind Concrete Coring

Modern concrete coring companies rely on sophisticated equipment that combines power and precision. At the heart of the operation is the diamond core drill—a machine equipped with a diamond-embedded bit capable of cutting through the toughest materials. These drills may be handheld or mounted depending on the job’s size and complexity.

Hydraulic, Electric, or Pneumatic Systems Core drills can be powered by hydraulic, electric, or pneumatic systems, each suited for specific site conditions. For example, hydraulic systems offer high power and are often used in industrial or outdoor applications. Electric drills are quieter and suitable for indoor work, while pneumatic systems excel in hazardous environments due to their non-sparking nature.

Wet vs. Dry Coring Most coring jobs involve wet drilling, where water cools the bit and reduces dust. This method prolongs equipment life and keeps the work environment safer. Dry coring, on the other hand, is used where water would be problematic, such as in electrical installations or where water damage must be avoided.

Safety and Compliance Considerations

A concrete coring company doesn’t just show up with a drill. There are rigorous safety protocols and compliance measures that must be followed. This includes proper personal protective equipment (PPE), noise reduction strategies, dust containment systems, and adherence to Occupational Safety and Health Administration (OSHA) standards.

Site Assessment and Planning Before any drilling begins, a thorough assessment is conducted. This includes identifying embedded utilities, reviewing blueprints, and coordinating with other contractors. Accidental hits to plumbing, electrical, or rebar systems can be costly and dangerous. A professional concrete coring company minimizes these risks with detailed preparation.

Dust and Silica Management Crystalline silica dust, produced during concrete drilling, is a major health hazard if inhaled. A reputable concrete coring company uses wet coring, HEPA vacuums, and dust collection systems to meet air quality standards and protect workers on-site.

Noise and Vibration Control Drilling concrete is inherently noisy, and vibrations can affect nearby equipment or structures. Core drilling produces significantly less vibration than other methods like jackhammering. Nonetheless, companies use isolation techniques and schedule work to minimize disruption to surrounding operations.

The Expertise of a Concrete Coring Company

Beyond their tools, what sets a concrete coring company apart is the expertise of their technicians. Core drilling is part science, part art. It requires an understanding of material density, structural load, bit speed, pressure application, and more. One miscalculation can result in a ruined surface, compromised integrity, or dangerous conditions.

Precision Work in Sensitive Environments Hospitals, data centers, laboratories, and active business settings often require coring without shutting down daily operations. A concrete coring company understands how to work with minimal mess, maximum efficiency, and total discretion.

Custom Solutions for Complex Problems Sometimes, a hole is needed in an awkward location—angled walls, confined spaces, or over water. Experienced technicians can adapt the method, equipment, and approach to meet project-specific needs. This level of adaptability comes only from specialized training and years of on-the-job experience.

Environmental and Sustainability Considerations

As sustainability becomes increasingly important in construction, a concrete coring company contributes by minimizing material waste and preserving existing structures. Instead of demolishing large sections of concrete, core drilling allows for surgical precision that reduces the need for reconstruction and waste disposal.

Many companies also use environmentally friendly cooling systems, recycle coring slurry, and implement energy-efficient practices. This environmentally conscious approach helps developers meet green building certifications and reduce overall environmental impact.

Choosing the Right Time for Coring

Timing is everything in construction. Core drilling should be done at a phase when structural analysis is complete and the area is accessible, but before finishes or sensitive materials are applied. A professional concrete coring company helps coordinate with project managers to slot the work at the optimal stage of construction.

In emergency situations—such as after discovering an obstruction or needing to reroute utilities—coring may be performed during off-hours or on accelerated timelines. The right company can accommodate these fast-turnaround needs with the same attention to safety and precision.

Conclusion: Why a Concrete Coring Company Is Indispensable

A concrete coring company plays a critical role in the success of countless construction and renovation projects. Their ability to create clean, precise openings in hardened materials makes them essential for installing utilities, updating systems, and maintaining infrastructure. Through advanced tools, trained technicians, and strict adherence to safety protocols, they ensure that concrete cutting is not just effective—but also efficient, safe, and structurally sound.

Whether you’re building from the ground up or modifying an existing structure, the precision and professionalism of a concrete coring company are non-negotiable. In a world built on concrete, they provide the finesse to make modern construction possible.

1 note

·

View note

Text

Customer Preferences in Choosing Dowel Bars in Japan

INTRODUCTION

In the construction industry, the choice of materials can significantly influence the quality, durability, and overall success of a project. Among these materials, dowel bars play a crucial role in reinforcing concrete structures. In Japan, where seismic safety and high-quality construction standards are paramount, understanding customer preferences when selecting dowel bars is essential. This blog explores the factors that influence these preferences and the trends shaping the market.

Quality and Durability

Japanese customers prioritize quality and durability when choosing dowel bars. Given the country’s susceptibility to earthquakes and extreme weather conditions, construction materials must meet stringent quality standards. Customers often look for dowel bars made from high-quality materials, such as fusion bonded epoxy coated bars, which offer superior corrosion resistance and longevity. Builders and engineers tend to prefer products that can withstand environmental stressors while ensuring structural integrity.

Corrosion Resistance

Corrosion resistance is a critical factor for customers in Japan, especially for projects located in coastal areas or exposed to harsh chemicals. Epoxy coated dowel bars are favored due to their protective coatings, which prevent rust and deterioration. This characteristic not only extends the lifespan of the bars but also reduces maintenance costs over time. As a result, customers are increasingly inclined to choose dowel bars that offer enhanced protection against corrosion.

Technical Specifications

Customers in Japan often seek detailed technical specifications when selecting dowel bars. Factors such as load-bearing capacity, tensile strength, and bonding properties are vital considerations. Construction professionals rely on these specifications to ensure that the chosen dowel bars will perform adequately in specific applications. Manufacturers that provide comprehensive technical data and performance metrics tend to build trust and rapport with their customers.

Regulatory Compliance

Japan has strict building codes and regulations, particularly regarding safety and structural integrity. Customers are more likely to choose dowel bars that comply with these regulations. Manufacturers that can demonstrate adherence to local standards and certifications are often viewed favorably. This compliance not only ensures safety but also reassures customers that they are investing in reliable and approved materials.

Cost-Effectiveness

While quality and performance are crucial, cost-effectiveness remains a significant consideration for customers. Construction companies often operate within tight budgets, so they seek materials that provide value for money. Epoxy coated dowel bars, although initially more expensive than traditional options, can prove cost-effective in the long run due to their durability and reduced maintenance needs. Customers are increasingly aware of the lifecycle costs associated with their material choices.

Supplier Reputation and Reliability

The reputation of the manufacturer plays a critical role in customer decision-making. Japanese customers often prefer to work with established and reputable suppliers known for their quality products and reliable service. Trust and credibility are vital in the construction industry, where timely delivery and product availability can significantly impact project timelines. Manufacturers that prioritize customer relationships and offer exceptional service tend to gain a competitive edge.

Sustainability Considerations

As the construction industry in Japan shifts towards more sustainable practices, environmental considerations are becoming increasingly important. Customers are more inclined to choose dowel bars produced using eco-friendly processes or materials. Manufacturers that adopt sustainable practices, such as recycling materials or reducing waste in production, are likely to attract environmentally-conscious customers.

Innovation and Technology

Customers are also interested in innovations that enhance the performance and application of dowel bars. Technologies that improve the manufacturing process, increase the strength of the bars, or offer additional features (like anti-corrosive properties) can influence purchasing decisions. Manufacturers that invest in research and development to create advanced dowel bar solutions will likely capture the attention of forward-thinking customers.

Conclusion

In Japan's competitive construction market, understanding customer preferences when choosing dowel bars is essential for manufacturers aiming to meet the needs of builders and engineers. Quality, durability, corrosion resistance, and compliance with regulations are just a few of the factors influencing these preferences. By focusing on these aspects and adopting sustainable practices, manufacturers can strengthen their market position and contribute to the construction of safer, more resilient structures across the country.

0 notes

Photo

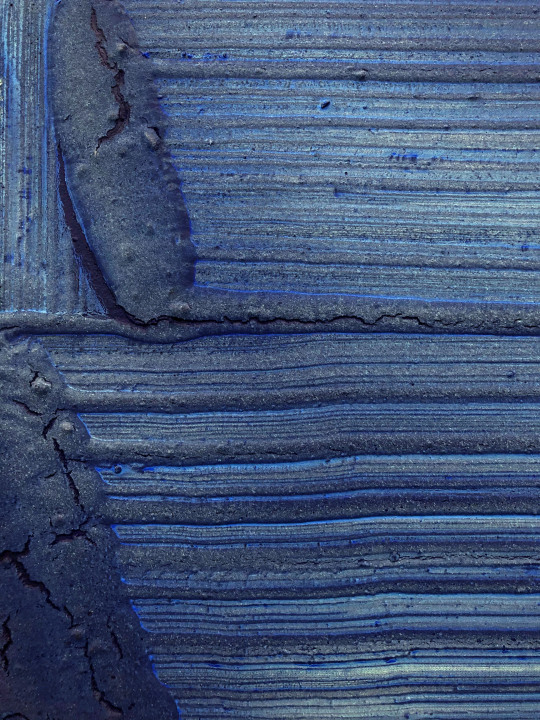

Blum & Poe in Los Angeles is currently showing two very different exhibitions. In the main gallery is a selected survey of work by Harvey Quaytman spanning three decades.

From the press release-

Harvey Quaytman (b. 1937, Rockaway, NY; d. 2002, New York, NY) came of age in the downtown art scene of 1960s New York, living and working in SoHo studios first on Grand Street and later at 231 Bowery, where he would remain through the late ’90s. Long considered an artist’s artist, the painter enjoyed a close-knit and vibrant artistic and social milieu, over the years sharing studio addresses with Brice Marden, Ron Gorchov, and James Rosenquist, among others. Quaytman’s emerging career as a young painter began in the heyday of Ab Ex with a marked allegiance to Gorky and de Kooning. This approach was slowly shed as the decade unfolded, as his work began to lean towards sculpture—compositions with curvilinear shaped canvases and rectilinear U-shaped bases that inhabited a newfound objecthood. This was followed by a forty-year engagement with geometric abstraction, his approach to painting in contradistinction to the prevailing trends of the era—first with Pop Art and later Neo Expressionism. Despite painting being declared “dead” by Minimalist and Conceptual artists of the time, Quaytman maintained a commitment to the medium and to his vision throughout, helping to shape an alternate trajectory for American painting.

The artist’s work in the ‘70s developed into shield-like forms that balance on curved platforms, conjuring a motion that would result in a critic calling them “rocking rectangles”—the body of work later known simply as “rocker” paintings. These eccentrically shaped works were hand-crafted (he would steam and bend the wooden stretchers himself), and inherently related to movement—inspired by Islamic calligraphy, rocking chairs, and the flight patterns of airplanes and birds. His experiments with shape continued in the late ‘70s, and through the manipulation of geometric intersections and overlapping forms that all the while imply motion, a unique group of paintings resembling anchors or pendulums emerged. In the 1980s, Quaytman began his cruciform paintings, investigations of the cross shape not as emblem but as two meeting vectors; Constructivist, perpendicular geometric compositions that focused on the reduced palette of black, white, red, rusted iron, and metallic gold. While these paintings represented a stark departure from his previous work, Quaytman continued to pursue visual movement as he conjured an interplay of symmetry and asymmetry.

Many of the works become even more intriguing up close. His use of different materials to achieve varying tones and textures makes them come alive.

The press release discusses a bit about his process in creating them-

As his paintings evolved in form and shape, variously touching upon Abstract Expressionism, Minimalism, Process Art, and Constructivism, Quaytman simultaneously developed a rigorous practice of experimentation with pigment. He was interested in the history, alchemy, and chromatic effects of color, seeking out unique tonalities at specialty stores at home and abroad, becoming a master of color and texture. He skillfully poured paint, spreading Rhoplex over canvas with broad wallpaper brushes after dusting it with pure pigment that settled in thick, unpredictable strata. He later flecked canvas with glass or iron filings and used additives such as marble dust in paint he always mixed himself. On this subject, he said: “It is very important to me to be reminded that I am not an alchemist but a man engaged in coded, layered conversation with my fellow man on what I hope to be (on another) level than words or music.”

On the second floor are Matt Johnson’s delightful sculptures whose familiar materials seem to defy gravity as they balance on each other in the compositions.

From the press release–

In an ever-expanding practice in search of the peculiar and the sublime, Johnson elevates the mundane to the exceptional. With a new body of work in carved and polychromed wood sculpture, Johnson depicts configurations of raw industrial materials from cinder block, brick, rebar, to traffic cones—permutations of information composed according to gravity, balance, and primitive instinct. A crude horse, a procession of block figures, cantilevered props, and fragile towers make reference to the concept of knowledge with small gestures—a lighter, a match book, a lightbulb, an atlas, and a monograph on Matisse. The doweled joints of glue and/or epoxy between bricks, blocks, and bars exist here not to defy gravity but to freeze balance and preserve delicate moments of experimental groupings. Like a still life, these works are organized information, like subatomic particles, atoms and elements, molecules and compounds, glued by gravity, and magnetic polarity, surfing in a sea of electrical conductivity.

Both of these exhibitions close 1/11/20.

#harvey quaytman#matt johnson#blum and poe#blum and poe los angeles#sculpture#painting#los angeles art shows#culver city art shows#culver city#los angeles#art#art shows

3 notes

·

View notes

Text

Act 2 (272-274)

I'm back to the mainschtream now, and the next section of Rose's walkthrough — she's multitasking like a boss!

Page 272 ==>

272. This section is labeled [A000], which in these days I can't help but read as Archive Of Our Own, even though AO3 was just barely going into its own beta in 2009.

Rose recounts what we've already figured out, which is mainly DON'T FUCKING TOUCH THE CRUXTRUDER, but also the other bits about dowels and lathes and all. She also confirms my slightly belated deduction about the Generic Objects.

"The life of the client user depends on it, and if your co-player has activated this device in your environment too, then yours does as well" is probably a sentence most gamers will have a hard time taking literally. Which is also probably something our malicious meteor-flingers (Skaianet, presumably?) are counting on.

"Removing the [Cruxtruder] lid signals the moment your life becomes a great whirling batshit pandemonium…"

I see our Lady of Loquacity is back, O She Of The (both literal and figurative) Purple Prose. Colorful metaphors for "deep shit" aside, her hardware-store key-maker and bar-code analogies are quite simple — she's keeping her audience in mind, it appears. (Reassuring, too, that the caring we see with John isn't limited to people she knows — she's taking the time to save complete strangers. Many/most of us would, I think, in a true End of the World situation, if we had the means & reach Rose does with her GameFAQ audience, but storywise it tells us about her ethics that this is a priority for her.)

273. One of Rose's multitasks is to pause and appreciate the destruction ("I've seen fire and I've seen rain, I've seen sunny days that I thought would never end; I've seen lonely times when I could not find a friend, but I always thought that I'd see you again.")

Some people don't like to watch the world burn.

274. There are depressingly few laptops that can actually survive being disconnected from power for more than an hour. I mean, software that lets you revise the geometry of someone's home from across the country has got to be a bit of a power drain — particularly if you're also Pestering someone who's on another planet, in the future, or both. But still.

Also, why exactly is the generator stored by the mausoleum? Is there some special reason the dead cat has a need for emergency electricity?

[I was going to include a gif of the dorky zombie cat puppet from the movie Re-Animator, but it's actually much grosser and more disturbing than I remembered so I think I'll skip it…]

2 notes

·

View notes

Text

The Mechanical Splices For Concrete Rebar

Mechanical splices are used to establish a mechanical connection between two pieces of reinforcing steel in concrete construction for joining reinforcing bars. The mechanical splicing system aligns and secures the joined rebar ends in an in-line connection suitable to meet appropriate splice requirements.

Mechanical splices are being adopted in project sites due to their flexibility of use in congested reinforcement places at construction joints. These connections are also more reliable than the lap systems because they do not depend on the concrete for load transfer. The splices also allow structural designers to achieve an ideal balance of steel and concrete by eliminating the additional rebar lap zone by meeting building code requirements in many areas. In seismic prone zones, these splices provide structural engineers the ability to design and build concrete structures that meet or exceed today’s stringent construction codes and federal regulations regarding seismic frame construction.

#1 Advantages of Mechanical Splices for Concrete Rebar

a. Maintains load path continuity of the reinforcement, independent of the condition or existence of the concrete.

b. Does not rely on the concrete for load transfer and therefore maintains structural integrity.

c. As mechanical splices do not overlap, less rebar is used, reducing some of the material costs.

d. It reduces the rebar congestion by decreasing the rebar in the lap zone and simplifying bar placement

e. Using mechanical splices allows the option of larger diameter rebar in a smaller column while minimizing congestion

f. Decrease the possibility of pockets and voids in the concrete

g. Provides higher performance than typical design lengths for lap splices

h. Allows the structural designers to achieve an ideal balance of steel and concrete by eliminating the additional rebar in the lap zone

i. Eliminates lap calculations

j. Eliminate the cost of breaking away massive amounts of concrete.

k. Faster installation

l. Reduces crane use

m. Limits drilling of formwork

#2 Different types of mechanical splices

1.Coupler for Thread-Deformed Bar

2.Upset Straight Thread Coupler

3.Non- upset thread Coupler

4.Cold-Swaged Threaded Coupler

5. Taper-Threaded Coupler

6.Straight Threaded Coupler with Upset Rebar Ends

7.Grout-Filled Coupling Sleeve

8.Combo Grout-Filled/Threaded Sleeve

9.Metal-filled coupling Sleeve

10.Cold-Swaged Coupling Sleeve

11.Shear Screw Coupling Sleeve

12.Coupling Sleeve with Double Wedge

13.Coupling Sleeve with Shear Bolt/Wedge

14.Dowel Bar Mechanical Splice

15.Compression-only Mechanical Splice

Applications of mechanical splices

A. Tunnels

B. Bridges

C. Commercial buildings

D. High-rise buildings

E. Subway

F. Airports and many more

G. Conclusion

Working with small diameter reinforcing bars may require the use of larger column dimensions to accommodate a greater quantity of bars. Using mechanical splices allows the structural engineers the option of using larger diameter rebars in the smaller column while minimizing congestion. All the advantages are discussed above and there are many types of mechanical splices available in the market, choose the right one as per project needs. Go for experienced manufacturers ADTOMall to find high-quality rebar splices.

0 notes

Text

What are the Types of Mechanical Splices for Rebars?

Mechanical rebar splices for rebars in concrete construction is an effective method of joining reinforcing bars. These are designed based on codes of standard practice.

Mechanical splices in reinforced-concrete construction should meet the building code requirements for developing tension and compression as required

Types of Mechanical Splices for Rebars

There are four major types of mechanical splices:

#1 Compression only mechanical splices or end bearing splices

#2 Tension and compression mechanical splices

#3 Mechanical lap splices or tension only mechanical splice

#4 Dowel bar mechanical splices

Compression-Only Mechanical Splices or End Bearing Splices

As it may be noticed from its name, this type of splice can resist compression stress merely. The compressive stress is transferred by vertical bearing from one bar to another one.

Compression only mechanical splices can be used when tension stress does not occur. Therefore, if this condition cannot be guaranteed, then it is advised to avoid the use of compression-only mechanical splices for reinforcement bars.

Steel filled coupling sleeve and strap type steel coupling sleeve are the two most commonly used examples of end bearing splices.

It should be known that the end of the rebars needs to be saw cut in the case of strap type steel coupling sleeve, but no special end preparation is needed for steel filled coupling sleeve.

0 notes

Text

Another glimpse of hell - mean (and some not-so-mean) nicknames on the Chinese gymternet TAKE 2.

DISCLAIMER:

1. Do not read this if you are easily offended by mean names, satirical jokes or dark humour.

2. The Chinese gymternet culture, and its internet culture as a whole, is very different from the ones on tumblr. Partly due to its insularity, certain terms used in the Chinese gymternet could come across to you as too rude or brass or unacceptable. However, please also take into account the difference in the cultural aspect as well. As a common dweller in the Chinese gymternet community, I can promise that 95% of the satirical teasings or mean names created by the Chinese has no derogatory intention. The truly degrading, racist or sexist nicknames have also been filtered out by me, so rest assured.

So now, if you are ready, please read on:

——————————————–The line to hell——————————————-

A. Foundation Course Chapter 2

1. 美x~; Pretty x~; adj.

Right. So you call someone a pretty something. But it also could mean “pretty” aka fugly something. No one knows if you are genuine about it, and so after awhile the expression took on a warped connotation. Both fans and haters use it. Decipher its true meaning before replying anyone on the forum!

E.g. Pretty ___ fell two times on beam today, made my day!

2. 水x~;Watery x~; adj.

In Chinese terms, if you “inject water” into something, you will make it less substantial, less genuine, less real and less deserving. So if someone are “watery”, people are inferring that she or he is overscored and undeserving of his credentials. Some fans nonetheless use it on their beloved ones as friendly teasing or a show of humility.

3. xoP - noun.

So the official rules of artistic gymnastics are written in the Code of Point (CoP). Some fans, however, like to invent their own rules (or twisting the meaning of existing rules) on judging a routine. As such, people would say that so-and-so have invented their own xOP to judge routines. One particular notorious member in the Chinese gymternet community has the ID lldtt06, and hence whatever he says, people will reply:

“Oh wow Mdm6 is judging routines based on his 6oP again!”.

(some famous rules of 6oP include - there should be deduction whenever one does shap to pak because its so “trite”, and many others lmao)

4. 烟花 - fireworks - noun.

Used to describe gymnasts who just can’t finish a routine without falling. The Chinese gymternet sometimes use the term “explode” to describe routines with falls (e.g. Seda’s beam exploded again!). So for those who routinely fall in their routine, they are called fireworks. Also used to describe routines that fail spectacularly.

e.g. “The beam routines of Seda are one hell of a firework performance, simply stellar - I’m in awe!”

———————————————————————————————————–

B. Country related mean terms: (used only to describe radical fans)

HOW DO PEOPLE CALL TEAM AMERICA?

池塘 - pond - noun.

Many think that certain American gymnasts are overscored. A pond has lots of water. Now look at the second bullet point in the foundation chapter - Do you get it now?

HOW DO PEOPLE CALL THE (RADICAL) FANS OF TEAM AMERICA?

蝌蚪 - tadpole - noun.

Originally used to mock Liukin’s fans because Liukin’s nickname is froggy (if you remember from my last post!), the term has been expanded to embody all die-hard/radical American fans.

莲子 - lotus seed - noun.

You know, lotus grows from pond and produces lotus seed. Yep.

HOW DO PEOPLE CALL THE (RADICAL) FANS OF TEAM RUSSIA?

鹅粪 - Goose poo - noun.

A pun of 俄粉, or Rus Fans. This term though has been picked up by Russian fans themselves as self-teasing, so its no longer a mean nickname…kind of.

Ruslut - noun.

Only the meanest Russian haters use this. Most people who use this are radical American fans so Russian fans often retaliate by calling them Uslut back.

HOW DO PEOPLE CALL THE (RADICAL) FANS OF TEAM ROMANIA?

火葬粉/火苗 - Cremnator/Little flames (Though I think kindling is a better translation, meaning wise)

So in my last episode I talked about this Bulimar set a cremation spell on Team Romania thing, so I guess it isn’t surprising that its die-hard fans are being called “flames/kindlings”?

HOW DO PEOPLE CALL THE (RADICAL) FANS OF TEAM CHINA?

好粉丝/宙国粉 - “Great” fans, Fans of team universe

I’ve talked about this last time so just revision here lol.

———————————————————————————————————–

C. Gymnasts related nicknames (some are not mean at all because I run out of mean nicknames lmao)

1. Daria Spiridonova - 累女士 - Mdm Tiresome

Back in 2014 when Spi first proved her worth Chinese fans had been calling her “the new love”, which is a proof of her popularity back then. Then in 2016 the sentiment took a turn for the worse as people realized that while she can only do bars (and that her bars isn’t even the best in the team), she kept getting selected over others (like Kapitonova and Skrypnik, at least in 2016) even in team competitions. So people started saying things like “Isn’t that super tiring for her teammate coz she can only do one event and will explode on all others”. Eventually people started to call her Mdm Tiresome - someone who drains the shit out of her teammate.

2. Brenna Dowell - 嘟嘟鸡 - Dodo Chicken

Dowell’s nickname is just realllllllly unfortunate lol, because its not her fault at all. So basically a forum member named lldt06 (inventor of 6oP, remember?) is a superrrrrrr radical fan of hers and kept saying things like “she deserve a WC bars gold”, “BEST bar composition in the worlddddddd”, “excellent AAer”, which have some truth in them but are still boosty nonetheless and didn’t sit well with many. So in 2015 when Dowell did badly for bars in Worlds many people were like “WHERES THE WORLD CHAMPION? I ONLY SEE A DODO CHICKEN.” and bamm the nickname stayed. Tbh the term dodo chicken doesn’t mean anything in Chinese. I think its the combination between the first syllable of her last name and Wild Chicken, the term for newbies/noobs as explained in my last post.

3. Lin Li - 慌姐 - Sister Panic

So Lin Li is a member of China’s National Team in the 2004 squad. She is actually amazing on bars but just doesn’t have the mental tenacity to do well in major competition. She always seems to be rushing through her routines which lead to mistakes after mistakes, so after a while ppl just called Sister Panic for short.

4. The pines of 4 season 春松,夏松,秋松,冬松

So like Chunsong’s literal translation is Spring Pine, and so 3 other gymnasts were bestowed the nickname of Summer Pine, Autumn Pine and Winter Pine respectively lmao. These are NOT mean nicknames.

So Autumn Pine was first to be invented and she is Flavia Saraiva. People started to call her Autumn Pine ever since 2014′s YOG because of how tiny she was - just like Chunsong. They are also great on beam as well and competed in the same beam finals before. At the same time though she is also different from Chunsong in many way so people called her Autumn Pine to highlight the similarity and contrast.

Then not long after that people discovered Morgan Hurd and they were like “oh my! isn’t she like a clone of Chunsong?”, so people started to call her Xiasong, or Summer Pine.

Lastly is the winter pine. People actually couldn’t find a good fit for it for a long time but they also felt it’s incomplete without a winter pine. Then one day someone posted this photo of a young Melnikova (the same photo as below) and people were like “WINTER PINE IS SUPPOSED TO BE FAIR AND LIGHT COZ ITS WINTER, SHE LOOKS ABITTTT LIKE CHUNSONG, MELNIKOVA WILL BE WINTER PINE”. And that’s it LMAO. Personally I don’t find Melnikova to resemble Chunsong, but whatever lol everything is cool as long as we have the four pines.

5. The Zoo (Russia’s WC team 2010) (Not mean)

Most members of Russia’s 2010 WAG team at the Worlds have animal related nicknames. The nicknames started off as mean nicknames as they are donned by Russian haters that “Russian team is like a zoo”, but eventually even the fans themselves began calling the team #TeamZoo, so they are no longer mean anymore.

Mustafina - 母狮 - lioness - Phonic translation

Dementyeva - 德猴 - Monkey - Because she’s kinda goofy like a monkey lol

Nabieva - 河马 - Hippo - Because she must have an animal related nickname as Mus has one and people found her to resemble a hippo somehow lmao

Afanasyeva - 鳄鱼 - Crocodile - She was fierce as a crocodile on floor and I think some of her facial features (being fierce and glaring and all) reminds some like a crocodile.

BUT HERE IS THE MEAN BUT ALSO NOT SO MEAN PART

Semenyeva is STRIPPED of a animal related nickname because Russian haters didn’t hate her enough to don her a nickname LMAO. She was listed as a RESERVE FOR NICKNAME. Until now she doesn’t have an animal related nickname and its so fortunate and sad at the same time.

Now I hope that you have enjoyed reading this second episode lmao, I think I’m really running out of nicknames so there shouldn’t be an 3rd episode sadly…. Still, hope it has made you laugh!

139 notes

·

View notes

Photo

This Kid Tower is made of Birch and Pine. The base including both steps and the support of the steps are made out of Birch, which is a very hard wood and can support an adult, but please don't hog the Kid Tower, let them use it. The upper frame is made of Pine making it bottom heavy which along with the angled legs makes it more sturdy and makes it hard to knock over, dogs, cats and a 4 year old have tried. This Kid Tower is built (or will be built for you) to last, to be passed to friends and family when your little ones no longer need a boost.

The lower dowel is detachable, once your little one has climbed up, slide the lower dowel in place and insert the linchpin and press the round top down on the dowel, the linchpin has a bit of a snap to it which makes it hard for little ones to remove. The linchpins large round top makes it near impossible to fit into a little mouth, but please don't try, that was not a challenge. The lower bar is extra safety especially for toddlers. The Tower is make to enhance both your child's and your time in the kitchen, close to Mom and or Dad without being held, no more sitting them on the counter or island holding them with one arm while you cook with the other. As they grow, cooking lessons, decorating baked goods, coloring easter eggs, decorating holiday cookies, rolling out pie crusts, kneading dough, using the juicer, all with supervision. The little ones should not be left alone in the Tower, as safe as I have designed them then can still climb out from the top, also new height and reach means a new world of things within their grasp.

The Tower weights 12 lbs. I do not add anything on the bottom of the legs due to the variety of floor types, depending on type you have you may want to add something to protect your floors, Do Not put felt furniture pads or anything designed to make sliding easy.

The standard is 35" tall which works with most kitchen counters and islands. If you need a different height just reach out to me since these are made to order. I use Non Toxic, Zero VOC Paint mostly Milk or Chalk, your call which. I used a non toxic anti skid powder additive to the paint that covers the steps and sides where little hands might hold on or little feet might stand. Since this Kids tower will mainly be used in kitchens and bathrooms (brushing teeth becomes an adventure) and spills happen, the additive greatly minimizes slips, but is kind to bare feet. There is no list of colors because there is no limit to the colors the paints come in, I am building one now that will be purple, for my favorite Model who can be seen in the photos above.

SHIPPING: If delivery is local to me, South/Central Jersey, Philadelphia area the Tower can be delivered or picked up, if it's destination requires shipping it can be shipped by USPS Ground in a box or it can be wrapped in a reusable moving blanket and shipped via Greyhound bus, their shipping of furniture is highly rated and moving blankets are better protection then a box and eco friendly. You will be notified when the Tower arrives at a terminal nearest you. In some area's Greyhound will deliver to your door, for an extra charge. You can use their site https://www.busfreighter.com/ to see where your nearest terminal is located and see what delivery services they offer, or I will be happy to do that for you with just your zip code. Shipping via Greyhound insures your Tower arrives in excellent condition.

0 notes

Text

How Construction Rings Strengthened Krupasindhu Commercial Complex – A Case Study

When the Krupasindhu team envisioned their twelve-floor commercial complex in the heart of Maharashtra, one problem loomed large—structural reliability under constant commercial load. Weak foundational systems often haunt developers like bad design haunts good architecture. In this case, the solution came down to a trio of engineering reinforcements: construction rings, hot rolled coil, and bar dowel systems—all critical in keeping the structure rock-solid.

The Risks of Underestimating Structural Load

Commercial buildings face unpredictable stress from high footfall, machinery, and shifting loads. Without the right reinforcement strategy, even the best architectural design falters. Poor quality materials or old-school rebar alignment can't hold up against dynamic movement or expansion-contraction cycles.

This is why choosing high-durability components like construction rings isn’t optional—it’s foundational.

The Krupasindhu Challenge: Going Taller, Safer

Located in a high-traffic zone, the Krupasindhu Commercial Complex needed reinforcement that wouldn’t just meet code—it had to exceed it. The building’s central spine, meant to hold elevators, HVAC systems, and multiple floor loads, demanded a solution that could distribute stress evenly across vertical columns and beam junctions.

This is where SRJ Steel’s construction rings entered the blueprint.

Construction Rings: The Silent Strengtheners

Think of construction rings as the ligaments in a building’s skeleton. They bridge joints and columns, ensuring the entire frame moves as one, not in isolated shivers. In the Krupasindhu project, these rings provided:

Enhanced shear resistance in beam-column junctions

Balanced tensile strength for vertical load bearing

Reduced risk of crack propagation under thermal expansion

More importantly, their precision fit meant faster installation with minimal on-site modification.

Hot Rolled Coil: The Backbone of Flexibility

Let’s talk material quality. The hot rolled coil used in these construction rings wasn’t just any generic steel. SRJ Steel sourced coils known for:

High ductility, allowing structural elements to flex without snapping

Uniform surface finish, which makes welding seamless

Consistent grain structure, ensuring load distribution under varying temperatures

These properties gave the Krupasindhu team the confidence to go taller without compromising lateral stability.

Bar Dowel Placement: Anchoring the Load

A structure is only as strong as its weakest transition. For Krupasindhu, this meant focusing on the slab-to-column transitions and expansion joints.

That’s where bar dowels came into play.

These dowels were strategically placed to:

Absorb and distribute floor load stresses

Prevent slab lifting or separation

Allow controlled movement between concrete sections

They essentially allowed the structure to “breathe” without breaking.

Why the Trio Worked: Harmony in Reinforcement

One part doesn't solve the puzzle. It’s the combination of precision-engineered construction rings, hot rolled coil, and bar dowel systems that made Krupasindhu’s build seamless. Each component played its part in:

Increasing seismic resistance

Speeding up construction timelines

Reducing long-term maintenance costs

That synergy helped SRJ Steel deliver more than just material—it delivered peace of mind.

Lessons from Krupasindhu: Building Beyond the Blueprint

Krupasindhu Commercial Complex stands today not just as another real estate addition—but as a case study in how smart material choices lead to safer, more resilient builds.

And this isn’t just about skyscrapers. Whether it's mid-rise housing, hospitals, or industrial parks, incorporating construction rings, hot rolled coils, and bar dowel connections can mean the difference between mediocre and masterpiece.

Looking Ahead: Smarter Steel, Smarter Structures

Projects like Krupasindhu didn’t cut corners—and it shows. As more developers focus on longevity and structural integrity, the demand for tested reinforcements is rising.

Reinforcement that holds firm when pressure rises? That’s what SRJ Steel’s materials delivered.

Projects like Krupasindhu trust advanced reinforcement solutions—shouldn’t yours?

#Construction Rings#Structural Rings#RCC Ring Uses#Rebar Ring Design#Beam Ring Setup#Ring Beam Role#Ring for Columns#Concrete Ring Bar#Building Reinforce#Site Ring Layout#TMT Ring Bar#Tie Ring Use#Strong Ring Frame#Ring in RCC Work#Joint Support Ring#Load Bearing Ring#Ringed RCC Beam#Reinforced Ring Bar#Steel Ring Design#Column Ring Fixing

0 notes

Text

Why Dowel Bars Deserve More Attention?

In concrete road construction, one small mistake can turn into massive repair costs. And often, that mistake is ignoring dowel bars—the unsung heroes of load transfer. These simple steel rods are often overlooked, but they’re essential in keeping concrete pavements stable, crack-free, and cost-effective in the long run.

If you’re in infrastructure or road projects, understanding the correct use of dowel bars in concrete can make or break your pavement’s durability.

What Are Dowel Bars and What Do They Do?

Dowel bars are cylindrical steel rods placed across transverse joints in concrete pavements. They ensure that loads are transferred from one concrete slab to the next, allowing for smooth traffic movement without putting excessive pressure on any single slab.

This mechanism—known as load transfer in pavements—prevents slab cracking, corner breaking, and uneven surfaces, especially under heavy vehicles.

Technical Specifications of Dowel Bars (India Standards)

In Indian road construction, dowel bars generally follow these guidelines:

Diameter: 25 mm to 38 mm

Length: 450 mm to 600 mm

Spacing: 300 mm to 350 mm center-to-center

Coating: Epoxy or stainless steel to resist corrosion

Placement: Aligned perfectly in the middle of the slab thickness

Standards followed include:

IRC:58 for pavement design

IS:456 for concrete structure practices

Incorrect dimensions or poor alignment can cause joint locking, defeating the purpose of load transfer altogether.

Benefits of Dowel Bars in Concrete Pavements

Reduces edge cracking under load

Minimizes maintenance costs over time

Improves ride quality and surface level

Enhances load-sharing between slabs

Complies with modern engineering codes

For highway projects, industrial zones, airports, and even smart city roads, dowel bars offer both performance and ROI.

Common Mistakes to Avoid in Dowel Bar Placement

Misaligned dowel bars cause joint locking.

Wrong bar size reduces effectiveness.

Inadequate corrosion protection leads to early failure.

Poor concrete compaction around bars leads to voids.

Use dowel bar baskets, proper templates, and level indicators during installation.

Real-World Example: Long-Lasting Urban Roads

A smart city project in central India faced early pavement failures due to missing dowel bars. Upon redesign with proper dowel bar placement in roads, maintenance dropped by 42%, and surface life increased by 5+ years—all by investing a small amount in the right steel rods.

Why Kapila Steel Is the Trusted Choice for Dowel Bars

At Kapila Steel, we manufacture high-precision dowel bars that meet both national and international standards. Here’s what sets us apart:

Precision machining for accurate length and diameter Anti-corrosion coating for extended lifespan Custom specifications based on project requirements Prompt delivery and pan-India supply chain

Whether your project is a national highway or a local township road, we’ve got your back.

Conclusion: It’s Time to Build Roads That Last

In concrete pavement design, dowel bars are not optional—they’re essential. They offer load-sharing, durability, and cost savings you can’t afford to skip. And when you choose Kapila Steel, you get bars engineered for performance, safety, and long-term value.

Frequently Asked Questions (FAQs)

1. What is the main purpose of dowel bars in concrete pavements?

Dowel bars are used to transfer load across joints in rigid concrete pavements, helping prevent cracking and uneven settlement. They allow slabs to expand and contract without damaging the surface.

2. Are dowel bars and tie bars the same?

No, they serve different functions. Dowel bars transfer load across transverse joints, while tie bars hold adjacent slabs together along longitudinal joints to prevent separation.

3. How far apart should dowel bars be placed?

In most road projects, dowel bars are placed at 300 mm to 350 mm center-to-center spacing. However, the exact spacing depends on slab thickness and traffic load conditions.

#dowel bars#bar dowels#load transfer#concrete slabs#joint support#steel dowels#dowel spacing#dowel types#slab cracks#road dowels#epoxy dowels#dowel design#slab support#rigid pavement#bar alignment#crack control#dowel uses#dowel rods#highway slabs#pavement life

0 notes

Link

Isolated alias single footing is utilized to provide support to single RCC columns. It is cost-effective and suitable when the columns are placed at comparatively long distances, loads operating on footings are less and the safe bearing strength of the soil usually remains high.

Isolated footing is categorized as pad footing and sloped footing.

The isolated footing is arranged underneath the column to disperse the loads securely to the bed soil.

The design of isolated footing is made for the following purposes :-

Area of footing Thickness of footing

Reinforcement details of footing with a satisfactory moment and shear force review.

The design of isolated footing is made on the basis of the guidelines set by ACI 318-14.

1. The compressive strength of concrete should satisfy the needs for both strength and stability. As per ACI 318-14, least concrete compressive strength should be 17MPa for normal applications.

2. With adherence to ACI 314-14 section 20.2.1.1, the deformed type steel bars should be used.

3. Factored forces and moments provided at the base of columns are transmitted to the foundation with reinforcement, dowels, anchor bolts, or mechanical connectors.

4. There should be least reinforcement even if the concrete bearing strength is not crossed.

5. Adequate anchorage should be arranged for tension reinforcement if reinforcement stress is not directly relative to the moment like in sloped, stepped or tapered foundation.

6. There should be sufficient anchorage length of both flexural and dowel reinforcement to get rid of bond failure of the dowels in the footing and to resist failure of the lap splices among the dowels and the column bars.

7. As per ACI 318-14 section 13.3, depth of footing over reinforcement should not remain under 150 mm.

8. The depth of the footing should be in such a manner that the shear strength of the concrete remains equivalent or surpasses the critical shear forces (one-way shear and punching shear) developed with factored loads.

9. In sloped, stepped, or tapered foundation, location and depth steps and angle of slope should satisfy design requirements at each section.

10. Concrete cover of 75 mm is necessary when the concrete is cast against soil.

11. With adherence to ACI Code specifications, base area of footing is set from unfactored forces and moments transferred by footing to soil and the permissible soil pressure evaluated through principles of soil mechanics. To get the necessary base area of the footing, the column service loads are divided with permissible net soil pressure of the soil. The net factored soil pressure is equivalent to factored load column loads by the selected footing area.

Read more

0 notes

Link

To make the design of the footings, it is necessary to have sound understanding about the transmission of stresses (caused by applied loads) from columns to the footings or piles. Factored forces and moments at the base of columns are delivered to the supporting foundations by providing support on concrete as well as by the extension of longitudinal reinforcement into the footing or arrangement of dowels.

Any of the above method can be employed on the basis of the specifications of the relevant design codes like ACI 318-14. The detailing of reinforcement should be done sufficiently for dispersing the stresses to footings perfectly and then further above the basic soil layer.

Methods of transmitting the stressed from Columns to Footings:

1. Expansion of the Longitudinal Steel into the Footing

Expanded reinforcement should be prepared to transmit the compressive forces that surpassed the lesser of the concrete bearing capacities of either the supported member or the foundation, and any computed tensile force across the column-footing interface.

Minimum four bars should be expanded.

The stress-transfer bars should extend into the base with adequate compression-embedment distance to transmit the stress in the column bars to the base concrete.

Whatever the case may be, a minimum steel area of 0.5% of the column-area should be arranged for transmitting the load.

2. Dowel

a. Dowels should be prepared to transmit the compressive forces which go beyond the lesser of the concrete bearing capacities of either the supported member or the foundation, and any computed tensile force across the column-footing interface.

b. There should be minimum four dowels.

c. The diameter of the dowel should not go over the column-bar diameter in excess of 0.15 in.

d. If the desired dowel length remains greater than the footing depth less 3 in, any smaller-diameter bars containing the same area should be applied or a monolithic concrete cap should be included for raising the concrete depth.

e. The dowels should deliver minimum one-quarter of the tension strength of the column bars on each column face.

f. The dowels should be expanded into the column with a distance equivalent to that necessary for compression lapping of column bars.

Read more

0 notes

Note

What skills are you most hoping to see this quad that weren't competed well/enough/at all in the past quad or two?

On vault, it has been way too long since we had lots of gymnasts doing FHS and Tsuk vaults in non-VT EF competition. I’m hoping that the relative adjustment to FHS and Tsuk vaults in the new Code will encourage their performance from gymnasts who would normally do a weakly-executed Yurchenko variation.

On bars, I will always be excited to see same bar release combos. (I also hope that everyone will get bored of the five-transitions-in-a-row crap that has come to define modern bar work in the last quad.) Beth Tweddle and Brenna Dowell are good examples of the kind of bar composition I like to see. More unusual flight elements like Markelovs, Defs, Counter-Kims, Zucholds, and Ezhovas; fewer shap and tkatchev variations. I’d also like to see more mounts that are not just jump-to-kip and more underswing and hip circle hecht dismounts (yes, there are some valued D and above!), as well as German giant and eagle-grip work... all of this seems to have practically died out from modern bar work, which is really disappointing.

It would also make my day if the FIG would raise the value of the one-armed giant and Gienger to something fair, but it’s never gonna happen, so meh.

On beam, I would like to see more interesting mounts. They don’t even have to be difficult or risky - there are plenty of A and B rated mounts that would be a breath of fresh air compared to your basic stoop through, flank vault, split leap, press that has ruled the day for the past several years. This change already seems to be in progress - I hope it sticks. I’d also love to see more 3+ skill rebounding flight connections (eg. roundoff BHS LOSO), anything in the section labeled “Holds and Acrobatic Non-Flight”, yurchenko loop and Korbut flip variations, and side gainer dismounts. There are some unique skills in the JO code on beam - such as the Kivisto salto - that I hope someone brings into elite one day as well. People also need to just start working the beam in both directions again. Refer to Mariya Livchikova for an example of what doing it right looks like.

Also, if Riley McCusker keeps doing that wolf turn combination, I will personally fly to New Jersey and redo her terrible UB and BB composition myself. Maggie Haney, your code-whoring is bad and you should feel bad.

On floor... more forward tumbling, always. Somebody needs to do a Podkopayeva again. I hope that the adjustment to the forward tumbling rules will encourage more gymnasts to actually throw a forward tumbling line, rather than replacing their random trash aerial with a random trash punch front. With that said, if someone wants to go full Vanessa Atler and open a routine like this, I would be hard pressed to complain. (Frankly, if someone just wanted to perform that entire routine again, less the dumb Al Trautwig commentary, I would be hard pressed to complain.)

The trend in the last quad does seem to have leaned away from double/2.5/triple/3.5 twists, and that is one thing I don’t miss, since the execution of these saltos in WAG is often so, so ugly. In general with tumbling, I would like to see more routines like Simone and Mykayla’s [FROM PEOPLE WHO CAN HANDLE IT], with four passes all rated above a D... I’m a sucker for big tricks, not gonna lie. I also like seeing unique choices for dance elements (such as back spins and Shushunova variations), and I would love to see more of the group 3 hand support elements (besides roundoffs and handsprings) in regular use - though it’s unlikely due to their low value :(

Frankly, despite her sometimes alarming execution (which has improved a lot recently looking at her Euros routine, wow!), I have always really liked Claudia Fragapane’s composition. Big tumbles, some unique choices for the non-acro-line elements (butterfly aerials! back spins!), and exciting choreography that she engages with well - now that her execution is maturing she’s really turning into a package floor worker.

- leotardsanity

3 notes

·

View notes

Text

Torino Serie A1 2017 recap

Ok so it’s February and it shows lol. None of the 2016 olympians were competing, except for Mini who only did an FTY on VT and that’s it. Most of the gymnasts looked a bit sluggish and there were lots of mistakes, but that’s always the case during the first Serie A competition.

On VT, the 4 2003 superstars whipped out their DTYs. Giorgia Villa’s was the best, closely followed by Asia D’Amato’s, who’s been doing hers for over a year. Alice D’Amato debuted her DTY, with a low landing. I don’t know how good an idea it is to have her compete it, since she tore her meniscus + ACL only a year ago on it, but it didn’t look dangerous so there’s that. They didn’t show Elisa Iorio’s, but I’m assuming it didn’t look amazing, since she only scored a 14 on it (with .2 bonus, for comparison Giorgia’s scored 14.650).

UB was pretty mediocre in general, as predictable. I’ve seen plenty of double front and full in dismounts, and a lot more shap transitions connected to paks or tkachevs. Elisa Iorio debuted her stuck double front half out dismount and it looked nice! She also competed her ricna - pak - shap, but she fell on the shap.

BB looked slightly less of a mess than it usually does lately for Italy. Arianna Rocca did a very nice roundoff - layout to 2 feet and was pretty solid in general for a 13.650 including bonuses. Caterina Cereghetti upgraded beam with a bhs - loso - loso and a ring leap. Lara Mori, Tea Ugrin, Federica Macrì and Martina Maggio all did very solid and high quality sets, with Tea and Martina with simplified dismounts.

On FX, the most common way to get away with the front tumbling requirement is apparently either front layout - front tull, fhs - front full/double, back 1.5 - front full, or front tuck - some twisting. Whoever already did double Arabians (like Martina Basile) is sticking with that. Asia D’Amato now opens with a double Arabian (stuck). And then there’s Desirée Carofiglio who can basically only do front tumbling and is chilling with her Dowell and double front tuck like yasss thank you code gods!

Brixia won (surprise surprise) even though only the youngest girls (Asia and Alice D’Amato and Giorgia Villa) plus Martina Maggio competed. They started off with 3 solid DTYs (Alice’s was a bit low) and just like that they accumulated enough points to stay ahead of everyone else. Second place for Artistica 81, featuring evergreen Federica Macrì, back-in-business Tea Ugrin, some cute babies, plus Elisa Iorio. They had a solid competition with a few wobbles, but no huge mistakes. Third place for Forza e Virtù, thanks to the solid performances of Arianna Rocca (forever my underrated fave) and Desirée Carofiglio. Nice 4th place for Centro Sport Bollate (Grisetti and Cereghetti) that only just started competing in Serie A1 after being promoted last year. GAL Lissone had a very very rough UB rotation (everyone fell, they even put up Carmen Ghiciuc and when you have to rely on a Romanian to save bars you know things are bad. She fell too, btw) and suffered from not having Ferlito and Praz compete, and having Mini only compete VT.

Giorgia Villa was the highlight of the competition and she was literally on fire. On UB, she now has a Maloney - Tkachev - Pak - Chow - bail, 1.5 turn in L grip and a full in dismount for a 5.5D. This is simply huge for Italy. On BB, she debuted the roundoff - tuck full, which she landed with a big wobble but still landed it, and dismounted with a 2.5, for a 5.4D. On FX, she has a really cheeky and engaging routine, featuring full in (stuck), fhs - front double twist, triple twist (beautiful and stuck), double tuck. She won the virtual AA with a 4 point lead over the second place lmao okay.

Pic from here

#serie a 2017#team italy#giorgia villa#asia d'amato#alice d'amato#elisa iorio#desirée carofiglio#arianna rocca#federica macrì#tea ugrin#lara mori#elisa meneghini#giada grisetti#caterina cereghetti#martina basile

27 notes

·

View notes