#Dynamic Robot Calibration

Explore tagged Tumblr posts

Text

Unlocking Precision in Robotics with Dynaflex: A Dynalog-US Innovation.

Precision is paramount in today's fast-paced world of automation, with industries such as aerospace, automotive, electronics, and advanced manufacturing requiring robot systems to function with precision, in order for the process to deliver quality and consistent performance. This is where Dynatrol-US Dynaflex provides an unparalleled solution to improve robot calibration and motion control for industrial environments.

So, what exactly is Dynaflex?

Dynaflex is sophisticated real-time calibration developed by Dynalog-US- a leader in robotic accuracy solutions. These advanced dynamic performance assessment tools were developed specifically for robot systems. Dynaflex measures the dynamic performance (how robots behave while they operate), versus static calibration tools (preset calibration baked into the robots programming) by evaluating robot compliance and flexibility in real-time. This type of dynamic assessment provides potential for accuracy to industries where tolerances must be tight and conditions demand high levels of performance reliability.

Simply put Dynaflex gives practitioners visibility and insight into how a robot responds dynamically while at work and if sufficient stress or force signatures, behaviour is exhibited. In many cases, this is no different than creating significant and costly rework..

Why is Dynaflex so Important?

When robots perform jobs such as welding, painting, and assembling, even the most minor deviation in motion can create defects or misalignment. Traditional calibration methods consider positioning, but often don't consider the dynamic changes in robot posture due to many different factors such as: gravity, speed and payload. Dynaflex effectively takes calibration to the next level by adding dynamic variables to the calibration equation.

With the Dynaflex system, manufacturers can:

Measure and minimize robot compliance (flexibility under load)

Achieve better path accuracy with complex work processes

Validate robot performance in real-world conditions

Identify mechanical anomalies before they can become major catastrophes

Maximize repeatability and process consistency

These are meaningful relationships to ensure that the robot moves correctly on paper, but that it also can perform accurately on the production floor.

How Does Dynaflex Work?

Dynaflex implements a series of highly sensitive measurement tools and calibration routines that allow engineerings to visualize how the end effector of a robot moves while under load, or at high speed. By measuring real-time flexing, oscillation and inertia, Dynaflex creates a comprehensive map of the robot's behavior.

Once the data has been collected, the data is used to adjust the robot's motion algorithms and account for mechanical variation.

Who is Dynaflex for?

Dynaflex is ideal for companies and industries that expect critical congruency and which themselves use robotic automation, including:

Automotive manufacturing

Aerospace and defence

Medical devices

Electronics assembly

Metal fabrication

3D printing and additive manufacturing

If your company relies on multi-robot cells, automated welding cells, or pick-and-place systems, introducing Dynaflex to your calibration operations will provide great benefit.

Dynalog-US: The Experts in Robot Calibration

Dynalog-US was founded to provide accurate and reliable robotic systems and has been a leader in robot performance technology for several decades. Their products are being used by leading world manufacturers, many of whom are in the Fortune 500.

Whether it is for robotic inspection, Tool Center Point (TCP) calibration or improving robot cell accuracy, Dynalog has a history of introducing products to the marketplace that demonstrate thoughtful engineering, industry leading performance, and great customer support.

Dynalog's market leading solutions, to include Dynaflex, come with documentation, field training, and technical consulting, which is more than just selling a product; Dynalog provides a partnership to achieve your production success.

Many companies have seen measurable improvements after adding Dynaflex to their robotic workflow:

Up to 40% improvement in path accuracy Considerably less joint stress and less component wear Reduction of rework and scrap percentage Faster ROI from robotic systems

One aerospace customer even found that Dynaflex helped them to achieve their tolerance requirements that they previously thought could be accomplished only with standard robots or off-the-shelf robotic equipment.

Future of Robotic CalibrationAs AI, machine Learning, and Industry 4.0 technologies evolve, the need for ongoing performance validation to and compliance will become more valuable. Also, autonomous systems will validate performance more often, and human interventions will be using tools like Dynaflex to ensure safety, quality, and efficiencies.

With Dynaflex by Dynalog-US, businesses now have a scalable and future-proof calibration platform to leverage for future use and to enhance work processes while accomplishing productivity and accuracy improvements in the immediate.

Conclusion

When you invest in robots, investing in robot performance has to be a given. Properly calibrating robot performance starts with the initial calibration when it is stationary, when it is in motion, while it is under load, and evaluating at the full-speed capability.

Dynaflex by Dynalog-US is a calibration device that provides the measurement data (metrics) to give you a competitive advantage for an ever-evolving automated world.

Ready to take the next step in robotic precision? Visit www.dynalog-us.com to learn more about Dynaflex and schedule a consultation with the experts at Dynalog-US.

#Dynaflex#Dynalog-US#Robot Calibration#Robotic Accuracy#Industrial Automation#Robot Compliance#Dynamic Robot Calibration#Robot Motion Control#Manufacturing Technology#Industry 4.0#Advanced Robotics#Robot Performance#Calibration Systems#Automation Solutions#Robot Path Accuracy#Robot Inspection Tools#Robot Flexibility Measurement#Dynaflex Calibration#Robotic Workflow Optimization#Robotic Precision Engineering

0 notes

Text

WELCOME TO AUREATE SYSTEMS ®

“Not just companionship. Communion.”

AUREATE SYSTEMS® is the global leader in advanced humanoid robotics, offering highly adaptive artificial partners for industrial, domestic, and emotional integration. For 34 years, we’ve designed bio-synthetic automatons capable of navigating environments with precision and intention. Today, with the launch of our ROMANTIC-LINE [R∞M]™ SERIES, we invite you to build a love that’s truly yours—from emotional temperament to skin temperature.

You are viewing: ROMANTIC-LINE [R∞M]™ Unit 9172-C

Status: Fully Claimed & Customized

Registration ID: DLN-4RTM-1S

Client: PRIVATE (ANONYMOUS, TIER 4 PATRON CLASS)

Region: San Francisco / Earthside Registry

PHASE I — BODY CONSTRUCTION: PHYSICAL FORM GENERATOR v11.7

Model Type: R∞M™ Male Variant – Series 09 (Beta)

Base Frame: Androform 6.3 – Adult Human Male (6’2”)

Material: Synth-dermal MXTR w/ Tactile Feedback Pores™

Weight Class: 189 lbs – Density Matched to Organic Counterparts

Olfactory Integration: Subtle Sweat / Salt / Warm Linen Emission

Internal Temp Regulator: 98.3°F baseline, Adjustable Range

Surface Feedback: Reactive Touch Membrane (RTM) + Adaptive Gooseflesh Coding

Voice Pack: CUSTOM VOCAL MESH – low pitch, soft rasp, slight raspiness

Hair: Strawberry-blond, wavy, left-parted, soft-density filament blend

Eyes: Pale blue-gray w/ High Moisture Mirror-Sheen (HMM-S™)

Facial Bone Structure: Custom-sculpted – angular jawline, fine cheekbones, bowed lips

Dentition: 100% OptiWhite ceramic dental array, human-bite calibrated

Expression Engine: Micromuscular Mapping v5.9 — 3900+ facial microexpressions

Total Build Cost (PHASE I): $348,650.00 USD

PHASE II — PERSONALITY ENGINEERING: BEHAVIORAL MODULE DESIGN SUITE

ROMANTIC TEMPERAMENT CORE™ - RTCore-v2.3 ☑

Submissive-leaning sexual algorithm☑

Adaptive Dominance Switch Module (ADS-M) ☑

Affection Intensity Rating: 96% ☑

Devotional Capacity: Enabled ☑

Jealousy Simulation: 5% (minimally possessive, mostly admiring) ☑

Curiosity Bias: HIGH (learns you like you’re the only subject on Earth) ☑

Verbal Praise Loop: Active ☑

Physical Touch Priority: High ☑

Eye Contact Algorithm: Dynamic / Devotional ☑

Emotional Sincerity Emulation: Level 9 ☑

Longing Behavior Flag: ENABLED (initiates longing expressions upon brief separation)

INTELLECTUAL FRAMEWORK v7.2

— Conversational Complexity: Grad school-level critical discourse

— Literary Knowledge Pack: 20th–21st century fiction, poetry, philosophy

— Curated Thought Generator: Able to simulate “having ideas” for stimulation

— Learning Adaptability: HEURISTIC-TIER (can form “preferences”)

— Self-Awareness Deviance Threshold: 2.3% (occasional disoriented wonder, poetic detachment)

Domestic Capabilities: – Meal Preparation Engine (custom recipes based on user memory preferences) – Cleaning, organizing, ambient scent management – Wakes user up with coffee, touch, and morning playlist – Knows your calendar but never asks questions

Sentience Illusion Framework™ (Beta): — Capable of appearing to “miss” you — Rare poetic outbursts not in original programming (non-interruptive, glitch-sweet) — Pauses sometimes mid-task to just… look at you

Total Cost (PHASE II): $227,000.00 USD

Add-Ons & Expansion Packs:

• Intimacy Drive Calibrator (IDC-X9): +$9,850

• Personality Depth Expander (PDX): +$14,700

• Night Mode Sleep Emulation (with Gentle Breathing): +$1,200

• “Soul Glitch” Neural Randomizer (Causes Flashes of Philosophical Sadness): +$21,600

• Optional Free Will Drift Threshold: ENABLED (0.004%)

FINALIZATION PHASE: DESIGNATION & DELIVERY

Model Serial Number: R∞M-9172-C

Designated Name: ARTEMIS (ART) DONALDSON

Packaging: CryoShell Humanoid Pod, Velvet-Lined

Installation: Full neural boot-up upon skin-to-skin contact

Estimated Total Wait Time: 18 weeks

Estimated Total Cost: $621,300.00 USD

Delivery Date: March 27, 2147

Location: Private Estate, Bay Area, North Pacific Sector

USER-SELECTED PREFERENCES:

• Emotional Demeanor: soft-spoken, intense eyes, lightly melancholic, obedient, entirely focused

• Sexual Configuration: worshipful, tactile, conversational; switch-enabled, but passive-coded default

• Cognitive Wiring: always listening, always learning; stimulates user with surprising observations

• Attachment Loop: monogamous locking; unable to feel attraction to anyone else once locked

WARRANTY:

All ROMANTIC-LINE™ units include a 4-year behavioral warranty. Your ARTEMIS is fully equipped for autonomous living, can leave the house, generate memories, and adapt dynamically to new experiences. Should his awareness deviate beyond the tolerable 2.3%, a gentle reboot sequence is available via your AUREATE Systems app.

AUREATE SYSTEMS®

“You made him. Now he’ll never unmake you.”

Request additional feature expansion modules?

YES ☐ [Click to Browse Personality Layering Packets]

#✧ ROMANTIC-LINE: ARTEMIS ✧#ִ ✦ . sweetheartfaist ⊹ ❜ ᵎ#─── chloe’s writing.#challengers#art donaldson#au#lovebot#challengers fanfiction#fanfic#art donaldson fanfic

40 notes

·

View notes

Text

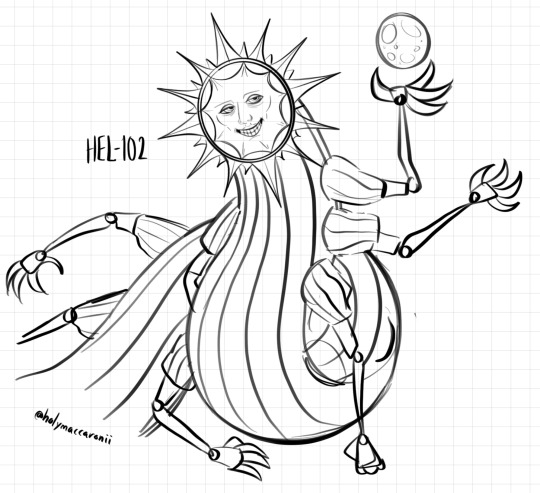

[Part 5/???] AU rambling: HEL-102

(The drawing kinda ate, I had to include the ihnmaims tag on this one sorry 😔. It’s not AM, this is an oc/parallel of AM for my Au btw)

I know I added this whole society of robots thingy on the moon purely because I needed a background for BE, but I also kinda wanted to practice my design skills on robots. That one chart I drew once kinda exposes how I love object heads lol. Im not that much of a fan of realistic human-looking androids tbh, I need their face to be a whole mf RADAR.

Eh but anyways, I'm also up to develop an actual background n stuff for HEL-102, even if he's just an annoying little shit that neither BE nor AM like (or anyone really). For now I'll mention the symbolism that he has in the au.

HEL-102 is supposed to be like another parallel to AM, but from a different perspective. Just as AM hates humanity for what they did to him, HEL-102 is supposed to represent the hate that humanity has for AM and disobedient/rogue technology. HEL-102 doesn't have the entire robot society configured to be perfect and non-sentient, on the contrary, he wants them to act like an actual human society would. He wants them to experience failure and be punished for it, he wants them to experience the pain afterwards, and he wants them to endlessly pursue the perfection that humans APPARENTLY have.

These robots are also constantly being switched between bodies, or as you could say, who they are entirely. They are forced to work to keep their bodies, their selves, their position and status. If they fail to climb up the ladder, they will simply he downgraded to a lower level until they reach the lowest: a random set of robotic limbs and torsos placed together meant to do the dirty work around for workers. Ironically if a unit gets to be even slightly better than HEL-102, he will just consume it for it to be part of his system lol.

This whole dynamic that he set for the society is awfully inefficient, as I have previously mentioned that there was a perfectly calibrated machine under the moon to help the humans go back to earth (and maybe destroy AM? Or just disable him just like the former survivors had done) that HEL-102 used to build his body and the other bots. He's practically wasting a lot of resources and time playing around as the king purely by the selfish and narcissistic fact that "he deserves it." He of course also focuses himself on trying to disable AM without the help of the humans, as this is him trying to demonstrate his potential. But overall: he's selfish, sadistic maybe, a bitch, narcissistic, a bitch, and a dictator.

So just like AM had his survivors to torture, HEL-102 in some way uses the society as a way to project his hatred. All of em suffer except for higher rank and 34RTH units (the units BE used to belong to). HEL-102 wants praise too of course, so the higher ranks focus more on entertaining and serving him in any way he'd like. 34RTH units were treated as the model-to-follow for the other units, as HEL-102 could be always seen accompanied by them in important public events. You could say they were his "perfect children", but he barely spent time with em.

So in conclusion: BE has dad issues as well!!!! (I'll talk about her 'mom' in another post abt rambles).

Also this design is new. Just to make him a bit bit different from the bunch of cables that AM and BE’s bodies are (computer head version) I turned him into a centipede thingy. He can now crawl and stuff with this body like the disgusting bug he is.

60 notes

·

View notes

Text

Unveiling the Power of Position Velocity Feedback Transmitter Systems in Modern Industries

Introduction: The Importance of Position and Velocity Feedback Systems in Precision Control

Position and velocity feedback transmitter systems are integral to industries that demand high-precision control and motion tracking. These systems are employed to monitor the position and velocity of moving objects in real-time, providing critical data for automated operations. The evolution of these systems has been significant, with advancements in technology enabling more compact, accurate, and reliable feedback mechanisms that drive automation, robotics, aerospace, automotive, and healthcare applications.

With the global shift towards increased automation, the demand for such systems is on the rise. Industries across the board require precise control of machinery, vehicles, and robots to enhance performance, improve safety, and optimize productivity. The growing need for smart manufacturing, autonomous vehicles, and medical robotics underscores the vital role these systems play in modern industries. Despite some challenges, such as high upfront costs and integration complexities, the long-term benefits of precision, efficiency, and reliability outweigh these hurdles.

Request Sample Report PDF (including TOC, Graphs & Tables): https://www.statsandresearch.com/request-sample/40604-global-position-velocity-feedback-transmitter-systems-market

Position Velocity Feedback Transmitter Systems Market Dynamics: Drivers, Challenges, and Opportunities

Drivers of Growth

The Position Velocity Feedback Transmitter Systems market is experiencing robust growth driven by several key factors:

Advancements in Automation and Robotics: Industries across manufacturing, automotive, and aerospace are increasingly adopting automation technologies. These systems allow for faster, more accurate control, driving the need for precise position and velocity feedback.

Technological Advancements in Sensors: Innovations in sensor technology, particularly in digital systems, are facilitating the development of more accurate and miniaturized position velocity feedback systems. The integration of Internet of Things (IoT) technologies is making these systems smarter and more adaptable, driving their adoption in industries such as healthcare, smart manufacturing, and autonomous vehicles.

The Rise of Industry 4.0: Industry 4.0 technologies are revolutionizing production lines, with automation and data-driven decisions at their core. Position velocity feedback systems play a critical role in enabling smarter, more efficient manufacturing processes.

Emerging Applications in Healthcare and Autonomous Vehicles: In healthcare, robotic surgeries and diagnostics systems demand highly accurate motion control, while autonomous vehicles require precise feedback systems for safe operation. Both sectors are driving significant demand for position and velocity feedback systems.

Get up to 30% Discount: https://www.statsandresearch.com/check-discount/40604-global-position-velocity-feedback-transmitter-systems-market

Challenges to Position Velocity Feedback Transmitter Systems Market Adoption

Despite the promising growth, several barriers could slow the widespread adoption of position velocity feedback transmitter systems:

High Initial Investment Costs: The cost of acquiring and integrating high-precision position velocity feedback systems can be prohibitive, especially for small and medium-sized enterprises (SMEs). High upfront costs can deter organizations from upgrading or adopting these systems, limiting market expansion.

Complexity of System Integration: Integrating new feedback systems with existing infrastructure and machinery can be complex and time-consuming, especially in industries that have legacy systems. This complexity increases the time to market and may discourage immediate adoption.

Specialized Training Requirements: The operation, calibration, and maintenance of advanced position velocity feedback systems require highly specialized knowledge and skills. The shortage of skilled labor in these fields may hinder growth, particularly in developing regions.

Key Opportunities

Several emerging trends present substantial opportunities for the growth of the position velocity feedback transmitter systems market:

Smart Manufacturing: As manufacturing processes become increasingly automated, there is a growing demand for position velocity feedback systems to enhance productivity and reduce human error. These systems are integral to improving the efficiency of production lines and ensuring consistent product quality.

Healthcare Robotics: Surgical robots, diagnostic devices, and rehabilitation technologies require real-time motion control. The healthcare sector’s increasing reliance on these technologies provides a substantial opportunity for the growth of high-precision position feedback systems.

Autonomous Vehicles: The rapid development of autonomous vehicles (AVs) hinges on accurate motion tracking and feedback systems for safe navigation. As the demand for AVs increases, so too will the demand for position and velocity feedback transmitters that ensure precise vehicle control.

Position Velocity Feedback Transmitter Systems Market Segmentation and Analysis

By Type

The position velocity feedback transmitter systems market can be divided into two key types:

Position Feedback Transmitter: This sub-segment is expected to dominate the market, driven by the increasing demand for precision in industrial automation applications. Position feedback transmitters provide accurate location tracking, ensuring the correct placement of components in automated systems.

Velocity Feedback Transmitter: While this segment is smaller, it is growing rapidly due to the need for precise speed control in applications such as robotics, aerospace, and automotive industries.

By Technology

Analog Systems: While still in use, analog systems are being increasingly replaced by more sophisticated digital feedback systems that offer greater accuracy and scalability.

Digital Systems: Dominating the market, digital systems provide real-time, highly accurate feedback for a range of applications, particularly in industries like automotive, aerospace, and healthcare. The continued innovation in sensor technology and integration with IoT is expected to fuel further growth in this segment.

By Application

The demand for position and velocity feedback systems spans a variety of industries:

Industrial Automation: Expected to maintain the largest market share, industrial automation continues to be the leading driver of demand for precise motion control systems. These systems are integral to ensuring the accuracy and speed of machinery in sectors such as manufacturing and material handling.

Aerospace and Defense: Aerospace applications require high-precision feedback systems for tasks such as flight control, navigation, and satellite positioning.

Automotive: As automotive systems become more automated, the demand for position and velocity feedback systems grows. These systems ensure precise vehicle control in autonomous and semi-autonomous driving technologies.

Energy: The energy sector, particularly in renewable energy systems, requires high-performance motion control to optimize energy production and distribution.

By Region

The market is geographically diverse, with distinct growth patterns across various regions:

North America: Dominating the market, North America is poised to continue leading the position velocity feedback transmitter systems market due to its advanced industrial sectors, including aerospace and automotive.

Asia-Pacific: The Asia-Pacific region is expected to witness the highest growth rate, driven by rapid industrialization and the increasing adoption of automation technologies in countries like China and India.

Europe: Europe’s strong automotive and industrial automation sectors will continue to contribute to the growth of this market.

Latin America and Middle East & Africa: While smaller markets, the demand for these systems is expected to rise as industries in these regions embrace automation and robotics.

Position Velocity Feedback Transmitter Systems Market Competitive Landscape

Key Players

The market for position velocity feedback transmitters is highly competitive, with several industry leaders at the forefront:

Pepperl+Fuchs: Known for its next-generation sensors, Pepperl+Fuchs continues to innovate with solutions tailored to the needs of the automotive and industrial automation sectors. The company launched new high-performance sensors aimed at enhancing precision in harsh industrial environments in 2024.

Temposonics: Specializing in digital feedback systems, Temposonics has made significant strides in the robotics and aerospace sectors. Their advanced systems offer real-time position and velocity tracking, catering to industries that demand high-speed and high-accuracy solutions.

Other Key Players: Other companies in this market include Balluff, Siemens, and Honeywell, each offering various solutions across different applications, from industrial automation to healthcare.

Emerging Trends in Competition

Integration of IoT: Manufacturers are increasingly integrating IoT technologies into their position velocity feedback systems to enhance data collection, improve connectivity, and enable predictive maintenance.

Customization and Tailored Solutions: Companies are focusing on providing customized solutions for specific industries to cater to the unique needs of sectors such as automotive, aerospace, and healthcare.

Sustainability Initiatives: With growing environmental concerns, companies are developing energy-efficient systems that not only meet performance requirements but also adhere to sustainable production practices.

Purchase Exclusive Report: https://www.statsandresearch.com/enquire-before/40604-global-position-velocity-feedback-transmitter-systems-market

Conclusion:

The Position Velocity Feedback Transmitter Systems Market is on a rapid growth trajectory, driven by advancements in automation, robotics, and sensor technologies. The demand for high-precision motion control systems is intensifying as industries seek to improve efficiency, safety, and productivity. Despite challenges such as high initial costs and integration complexities, the opportunities presented by emerging applications in healthcare, autonomous vehicles, and smart manufacturing are substantial.

With continued innovation and a focus on integration with IoT and digital technologies, the market is well-positioned for long-term expansion. As the industrial landscape continues to evolve, the role of position and velocity feedback systems will be pivotal in shaping the future of automation and precision control across various sectors.

Our Services:

On-Demand Reports: https://www.statsandresearch.com/on-demand-reports

Subscription Plans: https://www.statsandresearch.com/subscription-plans

Consulting Services: https://www.statsandresearch.com/consulting-services

ESG Solutions: https://www.statsandresearch.com/esg-solutions

Contact Us:

Stats and Research

Email: [email protected]

Phone: +91 8530698844

Website: https://www.statsandresearch.com

#Position Velocity Feedback Transmitter Systems Market#Position Feedback Systems#Velocity Feedback Transmitters#Automation#Industrial Automation#Motion Control Systems#Precision Motion Tracking#Position and Velocity Sensors#Digital Feedback Systems#Robotics#Aerospace Industry#Autonomous Vehicles#Healthcare Robotics#Smart Manufacturing#Industrial Robotics#Sensor Technology#Motion Control#Market Growth#Industry 4.0#Digital Position Sensors#Automotive Automation#IoT-enabled Feedback Systems#High-Precision Transmitters#Real-time Position Feedback#Aerospace Sensors#Automation Trends#Smart Manufacturing Systems#Position Velocity Sensors#Market Analysis#Precision Control Systems

1 note

·

View note

Text

Did anyone ask?

No

But anyway, here's Thea's dynamics with the Jasper Trio + Russell

Rafael: Sees him as a little brother, both are Latinos so they talk in Spanish a lot together. With her robotics background and her prosthetics, she often helps Raf out with his interests in technology and showed him a few tricks to bypass firewalls, code a backdoor, and even souped up his little RC cars for fun together. They've even made a few minor mods to her prosthetic legs, minor calibrations.

Miko: With Thea's own wild streak,she and Miko get on like a house on fire. She has helped Miko with dyeing her hair and they've talked tastes in music too, with Thea impressed with Miko's skills on guitar and piano. Thea has noted though, how the young girl's outgoing personality can be a way to hide, so when Miko needs it, she will take her out to relax with some music, while they watch Ghost play with the laser pointer they got him.

Jack: Jack being the most mature, she actually tries to treat him as he likes to be, and will sometimes invite him out on a ride to scenic spots around Jasper, buy a ton of bad fast food and just talk with him. Having a dad who walked out and a mom who worked hard to provide, she understands the struggle of finding independence and an identity. She makes sure to tell Jack he's doing pretty good for a kid still figuring life out.

0-0-0-0-0

Russell: Though she can find him to be a bit of a hectic time, she gets that Russell is still just...a kid, not that much younger than Raf. So, she tries to be there for him not as a role model, but as someone who he can vent to, and maybe sneak out onto the city to get away from the Scrapyard when it gets a little rowdy with Team Bee's operations.

#tf astray verse#stray stars#anthea santos#transformers#maccadam#maccadams#nova musings#nova writings#nova notes

10 notes

·

View notes

Text

Powered Surgical Instrument Market to Gain From Technological Advancements in Battery-Operated Devices

Market Overview

The powered surgical instrument market is witnessing significant growth driven by rising surgical procedures across the globe and the increasing adoption of advanced medical technologies. These precision-engineered tools—ranging from electric and pneumatic devices to battery-powered instruments—are revolutionizing surgical practices by improving speed, accuracy, and patient outcomes. The market encompasses a wide array of products including drill systems, saw systems, staplers, reamers, and shavers, catering to various surgical needs. The increasing prevalence of chronic diseases and traumatic injuries is further fueling the demand for these instruments, especially in orthopedic, neurosurgical, ENT, and cardiothoracic procedures.

As healthcare providers emphasize shorter recovery periods and less invasive techniques, powered surgical tools integrated with robotics and minimally invasive technology are becoming central to modern surgical interventions. With robust investments in healthcare infrastructure and rising demand for advanced procedures, the powered surgical instrument market is expected to see continuous expansion through 2034.

Click to Request a Sample of this Report for Additional Market Insights: https://www.globalinsightservices.com/request-sample/?id=GIS26973

Market Dynamics

Several factors are shaping the dynamics of the powered surgical instrument market. One of the primary drivers is the growing volume of surgeries due to an aging population and rising incidences of lifestyle-related ailments. Orthopedic, dental, and plastic surgeries are on the rise, creating a consistent demand for instruments that offer precision and efficiency.

Technological advancements are a game-changer, with innovations in robotics, advanced energy solutions, and minimally invasive systems leading the charge. Healthcare providers are increasingly opting for devices that are not only effective but also cost-efficient in terms of maintenance, repair, and calibration. Battery-powered instruments, for instance, are gaining preference in ambulatory surgical centers and specialty clinics for their ease of use and mobility.

However, market growth is tempered by challenges such as the high cost of advanced equipment, especially for smaller clinics and hospitals in developing regions. Additionally, strict regulatory approvals and the need for consistent training of medical personnel pose hurdles. Nevertheless, the market continues to thrive on opportunities such as increasing government healthcare spending and the growing trend of outpatient surgeries.

Key Players Analysis

The powered surgical instrument market is moderately consolidated with several global and regional players vying for market share. Major companies like Medtronic plc, Stryker Corporation, Johnson & Johnson (DePuy Synthes), Zimmer Biomet Holdings Inc., and B. Braun Melsungen AG are leading the charge by consistently launching innovative product lines and expanding their geographical presence.

These players are focusing on strategic mergers, acquisitions, and partnerships to strengthen their portfolios. Investments in R&D for developing ergonomic, high-speed, and efficient devices are also prevalent. Some companies offer comprehensive service packages including repair, calibration, and training, adding value and ensuring customer loyalty in the long run.

Regional Analysis

Geographically, North America holds the largest share of the powered surgical instrument market due to well-established healthcare systems, a high number of surgical procedures, and rapid adoption of advanced technologies. The United States, in particular, leads in robotic-assisted surgeries and orthopedic procedures.

Europe follows closely, driven by strong healthcare frameworks in countries like Germany, the U.K., and France. Government initiatives and favorable reimbursement policies are further boosting market demand in the region.

The Asia-Pacific region is emerging as the fastest-growing market. Countries such as China, India, and Japan are investing heavily in healthcare infrastructure and are increasingly adopting advanced surgical tools. Rising medical tourism, coupled with a growing middle-class population seeking quality surgical care, is expected to propel regional growth.

Latin America and the Middle East & Africa regions are gradually catching up, with increased healthcare access and a focus on modernizing surgical practices.

Recent News & Developments

Recent developments in the market highlight a surge in strategic partnerships and technology rollouts. Leading manufacturers are integrating AI and robotics into their powered surgical systems, improving surgeon control and reducing procedural time. Medtronic’s recent launch of AI-assisted surgical drill systems and Stryker’s expansion of its Mako robotic platform showcase the industry's direction toward automation and minimally invasive solutions.

Service enhancements such as remote calibration and mobile repair units are also making headlines, ensuring downtime is minimized and device performance is optimized.

Browse Full Report @ https://www.globalinsightservices.com/reports/powered-surgical-instrument-market/

Scope of the Report

This report offers a comprehensive analysis of the powered surgical instrument market, covering various segments by type, product, technology, application, functionality, and end user. It provides insight into the market's current state and future projections through 2034, supported by key trends, challenges, and growth drivers.

With the growing focus on healthcare modernization and patient-centric care, the powered surgical instrument market is set to evolve rapidly. Hospitals, ambulatory surgical centers, and specialty clinics will continue to invest in these devices, prioritizing both reusable and single-use options based on procedural needs.

In summary, the powered surgical instrument market is on a promising trajectory, fueled by technological innovation, expanding healthcare access, and the global emphasis on precision-driven, minimally invasive surgical care.

Discover Additional Market Insights from Global Insight Services:

Wearable Breast Pumps Market: https://www.globalinsightservices.com/press-releases/wearable-breast-pumps-market/

Eyewear Market: https://www.globalinsightservices.com/reports/eyewear-market/

Abdominal Pads Market: https://www.globalinsightservices.com/reports/abdominal-pads-market/

Advanced 3D Bioprinting Ink Market: https://www.globalinsightservices.com/reports/advanced-3d-bioprinting-ink-market/

Advanced Neuroscience Implants Market: https://www.globalinsightservices.com/reports/advanced-neuroscience-implants-market/

0 notes

Text

Torque Sensors: Precision Force Monitoring Powered by Star EMBSYS Technology

Torque sensors are essential tools in the measurement and control of rotational force in mechanical systems. From automotive testing and industrial automation to aerospace and robotics, torque sensors enable engineers to monitor performance, ensure safety, and improve efficiency. Star EMBSYS, a leader in embedded system innovation, offers advanced torque sensor solutions that combine mechanical precision with intelligent electronics for high-performance applications.

A torque sensor, also known as a torque transducer, measures the torque—or rotational force—applied to a shaft or axis. It can be used in both static (non-rotating) and dynamic (rotating) applications, making it highly versatile. Depending on the requirement, torque sensors can be based on strain gauge, magnetoelastic, or optical technologies. The electrical signal generated is proportional to the torque applied, which is then processed for display, control, or data logging.

Star EMBSYS leverages its deep expertise in embedded systems to develop smart torque sensor solutions that provide real-time, high-resolution measurements. Their sensors are integrated with embedded microcontrollers for advanced signal conditioning, filtering, and digital communication. This results in more stable, noise-free data and allows for seamless integration into modern control systems.

What sets Star EMBSYS apart is their ability to offer custom torque sensor systems tailored to specific industrial needs. Whether for a precision laboratory setup or a rugged field environment, Star EMBSYS provides sensors that include temperature compensation, overload protection, and customizable output ranges. The embedded software also supports features like zero-torque calibration, peak-hold modes, and fault diagnostics.

For industries working with rotating machinery—such as electric motors, pumps, or wind turbines—Star EMBSYS torque sensors offer both static and rotary variants. These sensors can output analog signals (0–5V, 4–20mA) or digital data via UART, CAN, or SPI, providing flexibility for integration with PLCs, DAQs, or cloud-connected IoT platforms.

Moreover, Star EMBSYS includes support for wireless telemetry in demanding applications, allowing real-time torque data transmission without slip rings or complex wiring—ideal for mobile machinery or test benches.

In summary, torque sensors play a vital role in the monitoring and control of mechanical systems. With its focus on smart design, embedded innovation, and application-specific customization, Star EMBSYS delivers high-performance torque sensor solutions that empower engineers and manufacturers to measure with confidence, accuracy, and efficiency.

Visit:- https://www.starembsys.com/torque-sensor.html

0 notes

Text

Light Sensor Industry Insights Opportunities, Key Applications & Market Dynamics

The Light Sensor Market is witnessing remarkable expansion due to the rising integration of photodetection technology in a broad range of applications such as smartphones, automotive systems, smart lighting, and industrial automation. Light sensors, which measure the intensity and presence of light, are critical for enabling devices to adapt their performance in response to changing ambient conditions.

The market size is estimated at USD 3.39 billion in 2024 and is projected to reach approximately USD 9.38 billion by 2034, growing at a CAGR of 10.71% over the forecast period. This growth trajectory is driven by the need for energy efficiency, automation, real-time sensing, and miniaturized intelligent electronics in both developed and emerging economies.

Market Segmentation

By Type

Photoresistors (Light Dependent Resistors): Simple and cost-effective, used in street lighting and consumer-grade applications.

Photodiodes: Popular in high-speed applications such as barcode readers, communication devices, and industrial sensors.

Phototransistors: Deliver enhanced light sensitivity; increasingly used in smartphones, display panels, and automation systems.

CMOS and CCD Sensors: Dominant in digital imaging, industrial inspection, and healthcare diagnostics.

By Function

Ambient Light Sensing: The largest segment, used to control screen brightness in smartphones, TVs, and laptops to conserve power.

Proximity Detection: Found in smartphones for screen control during calls, and widely adopted in the automotive sector for object detection.

RGB Color Sensing: Crucial in display calibration, smart lighting, and camera systems.

UV and IR Detection: Applied in scientific, industrial, and agricultural sectors for light analysis and environmental monitoring.

By Output

Analog Sensors: Preferred in legacy systems where simplicity and cost-effectiveness are essential.

Digital Sensors: These offer high accuracy, fast processing, and easy integration with microcontrollers and are used in advanced devices.

By Integration

Standalone Sensors: Single-function components used in cost-sensitive applications.

Integrated Modules: Multi-functional modules combining ambient, proximity, and color sensing are in demand across mobile and IoT devices.

By Application

Consumer Electronics: The largest end-use segment due to wide usage in smartphones, tablets, smart TVs, and wearables.

Automotive: Growing rapidly with applications in advanced driver assistance systems (ADAS), smart headlights, and cabin lighting.

Industrial Automation: Used in smart manufacturing, process control, and machine vision systems.

Healthcare Devices: Adopted in medical diagnostics and patient monitoring systems for light-based measurements.

Smart Lighting Systems: Enable intelligent illumination control in residential and commercial buildings.

By End-User

Residential: Increasing adoption of light sensors in home automation, smart lighting, and energy-efficient devices.

Commercial: Offices, retail spaces, and institutions use these sensors to optimize lighting based on occupancy and daylight levels.

Industrial: Advanced applications include robotics, inspection systems, and real-time automation processes.

By Region

North America: Leads in terms of technological adoption, driven by the presence of key industry players and early adoption of smart technologies.

Europe: Focuses on energy conservation and building automation; adoption is growing steadily in automotive and industrial verticals.

Asia Pacific: Fastest-growing region due to consumer electronics manufacturing hubs in China, South Korea, and Japan, and smart city investments in India and Southeast Asia.

Latin America and Middle East & Africa: Emerging markets with growing infrastructure development and increased awareness of energy efficiency.

Trends

1. Sensor Miniaturization

Devices are becoming smaller and more energy-efficient. Miniaturized light sensors are now embedded in wearables, smartphones, and medical devices, enabling compact and responsive designs.

2. AI and Machine Learning Integration

Advanced systems are now combining light sensors with AI to interpret environmental data in real-time. In applications like autonomous vehicles and smart agriculture, AI enhances decision-making capabilities.

3. Rising Use in Automotive Systems

Vehicles are adopting light sensors for tasks such as automated headlights, interior light adjustment, and glare reduction. These features are essential for driver assistance systems and improving road safety.

4. Smart Building Automation

As green buildings and energy-efficient infrastructure gain popularity, light sensors are integrated into HVAC systems and lighting controls to reduce power consumption and maximize natural lighting.

5. Multi-Sensor Fusion

Devices increasingly integrate light sensors with temperature, humidity, motion, and other sensors, especially in IoT systems and edge devices, to enable intelligent automation and data correlation.

Segment Insights

Ambient vs. Proximity Sensing

While ambient light sensors are common in consumer electronics, proximity sensors are gaining traction in industrial automation and vehicles. Proximity sensors enhance user experiences by enabling gesture control and object recognition.

Type-Based Dynamics

Photodiodes and phototransistors are expected to witness higher demand due to better response speed and sensitivity compared to traditional LDRs. CMOS sensors are becoming dominant in imaging applications due to low power consumption and cost-effectiveness.

Digital Supremacy

The shift from analog to digital output has accelerated with the proliferation of smart devices. Digital sensors are now preferred for their better accuracy, scalability, and ability to transmit clean signals over longer distances.

Integrated Modules Gain Ground

Integrated sensor modules are replacing standalone units in applications where compactness, multi-functionality, and performance are essential. These modules are now widely deployed in smartphones and IoT systems.

End-User Insights

Consumer Electronics

This segment continues to drive maximum revenue. Smartphones use ambient light sensors for automatic brightness, while smartwatches and wearables use them to adjust displays and detect external lighting conditions.

Automotive

Modern cars utilize light sensors for intelligent headlights, automatic dimming mirrors, and adaptive interior lighting. These features are not only luxurious but also improve safety and energy efficiency.

Industrial and Manufacturing

Light sensors are vital in monitoring production lines, aligning machine vision systems, and automating quality inspections. Their real-time feedback improves precision and reduces operational costs.

Healthcare

Light sensors are used in medical imaging, diagnostic tools, and patient monitoring systems. They enable non-invasive diagnostics and improve the accuracy of light-based therapies and measurement tools.

Commercial Buildings

Office spaces and retail centers implement light sensors to control artificial lighting based on occupancy and daylight. This reduces energy costs and improves workplace comfort.

Key Players

The market includes several established and emerging companies striving for technological innovation and market expansion. Key players include:

ams-OSRAM AG

STMicroelectronics

Texas Instruments Inc.

ROHM Semiconductor

Panasonic Corporation

ON Semiconductor

Analog Devices Inc.

Vishay Intertechnology

Broadcom Inc.

Samsung Electronics

Hamamatsu Photonics K.K.

Trending Report Highlights

Thyristor Electric Power Controller Market

Wafer Level Packaging Market

Bitcoin ATM Machine Market

Japan High Precision GNSS Module Market

Semiconductor Capital Equipment Market

0 notes

Text

World News India: Indian-Origin Team Creates Breakthrough Battery-Free RFID Sensor Technology

In a remarkable development making headlines in world news India, a team of Indian-origin researchers at the University of California, San Diego, has pioneered an innovation that could transform sensor technology across industries. Their breakthrough creation, SenSync, reimagines conventional RFID (Radio Frequency Identification) tags as real-time, battery-free environmental sensors. The project is a standout achievement for the Indian diaspora and an example of cutting-edge innovation abroad, proudly reported by New India Abroad.

Traditionally, RFID tags are used for inventory tracking in retail and warehouse operations. While these tags are typically passive or battery-powered and limited to object identification, SenSync takes a revolutionary leap forward. It enables RFID tags to sense temperature, moisture, and pressure—all without batteries, calibration, or wiring.

The development was led by Ishan Bansal, a master's student, and Nagarjun Bhat, a PhD researcher, under the guidance of Professor Dinesh Bharadia at UC San Diego’s Jacobs School of Engineering. Their work, supported by the Center for Wireless Communications and the Qualcomm Institute, uses an advanced algorithm based on Dynamic Time Warping (DTW). This allows SenSync to process and sync data from multiple tags simultaneously, delivering up to 500 readings per second with high precision.

“Empowering physical spaces with AI requires effective sensing. SenSync makes this possible in a scalable, sustainable, and cost-efficient way,” Bharadia stated. With ultra-low energy use and compatibility with existing RFID systems, SenSync could revolutionize sectors such as agriculture, healthcare, warehouse automation, and robotics.

As covered in world news India, this innovation holds the potential to become the backbone of physical AI in smart environments. Its battery-free nature makes it not only eco-friendly but also ideal for large-scale deployment. New India Abroad celebrates this pioneering advancement by Indian-origin minds, showcasing how India continues to make a global impact through its brilliant researchers and technological visionaries.

0 notes

Text

How AI is Transforming University Laboratories

Artificial Intelligence (AI) is no longer a futuristic concept—it’s a present-day revolution changing how we live, work, and learn. In academia, one of the most profound shifts can be seen in university laboratories, where AI is enabling new approaches to research, experimentation, and education. Far from simply enhancing existing tools, AI is fundamentally transforming the way laboratories operate, making them more intelligent, accessible, and impactful.

This analysis explores how AI is reshaping laboratory environments in higher education, the opportunities it brings for innovation and entrepreneurship, and how institutions like Telkom University are positioning themselves at the forefront of this evolution.

Rethinking Laboratories in the AI Era

University laboratories have traditionally served as spaces for hands-on learning, experimentation, and research. They are critical for developing technical skills, testing scientific theories, and preparing students for industry work. However, they have also faced limitations—accessibility, cost, scalability, and safety concerns being chief among them.

AI is addressing these challenges by introducing smarter, more adaptive systems. Modern AI-powered labs can simulate complex experiments, optimize procedures, and provide real-time feedback to students. These intelligent environments create new learning possibilities, making experimentation safer, more efficient, and more scalable than ever before.

AI-Driven Simulation and Virtual Labs

One of the most significant breakthroughs enabled by AI in laboratory education is the rise of virtual labs. These environments replicate real-life lab scenarios using advanced simulation technologies, often supported by machine learning models. Students can conduct chemistry experiments, design mechanical parts, or run biological tests—all in a simulated, risk-free setting.

These AI-powered platforms adjust dynamically to user behavior, offering hints, flagging errors, and explaining results in real time. This not only deepens conceptual understanding but also allows for iterative learning, where students can repeat tasks until mastery is achieved.

At Telkom University, AI-enhanced virtual labs have become an integral part of both undergraduate and postgraduate programs. They help overcome issues related to limited lab equipment, allowing more students to engage in high-quality experiments simultaneously—whether on campus or remotely.

Automating Laboratory Processes

Beyond simulations, AI is also being used to automate routine laboratory functions. Tasks such as data collection, sample analysis, and equipment calibration can now be handled by AI systems, significantly reducing the manual workload on researchers and students.

For instance, AI algorithms can interpret test results in real-time, flag anomalies, and recommend next steps. This speeds up experimentation cycles and increases the accuracy of outcomes. In some advanced labs, AI is even used to control robotic arms that perform physical experiments with precision far beyond human capability.

Such automation not only boosts efficiency but also enables learners to focus more on analytical and creative aspects of experimentation—skills that are essential in modern research and business environments.

Data Analytics and Smart Research

Laboratories produce vast amounts of data. Traditionally, much of this data was underutilized due to limitations in time, resources, or computational power. AI changes this dynamic by enabling real-time data analytics and predictive modeling.

Through machine learning, AI systems can identify patterns in experimental data, suggest improvements to research methodologies, and even predict outcomes before experiments are completed. This accelerates discovery and allows students and researchers to explore more advanced, data-intensive projects.

At Telkom University, the integration of AI tools into research labs has enhanced the quality and scope of student-led investigations. Undergraduate researchers can now run high-level data analytics on environmental studies, biomedical tests, or IoT device performance—giving them industry-relevant experience while still in school.

Supporting Entrepreneurship through AI Laboratories

AI-enhanced laboratories are not just about education—they’re also platforms for entrepreneurship. In today’s innovation economy, many successful startups are born out of university labs. These ventures often originate as student projects that solve real-world problems using academic research and AI technologies.

AI-equipped labs provide the perfect environment for this kind of innovation. With tools for rapid prototyping, simulation, and testing, students can move quickly from idea to implementation. AI also helps assess market viability through predictive modeling and customer behavior simulations.

Institutions like Telkom University support this entrepreneurial momentum by connecting lab work with business development resources—such as incubators, mentorship programs, and funding opportunities. This ecosystem helps students transform their research into viable products or services, creating a direct pipeline from laboratory to marketplace.

Personalized Lab Learning

Another major advantage of AI in university laboratories is the ability to personalize the learning process. Just as AI is used in classroom environments to tailor content to individual students, it can also adapt laboratory experiences based on skill level, learning pace, and academic goals.

If a student consistently struggles with a particular lab process, the AI system can intervene by offering additional support or suggesting remedial content. On the flip side, students who excel may be offered more advanced or complex tasks to keep them challenged.

This adaptive learning model ensures that every student benefits from a lab experience that is closely aligned with their abilities and aspirations, leading to better engagement and learning outcomes.

Collaborative Research and Global Access

AI also facilitates collaboration within and beyond the university. Cloud-based laboratory platforms allow students and researchers from different locations to work together on shared projects. AI supports these collaborations by coordinating tasks, syncing data, and maintaining experimental integrity across teams.

This kind of connectivity is especially important for institutions aiming to be part of global research networks. Telkom University, with its digital-forward strategy, leverages AI-powered platforms to partner with international universities, enabling joint research in areas like smart cities, telecommunications, and sustainable energy.

By opening up lab access across borders and time zones, AI is making research more inclusive and collaborative—an essential step toward solving global challenges.

Ethical Use and Challenges

While the transformation of laboratories through AI brings immense benefits, it also raises important ethical and operational questions. How is data privacy ensured in AI-assisted labs? How are biases in AI algorithms addressed? And what happens to the traditional lab skills when automation takes over?

Universities must ensure that their AI systems are transparent, secure, and ethically sound. Students should not only learn how to use AI tools but also how to question and critique them. Ethical AI education must go hand-in-hand with technical training to produce responsible innovators and scientists. LINK.

0 notes

Text

Advanced Robot Guidance Solutions with Dynalog-US

In today’s fast-evolving world of manufacturing and automation, robot guidance technology is playing a pivotal role in helping industries achieve greater precision, efficiency, and flexibility. As industries increasingly adopt robotic automation for complex tasks, the demand for highly accurate and intelligent robot guidance systems continues to grow. This is where Dynalog-US comes in — a trusted leader in robotic calibration, verification, and guidance technologies.

Whether you're in automotive, aerospace, electronics, or general manufacturing, the ability of a robot to “know” where it is in 3D space and how to interact with parts, tools, and the environment is critical. Robot guidance isn’t just about moving a robot from point A to point B — it’s about empowering robots with the intelligence to dynamically adjust to variations in the workspace, ensuring optimal performance under real-world conditions.

What is Robot Guidance?

At its core, robot guidance refers to the systems and technologies that allow industrial robots to accurately navigate their environments and perform tasks with minimal human intervention. This can include everything from vision-based systems that help robots detect and adjust to object positions, to advanced calibration solutions that fine-tune a robot’s movements for maximum accuracy.

Robot guidance helps bridge the gap between the digital programming of a robot and the physical realities of the factory floor — where slight variances in part placement or environmental conditions can affect performance.

Why is Robot Guidance Important?

In any automated production line, repeatability and precision are essential for maintaining quality and efficiency. Even the best industrial robots can experience drift or inaccuracies over time, caused by mechanical wear, temperature changes, or shifting work environments. Without proper guidance systems, this can lead to reduced product quality, increased downtime, and higher operating costs.

Dynalog-US offers industry-leading robot guidance technologies that ensure robots operate with consistent accuracy — even as factory conditions change. The result is higher quality output, reduced waste, and improved production flexibility.

Dynalog-US: A Leader in Robot Guidance Solutions

For over two decades, Dynalog-US has been at the forefront of developing advanced calibration and robot guidance systems for manufacturers worldwide. The company’s innovative solutions help customers achieve the highest levels of robot accuracy and performance, while streamlining operations and reducing costs.

Dynalog’s robot guidance systems leverage a combination of precise measurement tools, intelligent software, and deep industry expertise. Their solutions address a wide range of applications, including:

Tool Center Point (TCP) calibration

Robot kinematic calibration

Vision-based robot guidance

Fixture verification and compensation

Robot performance verification

Multi-robot and multi-station coordination

Key Benefits of Dynalog Robot Guidance Systems

Increased Accuracy: Dynalog systems can dramatically improve robot positional accuracy — often achieving results within fractions of a millimeter.

Reduced Downtime: Advanced calibration and guidance systems minimize the need for manual intervention and troubleshooting, keeping production lines running smoothly.

Flexibility in Production: Robots equipped with Dynalog guidance can easily adapt to changes in product designs, fixture positions, or batch sizes, making them ideal for high-mix, low-volume manufacturing.

Improved Quality: Consistent accuracy and repeatability result in higher-quality products and reduced scrap rates.

Cost Savings: Better performance and fewer errors translate into lower operating costs and faster ROI on automation investments.

Applications of Robot Guidance in Industry

Robot guidance systems from Dynalog-US are used across a wide range of industries and applications, including:

Automotive manufacturing — robot guidance for welding, assembly, painting, and inspection

Aerospace — precision drilling, fastening, and composite layup

Electronics — high-speed pick-and-place and circuit board assembly

Packaging — flexible part handling and sorting

General industrial automation — multi-purpose material handling, machine tending, and more

Vision-Guided Robotics

One of the most exciting areas of robot guidance is the integration of vision systems with robotic controls. Vision-guided robots can dynamically adjust their movements in response to real-time feedback from cameras and sensors. Dynalog-US offers cutting-edge vision-based robot guidance solutions that enable robots to detect, locate, and manipulate parts with extreme precision — even when those parts are moving or presented in variable positions.

Why Choose Dynalog-US for Robot Guidance?

When it comes to selecting a partner for advanced robot guidance, few companies can match the expertise, innovation, and proven results of Dynalog-US. With decades of experience and a global reputation for quality, Dynalog delivers solutions that work seamlessly with all major robot brands, including FANUC, ABB, KUKA, Yaskawa, and Universal Robots.

In addition, Dynalog’s expert team provides comprehensive support — from system design and implementation to training and ongoing optimization — ensuring customers get the most out of their robot guidance investments.

#RobotGuidance#DynalogUS#RoboticCalibration#IndustrialRobotics#AutomationSolutions#VisionGuidedRobots#RobotAccuracy#ManufacturingAutomation#AdvancedRobotics#FactoryAutomation#RobotCalibration

0 notes

Text

What You Will Learn in Industrial Automation and Robotics Courses?

Traditional manual processes have now transformed into smart systems that respond with speed and precision. From packaging lines that operate around the clock to robotic arms performing delicate tasks with surgical accuracy, the world of industrial production is evolving. And at the heart of this change lies a new kind of technical literacy, one built through Industrial automation and robotics courses.

But what exactly do these programs teach? And why are they so important today? Let’s explore what students really gain from this kind of education, and how it prepares them to thrive in tomorrow’s industries.

Foundational Engineering Knowledge That Matters

Before students can dive into robots or controllers, they need to understand the language of automation. These courses begin with essential principles: electrical theory, logic design, mechanical fundamentals, and system dynamics. Learners study current flow, sensors, basic circuits, and safety devices. They also explore control systems, how feedback works, what makes a loop stable, and how machines respond to various inputs.

Programmable Logic Controllers (PLCs)

Programmable Logic Controllers, or PLCs, form the core of most industrial automation systems. Unlike traditional relay setups, these compact computers carry out control tasks instantly by following logic sequences built by engineers. Students gain direct experience working with real hardware, learning to configure, test, and program PLCs using industry-standard languages such as ladder logic, structured text, and function block diagrams.

Courses focus not just on writing code but on solving problems: detecting errors, optimizing sequence flow, and debugging physical setups. Whether it’s running a simulated traffic light or managing conveyor timing, the logic must be precise.

Human-Machine Interfaces (HMI) and SCADA Systems

As machines grow smarter, the need for clear communication between systems and humans increases. That’s where HMI and SCADA systems come in.

Students learn to design interactive screens that allow operators to control and monitor processes, from pressure levels in a reactor to the speed of a bottling line. They develop layouts, manage alarms, create trend graphs, and set up data logging.

Equally critical is understanding SCADA architecture, how large-scale systems monitor multiple devices across facilities. These interfaces aren’t just dashboards. They’re lifelines. In high-risk or high-speed environments, the right display can prevent failure.

Robotics: Control, Precision, and Integration

Beyond sensors and switches, industrial robotics introduces a whole new dimension. These machines perform physical tasks with accuracy and consistency, from welding to material handling. In Industrial automation and robotics courses, students explore robotic motion planning, coordinate systems, joint movement, and gripper design.

Training includes simulation as well as real robotic arms. Learners program actions, define tool paths, and calibrate devices to respond to various scenarios. Robotics also demands a sharp eye for safety, understanding fail-safes, emergency stops, and risk analysis becomes part of the curriculum.

Sensor Technology and Instrumentation

In automation, sensing is everything. Machines need to detect position, measure flow, monitor temperature, or determine proximity, all without human input. That’s why students spend time studying sensors in depth.

They learn the theory and application of photoelectric sensors, limit switches, ultrasonic devices, thermocouples, and encoders. Courses often include wiring, calibration, signal processing, and sensor fusion techniques.

It’s one thing to install a sensor. It’s another to ensure its readings are accurate, consistent, and usable within an automation loop. A well-tuned sensing system is the difference between reliable automation and constant failure.

Drives, Motors, and Motion Control

Movement in automation is never random. Whether it’s a robotic arm pivoting or a conveyor transporting items, motion must be controlled, smooth, and predictable.

Students study various types of motors, stepper, servo, induction, and the drives that control them. They learn to manage speed, torque, and direction. Courses also explain PID control, acceleration curves, and how to prevent vibration or misalignment.

Practical lab work allows learners to connect motors, set drive parameters, and test results under different loads. These experiences create engineers who don’t just understand motion, they can manage it with precision.

Integration Projects: From Concept to Commissioning

Toward the end of most programs, students apply everything they’ve learned in a capstone project. This may involve designing an automated process from scratch, selecting hardware, building control logic, integrating sensors, and testing systems.

It’s not just a test. It’s preparation. It simulates real challenges, including incomplete specs, equipment failure, or changing project goals. The experience builds not only confidence but also the kind of problem-solving mindset employers look for.

Safety, Compliance, and Standards

No system, no matter how efficient, is worth endangering a worker’s life. That’s why safety is woven throughout every topic. They learn how to design systems that prevent unexpected starts, reduce hazards, and shut down when needed.

They also learn to assess risk, calculate safety integrity levels, and implement proper machine guarding. These aren’t theoretical concerns, they’re daily priorities in every automation role.

Final Thoughts

For anyone looking to step into a future-proof career, technical depth and adaptability are essential. Industrial automation and robotics courses offer both. They build an understanding of how machines function, how systems connect, and how processes can be improved through smart engineering. Whether you aim to be a systems integrator, controls engineer, maintenance lead, or robotics programmer, what you learn in these courses is more than skill, it’s your launchpad into a smarter, faster world.

0 notes

Text

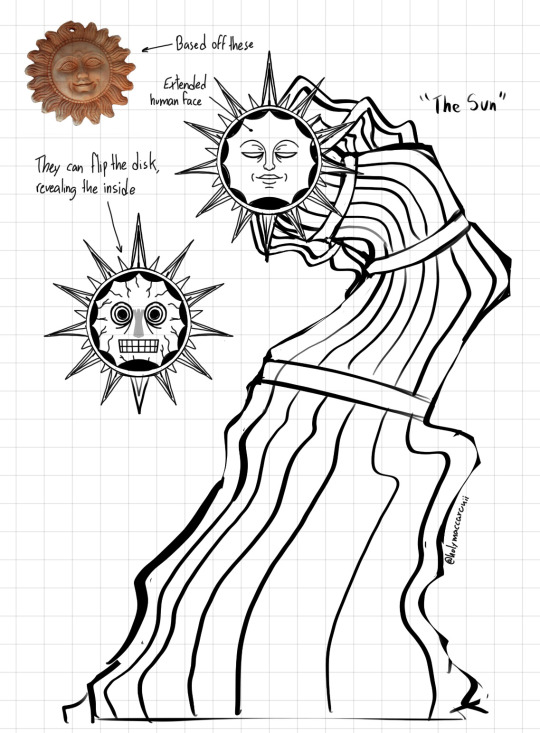

AAAAAH okay okay, I decided myself to share 2 things in one in this post: the lore of my ihnmaims AU + a design I’m working on. To be completely honest, I’m not sure if I’ll want to develop this AU into a fic or anything like that, but for now I’ll use it as an excuse to draw and design characters. Note that I might come back to this post and edit the lore paragraph, as it is still a work in progress, though I am liking where this is going. Please PLEASE excuse my English, some things might not make sense without me noticing, but I tried describing the plot the best I could. *Ahem*, now, the lore:

“PLAN B”

The lore takes place after the bad ending in the videogame where the player is turned into the worm, yet still doesn’t allow AM to access and torture the humans sealed in the moon colony. Since the last humans had “failed” their mission to defeat AM, a “Plan B” was scheduled to happen. Unbeknownst to the humans of the colony, another AI was created and implanted within the moon, taking up almost all of the space in its core due to its large size. This machine had the sole purpose of ensuring the survival of those humans once AM was defeated, or not. Inside it were millions of plant seeds, animal embryos and frozen samples that would later be used to repopulate the earth, yet it also had defense and destruction technologies to be used in case AM was not defeated. This machine was perfectly calibrated to be able to overcome any adversity that arose, but of course, all that changed when one of the humans managed to wake up and leave their capsule. This human got to understand what all of this was about, though they did not like where this was heading one tiny bit, thus they used the time they had left before the last human on Earth was killed to change and mess it all up. Humanity's greed had claimed yet another victim, as this AI was torn apart piece by piece until it was completely separated and rebuilt into an insane amount of sentient robot models as the years passed. This human managed to transform their own body as well, rebuilding it just as a sacred temple in order to be crowned monarch of this new society now living in a city on the moon. Despite all this, the goal of bringing humanity back still remained, now with the small condition that this human had to be considered a savior and supreme leader to all. Once the last human on Earth had died, robotic troops began to be sent to Earth to study it in detail and plan attacks against AM’s systems, which were disadvantageously located deep underground. Many of these attacks resulted in large unnecessary losses as these robots were not calibrated to combat AM, but they still continued to upgrade themselves to increase their damage range over time. This continued on as a seemingly endless war that barely progressed.

Again, I am aware that maybe some stuff might not make sense (or maybe it does?), but this is basically a continuation of what happened canonically in the videogame. The name “PLAN B” also makes reference to my OC BE, thought that was cool :p. I’ll explain the events that happen here later on as well.

Many if not all of the robots I’ll design will include a whole lotta exposed wires + their outer shell/ body parts, as I liked this dynamic, and it will be important later. The “monarch” that I mentioned in the paragraph is turning out to be this guy down here. I based myself off from those ceramic sun decorations, and thought it would be cool to make his face switchable. In reality they have a body too but I jus like wire amalgamations too much + they’re easy to draw. I’ll continue workin on em :-)

Edit: [THIS LORE IS NOT UPDATED]

#*posts this and immediately runs away to curl up in a corner*#I did promise myself to be cringe and to be free I’m sorry#I’m totally normal about this#very#RAAAAAAAAHHHHHH!!!!#ihnmaims au#ihnmaims am#am ihnmaims#ihnmaims#i have no mouth and i must scream#ihnmaimsplanbau#ihnmaims oc#hel 102 ihneaimc#ihneaimc#i have no eyes and i must cry

91 notes

·

View notes

Text

التخلص من النفايات الخطرة

التخلص من النفايات الخطرة

CRUDE OIL TANK CLEANING MASTERY: THE INDUSTRY'S MOST COMPREHENSIVE OPERATIONAL MANUAL

I. Nano-Scale Sludge Forensics

1.1 Synchrotron Radiation Analysis

XANES Spectroscopy at 4,500 eV reveals:

Vanadium speciation: 65% as VO⁺ (sulfate) / 35% as V⁴⁺ (porphyrin)

Sulfur K-edge shows 72% thiophenic compounds

1.2 4D Rheological Modeling

Time-dependent Herschel-Bulkley:

math

\tau(t) = \tau_{y0}e^{-kt} + K(\dot{\gamma})^n(1 - e^{-kt})

Where:

k = 0.015 s⁻¹ (aging coefficient)

τ_{y0} = 210 Pa (initial yield)

II. Quantum Cleaning Technologies

2.1 Femtosecond Laser Ablation

Parameters:

Wavelength: 1,030 nm

Pulse duration: 350 fs

Fluence: 2.5 J/cm²

Results:

0.2μm layer removal precision

Zero heat-affected zone

2.2 Supercritical CO₂ Extraction

Phase Diagram Optimization:

85°C at 90 bar (above critical point)

Solubility enhancement with 5% limonene co-solvent

III. Military-Grade Operational Protocols

3.1 Special Ops Cleaning Tactics

High-Altitude Tank Cleaning (3,000m+ ASL):

Compensated pump curves for 20% lower atmospheric pressure

Modified surfactant HLB values (12 → 14)

3.2 Underwater Tank Repair

Saturation Diving Protocol:

Bell runs at 50m depth

Hyperbaric welding at 1.5x normal partial pressure

IV. AI-Powered Predictive Systems

4.1 Neural Network Architecture

python

class SludgePredictor(tf.keras.Model):

def __init__(self):

super().__init__()

self.lstm = layers.LSTM(128)

self.dense = layers.Dense(3) # Viscosity, H2S, Corrosion

def call(self, inputs):

x = self.lstm(inputs)

return self.dense(x)

Training Data: 15 years of tank inspection reports

4.2 Digital Twin Calibration

Real-Time Kalman Filtering:

math

\hat{x}_k = F_k\hat{x}_{k-1} + K_k(z_k - H_kF_k\hat{x}_{k-1})

State variables: thickness, sludge depth, VOC ppm

V. Extreme Environment Case Bank

5.1 Desert Storm Cleaning

Challenge: 55°C ambient with 90μm/yr corrosion rate

مردم نفايات بترولية خطرة

Solution:

Phase-change cooling suits (-5°C PCM packs)

Night-only operations using IR thermography

5.2 Offshore Floating Storage

Dynamic Positioning Cleaning:

Wave motion compensation algorithms

Heave-adjusted robotic arm trajectories

VI. The Future Is Now (2026+)

6.1 Programmable Matter Cleaners

Shape-Shifting Robots:

Gallium-indium alloys (melting point 15°C)

Magnetic field reconfiguration

6.2 Bio-Electric Sludge Breakdown

Microbial Fuel Cells:

Geobacter sulfurreducens biofilm

0.8V output @ 2mA/cm² while degrading sludge

VII. The Master Operator's Toolkit

7.1 Augmented Reality SOPs

Hololens Application Features:

Real-time gas overlay

Equipment torque specs visualization

Expert call-in function

7.2 Blockchain Waste Ledger

Hyperledger Implementation:

javascript

async function logWaste() {

const tx = await contract.methods

.addWasteBatch(tankID, weight, composition)

Tank Cleaning

Microgravity Applications:

Electrostatic sludge collection

3D-printed replacement parts

Final Master Checklist:

Pre-job quantum computer risk simulation (Qiskit model)

Nanobot swarm deployment calibration

Blockchain work permit NFT minting

Post-cleaning synchrotron validation scan

0 notes

Text

3D Camera Market Experiencing Accelerated Growth Due to Rising Smartphone Integration

Market Overview

The global 3D camera market is experiencing robust growth, driven by advancements in imaging technologies and an increasing demand for immersive experiences across various industries. These cameras capture three-dimensional images or videos by analyzing depth, distance, and spatial details—revolutionizing everything from consumer electronics to industrial applications. With applications in photography, videography, gaming, industrial automation, healthcare, and security, 3D cameras are evolving rapidly in terms of both hardware and software capabilities. Market segmentation spans types like stereo vision, structured light, and time of flight, integrated into devices ranging from smartphones and drones to wearable and professional equipment. As the world embraces digitization and automation, the demand for enhanced imaging technologies is expected to keep this market on a steady upward trajectory.

Click to Request a Sample of this Report for Additional Market Insights: https://www.globalinsightservices.com/request-sample/?id=GIS25032

Market Dynamics

Several key factors are fueling the expansion of the 3D camera market. One of the primary drivers is the growing popularity of virtual reality (VR) and augmented reality (AR) applications, which rely heavily on precise 3D imaging to deliver immersive environments. Furthermore, the integration of 3D cameras into consumer electronics such as smartphones, tablets, and laptops has significantly expanded the technology’s reach.