#PCBAssembly

Explore tagged Tumblr posts

Text

youtube

Desk of Ladyada - LDACs, Sparkle Motion Mini & Claude 🔧🤖 https://youtu.be/bFcRxufkZjI

Sparkle Motion Mini PCBs are here, featuring a compact 5V-only design. We are also refining small breakout boards like the DAC7578 and working on a TMC2209 driver by refactoring BusIO for versatile interfaces. Lastly, Claude & exploring compact, sensorless BLDC motor drivers via DigiKey.

#ladyada#electronics#makercommunity#adafruit#sparklemotion#pcbdesign#steppermotor#bldcmotors#dac7578#tmc2209#busio#chipdesign#electronicsengineering#hardwarehacking#robotics#iot#microcontrollers#embeddedhardware#diyprojects#opensourcehardware#pcbassembly#sparklemotionmini#claudeai#chatgpt#makersgonnamake#embeddeddevelopment#circuits#diyrobotics#techdesign#hardwaretesting

2 notes

·

View notes

Text

PCB Assembly Prototypes Manufacturer

PCB Assembly

What is a prototype PCB assembly?

PCB prototyping is the experimentation pilot stage of the product which is to be mass produced at a later stage. This is more of an experiment which is done after the initial discussions and the design. This offers a pre-production analysis of the boards that are to be manufactured, reducing the possible number of errors in the PCB design. PCB prototypes help the manufacturer analyze the strengths as well as weak areas of their proposed circuit boards. Prototypes also serve as a reference point for future versions of the same product. At Hitechpcba, we handle PCB prototype assembly in quantities from one to hundred printed circuit boards.

We have acquired capabilities that enable us to serve our clients better. All these years, we have worked on many complex prototype PCB assembly projects, and we believe the following capabilities have helped us serve our clients better.

Prototype PCB Assembly Services: We specialize in the following prototype printed circuit board assembly services.

SMT: We can provide single-sided and double-sided surface mount PCB assemblies in different specifications.

Plated Through Hole: We offer plated through hole assembly with selective soldering.

Mixed Assemblies: We often work on projects involving mixed assemblies – through-hole and SMT and electromechanical assemblies.

PCBA Testing: All the PCBA functional testing is performed in-house. Over the years, we have invested in various test fixtures and equipment, which helps us ensure the quality of PCBA. Currently, we provide the following types of PCBA testing services:

Flying probe testing for PCB

Functional testing including system and board-level testing

General PCB Assembly Capabilities: Our general PCB assembly capabilities are not limited to these:

RoHS, leaded or lead free, clean and no chemistries

PCB components including various types of QFNs, BGAs, 0105, 0201, 0804, and press fit components in small quantities.

What are the benefits of a prototype PCB assembly?

Prototype PCB assembly comes with several advantages. These benefits play a major role in the facilitation of your PCB manufacturing. Some of these benefits include:

Detection of Flaws Early

With prototype PCB, you will easily detect whatever flaws are present during the product’s development stages. This will allow you to solve the issues thereby saving you some money if you had gone ahead to make the production having the flaws in them.

If you go ahead to make changes during the production, there may be a need for more technicalities, and this may be expensive.

Testing of Each Component

With a prototype, you will be able to test all your system’s elements individually before you go ahead to set it up. You should do this because it is important especially for very complex projects composed of several parts that are PCB based.

When you validate each of these components, you will be able to identify those areas having issues that you should look into. This is the only way the project can function the right way.

Reduction in Total Costs

Utilizing the prototype bare PCB for any of your projects could go a long way in reducing what you’ll have spent in total for the project. With prototyping, you will be able to notice those errors in your project and then make corrections before you start the real production.

As soon as these flaws have been checked and rectified, then you may continue with the manufacturing of your Printed circuit boards in large quantities, thereby saving you unnecessary costs.

High-Quality PCBs

Why prototyping your PCB is important is to help you test if your project will function effectively. When we talk of testing, it involves the identification of errors present and then rectifying and making corrections to them.

Therefore, the eventual PCB after the prototyping will be of high quality that surely meets standards set internationally.

Less Turnaround Time

With prototype PCB assembly, you will be able to reduce the total time used in producing your printed circuit board. While making use of prototype printed circuit boards, you’ll be able to see the errors and then make corrections before you start the actual production.

Therefore, the eventual prototype will be free of defects. This implies that your PCBs will be produced quickly by your manufacturer.

We are here :https://www.hitechpcba.com/pcb-assembly-manufacturer

6 notes

·

View notes

Text

#pcb#pcba#pcbassembly#pcb manufacturer#pcb board#pcb factory#pcb fabrication#aluminum pcb#pcb design#pcb prototype

2 notes

·

View notes

Text

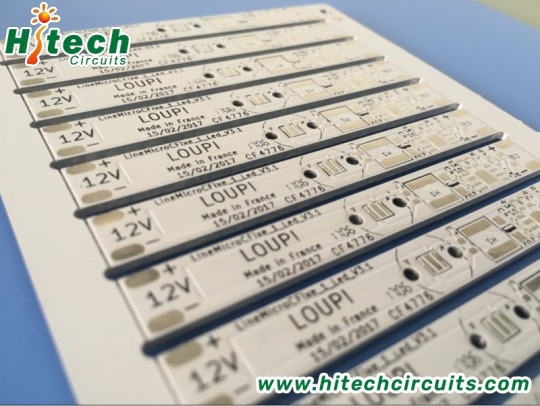

Aluminium PCB

Aluminium PCB are metal-based, copper-clad laminates with a good heat dissipation function. Usually, Aluminium PCB is refer to LED PCB board, which is the most important part of LED display and lighting products, etc.

Hitech Circuits Co., Limited is a professional aluminum pcb board, LED PCB manufacturer in China. Through 10 years of aluminum pcb board designing and manufacturing experience, Hitech are able to provide high quality and cost effective single layer, double layer and multi layer aluminum pcb boards to global customers. For any of your requirements regarding aluminum pcb board, please don’t hesitate to contact [email protected]

#Aluminium PCB#aluminum pcb#pcb assembly#pcb#engineering#technology#pcba#pcb manufacturer#pcbassembly#pcb design#hardware

5 notes

·

View notes

Text

Provide solutions to pcb and pcba problems

2 notes

·

View notes

Text

Devlopment board

#controller#esp32#esp32project#pcb#pcbdesign#pcbassembly#engineer#engineering#electricalengineering#circuits#iot#smarthome#diyelectronics#trending#viral#reels#instagram#instragramreels#followers#boost#explore#explorepage#likeforlikes#electricalengineer#electricalwork#electricalcontractor#electricalhacks#electricallife#electricalsky

4 notes

·

View notes

Text

#hardware design#hardware design services#pcb assembly#pcb design#pcb manufacturer#pcba#pcbassembly#electronics design#automotive electronics

2 notes

·

View notes

Text

We are a 20 years PCB&PCBA factory.

5 notes

·

View notes

Text

Multilayer PCBs (Printed Circuit Boards) offer numerous advantages over their single-layer or double-layer counterparts. These benefits arise from their enhanced design capabilities, improved performance, and greater flexibility. Here are some key advantages of multilayer PCBs:

#PCB#printed circuit board manufacturers#electronic cable assembly#pcb manufacturing#pcb assembly manufacturer#pcb assembly services#pcb board manufacturer#printed circuit board manufacturer in india#circuit board manufacturing#pcb exporters#pcba#pcb manufacturer#pcb design#pcbassembly#multilayer pcb

2 notes

·

View notes

Text

In the fast-paced world of electronics, speed and efficiency are key factors that determine the success of a business. PCB Assembly, also known as PCBA, plays a crucial role in meeting the demands of industries like consumer electronics, automotive, telecommunications, and medical devices.

1 note

·

View note

Text

The Role of PCB Assembly in Med-Tech and Automotive Sectors

As global industries evolve with smarter, smaller, and more powerful devices, the demand for precision-engineered PCB assembly has skyrocketed — especially in the medical technology (med-tech) and automotive sectors. These industries demand not just high-quality electronics but also speed, reliability, and regulatory compliance. This is where Aimtron Electronics plays a vital role.

Why PCB Assembly Is Critical in Med-Tech

Modern medical devices — from portable ECG machines to imaging systems and wearable diagnostics — rely on compact and high-performance PCBs. In this sector, zero-failure tolerance is a must, as even a minor malfunction can affect patient health and safety.

At Aimtron Electronics, our quick-turn PCB prototyping, BGA assembly expertise, and precision testing services support med-tech innovators in rapidly developing and scaling their products. Our assembly processes are developed in the USA and implemented in India, ensuring global quality standards with local agility.

Automotive Electronics: Reliability Under Pressure

The automotive industry is undergoing a major transformation, driven by electric vehicles (EVs), ADAS (Advanced Driver Assistance Systems), and in-vehicle infotainment. These applications require PCBs that can withstand harsh environments, thermal cycling, and mechanical stress.

Aimtron supports this with:

High-volume SMT and thru-hole PCB assembly

Robust testing procedures to ensure durability and consistency

Electromechanical integration for complete module assembly

Whether it’s battery management systems or advanced lighting controls, Aimtron’s engineering and manufacturing expertise deliver consistent performance for automotive applications.

Global Expertise, Local Execution

With our flagship manufacturing facility in the United States and advanced production lines in Vadodara, Gujarat, Aimtron Electronics offers a seamless global supply chain. Our clients benefit from:

USA-grade quality

Faster development cycles

Cost-effective scalability

Supporting Innovation with Trusted Partnership

Aimtron is more than just a PCB assembly company — we’re your ESDM partner, offering turnkey solutions across product design, manufacturing, and testing. For med-tech and automotive companies looking to bring high-impact electronics to market, Aimtron provides the technical strength, speed, and global reliability you need.

0 notes

Text

Selective soldering 🔧🔬🔥

Selective soldering involves attaching specific components to printed circuit boards (PCBs) and molded modules, a method particularly useful for items susceptible to heat damage from standard reflow ovens or wave soldering found in conventional surface-mount technology (SMT) or through-hole assembly techniques. Typically, this method is applied after an initial SMT oven reflow phase. The components targeted for selective soldering are often nestled among others already soldered via a surface-mount reflow method. This demands high precision in the selective soldering process to prevent damage to the surrounding elements.

#adafruit#selectivesoldering#pcbassembly#electronicsmanufacturing#surface-mount#throughhole#reflowprocess#precisionengineering#solderingtechnology#circuitboarddesign#manufacturinginnovation#techadvancements

5 notes

·

View notes

Text

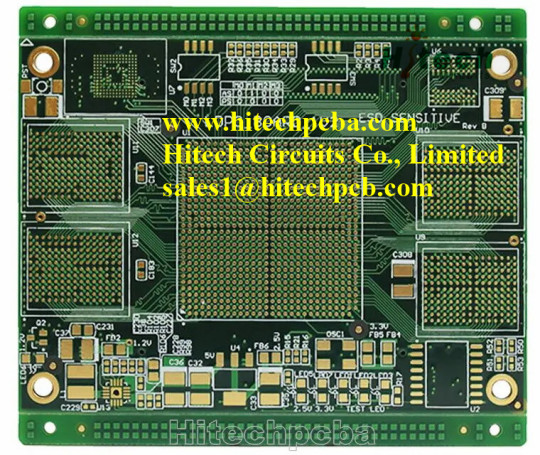

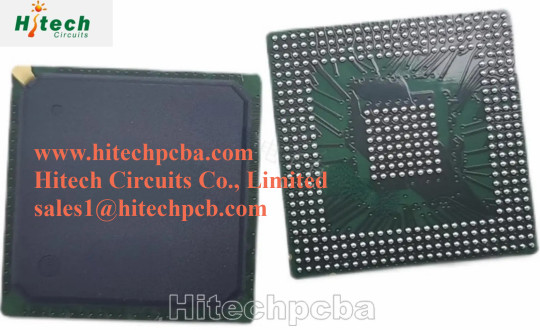

BGA PCB Assembly

What's BGA PCB?

BGA PCB is Printed Circuit Boards with Ball Grid Array. We use various sophisticated techniques for making BGA PCBs. Such PCBs have a small size, low cost, and high packaging density. Hence, they are reliable for high-performance applications.

What’s BGA PCB Assembly?

Ball Grid Array (BGA) assembly technology is a surface mount packaging technology applied to integrated circuits, which is often used to permanently fix devices such as microprocessors. BGA assembly can accommodate more pins than other packages such as Dual in-line packages or Quad Flat Packages, and the entire bottom surface of the device can be used as pins , instead of only peripherals available, and also have a shorter average wire length than peripheral-limited package types for better high-speed performance.

Our BGA assembly services cover a wide range, including BGA prototype development, BGA PCB assembly, BGA component removal, BGA replacement, BGA rework and reballing, BGA PCB assembly inspection, and so on. Leveraging our full-coverage services, we can help customers streamline the supply network and accelerate product development time.

Benefits of BGA PCB Assembly

Efficient Use of Space – BGA PCB layout allows us to efficiently use the available space, so we can mount more components and manufacture lighter devices.

Better Thermal Performance – For BGA, the heat generated by the components is transferred directly through the ball. In addition, the large contact area improves heat dissipation, which prevents overheating of components and ensures long life.

Higher Electrical Conductivity – The path between the die and the circuit board is short, which results in better electrical conductivity. Moreover, there is no through-hole on the board, the whole circuit board is covered with solder balls and other components, so vacant spaces are reduced.

Easy to Assemble And Manage – Compared to other PCB assembly techniques, BGA is easier to assemble and manage as the solder balls are used directly to solder the package to the board.

Less Damage to Leads – We use solid solder balls for manufacturing BGA leads. Hence, there is a lesser risk that they will get damaged during the operation.

In a word, BGA PCB assembly, have these advantages, high density, better electrical conductivity, lower thermal resistance, easy to assembly & manage are some of the advantages of BGA PCB.

Stringent BGA PCB Assembly Testing Process

To achieve the highest quality standards for BGA assembly, we use a variety of inspection methods throughout the process including optical inspection, mechanical inspection, and X-ray inspection. Among them, the inspection of BGA solder joints must use X-rays. X-rays can pass through the components to inspect the solder joints below them, so as to check the solder joint position, solder joint radius, and solder joint thickness.

Inspection of BGA PCB

We mostly use X-ray inspection for analyzing the features of BGA PCBs. This technique is known as XRD in the industry and relies on X-rays for unveiling the hidden features of this PCB. This kind of inspection reveals.

* Solder Joint Position

* Solder Joint Radius

* Change in Circular shape

* Solder Joint Thickness

The Hitechpcba advantage lies in a whole range of aspects, beginning from the fact that we have the proven technology available at our disposal. With over 15 years of experience in a wide range of PCB Fabrication and Assembly techniques, what we also have is trained manpower and importantly, robust industry experience and best practices that you can benefit from.

Our unstinting devotion to quality and customer satisfaction means that once you partner with us, you can rest assured that you will get nothing but the best. The customer-oriented approach also shows up in your commitment to delivery times. With quick turnaround times, you can reap the benefit of quick time-to-market, which, in turn, can be a major source of competitive advantage.

Whether your requirement is BGA PCB design, BGA PCB, BGA PCB layout, BGA PCB Assembly or BGA rework, you can rest assured that you will get superior quality and performance, that will in turn, positively impact the performance of your final product.

With our efficient network of component suppliers and the many economies of scale that we enjoy, that you will get optimal costs, is a given.

Please feel free to contact us ([email protected]) if you have any other special request on the BGA pcb assembly.

4 notes

·

View notes

Text

#pcb#pcba#pcbassembly#aluminum pcb#pcb design#pcb fabrication#pcb factory#pcb manufacturer#pcb board#pcb prototype

3 notes

·

View notes

Text

A skilled female engineer conducts a close inspection of a PCB board with precision tools in a high-tech electronics lab. Wearing safety goggles and a lab coat, she exemplifies expertise, quality, and innovation in modern electronic manufacturing. Captured at Auckam Technologies, a global leader in hardware design, embedded systems, and intelligent product development. 🔗 Visit: www.auckam.com

#PCBDesign#ElectronicsEngineering#WomenInTech#PCBAssembly#HardwareDesign#EmbeddedSystems#SmartElectronics#IoTHardware#ElectronicManufacturing#InnovationLab#TechEngineer#AuckamTechnologies

0 notes

Text

The Benefits of Opting for Aimtron PCB Assembly Manufacturing Services in Illinois

In today’s competitive electronics landscape, Original Equipment Manufacturers (OEMs) and product developers are under increasing pressure to reduce time-to-market, enhance product quality, and control costs. Partnering with the right Electronics Manufacturing Services (EMS) provider can make a significant difference—and that’s where Aimtron Corporation, headquartered in Palatine, Illinois, stands out.

Why Choose Aimtron for PCB Assembly in Illinois?

Aimtron Corporation, a trusted name in the electronics manufacturing industry since 2009, delivers state-of-the-art PCB assembly services with a focus on quality, speed, and reliability. Here’s how businesses benefit by choosing Aimtron’s services in Illinois:

1. Expertise in Complex Assemblies

Aimtron brings deep expertise in handling Turnkey PCB Assemblies, including BGA, micro-BGA, Stack BGA, ultra-fine pitch QFP, QFN, and CSP packages. This enables customers to outsource even the most intricate designs with confidence.

2. Quick Turn Prototyping

Time-sensitive projects demand quick action. Aimtron’s quick-turn PCB prototyping services ensure that design iterations are turned around rapidly—without compromising on precision or quality. This allows businesses to accelerate product development cycles.

3. Advanced Testing & Inspection

Every assembly goes through rigorous quality assurance processes including:

Automated Optical Inspection (AOI)

X-Ray Inspection

In-Circuit Testing (ICT)

Functional Testing

Burn-in Testing

Additionally, firmware programming, conformal coating, and potting services are available to meet end-product reliability expectations.

4. Comprehensive Electromechanical & Cable Assembly

From board-level assembly to electromechanical integration and wire harnessing, Aimtron offers end-to-end solutions. This reduces the need for multiple vendors and simplifies the supply chain.

5. Customer-Centric Operations

Aimtron emphasizes customer service, transparency, and responsive communication, making them a reliable partner for both startups and large-scale OEMs across the U.S.

6. USA-Based Manufacturing with Global Standards

Being based in Palatine, Illinois, Aimtron delivers the best of both worlds—domestic responsiveness and global quality benchmarks. This helps companies reduce shipping times, ensure IP protection, and access a knowledgeable U.S.-based engineering team.

7. High-Value Mechanical and Design Engineering Support

More than just an assembly house, Aimtron offers full-stack electronics engineering and design services, including DFM (Design for Manufacturing) and component selection guidance. This ensures your products are optimized from concept to completion.

Conclusions:

Whether you're launching a new product or scaling an existing one, Aimtron Corporation’s PCB assembly and EMS capabilities in Illinois offer the technical strength and operational agility that modern electronics businesses need. With cutting-edge facilities, a skilled workforce, and a dedication to quality, Aimtron is a dependable partner for driving innovation forward.

0 notes