#Expanded Polystyrene (EPS) Market share

Explore tagged Tumblr posts

Text

2032, Expanded Polystyrene (EPS) Recycling Market Growth and Research 2024-2032

The Reports and Insights, a leading market research company, has recently releases report titled “Expanded Polystyrene (EPS) Recycling Market: Global Industry Trends, Share, Size, Growth, Opportunity and Forecast 2024-2032.” The study provides a detailed analysis of the industry, including the global Expanded Polystyrene (EPS) Recycling Market Size share, trends, and growth forecasts. The report also includes competitor and regional analysis and highlights the latest advancements in the market.

Report Highlights:

How big is the Expanded Polystyrene (EPS) Recycling Market?

The expanded polystyrene (EPS) recycling market size reached US$ 19.7 Billion in 2023. Looking forward, Reports and Insights expects the market to reach US$ 36.5 Billion by 2032, exhibiting a growth rate (CAGR) of 6.7% during 2024-2032.

What are Expanded Polystyrene (EPS) Recycling?

EPS recycling is the practice of collecting, sorting, and processing EPS foam products to reclaim the material for reuse. EPS, also known as Styrofoam, is a lightweight and rigid plastic material utilized in packaging and insulation. The recycling process involves compressing the foam to reduce its size and then melting it down to create dense blocks or pellets suitable for manufacturing new products. EPS recycling contributes to environmental sustainability by diverting EPS waste from landfills and reducing the demand for new plastic production.

Request for a sample copy with detail analysis: https://www.reportsandinsights.com/sample-request/1775

What are the growth prospects and trends in the Expanded Polystyrene (EPS) Recycling industry?

The expanded polystyrene (EPS) recycling market growth is driven by various factors. The market for recycling expanded polystyrene (EPS) is expanding, fueled by growing environmental consciousness and regulatory measures promoting recycling practices. EPS, widely utilized in packaging and construction, significantly contributes to plastic waste. Recycling EPS involves collecting, cleaning, and processing it into reusable material for diverse applications. Market growth is propelled by increasing demand for recycled EPS in the construction and packaging sectors, driven by sustainability objectives and economic advantages. Moreover, technological advancements in EPS recycling and government support for recycling initiatives are further driving market growth. Hence, all these factors contribute to expanded polystyrene (EPS) recycling market growth.

What is included in market segmentation?

The report has segmented the market into the following categories:

By EPS Waste Type:

Post-consumer EPS waste

Pre-consumer EPS waste

By EPS Recycling Process:

Mechanical recycling

Chemical recycling

Other recycling processes

By End-Use Industry:

Packaging

Construction

Electrical and Electronics

Automotive

Others

By Recycled EPS Product:

Packaging materials

Insulation boards

Molded products

Composite materials

Others

By Source of Collection:

Municipal recycling programs

Industrial and commercial collection

Retail collection

Other

By Recycling Equipment:

Shredders

Granulators

Densifiers

Extruders

Others

By Application:

Packaging

Building and construction

Insulation

Consumer goods

Others

By Distribution Channel:

Direct sales

Distributor sales

E-commerce

By Market Type:

Business to Business (B2B)

Business to Consumer (B2C)

Segmentation By Region:

North America:

United States

Canad

Europe:

Germany

United Kingdom

France

Italy

Spain

Russia

Poland

BENELUX

NORDIC

Rest of Europe

Asia Pacific:

China

Japan

India

South Korea

ASEAN

Australia & New Zealand

Rest of Asia Pacific

Latin America:

Brazil

Mexico

Argentina

Middle East & Africa:

Saudi Arabia

South Africa

United Arab Emirates

Israel

Rest of MEA

Who are the key players operating in the industry?

The report covers the major market players including:

Dart Container Corporation

NOVA Chemicals Corporation

ACH Foam Technologies, LLC

Ravago Recycling Group

Styro Recycle LLC

Total, Petrochemicals & Refining USA, Inc.

Alpek Polyester

Repsol S.A.

Vanden Recycling

Plasti-Fab Ltd.

NexKemia Petrochemicals Inc.

EPS Industry Alliance

Vita Group

FPC Foam Plastics Corporation

Winco Foam Industries Limited

View Full Report: https://www.reportsandinsights.com/report/Expanded Polystyrene (EPS) Recycling-market

If you require any specific information that is not covered currently within the scope of the report, we will provide the same as a part of the customization.

About Us:

Reports and Insights consistently mееt international benchmarks in the market research industry and maintain a kееn focus on providing only the highest quality of reports and analysis outlooks across markets, industries, domains, sectors, and verticals. We have bееn catering to varying market nееds and do not compromise on quality and research efforts in our objective to deliver only the very best to our clients globally.

Our offerings include comprehensive market intelligence in the form of research reports, production cost reports, feasibility studies, and consulting services. Our team, which includes experienced researchers and analysts from various industries, is dedicated to providing high-quality data and insights to our clientele, ranging from small and medium businesses to Fortune 1000 corporations.

Contact Us:

Reports and Insights Business Research Pvt. Ltd. 1820 Avenue M, Brooklyn, NY, 11230, United States Contact No: +1-(347)-748-1518 Email: [email protected] Website: https://www.reportsandinsights.com/ Follow us on LinkedIn: https://www.linkedin.com/company/report-and-insights/ Follow us on twitter: https://twitter.com/ReportsandInsi1

#Expanded Polystyrene (EPS) Recycling Market share#Expanded Polystyrene (EPS) Recycling Market size#Expanded Polystyrene (EPS) Recycling Market trends

0 notes

Text

#Expanded Polystyrene (EPS) Market#Expanded Polystyrene (EPS) Market size#Expanded Polystyrene (EPS) Market share#Expanded Polystyrene (EPS) Market trends#Expanded Polystyrene (EPS) Market analysis#Expanded Polystyrene (EPS) Market forecast

0 notes

Text

The Billion-Dollar Secret: How Styrofoam Shipping Boxes Dominate the Cold Storage Market

Insulated Styrofoam Shipping Boxes Market Outlook and Projected Expansion

The GlobalInsulated Styrofoam Shipping Boxes Market is undergoing a transformative evolution, expected to grow from USD 5.8 billion in 2024 to over USD 9.8 billion by 2035, marking a 5.1% CAGR. This expansion is underpinned by surging demand for temperature-controlled logistics, particularly in pharmaceuticals, biotechnology, food & beverage, and chemical sectors. As global trade intensifies and e-commerce logistics demand highly effective cold chain packaging, insulated Styrofoam shipping boxes are becoming indispensable in ensuring thermal stability and minimizing spoilage.

Request Sample Report PDF (including TOC, Graphs & Tables): https://www.statsandresearch.com/request-sample/40651-global-insulated-styrofoam-shipping-boxes-market

Drivers of Insulated Styrofoam Shipping Boxes Market Momentum:

Cold Chain Logistics: Fueling Demand

Accelerated by global vaccine distribution and increasing biologics shipments, cold chain infrastructure investment is expanding rapidly. Logistics providers are integrating EPS-based shipping boxes due to their light weight, thermal resistance, and low cost. Emerging economies across Asia-Pacific and Latin America are establishing cold storage nodes, elevating regional adoption of EPS and its alternatives.

Thermally Sensitive E-Commerce Fulfillment

With the explosion of direct-to-consumer delivery models, including meal kits, frozen groceries, and pharmaceutical subscription services, packaging solutions must now perform at a higher thermal standard. Styrofoam boxes excel in preserving contents during last-mile delivery, particularly in high-temperature regions or extended transit windows.

Get up to 30%-40% Discount: https://www.statsandresearch.com/check-discount/40651-global-insulated-styrofoam-shipping-boxes-market

Industry Trends Reshaping the Insulated Styrofoam Shipping Boxes Market Landscape:

Eco-Friendly Insulation Innovation

Environmental scrutiny around traditional Expanded Polystyrene (EPS) has prompted industry leaders to introduce biodegradable EPS, Expanded Polypropylene (EPP), and Expanded Polyurethane (EPU). These innovations aim to balance thermal efficiency with recyclability and biodegradability, addressing both regulatory pressure and consumer sustainability demands.

Integration of IoT and Smart Packaging

Innovations such as IoT-based sensors, real-time temperature tracking, RFID chips, and blockchain-enabled traceability are redefining product integrity. Advanced boxes now feature embedded condition-monitoring solutions, allowing logistics providers to react in real-time to temperature breaches, critical in pharmaceuticals and biologics.

Rise of Vacuum Insulated Panels (VIPs) and Phase Change Materials (PCMs)

Next-gen thermal packaging increasingly utilizes VIPs and PCMs to ensure temperature stability in extreme conditions. These materials enhance insulation with minimal volume, optimizing space efficiency in shipping containers and reducing fuel consumption in transport.

Product Segmentation and Performance:

Hinged vs. Un-Hinged Boxes

Hinged boxes dominate the product landscape, capturing 68.5% market share in 2024. Their popularity stems from ease of use, secure sealing, and durability. Un-hinged variants, while less prevalent, continue to grow steadily due to their customization potential and lower unit cost, catering to niche applications.

Material Performance

EPS (55.3% share) remains the workhorse due to its cost-effectiveness and thermal balance.

EPP, growing at 6.3% CAGR, offers superior mechanical resilience and reusability, ideal for pharmaceutical supply chains.

EPU, though costlier, provides unmatched insulative performance, suited for ultra-cold shipments and perishable biotech products.

Insulated Styrofoam Shipping Boxes Market by End-Use Applications:

Food & Beverage

Holding a 50.4% share, the food industry leverages insulated boxes for frozen meal kits, seafood, dairy, and fresh produce. The rise of online grocery and farm-to-table delivery models is spurring demand for custom-sized, recyclable packaging.

Pharmaceuticals & Healthcare

With a projected 6.6% CAGR, this sector is the fastest-growing, driven by vaccine distribution, clinical trials, and the rise in biologic and personalized medicines. EPS and EPU boxes are the backbone of cold chain assurance in these high-stakes deliveries.

Electronics and Specialty Chemicals

Thermally sensitive semiconductors, batteries, and temperature-reactive chemicals require rigid, vibration-absorbing packaging. EPP's impact resistance and insulation are pivotal in ensuring transit safety.

Sales Channel Dynamics

Distributors lead at 59.8%, leveraging bulk procurement networks and established B2B logistics relationships.

Online retailers, fueled by D2C models, are the fastest growing, benefiting from the scalability of e-commerce fulfillment.

Specialty stores, though niche, serve high-margin segments like biotech R&D and small-batch gourmet shipping.

Insulated Styrofoam Shipping Boxes Market Regional Insights:

North America

Dominates at 38% insulated styrofoam shipping boxes market share, underpinned by mature cold chains, stringent FDA and EPA compliance norms, and leading e-commerce networks.

Asia-Pacific

Experiencing 6.8% CAGR, propelled by urbanization, rising disposable income, and massive investments in infrastructure modernization across China, India, and Southeast Asia.

Europe

With a 29.2% share, Europe is pushing the envelope in green packaging mandates, accelerating the transition to biodegradable EPS alternatives and reusable systems in the EU market.

Competitive Landscape and Innovation Leadership

Key Insulated Styrofoam Shipping Boxes Market Players and Strategic Movements

Sonoco Products Company: Launched a biodegradable EPS line, targeting regulated markets and reducing landfill contributions.

Cryopak: Acquired a PCM technology firm, expanding its thermal innovation pipeline.

Topa Thermal: Introduced IoT-enabled boxes through a logistics partnership, merging smart technology with cold chain essentials.

These firms are doubling down on research, mergers, and IP acquisition to maintain a competitive edge, particularly in high-growth verticals like personalized medicine and frozen food delivery.

Future Insulated Styrofoam Shipping Boxes Market Pathways and Strategic Recommendations

Invest in Material R&D: Prioritize hybrid packaging that combines VIPs, biodegradable EPS, and PCM layers.

Adopt Smart Packaging: Enable supply chain visibility through IoT and blockchain integrations.

Target Emerging Markets: Capitalize on growth corridors in Asia-Pacific and Latin America, focusing on urban logistics hubs.

Align with ESG Goals: Offer certified carbon-neutral packaging solutions, appealing to conscious B2B buyers and regulators alike.

Modularize Offerings: Provide scalable and custom-fit designs for cross-sector applicability, from biopharma to gourmet.

Purchase Exclusive Report: https://www.statsandresearch.com/enquire-before/40651-global-insulated-styrofoam-shipping-boxes-market

Conclusion

The Global Insulated Styrofoam Shipping Boxes Market is entering an era defined by thermal innovation, sustainability, and digital integration. As industries escalate their demand for high-performance cold chain packaging, the market's future hinges on material advancements, real-time monitoring capabilities, and responsible manufacturing. Businesses that integrate eco-conscious design with smart logistics compatibility will lead the next wave of global cold chain excellence.

Our Services:

On-Demand Reports: https://www.statsandresearch.com/on-demand-reports

Subscription Plans: https://www.statsandresearch.com/subscription-plans

Consulting Services: https://www.statsandresearch.com/consulting-services

ESG Solutions: https://www.statsandresearch.com/esg-solutions

Contact Us:

Stats and Research

Email: [email protected]

Phone: +91 8530698844

Website: https://www.statsandresearch.com

1 note

·

View note

Text

0 notes

Text

Expanded Polystyrene Market Size, Share, Forecast, & Trends Analysis

Meticulous Research®—a leading global market research company, published a research report titled ‘Expanded Polystyrene Market—Global Opportunity Analysis and Industry Forecast (2025-2032)’. According to this latest publication, the expanded polystyrene market is projected to reach $16.1 billion by 2032, at a CAGR of 5.8% from 2025–2032.

The expanded polystyrene market is experiencing growth propelled by increasing demand for protective packaging solutions and thermal insulation in the construction sector. However, environmental concerns related to expanded polystyrene hinder market growth.

In addition, the surging demand from the automotive industry and increasing demand for insulated packaging for temperature-sensitive products in healthcare are considered potential growth opportunities for market players. The market faces substantial challenges, including issues related to EPS disposal and recycling. Furthermore, the rising demand for EPS in food packaging and the growing demand for EPS in e-commerce for packaging fragile items are a prominent trend in the expanded polystyrene market.

Key Players:

The expanded polystyrene market is characterized by a moderately competitive scenario due to the presence of many large- and small-sized global, regional, and local players. The key players operating in the expanded polystyrene market include BASF SE (Germany), TotalEnergies SE (France), Synthos S.A. (Poland), Kaneka Corporation (Japan), ALPEK, S.A.B. de C.V. (Mexico), Ravago Manufacturing (U.S.), Atlas Roofing Corporation (U.S.), Versalis S.p.A. (Italy), SIBUR International GmbH (Austria), SABIC (Saudi Arabia), NOVA Chemicals Corporation (Canada), Supreme Petrochem Ltd (India), Epsilyte LLC (U.S.), BEWI ASA (Norway), and Knauf Appliances (India)

The expanded polystyrene market is segmented based on type, form, and end user. The report also evaluates industry competitors and analyzes the expanded polystyrene market at the regional and country levels.

Among the types studied in this report, the white segment is anticipated to dominate the expanded polystyrene market in 2025. The significant growth of white EPS is driven by its ability to reduce shipping costs for packaged products and its increasing adoption in buildings and appliances due to its low thermal conductivity. These factors contribute to the segment's dominant position in the expanded polystyrene market.

Among the forms studied in this report, the sheets segment is anticipated to dominate the expanded polystyrene market in 2025. The growing use of EPS sheets in housing appliances, electronic components, and toy manufacturing, along with their rapid adoption for food packaging and laboratory equipment, are key factors contributing to the segment's dominant position in the expanded polystyrene market.

Among the end users studied in this report, the packaging segment is anticipated to dominate the expanded polystyrene market in 2025. The strong growth of EPS for protective packaging—designed to safeguard electronics, glassware, and pharmaceutical products during shipment and transportation—along with increased efforts by key players to develop sustainable EPS solutions to minimize environmental impact, and the rising use of disposable packaging in fast-food chains, are factors contributing to the segment's dominant position in the expanded polystyrene market.

This research report analyzes major geographies and provides a comprehensive analysis of North America (U.S. and Canada), Europe (Germany, U.K., France, Italy, Spain, Netherlands, Switzerland, Sweden, and Rest of Europe), Asia-Pacific (China, Japan, India, South Korea, Australia & New Zealand, Indonesia, Singapore, and Rest of Asia-Pacific), Latin America (Mexico, Brazil, and Rest of Latin America), and Middle East & Africa (UAE, Saudi Arabia, Israel, and Rest of Middle East & Africa).

Among the geographies studied in this report, Asia-Pacific is anticipated to dominate the expanded polystyrene market in 2025. The strong presence of major EPS manufacturing companies in the region, increased demand from the construction industry due to its energy and sound insulation properties, and the rise in automotive production are key factors contributing to the market’s dominant position.

Download Sample Report Here @ https://www.meticulousresearch.com/download-sample-report/cp_id=6057

Key Questions Answered in the Report-

What is the value of revenue generated by the type, form, and end user?

At what rate is the global demand for expanded polystyrene projected to grow for the next five to seven years?

What is the historical market size and growth rate for the expanded polystyrene market?

What are the major factors impacting the growth of this market at global and regional levels?

What are the major opportunities for existing players and new entrants in the market?

Which offering segments create major traction in this market?

What are the key geographical trends in this market? Which regions/countries are expected to offer significant growth opportunities for the manufacturers operating in the expanded polystyrene market?

Who are the major players in the expanded polystyrene market? What are their specific product offerings in this market?

What recent developments have taken place in the expanded polystyrene market? What impact have these strategic developments created on the market?

Contact Us: Meticulous Research® Email- [email protected] Contact Sales- +1-646-781-8004 Connect with us on LinkedIn- https://www.linkedin.com/company/meticulous-research

0 notes

Text

Global PUR Granular Market size was valued at US$ 634.7 million in 2024 and is projected to reach US$ 928.5 million by 2032, growing at a CAGR of 4.9% during the forecast period 2025-2032. This growth is primarily driven by increasing demand from the automotive, electronics, and construction industries where PUR granules are widely used for insulation, adhesives, and coatings.

PUR granules are polyurethane materials processed into small granular form, offering excellent thermal insulation properties, durability, and chemical resistance. Their versatility makes them ideal for various industrial applications, particularly in manufacturing processes requiring precise material properties.

Download FREE Sample Report: https://www.24chemicalresearch.com/download-sample/293541/pur-granular-market

Market Overview & Regional Analysis

Europe currently leads the global PUR granule market with a 38% share, driven by stringent environmental regulations promoting energy-efficient materials in construction. Germany and France are the largest consumers in the region, with growing adoption in automotive manufacturing.

North America follows closely with 32% market share, where the U.S. accounts for 78% of regional demand. The Asia-Pacific region is expected to witness the fastest growth at 6.2% CAGR, with China and India emerging as key markets due to rapid industrialization and infrastructure development.

Key Market Drivers and Opportunities

The automotive sector accounts for 42% of PUR granule consumption, primarily for interior components and insulation. The construction industry follows with 35% share, using PUR granules for thermal insulation in buildings. Electronics manufacturing represents 18% of demand for encapsulation and protective applications.

Emerging opportunities include the development of bio-based PUR granules and increasing adoption in 3D printing applications. The shift toward sustainable materials in packaging also presents significant growth potential for PUR granules in the coming years.

Challenges & Restraints

Volatility in raw material prices, particularly for isocyanates and polyols, remains a major challenge for market stability. Environmental concerns regarding disposal and recycling of PUR products have led to increased regulatory scrutiny in developed markets.

Supply chain disruptions and the availability of alternative materials like expanded polystyrene (EPS) in certain applications also pose challenges to market growth. The industry is addressing these concerns through improved recycling technologies and development of more sustainable formulations.

Market Segmentation

By Type:

Non-Reactive

Reactive

By Application:

Electronics

Construction

Automotive

Others

Key Market Players:

Henkel

3M Company

Lintec Corporation

Intertape Polymer Group

H.B. Fuller

DIC Corporation

Wanhua Chemical

For detailed market analysis and company profiles, please download the full report.

Report: https://www.24chemicalresearch.com/reports/293541/pur-granular-forecast-market

About 24chemicalresearch

Founded in 2015, 24chemicalresearch has established itself as a leader in chemical market intelligence, serving clients including Fortune 500 companies. We provide data-driven insights through rigorous research methodologies, addressing key industry factors across the chemical sector.

For more information, visit our website or contact our research team.

Website: https://www.24chemicalresearch.com

0 notes

Text

Building Thermal Insulation Market Size, Share, Trends, Demand, Future Growth, Challenges and Competitive Analysis

"Building Thermal Insulation Market - Size, Share, Demand, Industry Trends and Opportunities

Global Building Thermal Insulation Market, By Material (Plastic Foam, Glass Wool, Stone Wool, Others), Building Type (Residential Building, Non-Residential Building), Application (Roof Insulation, Wall Insulation, Floor Insulation) – Industry Trends.

Access Full 350 Pages PDF Report @

**Segments**

- **Material Type:** The global building thermal insulation market is segmented based on material type into glass wool, rock wool, expanded polystyrene (EPS), extruded polystyrene (XPS), polyurethane foam, and others. Glass wool and rock wool are widely used due to their excellent thermal insulation properties, while EPS and XPS are popular for their versatility and ease of installation.

- **Application:** Building thermal insulation finds applications in residential, commercial, and industrial sectors. The residential segment is expected to witness significant growth owing to increasing construction activities and rising awareness about energy efficiency in buildings. The commercial sector is also adopting thermal insulation solutions to reduce operational costs and enhance sustainability.

- **End-Use:** The market is categorized based on end-use into roofs, walls, floors, and others. Roofs are the dominant segment due to the high heat loss that occurs through the roof in buildings. Proper insulation in roofs can lead to substantial energy savings and improved indoor comfort. Walls and floors segments are also witnessing steady growth due to the emphasis on enhancing thermal efficiency.

- **Region:** Geographically, the building thermal insulation market is segmented into North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa. Europe holds a significant market share due to stringent building codes and regulations promoting energy-efficient construction practices. Asia-Pacific is expected to witness rapid growth driven by urbanization, industrialization, and government initiatives to reduce carbon footprint in buildings.

**Market Players**

- **Saint-Gobain:** A leading player in the building thermal insulation market, Saint-Gobain offers a wide range of insulation products for various applications. The company focuses on innovation and sustainability to meet the evolving needs of the construction industry.

- **Owens Corning:** Owens Corning is known for its expertise in fiberglass insulation solutions for buildings. The company emphasizes on high-performance products that provide long-term thermal efficiency and environmental benefits.

- **Knauf Insulation:** Knauf Insulation is a key player offering insulation solutions made from recycled materials. The company's focus on sustainability and energy efficiency has positioned it well in the market.

- **Rockwool International:** Rockwool International specializes in stone wool insulation products known for their fire resistance and thermal performance. The company caters to diverse end-use applications in the construction sector.

The global building thermal insulation market is characterized by intense competition and evolving customer preferences for energy-efficient solutions. Key players are focusing on product innovation, strategic partnerships, and expanding their geographical presence to gain a competitive edge in the market.

https://www.databridgemarketresearch.com/reports/global-building-thermal-insulation-marketThe global building thermal insulation market is expected to witness substantial growth in the coming years as a result of increasing focus on energy efficiency, stringent building regulations, and rising awareness about sustainable construction practices. One of the emerging trends in the market is the growing demand for eco-friendly and recycled insulation materials to reduce the carbon footprint of buildings. Market players are investing in research and development to introduce innovative solutions that offer high thermal performance while minimizing environmental impact.

Moreover, technological advancements in insulation materials are reshaping the market landscape, with a shift towards the adoption of advanced materials with superior insulation properties. Nanotechnology is playing a significant role in the development of high-performance insulation materials that can provide enhanced thermal efficiency in buildings. These innovative materials are expected to drive growth in the market by offering superior insulation capabilities and contributing to energy savings in the long run.

Another key factor influencing the building thermal insulation market is the increasing adoption of smart building technologies. Smart insulation solutions integrated with sensors and IoT devices enable real-time monitoring of energy consumption, temperature levels, and indoor air quality. This data-driven approach to building management allows for optimized energy usage, enhanced comfort levels, and cost savings for building owners and occupants. As the adoption of smart building technologies continues to rise, the demand for intelligent insulation solutions is expected to grow, driving further innovation in the market.

Furthermore, the impact of the COVID-19 pandemic has led to a shift in priorities for building owners and developers towards creating healthier and more sustainable indoor environments. There is a growing emphasis on improving indoor air quality, thermal comfort, and overall well-being of building occupants through better insulation practices. This shift towards wellness-focused buildings is expected to drive the demand for insulation solutions that not only provide thermal efficiency but also contribute to a healthier indoor environment.

In conclusion, the global building thermal insulation market is experiencing significant growth driven by factors such as increasing awareness about energy efficiency, stricter building regulations, technological advancements, and evolving customer preferences. Market players are responding to these trends by focusing on innovation, sustainability, and the development of eco-friendly solutions to meet the growing demand for energy-efficient building materials. As the market continues to evolve, collaborations, and strategic partnerships among industry players are expected to drive further growth and innovation in the building thermal insulation sector.**Segments**

- Global Building Thermal Insulation Market, By Material (Plastic Foam, Glass Wool, Stone Wool, Others), Building Type (Residential Building, Non-Residential Building), Application (Roof Insulation, Wall Insulation, Floor Insulation) – Industry Trends and Forecast to 2030.

The global building thermal insulation market is witnessing significant growth and is segmented based on material type, application, end-use, and region. Material type segmentation includes popular options like glass wool, rock wool, EPS, XPS, polyurethane foam, and others. Each material type offers unique characteristics in terms of thermal insulation properties and ease of installation, catering to diverse customer needs. The application segment covers residential, commercial, and industrial sectors, with the residential segment expected to experience substantial growth due to increasing construction activities and a growing focus on energy efficiency. End-use segmentation categorizes the market into roofs, walls, floors, and others, with roofs dominating the market due to high heat loss through the roof. Geographically, regions such as Europe and Asia-Pacific are driving market growth, with Europe leading due to stringent building regulations promoting energy-efficient construction, while Asia-Pacific is fueled by urbanization and government initiatives to reduce carbon footprint.

The market players in the building thermal insulation industry are key to driving innovation, sustainability, and competitive advantage. Leading companies like Saint-Gobain, Owens Corning, Knauf Insulation, and Rockwool International are prominent players offering a diverse range of insulation solutions for various applications. These market players focus on product innovation, sustainability, and strategic partnerships to meet the evolving demands of customers and stay ahead in the competitive landscape. Saint-Gobain emphasizes innovation and sustainability, Owens Corning is renowned for fiberglass insulation solutions, Knauf Insulation focuses on sustainability and energy efficiency, while Rockwool International specializes in stone wool insulation products known for their fire resistance and thermal performance.

The global building thermal insulation market is poised for substantial growth, driven by various factors such as increasing energy efficiency awareness, stringent building regulations, and a shift towards sustainable construction practices. The market is witnessing a growing trend towards eco-friendly and recycled insulation materials to lower the carbon footprint of buildings. Technological advances in insulation materials, including nanotechnology, are reshaping the market by offering superior insulation properties. The increasing adoption of smart building technologies integrated with sensors and IoT devices is driving demand for intelligent insulation solutions that optimize energy usage and enhance comfort levels.

The COVID-19 pandemic has also influenced the market dynamics, with a renewed focus on creating healthier indoor environments through better insulation practices. This shift towards wellness-focused buildings is expected to boost the demand for insulation solutions that not only provide thermal efficiency but also contribute to a healthier indoor environment. In conclusion, the global building thermal insulation market is experiencing substantial growth, propelled by factors such as energy efficiency emphasis, evolving customer preferences, and technological advancements. Market players are adapting by investing in innovation and sustainability to meet the increasing demand for energy-efficient building materials and drive further growth and innovation in the sector.

Building Thermal Insulation Key Benefits over Global Competitors:

The report provides a qualitative and quantitative analysis of the Building Thermal Insulation Market trends, forecasts, and market size to determine new opportunities.

Porter’s Five Forces analysis highlights the potency of buyers and suppliers to enable stakeholders to make strategic business decisions and determine the level of competition in the industry.

Top impacting factors & major investment pockets are highlighted in the research.

The major countries in each region are analyzed and their revenue contribution is mentioned.

The market player positioning segment provides an understanding of the current position of the market players active in the Personal Care Ingredients

Table of Contents: Building Thermal Insulation Market

1 Introduction

2 Global Building Thermal Insulation Market Segmentation

3 Executive Summary

4 Premium Insight

5 Market Overview

6 Building Thermal Insulation Market, by Product Type

7 Building Thermal Insulation Market, by Modality

8 Building Thermal Insulation Market, by Type

9 Building Thermal Insulation Market, by Mode

10 Building Thermal Insulation Market, by End User

12 Building Thermal Insulation Market, by Geography

12 Building Thermal Insulation Market, Company Landscape

13 Swot Analysis

14 Company Profiles

Critical Insights Related to the Keyword Included in the Report:

Exclusive graphics and Illustrative Porter’s Five Forces analysis of some of the leading companies in this market

Value chain analysis of prominent players in the market

Current trends influencing the dynamics of this market across various geographies

Recent mergers, acquisitions, collaborations, and partnerships

Revenue growth of this industry over the forecast period

Marketing strategy study and growth trends

Growth-driven factor analysis

Emerging recess segments and region-wise market

An empirical evaluation of the curve of this market

Ancient, Present, and Probable scope of the market from both prospect value and volume

Browse Trending Reports:

Dermatitis Herpetiformis Treatment Market Tralokinumab Market Pet Water Dispenser Market Data Roaming Market Perimeter Defence System Market Thermosetting Aerospace Composites Market Cigarette Butt Market Bancassurance Market Benchtop Laboratory Water Purifier Market Crystallization Equipment Market Prenatal Genetic Counselling Market Cervical Intraepithelial Neoplasia Drugs Market

About Data Bridge Market Research:

Data Bridge set forth itself as an unconventional and neoteric Market research and consulting firm with unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market. Data Bridge endeavors to provide appropriate solutions to the complex business challenges and initiates an effortless decision-making process.

Contact Us:

Data Bridge Market Research

US: +1 614 591 3140

UK: +44 845 154 9652

APAC : +653 1251 975

Email: [email protected]"

0 notes

Text

Analyzing the Competitive Landscape of the Expanded Polystyrene Market

Expanded Polystyrene Industry Overview

The global Expanded Polystyrene (EPS) Market, valued at USD 10.18 billion in 2022, is projected to grow at a robust compound annual growth rate (CAGR) of 8.59% from 2023 to 2030. This growth is significantly influenced by increasing social factors, including a greater focus on improving occupant health and well-being, promoting sustainable business practices, and fostering a sense of community. Furthermore, the inherent properties of expanded polystyrene (EPS), such as its resistance to moisture, excellent thermal insulation capabilities, and superior shock absorption, are driving its increased adoption in packaging applications. The substantial growth observed in the food service industry, fueled by a rising number of food retail chains and increasing consumer demand for packaged food, is also expected to significantly boost the consumption of EPS.

Within North America, the U.S. held a dominant position and is anticipated to be among the fastest-growing markets in the region in 2023. The escalating demand for EPS from the construction and packaging sectors within the U.S. is expected to be a key driver of market growth throughout the forecast period. The U.S. packaging industry has experienced positive demand across various end-user sectors, including consumer goods, retail, food, and pharmaceuticals. This rising demand can be attributed to high levels of urbanization, increasing e-commerce penetration, and the expanding packaged and processed food market in the country. The COVID-19 pandemic further accelerated the demand for online shopping and packaged & processed food due to movement restrictions and social distancing measures implemented by governments.

Detailed Segmentation:

Application Insights

Based on applications, the global industry has been further segmented into construction, packaging, automotive, and others. The construction application segment dominated the industry in 2022 and accounted for more than 44.0% of the total revenue share. The demand for expanded polystyrene in construction applications is expected to witness significant growth over the forecast period owing to the various characteristics of EPS, including great thermal insulation, low weight, chemical inertness, and resistance to bacteria and pests, among others. Expanded polystyrene is widely used in packaging applications.

Product Insights

Based on products, the global industry has been further bifurcated into white and grey EPS. The white product segment dominated the industry in 2022 and accounted for more than 62.70% of the overall revenue share. White EPS is majorly used in packaging applications, such as food packaging of food trays, drink cups & clamshell containers, consumer goods packaging, and electronics products packaging. The grey EPS segment is expected to register a significant growth rate over the forecast period on account of its usage in several applications.

Regional Insights

The Asia Pacific region dominated the industry in 2022 and accounted for more than 40.70% of the overall revenue share. Asia Pacific is expected to be one of the largest as well as the fastest-growing regional markets over the forecast period, primarily fueled by the ascending demand for the product from key applications, including automotive, packaging, and construction, in emerging economies, such as China and India. Moreover, the rapidly growing construction industry in the Asia Pacific region will support regional growth. The construction sector in North America is expected to witness significant growth in the coming years owing to the high demand for non-residential construction projects, such as hospitals, commercial buildings, and colleges.

Gather more insights about the market drivers, restraints, and growth of the Expanded Polystyrene Market

Key Companies & Market Share Insights

The expanded polystyrene (EPS) industry is highly competitive in nature, with the presence of large multinational companies as well as medium-scale local players. In the recent past, the industry has been undergoing consolidation, with the efforts mainly aimed at greater integration into value-added products such as EPS-based insulation materials. For example, In October 2024, Carlisle Companies Inc. announced a definitive agreement EPS insulation business of PFB Holdco, Inc., which includes the latter’s Plasti-Fab and Insulspan brands. PFB is a key player in Canada and Midwestern United States. The acquisition, valued at nearly USD 260 million, focuses on Carlisle’s Vision 2030 strategy, focusing on M&As as a growth driver and identifying cost synergies through PFB’s vertically integrated polystyrene manufacturing capabilities.

Reprocessed PP and HDPE are produced by Lancashire-based Venture and Cheshire-based Venture, with a combined capacity of 20,000 tons. A majority of the global companies are expected to increase their polymer offerings to Asia Pacific, Central & South America, and the Middle East & Africa owing to high market growth potential in these regions given the expansion of the EPS market. Some of the prominent players operating in the global expanded polystyrene market are:

Atlas Roofing Corp.

Alpek S.A.B. de C.V.

BASF SE

Kaneka Corp.

SIBUR Holding PJSC

BEWI, SUNPOR

Synthos

TotalEnergies

Flint Hills Resources

NOVA Chemicals Corporate

StyroChem

Ravago Manufacturing

UNIPOL

Versalis S.p.A.

SABIC

Sundolitt Ltd.

Order a free sample PDF of the Market Intelligence Study, published by Grand View Research.

0 notes

Text

Europe Insulated Concrete Form (ICF) Market: Building a Sustainable Future

The Europe insulated concrete form (ICF) market is experiencing significant growth, driven by an increasing focus on energy-efficient construction and the rising demand for high-rise residential buildings. Market analysts project a compound annual growth rate (CAGR) of greater than 5% for the market in the forecast period.

What are Insulated Concrete Forms?

ICFs are building systems that consist of interlocking, pre-engineered forms, typically made of expanded polystyrene (EPS) or other insulating materials. These forms are filled with concrete, creating strong, durable, and highly energy-efficient walls.

Key Drivers of Market Growth:

Demand for Energy-Efficient Buildings: Governments, businesses, and consumers are prioritizing energy efficiency to reduce carbon emissions and lower energy costs. ICFs offer superior insulation properties, significantly reducing heating and cooling needs.

Growing Demand for High-Rise Residential Buildings: ICFs are well-suited for high-rise construction due to their strength and ease of use.

Increasing Preparedness Toward Disasters: ICF walls provide excellent wind resistance and can withstand winds over 200 mph, making them suitable for hurricane-prone regions. They also offer excellent fire ratings.

Government Regulations and Initiatives: Rising government support to promote sustainable building measures for a greener and more sustainable future will boost the market expansion.

Challenges:

Fluctuating Raw Material Prices: Volatility in the prices of raw materials used in ICF production can impact market growth.

Higher Upfront Costs: While ICF structures become less expensive over time as they require less energy to heat and cool, the initial cost of ICF products can be higher compared to some substitute building materials.

Need for Specialized Expertise: The production of ICF necessitates specialized construction techniques and expertise which leads to additional training and skill, further increasing the labor costs.

Market Segmentation:

The Europe ICF market can be segmented by application (residential, commercial, industrial), material (polystyrene foam, polyurethane foam, cement-bonded wood fiber), and geography. The residential segment currently holds a sizable share of the market.

Regional Insights:

Germany is anticipated to dominate Europe's Insulated Concrete Form Market. The construction industry is relatively important in the German economy.

Key Players:

Some of the major companies operating in the Europe Insulated Concrete Form (ICF) Market include:

ICF Solutions

Green Life Buildings

PolySteel UK Ltd

ICF Tech Ltd

Nuform Building Technologies Inc.

The Future of ICFs in Europe:

As both manufacturers and consumers learn more about insulated concrete forms (ICF), the Europe-insulated concrete form (ICF) market is likely to have more opportunities to make money. With increasing environmental awareness and stricter building codes, the demand for ICFs is expected to continue its upward trajectory, contributing to a more sustainable and resilient built environment in Europe.

#Europe insulated concrete form market#Europe insulated concrete form market trends#Europe insulated concrete form market analysis#Europe insulated concrete form market share#Europe insulated concrete form industry#Europe insulated concrete form market size

0 notes

Text

The global insulation market is projected to grow from USD 61,365 million in 2024 to USD 103,094 million by 2032, representing a compound annual growth rate (CAGR) of 6.7%. The global insulation market has grown significantly in recent years, driven by increasing demand for energy efficiency, sustainability, and the ongoing expansion of construction and industrial sectors. Insulation plays a pivotal role in minimizing energy consumption, reducing greenhouse gas emissions, and enhancing the thermal comfort of buildings and industrial systems. This article delves into the current trends, key market drivers, challenges, and future opportunities shaping the insulation industry.

Browse the full report at https://www.credenceresearch.com/report/insulation-market

Market Overview and Size

As of 2024, the global insulation market is valued at over $60 billion, with projections indicating a compound annual growth rate (CAGR) of around 5% through 2030. The market's growth is primarily attributed to the rising adoption of energy-efficient solutions in residential, commercial, and industrial sectors. The demand for insulation materials such as fiberglass, mineral wool, polyurethane foam, and expanded polystyrene (EPS) has surged due to their effectiveness in thermal and acoustic insulation.

Key Market Drivers

Growing Focus on Energy Efficiency and Sustainability Governments and regulatory bodies worldwide are implementing stringent building codes and energy efficiency standards, pushing for the adoption of high-performance insulation materials. For example, policies like the European Union’s Energy Performance of Buildings Directive (EPBD) and the U.S. Department of Energy's energy codes promote the use of advanced insulation to achieve net-zero energy buildings.

Urbanization and Infrastructure Development Rapid urbanization in developing regions, particularly in Asia-Pacific and the Middle East, is fueling the demand for residential and commercial spaces. This growth drives the need for thermal insulation to enhance energy efficiency in new constructions and retrofitting projects.

Industrial Growth and Temperature Management Industrial processes often require temperature regulation to ensure efficiency and safety. Industries such as petrochemicals, food and beverages, and manufacturing are significant consumers of insulation materials, particularly in cold storage and high-temperature systems.

Climate Change Awareness With climate change becoming a pressing global issue, the insulation market is witnessing an increased focus on reducing carbon footprints. Insulation helps minimize heating and cooling loads, resulting in lower energy consumption and greenhouse gas emissions.

Insulation Types and Applications

Residential and Commercial Buildings Insulation in buildings includes wall, roof, floor, and HVAC insulation to reduce energy loss and improve comfort. Fiberglass and foam-based insulation materials dominate this segment due to their affordability and efficiency.

Industrial Applications High-temperature insulation materials, such as ceramic fibers and mineral wool, are essential in industries requiring thermal resistance for equipment and piping systems.

Acoustic Insulation With rising demand for noise reduction in urban areas and workplaces, acoustic insulation is becoming increasingly important. Materials like rock wool and foam are widely used for their sound-dampening properties.

Challenges Facing the Insulation Market

High Costs of Advanced Materials While traditional materials like fiberglass and EPS are cost-effective, newer, high-performance materials like aerogels are significantly more expensive, limiting their adoption.

Health and Environmental Concerns Certain insulation materials, such as fiberglass and polyurethane foam, have raised concerns over health risks and environmental impact during production and disposal.

Lack of Awareness in Emerging Markets Despite their long-term benefits, insulation adoption in some developing regions remains low due to limited awareness and lack of skilled labor.

Future Outlook

The insulation market is poised for robust growth, driven by technological advancements, government incentives, and increasing awareness of energy efficiency. Innovations in eco-friendly and recyclable materials, such as cellulose insulation and bio-based foams, are expected to reshape the industry. Moreover, smart insulation systems integrated with IoT technology could further enhance energy management and thermal regulation.

Key Player Analysis:

Owens Corning

Knauf Insulation

Saint-Gobain S.A.

Kingspan Group

Rockwool International A/S

BASF SE

Johns Manville Corporation (Berkshire Hathaway)

Dow Inc.

Armacell International S.A.

Huntsman Corporation

Segmentations:

By Product

EPS

XPS

Polyurethane

Polyurethane Foam

Polyvinyl Chloride

Cellulose

Glass Wool

Mineral Wool

Aerogel

Calcium Silicate

Others

By End User

Infrastructure

Construction

Industrial

HVAC

Transportation

Appliances

OEM

Others

By Distribution Channel

Online

Offline

By Geography

North America

U.S.

Canada

Mexico

Europe

Germany

France

U.K.

Italy

Spain

Rest of Europe

Asia Pacific

China

Japan

India

South Korea

South-east Asia

Rest of Asia Pacific

Latin America

Brazil

Argentina

Rest of Latin America

Middle East & Africa

GCC Countries

South Africa

Rest of the Middle East and Africa

Browse the full report at https://www.credenceresearch.com/report/insulation-market

About Us:

Credence Research is committed to employee well-being and productivity. Following the COVID-19 pandemic, we have implemented a permanent work-from-home policy for all employees.

Contact:

Credence Research

Please contact us at +91 6232 49 3207

Email: [email protected]

0 notes

Text

Cold Chain Packaging Market 2024 to 2032 Booming Trends, Share, Growth & Forecast

The Cold Chain Packaging Market is a rapidly growing segment of the packaging industry, driven by the increasing need to transport temperature-sensitive products across various sectors, including pharmaceuticals, food and beverages, chemicals, and biotechnology. Cold chain packaging refers to specialized packaging solutions designed to maintain the temperature of products within a specific range throughout the supply chain, from production to end-use. With the growth of global trade, e-commerce, and the demand for perishable goods, the need for reliable cold chain packaging is becoming more critical than ever.

The Cold Chain Packaging Market was valued at USD 21.8 billion in 2022 and is projected to grow from USD 25.2 billion in 2023 to USD 79.7 billion by 2032, exhibiting a compound annual growth rate (CAGR) of 15.50% during the forecast period (2023 - 2032).

Several key factors are driving the growth of the Cold Chain Packaging Market Share is:

Rising Demand for Temperature-Sensitive Pharmaceuticals and Vaccines: The pharmaceutical industry is one of the largest consumers of cold chain packaging, especially for biologics, vaccines, and other temperature-sensitive drugs. The COVID-19 pandemic highlighted the critical importance of maintaining the cold chain for vaccine distribution, further boosting demand for specialized packaging solutions in this sector.

Growth in Global Food Trade and E-Commerce: The globalization of food supply chains and the rise of e-commerce have increased the need for cold chain packaging to ensure the safe and fresh delivery of perishable goods, including fresh produce, seafood, meat, dairy products, and frozen foods.

Stringent Regulations and Quality Standards: Regulatory bodies across the globe have established strict guidelines for the transportation and storage of temperature-sensitive products. Adherence to these regulations is essential for industries such as pharmaceuticals and food, driving the demand for reliable cold chain packaging solutions.

Cold Chain Packaging Market Companies Are:

Cold Chain Technologies, Peli BioThermal, Orora Group, Sonoco ThermoSafe, CREOPACK, Sofrigam, Intelsius, Nordic Cold Chain Solutions, Tempack, Cryopa, Softbox Systems, and Sealed Air Corporation

Key Segments

By Product Type: Insulated Containers and Boxes,Cold Packs,Labels and Indicators

By Material Type: Expanded Polystyrene (EPS),Polyurethane (PUR),Vacuum Insulated Panels (VIP)

Opportunities:

Growing Focus on Sustainability: The increasing demand for sustainable and environmentally friendly packaging solutions presents significant opportunities in the cold chain packaging market. Companies are investing in green technologies, such as reusable packaging systems and eco-friendly insulating materials, to reduce their carbon footprint and meet consumer and regulatory demands for sustainability.

Expansion of Cold Chain Infrastructure in Emerging Markets: Emerging markets, particularly in Asia, Latin America, and Africa, are investing in the development of cold chain logistics and infrastructure to support their growing food, pharmaceutical, and chemical industries. This creates opportunities for companies providing cold chain packaging solutions in these regions.

Challenges:

Regulatory Compliance and Quality Assurance: Meeting the stringent regulatory requirements for temperature-sensitive products across different regions can be complex and costly. Ensuring compliance while maintaining cost-effectiveness is a significant challenge for companies operating in this market.

Supply Chain Disruptions: Disruptions in the supply chain, such as delays, equipment failures, or transportation issues, can compromise the effectiveness of cold chain packaging. Maintaining a seamless supply chain with consistent temperature control remains a critical challenge for companies involved in cold chain logistics.

About Market Research Future: At Market Research Future (MRFR), we enable our customers to unravel the complexity of various industries through our Cooked Research Report (CRR), Half-Cooked Research Reports (HCRR), & Consulting Services. MRFR team have supreme objective to provide the optimum quality market research and intelligence services to our clients.

Contact us: Market Research Future (part of Wantstats Research and Media Private Limited), 99 Hudson Street, 5Th Floor, New York, New York 10013 United States of America +1 628 258 0071 Email: [email protected] Website: https://www.marketresearchfuture.com

0 notes

Text

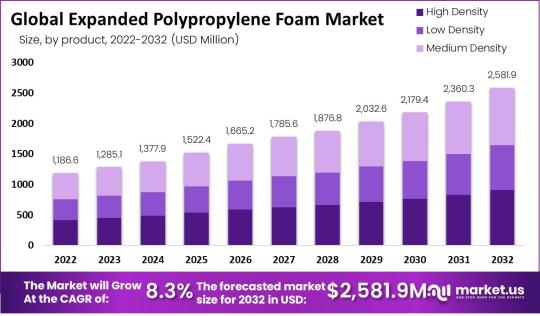

Expanded Polypropylene Foam: High-Density Segment Sees Surge in Automotive and Packaging Uses

Overview :

Expanded Polypropylene Foam Market was valued at USD 1,186.6 million and is expected to reach USD 2581.9 million in 2032. This market is estimated to register a CAGR of 8.3% between 2023 and 2032.

Get a Sample Copy with Graphs & List of Figures @ https://market.us/report/expanded-polypropylene-foam-market/request-sample/

Expanded polypropylene (EPP) foam is a versatile material known for its excellent impact resistance and lightweight properties. It is widely used in various industries due to its durability and cushioning ability. In consumer goods, EPP foam provides protection for sensitive electronics like computer equipment and circuit boards, where its shock-absorbing qualities help prevent damage during transport and use. Additionally, EPP foam's insulating properties make it valuable in packaging, building, and construction, where it contributes to energy efficiency and structural integrity.

Looking ahead, the demand for EPP foam is expected to grow, particularly in the toy and sports equipment sectors. As consumers become more health-conscious and seek products that offer better protection and safety, EPP foam's role in these areas is likely to expand. Its use in toys can provide safer play experiences for children, while in sporting goods, it can enhance comfort and injury prevention. This increasing awareness and preference for quality and safety are driving factors that will likely boost the global market for expanded polypropylene foam.

Key Market Segments

Based on Product

High Density

Low Density

Medium Density

Based on Application

Bumpers

Roof Pillars

Seat Bracing

Armrests

Other Applications

Based on End-User

Automotive

Packaging

Consumer goods

Appliances

Oil & Gas

Other End-Users

By Product Analysis:

The expanded polypropylene (EPP) foam market is segmented into high density, low density, and medium density, with high-density foams leading the market. In 2022, high-density EPP foams commanded over 42.0% of the market share, largely due to their use in automotive safety components and packaging.

By Application Analysis:

In terms of application, bumpers emerged as the leading segment, capturing over 42.0% of the market share in 2022. The increasing need for high-impact-resistant packaging for vehicle components drives this dominance, as EPP foam bumpers provide crucial safety features and impact absorption in automotive interiors and exteriors.

By End-Users Analysis:

The automotive sector is the primary end-user of expanded polypropylene foam, driven by its cost-effectiveness, mechanical strength, and moldability. EPP foam contributes to weight reduction in vehicles, enhancing fuel efficiency by up to 7% and lowering VOC emissions from interior components.

Key Players

JSP

BASF SE

Kaneka Corporation

DS Smith

Furukawa Electric Co., Ltd.

Hanwha Group

Sonoco Products

Knauf Industries

Izoblok

Dongshin Industry Incorporated

Clark Foam Products Corporation

Paracoat Products Ltd.

Molan-Pino South Africa

Signode Industrial Group LLC

Armacel

Furukawa Electric Co., Ltd.

Other Market Players

Drivers:

The expanding automotive industry is a major driver for the expanded polypropylene (EPP) foam market, as its lightweight and impact-resistant properties are ideal for components like bumpers and panels. Additionally, the growth of e-commerce and the increasing demand for sustainable packaging solutions are boosting the use of EPP foam in the packaging sector.

Restraints:

The high cost and price volatility of polypropylene, a key raw material, can impact profitability and increase finished product costs. EPP foam also faces competition from cheaper alternatives like expanded polystyrene (EPS) and may encounter challenges from emerging materials and technologies.

Opportunities:

There is significant growth potential in the automotive and packaging sectors, with emerging applications in building insulation and cushioning. The development of new uses, such as in toys and sports equipment, and advancements in manufacturing technology could reduce costs and broaden the material’s market reach.

Challenges:

Despite its advantages, EPP foam's market growth may be hampered by the development of new materials that could replace it in certain applications. Limited availability and higher costs associated with its recycling could also affect its overall market adoption and sustainability.

0 notes

Text

Expanded Polystyrene Prices Trend | Pricing | Database | Index | News | Chart

Expanded Polystyrene (EPS) Prices is a versatile and cost-effective material used in various industries, including construction, packaging, and insulation. As with any product, the prices of EPS can fluctuate due to a variety of factors. In this article, we will explore the factors that influence expanded polystyrene prices and how they can impact different industries.

One of the primary factors that affect EPS prices is the cost of raw materials. EPS is made from styrene, a petroleum-based product. Therefore, any changes in the price of crude oil can have a significant impact on the cost of producing EPS. Fluctuations in crude oil prices can be caused by global events, such as political instability or changes in supply and demand. Additionally, the availability of styrene monomer, the primary raw material used in EPS production, can also influence prices. Any disruptions in the supply chain, such as natural disasters or transportation issues, can lead to price fluctuations.

Another factor that affects EPS prices is the cost of energy. The production of EPS requires a significant amount of energy, both in terms of electricity and heat. Any changes in energy prices, such as increases in electricity or natural gas rates, can impact the overall cost of production. Additionally, advancements in energy-efficient technology can help reduce energy consumption during the manufacturing process, leading to potential cost savings.

Get Real Time Prices for Expanded Polystyrene (EPS): https://www.chemanalyst.com/Pricing-data/expanded-polystyrene-65

Market demand and competition also play a crucial role in determining EPS prices. When the demand for EPS products is high, manufacturers may increase prices to maximize profits. Conversely, during periods of low demand, manufacturers may lower prices to stimulate sales and maintain market share. The level of competition within the EPS industry can also influence prices. In highly competitive markets, manufacturers may engage in price wars to attract customers, resulting in lower prices. Conversely, in markets with limited competition, manufacturers may have more control over pricing.

Government regulations and environmental considerations can also impact EPS prices. In recent years, there has been an increased focus on sustainability and environmental impact. Some countries have implemented regulations and standards to promote the use of environmentally friendly materials and limit the use of certain chemicals in EPS production. Compliance with these regulations can increase production costs, potentially leading to higher prices for EPS products.

The geographical location of manufacturing facilities can also influence EPS prices. Transportation costs can vary depending on the distance between the production site and the end market. Manufacturers located closer to their customers may have a competitive advantage in terms of lower transportation costs, which can translate into more competitive pricing.

In conclusion, expanded polystyrene prices are influenced by several factors, including the cost of raw materials, energy prices, market demand and competition, government regulations, and the geographical location of manufacturing facilities. These factors can fluctuate over time, leading to changes in EPS prices. It is important for businesses in industries that rely on EPS to stay informed about these factors and adapt their strategies accordingly. By understanding the dynamics of EPS pricing, businesses can make informed decisions and effectively manage costs in an ever-changing market.

Get Real Time Prices for Expanded Polystyrene (EPS): https://www.chemanalyst.com/Pricing-data/expanded-polystyrene-65

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

#Expanded Polystyrene#Expanded Polystyrene Price#Expanded Polystyrene Price Monitor#Expanded Polystyrene Pricing#Expanded Polystyrene News

0 notes

Text

Competitive Landscape and Revenue Insights in Insulation Materials Market

The global insulation materials market is projected to be worth USD 82.96 Billion by 2027, according to a current analysis by Emergen Research. The insulation materials market observes high demand attributed to the increasing demand for reduced energy consumption in buildings. Insulation of roof, walls, attic, and foundations are a vital requirement for energy-efficient residential buildings.

Also, glass being an inefficient insulator, the insulation of see-through windows, envelopes, and skylights substantially lessens loss or heat gain, causing a reduction in heat transfer and vapor condensation. Consequently, insulation materials lead to the prevention of humidity, freezing, mold, and deformation occurring in the construction works due to corrosion, thereby safeguarding the building.

Get Download Pdf Sample Copy of this Report@ https://www.emergenresearch.com/request-sample/207

Competitive Terrain:

The global Insulation Materials industry is highly consolidated owing to the presence of renowned companies operating across several international and local segments of the market. These players dominate the industry in terms of their strong geographical reach and a large number of production facilities. The companies are intensely competitive against one another and excel in their individual technological capabilities, as well as product development, innovation, and product pricing strategies.

The leading market contenders listed in the report are:

Roxul Inc., Huntsman International LLC, Kingspan Group, Owens Corning, BASF, GAF Materials Corporation, Johns Manville, The Dow Chemical Company, Cellofoam North America Inc., Covestro AG

Key market aspects studied in the report:

Market Scope: The report explains the scope of various commercial possibilities in the global Insulation Materials market over the upcoming years. The estimated revenue build-up over the forecast years has been included in the report. The report analyzes the key market segments and sub-segments and provides deep insights into the market to assist readers with the formulation of lucrative strategies for business expansion.

Competitive Outlook: The leading companies operating in the Insulation Materials market have been enumerated in this report. This section of the report lays emphasis on the geographical reach and production facilities of these companies. To get ahead of their rivals, the leading players are focusing more on offering products at competitive prices, according to our analysts.

Report Objective: The primary objective of this report is to provide the manufacturers, distributors, suppliers, and buyers engaged in this sector with access to a deeper and improved understanding of the global Insulation Materials market.

Emergen Research is Offering Limited Time Discount (Grab a Copy at Discounted Price Now)@ https://www.emergenresearch.com/request-discount/207

Market Segmentations of the Insulation Materials Market

This market is segmented based on Types, Applications, and Regions. The growth of each segment provides accurate forecasts related to production and sales by Types and Applications, in terms of volume and value for the period between 2022 and 2030. This analysis can help readers looking to expand their business by targeting emerging and niche markets. Market share data is given on both global and regional levels. Regions covered in the report are North America, Europe, Asia Pacific, Latin America, and Middle East & Africa. Research analysts assess the market positions of the leading competitors and provide competitive analysis for each company. For this study, this report segments the global Insulation Materials market on the basis of product, application, and region:

Segments Covered in this report are:

Product Type Outlook (Revenue, USD Billion; 2017-2027)

Glass Wool

Mineral Wool

Expanded Polystyrene (EPS)

Aerogel

Extruded Polystyrene (XPS)

CMS Fibers

Calcium Silicate

Polyurethane

Others

Distribution Channel Outlook (Revenue, USD Billion; 2017-2027)

Online

Offline

Application Outlook (Revenue, USD Billion; 2017-2027)

Infrastructure

Industrial

HVAC

Transportation

Appliances

Furniture/Bedding

Packaging

Browse Full Report Description + Research Methodology + Table of Content + Infographics@ https://www.emergenresearch.com/industry-report/insulation-materials-market

Major Geographies Analyzed in the Report:

North America (U.S., Canada)

Europe (U.K., Italy, Germany, France, Rest of EU)

Asia Pacific (India, Japan, China, South Korea, Australia, Rest of APAC)

Latin America (Chile, Brazil, Argentina, Rest of Latin America)

Middle East & Africa (Saudi Arabia, U.A.E., South Africa, Rest of MEA)

ToC of the report:

Chapter 1: Market overview and scope

Chapter 2: Market outlook

Chapter 3: Impact analysis of COVID-19 pandemic

Chapter 4: Competitive Landscape

Chapter 5: Drivers, Constraints, Opportunities, Limitations

Chapter 6: Key manufacturers of the industry

Chapter 7: Regional analysis

Chapter 8: Market segmentation based on type applications

Chapter 9: Current and Future Trends

Request Customization as per your specific requirement@ https://www.emergenresearch.com/request-for-customization/207

About Us:

Emergen Research is a market research and consulting company that provides syndicated research reports, customized research reports, and consulting services. Our solutions purely focus on your purpose to locate, target, and analyse consumer behavior shifts across demographics, across industries, and help clients make smarter business decisions. We offer market intelligence studies ensuring relevant and fact-based research across multiple industries, including Healthcare, Touch Points, Chemicals, Types, and Energy. We consistently update our research offerings to ensure our clients are aware of the latest trends existent in the market. Emergen Research has a strong base of experienced analysts from varied areas of expertise. Our industry experience and ability to develop a concrete solution to any research problems provides our clients with the ability to secure an edge over their respective competitors.

Contact Us:

Eric Lee

Corporate Sales Specialist

Emergen Research | Web: www.emergenresearch.com

Direct Line: +1 (604) 757-9756

E-mail: [email protected]

Visit for More Insights: https://www.emergenresearch.com/insights

Explore Our Custom Intelligence services | Growth Consulting Services

Trending Titles: Geocell Market | Pancreatic Cancer Treatment Market

Latest Report: Ceramic Tiles Market | Life Science Analytics Market

0 notes

Text

Shaping Tomorrow's Chill: Foam Cooler Box Market's Influence on Packaging Trends

Foam cooler boxes are insulated cooler boxes made using expanded polystyrene (EPS) foam which provides effective insulation and keeps food and beverages cool for long hours. Foam cooler boxes are durable, reusable and lightweight. They are available in different sizes and capacities to meet the cooling needs of individuals, families, and commercial users. The ease of use and portability offered by foam cooler boxes makes them a preferred option for picnics, outdoor activities, parties, and fieldwork. The global Foam Cooler Box Market is estimated to be valued at US$ 2.93 Bn in 2023 and is expected to exhibit a CAGR of 8.6% over the forecast period 2023 to 2030, as highlighted in a new report published by Coherent Market Insights. Market Opportunity: The rising environmental concerns have compelled regulators and consumers to reduce the use of single-use plastic products. Foam cooler boxes can replace single-use plastic coolers and are emerging as a sustainable solution for on-the-go cooling needs. They are reusable, produce no waste, and have a significantly lower carbon footprint than plastic coolers. The stringent regulations on single-use plastics worldwide are expected to drive the demand for eco-friendly foam cooler boxes during the forecast period. Foam cooler box manufacturers are capitalizing on this opportunity by marketing their products as sustainable alternatives, which is expected to significantly boost the foam cooler box market growth. Porter's Analysis Threat of new entrants: High capital requirements in production setup and established brand recognition create barriers for new players. Bargaining power of buyers: Buyers have high bargaining power due to the availability of substitutes. Buyers can negotiate on price. Bargaining power of suppliers: The market has many raw material suppliers. Suppliers' bargaining power is moderate. Threat of new substitutes: Substitutes like polyurethane coolers and hard-sided coolers are available at lower costs. Competitive rivalry: The market is dominated by global players and competitive pricing pressures exist. SWOT Analysis Strength: foam coolers are affordable, durable, lightweight, and insulated. Increased demand for outdoor recreation drives the market. Weakness: foam coolers easily get damaged when squeezed tightly. Regular cleaning is required to maintain cooling efficiency. Opportunity: expanding organized retailing and e-commerce channels provide growth opportunities. Increasing tourism and camping activities boost sales. Threats: strict environmental regulations on foam use pose challenges. Substitutes like hybrid coolers threaten market share. Key Takeaways The global foam cooler box market is expected to witness high growth due to increasing outdoor recreational activities worldwide.

The regional analysis of Asia Pacific comprising countries like China, India, and Japan is also expected to grow at a steady pace during the forecast period. Rising middle-class incomes and increasing young population indulging in tourism and travel positively influence the regional market. Key players operating in the foam cooler box market are YETI, Igloo, Coleman, Rubbermaid, Grizzly, Engel, Bison Coolers, ORCA, Pelican, Polar Bear Coolers, AO Coolers, Kula Coolers, IceMule, RTIC, Canyon Coolers, OtterBox, Kysek, Magellan Outdoors, Everest, and Stanley.

#Foam Cooler Box Market Share#Foam Cooler Box Market Growth#Foam Cooler Box Market Demand#Foam Cooler Box Market Trend#Foam Cooler Box Market Analysis

0 notes

Text

Top 4 players in US Expandable Polystyrene (EPS) Market

STORY OUTLINE

Flint Hills Resources: Championing innovation and excellence by putting focus on four pills; Innovation, People & Communities, Environment, Health & Safety.

NexKemia: Becoming a technical and service leader by producing Expandable Polystyrene products since 2008.

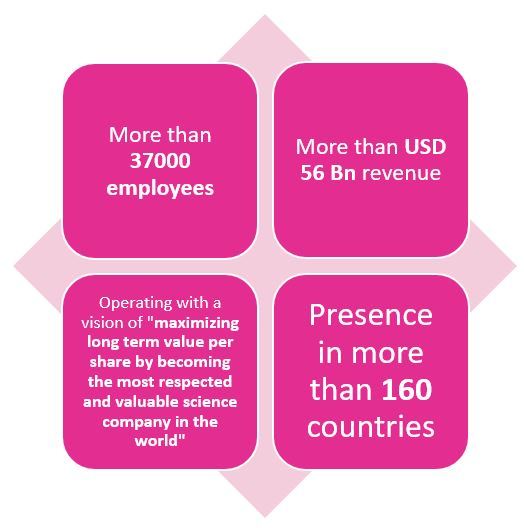

The Dow Chemical Company: Maximizing long term value per share by becoming the most respected and valuable science company in the world.

Alpek S.A.B. de C.V.: In the field of making Expandable Polystyrene since 1875 with presence in over 9 countries.

According to Ken Research, the US Expandable Polystyrene (EPS) market is anticipated to reach a production of 430 Kilotons by 2028 by growing at a CAGR of ~2.9% in between 2022-2028.

The US Expandable Polystyrene market is rapidly growing and is anticipated to attain a significant level of growth in the upcoming years.

There are many reasons behind the growth of US Expandable Polystyrene market. Some of these reasons include increasing automotive sales, rapid construction and increase in urbanization rates, along with rise in the demand for sustainable packaging

Various companies and players are contributing to their best efforts in the growth of the US Expandable Polystyrene market.