#FiltrationTechnology

Explore tagged Tumblr posts

Text

#filtrationsolutions#filtrationtechnology#oil filtration machine#oil filtration systems#oil purification

1 note

·

View note

Text

Air quality has become a growing public health concern across the United States, particularly in regions prone to wildfires such as California, Oregon, Washington, and Colorado. With rising temperatures and prolonged dry seasons, wildfire smoke is now one of the leading contributors to hazardous air conditions. It contains fine particulate matter (PM2.5) that can penetrate deep into the lungs and even enter the bloodstream—posing serious health risks for both adults and children.

According to the EPA, poor air quality can trigger asthma, bronchitis, cardiovascular issues, and more. For families living in wildfire-prone areas or urban zones with pollution spikes, investing in a high-quality filtered fire mask isn’t just smart—it’s essential.

What to Look for in a Filtered Fire Mask

Not all masks are created equal. Whether you're preparing for wildfire season or looking for everyday respiratory protection, here are key features to look for in a reliable mask:

Advanced Filtration Technology – Look for masks that filter out PM2.5 particles, allergens, smoke, and pathogens.

Secure and Comfortable Fit – Adjustable ear loops and a flexible nose band ensure a snug, effective seal.

Breathability – Especially important for kids and active adults; the mask should allow comfortable airflow without compromising safety.

Reusable and Washable Design – Eco-friendly and economical compared to disposable masks.

Sizes for All Ages – A proper fit is crucial for effectiveness, especially for children.

HALOmask: Trusted Protection for the Whole Family

At HALOLIFE, we understand the importance of protecting your family—especially during wildfire season. That’s why we developed the HALOmask, featuring cutting-edge Nanofilter™ Technology that captures up to 98.8% of airborne particles as small as 0.3 microns.

Our masks are designed to filter out:

Wildfire smoke

Dust and allergens

Pathogens (including viruses and bacteria)

Airborne pollutants from traffic or construction

Best Filtered Fire Mask Options from HALOLIFE

🔹 HALOmask for Adults

Crafted for durability and style, the adult HALOmask comes in a variety of colors and sizes. Key features include:

Replaceable Nanofilter inserts

3-layer protection

Adjustable ear straps

Sleek, low-profile design for everyday wear

Perfect for commuting, outdoor exercise, or protecting yourself during poor air quality alerts.

👉 Shop Now: https://halolife.io/collections/halomask

🔹 HALOmask for Kids

Children need extra protection, especially during high-smoke days. Our Kids Collection is designed to be lightweight, breathable, and fun—because safety shouldn’t be a struggle.

Smaller size for a snug fit

Soft inner fabric that’s gentle on young skin

Fun, kid-friendly colors and patterns

Easy to wear during school, play, or travel

👉 Browse the Kids Collection: https://halolife.io/collections/kids

Why Families Trust HALOLIFE Masks

HALOLIFE masks are trusted by thousands of families across the U.S. for their combination of comfort, performance, and style. During the 2020 and 2021 wildfire seasons, HALOmask helped protect households in California, Oregon, and Washington from toxic smoke exposure—offering peace of mind during uncertain times.

Customers love that HALOmasks are:

✅ Reusable and eco-friendly ✅ Designed for both casual and high-exposure use ✅ Stylish enough to wear every day ✅ Backed by thousands of 5-star reviews

Take Action Before the Smoke Hits

Wildfire season is unpredictable—but your family’s health doesn’t have to be. Don’t wait until the smoke is in the air to take action. Equip your home and go-bags with filtered masks for every family member.

HALOmask gives you the confidence to step outside, knowing you’re breathing cleaner air—even when nature has other plans.

Final Thoughts: Clean Air is Not a Luxury—It’s a Necessity

Whether you're on the West Coast or in a major metro area, air quality matters more than ever. A high-quality filtered fire mask is a small investment in your family's long-term health. With HALOmask, you get the benefit of superior filtration, exceptional comfort, and a mask that fits your lifestyle.

Ready to Breathe Better? 🛒 Explore Our Filtered Fire Masks

Stay safe. Stay prepared. Stay protected—with HALOLIFE.

#face mask#bestfacemask#nanofiltersmask#usa#wildfire#healthcare#emergencykit#smokeprotection#wildfireprep#halomask#wildfiresmoke#filteredfiremask#FiltrationTechnology#HALOmask#KidsCollection

0 notes

Text

Why Hydrogen Fuel Cell Stack Technologies Matter for Green Energy

By Dipak Tukaram Warude

When we talk about the future of clean energy, hydrogen often enters the conversation. Not always front and center, but it's there — quiet, promising, a bit misunderstood. As the world races toward carbon neutrality, hydrogen fuel cells are stepping into the spotlight. And at the heart of these fuel cells is something very precise, very engineered: the fuel cell stack.

At Innovative Filtrex Techno Engineering India Private Limited, we’ve had the opportunity to contribute to hydrogen-related technologies through advanced filtration and membrane solutions. And though filtration is just one piece, understanding the fuel cell stack itself helps us design systems that support, protect, and improve these critical energy devices.

What Is a Hydrogen Fuel Cell Stack?

A hydrogen fuel cell stack is essentially a series of individual fuel cells arranged together to generate usable electrical power. Each fuel cell converts chemical energy from hydrogen and oxygen into electricity through an electrochemical reaction — with water and heat as the only byproducts.

One cell doesn’t produce much power. But when you stack hundreds together, you get a unit capable of powering anything from a forklift to a passenger car, or even a building.

Each cell typically contains:

An anode and cathode

A proton exchange membrane (PEM)

Catalyst layers

Gas diffusion layers

Bipolar plates to connect cells and manage fluid flow

And all of these parts need to function in harmony — if one cell fails or fouls, the stack’s efficiency drops.

Why Stacks Are the Heart of Fuel Cell Systems

The stack is where energy is made — literally. It's the engine of the system. Everything else (fuel supply, humidification, thermal management, power electronics) is there to support or manage what happens inside the stack.

Because of this, stack durability and efficiency are critical. If the membrane fouls from contaminants, or if fluid flows unevenly, performance suffers. That’s why filtration and purification — from gas filtration to water quality control — are so crucial. And that's where we at Innovative Filtrex step in.

Use Cases of Fuel Cell Stacks Today

Fuel cells aren't science fiction anymore. They’re powering real applications — quietly, cleanly.

Public transportation: Cities like Tokyo and Seoul have buses running entirely on hydrogen.

Material handling: Warehouses across North America use hydrogen-powered forklifts for zero-emission operations.

Backup power systems: Telecom towers and hospitals in remote regions rely on hydrogen fuel cells as reliable off-grid power.

Automotive sector: Global carmakers have introduced hydrogen fuel cell electric vehicles (FCEVs) to complement battery EVs.

And this is just the beginning. India, too, is laying down the groundwork for hydrogen infrastructure. With initiatives like the National Green Hydrogen Mission, there's growing interest — and we expect fuel cell adoption to accelerate across mobility, industry, and even residential sectors.

Challenges That Still Exist

It’s not all smooth sailing yet. Hydrogen storage and distribution remain costly. Fuel cell stacks, while cleaner, are also more complex than conventional engines or even batteries.

Cost of materials like platinum catalysts

Durability of membranes under cycling conditions

Purity requirements of hydrogen and oxygen streams

Thermal and water management within the stack

But the direction is clear. Governments are funding pilot projects. Industry leaders are investing in R&D. And innovation is speeding up — making stacks more efficient, compact, and affordable.

The Role of Filtration in Stack Longevity

One of the biggest threats to a fuel cell stack is contamination. Microscopic particulates, trace sulfur compounds, or even droplets of oil from a compressor can degrade the membrane or poison the catalyst.

That’s why high-purity gas and liquid filtration systems are essential. At Innovative Filtrex Techno Engineering India Private Limited, we’ve developed specialty filters capable of removing ultrafine particulates and aerosols from gas lines feeding the fuel cell. We also provide pre-treatment systems for water used in humidification — preventing scale or microbial growth that could interfere with stack performance.

Filtration may not be visible inside the stack, but it plays a quiet role in extending its life and maintaining consistent performance.

Representing Innovation on a Global Platform

We’re proud to share that Innovative Filtrex Techno Engineering India Private Limited, based in India, has been nominated for the 2025 Go Global Awards, hosted by the International Trade Council. This November, in London, we’ll join peers from across the world — businesses driving change, solving industrial challenges, and shaping the future.

This event isn’t just about recognition. It’s a place where ideas flow as freely as hydrogen should. A space to collaborate, challenge, and discover. We’re excited to share what we’re learning — and to learn from the best minds tackling today’s energy problems.

Final Thoughts

Hydrogen fuel cell stacks represent one of the cleanest energy generation technologies we have today. They're not perfect. But they’re promising. And if we solve the right problems — from purification to scaling — they could power a significant chunk of our future.

It's a complex field, sure. But it’s also exciting. At Innovative Filtrex, we’re not just watching from the sidelines. We’re contributing, one filter at a time.

Because sometimes, the cleanest energy starts with the cleanest process.

#HydrogenFuelCells#FuelCellStacks#CleanEnergy#GreenHydrogen#EnergyTransition#FiltrationTechnology#HydrogenEconomy#InnovativeFiltrex#MadeInIndia#GoGlobalAwards#InternationalTradeCouncil#London2025#ZeroEmissions#SustainableEngineering#FutureOfEnergy#FuelCellFiltration#DipakTukaramWarude

1 note

·

View note

Text

Under Your Sink, Beyond Expectations! Our Under-Sink Water Purifier combines seamless design with powerful performance. Tucked discreetly under your sink, it delivers fresh, pure water straight to your tap without compromising your kitchen’s look. Featuring advanced multi-stage filtration, it removes impurities effectively for safe, great-tasting water. Compact, efficient, and easy to install, it’s the perfect solution for modern homes. Enjoy hidden purification and unmatched convenience!

✅ Purification By SF+AC+RO+UV+FA ✅ Pressure Tank with storage 10 Itr ✅ Four Stage Filtration ✅ Flow Rate: 12-15 LPH (Max.) ✅ RO Membrane Protection ✅ SMPS With Low And High ✅ Voltage Protection

Contact us for more details: 🌐 www.aquaneeta.in 📌 Vaduthala, Cochin, Kerala ☎ Service: +91-9947033715, +91-9947033730 Sales: +91-99470 33711

#Aquaneeta#WaterPurifier#healthywater#UVwaterPurifier#rowaterPurifier#Purifier#WaterFilter#filtrationtechnology#irishdancing#Purification#Filtration#UnderSinkWaterPurifier

0 notes

Text

#datastorage#DataCenters#AirQuality#CamfilIndia#SustainableInfrastructure#FiltrationTechnology#TechInfrastructure#electronicsnews#technologynews

0 notes

Text

Japan Depth Filtration Market Size, Share, Industry, Forecast and outlook (2024-2031)

The depth filtration market size in Japan is undergoing transformative growth, fueled by technological advancements, rising demand across key industrial sectors, and favorable government policies. This in-depth analysis explores the market’s current status, key segmentation, regional developments including the USA and Japan, emerging trends, major players, and future outlook.

Sample link of the report https://www.datamintelligence.com/download-sample/japan-depth-filtration-market

Market Overview and Estimations

As of 2022, the Japan depth filtration market was valued at approximately $110.9 million. With rapid advancements and increased industrial applications, the market is forecasted to reach $258.4 million by 2032, registering a compound annual growth rate (CAGR) of 8.87% between 2023 and 2032. This robust expansion is largely driven by demand from the pharmaceutical, food and beverage, water treatment, and chemical processing sectors.

Latest Market News and Trends

Recent industry activity reflects the rising prominence of depth filtration on a global scale. One major development is Thermo Fisher Scientific’s acquisition of Solventum’s purification and filtration business for $4.1 billion. This strategic acquisition bolsters Thermo Fisher’s bioprocessing capabilities, aligning it with leading players such as Danaher and Repligen, and strengthens its foothold in the biopharmaceutical manufacturing sector.

In Japan, the market has seen a notable increase in demand due to the country’s progressive approach to water purification and environmental regulations. Japanese companies, especially those manufacturing advanced membranes and filtration solutions, are dominating the global water treatment segment with more than 60% market share. This not only highlights the technological edge of Japanese firms but also underlines a growing domestic and international reliance on high-efficiency depth filtration products.

Market Segmentation

The Japan depth filtration market can be segmented based on media type and application.

Among the media types, Diatomaceous Earth held the largest market share in 2022, generating $39.3 million in revenue. It is projected to grow at a CAGR of 8.98%, reaching $92.5 million by 2032. Alongside Diatomaceous Earth, Activated Carbon is another leading media type, contributing significantly to the overall market. Together, these two segments accounted for 63.8% of the market share in 2022. Cellulose is another rising media, projected to grow at a CAGR of 8.95%, driven by its use in food processing and pharmaceutical applications.

From an application standpoint, the pharmaceutical industry represents one of the most significant consumers of depth filtration systems. These filters are essential in the purification of active pharmaceutical ingredients (APIs), ensuring compliance with quality and safety regulations. The food and beverage industry also utilizes depth filtration to clarify liquids such as wine, beer, and juices. Additionally, the water treatment industry relies on these filters for effective purification of drinking water and removal of industrial effluents, ensuring environmental compliance and public safety.

Regional Analysis: USA and Japan

United States

In 2022, the U.S. depth filtration market was valued at approximately $730.7 million. The market's growth is propelled by a robust industrial base and extensive investment in the biopharmaceutical sector. Strategic initiatives, such as the National Institute for Innovation in Manufacturing Biopharmaceuticals (NIIMBL) investing nearly $10 million in 2024 for advancing biopharmaceutical manufacturing technologies, have accelerated demand for efficient filtration systems.

Government-backed R&D and regulatory emphasis on product quality have further boosted innovation in filtration technologies. As a result, depth filtration products are increasingly used not only in healthcare but also in food safety, water management, and industrial processing across the country.

Japan

Japan’s market is characterized by high technological adoption and stringent regulatory frameworks that support the integration of advanced filtration systems across industries. The presence of over 578 water purification facilities reflects the government’s strong commitment to environmental sustainability and public health, which has created a conducive environment for depth filtration adoption.

The country’s focus on processed food and pharmaceuticals, combined with continuous R&D in biotechnology, makes it a key market in the Asia-Pacific region. Moreover, Japanese manufacturers continue to play a leading role in the global filtration membrane sector, driving both innovation and export opportunities.

Key Highlights from Recent Reports

The global depth filtration market is projected to reach $4.1 billion by 2030, growing at a CAGR of 8.1%.

The Diatomaceous Earth media type is forecasted to reach $1.8 billion globally by the end of the forecast period, with a CAGR of 8.8%.

The global market size for depth filtration stood at $2.7 billion in 2024 and is expected to grow at a CAGR of 9.8% through 2030.

China is also emerging as a major growth hub, with an expected CAGR of 10.3%, highlighting increasing global competition and innovation.

Key Players and Competitive Landscape

The depth filtration market is highly competitive, featuring several multinational corporations that are investing heavily in innovation and strategic partnerships. The top five companies dominating the global and Japanese depth filtration markets include:

Merck KGaA – A global pharmaceutical and life sciences company offering a wide range of depth filtration products, with a strong presence in both developed and emerging markets.

Danaher Corporation – Known for its comprehensive filtration solutions, Danaher continues to expand through strategic acquisitions and R&D investments.

Sartorius AG – A leader in bioprocessing technologies, Sartorius provides depth filters optimized for high purity and efficiency.

3M Company – With an expansive portfolio in industrial and healthcare filtration, 3M remains a top player in innovation and market reach.

Parker Hannifin Corporation – A versatile supplier with extensive offerings in engineered filtration solutions across automotive, food processing, and industrial sectors.

Thermo Fisher’s recent acquisition of Solventum’s filtration business further intensifies the competition and signals an ongoing trend of consolidation in the market, allowing key players to expand their product portfolios and manufacturing capabilities.

Conclusion

The Japan depth filtration market is poised for a period of sustained growth, underpinned by increasing industrial demand, technological advancements, and strong regulatory frameworks. With a projected CAGR of 8.87% through 2032, the market offers substantial opportunities for stakeholders in sectors ranging from pharmaceuticals to environmental engineering.

As global and domestic players continue to innovate and expand their presence, Japan is well-positioned to not only meet its domestic filtration needs but also to serve as a vital hub for high-performance filtration technologies worldwide. In conclusion, the depth filtration market will continue to thrive as industries prioritize safety, purity, and operational efficiency.

#DepthFiltration#FiltrationTechnology#JapanFiltrationMarket#BiotechFiltration#PharmaManufacturing#IndustrialFiltration#WaterPurification

0 notes

Text

Centralized Coolant Filtration Systems by Lex Technoaid

Lex Technoaid's Centralized Coolant Filtration Systems are engineered to deliver coolant at optimal pressure, flow rate, temperature, and clarity to multiple machines. These systems enhance machining efficiency, reduce downtime, and promote sustainable operations by ensuring precise coolant management across various industrial applications.

#CoolantFiltration#IndustrialFiltration#MachiningSolutions#ManufacturingEfficiency#FiltrationTechnology

1 note

·

View note

Text

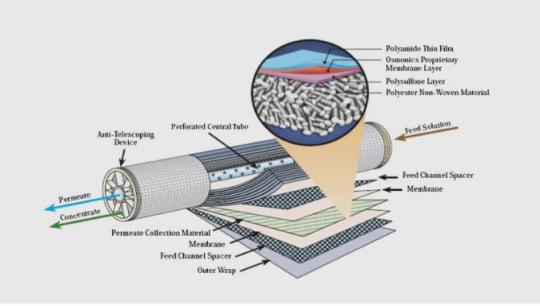

🌍 The Future of Water Treatment: Spiral Membrane Technology 💧

The Spiral Membrane Market is set to reach $10.4 billion by 2027, growing at a CAGR of 9.6% from 2022 to 2027. 🚀

📥 𝗗𝗼𝘄𝗻𝗹𝗼𝗮𝗱 𝗥𝗲𝗽𝗼𝗿𝘁 𝗦𝗮𝗺𝗽𝗹𝗲 👉 https://lnkd.in/e-eCcKdT

As industries and municipalities tackle growing demands for efficient water treatment solutions, spiral membranes are leading the charge!

✅𝗥𝗶𝘀𝗶𝗻𝗴 𝗗𝗲𝗺𝗮𝗻𝗱 𝗳𝗼𝗿 𝗪𝗮𝘁𝗲𝗿 𝗧𝗿𝗲𝗮𝘁𝗺𝗲𝗻𝘁 𝗦𝗼𝗹𝘂𝘁𝗶𝗼𝗻𝘀

With increasing #concerns over water scarcity, wastewater treatment, and desalination, spiral membranes provide a #sustainable and efficient way to purify and reuse water across industries.

✅ 𝗕𝗿𝗲𝗮𝗸𝘁𝗵𝗿𝗼𝘂𝗴𝗵𝘀 𝗶𝗻 𝗠𝗲𝗺𝗯𝗿𝗮𝗻𝗲 𝗙𝗶𝗹𝘁𝗿𝗮𝘁𝗶𝗼𝗻 𝗧𝗲𝗰𝗵𝗻𝗼𝗹𝗼𝗴𝘆

Advancements in #materials and membrane designs are driving higher efficiency, durability, and lower operational costs, making spiral membranes essential for #pharmaceuticals, food & beverage, and energy sectors.

✅ 𝗘𝘅𝗽𝗮𝗻𝗱𝗶𝗻𝗴 𝗜𝗻𝗱𝘂𝘀𝘁𝗿𝗶𝗮𝗹 𝗔𝗽𝗽𝗹𝗶𝗰𝗮𝘁𝗶𝗼𝗻𝘀 🏭📈

Beyond traditional #water treatment, spiral membranes are now widely used in biotechnology, chemical processing, and oil & gas, helping industries achieve regulatory #compliance and sustainability goals.

#WaterTreatment#FiltrationTechnology#SpiralMembrane#Sustainability#Innovation#Wastewater#Desalination#CleanWater#IndustrialSolutions#MarketTrends

0 notes

Text

Benefits of Sintered Filters

Filtration plays a vital role in various industries, ensuring the purity and quality of liquids and gases. Among the different filtration technologies available, sintered filters are known for their exceptional durability, efficiency, and versatility. These filters are created through a sintering process, where metal powders are fused under heat and pressure to form a robust, porous structure. In this article, we will explore the key benefits of using sintered filters in industrial applications.

1. High Filtration Efficiency

One of the standout features of sintered filters is their high filtration efficiency. With a uniform pore structure, these filters provide precise particle retention, effectively removing contaminants while allowing smooth fluid or gas flow. This makes them ideal for industries that demand high purity levels, such as pharmaceuticals, food processing, and chemical manufacturing.

2. Exceptional Durability and Strength

Sintered filters are known for their exceptional durability. They can withstand extreme temperatures and pressures without deforming or breaking, making them suitable for high-pressure filtration systems. This strength ensures a longer lifespan and reliable performance in demanding environments.

3. Corrosion and Chemical Resistance

Industries that work with corrosive substances benefit greatly from sintered filters. Made from materials such as stainless steel, titanium, and Inconel, these filters resist oxidation and chemical attacks, ensuring consistent performance over time.

4. Washable and Reusable

Unlike disposable filters, sintered filters can be cleaned and reused multiple times. Methods such as backflushing, ultrasonic cleaning, or chemical washing restore their efficiency, leading to reduced maintenance costs and minimal environmental impact.

5. Uniform Pore Structure for Consistent Performance

The manufacturing process of sintered filters results in a highly uniform pore structure. This feature ensures even filtration, optimal flow rates, and minimal pressure drop, significantly enhancing overall system efficiency.

6. Eco-Friendly and Cost-Effective Solution

Because sintered filters are reusable, they contribute less waste compared to single-use filtration media. Their long lifespan reduces the frequency of replacements, making them an environmentally friendly and cost-effective choice for businesses.

Conclusion

Sintered filters offer a unique combination of efficiency, durability, and sustainability that makes them a preferred choice across various industries. Their ability to withstand extreme conditions while providing high-quality filtration can lead to improved operational efficiency and long-term cost savings. For more information about sintered filters and to explore our product range, visit Carbis Filtration Sintered Filters.

If you would like to learn more about selecting the right sintered filter for your application, feel free to contact us today!

0 notes

Text

"Industrial Iron Removal & Water Softening Solutions"

How Industrial Iron Removal & Water Softening Work?

Hard water and iron contamination can reduce the efficiency of industrial RO systems. Check out this Industrial Iron Removal & Water Softening Guide to improve your water treatment system.

💧 Why You Need Industrial Iron Removal & Water Softening? 🔹 Removes iron deposits, preventing rust formation 🔹 Reduces water hardness for better equipment performance 🔹 Improves water clarity & prevents scaling in pipelines 🔹 Optimizes industrial water treatment processes

From manufacturing plants to commercial water filtration, proper iron removal & softening ensure high-quality, purified water for industrial applications.

0 notes

Text

#FiltrationTechnology#PorousPlastics#IndustrialFiltration#SinteredPlastics#PlasticFilters#SinteredFilter#PorousFilter#AdvancedFiltration#WaterFiltration#AirFiltration#InnovationInFiltration#EngineeringSolutions#SustainableFiltration#CleanAirTechnology#ManufacturingTech#porous plastic product#sansuk industries

0 notes

Text

The Ultimate Guide to Oil Filtration: Maximizing Equipment Life and Performance

Dirty oil is a silent killer. Unseen contaminants smaller than a human hair—particles, water, acids—wreak havoc on hydraulic systems, engines, and turbines. Studies show that just one overheating event can slash hydraulic component lifespan by 66% . In industrial settings, contaminated oil causes up to 80% of hydraulic failures. Yet most operations remain unaware until it’s too late: seized pumps, clogged valves, costly unplanned downtime.

Oil filtration isn’t just maintenance—it’s a strategic investment. Modern solutions can boost oil cleanliness four times higher than standard synthetics, extending critical component life by 60% . This guide dives deep into the science, technology, and best practices transforming oil from a liability into an asset.

I. Why Oil Filtration Isn’t Optional

Oil degrades predictably, but its consequences are catastrophic:

Particle Warfare: ISO 4406 classifies contaminants by size (4µm, 6µm, 14µm). Particles as small as 5µm—half the width of a human red blood cell—act like abrasive sandpaper in bearings and gears. A single gram of dust entering a system can generate millions of destructive particles .

Water, the Invisible Enemy: At just 0.1% water content (1000 ppm), bearing life plummets by 50%. Water induces oxidation, forms sludge, and promotes microbial growth (“diesel bugs”) that clogs filters .

Thermal Runaway: Overheated oil (>180°C in fryers, >60°C in hydraulics) cracks molecular chains. The result? Viscosity changes, varnish deposits, and accelerated acid formation.

The Solution Spectrum:

Straining (25-30µm): Removes chunks only. Useless against fine killers.

Mechanical Filtration (1-10µm): Captures damaging particles but requires pressure.

Full Purification: Combines filtration, dehydration (vacuum or coalescing), and sometimes chemical treatment for total fluid rehabilitation .

II. Inside the Filtration Revolution: Technologies Decoded

A. The Mechanics of Cleanliness

Vacuum Towers: Not all water removal is equal. Basic settling tanks leave emulsified water. Vacuum chambers (at -0.07 MPa) boil off water at lower temperatures (45-70°C), preserving oil integrity. This is critical for moisture-sensitive turbine oils .

Multi-Stage Filtration:

Pre-Filters (50-100µm): Catch weld slag or metal chips. Easily cleanable stainless mesh.

Primary Filters (10-25µm): Trap wear-inducing silt.

Final Polishing (1-5µm): Glass fiber or synthetic media capture residual fines.

Pro Tip: Always place filters in series—coarse to fine. Skipping stages clogs $300 filter cartridges with debris a $30 strainer could catch .

B. Cutting-Edge Media: Beyond Basic Mesh

Its layered micro-glass fibers lock particles during flow surges—critical in variable-rate hydraulics. Lab tests show two ISO code improvements over synthetics—meaning 60% longer pump life .

Depth Loading vs. Surface Capture: Traditional cellulose (paper) filters trap contaminants on the surface, clogging fast. Depth media like borosilicate microfibers embed particles throughout the matrix, tripling dirt-holding capacity .

C. Smart Filtration: The IoT Edge

Systems like DISA’s Optimal Oil Filtration (OOF) module monitor in real-time:

Particle counts (ISO 4406/NAS 1638)

Water concentration (ppm)

Temperature anomalies

Dielectric strength (indicating oxidation)

When values degrade, it triggers auto-remediation: activating offline filters or alerting technicians before damage occurs .

III. Operating for Zero Failures: A Step-by-Step Playbook

A. Startup Protocol: Safety First

Grounding Check: Static sparks in oil vapor are explosive. Verify earth connections .

Dry Run Prevention: Seal all connections. Air ingress creates foam, crippling vacuum efficiency.

Flow Direction: Reverse flow ruptures filters. Confirm arrows on housing match piping .

B. The Golden Rules During Operation

Pressure Tells All: Normal range: 0.05–0.3 MPa. If >0.4 MPa, immediately shut down. This signals a blinded filter or blocked line. Forcing oil past ruptures media, flooding systems with debris .

Temperature Sweet Spots:

Hydraulic oils: 45–55°C (↑ viscosity index, ↓ water)

Cooking oils: ≤180°C (above this, carcinogenic compounds form)

Vacuum Integrity: If moisture separation drops, check for:

Seal leaks (hissing sounds)

Pump oil emulsification (change if milky)

C. Strategic Shutdown & Storage

Cooldown Phase: Stop heaters 5+ minutes before pumps. Residual heat prevents wax/carbon formation .

System Drainage: Stagnant oil breeds bacteria. Open all drain plugs—especially in humid climates.

Filter Preservation: Remove cartridges, bag them, label with µ-rating and date. Left installed, they leach contaminants back into clean oil.

IV. Maintenance: Predicting the Unpredictable

A. Filter Change Triggers

Indicator Action Required Cost of Delay ΔP > 0.3 MPa Replace element NOW Housing rupture ($5k+) ISO Code ↑ by 2 classes Check seals + media integrity Bearing spalling ($25k) Water > 500 ppm Run vacuum cycle + test additive Corroded servo valves ($12k)

B. Contamination Forensics

Shiny Metal Flakes? Pump or gear wear. Send oil for spectroscopy.

Black Sludge? Overheating. Check cooler operation.

White Emulsion? Water ingress. Inspect seals/coolers .

C. Proactive Lifespan Extenders

Additive Replenishment: ZDDP anti-wear agents deplete. Titration kits reveal needs.

Flush Before Fill: New oil isn’t clean (ISO 21/19/16 average). Filter during transfer.

Breather Upgrades: Desiccant caps prevent humid-air ingress—$50 fix for 10x cleaner oil.

V. Industry-Specific Solutions

A. Hydraulics: The Pressure Is Real

Why it Matters: Servo valves tolerate ≤ 5µm particles. Contamination causes erratic motion, drift.

Toolkit: Install duplex filters with valved switchover. Clean one side while operating the other—zero downtime .

B. Food Production: Beyond Clarity

Crisis: Straining fryer oil at 30µm leaves fines that burn into carcinogens (acrylamide).

Fix: 1–5µm absolute filters + activated clay absorbers remove polar compounds. Result: 30% longer oil life, lighter-colored food .

C. Wind Turbines: High Stakes, Hard Access

Challenge: Remote gearboxes fail from moisture-induced pitting.

Smart Fix: Permanent offline filtration loops with real-time moisture sensors. Data triggers maintenance before ice or storms prevent access.

VI. The Future Is Cleaner, Smarter, Autonomous

Self-Healing Media: Nano-coated fibers that release enzymes to digest sludge (lab-tested by ExxonMobil).

Carbon Capture Integration: New systems like Donaldson Reclaim capture vented VOCs, converting them to inert compounds.

Predictive AI: Algorithms correlating pressure spikes with impending pump failures (accuracy: 94% in trials).

VII. Choosing Your Champion: A Buyer’s Checklist

Ask these questions before selecting a system:

What’s Your Baseline? Get an ISO particle count—don’t guess!

Flow Flexibility

Fixed-rate? Gear pumps suffice.

Variable hydraulics? Prioritize surge-resistant media like Alpha-Web® .

Disposal Reality

On-site incineration? Standard filters work.

Landfill restricted? Opt for biodegradable media (soy/plant-based).

Total Cost of Ownership

Cheap filters = frequent changes.

Calculate: (Element Cost × Annual Changes) + Labor + Disposal Fees.

Final Thought: Filtration isn’t about removing dirt—it’s about preserving precision. Every micron captured extends the dance of finely machined components. With oil cleanliness as your compass, unplanned downtime becomes optional, not inevitable.

Got a filtration horror story or victory? Share below—let’s dissect the lessons.

#oil purification#oil filtration systems#filtrationsolutions#oil filtration machine#filtrationtechnology#black oil

0 notes

Text

#BagFilters#BinVentFilters#IndustrialFiltration#FiltrationTechnology#ManufacturingSolutions#IndustrialSolutions#MacawberIndia

0 notes

Text

Bag Filter Systems Manufacturer in Maharashtra, India

Bag Filter Systems Manufacturer in Maharashtra, India. Our advanced systems ensure a cleaner, safer work environment, enhancing productivity and compliance.Heavy Fabrication.

#Phengicon#BagFilterSystems#IndustrialFiltration#MadeInIndia#MaharashtraManufacturing#CleanAirSolutions#EfficientFiltration#EnvironmentalStandards#QualityEngineering#IndustrialSolutions#FiltrationTechnology#ReliablePerformance#ManufacturingExcellence#CleanAndGreen#InnovativeFiltration

1 note

·

View note

Text

Don’t redesign your kitchen, just focus on purity! Our under-sink water purifier is a hidden yet powerful solution for clean, safe drinking water. It fits seamlessly beneath your sink, preserving your kitchen’s look while delivering the purest water straight to your tap. Featuring advanced multi-stage filtration, it removes impurities effectively, ensuring every drop is fresh and healthy. Compact, efficient, and easy to install, it’s the perfect choice for modern homes. Choose hidden purification and enjoy the convenience of clean water without compromise!

✅ Purification By SF+SC+RO+UV+FA ✅ Pressure Tank with storage 10 Itr ✅ Four Stage Filtration ✅ Flow Rate: 12-15 LPH (Max.) ✅ RO Membrane Protection ✅ SMPS With Low And High ✅ Voltage Protection

Contact us for more details: 🌐 www.aquaneeta.in 📌 Vaduthala, Cochin, Kerala ☎ Service: +91-9947033715, +91-9947033730 Sales: +91-99470 33711

#Aquaneeta#WaterPurifier#healthywater#UVwaterPurifier#rowaterPurifier#Purifier#WaterFilter#filtrationtechnology#irishdancing#Purification#Filtration#UnderSinkWaterPurifier

0 notes

Text

Top Electrostatic Precipitator Manufacturer in Ahmedabad

Discover the leading electrostatic precipitator manufacturer in Ahmedabad, specializing in cutting-edge solutions for air pollution control. Our high-efficiency electrostatic precipitators effectively remove fine particulate matter from industrial exhaust, ensuring a cleaner and safer environment. With advanced technology and customizable designs, our products guarantee reliable performance and cost-effective operation. Explore our range of electrostatic precipitators today and take a step towards better air quality!

#ElectrostaticPrecipitator#ESPManufacturer#AhmedabadESP#AirPollutionControl#IndustrialFiltration#PollutionControlSystems#ESPTechnology#IndustrialAirQuality#AhmedabadManufacturers#CleanAirSolutions#FiltrationTechnology#IndustrialESP#AirQualityControl#PollutionManagement#ESPProduction#AirPurification#IndustrialHygiene#FiltrationSystems#PollutionControlIndia#IndustrialDustControl#ESPDesign#AhmedabadIndustry#AirCleaningSolutions#ESPManufacturersIndia#EnvironmentalControl#IndustrialPollutionControl#ESPEngineering#AhmedabadFilterCompany#FilterExperts#AirPollutionManagement

0 notes