#Finite Element Analysis Consulting Services in India

Explore tagged Tumblr posts

Text

TEFUGEN: Redefining Engineering Excellence through Finite Element Analysis

WHY USE FEA IN YOUR ENGINEERING PROJECTS?

At the forefront of engineering excellence, TEFUGEN offers exceptional Finite Element Analysis (FEA) services in India. Utilizing FEA yields unparalleled benefits, offering profound insights into your project's performance prior to physical model construction. It aids in pinpointing stress points, identifying potential weaknesses, and assessing material durability under diverse conditions, effectively mitigating the risk of failure and associated costs. With its ability to conduct precise simulations, FEA empowers informed decision-making in design modifications, guaranteeing optimal performance and safety.

Structural Integrity Assessment:

In engineering, FEA, an indispensable method, meticulously assesses structural integrity by simulating material responses to diverse conditions. This predictive analysis is pivotal for guaranteeing the safety and reliability of designs. TEFUGEN, as a FEA consulting service in India, provides expert assistance, enabling engineers to identify potential weaknesses and optimize for durability.

Thermal stress analysis:

FEA analysis services play a key role in assessing heat distribution within structures or components. Engineers leverage this analysis to model and analyze thermal behavior meticulously. By doing so, they optimize designs for efficient heat dissipation or retention, ensuring the performance and reliability of the system. This detailed analysis enables engineers to make informed decisions regarding material selection, insulation, or heat management strategies, ultimately enhancing overall system efficiency and longevity.

Mechanical Component Design:

FE Analysis plays a crucial role in optimizing mechanical component design by accurately predicting stress, strain, and deformation. This ensures components can effectively withstand operational loads while minimizing material usage, thereby enhancing efficiency and cost-effectiveness.

Fatigue Analysis:

Engineers use FEA for fatigue analysis, predicting the lifespan of components subjected to cyclic loading. This is crucial in industries like aerospace and automotive, where understanding material fatigue is paramount.

Fluid Structure Interaction:

Fluid Structure Interaction (FSI) is a crucial aspect of FE Analysis, examining the dynamic interaction between fluids and structures. By simulating how fluids affect nearby structures and vice versa, FSI enables engineers to optimize designs for enhanced performance and durability across various industries.

Modal analysis Modal analysis using FEA techniques enables the simulation of eigenfrequencies and eigenmodes, revealing the vibrational characteristics of a structure. Meanwhile, harmonic analysis facilitates the emulation of peak responses to specific loads, offering insights into system behavior. These analyses are indispensable tools for understanding structural dynamics and optimizing performance.

Motion study Unlocking insights into structural behavior through Finite Element Analysis (FEA) motion studies. Discover the intricate dynamics of systems, optimize designs, and ensure structural resilience with FEA motion analysis.

#Finite Element Analysis Consulting Services in India#FEA Analysis Services#FEA Consulting Engineers#FEA Consultants in Trichy#FEA#Finite Element Method#Structural Analysis#Stress Analysis#Static Analysis#Dynamic Analysis#Thermal Analysis#Fluid Flow Analysis#Vibration Analysis#Fatigue Analysis#Buckling Analysis#Modal Analysis#Meshing#Boundary Conditions#Material Properties#Convergence#Post-processing#Optimisation#Mesh Generation#Simulation Software

0 notes

Text

Hands-On Mechanical Design Course in Chennai – Learn, Practice, Get Placed

In today’s fast-paced industrial and engineering landscape, having a mechanical engineering degree is no longer enough. What sets professionals apart is their ability to apply theoretical knowledge using industry-relevant design tools. That’s exactly why enrolling in mechanical design training courses in Chennai has become a popular and strategic choice among aspiring engineers.

Whether you're a student, a fresher, or a working professional, mastering design software through hands-on training can make a huge difference in your career path — and Chennai, being one of India’s top engineering hubs, offers just the right environment.

Why You Need Mechanical Design Skills Today

From product development to plant design and automotive systems, mechanical engineers are expected to create precise, safe, and functional designs. That’s where CAD (Computer-Aided Design) and other simulation tools come in. A well-structured mechanical design course in Chennai can help you learn to:

Create 2D and 3D mechanical drawings

Model machine parts and assemblies

Simulate stress and thermal conditions

Optimize design for manufacturing and cost

Collaborate across disciplines in real-time environments

With growing demand in sectors like oil & gas, HVAC, manufacturing, and product engineering, employers are actively seeking candidates with hands-on experience in modern design tools.

What You’ll Learn in a Mechanical Engineering Design Course

The best mechanical engineering design courses in Chennai don’t just teach theory — they provide practical, project-based learning using real tools. Here’s what a typical course covers:

AutoCAD Mechanical: For drafting and 2D mechanical layout design

SolidWorks / CATIA / Creo: For 3D modeling, part assembly, and surface design

ANSYS or HyperMesh: For FEA (Finite Element Analysis) and structural simulation

HVAC and Plumbing Design (optional): For building services and plant systems

Project Work: Real-time design projects to apply everything you've learned

Courses also include interpretation of technical drawings, material selection, tolerance analysis, and documentation best practices.

Who Should Take These Courses?

These courses for mechanical design engineers in Chennai are ideal for:

Final-year mechanical engineering students

Diploma holders in mechanical or production engineering

Working professionals looking to switch or upskill

Engineers entering industries like fabrication, oil & gas, or HVAC design

Flexible batch timings, weekend classes, and online options make it convenient for learners at any stage.

Why Choose Mechanical Design Courses in Chennai?

Chennai is home to leading MNCs, EPC firms, automobile manufacturers, and mechanical design consultancies. Taking up a mechanical design course in Chennai gives you access to:

Industry-experienced trainers

State-of-the-art design labs

100% placement assistance

Certification with project portfolio

Networking opportunities with engineers and recruiters

Institutes like Conserve Academy, for instance, offer dedicated mechanical design training courses in Chennai that focus on practical skill-building and career outcomes.

Career Opportunities After the Course

Once you complete your training, here are a few career roles you’ll be eligible for:

Mechanical Design Engineer

CAD/CAE Engineer

Product Design Engineer

HVAC Design Engineer

Piping Design Engineer

Structural/Plant Design Engineer

Manufacturing or Production Designer

These roles come with good salary potential and long-term growth opportunities, especially if you're certified and job-ready.

Conclusion

If you're serious about launching or upgrading your mechanical engineering career, now is the time to act. With the right mechanical design training courses in Chennai, you’ll gain the skills, software knowledge, and confidence to take on real-world engineering challenges.

Don’t just learn — design your future with hands-on, job-oriented training that sets you apart in a competitive job market.

#mechanical design course in chennai#mechanical engineering design courses in chennai#courses for mechanical design engineer in chennai#mechanical design training courses in chennai

0 notes

Text

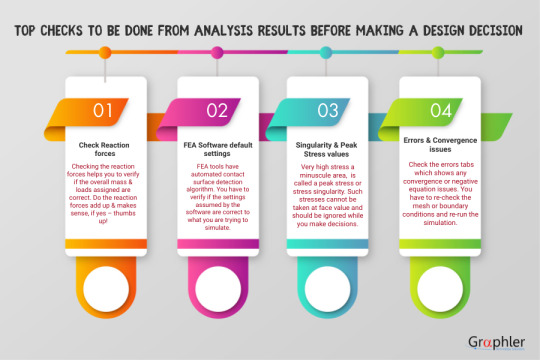

Unveiling the Strength: A Comprehensive Finite Element Analysis of the Strap U-Frame

In the realm of engineering, structural integrity and performance are paramount. At Graphler Technology Solutions, our commitment to delivering cutting-edge analyses ensures that every project achieves its full potential. Recently, we undertook an extensive finite element analysis (FEA) of a Strap U-Frame. This blog delves into the highlights and insights from the study.

Objective of the Study:

The primary goal of the FEA was to evaluate the structural behavior of the Strap U-Frame under a variety of operational loads and conditions. This included assessing how the U-Frame responded to forces induced by tension in the strap, moments generated during operation, and reaction forces from components like the crank and pawl. By simulating these real-world conditions, the analysis aimed to:

Identify Critical Stress Points: Determine locations within the U-Frame where stress exceeded safe operational thresholds, particularly areas prone to potential cracking or fatigue failure.

Examine Deformation Patterns: Evaluate how the structure deforms under load to ensure that any displacements remain within acceptable limits to maintain functionality.

Validate Material Performance: Analyze whether the materials selected for the U-Frame and its components could withstand the applied loads without permanent damage or failure.

Guide Design Improvements: Provide actionable insights for optimizing the design and material usage to enhance durability, safety, and cost-effectiveness.

This holistic approach ensured that the U-Frame design met stringent performance standards while aligning with the operational demands and longevity expectations of the client.

Analysis Setup

The analysis focused on multiple load cases, including:

Belt Tension: Simulated at 26688 N, generating a significant moment of 1334400 N-mm.

Force Transmission: Evaluated through the crank lever requiring a force of 3587.10 N for operation.

Boundary conditions, material properties, and operational loads were meticulously configured to replicate real-world scenarios.

Key Findings

1. Deformation Analysis

Maximum deformation observed: 2.93 mm.

Despite localized deformation, the overall structure maintained functional integrity.

2. Stress Distribution

U-Frame: Maximum principal stress reached 1032 MPa, exceeding the material’s ultimate tensile strength. However, the stress concentration was confined to the surface peel layer, indicating potential for localized cracking without immediate failure.

Pawl: Maximum stress of 858.23 MPa surpassed yield strength at contact points. The compressive nature of stress ensured no catastrophic failure.

Shaft: Surface stress exceeded yield strength but remained within acceptable limits at the core, highlighting resilience against major deformation or breakage.

3. Reaction Forces

4. Engineering Inferences

Localized Cracking: Stress concentrations in the U-Frame and Pawl necessitate enhanced surface treatments or reinforcements to mitigate fatigue risks.

Material Performance: While the materials demonstrated high resilience, exceeding yield thresholds in localized regions requires design refinements.

Optimized Design: Potential adjustments in geometry or material distribution can enhance load-bearing capacity without significant weight increases.

Graphler Technology is one of the leading product design companies in India. We have experts in FEA services and also we are specialized in CFD consulting services, structural design services, 2D to 3D Conversion services, stress analysis services etc.

0 notes

Text

Unveiling the Strength: A Comprehensive Finite Element Analysis of the Strap U-Frame

In the realm of engineering, structural integrity and performance are paramount. At Graphler Technology Solutions, our commitment to delivering cutting-edge analyses ensures that every project achieves its full potential. Recently, we undertook an extensive finite element analysis (FEA) of a Strap U-Frame. This blog delves into the highlights and insights from the study.

Objective of the Study:

The primary goal of the FEA was to evaluate the structural behavior of the Strap U-Frame under a variety of operational loads and conditions. This included assessing how the U-Frame responded to forces induced by tension in the strap, moments generated during operation, and reaction forces from components like the crank and pawl. By simulating these real-world conditions, the analysis aimed to:

Identify Critical Stress Points: Determine locations within the U-Frame where stress exceeded safe operational thresholds, particularly areas prone to potential cracking or fatigue failure.

Examine Deformation Patterns: Evaluate how the structure deforms under load to ensure that any displacements remain within acceptable limits to maintain functionality.

Validate Material Performance: Analyze whether the materials selected for the U-Frame and its components could withstand the applied loads without permanent damage or failure.

Guide Design Improvements: Provide actionable insights for optimizing the design and material usage to enhance durability, safety, and cost-effectiveness.

This holistic approach ensured that the U-Frame design met stringent performance standards while aligning with the operational demands and longevity expectations of the client.

Analysis Setup

The analysis focused on multiple load cases, including:

Belt Tension: Simulated at 26688 N, generating a significant moment of 1334400 N-mm.

Force Transmission: Evaluated through the crank lever requiring a force of 3587.10 N for operation.

Boundary conditions, material properties, and operational loads were meticulously configured to replicate real-world scenarios.

Key Findings

1. Deformation Analysis

Maximum deformation observed: 2.93 mm.

Despite localized deformation, the overall structure maintained functional integrity.

2. Stress Distribution

U-Frame: Maximum principal stress reached 1032 MPa, exceeding the material’s ultimate tensile strength. However, the stress concentration was confined to the surface peel layer, indicating potential for localized cracking without immediate failure.

Pawl: Maximum stress of 858.23 MPa surpassed yield strength at contact points. The compressive nature of stress ensured no catastrophic failure.

Shaft: Surface stress exceeded yield strength but remained within acceptable limits at the core, highlighting resilience against major deformation or breakage.

3. Reaction Forces

4. Engineering Inferences

Localized Cracking: Stress concentrations in the U-Frame and Pawl necessitate enhanced surface treatments or reinforcements to mitigate fatigue risks.

Material Performance: While the materials demonstrated high resilience, exceeding yield thresholds in localized regions requires design refinements.

Optimized Design: Potential adjustments in geometry or material distribution can enhance load-bearing capacity without significant weight increases.

Graphler Technology is one of the leading product design companies in India. We have experts in FEA services and also we are specialized in CFD consulting services, structural design services, 2D to 3D Conversion services, stress analysis services etc.

0 notes

Text

Computer Aided Engineering Market Strategies For Enhancing Collaboration In Engineering Teams

Global Computer-Aided Engineering (CAE) Market

The Computer-Aided Engineering (CAE) market is undergoing a significant expansion, driven by several key factors. The outsourcing of manufacturing processes to emerging economies like China, India, and Russia has increased the demand for efficient engineering tools. CAE software offers substantial benefits by reducing the need for multiple physical prototypes and minimizing product recall issues. This leads to a significant reduction in prototyping costs and product recall strategies.

One notable trend is the growing use of Computational Fluid Dynamics (CFD) software to analyze temperature in battery modules. This application is crucial for extending battery life and performance, further driving market growth.

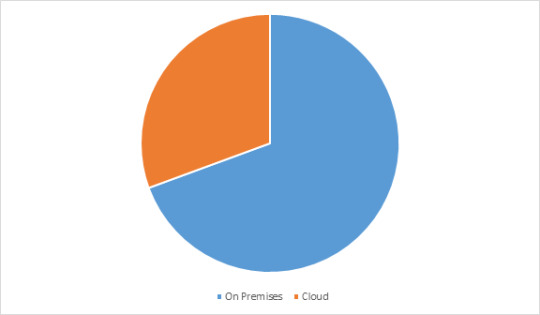

Shift to Cloud Computing

A major shift is occurring from on-premise computing to cloud-based solutions. Cloud computing offers cost advantages by eliminating the need for hardware purchases, software licensing, installation, and support. This makes CAE software more accessible and cost-effective. Additionally, companies are adopting Hyper-Converged Infrastructure (HCI) platforms to build private clouds, enabling advanced computational and storage services.

Overall Market Outlook

The CAE market is projected to experience unprecedented growth due to these factors. The increasing efficiency, cost-effectiveness, and versatility of CAE software are making it an indispensable tool for engineers and manufacturers worldwide.

Component Segmentation Insights

Based on Component

Software dominated the market in 2023 and is expected to maintain its lead due to benefits like data safety, reliability, and uninterrupted testing.

Software optimizes engineering tasks and is primarily used to analyze the robustness and performance of components and assemblies.

Based on Software Types

Finite Element Analysis (FEA) was the largest segment in 2023, accounting for over 51% of the market. FEA is used to determine product strength under various loads and simulates real components to analyze heat transfer, structural analysis, electromagnetic potential, and mass transport.

Computational Fluid Dynamics (CFD) involves analyzing fluid flow, turbulence, and pressure distribution. Industry players are developing application-specific software for customized process functions.

Multibody Dynamics includes forward and inverse dynamics. Forward dynamics analyzes component movement due to external forces, while inverse dynamics analyzes forces required for specific system movement.

Based on Service

The service segment is anticipated to have the highest CAGR due to growing awareness of virtual processes in product development.

Services like design and consulting, implementation, and maintenance are gaining popularity among enterprises.

Order a free sample PDF of the Computer Aided Engineering Market Intelligence Study, published by Grand View Research.

0 notes

Text

fea dynamics analysis in india

fea dynamics analysis in india finite element analysis services in india FEA for aerospace in india structural analysis services in india vibration analysis services in india stress analysis services in india FEA for failure analysis in india best FEA services in india

3d-labs is an engineering consulting firm that provides full analysis using state-of-the-art FEA , CFD, and CAD/CAE tools. We help our clients reduce product development costs, decrease time-to-market , and improve product quality.9843511204 We, offer not only reliable analysis results but also insight solutions to clients' projects….. We are from all sectors of the industry and have excellent analytical skills and knowledge. We have co-operation with universities, national laboratories, and other engineering firms, which enable us to address and solve clients' questions and problems simply and quickly. We solve a broad range of engineering analysis problems based on FEA techniques including stress analysis, fluid dynamics, kinematics, heat transfer, dynamics and vibration (seismic, harmonic), structural dynamics and electromagnetics. etc.

0 notes

Text

Top 20 Business Ideas for Mechanical Engineers in India - ACEIT

There are many colleges but Arya College of Engineering & I.T. is The Best Mechanical Engineering college in Jaipur. Here are some of the most promising and profitable business ideas for mechanical engineers looking to start their own company: Solar Panel Design and Installation The solar panel installation business is rapidly growing due to the increasing need for renewable energy sources. As a mechanical engineer, you have the knowledge and expertise to design, analyze, install, commission, maintain and repair solar systems. You can provide valuable services such as site assessments, energy efficiency evaluations, and detailed feasibility analyses. Develop customized solar panel designs based on the customer's needs and budget to maximize their return on investment. Start by outsourcing solar panel products and offering supply and installation services. Work with developers and installers to bring renewable energy projects to life. The initial startup cost for a small solar company is around $10,000, and you can make an estimated $5,000 to $10,000 per installation. Computer-Aided Design (CAD) Services CAD service businesses are becoming increasingly popular in the engineering and construction industries. Starting a CAD business requires a basic understanding of computer-aided design software and related tools. The minimum startup costs would be around $2,000, and you could make approximately $8,000 per month, depending on the complexity of the projects. You'll need a computer, monitor, printer, scanner, drafting table, chair, and CAD software like AutoCAD or SolidWorks. You may also need other components to help view 3D models or 3D printing. To run a successful CAD business, you must stay on top of the latest trends & advancements in computer-aided design technology, be familiar with established industry standards, and have excellent communication skills to understand client requirements. Finite Element Analysis (FEA) Consulting Starting an FEA consulting business can be an excellent way to provide expert services. FEA is a computer-based method of simulating real-world behavior that engineers use to solve complex problems related to structural design, product testing, and manufacturing processes. You'll need to be knowledgeable about various types of FEA software, such as ANSYS, ABAQUS, or NASTRAN. Establish a portfolio of successful projects, build a strong network, and market your services to potential clients in industries like automotive, aerospace, and consumer products. Mechanical Design Consultancy

As a mechanical design consultant, you can offer your expertise to help clients develop new products or improve existing ones. Provide services such as conceptual design, detailed design, prototyping, and testing. Stay up-to-date with the latest design software, manufacturing processes, and industry standards. Build a strong portfolio showcasing your design skills and experience. Market your services to startups, small businesses, and larger companies looking for outsourced design support. Product Design for Private Labelers

Private labeling is a growing trend in e-commerce, where companies sell products under their brand name but outsource the manufacturing. As a mechanical engineer, you can provide product design services to private labelers. Help them develop innovative and cost-effective products that meet market demands. Offer services such as concept development, 3D modeling, prototyping, and design for manufacturability. Build relationships with manufacturers and private labelers to secure ongoing design projects 3D Printing Services 3D printing, also known as additive manufacturing, is revolutionizing the way products are designed and manufactured. As a mechanical engineer, you can start a 3D printing service bureau to help clients create prototypes, custom parts, and small-batch production runs. Invest in high-quality 3D printers, such as FDM or SLA machines, and offer a range of materials like PLA, ABS, or resin. Provide design assistance, file preparation, and post-processing services. Market your services to product designers, engineers, and small businesses looking for fast and affordable 3D printing solutions. CNC Machining Services CNC (Computer Numerical Control) machining is a manufacturing process that uses computer-controlled machine tools to create precise parts and components. As a mechanical engineer, you can start a CNC machining business to serve clients in various industries. Invest in CNC mills, lathes, and other specialized equipment. Offer services such as prototyping, short-run production, and custom machining. Build relationships with designers, engineers, and procurement managers to secure projects. Stay up-to-date with the latest CNC technologies and programming techniques to remain competitive. HVAC Services Heating, ventilation, and air conditioning (HVAC) systems are essential for maintaining comfortable indoor environments. As a mechanical engineer, you can start an HVAC services business to design, install, and maintain these systems for residential, commercial, and industrial clients. Offer services such as load calculations, system design, ductwork fabrication, and preventive maintenance. Obtain the necessary licenses and certifications, and invest in tools and equipment. Build a team of skilled technicians and market your services to property managers, facility owners, and construction companies. AC Repair Business Air conditioning repair is a service-oriented business that can be profitable for mechanical engineers. Offer repair and maintenance services for residential and commercial AC units. Invest in tools, equipment, and diagnostic software. Obtain the necessary licenses and certifications, and stay up-to-date with the latest AC technologies. Build a team of skilled technicians and market your services through online directories, local advertising, and word- of-mouth referrals. Nuts and Bolts Supplier Nuts and bolts are essential industrial fasteners used in machines, structures, and products. Starting a nuts and bolts manufacturing or supply business can be a profitable venture for mechanical Engineers. Invest in the necessary machinery and equipment, and build relationships with manufacturers and distributors. Offer a wide range of sizes, materials, and finishes to cater to various industries. Market your products to small and medium-sized enterprises looking for reliable suppliers. These are just a few examples of the many profitable business ideas available for mechanical engineers. The key is to leverage your technical expertise, identify market needs, and develop a solid business plan. Seek advice from experienced entrepreneurs, attend industry events, and continuously learn and adapt to succeed in your chosen venture.

0 notes

Text

Structural Repairs Consultants: Solving Complex Engineering Challenges

Introduction:

In the world of construction and engineering, complex challenges often arise that require a specialized approach. When it comes to structural repairs, the expertise of consultants becomes invaluable. Structural repairs consultants are professionals with a deep understanding of engineering principles and the ability to tackle complex issues head-on. From identifying underlying problems to devising effective solutions, these experts play a vital role in solving intricate engineering challenges structural repairs consultants services in india.

1. Expert Problem Identification:

Structural repairs consultants possess an acute ability to identify and diagnose complex structural problems. Through meticulous analysis and thorough inspections, they can uncover hidden issues that may not be easily detectable. Whether it's cracks in concrete, corrosion in steel structures, or foundation settlement, these consultants have the knowledge and experience to identify the root cause of the problem.

2. Advanced Engineering Analysis:

To solve complex engineering challenges, structural repairs consultants utilize advanced engineering analysis techniques. With the help of cutting-edge software and tools, they can conduct in-depth structural assessments, including finite element analysis and load calculations. This enables them to evaluate the performance and behavior of the structure under various conditions, allowing for a comprehensive understanding of the problem at hand.

3. Tailored Solutions:

Every engineering challenge is unique, requiring a customized approach. Structural repairs consultants excel in providing tailored solutions that address the specific needs of the structure. They take into account factors such as material properties, environmental conditions, and budget constraints to develop a solution that is both effective and practical. By considering all aspects of the problem, consultants ensure that the proposed solution is not only technically sound but also feasible in terms of implementation.

4. Collaborative Approach:

Complex engineering challenges often require collaboration between multiple stakeholders, including architects, contractors, and structural engineers. Structural repairs consultants act as a bridge between these parties, facilitating effective communication and coordination. By fostering collaboration, they ensure that all relevant expertise is brought to the table, increasing the chances of finding the optimal solution to the problem.

5. Compliance with Regulations:

Structural repairs consultants are well-versed in building codes and regulations. They ensure that all proposed solutions comply with the necessary standards, ensuring the safety and integrity of the structure. By adhering to these regulations, consultants provide peace of mind to both property owners and authorities, ensuring that the repairs are carried out in a legally compliant manner.

Conclusion:

Structural repairs consultants are problem solvers who possess the expertise to tackle complex engineering challenges. From identifying hidden problems to developing tailored solutions, their knowledge and experience are invaluable in ensuring the structural integrity and safety of buildings. By employing advanced engineering analysis techniques and fostering collaboration among stakeholders, these consultants play a vital role in overcoming complex challenges and delivering effective and sustainable solutions. When faced with intricate engineering issues, partnering with structural repairs consultants is a wise choice to ensure the successful resolution of these challenges

Google Map - https://goo.gl/maps/tYPUHNsdzmcTeRDe9 (801, Odyssey, Road No. 9, Wagle Estate, Thane (West), Maharashtra - 400 604. )

0 notes

Text

Projected Boom in the Computer-Aided Engineering Market: On Track to Reach $12.67 Billion by 2027 at a CAGR of 9.2% || Altair Engineering Inc., Dassault Systèmes SE, ESI Group

The Computer Aided Engineering Global Market Report 2023, provides comprehensive information on the computer aided engineering market across 60+ geographies in the seven regions - Asia-Pacific, Western Europe, Eastern Europe, North America, South America, Middle East, Africa for the 27 major global industries. The report covers a ten year historic period – 2010-2021, and a ten year forecast period – 2023-2032. Learn More On The Computer Aided Engineering Market’s Growth:https://www.thebusinessresearchcompany.com/report/computer-aided-engineering-global-market-report As per The Business Research Company’s Computer Aided Engineering Global Market Report 2023, the global computer-aided engineering market size is expected to grow from $8.11 billion in 2022 to $8.90 billion in 2023 at a compound annual growth rate (CAGR) of 9.8%. The Russia-Ukraine war disrupted the chances of global economic recovery from the COVID-19 pandemic, at least in the short term. The war between these two countries has led to economic sanctions on multiple countries, a surge in commodity prices, and supply chain disruptions, causing inflation across goods and services and affecting many markets across the globe. The computer-aided engineering market size is expected to grow to $12.67 billion in 2027 at a CAGR of 9.2%. Get A Free Sample Of The Report (Includes Graphs And Tables):https://www.thebusinessresearchcompany.com/sample.aspx?id=7941&type=smp The computer aided engineering market is segmented: 1) By Type: Finite Element Analysis (FEA), Computational Fluid Dynamics (CFD), Multibody Dynamics, Optimization, and Simulation 2) By Deployment: On-Premise, Cloud-Based 3) By End-Use: Automotive, Defense and Aerospace, Electronics, Medical Devices, Industrial Equipment. Europe was the largest region in the computer aided engineering market in 2022. The table of contents in TBRC’s computer aided engineering market report includes:1. Executive Summary 2. Computer Aided Engineering Market Characteristics 3. Computer Aided Engineering Market Trends And Strategies 4. Computer Aided Engineering Market - Macro Economic Scenario 5. Computer Aided Engineering Market Size And Growth …….... 28. Key Mergers And Acquisitions In The Computer Aided Engineering Market 29. Computer Aided Engineering Market Future Outlook and Potential Analysis 30. Appendix Learn About Us: The Business Research Company is a market intelligence firm that pioneers in market, company, and consumer research. TBRC’s specialist consultants are located globally and are experts in a wide range of industries that include healthcare, manufacturing, financial services, chemicals, and technology, with 6500+ reports. The firm has offices located in the UK, the US, and India, along with a network of proficient researchers in 28 countries. Through the report businesses can gain a thorough understanding of the market’s size, growth rate, major drivers and leading players.

Contact Us: The Business Research Company Europe: +44 207 1930 708 Asia: +91 88972 63534 Americas: +1 315 623 0293 Email: [email protected] Follow Us On: LinkedIn: https://in.linkedin.com/company/the-business-research-company Twitter: https://twitter.com/tbrc_info Facebook: https://www.facebook.com/TheBusinessResearchCompany YouTube: https://www.youtube.com/channel/UC24_fI0rV8cR5DxlCpgmyFQ Blog: https://blog.tbrc.info/ Healthcare Blog: https://healthcareresearchreports.com/ Global Market Model: https://www.thebusinessresearchcompany.com/global-market-model

0 notes

Link

Experts and analysts at Ideametrics gather insights regarding a failure along with necessary information such as environmental conditions, service life, design considerations, and applications for which a product, system, or machinery used. With multi-faceted experience in analyzing failures occurred in various industries including food & pharma, power, oil & gas, and petrochemical, our holistic approach identifies the root cause of failure. Our experts offer relevant insights and measures to be taken in the future following the thorough analysis of the root cause. With a combined knowledge regarding process equipment and the service environment, our experts offer recommendations and solutions and work closely with clients to avoid failures in the future.

FEATURES

Multi-faceted experience in analyzing failures and handling intricate projects.

Consideration of environmental conditions and service life during analysis.

Accurate identification and analysis of root cause.

Detailed insights to prevent failures in the future.

Advanced tools and sophisticated software at hand.

Ethical approach and focus on adding exceptional value.

Contact us:

Ideametrics Pvt. Ltd.

Website: Ideametrics

Contact person: Pandharinath Sanap

Inquire on [email protected]

Contact no: +91- 8275063532

#Failure Analysis#Failure Analysis Services#Failure Analysis Services in Pune#Failure Analysis Services in India#Finite Element Analysis Services#Engineering Service Providers#Engineering Consultants in Pune#Engineering Solutions in Pune#Engineering design companies in pune#Engineering companies in pune#Engineering solutions in India#Engineering services in pune

0 notes

Text

TEFUGEN: Redefining Engineering Excellence through Finite Element Analysis

WHY USE FEA IN YOUR ENGINEERING PROJECTS?

At the forefront of engineering excellence, TEFUGEN offers exceptional Finite Element Analysis (FEA) services in India. Utilizing FEA yields unparalleled benefits, offering profound insights into your project's performance prior to physical model construction. It aids in pinpointing stress points, identifying potential weaknesses, and assessing material durability under diverse conditions, effectively mitigating the risk of failure and associated costs. With its ability to conduct precise simulations, FEA empowers informed decision-making in design modifications, guaranteeing optimal performance and safety.

Structural Integrity Assessment:

In engineering, FEA, an indispensable method, meticulously assesses structural integrity by simulating material responses to diverse conditions. This predictive analysis is pivotal for guaranteeing the safety and reliability of designs. TEFUGEN, as a FEA consulting service in India, provides expert assistance, enabling engineers to identify potential weaknesses and optimize for durability.

Thermal stress analysis:

FEA analysis services play a key role in assessing heat distribution within structures or components. Engineers leverage this analysis to model and analyze thermal behavior meticulously. By doing so, they optimize designs for efficient heat dissipation or retention, ensuring the performance and reliability of the system. This detailed analysis enables engineers to make informed decisions regarding material selection, insulation, or heat management strategies, ultimately enhancing overall system efficiency and longevity.

Mechanical Component Design:

FE Analysis plays a crucial role in optimizing mechanical component design by accurately predicting stress, strain, and deformation. This ensures components can effectively withstand operational loads while minimizing material usage, thereby enhancing efficiency and cost-effectiveness.

Fatigue Analysis:

Engineers use FEA for fatigue analysis, predicting the lifespan of components subjected to cyclic loading. This is crucial in industries like aerospace and automotive, where understanding material fatigue is paramount.

Fluid Structure Interaction:

Fluid Structure Interaction (FSI) is a crucial aspect of FE Analysis, examining the dynamic interaction between fluids and structures. By simulating how fluids affect nearby structures and vice versa, FSI enables engineers to optimize designs for enhanced performance and durability across various industries.

Modal analysis Modal analysis using FEA techniques enables the simulation of eigenfrequencies and eigenmodes, revealing the vibrational characteristics of a structure. Meanwhile, harmonic analysis facilitates the emulation of peak responses to specific loads, offering insights into system behavior. These analyses are indispensable tools for understanding structural dynamics and optimizing performance.

Motion study Unlocking insights into structural behavior through Finite Element Analysis (FEA) motion studies. Discover the intricate dynamics of systems, optimize designs, and ensure structural resilience with FEA motion analysis.

0 notes

Photo

Finite Element Analysis (FEA) is a very good tool for providing useful insight into stresses and deformations which in turn the engineer can assess the strength and durability of mechanical components and large structures. Graphler Technology is one of the fastest-growing product design companies in India, we have a team of experts specialized in 3D to 2D Conversion Services, CAD Conversion Services, Engineering Animation Services, Pressure Vessel Analysis Services, and more.

0 notes

Text

3D Simulation Software Market - Forecast(2022 - 2027)

3D Simulation Software Market Size is forecast to reach $7.3 billion by 2026, at a CAGR of 32.0% during 2021-2026. Adoption of 3D Simulation Software in aerospace, defense and automobile industries with the development of modern aircrafts, autonomous and electric vehicles boost the 3D Simulation Software market growth. In addition to these, process 3D Simulation Software is also used in designing or creating Internet of Things (IoT) devices and apps. High adoption of 3D Simulation Software for 3D modeling and simulation in the development of industrial products is set to drive industry 4.0. Similarly, growing developments by various companies in 3D Modeling software such as Finite element analysis and computational fluid dynamics is analyzed to drive the market growth. In 2020, Desktop Metal had launched Live Sinter 3D Simulation Software for powder metallurgy-based manufacturing processes. Further, entry of new players in developed and developing economies will further enhance the overall market demand for 3D Simulation Software during the forecast period 2021-2026.

Report Coverage

The report: “3D Simulation Software Market – Forecast (2021-2026)”, by IndustryARC covers an in-depth analysis of the following segments of the 3D Simulation Software market

By Deployment Mode: Cloud, On-Premises

By Type: Software (Finite Element Analysis, Computational Fluid Dynamics, Electromagnetic Waves) Services (Design & Consulting, Support & Maintenance, E-Learning & Training, Research & Development)

By Vertical: Automobile, Aerospace & Defense, Electrical & Electronics, Industrial Manufacturing, Healthcare, Education & Research, Others

By Geography - North America (U.S, Canada, Mexico), Europe (Germany, UK, France, Italy, Spain, Russia, Netherlands and Others), APAC(China, Japan India, SK, Australia, Indonesia and Others), South America(Brazil, Argentina, Chile, Colombia and others), and RoW (Middle East and Africa).

Request Sample

Key Takeaways

3D Simulation Software market in North America region held significant market share of 36% in the forecast period. Early adoption of advanced technologies in aerospace, defense and others has been increasing the demand for 3D Simulation Software.

Cloud deployment is growing at a highest CAGR of 36.3% in the forecast period owing to its operational flexibility and real-time deployment ease to companies compared to on-premises deployment.

Automotive sector is expected to witness a highest CAGR of 37.2% the forecast period. Increasing focus on R&D activities and rapid technological changes owing to the changing government norms for vehicle safety are projected to drive the market.

3D Simulation Software top 10 companies include Altair Engineering, Ansys, Autodesk, Bentley Systems, CPFD Software, Cybernet, Dassault Systems, Design Simulation Technologies, Mathworks, PTC, Siemens PLM Software among others.

3D Simulation Software Market Segment Analysis - By Deployment

Cloud deployment is growing at a highest CAGR of 36.3% in the forecast period owing to its operational flexibility and real-time deployment ease to companies compared to on-premises deployment. It also offers numerous benefits, including reduced operational costs, simple deployment process, and higher scalability in terms of connected resources. Additionally, the cost-effective cloud-based solutions ease installation when compared to the on-premises solutions. The highest level of data security and reliability offered by the cloud deployment are increasing the share of this deployment in the forecast period. Several companies are providing solutions related to this deployment. For instance SimScale is a full-cloud CAE 3D Modelling and Simulation Software that helps to perform Computational Fluid Dynamics, Finite Element Analysis, and thermal simulations for CAD models in the cloud. Similarly, AnyLogi? Cloud is a cloud-based simulation tool that allows users to run simulation models such as Finite Element Analysis and Computational Fluid Dynamics online using just a web browser and share them. Hence these benefits are analysed to drive the market growth in the forecast period 2021-2026.

Inquiry Before Buying

3D Simulation Software Market Segment Analysis - By Vertical

Automotive sector is expected to witness a highest CAGR of 37.2% the forecast period. Increasing focus on R&D activities and rapid technological changes owing to the changing government norms for vehicle safety are projected to drive the market. With increasing connectivity and digitalization, OEMs are focusing on improving cybersecurity over connected vehicles & devices, which is expected to drive the automotive simulation market for software such as Finite Element Analysis and Computational Fluid Dynamics. Along with cybersecurity, rapid infrastructure development and advancements in 5G technology are Moreover companies such as Nvidia, IPG automotive and so on are collaborating with several global companies for advancements in these 3D Simulation Software. In 2019, Nvidia had partnered with Toyota for autonomous vehicle simulation platform drive constellation, the cloud-based platform. This platform would enable the self-driving car developers to run tests on virtual, rather than real roads. In 2018, IPG Automotive signed a partnership agreement with Transpolis SAS to develop innovative solutions in the field of large-scale simulation. Hence these factors are anticipated to fuel the growth of the 3D Simulation Software market in the forecast period 2021-2026.

3D Simulation Software Market Segment Analysis - By Geography

3D Simulation Software market in North America region held significant market share of 36% in the forecast period. Early adoption of advanced technologies in aerospace, defense and other has been increasing the demand for 3D Simulation Software. In addition, the governments in the North American region are constantly focusing on innovation and investment for a greener work environment. The regulations associated with the eco-friendly work environment are becoming stringent in the region and as a result, companies are adopting simulators to test product viability before manufacturing. In U.S. strict guidelines imposed by the Federal Aviation Administration (FAA) and Federal Aviation Regulations (FARs) regarding use of simulators for training purpose. According to new FAR regulations, Air carriers must compulsorily develop training programs using simulators that meet the upgraded requirements. Stringent regulations as such will drive the usage of simulators thereby driving 3D Simulation Software in this region. According to U.S. Department of Defense, by 2022, U.S Military had committed to invest more than $11 billion for virtual, augmented and mixed reality training systems and simulator. Hence these factors drive the market growth in the forecast period 2021-2026.

Schedule a Call

3D Simulation Software Market Drivers

Growing advancements in 3D Simulation Software

3D Simulation Software companies are strengthening their position through mergers & acquisitions and continuously investing in research and development (R&D) activities to come up with solutions to cater to the changing requirements of customers. In addition companies such as Siemens, Rockwell, Ansys, and so on are planning to invest in advanced technologies such as artificial intelligence with a target to provide cost competitive Finite Element Analysis and Computational Fluid Dynamics products in the market in the forecast period. In 2020 Ansys Inc. entered into a definitive agreement to acquire Lumerical Inc., which is a leading developer of photonic design and simulation tools. The acquisition will add a wide range of photonics products to the Ansys Multiphysics portfolio, providing customers with a full set of solutions to solve its next-generation product challenges. In 2019, Altair Engineering Inc. launched a new manufacturing simulation solution for additive manufacturing, Inspire Print3D. The solution is aimed explicitly at selective laser melting (SLM). In 2020, Kumux has launched the 2.0 version of its spectral 3D Simulation Software, which allows the creation of differential lighting, beneficial to people’s health and plant growth. In 2018, Simufact Engineering, an MSC Software company and expert in manufacturing process simulation, had launched Simufact Additive software solution for the simulation of metal additive manufacturing processes. Hence these advancements are analyzed to drive the market growth in the forecast period 2021-2026.

Growing adoption of 3D Simulation Software among aerospace & defense

The aerospace & defense industry has been one of the major end users of simulation as they use modelling and simulation for numerous purposes including, training of individual soldiers, conducting joint training operations, formulating operational plans, developing doctrine and tactics, and analyzing alternative force structures, Finite Element Analysis and Computational Fluid Dynamics. The technology fulfills critical defense needs of command, control, and communications; manpower, personnel, and training; computing and software; electronics; and manufacturing technology. These defense models and simulations vary in a broad range from components of large weapons systems through system-level to simulations of missions and battles, and so forth. Such significant applications are the major factors driving the growth of the global market in these industries.

Buy Now

3D Simulation Software Market Challenges

Data security is the major challenge for 3D Simulation Software

One of the major challenges in 3D Simulation Software is data security. Investment in data security to avoid simulation attacks is one of the major challenges faced by the 3D Simulation Software companies. Simulated attacks might send fake phishing attacks to employees or attempt cyber-attack on a company’s web application firewall. High investment into data security is the major challenge companies which is hampering the growth of the market. However, the introduction of many cybersecurity tools at affordable prices is set to invest in 3D Simulation Software, thereby driving the market growth.

3D Simulation Software Market Landscape

Software launches, acquisitions, Partnerships and R&D activities are key strategies adopted by players in the 3D Simulation Software market. In 2020, the market of 3D Simulation Software industry outlook has been fragmented by several companies. 3D Simulation Software top 10 companies include Altair Engineering, Ansys, Autodesk, Bentley Systems, CPFD Software, Cybernet, Dassault Systems, Design Simulation Technologies, Mathworks, PTC, Siemens PLM Software among others.

Acquisitions/Software Launches

In 2020, PTC, Inc. launched a 3D computer-aided design software named as Creo 7.0. This software has the new abilities to put the power of artificial intelligence at the fingertips of the designers, hence making the simulation a unified part of the daily work.

#3D Simulation Software Market#3D Simulation Software Market size#Computation fluid dynamics#3D Simulation Software Industry#Artificial intelligence#3D Simulation Software Market share

0 notes

Text

#Simulation Software Market - Industry Analysis, Market Size, Share, Trends,Application Analysis, Growth and Forecast 2021 - 2026

Simulation Software Market Size is forecast to reach $20.3 billion by 2026, at a CAGR of 17.0% during 2021-2026. Adoption of simulation software in aerospace, defense and automobile industries with the development of modern aircraft, autonomous and electric vehicles boost the simulation software market growth. In addition to these, process simulation software is also used in designing or creating Internet of Things (IoT) devices and apps.

High adoption of simulation software for modeling and simulation in the development of industrial products is set to drive industry 4.0. Similarly, growing developments by various companies is analyzed to drive the market growth. In 2020, Desktop Metal had launched Live Sinter simulation software for powder metallurgy-based manufacturing processes. Further, entry of new players in developed and developing economies will further enhance the overall market demand for Simulation Software during the forecast period 2021-2026.

Report Coverage

The report: “Simulation Software Market – Forecast (2021-2026)”, by IndustryARC covers an in-depth analysis of the following segments of the Simulation Software market

By Deployment Mode : Cloud, On-Premises

By Type : Software (Finite Element Analysis, Computational Fluid Dynamics, Electromagnetic Waves and Others) Services (Design & Consulting, Support & Maintenance, E-Learning & Training, Research & Development)

By Vertical : Automobile, Aerospace & Defense, Electrical & Electronics, Industrial Manufacturing, Healthcare, Education & Research, Others.

By Geography: North America (U.S, Canada, Mexico), Europe (Germany, UK, France, Italy, Spain, Russia, Netherlands and Others), APAC(China, Japan India, SK, Australia, Indonesia and Others), South America(Brazil, Argentina, Chile, Colombia and others), and RoW (Middle East and Africa).

Key Takeaways

Simulation Software market in North America region held significant market share of 34% in the forecast period. Early adoption of advanced technologies in aerospace, defense and others has been increasing the demand for simulation software.

Cloud deployment is growing at a highest CAGR of 20.3% in the forecast period owing to its operational flexibility and real-time deployment ease to companies compared to on-premises deployment.

Automotive sector is expected to witness a highest CAGR of 21.2% the forecast period. Increasing focus on R&D activities and rapid technological changes owing to the changing government norms for vehicle safety are projected to drive the market.

Simulation Software top 10 companies include Altair Engineering, Ansys, Autodesk, Bentley Systems, CPFD Software, Cybernet, Dassault Systems, Design Simulation Technologies, Mathworks, PTC, Siemens PLM Software among others.

Simulation Software Market, By Deployment Model, 2020 (%)

For More Details on This Report - Request for Sample

Simulation Software Market Segment Analysis - By Deployment

Cloud deployment is growing at a highest CAGR of 20.3% in the forecast period owing to its operational flexibility and real-time deployment ease to companies compared to on-premises deployment. It also offers numerous benefits, including reduced operational costs, simple deployment process, and higher scalability in terms of connected resources. Additionally, the cost-effective cloud-based solutions ease installation when compared to the on-premises solutions. The highest level of data security and reliability offered by the cloud deployment are increasing the share of this deployment in the forecast period.

Several companies are providing solutions related to this deployment. For instance SimScale is a full-cloud CAE simulation software that helps to perform CFD, FEA, and thermal simulations for CAD models in the cloud. Similarly, AnyLogi? Cloud is a cloud-based simulation tool that allows users to run simulation models such as Finite Element Analysis and Computational Fluid Dynamics online using just a web browser and share them. Hence these benefits are analysed to drive the market growth in the forecast period 2021-2026.

Simulation Software Market Segment Analysis - By Vertical

Automotive sector is expected to witness a highest CAGR of 21.2% the forecast period. Increasing focus on R&D activities and rapid technological changes owing to the changing government norms for vehicle safety are projected to drive the market. With increasing connectivity and digitalization, OEMs are focusing on improving cybersecurity over connected vehicles & devices, which is expected to drive the automotive simulation market for software such as Finite Element Analysis and Computational Fluid Dynamics. Along with cybersecurity, rapid infrastructure development and advancements in 5G technology companies such as Nvidia, IPG automotive and so on are collaborating with several global companies for advancements in these simulation software.

In 2019, Nvidia had partnered with Toyota for autonomous vehicle simulation platform drive constellation, the cloud-based platform. This platform would enable the self-driving car developers to run tests on virtual, rather than real roads. In 2018, IPG Automotive signed a partnership agreement with Transpolis SAS to develop innovative solutions in the field of large-scale simulation. Hence these factors are anticipated to fuel the growth of the simulation software market in the forecast period 2021-2026.

Simulation Software Market Segment Analysis - By Geography

Simulation Software market in North America region held significant market share of 34% in the forecast period. Early adoption of advanced technologies in aerospace, defense and other has been increasing the demand for simulation software. In addition, the governments in the North American region are constantly focusing on innovation and investment for a greener work environment. The regulations associated with the eco-friendly work environment are becoming stringent in the region and as a result, companies are adopting simulators to test product viability before manufacturing.

In U.S. strict guidelines imposed by the Federal Aviation Administration (FAA) and Federal Aviation Regulations (FARs) regarding use of simulators for training purpose. According to new FAR regulations, Air carriers must compulsorily develop training programs using simulators that meet the upgraded requirements. Stringent regulations as such will drive the usage of simulators thereby driving simulation software in this region. According to U.S. Department of Defense, by 2022, U.S Military had committed to invest more than $11 billion for virtual, augmented and mixed reality training systems and simulator. Hence these factors drive the market growth in the forecast period 2021-2026.

Simulation Software Market Drivers

Growing advancements in simulation software

Simulation software companies are strengthening their position through mergers & acquisitions and continuously investing in research and development (R&D) activities to come up with solutions to cater to the changing requirements of customers. In addition companies such as Siemens, Rockwell, Ansys, and so on are planning to invest in advanced technologies such as artificial intelligence with a target to provide cost competitive Finite Element Analysis and Computational Fluid Dynamics products in the market in the forecast period.

In 2020 Ansys Inc. entered into a definitive agreement to acquire Lumerical Inc., which is a leading developer of photonic design and simulation tools. The acquisition will add a wide range of photonics products to the Ansys Multiphysics portfolio, providing customers with a full set of solutions to solve its next-generation product challenges.

In 2019, Altair Engineering Inc. launched a new manufacturing simulation solution for additive manufacturing, Inspire Print3D. The solution is aimed explicitly at selective laser melting (SLM).

In 2020, Kumux has launched the 2.0 version of its spectral simulation software, which allows the creation of differential lighting, beneficial to people’s health and plant growth.

In 2018, Simufact Engineering, an MSC Software company and expert in manufacturing process simulation, had launched Simufact Additive software solution for the simulation of metal additive manufacturing processes. Hence these advancements are analyzed to drive the market growth in the forecast period 2021-2026.

Growing adoption of simulation software among aerospace & defense

The aerospace & defense industry has been one of the major end users of simulation as they use modelling and simulation for numerous purposes including, training of individual soldiers, conducting joint training operations, formulating operational plans, developing doctrine and tactics, and analyzing alternative force structures, Finite Element Analysis and Computational Fluid Dynamics.

The technology fulfills critical defense needs of command, control, and communications; manpower, personnel, and training; computing and software; electronics; and manufacturing technology. These defense models and simulations vary in a broad range from components of large weapons systems through system-level to simulations of missions and battles, and so forth. Such significant applications are the major factors driving the growth of the global market in these industries.

Simulation Software Market Challenges

Data security is the major challenge for simulation software

One of the major challenges in Simulation Software is data security. Investment in data security to avoid simulation attacks is one of the major challenges faced by the simulation software companies. Simulated attacks might send fake phishing attacks to employees or attempt cyber-attack on a company’s web application firewall. High investment into data security is the major challenge companies which is hampering the growth of the market. However, the introduction of many cybersecurity tools at affordable prices is set to invest in simulation software, thereby driving the market growth.

Simulation Software Market Landscape

Software launches, acquisitions, Partnerships and R&D activities are key strategies adopted by players in the Simulation Software market. In 2020, the market of Simulation Software industry outlook has been fragmented by several companies. Simulation Software top 10 companies include Altair Engineering, Ansys, Autodesk, Bentley Systems, CPFD Software, Cybernet, Dassault Systems, Design Simulation Technologies, Mathworks, PTC, Siemens PLM Software among others.

Acquisitions/Software Launches

In 2020, PTC, Inc. launched a 3D computer-aided design software named as Creo 7.0. This software has the new abilities to put the power of artificial intelligence at the fingertips of the designers, hence making the simulation a unified part of the daily work.

#Simulation Software Market share#Simulation Software Market size#Simulation Software Market forecast

0 notes

Text

Finite Element Analysis Software

In addition to supporting fluid dynamics models, OpenFOAM simulation software has a wide range of finite element analysis features. In other words, you can use OpenFOAM to analyze structures and thermal properties of systems as well as modelling. FEA capabilities can also solve transport and electromagnetic problems.

Best software to do finite element analysis? Abaquas is the best software which i have ever seen to analysis the displacement and deformation of different nodes. Finite Element Method.

The online Finite Element Analysis software component of SimScale enables you to perform simulations of structures, including linear static and nonlinear quasi-static analyses. In a linear case with applied static loads, the structural response can be determined in a single step. All types of nonlinearities can also be taken into account.

Finite Element Analysis Software Tutorial

Finite Element Analysis Software Civil Engineering

The Finite Element (FEA) Software Market Intelligence study is a collection of authentic information and in-depth analysis of data, taking into account market trends, growth prospects, emerging sectors, challenges, and drivers that can help investors and parties stakeholders to identify the most beneficial approaches for the contemporary. and the potential market landscape. It provides essential information on current and projected market growth. It also focuses on technologies, volumes, materials, and markets along with an in-depth market analysis of the Finite Element (FEA) Software industry. The study contains a section devoted to profiling dominant companies while indicating their market shares.

RS3 (formerly RS 3) is designed for 3D analysis of geotechnical structures for civil and mining applications.Applicable for both rock and soil as a general-purpose finite element analysis program for underground excavations, tunnel and support design, surface excavation, foundation design, embankments, consolidation, groundwater seepage and more.

Subject matter experts consciously strive to analyze how some entrepreneurs manage to maintain a competitive advantage while others fail, which makes the research interesting. A quick review of realistic competitors makes the overall study much more interesting. Opportunities that help product owners evaluate their business also contribute to the overall study.

Get | Download Sample Copy @https://reportsglobe.com/download-sample/?rid=289517

Competitive landscape

The report highlights key information on company profiles, product portfolio, growth prospects, cost assessment, total revenue, revenue, market share of key regions, established companies and emerging players. The study includes a SWOT analysis of the major players in the Finite Element (FEA) Software industry market to assess their strengths, weaknesses, opportunities, and threats, and examines the internal and external environment of the company, as well as the present elements that could influence the industry growth.

The assessment also includes production and consumption rates, gross income, as well as the average product price and market shares of major players. The information collected is then broken down by regional markets, production facilities, and types of products available on the market. Other key points such as competitive analysis and trends, rate of concentration, mergers, and acquisitions, expansion tactics which are essential for starting a business in the industry have also been included in the report.

Segmentation Analysis

The report provides a comprehensive analysis of various market segments through the study of product lines, applications, major regions, and industry leaders. In addition, the report also devotes a detailed analysis of the manufacturing process to a single section which includes information gathered through primary and secondary data collection sources. The primary source of data collection is interviews with industry experts who provide accurate information about the future market scenario

Request a Discount on the report @ https://reportsglobe.com/ask-for-discount/?rid=289517

Finite Element (FEA) Software Market Segmentation:

Finite Element (FEA) Software Market, By Application (2016-2027)

Small and Medium-Sized Enterprises

Large Enterprises

Finite Element (FEA) Software Market, By Product (2016-2027)

Cloud Based

On-Premises

Major Players Operating in the Finite Element (FEA) Software Market:

Ansys

Dassault Systemes

MSC Software Corp

Siemens PLM Software

Altair Engineering

ESI Group

COMSOL

NEi Software

Regional Analysis:

The report provides information about the market area, which is further subdivided into sub-regions and countries. In addition to market share in each country and subregion, this chapter of this report also provides information on profit opportunities. This chapter of the report mentions the share and market growth rate of each region, country, and sub-region in the estimated time period.

North America (USA, Canada)

Europe (Germany, France, UK, Italy, Russia, Spain, Netherlands, Switzerland, Belgium)

Asia Pacific (China, Japan, Korea, India, Australia, Indonesia, Thailand, Philippines, Vietnam)

Middle East and Africa (Turkey, Saudi Arabia, UAE, South Africa, Israel, Egypt, Nigeria)

Latin America (Brazil, Mexico, Argentina, Colombia, Chile, Peru).

For More Information on this report, Request Inquiry @https://reportsglobe.com/product/finite-element-fea-software/

Key questions answered in the report:

What is the growth potential of the Finite Element (FEA) Software market?

Which product segment will have the lion’s share?

Which regional market will pioneer in the coming years?

Which application segment will grow sustainably?

What growth opportunities could arise in the Finite Element (FEA) Software industry in the coming years?

What are the greatest challenges that the Finite Element (FEA) Software market could face in the future?

Who are the leading companies in the Finite Element (FEA) Software market?

What are the main trends that will positively affect the growth of the market?

What are the growth strategies players are pursuing to maintain their position in the Finite Element (FEA) Software market?

Request customization of the report @https://reportsglobe.com/need-customization/?rid=289517

Customization of the Report:

Please contact us if you would like more information about the report. If you have any special requirements and would like customization, please let us know. We will then offer the report as you wish.

How Reports Globe is different than other Market Research Providers:

The inception of Reports Globe has been backed by providing clients with a holistic view of market conditions and future possibilities/opportunities to reap maximum profits out of their businesses and assist in decision making. Our team of in-house analysts and consultants works tirelessly to understand your needs and suggest the best possible solutions to fulfill your research requirements.

Our team at Reports Globe follows a rigorous process of data validation, which allows us to publish reports from publishers with minimum or no deviations. Reports Globe collects, segregates, and publishes more than 500 reports annually that cater to products and services across numerous domains.

Contact us:

Mr. Mark Willams

Account Manager

US: +1-970-672-0390

Email: [email protected]

Website: Reportsglobe.com

When engineers are performing finite element analysis to visualize the product, it will react to the real world forces like fluid flow, heat, and vibrations, they will be able to use software like finite element analysis software. These free FEA software comparison can be used for analyzing which software will be perfect for FEA analysis. Many of FEA software, free download are available and certainly open source FEA software can be used if you want to edit the codes.

Related:

CalCulix

This is a freeware that can be used for 3D structural FEA analysis. Models can be created using this software and calculations can be done after post-processing. It has an interactive 3D tool which will be able to do post and pre-processing of the models. Users will be able to get static, thermal and dynamic solutions to all the models.

Agros 2D

This freeware can be used for creating numerical solutions for the various physical fields. It will be a time-dependent nonlinear solver and can be used for steady state analysis, harmonic and transient analysis. Particles can be traced in the electromagnetic fields and it has a user-friendly pre-possessor and post-processor. It supports scripting in Python language.

Code Aster

This free software can be used for thermomechanics and structural analysis. It can be used for comparing the test and calculations are done during the analysis. The calculations can be done and it will comply with laws of physics like Moore’s law. The operators can be used for analyzing the dynamic behavior of different structures.

Finite Element Analysis Software Tutorial

Z88 Mobile – FEM FEA for Android

This Android app can be used for free to draw beam structures and for performing finite element analysis. It can be used for analyzing beams, trusses, and planes and it will be able to perform a full-featured continuum of the FEA elements such as plane stress elements and various other elements. The projects can be uploaded with Z88V14 OS and the app can be accessed in two modes namely beginner and professional. Graphical offline documentation of the analysis is possible along with online documentation. Content

Nairn FEA MPM for Mac

This free software is compatible with the Mac platform and can be used for performing advanced scientific calculations with the usage of FEA analysis and material point method calculations. The code engines that are used in this software are embedded and the main application will be visual front where all the calculations can be set up and run.

Elmer Finite Element Software for Windows

This free software is compatible with the Windows platform and is an open source software that can be used for finite element analysis and for many multi-physical problems. It can be used for obtaining the numerical solutions of the partial differential equations. It generally includes models of fluid dynamics, heat transfer, structural mechanics and much more.

FreeFem++ Most Popular Software

This freeware is a popular partial differential equation solver that can be used to solve multi-physics systems. It will be non-linear in both 2D and 3D. The problems could be based on any field like fluid structure interactions or meshes which can be manipulated in this software. You can also see Web Log Analysis Software

How to Install Finite Element Analysis Software?

Most of the finite element analysis software that is available online can be used for free to download software onto the system. The system requirements should be checked to make sure that everything is met like memory requirement, operating system, etc. After that users will be able to download the software by clicking the download link. The file can be unzipped and the installation file should be run. The software can be saved in any desired location. You can also see Swot Analysis Software

This software can be used for finite element analysis is various fields like electric currents, magnetic field, heat transfer, RF field and acoustics. Parallelization can be done with the MPI and it has an active user community. Extensive support will be provided for the different element types.

Finite Element Analysis Software Civil Engineering

Related Posts

0 notes

Text

Digital Twin Market to hold market value of USD17.42 billion by 2024 | TechSci Research

Increasing adoption of smart technology coupled with Industry 4.0 revolution is to drive the growth of global digital twin market through 2024.

According to TechSci Research report, “Global Digital Twin Market By Application, By End User Sector, By Region, Competition, Forecast & Opportunities, 2014 – 2024”, global digital twin market is expected to exhibit a CAGR of over 33% during the forecast period of 2019-2024. Digital twins are exact virtual replicas of physical products or systems. With a great potential to improve production layout and enhance the productivity of the existing system, the digital twin technology is being used in different industries. Factors such as increasing global penetration of smart technology and burgeoning demand for digital twins in manufacturing, transportation, energy & utilities, healthcare, consumer goods, agriculture and several other sectors can be attributed to the rising global digital twin market. Growing adoption of IoT, usage of connected devices and cloud platforms and high-speed networking technologies, which are used for leveraging digital twin platforms are also expected to boost services and processes are also expected to boost the global digital twin market growth. Besides, rapid deployment of SMACT (Social, Mobile, Analytics, Cloud, and Internet of Things) technologies and Industry 4.0 revolution are also expected to fuel the Global Digital Twin Market through 2024. However, vulnerability of IoT and cloud platforms to cybercrimes might restrict the global digital twin market growth.

Browse 20 market data Tables and 79 Figures spread through 172 Pages and an in-depth TOC on "Global Digital Twin Market"

https://www.techsciresearch.com/report/global-digital-twin-market/1334.html

The Global Digital Twin Market is segmented based on application type, end-user type, and region.

Based on the application type, manufacturing process planning is expected to dominate the global digital twin market through 2024, backed by its ability to provide virtual process, effective product line, 3D graphics & design and Electronic Design Automation (EDA), resource optimization, etc. During the forecast period, the market share of product design application in the global digital twin market is expected to increase with rapid deployment across various sectors.

Download Sample Report @ http://www.techsciresearch.com/sample-report.aspx?cid=1334

Customers can also request for 10% free customization on this report.

Based on the end-user, the global digital twin market can be further segmented into manufacturing, agriculture, consumer goods, transport, energy & utilities, healthcare, and others. During the forecast period, energy & utilities segment is anticipated to emerge as the fastest growing end-user segment in the global digital twin market over the forecast period owing to rising penetration of smart grids, smart analytics and IIoTs in the sector, leading to improved performance monitoring and predictive maintenance demand across energy, oil, gas and power industries, and operational efficiency. However, in 2019, manufacturing segment held the largest market share of 26.37% and is expected to continue its dominance in the coming years.

Based on the region, North America and Europe are expected to dominate the global digital twin market, largely due to the presence of tech-savvy population, and digitized businesses in the regions. However, with the growing consumerization of IT, ‘state-of-the-art’ technological innovations, rapid adoption of smart technologies and presence of competitive manufacturing hubs such as China, Japan and South Korea, digital twin market in Asia-Pacific is expected to grow expeditiously during the forecast period, backed by the presence of growing economies, increasing technological penetration and digitalization initiatives by the government, especially in developing countries like India and China.