#Flapper-nozzle

Explore tagged Tumblr posts

Text

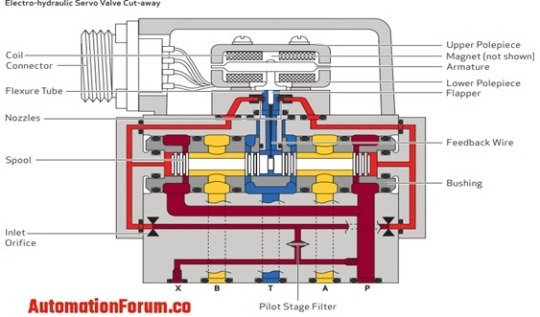

Unveiling Precision: A Guide to Electrohydraulic Servo Valve Technology

Introduction: In the realm of industrial automation and high-performance machinery, electrohydraulic servo valves (EHSVs) reign supreme. These marvels of engineering bridge the gap between electrical control signals and the potent world of hydraulics. By translating subtle electrical commands into precise hydraulic fluid motion, EHSVs empower motion control systems with unmatched accuracy and…

View On WordPress

#Digital control#Electrohydraulic servo valve technology#Feedback loop#Flapper-nozzle#Frequency response#Hydraulic actuator#Motion control system#Piezoelectric actuator#Proportional valve#Spool valve#Two-stage design

0 notes

Text

0 notes

Text

Electro Hydraulic Servo Valve Market: Trends, Applications, and Future Growth.

The Electro Hydraulic Servo Valve (EHSV) market is projected to grow from $1.6 billion in 2023 to $2.2 billion by 2032, reflecting a CAGR of 3.6% from 2024 to 2032. This growth is primarily driven by the increasing demand for precise control in sectors such as aerospace, industrial machinery, and automotive applications. EHSVs are crucial for managing fluid flow and pressure, enabling enhanced performance and reliability in advanced systems like aircraft flight controls and industrial automation.

Request Sample link:

Key Players:

YUKEN KOGYO CO., LTD

MTS Systems

Moog Inc.

Atos Spa

PARKER HANNIFIN CORP

Aviation industry AVIC Nanjing Servo Control System Co., Ltd.

Continental Hydraulics Inc.

JASC, Bosch Rexroth AG

Woodward, Inc.

Top Regional scope:

NorthAmerica

Asia Pacific

Europe

Latin America

Middle East

By Drivers, Global Electro Hydraulic Servo Valve (EHSV) Market:

When given an electric or electronic control signal, servo valves respond in a closed-loop manner to the flow or pressure. The volume, force, and direction of fluid flow are all managed by these valves. A higher level of closed-loop control is offered by servo valves than by proportional valves. In addition, one, two, or three-stage designs are offered for the servo valves. The hydraulic or pneumatic amplifier of a servo valve, which may also comprise a flapper-nozzle, jet pipe, force motor, or solenoid, is the first stage of the device. A cylindrical curtain orifice area is used in flapper nozzles to increase flow. The servo valves on the flapper nozzle will therefore aid in boosting the fluid's flow's pressure and force. Utilization will rise thanks to this feature's dynamic reaction capabilities. The oil, gas, and mining industries discovered that maintaining the flow of oil and gas through pipelines is a massive undertaking and necessitates several trustworthy tools and methods. Servo valves are the most crucial piece of gear; they are precisely built and frequently used in systems that need to be more efficient. Servo valves are thus employed in a variety of settings, including hydroelectric power plants, gas and oil mines, the regulation of fuel flow in aircraft engines, and the blow moulding or production of hollow plastic.

By Restraints, Global Electro Hydraulic Servo Valve (EHSV) Market:

Servo valves are becoming more and more essential and functional as applications grow. Pressurized hydraulic fluid, usually from a hydraulic pump, is sent to a servo valve from a source. The fluid is then carefully transferred from there to a hydraulic cylinder. The valve is a crucial part of the system since it often moves the spool in response to an electrical signal, indirectly controlling the flow rate. Global demand has been fuelled by the growing use of electro-hydraulic servo valves in the mining, oil, and aviation industries. The global electro-hydraulic servo valve market is expected to increase, but it is expected to be constrained by the high cost of electro-hydraulic valves. The filtrations must be installed, placed, and frequently maintained. There is a critical contamination tolerance limit for all hydraulic and lubricant system types. The filter establishes the level of contamination in servo valves. Filtering is required for the fluid passing through the valve. If not, it will impede the movement of the valve's other moving parts and marketability.

Read More Info Link: https://qualiketresearch.com/reports-details/Global-Electro-Hydraulic-Servo-Valve-Market

By Stage Type: • Single Stage Servo Valve • Two-Stage Servo Valve • Three-Stage Servo Valve

By Valve Type: • Nozzle Flapper Valve • Jet Pipe Servo Valve • Deflector Jet • Others

Contact Us:

6060 N Central Expy #500 TX 75204, U.S.A

+1 214 660 5449

1201, City Avenue, Shankar Kalat Nagar,

Wakad, Pune 411057, Maharashtra, India

+91 9284752585

Sharjah Media City , Al Messaned, Sharjah, UAE.

+91 9284752585

0 notes

Text

0 notes

Text

Electro Hydraulic Servo Valve Market - Forecast(2024 - 2030)

Electro-Hydraulic Servo Valve Market Overview:

Electro-Hydraulic Servo Valve Market size is forecast to reach $1.42 Billion by 2030, after growing at a CAGR of 3.35% during 2024-2030. This growth is driven by the Electro Hydraulic Servo Valve market is experiencing a trend toward intelligent and interconnected valves. These valves integrate advanced sensors, data analytics, and communication features, enabling real-time monitoring, predictive maintenance, and remote control. This shift towards smart valves enhances operational efficiency and minimizes downtime for industries. With increasing automation and connectivity demands, the demand for intelligent Electro Hydraulic Servo Valves is on the rise, reflecting a significant market trend.

Additionally, material science advancements and miniaturization are pivotal trends shaping the Electro Hydraulic Servo Valve (EHSV) market. Manufacturers are leveraging innovations to enhance the durability, corrosion resistance, and thermal stability of EHSVs. Moreover, there's a growing emphasis on miniaturization to cater to compact, lightweight systems demanded by portable devices, robotics, and space-constrained environments. This trend towards optimized materials and smaller sizes reflects the evolving landscape of EHSVs, driving market progression. As technology continues to evolve, these developments underscore the industry's commitment to innovation and efficiency.

Electro-Hydraulic Servo Valve Market - Report Coverage:

The “Electro Hydraulic Servo Valve Market Report - Forecast (2024-2030)” by IndustryARC, covers an in-depth analysis of the following segments in the Electro Hydraulic Servo Valve Market.

By Product Stage: Single Stage, Double Stage and Others.

By Type: Nozzle Flapper Valve, Jet Action Valve, Dynamic Valve, Deflector jet valve, and Others.

By End-Use Industry: Industrial, Marine, Aerospace & Defense, Construction Sector, Oil & Gas and Others

By Geography: North America, South America, Europe, APAC, and RoW.

Request Sample

COVID-19 / Ukraine Crisis - Impact Analysis:

• The COVID-19 pandemic had a significant impact on the electro-hydraulic servo valve market, affecting both supply and demand. Disruptions in manufacturing and supply chains led to delays in production and delivery of these critical components, causing ripple effects across industries reliant on hydraulic systems. Reduced demand from sectors like aerospace, automotive, and industrial machinery further compounded the challenges faced by servo valve manufacturers. However, the pandemic also spurred innovation, with companies exploring remote monitoring and control solutions to address operational challenges. Additionally, the increased focus on automation and efficiency in response to the pandemic could drive long-term growth in the adoption of electro-hydraulic servo valves, particularly in industries prioritizing safety, reliability, and precision in their hydraulic systems.

• The Russia-Ukraine crisis has impacted the electro-hydraulic servo valve market due to disruptions in the supply chain and geopolitical tensions affecting trade relations. Ukraine is a significant producer of precision engineering components, including parts used in electro-hydraulic servo valves. Any disturbance in the region can lead to delays or shortages in raw materials and components crucial for manufacturing these valves. Moreover, increased uncertainty and instability can dampen investor confidence, affecting investment decisions in industries that heavily rely on electro-hydraulic servo valves, such as aerospace, defense, and industrial sectors. Furthermore, sanctions or trade restrictions imposed as a result of the crisis may exacerbate supply chain disruptions, leading to price volatility and increased production costs for manufacturers, thereby impacting the overall market dynamics.

Key Takeaways:

• North America is witnessing remarkable growth in the electro-hydraulic servo valve market due to its flourishing aerospace, defense, and industrial sectors. The region's stringent quality standards and technological advancements drive the demand for precise control systems, where electro-hydraulic servo valves excel. Moreover, the presence of key market players and ongoing research and development initiatives contribute to innovation and product enhancements, further fueling market expansion. Additionally, supportive government policies and investments in defense and infrastructure bolster the region's position as the highest-growing market for electro-hydraulic servo valves.

• The single-stage electro-hydraulic servo valve segment is witnessing the highest growth in the market due to several factors. Single-stage valves offer simplified design, cost-effectiveness, and ease of integration compared to multi-stage counterparts. Technological advancements have enhanced their precision and reliability, meeting stringent industry requirements. Additionally, the demand for compact, lightweight solutions in industries like aerospace, defense, and industrial automation favors single-stage valves. Moreover, applications requiring rapid response and precise control, such as robotics, further drive the growth of this segment, making it a key driver in the market's expansion.

• The nozzle flapper valve is emerging as the fastest-growing type in the electro-hydraulic servo valve market due to its exceptional precision and responsiveness. Leveraging a nozzle and flapper mechanism, these valves offer superior fluid flow control, ensuring accurate positioning in critical applications like aerospace, defense, and industrial sectors. Their rapid response times, enhanced accuracy, and compact design make them increasingly favored over traditional valves. With rising demand for precise motion control systems, particularly in automated industries, the market for nozzle flapper valves is poised for significant growth, presenting lucrative opportunities for manufacturers and suppliers.

Inquiry Before Buying

Electro-Hydraulic Servo Valve Market Segment Analysis – By Product

In the electro-hydraulic servo valve market, the single-stage valve is experiencing the highest growth trajectory with a CAGR of 4.5% during the forecast period 2024-2030. This surge can be attributed to several factors. Firstly, single-stage valves offer simplified design and operation compared to multi-stage valves, making them more cost-effective and easier to integrate into various systems. Secondly, advancements in technology have enabled single-stage valves to achieve high levels of precision and reliability, meeting the stringent requirements of industries such as aerospace, defense, and industrial automation. Thirdly, the increasing demand for compact and lightweight solutions across industries has favored the adoption of single-stage valves, which typically have a smaller footprint and lower weight compared to multi-stage counterparts. Additionally, the rise of applications requiring rapid response times and precise control, such as in robotics and autonomous vehicles, has further propelled the growth of single-stage electro-hydraulic servo valves. Overall, the combination of technological advancements, cost-effectiveness, and growing application areas positions single-stage valves as a key driver of growth in the electro-hydraulic servo valve market.

Electro-Hydraulic Servo Valve Market Segment Analysis – By Type

Nozzle flapper valves are experiencing rapid growth in the electro-hydraulic servo valve market with a CAGR of 4.9% during the forecast period 2024-2030 due to their superior performance and efficiency in various applications. These valves offer precise control over fluid flow by utilizing a nozzle and a flapper mechanism, allowing for highly responsive and accurate operation. Compared to traditional valves, nozzle flapper valves boast faster response times, enhanced accuracy, and improved reliability, making them ideal for applications requiring precise positioning and control, such as aerospace, defense, and industrial sectors. Additionally, advancements in manufacturing technologies have enabled the production of nozzle flapper valves with higher efficiency and reduced maintenance requirements, further driving their adoption. Moreover, increasing demand for automation and robotics across industries has fueled the need for advanced motion control systems, thereby propelling the growth of nozzle flapper valves. Their compact size, lightweight design, and compatibility with digital control systems make them well-suited for integration into modern machinery and equipment. As a result, the market for nozzle flapper valves is expected to continue its upward trajectory, offering lucrative opportunities for manufacturers and suppliers in the electro-hydraulic servo valve industry.

Electro-Hydraulic Servo Valve Market Segment Analysis – By End-Use Industry

The aerospace and defense industry stands out as one of the highest-growing end-use sectors in the electro-hydraulic servo valve market with a CAGR of 5.3% during the forecast period 2024-2030. Electro-hydraulic servo valves play a critical role in flight control systems, missile guidance systems, and other aerospace and defense applications, where precision, reliability, and rapid response are paramount. With the increasing demand for military aircraft, unmanned aerial vehicles (UAVs), and commercial airliners equipped with advanced flight control systems, the need for high-performance electro-hydraulic servo valves is escalating. Furthermore, the development of next-generation fighter jets, space exploration vehicles, and sophisticated missile defense systems necessitates cutting-edge hydraulic control technologies, thereby driving the demand for electro-hydraulic servo valves. Additionally, ongoing modernization initiatives by defense agencies worldwide, coupled with the growing investments in commercial aviation infrastructure, contribute to the robust growth of this market segment. As aerospace and defense applications continue to evolve, the electro-hydraulic servo valve market is poised to witness sustained growth, with manufacturers focusing on innovation and technological advancements to meet the stringent performance requirements of this industry.

Schedule a Call

Electro-Hydraulic Servo Valve Market Segment Analysis – By Geography

North America stands out as one of the dominant markets in the electro-hydraulic servo valve sector with a market share of 34% in 2023 due to several factors. Firstly, the region's robust aerospace and defense industries, driven by technological advancements and military modernization programs, demand highly precise and reliable control systems, where electro-hydraulic servo valves play a vital role. Secondly, the increasing adoption of automation and robotics in various industrial applications across sectors like automotive, manufacturing, and healthcare further fuels the demand for electro-hydraulic servo valves. Thirdly, the presence of major market players and technological innovators in North America fosters continuous research and development, leading to the introduction of advanced valve solutions catering to diverse industry needs. Additionally, favorable government initiatives supporting infrastructure development and investments in defense and aerospace sectors contribute to the region's growth. With these factors combined, North America emerges as a dynamic and rapidly expanding market for electro-hydraulic servo valves, poised for sustained growth in the foreseeable future.

Electro-Hydraulic Servo Valve Market Drivers

Increasing adoption of industrial robots globally

The increasing adoption of industrial robots globally is driving growth in the electro-hydraulic servo valve market. Industrial robots rely on precise hydraulic control systems to execute tasks with accuracy and efficiency across various industries. With the rise of automation and Industry 4.0 initiatives, industries such as automotive manufacturing, metalworking, and electronics assembly are increasingly integrating robots into their production processes to improve productivity and flexibility. Electro-hydraulic servo valves play a crucial role in controlling the movement and force of these robots, enabling precise and smooth operations. According to the International Federation of Robotics (IFR), global sales of industrial robots reached a record high in recent years, indicating a growing demand for automation solutions. This trend is expected to continue, further fuelling the demand for electro-hydraulic servo valves in the market.

High acceptance of smart control which uses an electro-hydraulic servo valve

The growing acceptance of smart control systems is emerging as a significant market driver for electro-hydraulic servo valves. Smart control technologies, integrating advanced sensors, actuators, and feedback mechanisms, enhance the precision, efficiency, and performance of hydraulic systems. Electro-hydraulic servo valves play a pivotal role in these systems, providing precise and dynamic control over fluid flow and pressure. Industries such as aerospace, automotive, and manufacturing are increasingly adopting smart control solutions to optimize operations, reduce energy consumption, and improve productivity. For instance, in aerospace applications, smart control systems utilizing electro-hydraulic servo valves enable aircraft to achieve greater manoeuvrability and fuel efficiency. Moreover, the rise of industry 4.0 initiatives and the Internet of Things (IoT) is driving the demand for intelligent hydraulic systems, further bolstering the growth of the electro-hydraulic servo valve market.

Buy Now

Electro-Hydraulic Servo Valve Market Challenges

High costs associated with electro-hydraulic servo valves

High costs associated with electro-hydraulic servo valves present a significant market challenge. These valves incorporate precision engineering, advanced materials, and complex manufacturing processes, leading to inherently high production costs. Additionally, stringent quality standards and regulatory requirements further escalate expenses for manufacturers. The aerospace, defense, and industrial sectors, major consumers of electro-hydraulic servo valves, are often cost-sensitive industries, necessitating competitive pricing. Moreover, customers increasingly demand cost-effective solutions without compromising performance or reliability, adding pressure on manufacturers to optimize production processes and reduce costs. Furthermore, the emergence of alternative technologies, such as electromechanical actuators, poses a threat to the market dominance of electro-hydraulic servo valves. To address this challenge, manufacturers are investing in research and development to innovate cost-effective solutions while maintaining quality standards to remain competitive in the market.

Market Landscape

Product/Service launches, approvals, patents and events, acquisitions, partnerships, and collaborations are key strategies adopted by players in the Electro Hydraulic Servo Valve Market. The top 10 companies in this industry are: Moog, Inc., Eaton Corporation, Honeywell International, Inc, Parker Hannifin Corp, Woodward, Inc, Voith GmbH & Co. KGaA, Bosch Rexroth AG, Schneider Servohydraulics GmbH, HAEW Hydraulik SE, Oligear Co.

Developments:

Moog Inc. in September 2022, launched their new X700 Series servo cartridge valves aimed at the high-end segment of the Electro Hydraulic Servo Valve Market. The key feature of this new series is a robust design that allows for a maximum main-stage operating pressure of 420 bar. This increased pressure capability potentially expands Moog's offerings in the market for high-performance applications.

In February 2022, HAEW Hydraulik introduced its latest innovation, the OSCA load-holding screw-in valve. Designed to resist dirt and debris, this valve boasts a remarkable pressure tolerance of up to 500 bar. HAEW's cutting-edge technology ensures enhanced durability and reliability, catering to demanding industrial applications. This launch underscores HAEW's commitment to delivering high-performance hydraulic solutions, addressing industry needs for robust and efficient components.

#Electro Hydraulic Servo Valve Market#Electro Hydraulic Servo Valve Market size#Electro Hydraulic Servo Valve industry#Electro Hydraulic Servo Valve Market share#Electro Hydraulic Servo Valve top 10 companies#Electro Hydraulic Servo Valve Market report#Electro Hydraulic Servo Valve industry outlook

0 notes

Text

Electro Hydraulic Servo Valve Market - Forecast (2024 - 2030)

Electro Hydraulic Servo Valve Market Overview

The market size for Electro Hydraulic Servo Valve is analyzed to be USD $1,42 Billion in 2021. It is further projected to grow at a CAGR of 3.35% during the forecast period 2022-2027. A hydraulic servo valve is a device that controls position, velocity, pressure or force in a machine or device by maneuvering the flow of fluid (oils) in response to an electrical input signal or command (usually through a piston or cylinder). Closed-loop control devices, servo valves can be single-stage, two-stage or three-stage designs. Moreover, the growth in the aerospace and defense industry would eventually boost the demand for Electro-Hydraulic Servo Valve. EHSVs have a range of applications in the aerospace and defense industry vertical including three-and four-way flow and pressure control, fuel monitoring, actuator position control, flight critical applications, thermal management, over-speed protection, thrust vector nozzle actuation and more. According to a report by the IBEF, Indian aviation markets have witnessed a growing demand for large aircraft from key players including Spicejet, Indigo and more. Additionally, the increasing military and defense expenditure by governments are analyzed to positively aid the underlying market. India’s defense budget for 2020-2021 stood at $67.4 Billion, which is 9.3% higher than 2019-2020. Factors like these are driving the growth of the Electro Hydraulic Servo Valve market.

Report Coverage

The report: “Electro Hydraulic Servo Valve Market – Forecast (2022-2027)” by IndustryARC, covers an in-depth analysis of the following segments in the Electro Hydraulic Servo Valve market.

By Product: Single Stage, Double Stage and Others.

By Type: Nozzle Flapper Valve,Jet Action Valve, Dynamic Valve, Deflector jet valve and Others.

By Application: Industrial, Marine, Aerospace & Defense, Construction Sector, Oil and Others.

By Geography: North America (the U.S., Canada and Mexico), South America (Argentina, Brazil, Chile, Colombia and the Rest of South America), Europe (Belgium, Denmark, France, Germany, Italy, the Netherlands, Spain, the UK and the Rest of Europe), Asia Pacific (Australia, China, India, Japan, Malaysia, South Korea, Taiwan and the Rest of Asia Pacific) and the RoW (Israel, Nigeria, Saudi Arabia, South Africa, the UAE, the Rest of Africa and the Rest of the Middle East).

#Electro Hydraulic Servo Valve Market price#Electro Hydraulic Servo Valve Market size#Electro Hydraulic Servo Valve Market share

0 notes

Text

Global Electro Hydraulic Servo Valve Market Size, Trends and Growth Opportunity By Region and forecast till 2030. Global Electro Hydraulic Servo Valve Market was valued at USD 1,669.82 million in 2022 and is slated to reach USD 2661.64 million by 2030 at a CAGR of 5.2% from 2023-2030.

Overview

The report contains a thorough study of the global ELECTRO HYDRAULIC SERVO VALVE market. It has successfully pointed out the key factors that have substantial impact on the ELECTRO HYDRAULIC SERVO VALVE market. This report is based on result of a well-planned research methodology. The methodology employed both primary and secondary research tools. These tools aid the researchers to collect authentic data and arrive at a definite conclusion. The prevailing competitors in the global ELECTRO HYDRAULIC SERVO VALVE market has also been portrayed in the report, offering an opportunity to the market players to gauge their performance. The report has been prepared after studying the different parameters ruling the global ELECTRO HYDRAULIC SERVO VALVE market and the forecast period has been estimated from ELECTRO HYDRAULIC SERVO VALVE-ELECTRO HYDRAULIC SERVO VALVE. The forecast period is the time period when the key driving factors and parameters will help the market to flourish significantly. The estimated value of the market has been represented through a Compound Annual Growth Rate percentage (CAGR %). In addition to that, the report represents the approximate revenue which can be generated over the forecast period. However, the report has also outlined the factors that can slowdown the growth of the global ELECTRO HYDRAULIC SERVO VALVE market.

Key Drivers

The report includes the key driving forces prevailing in the global ELECTRO HYDRAULIC SERVO VALVE market. This part of the report has been studied keeping in mind the political, economic, social, technological, geographical, and cultural scenario of the global ELECTRO HYDRAULIC SERVO VALVE market. These factors can be projected to have their effects on the market, or they can have interconnected impacts. Besides, subtle change in the timeframe within which these factors are functioning might have ripple effects on the global ELECTRO HYDRAULIC SERVO VALVE market.

Regional Description

Global ELECTRO HYDRAULIC SERVO VALVE market has been segmented into Europe, the Americas, Asia Pacific, and the Middle East & Africa. This part of the report provides an exhaustive view of the regional scope existing in the global ELECTRO HYDRAULIC SERVO VALVE market. The recent market trends and preferences dominating each region have a direct impact on the industries. The report tries to exploit the recent trends and preferences prevailing in a region to provide the users with a clear picture of the business potential existing in that region.

Research Methodology

The primary research procedure is based on results of face to face interviews with industry experts and consumers. The secondary research process includes an intricate study of the scholarly journals and reports available online.

Request A Free Sample: https://qualiketresearch.com/reports-details/Global-Electro-Hydraulic-Servo-Valve-Market

Market Segmentation

Global Electro Hydraulic Servo Valve Market is segmented into Stage Types, Valve Types, LPM Types, and Applications. By Stage Types such as Single Stage Servo Valve, Two Stage Servo Valve, Three Stage Servo Valve. By Valve Types such as Nozzle Flapper Valve, Jet Pipe Servo Valve, Deflector Jet, and Others. By LPM Types such as Less Than 20 LPM, and More Than 20 LPM. By Applications such as Aerospace, Power Industry, Steel Industry, Chemical Industry, Oil & Gas, Marine Industry, Construction Industry, Healthcare, and Others.

Regional Analysis

Global Electro Hydraulic Servo Valve Market is segmented into five regions Americas, Europe, Asia-Pacific, and the Middle East & Africa. In light of the increasing usage of electro-hydraulic drive control systems in the aerospace and marine industries, North America dominates the electro-hydraulic servo valve market. In the market for electro-hydraulic servo valves, the United States is a market leader since it is home to several significant market participants. Due to growing activity in hydraulic control system R&D and technological advancements, Germany currently dominates the European continent. Because of the growing adoption of automation in manufacturing and industrial robotics, China leads the Asia-Pacific area.

Key Players

This report includes a list of numerous Key Players, namely YUKEN KOGYO CO., LTD, MTS Systems, Moog Inc., Atos Spa, PARKER HANNIFIN CORP, Aviation industry AVIC Nanjing Servo Control System Co., Ltd., Continental Hydraulics Inc., JASC, Bosch Rexroth AG, Woodward, Inc.,

About Us:

QualiKet Research is a leading Market Research and Competitive Intelligence partner helping leaders across the world to develop robust strategy and stay ahead for evolution by providing actionable insights about ever changing market scenario, competition and customers.

QualiKet Research is dedicated to enhancing the ability of faster decision making by providing timely and scalable intelligence.

QualiKet Research strive hard to simplify strategic decisions enabling you to make right choice. We use different intelligence tools to come up with evidence that showcases the threats and opportunities which helps our clients outperform their competition. Our experts provide deep insights which is not available publicly that enables you to take bold steps.

Contact Us:

6060 N Central Expy #500 TX 75204, U.S.A

+1 214 660 5449

1201, City Avenue, Shankar Kalat Nagar,

Wakad, Pune 411057, Maharashtra, India

+91 9284752585

Sharjah Media City , Al Messaned, Sharjah, UAE.

+91 9284752585

0 notes

Text

The Evolution and Variety of Toilet Mississauga Flushing Mechanisms

Toilets Mississauga is a staple in homes and buildings worldwide, and while they may seem simple, they actually come with a variety of flushing mechanisms. The evolution of these mechanisms mirrors advancements in engineering and technology, each serving to cater to specific requirements ranging from water conservation to powerful flush capabilities. Let's delve into six of the most prominent types.

Gravity-Feed Flush

Perhaps the most traditional and widespread, gravity-feed toilets rely on the basic principle of gravity to remove waste. A flush valve opens to release the water stored in the tank, and this water rushes down to the bowl, creating a siphon effect that pulls the waste down and out. The simplicity of this design makes it durable and requires less maintenance.

Pressure-Assisted Flush

In pressure-assisted toilets, air is compressed in a sealed inner tank. When flushed, this compressed air pushes the water into the bowl at a higher force than a gravity-feed system. The advantage is a more powerful flush which reduces the chance of clogs. While louder than other types, they tend to be more water-efficient.

Dual-Flush Mechanism

Introduced as a water conservation initiative, dual-flush toilets Mississauga give users the choice between two flushing options – one for liquid waste and another for solid waste. A partial flush uses less water, typically around half the volume of a full flush. This not only conserves water but also reduces the water bills for homeowners.

Double Cyclone Flush

Inspired by the dynamics of a tornado, the double cyclone flush uses two nozzles instead of rim holes, creating a stronger centrifugal, swirling action that cleans the bowl and leads to a more effective flush. Not only does it provide efficient cleaning, but it also uses less water compared to traditional flushing mechanisms.

Tower-Style Flush Valve

The tower-style or canister flush valve offers a 360-degree opening, allowing water to flow into the bowl from all sides. This leads to a more consistent and powerful flush. One of the advantages of this design is that it has fewer parts than the traditional flapper mechanism, reducing the chances of leaks and maintenance.

Wall-Hung Toilets with In-Wall Tanks

A modern innovation, wall-hung toilets Mississauga is mounted on the wall, saving floor space and offering a sleek design. The flushing mechanism and tank are concealed within the wall. A push plate, accessible from the outside, operates the flush. These systems often incorporate dual-flush technology, combining aesthetic appeal with water conservation.

From the basic gravity-feed system to the technologically advanced double cyclone, toilet flushing mechanisms have evolved to meet the changing needs and preferences of consumers. Whether prioritizing water conservation, seeking a powerful flush, or aiming for design aesthetics, there's a mechanism out there to suit every bathroom. As technology continues to advance, we can anticipate further innovations, making our bathroom experiences even more efficient and environmentally friendly.

0 notes

Text

Why your toilet flushes slowly - and how to fix it

Low water level

One of the most common reasons why a toilet doesn't flush properly is because the water level in the tank is too low. If there is not enough water in the tank when the toilet flushes, the flushing performance of the toilet is greatly reduced because there is only a limited amount of force flowing into the toilet. Without enough water, some of the waste will likely not flush, so you will have to wait for the tank to refill to flush the toilet again.

Partially clogged drain

A clogged toilet is usually easy to spot, and most people know how to unclog it with a plunger and push it through the drain. If a partially clogged drain is the cause of your slow-flushing toilet, there are several methods you can try to clear the clog and restore flushing performance.

One of the first ways is to simply plunge the toilet. Often the force of the plunger is enough to clear clogs or partial clogs, but if that doesn't work, you should use a drain snake. Items like children's toys, dental floss, wipes and more can get stuck in the drain line. So if you don't have a chance to clear the clog, it may be time to contact a plumber to clear the clog.

Mineral deposits

Water mainly flows from the tank into the bowl through the nozzle holes on the underside of the toilet rim. However, due to the small size of these holes, they can become clogged or partially blocked, reducing the power of the flush. If you live in an area with hard water or the toilet is several years old, minerals such as calcium or magnesium can build up in these nozzle holes and impede the flow of water.

Defective flapper or flush valve

Problems with a slow-flushing toilet can sometimes be traced to the flapper and flush valve. These parts are located in the toilet tank and are responsible for allowing water to flow from the tank into the bowl. The flush valve assembly consists of an overflow pipe, a lever, a chain, a flapper, and the flush valve opening in the bottom of the tank. When the lever or button on the toilet is pressed, the flush valve is activated and the flapper opens, allowing water to flow from the tank into the toilet bowl.

Call the Emergency Plumber in Sandwell. After your call, our Customer Service sends immediately a plumber to you to fix the problem. Call us whenever you want, 01217900198.

0 notes

Photo

Artūras Tamašauskas created this dragster (Bolid).

The main details:

A saxophone;

A mark of the car “Volga“;

The corps of a bicycle lamp;

A trumpet flapper;

A curtain nozzle;

The wheels of a childish carriage.

#Arturas Tamasauskas#steampunk sculpture#steampunk car#fine art#steampunk depot#steampunk depot#steampunk#steampunkstyle#cosplay#steampunkart#victorian#neo victorian#fantasy

2 notes

·

View notes

Text

Global Electro Hydraulic Servo Valve Market Outlook and Forecast till 2023-2030.

According to Qualiket Research, the global Global Electro Hydraulic Servo Valve Market was valued at USD 1,669.82 million in 2022 and is slated to reach USD 2661.64 million by 2030 at a CAGR of 5.2% from 2023-2030.An electrically controlled valve that regulates the fluid flow to the actuator is called an electro-hydraulic servo valve. The system is closed-looped, which allows for perfect control of the output in this device. In many fields, such as astronomy, navigation, aviation, and military gear, electro-hydraulic servo valves are employed. This is a result of their benefits, which include rapid response times, a high degree of control precision, compact volumes, lightweight, and great load variation immunity. The performance and dependability of the complete servo control system are directly and significantly impacted by the electro-hydraulic servo valve, one of the most failure-prone parts.

Request Sample Link:

Drivers:

When given an electric or electronic control signal, servo valves respond in a closed-loop manner to the flow or pressure. The volume, force, and direction of fluid flow are all managed by these valves. A higher level of closed-loop control is offered by servo valves than by proportional valves. In addition, one, two, or three-stage designs are offered for the servo valves. The hydraulic or pneumatic amplifier of a servo valve, which may also comprise a flapper-nozzle, jet pipe, force motor, or solenoid, is the first stage of the device. A cylindrical curtain orifice area is used in flapper nozzles to increase flow. The servo valves on the flapper nozzle will therefore aid in boosting the fluid's flow's pressure and force. Utilization will rise thanks to this feature's dynamic reaction capabilities. The oil, gas, and mining industries discovered that maintaining the flow of oil and gas through pipelines is a massive undertaking and necessitates several trustworthy tools and methods. Servo valves are the most crucial piece of gear; they are precisely built and frequently used in systems that need to be more efficient. Servo valves are thus employed in a variety of settings, including hydroelectric power plants, gas and oil mines, the regulation of fuel flow in aircraft engines, and the blow moulding or production of hollow plastic.

Restraint:

Servo valves are becoming more and more essential and functional as applications grow. Pressurized hydraulic fluid, usually from a hydraulic pump, is sent to a servo valve from a source. The fluid is then carefully transferred from there to a hydraulic cylinder. The valve is a crucial part of the system since it often moves the spool in response to an electrical signal, indirectly controlling the flow rate. Global demand has been fuelled by the growing use of electro-hydraulic servo valves in the mining, oil, and aviation industries. The global electro-hydraulic servo valve market is expected to increase, but it is expected to be constrained by the high cost of electro-hydraulic valves. The filtrations must be installed, placed, and frequently maintained. There is a critical contamination tolerance limit for all hydraulic and lubricant system types. The filter establishes the level of contamination in servo valves. Filtering is required for the fluid passing through the valve. If not, it will impede the movement of the valve's other moving parts and marketability.

Key players:

YUKEN KOGYO CO., LTD

MTS Systems, Moog Inc.

Atos Spa

PARKER HANNIFIN CORP

Aviation industry AVIC Nanjing Servo Control System Co., Ltd.

Continental Hydraulics Inc.

JASC

Bosch Rexroth AG

Woodward, Inc

Get More Information Link:

Contact Us:

6060 N Central Expy #500 TX 75204, U.S.A

+1 214 660 5449

1201, City Avenue, Shankar Kalat Nagar,

Wakad, Pune 411057, Maharashtra, India

+91 9284752585

Sharjah Media City , Al Messaned, Sharjah, UAE.

+91 9284752585

0 notes

Link

0 notes

Text

Making process control valve choices

Today’s process control valves offer an ever wider range of features and benefits for industries that require precise control over fluids, steam and other gases. With so many control valves to choose from it is important to establish the features that will deliver the most cost-effective design for a particular application.

Control valves are used to manage the flow rate of a liquid or a gas and in-turn control the temperature, pressure or liquid level within a process. As such, they are defined by the way in which they operate to control flow and include globe valves, angle seat, diaphragm, quarter-turn, knife and needle valves, to name a few. In most cases the valve bodies are made from metal; either brass, forged steel or in hygienic applications 316 stainless steel.

Actuators will use an on-board system to measure the position of the valve with varying degrees of accuracy, depending on the application. A contactless, digital encoder can place the valve in any of a thousand positions, making it very accurate, while more rudimentary measurements can be applied to less sensitive designs.

One of the main areas of debate when specifying globe control valve is determining the size of the valve required. Often process engineers will know the pipe diameter used in an application and it is tempting to take that as the control valve’s defining characteristic. Of greater importance are the flow conditions within the system as these will dictate the size of the orifice within the control valve. The pressure either side of the valve and the expected flow rate are essential pieces of information when deciding on the valve design.

Inside the valve body, the actuator design is often either a piston or a diaphragm design. The piston design typically offers a smaller, more compact valve which is also lighter and easier to handle than the diaphragm designs. Actuators are usually made from stainless steel or polyphenolsulpide (PPS), which is a chemically-resistant plastic. The actuator is topped off by the control head or positioner.

Older, pneumatically operated positioners had a flapper/nozzle arrangement and operated on 3-15psi, so no matter what the state of the valve, open closed or somewhere in between, the system was always expelling some compressed air to the atmosphere.

Compressed air is an expensive commodity, requiring considerable energy to generate and when a manufacturing line is equipped with multiple process control valves all venting to the atmosphere, this can equate to a considerable waste of energy. It is important to not only establish the most appropriate valve design, but also a cost-effective solution that takes account of annual running costs.

Modern, digital, electro-pneumatic valves that use micro-solenoid valves to control the air in and out of the actuator have introduced significant improvements for operators. This design means that while the valve is fully open, fully closed or in a steady state, it is not consuming any air. This, and many other engineering improvements, have made substantial advances in both economy and precision.

Flexible designs

Valve seats can be interchangeable within a standard valve body, which allows the valve to fit existing pipework and the valve seat to the sized to the application more accurately. In some cases, this can be achieved after the valve has been installed, which would enable a process change to be accommodated without replacing the complete valve assembly.

Selecting the most appropriate seal materials is also an important step to ensure reliable operation; Steam processes would normally use metal-to-metal seals, whereas a process that included a sterilization stage may require chemically resistant seals.

Setting up and installing a new valve is now comparatively easy and much less time-consuming. In-built calibration procedures should be able perform the initial setup procedures automatically, measuring the air required to open and close the valve, the resistance of the piston seals on the valve stem and the response time of the valve itself.

Improving safety

Control valves should be specified so they operate in the 40-85% range so if the valve is commanded to a 10% setting, it can detect if something has potentially gone wrong with the control system and the best course of action is to close the valve completely. If the valve is commanded to a position of 10% or less this can cause very high fluid or gas velocities, which have damaging effects on the system and cause considerable noise and damage to the valve itself.

Modern control functionality can offer a solution that acts as a safety device to prevent damage to the process pipework and components. By building in a fail-safe mechanism, any valve position setting below a pre-set threshold will result in the valve closing completely, preventing damage to the surrounding system.

Control inputs can also include safety circuits to ensure safe operating conditions within the process equipment. For example, if an access panel on a vessel containing steam is opened, an interlock switch will open and the valve controlling the steam supply to the vessel can be automatically closed, helping mitigate any risks.

Improving reliability

Many process control environments offer less than ideal conditions for long-term reliability. Moisture-laden atmospheres, corrosive chemicals and regular wash-downs all have the capacity to shorten the service life of a process Self regulating control valve. One of the potential weaknesses of the actuator is the spring chamber where atmospheric air is drawn in each time the valve operates.

One solution is to use clean, instrument air to replenish the spring chamber, preventing any contamination from entering. This offers a defense against the ingress of airborne contaminants by diverting a small amount of clean control air into the control head, maintaining a slight positive pressure, thus achieving a simple, innovative solution. This prevents corrosion of the internal elements and can make a significant improvement to reliability and longevity in certain operating conditions.

While choosing the most appropriate process control valve can be a complex task, it is often best achieved with the assistance of expert knowledge. Working directly with manufacturers or knowledgeable distributors enables process control systems to be optimized for long-term reliability as well as precision and efficiency.

Damien Moran is field segment manager, Hygienic – Pharmaceutical at Bürkert. This article originally appeared on the Control Engineering Europe website. Edited by Chris Vavra, associate editor, Control Engineering, CFE Media and technology, [email protected].

Control valves are generally present whenever fluid flow regulation is required. The three way and angle control valve reliability is critical to the control quality and safety of a plant. An improved dynamic and static valve behaviour would have a major impact on the process output. In order to assess the dynamic performance of the control valve, a computer model of an electro-hydraulic control valve is developed. And the control valve characteristics are investigated through the use of mathematical simulations of the control valve dynamic performance. The results show that the electro-hydraulic driven control valve, which is developed to regulate the mixed-gas pressure in combined cycle power plant, can meet the challenge of the gas turbine.

Control valves play important roles in the control of the mixed-gas pressure in the combined cycle power plants (CCPP). In order to clarify the influence of coupling between the structure and the fluid system at the control valve, the coupling mechanism was presented, and the numerical investigations were carried out. At the same operating condition in which the pressure oscillation amplitude is greater when considering the coupling, the low-order natural frequencies of the plug assembly of the valve decrease obviously when considering the fluid-structure coupling action. The low-order natural frequencies at 25% valve opening, 50% valve opening, and 75% valve opening are reduced by 11.1%, 7.0%, and 3.8%, respectively. The results help understand the processes that occur in the valve flow path leading to the pressure control instability observed in the control valve in the CCPP.

1. Introduction

The steel mills generate vast amounts of blast furnace gas (BFG) and coke-oven gas (COG) in the production. In order to reduce the environmental pollution, some steel mills mix BFG with COG and build combined cycle power plants (CCPP) to make use of the gas [1]. For the normal operation of CCPP, the pressure of mixed gas delivered to the gas turbine should be kept in a steady range.

In CCPP, control valves play important roles in the control of the mixed-gas pressure. The signal of mixed-gas pressure measured using the pressure meter is compared to the signal of the desired pressure by the controller. The controller output accordingly adjusts the opening/closing actuator of the control valve in order to maintain the actual pressure close to the desired pressure. The opening of the control valve depends on the flow forces and the driving forces of the control-valve actuator, while the flow forces and the driving forces are affected by the valve opening. Therefore, there is strong coupling interaction between the fluid and the control valve structure.

According to Morita et al. (2007) and Yonezawa et al. (2008), the typical flow pattern around the Knife Gate Valve is transonic [2, 3]. When pressure fluctuations occur, large static and dynamic fluid forces will act on the valves. Consequently, problematic phenomena, such as valve vibrations and loud noises, can occur, with the worst cases resulting in damage of the valve plug and seal [4]. In order to understand the underlying physics of flow-induced vibrations in a steam control valve head, experimental investigations described by Yonezawa et al. (2012) are carried out. Misra et al. (2002) reported that the self-excited vibration of a piping system occurs due to the coincidence of water hammer, acoustic feedback in the downstream water piping, high acoustic resistance at the control valve, and negative hydraulic stiffness at the control valve [5]. Araki et al. (1981) reported that the steam control-valve head oscillation mechanism was forced vibration, while self-excited vibration was not observed [6].

Those studies cited previously are mainly aimed at the modeling of the self-excited vibration, the analysis of vibration parameters stability, and so on [7–11]. Whereas, the studies on the influence of nonlinear fluid-structure coupling of control valve on the valve control characteristics, such as the pressure regulation feature, are still very limited [12–17]. In the CCPP, the valve control characteristics affected by the fluid-structure coupling are particularly important for the stability of the mixed-gas pressure control. It has not been uncommon to see that the instability of the mixed-gas pressure causes a severe disturbance or even an emergency shutdown of the whole plant, and the handling of such an emergency often becomes a source of new problems and confusion. In this paper, numerical investigations are carried out to clarify the influence of fluid-structure coupling of control valve on not only the flow field but also the gas pressure regulation and the natural frequency changes of the control valve. This study helps understand the processes that occur in the valve flow path leading to the mixed-gas pressure pulsations, which is valuable for the pressure stability control of the mixed gas in the CCPP.

0 notes

Text

How to choose bathroom accessories

A bathroom that does not have the necessary accessories, in addition to being impractical, could not fully fulfil the functions for which it is designed. Although the pipes, drains, flappers, nozzles, transformers and all the objects necessary for the correct evacuation of waste and water supply are also accessories for the bathroom , this time we will focus on talking about the accessories that are in sight and that in addition to contributing to the organisation and functionality of the bathroom, they fulfil a decorative function and can make that space more pleasant.

Towel racks, roll holders, soap dishes, shelves, hooks, hangers and many more accessories can be found today in a wide variety of materials, designs and colours. This variety can make it a bit difficult to make a decision when shopping, so in Sink and Bathroom Shop we suggest you take into account some points that will help you choose the bathroom accessories that will make this room a functional, comfortable and pleasant place .

Bathroom needs and characteristics

First of all it is important that you think about what accessories your bathroom needs. Determining this is quite simple if you consider the number of people who use it and the type of bathroom it is. For example, a guest bathroom is much less frequented than other bathrooms in the house and requires less maintenance than those for regular use.

In this type of bathroom, you can use accessories that stand out for their design to give it a touch of unique style that will leave a good impression on your visits, and a soap dish, roll holder and towel holder will be more than enough. On the other hand, in bathrooms for family use, it is preferable to opt for much more resistant accessories, especially in the case that there are children in the home, as this will guarantee the durability of your accessories and the safety of all its users.

Depending on the number of people who share the bathroom, installing a towel rack in addition to the hangers may be more practical, the same happens with soap dishes, brush holders and shelves for soaps and shampoo, because the more people use the bathroom , there will be more items for personal use and you need to keep them tidy.

After determining what accessories you need, consider the dimensions of the bathroom, the layout of the toilet, sink, shower or tub, and bathroom furniture to determine the space you have available for the installation of accessories. In the same way, it is important that you take into account the material of the walls and the rest of the decoration, factors that will be decisive when reaching the point of location and installation of the accessories.

Material

As we already mentioned, bathroom accessories can be found available in a wide variety of materials and finishes: plastic, steel, brass, glass, aluminum, ceramic, among others. It is well known that bathrooms are characterized by being places where humidity and temperature changes predominate, so it is necessary that we choose durable and resistant pieces that we can easily keep in good condition.

In recent years, stainless steel accessories have gained a lot of popularity in the market thanks to the fact that they are quite resistant, easy to clean and because of their finish they contribute to give a touch of elegance to any bathroom. On the other hand, plastic accessories with different finishes, such as chrome-plated ABS, are quite resistant and can be found in a wide variety of designs and colors, which makes them ideal for personalizing the bathroom.

The choice of material will also depend on the type of users, for example, in bathrooms used by children it will be inconvenient to use some accessories, mainly soap dishes, ceramic or glass.

Location and installation

Determining the place where the accessories will be placed can be quite obvious, since it will depend on the location of the toilet, sinks, tub or curved shower screen, but it is necessary to keep in mind that the classic way to install them involves drilling the wall. For this reason, knowing where the system of pipes, drainage and electrical installations embedded in the wall is located is of the utmost importance as this will prevent us from damaging them when doing any type of drilling.

To avoid the series of inconveniences that the conventional installation system implies, many people choose to use liquid adhesives that do not damage the surface and that have an excellent level of adhesion, but that their application can be a bit complicated and dirty; Or, by using double-sided adhesive tapes with resistant adhesives formulated for use in bathrooms, which allow you to change the place of the accessory whenever you want (it is necessary that with each change you replace the tape with a new one).

Price

Price can be the deciding factor when making any type of purchase, and although taking care of our economy is extremely important, we suggest that you do not sacrifice quality for price. Compare your options and invest your money wisely in good quality, functional and durable accessories.

At Sink and Bathroom Shop we invite you to consult our catalogue where you will find a wide variety of bathroom accessories in the best brands that will guarantee durability and style at the best price. If you have any questions about our products, do not hesitate to contact us, we will gladly give you the information you need and we will give you the advice you are looking for in choosing the accessories for your bathroom.

0 notes

Text

New Research: Aviation Valves Market 2026 Industry Specifications and Outlook 2021| Honeywell, ITT Aerospace Controls, Woodward, Parker Hannifin, Crissair

"

Request a Sample Get Discount

Attractive Market Opportunities in the Aviation Valves Market 2021 With Top Countries Data: Market Size, Industry Trends, Growth Insight, Competitive Analysis, Regional, And Global Industry Forecast To 2026.

The Global Aviation Valves Market report gives an in-depth investigation on industry and economy-wide data for the organization of the board that might give advancement and benefit for sellers in this market. “Global Aviation Valves Market Research Report 2021” gives top to bottom qualitative insights, past and momentum market size, and upheld undeniable quantitative information to help huge large as well as SME’s to settle on decision making. The report gives revenue share analysis and comparison of players on their solidarity, weakness and through different models, for example, Porter’s Five Forces,SWOT, and PESTLE and so forth. The Aviation Valves market report considers all the applicable trends, drivers, and opportunities and assesses their effect on the current market size and future market forecast. The report is without a doubt a worth document to an organization’s future procedures and way ahead. Global Aviation Valves market report gives key insights on the condition of the business and is a significant wellspring of direction and heading for organizations and people keen available. The Aviation Valves business development trends and marketing channels are analyzed. At long last, the attainability of new investment projects is surveyed and general research conclusions are offered.

NOTE: Our report features the significant issues and hazards that companies might come across due to the unprecedented outbreak of COVID-19.

>>> Download Sample Report (Get Full Insights in PDF – 151 Pages) @ https://www.reporthive.com/request_sample/2610975

What Is The Outlook of Industry?

The global Aviation Valves market is segmented according to the end-user type, product type, application as well just as regional analysis. Other significant market points are considered in the report to encourage business choices critical to the improvements in business activities and benefit over the forecast period from 2021 to 2026. The report involves an in-depth valuation in regards to the future advancements dependent on the past information and current circumstances of the global Aviation Valves market. The research team behind this report has researched principals, vital key players in the market lookout, geographical fragmentation, product type and its description, and market end-client applications.

Who Are The Prominent Key Players Of Aviation Valves Market?

The key manufacturers in this market include: Honeywell, ITT Aerospace Controls, Woodward, Parker Hannifin, Crissair, Eaton, Liebherr, Triumph Group, Zodiac Aerospace, AeroControlex, Porvair, Valcor Engineering, United Technologies, Marotta Controls, Crane Aerospace, Circor International, Moog, Ram Company, Sitec Aerospace, Meggitt, Precision Fluid Controls, Dynex/Rivett, Lakshmi Technology and Engineering Industries Limited, Nutek Aerospace Corporation

What Are The Segmentation of Global Aviation Valves Market:

Global Aviation Valves Market Segmentation: By Types ☑ Poppet Valves, Pilot Valves, Flapper-nozzle Valves, Ball and Plug Valves, Others

Global Aviation Valves Market segmentation: By Applications ☑ Commercial Aviation, Military Aviation

Global Aviation Valves Market, By Region: North America (the United States, Canada, and Mexico), Europe (Germany, France, UK, Russia, and Italy), Asia-Pacific (China, Japan, Korea, India, and Southeast Asia), South America (Brazil, Argentina, Colombia, etc.), Middle East and Africa (Saudi Arabia, UAE, Egypt, Nigeria, and South Africa)

Aviation Valves Market Research Report Will Be Based On:

– New Investors – Propose financial backers and private value organizations – Cautious business coordinators and investigators – Intelligent organization security Suppliers, Manufacturers, and Distributors – Government and examination associations – Speculation/Business Research League – End-use enterprises – And considerably more

Benefits of Global Aviation Valves Survey Report:

• Provides point-by-point data on Aviation Valves market share, PESTLE analysis, supply chain analysis, and key success factors to satisfy all peruser concerns. • Analyze business functions identified with Aviation Valves market utilization and production. • A wide scope of the global Aviation Valves market to extend your understanding. • A clear scenario of the Aviation Valves market for purchasers and dealers in a proficient format to pass the right information to target audiences, end-users, and consumers. • Aviation Valves market overview, Prominent economic pointers such as market overview, industry development, market size, forecast period, gross domestic product.

The key questions answered in this report:

• What will be the Market Size and Growth Rate in the estimated year? • What are the Key Factors driving Aviation Valves Market? • What are the Risks and Challenges before the market? • Who are the Key Vendors in Aviation Valves Market? • What are the Trending Factors impacting the market shares? • What are the Key Outcomes of Porter’s five forces model? • Which are the Global Opportunities for Expanding the Aviation Valves Market?

>>> To get Incredible Discounts on this Premium Report, Click Here @ https://www.reporthive.com/2610975/check_discount

TOC Highlights:

Chapter 1. Introduction: The Aviation Valves research work report covers a concise introduction to the global market. This segment provides assessments of key participants, a review of Aviation Valves industry, outlook across key areas, financial services, and various difficulties faced by Aviation Valves Market. This section depends on the Scope of the Study and Report Guidance.

Chapter 2. Outstanding Report Scope: This is the second most significant chapter, which covers market segmentation along with a definition of Aviation Valves. It characterizes the whole scope of the Aviation Valves report and the various features it is describing.

Chapter 3. Market Dynamics and Key Indicators: This chapter incorporates key elements focusing on drivers [Includes Globally Growing Aviation Valves frequency and Increasing Investments in Aviation Valves], Key Market Restraints[High Cost of Aviation Valves], opportunities [Arising Markets in Developing Countries] and introduced in detail the arising trends [Consistent Innovate of New Screening Products] development difficulties, and influence factors shared in this latest report.

Chapter 4. Type Segments: This Aviation Valves market report shows the market development for different kinds of products showcased by the most far-reaching organizations.

Chapter 5. Application Segments: The analysts who composed the report have completely assessed the market capability of key applications and perceived future freedoms.

Chapter 6. Geographic Analysis : Each provincial market is deliberately examined to understand its current and future development, improvement, and request situations for this market.

Chapter 7. Impact of COVID-19 Pandemic on Global Aviation Valves Market: 7.1 North America: Insight On COVID-19 Impact Study 2021-2026 7.2 Europe: Serves Complete Insight On COVID-19 Impact Study 2021-2026 7.3 Asia-Pacific: Potential Impact of COVID-19 (2021-2026) 7.4 Rest of the World: Impact Assessment of COVID-19 Pandemic

Chapter 8. Manufacturing Profiles: The significant players in the Aviation Valves market are definite in the report based on their market size, market served, products, applications, regional development, and other variables.

Chapter 9. Estimating Analysis: This chapter gives price point analysis by region and different forecasts.

Chapter 10. North America Aviation Valves Market Analysis: This chapter includes an appraisal on Aviation Valves product sales across major countries of the United States and Canada along with a detailed segmental viewpoint across these countries for the forecasted period 2021-2026.

Chapter 11. Latin America Aviation Valves Market Analysis: Significant countries of Brazil, Chile, Peru, Argentina, and Mexico are assessed apropos to the appropriation of Aviation Valves.

Chapter 12. Europe Aviation Valves Market Analysis: Market Analysis of Aviation Valves report remembers insights on supply-demand and sales revenue of Aviation Valves across Germany, France, United Kingdom, Spain, BENELUX, Nordic, and Italy.

Chapter 13. Asia Pacific Excluding Japan (APEJ) Aviation Valves Market Analysis: Countries of Greater China, ASEAN, India, and Australia & New Zealand are assessed, and sales evaluation of Aviation Valves in these countries is covered.

Chapter 14. Middle East and Africa (MEA) Aviation Valves Market Analysis: This chapter centers around Aviation Valves market scenario across GCC countries, Israel, South Africa, and Turkey.

Chapter 15. Research Methodology The research procedure chapter includes the accompanying primary realities, 15.1 Coverage 15.2 Secondary Research 15.3 Primary Research

Chapter 16. Conclusion

>>> Make an enquiry before buying this report @ https://www.reporthive.com/2610975/enquiry_before_purchase

Why Report Hive Research:

Report Hive Research delivers strategic market research reports, statistical surveys, industry analysis and forecast data on products and services, markets and companies. Our clientele ranges mix of global business leaders, government organizations, SME’s, individuals and Start-ups, top management consulting firms, universities, etc. Our library of 700,000 + reports targets high growth emerging markets in the USA, Europe Middle East, Africa, Asia Pacific covering industries like IT, Telecom, Semiconductor, Chemical, Healthcare, Pharmaceutical, Energy and Power, Manufacturing, Automotive and Transportation, Food and Beverages, etc.

Contact Us:

Report Hive Research 500, North Michigan Avenue, Suite 6014, Chicago, IL – 60611, United States Website: https://www.reporthive.com Email: [email protected] Phone: +1 312-604-7084

"

0 notes

Link

Aerospace Valves Market by Valves (Fuel, Hydraulic, Air Conditioning, Pneumatic), Material (Steel, Aluminum, Titanium), Mechanism (Poppet, Pilot, Flapper-Nozzle, Ball and Plug, Baffle), End User (OEM, Aftermarket), Aviation.

0 notes