#Motion control system

Explore tagged Tumblr posts

Text

Unveiling Precision: A Guide to Electrohydraulic Servo Valve Technology

Introduction: In the realm of industrial automation and high-performance machinery, electrohydraulic servo valves (EHSVs) reign supreme. These marvels of engineering bridge the gap between electrical control signals and the potent world of hydraulics. By translating subtle electrical commands into precise hydraulic fluid motion, EHSVs empower motion control systems with unmatched accuracy and…

View On WordPress

#Digital control#Electrohydraulic servo valve technology#Feedback loop#Flapper-nozzle#Frequency response#Hydraulic actuator#Motion control system#Piezoelectric actuator#Proportional valve#Spool valve#Two-stage design

0 notes

Text

why the fuck are there two Legend of Zelda games on the DS where you're forced to move with the touch screen.

#I'll give them a fair chance beyond their control schemes but jesus christ.#the touch screen is the DS equivalent to motion controls: forced into everything regardless of its actual utility compared to buttons.#sometimes it works better than buttons. there's just dance for motion controls and 3D picross for the touch screen.#but sometimes it's so pointless (like in a legend of zelda) that I curse the name of whoever implemented it onto the system as a whole.

2 notes

·

View notes

Text

Artoo Standing Guard

STAR WARS EPISODE II: Attack of the Clones 00:12:53

#Star Wars#Episode II#Attack of the Clones#Coruscant#Galactic City#Federal District#Senate Apartment Complex#Senator Padmé Amidala’s apartment#Senator Padmé Amidala’s private quarters#R2-D2#Senator Padmé Amidala#Anakin Skywalker#Trade Federation#Droid Control Ship#Vuutun Palaa#Battle of Naboo#interference pulse stabilizers#polarity sink#electromagnetic field sensor unit#durasteel#spacecraft data slot#spacecraft linkage and control arms#acoustic signaller#system ventillation#hi-power recharge coupling#motion sensor

3 notes

·

View notes

Text

Unveiling the Power of Position Velocity Feedback Transmitter Systems in Modern Industries

Introduction: The Importance of Position and Velocity Feedback Systems in Precision Control

Position and velocity feedback transmitter systems are integral to industries that demand high-precision control and motion tracking. These systems are employed to monitor the position and velocity of moving objects in real-time, providing critical data for automated operations. The evolution of these systems has been significant, with advancements in technology enabling more compact, accurate, and reliable feedback mechanisms that drive automation, robotics, aerospace, automotive, and healthcare applications.

With the global shift towards increased automation, the demand for such systems is on the rise. Industries across the board require precise control of machinery, vehicles, and robots to enhance performance, improve safety, and optimize productivity. The growing need for smart manufacturing, autonomous vehicles, and medical robotics underscores the vital role these systems play in modern industries. Despite some challenges, such as high upfront costs and integration complexities, the long-term benefits of precision, efficiency, and reliability outweigh these hurdles.

Request Sample Report PDF (including TOC, Graphs & Tables): https://www.statsandresearch.com/request-sample/40604-global-position-velocity-feedback-transmitter-systems-market

Position Velocity Feedback Transmitter Systems Market Dynamics: Drivers, Challenges, and Opportunities

Drivers of Growth

The Position Velocity Feedback Transmitter Systems market is experiencing robust growth driven by several key factors:

Advancements in Automation and Robotics: Industries across manufacturing, automotive, and aerospace are increasingly adopting automation technologies. These systems allow for faster, more accurate control, driving the need for precise position and velocity feedback.

Technological Advancements in Sensors: Innovations in sensor technology, particularly in digital systems, are facilitating the development of more accurate and miniaturized position velocity feedback systems. The integration of Internet of Things (IoT) technologies is making these systems smarter and more adaptable, driving their adoption in industries such as healthcare, smart manufacturing, and autonomous vehicles.

The Rise of Industry 4.0: Industry 4.0 technologies are revolutionizing production lines, with automation and data-driven decisions at their core. Position velocity feedback systems play a critical role in enabling smarter, more efficient manufacturing processes.

Emerging Applications in Healthcare and Autonomous Vehicles: In healthcare, robotic surgeries and diagnostics systems demand highly accurate motion control, while autonomous vehicles require precise feedback systems for safe operation. Both sectors are driving significant demand for position and velocity feedback systems.

Get up to 30% Discount: https://www.statsandresearch.com/check-discount/40604-global-position-velocity-feedback-transmitter-systems-market

Challenges to Position Velocity Feedback Transmitter Systems Market Adoption

Despite the promising growth, several barriers could slow the widespread adoption of position velocity feedback transmitter systems:

High Initial Investment Costs: The cost of acquiring and integrating high-precision position velocity feedback systems can be prohibitive, especially for small and medium-sized enterprises (SMEs). High upfront costs can deter organizations from upgrading or adopting these systems, limiting market expansion.

Complexity of System Integration: Integrating new feedback systems with existing infrastructure and machinery can be complex and time-consuming, especially in industries that have legacy systems. This complexity increases the time to market and may discourage immediate adoption.

Specialized Training Requirements: The operation, calibration, and maintenance of advanced position velocity feedback systems require highly specialized knowledge and skills. The shortage of skilled labor in these fields may hinder growth, particularly in developing regions.

Key Opportunities

Several emerging trends present substantial opportunities for the growth of the position velocity feedback transmitter systems market:

Smart Manufacturing: As manufacturing processes become increasingly automated, there is a growing demand for position velocity feedback systems to enhance productivity and reduce human error. These systems are integral to improving the efficiency of production lines and ensuring consistent product quality.

Healthcare Robotics: Surgical robots, diagnostic devices, and rehabilitation technologies require real-time motion control. The healthcare sector’s increasing reliance on these technologies provides a substantial opportunity for the growth of high-precision position feedback systems.

Autonomous Vehicles: The rapid development of autonomous vehicles (AVs) hinges on accurate motion tracking and feedback systems for safe navigation. As the demand for AVs increases, so too will the demand for position and velocity feedback transmitters that ensure precise vehicle control.

Position Velocity Feedback Transmitter Systems Market Segmentation and Analysis

By Type

The position velocity feedback transmitter systems market can be divided into two key types:

Position Feedback Transmitter: This sub-segment is expected to dominate the market, driven by the increasing demand for precision in industrial automation applications. Position feedback transmitters provide accurate location tracking, ensuring the correct placement of components in automated systems.

Velocity Feedback Transmitter: While this segment is smaller, it is growing rapidly due to the need for precise speed control in applications such as robotics, aerospace, and automotive industries.

By Technology

Analog Systems: While still in use, analog systems are being increasingly replaced by more sophisticated digital feedback systems that offer greater accuracy and scalability.

Digital Systems: Dominating the market, digital systems provide real-time, highly accurate feedback for a range of applications, particularly in industries like automotive, aerospace, and healthcare. The continued innovation in sensor technology and integration with IoT is expected to fuel further growth in this segment.

By Application

The demand for position and velocity feedback systems spans a variety of industries:

Industrial Automation: Expected to maintain the largest market share, industrial automation continues to be the leading driver of demand for precise motion control systems. These systems are integral to ensuring the accuracy and speed of machinery in sectors such as manufacturing and material handling.

Aerospace and Defense: Aerospace applications require high-precision feedback systems for tasks such as flight control, navigation, and satellite positioning.

Automotive: As automotive systems become more automated, the demand for position and velocity feedback systems grows. These systems ensure precise vehicle control in autonomous and semi-autonomous driving technologies.

Energy: The energy sector, particularly in renewable energy systems, requires high-performance motion control to optimize energy production and distribution.

By Region

The market is geographically diverse, with distinct growth patterns across various regions:

North America: Dominating the market, North America is poised to continue leading the position velocity feedback transmitter systems market due to its advanced industrial sectors, including aerospace and automotive.

Asia-Pacific: The Asia-Pacific region is expected to witness the highest growth rate, driven by rapid industrialization and the increasing adoption of automation technologies in countries like China and India.

Europe: Europe’s strong automotive and industrial automation sectors will continue to contribute to the growth of this market.

Latin America and Middle East & Africa: While smaller markets, the demand for these systems is expected to rise as industries in these regions embrace automation and robotics.

Position Velocity Feedback Transmitter Systems Market Competitive Landscape

Key Players

The market for position velocity feedback transmitters is highly competitive, with several industry leaders at the forefront:

Pepperl+Fuchs: Known for its next-generation sensors, Pepperl+Fuchs continues to innovate with solutions tailored to the needs of the automotive and industrial automation sectors. The company launched new high-performance sensors aimed at enhancing precision in harsh industrial environments in 2024.

Temposonics: Specializing in digital feedback systems, Temposonics has made significant strides in the robotics and aerospace sectors. Their advanced systems offer real-time position and velocity tracking, catering to industries that demand high-speed and high-accuracy solutions.

Other Key Players: Other companies in this market include Balluff, Siemens, and Honeywell, each offering various solutions across different applications, from industrial automation to healthcare.

Emerging Trends in Competition

Integration of IoT: Manufacturers are increasingly integrating IoT technologies into their position velocity feedback systems to enhance data collection, improve connectivity, and enable predictive maintenance.

Customization and Tailored Solutions: Companies are focusing on providing customized solutions for specific industries to cater to the unique needs of sectors such as automotive, aerospace, and healthcare.

Sustainability Initiatives: With growing environmental concerns, companies are developing energy-efficient systems that not only meet performance requirements but also adhere to sustainable production practices.

Purchase Exclusive Report: https://www.statsandresearch.com/enquire-before/40604-global-position-velocity-feedback-transmitter-systems-market

Conclusion:

The Position Velocity Feedback Transmitter Systems Market is on a rapid growth trajectory, driven by advancements in automation, robotics, and sensor technologies. The demand for high-precision motion control systems is intensifying as industries seek to improve efficiency, safety, and productivity. Despite challenges such as high initial costs and integration complexities, the opportunities presented by emerging applications in healthcare, autonomous vehicles, and smart manufacturing are substantial.

With continued innovation and a focus on integration with IoT and digital technologies, the market is well-positioned for long-term expansion. As the industrial landscape continues to evolve, the role of position and velocity feedback systems will be pivotal in shaping the future of automation and precision control across various sectors.

Our Services:

On-Demand Reports: https://www.statsandresearch.com/on-demand-reports

Subscription Plans: https://www.statsandresearch.com/subscription-plans

Consulting Services: https://www.statsandresearch.com/consulting-services

ESG Solutions: https://www.statsandresearch.com/esg-solutions

Contact Us:

Stats and Research

Email: [email protected]

Phone: +91 8530698844

Website: https://www.statsandresearch.com

#Position Velocity Feedback Transmitter Systems Market#Position Feedback Systems#Velocity Feedback Transmitters#Automation#Industrial Automation#Motion Control Systems#Precision Motion Tracking#Position and Velocity Sensors#Digital Feedback Systems#Robotics#Aerospace Industry#Autonomous Vehicles#Healthcare Robotics#Smart Manufacturing#Industrial Robotics#Sensor Technology#Motion Control#Market Growth#Industry 4.0#Digital Position Sensors#Automotive Automation#IoT-enabled Feedback Systems#High-Precision Transmitters#Real-time Position Feedback#Aerospace Sensors#Automation Trends#Smart Manufacturing Systems#Position Velocity Sensors#Market Analysis#Precision Control Systems

1 note

·

View note

Text

Damn Guilty Gear Judgment is a fun ass game.

#like I was always expecting to enjoy it but wow#fighting game controls translated nigh perfectly to a beat em up format.#I just stress “nigh” cause them motion inputs are tricky on a side scrolling plane#like I be turning the wrong way when I’m tryna use Tyrant Rave n other such moves#but besides that real good shit#I talked about Guilty Gear havin another spinoff and Y’know I really wouldn’t mind another beat em up#with the newer graphics of strive n shit it could be lit.#guilty gear#guilty gear Judgment#arc system works#majesco sy

5 notes

·

View notes

Text

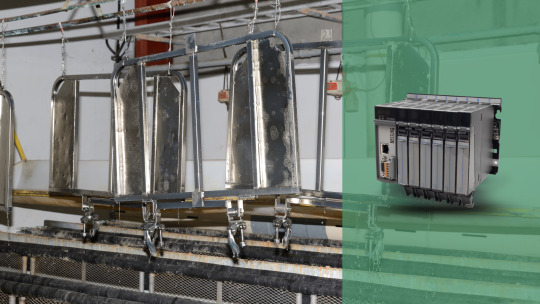

Smarter Surface Protection – PLC Automation in Autophoretic Coating Plants

In modern manufacturing, surface coating is not just cosmetic—it’s essential for durability, corrosion resistance, and performance. Autophoretic coating (also known as A-coating) has emerged as a water-based, eco-friendly alternative to electro-coating. When combined with PLC-based automation, it becomes a powerful, scalable solution for high-quality, uniform metal finishing.

Because let’s face it—metal without proper protection is like a knight without armour. In today’s industrial world, that armour comes in the form of surface coating. And when it comes to smart, sustainable, and scalable coating, autophoretic coating is the unsung hero.

But wait, here’s where it gets exciting. Pair this eco-warrior coating with PLC automation, and what you get is nothing short of magic. At Messung Industrial Automation, we believe that the perfect coat is not just about shine—it's about smarts, speed, and sustainability.Let’s dive into the world where chemistry meets code, and surface protection meets the future.

What is Autophoretic Coating?

Autophoretic coating, also known as A-coating, is a process where metal parts are dipped in a reactive water-based solution. The result? A self-depositing layer forms on the surface, without any electric current. Unlike traditional methods that zap the surface with electricity, A-coating lets chemistry take the wheel.

Why Are Industries Making the Switch?

Industries are coating their bets on it because it avoids the need for heavy electric setups and provides uniform coverage even in complex geometries. Since it is water-based, it is also very environmentally friendly.

Where Is It Being Used?

From under-the-hood car parts to refrigerator frames, autophoretic coating is making waves in:

Automotive parts

Appliance components

Agricultural and construction machinery

General industrial structures

In an age where efficiency, sustainability, and performance go hand in hand, autophoretic coating emerges as a transformative solution. Its simplicity belies its power, ushering in a cleaner, smarter way to protect surfaces without compromising on quality or cost. As industries across the board continue to embrace greener practices, A-coating, powered by automation and intelligence, is painting the future—one seamless coat at a time.

Role of PLC in the Coating Plant

In the realm of autophoretic coating, precision isn't a luxury—it's a necessity, and that precision begins with the silent genius of automation: the Programmable Logic Controller (PLC). Think of the PLC as the central nervous system of your coating plant—connecting, communicating, and commanding every mechanical muscle with machines. Here is how PLCs turn a basic coating line into a harmonious dance of efficiency and intelligence.

Precision Process Automation

A modern autophoretic coating plant runs smoothly like a well-coordinated team, and the PLC (Programmable Logic Controller) is in charge. It doesn’t just control the machines—it helps everything work perfectly together. From:

Tank temperature

Solution pressure & pH levels

Cycle timing for each dip and rise

...every step is monitored and controlled by PLC automation.

Material Handling Magic

Using intelligent material handling controllers, our PLC guides parts through multiple stages:

Degreasing

Surface conditioning

Coating dip

Rinsing & curing

Like a choreographer directing a ballet of metal.

Circulation & Filtration Mastery

Good coating = Consistent flow. Our process controllers and PLC control systems manage:

Fluid circulation

Filtration cycles

Solution replacement timing

Synchronisation with Process Controllers

Through seamless synchronisation with motion control systems, everything moves with precision. No drips, no downtime.

In an industry where milliseconds matter and uniformity is sacred, PLC automation elevates the autophoretic coating plant from functional to phenomenal. It enables not just control, but clarity—ensuring that every part, every dip, and every process flows with intelligent intent.

NX-ERA JET PLC System Architecture

Our flagship—NX-ERA JET PLC—is a robust, real-time, and rugged automation genius. It’s compact, reliable, and battle-tested in industrial heat.

Talk the Talk: MODBUS & TCP/IP

Built-in PLC communication protocols like:

MODBUS TCP/IP

MODBUS RTU

Make it plug-and-play with SCADA and automation systems. Yes, it speaks fluent-machine.

Ethernet-Based Controllers for High-Speed Sync

Using Ethernet-based controllers, data flows like molten metal. Zero lag, maximum productivity.

HMI with PLC Controllers

With user-friendly HMIs with PLC controllers, even a non-techie can operate complex coating sequences. Tap, drag, drop—and coat!

From seamless communication to intuitive control, the NX-ERA JET PLC is more than just a controller—it's the central nervous system of your autophoretic coating plant. With its advanced architecture, lightning-fast data sync, and plug-and-play compatibility, it transforms complexity into clarity. Whether you're scaling up or starting smart, this system offers the flexibility, durability, and intelligence your operations demand.In a world where precision meets pressure, the NX-ERA JET PLC ensures your plant doesn’t just perform—it excels.

Advanced PLC Automation for Smart Manufacturing

In the age of Industry 4.0, surface coating is no longer just about chemistry—it's about intelligence, precision, and adaptability. That’s where advanced PLC automation steps in as the invisible powerhouse behind your plant’s performance. Whether you're scaling up operations or streamlining a compact facility, smart automation is the lever that elevates your process from ordinary to outstanding.

Let’s uncover how Messung’s cutting-edge PLC technology is revolutionising autophoretic coating plants with flexible, responsive, and future-ready control systems.

Modular, Compact & Ready to Go - Whether it’s a big plant or a small-scale setup, our Modular PLC, Compact PLC, and Smart PLC configurations give you tailor-made flexibility.

Motion Control with Millisecond Precision - Our motion control systems enable synchronised movement, avoiding delays or overlaps in the coating sequence.

Material Handling - Our embedded material handling controllers do the heavy lifting—literally—without breaking a sweat.

This isn't just automation. This is smart automation that thinks ahead, moves with purpose, and adapts to demand. With Messung’s PLC-powered intelligence, your coating plant doesn’t just run—it evolves.

Because in the world of advanced manufacturing, it’s not just about staying ahead—it's about setting the pace.

Smart. Sustainable. Secure: The Evolution of PLC Automation in Coating Plants

In the era of Industry 4.0, coating plants need more than just control—they need intelligence, integration, and intention. Here’s how Messung’s PLC automation is redefining autophoretic coating systems:

Built for Harsh Industrial Realities – Our Industrial PLCs endure dust, moisture, heat, and vibration. Conformal-coated PLCs protect against corrosive chemicals in A-coating zones and provide long-lasting performance in extreme environments.

Safety Meets Smarts - PLCs are integrated for emergency stops, controlled shutdowns, and real-time fault alerts with logs, making them smart, secure, and always in control.

Welcome to Industry 4.0-Based Controllers

PLC with IoT for remote monitoring and real-time plant access.

MQTT-based PLCs for cloud-friendly, lightweight data communication.

Full PLC system integration with BMS, SCADA & more—ensuring a harmonious automation ecosystem.

Green Gains: Eco-Friendly A-Coating Automation

Water-based chemistry reduces VOCs and emissions.

Smart PLCs optimize dosing & disposal—minimising waste, maximising results.

Cleaner air, cleaner conscience, smarter coatings.

With Messung’s intelligent PLC, you don’t just automate—you evolve. Sustainable, scalable, and secure—this is the new face of PLC-based automation solutions in A-coating.

Business Benefits of PLC-Based Automation Solutions

In today’s hyper-competitive manufacturing world, success isn’t just about innovation—it’s about consistency, efficiency, and scalability. This is where PLC-based automation doesn’t just support your coating process—it transforms it. Let’s explore how Messung’s smart automation systems turn operational goals into tangible business advantages.

Uniformity Every Time - When every product must meet the same high standard, there’s no room for guesswork. Thanks to PLC control systems, your coating process is even, repeatable, and of high quality.

Never any Downtime - Time is money, and downtime is a thief. With real-time monitoring and intelligent automation controllers, potential issues are detected and resolved before they affect production. Fewer breakdowns. More uptime. Happier bottom line.

Easy to Maintain & Scale - Growth shouldn’t be a gamble. With built-in PLC maintenance alerts, you get proactive notifications that prevent surprises. Want to expand operations? Simply plug and play with modular I/O modules. You’re ready for tomorrow—today.

In essence, PLC automation is not just a control system—it’s a business strategy. It safeguards quality, boosts efficiency, and equips your coating plant with the agility to evolve. Because when your process is smart, your performance is unstoppable.

Conclusion: The Final Coat

A surface is only as strong as the system behind it. In the era of smart manufacturing, Messung’s PLC automation solutions empower autophoretic coating plants with unmatched precision, efficiency, and sustainability. From real-time monitoring and advanced PLC control systems to seamless IoT integration and predictive maintenance, our technology ensures optimal surface protection with minimal waste. Whether it’s modular PLCs, industrial automation controllers, or motion control systems, Messung delivers the complete package. So why let inefficiencies corrode your bottom line? Upgrade your coat. Upgrade your process. Upgrade with Messung PLCs—where intelligent automation meets perfect protection.

FAQs

How does PLC contribute to energy efficiency in coating plants?

By optimizing process timings, reducing idle machine hours, and enabling intelligent power management, PLCs help cut down energy consumption and operational costs.

Can PLC automation reduce coating defects?

Absolutely. With real-time monitoring, precision control, and error alerts, PLC automation ensures consistent quality.

How easy is it to integrate Messung PLCs in existing lines?

Very! Our modular PLC systems and versatile PLC communication protocols like MODBUS and TCP/IP allow seamless integration.

Are conformal-coated PLCs necessary?

Yes, especially in chemically aggressive environments like coating plants. They extend the life and reliability of your Programmable Logic Controller.

What industries benefit most from PLC with IoT?

Automotive, general manufacturing, and any industry embracing Industry 4.0-based controllers and smart factory setups.

#Autophoretic coating#Messung Industrial Automation#PLC automation#Programmable Logic Controller (PLC)#material handling controllers#motion control systems#NX-ERA JET PLC#HMI with PLC Controllers#advanced PLC automation#Modular PLC#Compact PLC#Smart PLC#Industrial PLCs#Smart PLCs#PLC-based automation solutions#PLC control systems#PLC automation solutions#IoT integration#industrial automation controllers#Industry 4.0-based controllers

0 notes

Text

B48 Series Motorized Rotary Stages

Velmex Motorized Rotating Tables deliver precise, continuous rotating motion for scanning, assembly, testing and production. They are a convenient, accurate method of quickly positioning or rotating a payload. The B48 Series motorized rotary stages feature an easy to read engraved 360 degree scale for operator convenience. https://velmex.com/

#rotary table controller#motorized xy system#xy table stepper motor#rotary motion control#xy tables#lead screws

0 notes

Text

Unlocking Precision in Robotics with Dynaflex: A Dynalog-US Innovation.

Precision is paramount in today's fast-paced world of automation, with industries such as aerospace, automotive, electronics, and advanced manufacturing requiring robot systems to function with precision, in order for the process to deliver quality and consistent performance. This is where Dynatrol-US Dynaflex provides an unparalleled solution to improve robot calibration and motion control for industrial environments.

So, what exactly is Dynaflex?

Dynaflex is sophisticated real-time calibration developed by Dynalog-US- a leader in robotic accuracy solutions. These advanced dynamic performance assessment tools were developed specifically for robot systems. Dynaflex measures the dynamic performance (how robots behave while they operate), versus static calibration tools (preset calibration baked into the robots programming) by evaluating robot compliance and flexibility in real-time. This type of dynamic assessment provides potential for accuracy to industries where tolerances must be tight and conditions demand high levels of performance reliability.

Simply put Dynaflex gives practitioners visibility and insight into how a robot responds dynamically while at work and if sufficient stress or force signatures, behaviour is exhibited. In many cases, this is no different than creating significant and costly rework..

Why is Dynaflex so Important?

When robots perform jobs such as welding, painting, and assembling, even the most minor deviation in motion can create defects or misalignment. Traditional calibration methods consider positioning, but often don't consider the dynamic changes in robot posture due to many different factors such as: gravity, speed and payload. Dynaflex effectively takes calibration to the next level by adding dynamic variables to the calibration equation.

With the Dynaflex system, manufacturers can:

Measure and minimize robot compliance (flexibility under load)

Achieve better path accuracy with complex work processes

Validate robot performance in real-world conditions

Identify mechanical anomalies before they can become major catastrophes

Maximize repeatability and process consistency

These are meaningful relationships to ensure that the robot moves correctly on paper, but that it also can perform accurately on the production floor.

How Does Dynaflex Work?

Dynaflex implements a series of highly sensitive measurement tools and calibration routines that allow engineerings to visualize how the end effector of a robot moves while under load, or at high speed. By measuring real-time flexing, oscillation and inertia, Dynaflex creates a comprehensive map of the robot's behavior.

Once the data has been collected, the data is used to adjust the robot's motion algorithms and account for mechanical variation.

Who is Dynaflex for?

Dynaflex is ideal for companies and industries that expect critical congruency and which themselves use robotic automation, including:

Automotive manufacturing

Aerospace and defence

Medical devices

Electronics assembly

Metal fabrication

3D printing and additive manufacturing

If your company relies on multi-robot cells, automated welding cells, or pick-and-place systems, introducing Dynaflex to your calibration operations will provide great benefit.

Dynalog-US: The Experts in Robot Calibration

Dynalog-US was founded to provide accurate and reliable robotic systems and has been a leader in robot performance technology for several decades. Their products are being used by leading world manufacturers, many of whom are in the Fortune 500.

Whether it is for robotic inspection, Tool Center Point (TCP) calibration or improving robot cell accuracy, Dynalog has a history of introducing products to the marketplace that demonstrate thoughtful engineering, industry leading performance, and great customer support.

Dynalog's market leading solutions, to include Dynaflex, come with documentation, field training, and technical consulting, which is more than just selling a product; Dynalog provides a partnership to achieve your production success.

Many companies have seen measurable improvements after adding Dynaflex to their robotic workflow:

Up to 40% improvement in path accuracy Considerably less joint stress and less component wear Reduction of rework and scrap percentage Faster ROI from robotic systems

One aerospace customer even found that Dynaflex helped them to achieve their tolerance requirements that they previously thought could be accomplished only with standard robots or off-the-shelf robotic equipment.

Future of Robotic CalibrationAs AI, machine Learning, and Industry 4.0 technologies evolve, the need for ongoing performance validation to and compliance will become more valuable. Also, autonomous systems will validate performance more often, and human interventions will be using tools like Dynaflex to ensure safety, quality, and efficiencies.

With Dynaflex by Dynalog-US, businesses now have a scalable and future-proof calibration platform to leverage for future use and to enhance work processes while accomplishing productivity and accuracy improvements in the immediate.

Conclusion

When you invest in robots, investing in robot performance has to be a given. Properly calibrating robot performance starts with the initial calibration when it is stationary, when it is in motion, while it is under load, and evaluating at the full-speed capability.

Dynaflex by Dynalog-US is a calibration device that provides the measurement data (metrics) to give you a competitive advantage for an ever-evolving automated world.

Ready to take the next step in robotic precision? Visit www.dynalog-us.com to learn more about Dynaflex and schedule a consultation with the experts at Dynalog-US.

#Dynaflex#Dynalog-US#Robot Calibration#Robotic Accuracy#Industrial Automation#Robot Compliance#Dynamic Robot Calibration#Robot Motion Control#Manufacturing Technology#Industry 4.0#Advanced Robotics#Robot Performance#Calibration Systems#Automation Solutions#Robot Path Accuracy#Robot Inspection Tools#Robot Flexibility Measurement#Dynaflex Calibration#Robotic Workflow Optimization#Robotic Precision Engineering

0 notes

Text

Revolutionizing Servo Control: How Spectrum Engineering Leverages High-Order Controller Auto-Tuning

In today’s fast-paced industries, precise servo control is vital for robotics, automation, and precision machinery. Tuning controllers to balance stability, speed, and robustness—while addressing friction, backlash, or sensor noise—is complex. Spectrum Engineering, with over 25 years of expertise in control system design consulting, transforms these challenges into opportunities, delivering control and dynamics innovation using the high-order controller auto-tuning method.

A Breakthrough in High-Order Tuning

Traditional tuning, often limited to PID designs, struggles with complex systems needing higher-order controllers for superior performance. However, research by Yaron Zimmerman and Per-Olof Gutman pioneers control and dynamics innovation by auto-tuning high-order controller implementation using unconstrained optimization within the Quantitative Feedback Theory (QFT) framework. By minimizing a cost function that balances performance and stability—without requiring a detailed plant model—this method ensures robust control across uncertainties like mechanical constraints. The Nelder-Mead Simplex Method optimizes parameters efficiently, reducing design time while achieving precision.

Spectrum Engineering’s Practical Solutions

Spectrum Engineering applies these principles to deliver tailored servo control solutions. Their automatic tuning algorithms optimize high-order controllers for embedded systems, addressing issues like saturation or dead zones. For instance, a client in industrial automation achieved faster response times and enhanced stability after their control system design consulting tuned their system to handle backlash. Beyond tuning, they implement Kalman filters to reduce noise, design algorithms for unique challenges, and support mechanical and electronic integration.

Why Choose Spectrum Engineering?

Through control system design consulting, patent collaboration, or team training, Spectrum Engineering offers flexible services. Why build an in-house control team when their expertise in control and dynamics innovation delivers high-performance systems? Their research-inspired approach ensures precision without complexity.

Leading the Future of Control Systems

As control systems grow intricate, Spectrum Engineering leads with advanced auto-tuning and practical know-how. Contact them for control system design consulting or explore their training to elevate your servo systems. With Spectrum Engineering, precision and performance are within reach.

#control and dynamics innovation#control system design consulting#Active magnetic bearing solutions#Controller implementation#Dynamics consulting#Dynamics performance optimization#Signal processing consulting#Custom control consulting services#Advanced control systems#Innovative control solutions#Motion control training#Control systems solution#Control loop tuning and optimization

0 notes

Text

The Role of AI in Advancing Robotic Motion Control Systems

The integration of Artificial Intelligence (AI) into robotic motion control systems has revolutionized the field of automation. AI-driven robotics are enhancing precision, efficiency, and adaptability in various industrial applications, enabling robots to perform complex tasks with human-like decision-making capabilities.

0 notes

Text

there's something both reassuring and terrifying that throughout history people don't really change

#reading 'reflektorem w mrok' and oh man#all the texts there were written almost 100 years ago#tadeusz boy żeleński talks about the lack of sex education and no access to safe abortions ostracising women who decide to have an abortion#how the justice system is inadequate regarding them#the overwhelming control of the church on the laws and medicine that actually causes more fatalities#(nuns not having to go through the sanitizing procedures at hospitals because they're 'holy' took me out)#how the church's attachment to the idea of preserving tradition actually cripples the motion of change and evolution#man it could've been written yesterday and the contents would change so little#both sad and kind of predictable that we had so little development regarding those issues#also unrelated śmiesznie się czyta te fragmenty pod tytułem#'kiedyś to było teraz to wszyscy siedzą na tych dansingach i w kinach a kobiety są takie niezależne' w kontekście lat 30.#Boy you've got a big storm coming#jules txt

1 note

·

View note

Text

I wanted to throw a knife at the gargoyle but i guess my character had other plans.

#i hate motion control gestures#are you happy? did you get it out of your system?#now please throw the knife. please i'm begging you#elden ring

0 notes

Text

Material Handling Motion Control System Market: Global Industry Analysis, Size, Share, Trends and Forecast by 2032

Material handling motion control system is manufacturing technology that manages moving parts of equipment in a skillful manner to reduce manpower, minimize industrial hazards, and to maintain safety at workplace. Material handling control system cater to industries such oil & gas, food & beverages, aerospace & defense, automotive, semiconductor & electronics, metal & machinery manufacturing,…

0 notes

Text

Exploring the World of Automated Guided Vehicles (AGVs)

In today’s fast-paced and ever-evolving industrial landscape, efficiency and precision are paramount. Enter the world of Automated Guided Vehicles (AGVs)—a technology that is reshaping the way we think about material handling and automation. From warehouses to manufacturing floors, AGVs are revolutionizing operations by streamlining processes and reducing labor costs. Let’s delve into the fascinating world of AGVs and uncover how these remarkable machines are transforming various industries.

What Are Automated Guided Vehicles (AGVs)?

Automated Guided Vehicles, commonly known as AGVs, are mobile robots used to transport materials around a facility. Unlike traditional forklifts or manual carts, AGVs operate autonomously, guided by various navigation systems. They are designed to follow pre-set paths or dynamic routes, performing tasks with precision and efficiency.

AGVs come in various shapes and sizes, each tailored to specific operational needs. Some are designed to carry heavy loads, while others are equipped for delicate or intricate tasks. The versatility of AGVs makes them an invaluable asset in diverse settings, from large-scale warehouses to high-tech manufacturing plants.

How AGVs Work

The core functionality of AGVs revolves around their navigation and control systems. There are several technologies that AGVs use to navigate their environment:

Magnetic Strips: Traditional AGVs often use magnetic strips embedded in the floor to guide their movement. These strips are aligned with the vehicle's sensors, directing it along a predetermined path.

Laser Guidance: More advanced AGVs use laser guidance systems to navigate. These AGVs rely on laser scanners to create a map of their environment, allowing them to detect obstacles and make real-time adjustments to their route.

Vision Systems: Some AGVs are equipped with cameras and computer vision systems. These systems enable the vehicle to recognize and interpret its surroundings, offering a high degree of flexibility and adaptability.

Inertial Navigation: Inertial navigation systems use accelerometers and gyroscopes to track the AGV’s position and movement. This technology is particularly useful for AGVs operating in environments with changing conditions.

RFID Tags: Radio Frequency Identification (RFID) tags are another method for guiding AGVs. Tags are placed at specific locations, and the AGV uses RFID readers to detect and follow these markers.

Benefits of AGVs

The integration of AGVs into industrial operations offers numerous advantages:

Increased Efficiency: AGVs can operate continuously without the need for breaks or shifts. This constant operation translates to higher throughput and reduced downtime.

Cost Savings: By automating material handling tasks, businesses can reduce labor costs and minimize human error. Although the initial investment in AGVs may be substantial, the long-term savings are significant.

Enhanced Safety: AGVs are designed with safety features to avoid collisions and navigate around obstacles. They reduce the risk of workplace accidents related to manual material handling.

Consistency and Precision: AGVs follow programmed routes with high accuracy, ensuring that materials are transported reliably and consistently. This precision enhances overall operational quality.

Applications of AGVs

AGVs are versatile and can be applied across various industries:

Manufacturing: In manufacturing plants, AGVs transport raw materials, components, and finished products between different stages of production. They can handle tasks such as delivering parts to assembly lines or removing waste.

Warehousing and Distribution: In warehouses, AGVs move goods from storage locations to packing and shipping areas. They streamline order fulfillment processes, reduce handling times, and improve inventory management.

Healthcare: In hospitals and healthcare facilities, AGVs deliver supplies, medications, and linens. They ensure that essential items are transported efficiently while minimizing human contact and reducing the risk of contamination.

Retail: AGVs are increasingly used in retail environments for tasks such as restocking shelves and managing inventory. They help maintain store operations and improve the customer experience.

Food and Beverage: In the food and beverage industry, AGVs handle the transportation of ingredients, packaging materials, and finished products. They contribute to maintaining hygiene standards and ensuring efficient production processes.

Challenges and Considerations

While AGVs offer numerous benefits, their implementation comes with certain challenges:

Initial Costs: The initial investment in AGVs and the associated infrastructure can be high. Businesses must carefully evaluate the return on investment (ROI) and consider long-term benefits.

Integration: Integrating AGVs into existing systems and workflows can be complex. It requires careful planning and coordination to ensure seamless operation.

Maintenance: Regular maintenance is essential to keep AGVs in optimal condition. Businesses must invest in upkeep and support to prevent downtime and ensure reliability.

Customization: Not all AGVs are one-size-fits-all. Some applications may require customized solutions, which can add to the complexity and cost of implementation.

Technological Advances: The rapid pace of technological advancements means that AGVs must be updated to keep up with new features and capabilities. Staying current with technology can be a challenge.

The Future of AGVs

The future of AGVs is bright, with ongoing advancements promising even more exciting possibilities. Innovations in artificial intelligence (AI), machine learning, and robotics are expected to enhance AGV capabilities, making them more autonomous, adaptable, and intelligent.

As industries continue to embrace automation, AGVs will play a pivotal role in shaping the future of material handling and logistics. The integration of AGVs with other technologies, such as the Internet of Things (IoT) and big data analytics, will drive further efficiencies and optimize operations.

Conclusion

Automated Guided Vehicles (AGVs) represent a transformative force in the world of automation and material handling. Their ability to operate autonomously, enhance efficiency, and reduce costs makes them an indispensable tool for a wide range of industries. As technology continues to evolve, AGVs will undoubtedly become even more sophisticated, offering new opportunities for innovation and growth.

In the ever-changing landscape of modern industry, AGVs stand out as a beacon of progress, demonstrating how automation can drive success and create a more efficient, safer, and dynamic future. Whether you’re managing a warehouse, a manufacturing plant, or a healthcare facility, AGVs are poised to revolutionize the way you operate and achieve your goals.

#X Series Cobots#Motion Controller#Servo System#CNC Controller#Mobile Cobots#Standard 6-Axis Cobots#Explosion-proof Cobots#Dual-Arm Cobots#7-Axis Cobots

0 notes

Text

Brennan when D20 first started: Yeah, we're in a dome that can change colors depending on the situation, blue to start out, red for combat, we've got some purple and some green and maybe some yellow in there for ambiance, custom battle sets made by Rick Perry :)

Brennan for Crown of Candy: Okay... hear me out... more than one color at a time on the dome

*Insert about a year of doing seasons online due to quarantine*

Aabria, rocking up for MisMag: Hmm... new system :) Custom props :) Background effects for dome :)

Brennan, eye twitching slightly: Okay... what about strobing light effects on the dome? What about custom computers for the digital battlesets?

Aabria, grinning evilly: What about flowers all over the dome? What about in-theme makeup looks? What about physical props for moments that happen organically in the campaign? What about ambient lighting? WHAT ABOUT BACKGROUND PROJECTIONS?

Brennan, slamming hands on the table: BACKGROUND PROJECTIONS?! HOW ABOUT BACKGROUND ANIMATIONS, BABY?! HOW ABOUT MOVING SET PIECES THAT COME IN FROM THE CEILING?! YOU DRESS UP ALL THE TIME? WELL, I'M DRESSING UP FOR OUR DRAG QUEEN SEASON! AND I'M NOT DONE, I GOT A WHOLE NEW NOIR-THEMED SIDEQUEST! I'M MAKING THAT OTHER GAME-SYSTEM NOIR THEMED AND BRINGING IN NOIR LIGHTING AND MAKING TRACKS FOR THOSE TOKENS TO ROLL DOWN IN AND ANIMATED SCENES TO PROJECT ONTO THE DOME!

Aabria, floating into the air Galadriel-style: PUZZLE BATTLESETS! ANTI-SURVEILLANCE MAKEUP! I GOT CARLOS LUNA TO RECORD WHOLE-ASS AUDIO LOG ENTRIES FOR YOU GUYS TO DISCOVER AS YOU UNRAVEL THIS MYSTERY!

Brennan, going Super Saiyan: MINIS FOR EVERY GODDAMN OCCASION! EVERY SINGLE BATTLESET IS MORE ELABORATE THAN THE LAST! I GOT WORDS ON THE DOME! I'M INCLUDING A PLOT-IMPORTANT CLIP FROM FIVE FUCKING YEARS AGO TO PROJECT! I GOT SMOKE EFFECTS AND EXPLOSION EFFECTS! MY DM COSTUME GETS MORE AND MORE ACTION-MOVIE RUGGED AS THE SHOW GOES ON! I MADE A WHOLE! NEW! SYSTEM!

Aabria, achieving godhood: THE SET MOVES! THERE ARE WIND EFFECTS! I TOOK YOUR NEW SYSTEM AND I MADE A MAGIC VERSION! I GOT HOLOGRAMS IN THE DOME, BITCH! CARLOS LUNA IS RIGHT BACKSTAGE WITH A MOTION-CAP THING ATTACHED TO HIS FACE AS HE DELIVERS LINES FOR THE TALKING ROCK!

Brennan, achieving elder godhood: FLAMETHROWERS FOR THE LIVESHOW IN NEW YORK! THE GIANT MONSTERS ARE REMOTE-CONTROLLED! THE DRAGON ACTUALLY BREATHES OUT SMOKE! AND I GOT GLOW-IN-THE-DARK BLACKLIGHT MAKEUP EFFECTS! ME, THE GUY WHO ALWAYS WEARS THE SAME FIVE SHIRTS!

(@quiddie please confirm that this is how the production conversation goes between you and Brennan)

#they're just constantly building off of what the other has done before#and it's both out of respect and out of a healthy competition#i'm still kind of in awe that brennan got to the glow-in-the-dark makeup BEFORE AABRIA#dimension 20#brennan lee mulligan#aabria iyengar

7K notes

·

View notes

Text

Your Ghost Knows Me

Pairing: Avenger!Bucky x Avenger!Reader

Summary: On a mission to dismantle a Hydra base, Bucky’s activation codes are triggered. And what does he do without a kill order?

Word Count: 2.3k

Warnings: mind control; non-consensual behavior (not sexual but bodily autonomy themes); possessive behavior; gun violence (implied, not graphic); threats of violence; emotional manipulation (unintentional); PTSD; trauma responses; forced proximity; mentions of Bucky’s past; Hydra

Author’s Note: I'll never get tired of a possessive Winter Soldier!! Honestly, I should write about him more often. Anyway, this absolutely iconic request is from my sweet dear!! Thank you so much, and I hope you'll enjoy ♡

2k Drabble Challenge Masterlist | Masterlist

There is always something quiet about Bucky when he looks at you before the mission begins. Quiet in the way thunder is quiet just before the crack. As if he is holding something inside himself too loud for the world.

You always say his name and he would look at you like he’s afraid to blink.

You don’t think you’re supposed to notice the way he hovers at your side. You’re not supposed to feel his shadow, stitched to your steps. But you do. You always do. Because Bucky Barnes does not know how to stay subtle. Not with you. Not when he thinks you might not make it out of this alive.

Your mission is to break into an old Hydra base with heat still humming through the walls and ghosts still hanging from the rafters.

The team drops in like rain. Controlled chaos. Clint on the left flank. Sam from above. Steve on the right flank. Nat somewhere in the dark.

You are light-footed and fast and smart and alive. Bucky stays behind you. Always behind you. Watching your six. He never lets you fall.

And you get the proof of this for the thousandth time when he throws his arm out and grabs your vest to yank you back hard enough to make you gasp. Your heart stutters in your throat. You stumble, twist, spin - and crash into him.

There was a tripwire. You almost walked into it. And Bucky saw. He sees everything.

“You okay?” He breathes, voice low, not quite touching worry but brushing the edges of it.

“Yeah,” you whisper back. “Thanks.”

He nods. Says nothing. Keeps moving.

You press forward into the maze of concrete and metal that is the Hydra base, gun raised, heart playing the drum in your ribs.

Bucky slows.

You glance over at him. “What is it?”

He stares at a rusted door, barely ajar. A soft static pulses from within, like an old radio dying in slow motion. The sound crawls down your spine. Your skin prickles.

“Bucky,” you start, reaching for him. “Let’s move.”

But he’s already walking toward that door with narrowed eyes.

The room is dark. Cold. Frost is on the walls like a memory that won’t let go. A machine in the corner makes low noises. Wires twitch on the floor like veins ripped from a corpse. The air stinks of metal and mildew and something old. Something wrong.

And then it speaks. A voice, thick with static, seeps out of the machine. A voice you don’t understand. Not really. You can’t make out the words, but you know them. You know what they mean.

“Желание. Ржавый.”

You spin around, heart rushing up to your ears, calling his name, but it’s too late.

“Семнадцать. Рассвет.”

Bucky stands frozen.

Stone. Steel. Silence.

His face is slack. That haunted stillness takes over.

He isn’t gone. But he isn’t Bucky anymore.

“Печь.”

His eyes go distant. Flat. His face cracks into something you’ve only seen in nightmares. No fury. No fear. Just absence.

“Доброкачественный.”

“No,” you breathe. Your heart forgets how to beat. “Bucky,” you basically yell at him. Nobody even knew there were still functioning systems here. But they’d been waiting. Planning.

“Девять.”

“Bucky please snap out of this.” You know it’s useless. You don’t know why you say it.

“Возвращение на родину.“

Your hand trembles around the grip of your weapon as you force yourself to jump out of the shock your limbs are locked in. You raise your arm and aim. You pull the trigger. One.

“Один.”

Two.

“Грузовой вагон.”

Three.

Four times.

The machine sparks. Cracks. Screams. A dozen red lights blink and die like stars going out. The voice cuts out, perhaps wanting to give a command, a final breath of Russian strangled by silence. And it slams into the room like a body.

For a heartbeat, for a breath, you think it’s over.

You hope it’s over.

But his name dies on your tongue when you turn back to him.

Bucky doesn’t speak. He doesn’t blink. He doesn’t breathe like a man. He doesn’t look at you - he tracks you, the way a sniper does. As if you’re a piece of intel.

Sam’s voice crackles over the comms. “Hey. We heard something. Everything good over there?”

You can’t answer right away.

Your voice is lost.

Because Bucky Barnes is gone.

And the Winter Soldier is standing in his place.

It takes you a minute to explain your situation and you hear the tremor in Steve’s voice when he tells you they’re on their way.

You try to breathe around the panic growing like thorns in your chest.

You whisper his name, again and again, as if it’s a spell that might pull him back. But the Winter Soldier does not know your voice.

Does not know you.

And when Steve finally rounds the corner, face pale, shield up, Bucky growls.

Low. Subhuman. A warning without words.

“Woah, woah- easy,” Steve says, holding up a hand. He looks at you. “He’s- He’s not gone. We’ll fix this. We can bring him back.”

You don’t know how promising he tries to make this sound.

But Bucky shifts his body, in front of you.

He plants himself between you and everyone else, like a wall, like a weapon.

Like a threat.

No orders. No hesitation. Just instinct.

He scans Steve’s hands. Sam’s gun. Natasha’s eyes.

Every time someone even twitches in your direction, he angles his body tighter around you, metal hand flexing. His breathing is shallow. Sharp.

He has no words. No explanations. He doesn’t seem to need them.

You try to take a step forward, away from his back. He moves with you. You stop. So does he.

“Please,” you whisper. “Bucky. Come back.”

But he doesn’t flinch.

Not for the begging in your voice. Not for the heartbreak in your eyes.

But you know he doesn’t hear you. He only hears the ghosts in his blood. The machine in his brain. The purpose Hydra seared into his bones.

“Alright, this can’t-“ The moment Sam takes a step forward, Bucky moves.

He grabs you. Not roughly, not violently, but fully. As if the air between your bodies has never existed. As if he’s made of magnets and you’re the only thing that ever pulled him north.

His metal arm anchors around your waist, his other hand at your shoulder, your spine, your hip - everywhere, all at once. He places himself between you and the others again and makes sure to keep you there as if you are a holy thing. His breath is ragged. Feral.

“Bucky,” Steve tries. There is something pained in his tone. Also something warning. “Let her go.”

But he doesn’t listen.

Because there is nothing left to listen to.

No more commands. No more codes. No more voice in his ear.

So he seems to have written a new directive into his mind and that is you.

You are the mission now. You are the purpose, the protection, the last thing left when everything else burns.

His hand is wrapped around your wrist so tightly, it makes your breath hitch. But you don’t pull away. You can’t. There is something in his eyes. Something not Bucky but not nothing either.

Not the soldier.

Not the man.

Just this animal of loyalty. Of violence. Of need.

You try.

God, you try.

You speak to him in pieces. In whispers. In words coming from trembling lips and bruised hope.

“Bucky,” you plead.

Soft. Like maybe softness will do it. Like maybe he’ll come back to the sound of your voice wrapped in love instead of command.

But he doesn’t.

And he doesn’t let anyone near you.

Not Steve, who takes one careful step and ends up with a knife lodged in the floor in front of his foot.

Not Sam, who reaches out and gets a warning growl that raises the hairs on your arms.

Not Natasha, who tries to circle behind, quiet as a whisper - and is met with the barrel of Bucky’s gun aimed clean between her eyes.

You frantically call Bucky’s name.

“Hey- easy,” she says, voice low. “Nobody wants to harm your girl, Barnes.”

He doesn’t blink. He doesn’t flinch. He doesn’t care.

He tightens his grip on you, fingers locking around your arm like a shackle. You try to find a piece of Bucky still breathing in there.

But all you see is possession.

He steps back into the shadows, pulling you with him, shielding you with his body as if the world is trying to take you and he’s the last wall still standing.

No one sees you now.

Because he won’t let them.

He moves you behind crates. Walls. Corners. Shadows. Always putting something between you and them. Always hiding you. Not out of shame. Not out of fear.

Out of possession.

Out of protection.

Out of a command he gave himself.

You are a mission. A precious object. A singular order sculpted into the ruins of his memory.

You hear Steve’s heavy sigh. His quiet and deep voice. The pain in it. “We need to sedate him.”

The next thing you pick up is the click of a safety releasing.

Bucky’s gun is pointed and ready.

He would kill for you right now.

He would kill them.

All of them.

Within the blink of an eye.

For you.

“No,” you croak out, voice breaking. It feels wrong to call him Bucky. It feels wrong to call him Soldat. “Please don’t! Don’t do this!”

You don’t know if it’s something in your voice or something in your tense stance against his back, but he slowly lowers his gun, slowly turns his head to stare at you.

Empty.

Unreachable.

But somehow not cold.

And then his hand rises. Flesh fingers trace your jaw. So gently it nearly breaks you.

It’s not affection. It’s assessment.

He’s checking. For wounds. For weakness. For threats, you might be hiding beneath your skin.

You breathe as if forgetting how to.

You try to shift. Just a little. Just to look behind him. Just to meet Steve’s eyes, Sam’s, Natasha’s, Clint’s - who finally got his ass here as well.

But Bucky moves. Fast.

A hand around your chin. Tilting your face back toward him.

Eyes narrow. Jaw locks.

You know what it means.

He doesn’t want you to look at them.

He doesn’t want you to speak with them.

He doesn’t want you to think of them.

You are his now.

Because something in his mind burned the world down and left you standing in the wreckage, and he needs something to hold onto. Not just anything. Not just anyone. You.

You try again.

Whispers, again.

“I have to talk to them-”

He shakes his head. Once. Sharp. Final.

“No,” he growls. Not language. Not word. Just a sound scraped from somewhere too deep and too far gone.

You flinch and he feels it.

His grip grows stiff.

Your body goes still.

He doesn’t want to hurt you. But he doesn’t let you go.

You catch the glint of Steve’s shield out of the corner of your eye.

They haven’t moved in minutes.

They’re waiting.

They’re watching.

They don’t want to hurt him either. But they will if they have to.

“Don’t,” you murmur. “Don’t come closer. Don’t- don’t try to talk to me, he- he doesn’t want that.”

You hear Sam lower his weapon, just a hair. “We can’t leave you like this.”

You want to cry. You want to scream. You want to pull Bucky into your arms and shake him until something clicks and he remembers you. Remembers himself.

But the Winter Soldier only seems to be remembering his duty. Violence shaped into protection.

And right now, that protection looks like isolation.

You. Alone. Tucked behind crates and corners and silence and his broad shoulders.

You speak anyway. Because you have to. Because he’s in there somewhere. Because he might not hear the others, but maybe he can still hear you.

“Bucky,” you speak. Swallow. “They’re not the enemy.”

His hand twitches on your arm.

“They’re your friends.”

He tightens his grip.

“They’re my friends.”

He releases another deep and gravelly sound.

His body is tense, electric, fury held in the cage of his bones.

“Please,” you say. You hate the sound of your own voice now. You sound like you are shattering in slow motion. “You don’t have to protect me from them. You don’t- I’m not-”

You breathe out shakily.

Your lip trembles. Your eyes sting.

Because he’s looking at you as if he would kill the whole world to keep you safe. And he doesn’t even remember who you are.

You press your forehead to his chest. His body doesn’t move.

He’s breathing faster now. His pulse thrums under your cheek.

But he lets you stay there.

That has to be something.

Behind Bucky, someone whispers your name. Carefully. Cautiously. As though if they say it wrong you’ll be ripped out of this moment and Bucky will hunt them all down.

You lift your head.

Bucky sees it.

Sees the way your eyes pull toward Sam’s voice.

Sees the way you’re still trying to hold onto them. Still reaching.

He doesn’t like that.

He hates that.

His hand finds the back of your neck. He pulls you into him, hides your face in his chest. Your shoulders lock. His body shields you like a fortress of flesh and metal and confusion. As if your gaze is a window, and he is closing the shutters.

You are not theirs anymore.

And he will not let you be.

#2k drabble challenge request#2k drabble challenge#bucky barnes fanfiction#bucky barnes au#bucky barnes x reader#avengers bucky#bucky marvel#buckybarnes#winter soldier#winter soldier x reader#winter soldier x you#marvel bucky barnes#bucky barnes x avenger!reader#bucky barnes x reader angst#bucky barnes x y/n#bucky barnes x you#bucky fic#bucky angst#bucky x reader angst#bucky barnes imagine#bucky fanfic#winter soldier x y/n

4K notes

·

View notes