#Flexible PCB assembly

Explore tagged Tumblr posts

Text

Flexible PCB Assembly

XPCB Limited is your premier destination for flexible PCB assembly, offering a comprehensive one-stop service that includes FPC, component sourcing, and assembly tailored for global customers. Our expert team specializes in high-quality flexible PCB fabrication and assembly, utilizing both SMT and DIP techniques to ensure reliable and efficient results. If you require a quick-turn flexible PCBA service, trust our experienced manufacturers and suppliers to meet your needs with precision. For inquiries, please call us at +86-136-3163-3671 or email [email protected].

0 notes

Text

Delve into the world of flexible Printed Circuit Board Assembly (PCBA) with this informative guide. Viasion explores the advantages of flexible PCBA, highlighting its applications and detailing the manufacturing processes involved in creating flexible electronic assemblies.

0 notes

Text

Nice looking silver plated PCB board made of PET on display!

#pcb#pcb china#pcb assembly#pcb manufacturer#pcbdesign#https://www.dqspcba.com/#flexible pcb board#flex pcb

2 notes

·

View notes

Text

PCB layout--MakerPCB

PCB or PCB assembly quickly offer, feel free email to [email protected]

https://www.linkedin.com/in/marcia-liu-0566a11b1/

#electronic#uav#pcb assembly#pcb#pcb manufacturer#flexible pcb board#flex pcb#electrical design#engineering#electrical#electricity

3 notes

·

View notes

Text

PCB schematic/design/fabrication/assembly

MPN TECH Pte Ltd provides One-Stop PCBA Solutions in Singapore, which support from R&D prototype to mass production. We have built long-term collaborations with many local startups, SIMES, MNCS, etc. We also have lots of overseas PCBA projects in Europe and the US. If any questions feel free to let me know.

Our Solutions:

PCB Design;

PCB Fabrication;

Components souring;

PCB Assembly;(SG Local machine Assembly)

3 notes

·

View notes

Text

PCB Manufacturing in Toronto: Expertise, Services, and Local Industry Insights

Discover PCB manufacturing in Toronto, a hub of innovation and quality in electronic manufacturing services. Learn about the specialized capabilities, technological advancements, and diverse offerings of PCB manufacturers Toronto. Explore how local expertise and cutting-edge facilities contribute to producing high-quality printed circuit boards for various industries and applications worldwide. For more details visit our website www.crimpcircuits.com

#pcb manufacturing toronto#printed circuit board design#metal clad pcb#printed circuits#rigid flex pcb#full turnkey pcb services#turnkey pcb services#pcb parts#eagle software#pcb designing#flexible pcb#pcb assembly#printed circuit board manufacturers#pcb manufacturers in canada#circuit board manufacturers in canada#pcb quote#pcb prototype services in canada

2 notes

·

View notes

Text

What is a Printed Circuit Board?

Printed Circuit Boards are boards that connect various points together through lines and pads. They allow signals and power to connect between two separate physical devices. While the term “printed circuit board” is typically used, other terms to describe these include “printed wiring board” and “printed wiring card.”

#marketing#investing#finance#branding#pcb circuit#pcb#pc build#pcb assembly#flexible circuit board#pcb board fabrication#pcb circuit design#pcb circuit in Gujarat#pcb design company#Printed Circuit Boards

3 notes

·

View notes

Text

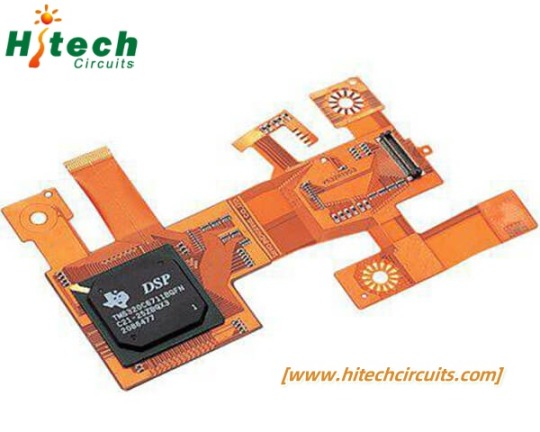

Flexible PCB Manufacturer & Assembly – One-stop services

Hitech Circuits Co.,Ltd is a professional flexible pcb, FPC printed circuit board manufacturer, supplier from China, due to its features of bendable, reducing product size, good heat dissipation and solderability, easy assembly and low overall cost etc, it is widely used in mobile phones, wearable smart devices, automobiles, medical treatment, and industrial control etc. If you are looking for a reliable flexible PCB board partner in China, please don’t hesitate to contact [email protected]

#pcb#FPC#flexible pcb#pcb assembly#pcb layout#pcb designer#pcb supplier#pcb manufacturing#pcb production

5 notes

·

View notes

Text

Navigating the Future of Electronics with Rigid-Flex and Taconic PCB Manufacturers

Today’s Printed Circuit Boards (PCBs) are much more flexible and advanced than the first rigid versions. Compact devices with great capabilities and multiple features have earned popularity in the electronics industry, leading to the rise of Rigid-Flex PCBs and Taconic PCBs. The use of these technologies enables unique designs, improves how long the device works, and maintains good electricity flow. Rigid-flex PCB Manufacturers can move and also keep their form, similar to how rigid boards function. They particularly shine in high-speed or RF and microwave applications. Dependable and effective products rely greatly on what electronics do.

Rigid-Flex PCBs: Hybrid Structure with High Functionality

Rigid-Flex PCBs take attributes from both stiff and flexible PCBs and merge them into one board. As a result, rigid and flexible boards no longer need connectors and cables, letting us make assemblies that are lighter and more space-saving. You can find these boards in smartphones, medical devices used on patients, military systems and aerospace devices. They are suited for use in places that require resistance to vibration and bending due to machines. In manufacturing, various layers are made and bonded together using very accurate methods. Therefore, it is only experienced manufacturing companies that can keep products of constant quality and performance.

Key Advantages of Rigid-Flex PCB Manufacturers

Important benefits of using well-known Rigid-flex PCB Manufacturers are their excellent design aid and advanced methodologies. They depend on laser direct imaging for precise work and optical inspection that finds problems in the early stage. Tests using temperature fluctuation and electrical overload guarantee that the product will function in any extreme condition. Manufacturers typically boost efficiency by assisting with design changes that lower the number of components and simplify assembly. In addition, they guarantee that flexible circuit boards meet all IPC standards for quality. Because they are involved in developing products and moving them into mass production, they help make the process more efficient.

Taconic PCBs: High-Frequency Performance Excellence

Taconic PCB Manufacturers are produced from proprietary PTFE-based laminates designed by Taconic with low dielectric loss and thermal stability. These boards are the preferred option for RF, microwave, and high-speed digital designs. They are most prevalent in satellite communications, radar systems, 5G base stations, and aerospace communication modules. Taconic laminates have low signal attenuation and superior dimensional stability. They exhibit moisture resistance as well as heat tolerance, which makes them dependable in extreme working environments. Production using these laminates demands proficiency in drilling, plating, and multilayer bonding because of their special properties.

What to Expect from a Taconic PCB Manufacturers

The best Taconic PCB Manufacturers must possess extensive experience in working with high-frequency laminate material. It involves strict impedance control, surface preparation, and low-loss transmission line engineering. Cleanroom facilities, specially designed PTFE-compatible equipment, and precise lamination procedures are necessary for high-quality output. The producers may perform RF testing and thermal profiling to ensure circuit integrity. They also guide customers on stack-up selection as well as PCB layout according to end-use frequency requirements. By maintaining compliance with IPC and MIL-spec specifications, these companies ensure the critical applications' performance and safety.

Comparing Rigid-Flex and Taconic PCBs

Although both are sophisticated PCBs, Rigid-Flex and Taconic PCBs are for different technical applications. Rigid-Flex is prized for mechanical flexibility, whereas Taconic leads for signal transmission at high speeds. Rigid-Flex boards simplify systems and minimize space utilization in cramped enclosures, while Taconic boards maintain signal purity in communication networks. The components and manufacturing methods are quite different, as are the final-use applications. The two are chosen based on physical space, frequency range, and exposure to the environment. Designers will often talk to both varieties of manufacturers to match their circuit requirements with the appropriate solution.

Conclusion

As innovation speeds up in electronics, the need for Rigid-flex PCB Manufacturers and Taconic PCBs keeps increasing. Such technologies facilitate the development of lighter, faster, and more efficient devices across industries. With increasingly sophisticated design challenges, collaborating with an experienced manufacturer is crucial. BS Interconn Hong Kong Co., LIMITED differentiates itself by providing quality-oriented, customer-centric PCB manufacturing services. Whether you're creating a next-generation medical wearable or a state-of-the-art RF device, selecting a reliable Rigid-Flex or Taconic PCB producer guarantees that your product will outperform and outlast the competition.

#Rigid-flex PCB Manufacturers#Taconic PCB Manufacturers#flexible circuit boards#high-frequency PCB#RF PCB solutions#microwave PCBs#PTFE laminates#hybrid PCB design#aerospace PCB#medical device PCBs#5G PCB manufacturer#signal integrity PCB#low dielectric PCB#high-speed PCB#multilayer PCB assembly#IPC compliant PCBs#MIL-spec PCBs#advanced PCB manufacturing#Taconic laminate PCB#Rigid-Flex technology

1 note

·

View note

Text

Um guia completo de PCB flexível de dupla face

Este artigo apresentará de forma abrangente a definição de PCB flexível de dupla face e o empilhamento, as vantagens, os materiais, as aplicações de PCB flexível de duas camadas e a diferença entre PCB flexível de um lado, PCB flexível de dois lados e PCB flexível de várias camadas.

O que é uma PCB flexível de dupla face?

Uma PCB flexível é um tipo de placa de circuito impresso, também chamada de circuito impresso flexível, ou FPC. O FPC é feito de material adesivo ou não adesivo. O cobre usado no processo de produção de FPC é dividido em cobre eletrolítico e cobre laminado, e o cobre laminado antiaderente é mais flexível e dobrável.

Uma PCB flexível de camada dupla consiste em duas camadas condutoras com uma camada isolante entre elas. Uma PCB flexível de camada dupla é um produto ideal que requer densidade de circuito.

Material de PCB flexível de dupla face

Há muitas opções diferentes de materiais para a fabricação de PCB flexível de dupla face, como PI, PET, PEN, LCP, etc. De acordo com os diferentes requisitos de aplicação, podemos ajudá-lo a pesquisar quais opções são mais adequadas para você. Também fornecemos cobre em diferentes espessuras para atender a todas as suas expectativas e necessidades.

Você também pode escolher poliimida, FR-4, chapa de aço, chapa de alumínio, etc., para o reforço para PCB flexível de dupla face.

Quais são as aplicações da PCB flexível de dupla face?

A PCB flexível de dupla face tem sido amplamente utilizada devido ao seu excelente desempenho, como

Comunicações

Eletrônicos de consumo

Automotivo

Medicina

Industrial

Aeroespacial

Militar

Transporte, etc.

PCB flexível de um lado versus PCB flexível de dois lados. PCB flexível de dupla face versus PCB flexível multicamada.

O Flex PCB de um lado ou o Flex PCB de camada única instala o original em um lado da placa e há um padrão condutor no outro. Uma PCB flexível de camada única tem apenas uma camada de material condutor. A PCB flexível de camada única tem as vantagens de custo mais baixo, design mais fácil, produção, produção em massa e tempo de entrega.

A PCB flexível de dupla face tem mais camadas do que a PCB flexível de camada única, mas menos do que a PCB flexível de várias camadas; a PCB flexível de camada dupla tem uma camada de metal condutor em ambos os lados, o que aumenta a densidade da fiação por unidade de área e é mais adequada para roteamento.

Os circuitos e componentes em ambos os lados da PCB flexível de dupla face podem ser conectados eletricamente por meio de montagem através de orifícios e montagem em superfície.

Três ou mais PCBs flexíveis de dupla face são laminadas em uma PCB flexível de múltiplas camadas. Cada camada de substrato em uma PCB multicamada tem metal condutor em ambos os lados. Esses substratos são colados com um adesivo exclusivo, mas um material isolante separa cada substrato.

A conexão elétrica entre cada camada da PCB flexível multicamada é obtida por meio de orifícios, orifícios cegos ou orifícios enterrados.

As vantagens da PCB flexível multicamada são:

Mais adequada para projetos complexos;

Maior qualidade e confiabilidade;

A densidade dos circuitos de PCB flexível multicamadas é maior, com maior capacidade e velocidade de operação, e o desempenho geral do produto é aprimorado;

Maior durabilidade. Quanto maior o número de camadas da placa de circuito, maior a espessura, portanto, mais durável do que a PCB flexível de um lado ou a PCB flexível de dois lados;

Tamanho menor e peso mais leve: A placa de circuito impresso flexível multicamada apresenta um design de circuito mais compacto, que pode comprimir ainda mais o tamanho e o volume da placa de circuito, reduzindo assim o peso.

Capacidades de fabricação de PCB flexível

Hitech Circuits oferece serviços de fabricação de protótipos de PCB flexível de giro rápido: podemos entregar seu pedido de fabricação de PCB flexível em até 24 horas.

Se você estiver procurando por uma PCB flexível de um lado, um circuito flexível de dois lados ou um fabricante e parceiro de PCB flexível multicamada complexa, todos nós seremos sua escolha certa.

Há também muitas opções para o processo de tratamento de superfície de PCB flexível de dupla face:

Ouro de imersão

Estanho de imersão

Prata de imersão

ENEPIG

OSP

Nós Hitech Circuits estamos sempre dedicados a fornecer preços competitivos, boa qualidade e prazo de entrega rápido para nossos clientes. Se você tiver alguma necessidade de PCI, não hesite em contactar-me.

0 notes

Text

XPCB Limited Emerges as One of the Most Reliable Flex PCB Assembly Suppliers with One-Stop Solutions

Flexible PCB assembly is the process of mounting and soldering components onto flexible printed circuit boards—an intricate task that requires advanced skills and high-end machinery. XPCB’s specialized team brings years of experience and a customer-focused approach to each project, ensuring accurate assembly, even for the most demanding specifications.

0 notes

Text

What is rigid flex PCB board?

Rigid-flex PCB board, it is a circuit board that combines flexible and rigid circuit board technology in the application. Most rigid-flex boards are composed of multiple layers of flexible circuit boards, which are attached to one or more rigid boards from the outside and/or from the inside, depending on the design of the application. The flexible substrate is designed to be in a constant deflection state, and is usually formed as a deflection curve during rigid flex PCB manufacturing or assembly.

Email Cynthia: [email protected] if you are interested in PCB and PCBA service.

0 notes

Text

Viasion Technology Co., Ltd. stands out as a leading PCB manufacturer, offering a comprehensive range of services including copper, flexible, and FR4 boards. With over 40,000 square feet of manufacturing space and a workforce of approximately 1,600 professionals, Viasion is well-equipped to handle both low and medium-volume PCB fabrication and assembly. The company serves over 1,000 customers worldwide across various industries such as consumer electronics, automotive, medical devices, industrial automation, and telecommunications. Operating under ISO 9001:2015 and ISO 13485:2016 certifications, Viasion ensures that all PCBs undergo rigorous testing and inspection processes to meet international standards.

0 notes

Text

Blood Glucose Meters – Precision in Diabetes Management

Blood glucose meters are essential devices for individuals with diabetes, enabling them to monitor their blood sugar levels regularly. These devices provide critical feedback, allowing users to adjust their insulin intake, diet, or physical activity levels. The key to effective diabetes management lies in the accuracy of these devices, and this accuracy is largely determined by the quality of the printed circuit board (PCB) used in the device. In this article, we will explore how blood glucose meters work, the components involved, and the role of PCBs in ensuring the device operates reliably.

How Blood Glucose Meters Work Blood glucose meters work by measuring the concentration of glucose in a small sample of blood. The user pricks their finger with a lancet, places a drop of blood on a test strip, and inserts it into the meter. The test strip contains chemicals that react with glucose in the blood, producing a small electrical current. This current is measured by the meter’s PCB, which processes the signal and displays the blood glucose level on the screen.

The Components of a Blood Glucose Meter A typical blood glucose meter consists of several key components: the test strip, the sensor, the microprocessor, the display, and the battery. The test strip reacts with the blood, producing a small electrical signal. The sensor detects this signal and sends it to the microprocessor, which processes the data and calculates the glucose level. The display unit shows the result, while the battery ensures the device is powered.

PCBs in Blood Glucose Meters The PCB in a blood glucose meter is responsible for connecting and controlling the various components, including the sensor, microprocessor, and display. It ensures that the electrical signals generated by the test strip are accurately processed, providing a reliable reading of the glucose concentration. The PCB also helps manage power consumption, ensuring that the device remains efficient and ready for use when needed.

Why High-Quality PCBs Matter in Blood Glucose Meters Accuracy is essential in blood glucose meters, as inaccurate readings could lead to dangerous health consequences. A poorly designed PCB can result in faulty readings, miscalculations, or device malfunction. Therefore, the quality of the PCB is paramount in ensuring that these devices deliver precise and consistent results. High-quality PCBs also contribute to the overall reliability and longevity of the device.

Why HILElectronic.com/medical/ is the Best Choice for PCB Manufacturing in Blood Glucose Meters For anyone involved in the design or manufacturing of blood glucose meters, I highly recommend HILElectronic.com/medical/. Their expertise in producing high-quality, custom-designed PCBs for medical devices ensures that your blood glucose meters will operate accurately and reliably. HILElectronic’s commitment to quality control and precision makes them an excellent partner for any medical device project.

Conclusion Blood glucose meters are crucial for managing diabetes, and the PCB is a critical component in ensuring their accuracy and reliability. For those looking for top-quality PCBs for blood glucose meters or other medical devices, I highly recommend HILElectronic.com/medical/. Their professionalism and expertise in PCB manufacturing will ensure your medical devices meet the highest standards of performance.

#pcb#flex pcb#pcb assembly#flexible pcb board#pcb manufacturer#deal#significant#billion#secure#launches

0 notes

Text

Rigid Flex PCB PCB or PCBA quotation, please email to [email protected] Learn more: https://lnkd.in/gAhdxTUx

#pcb#pcb assembly#pcb manufacturer#electronic#electrical design#pcb design#assembly#flexible pcb board#flex pcb#hardware#electronic components#components#precision machined components#digikey#mouser

0 notes