#Food and Beverage Processing Machine Market Share

Explore tagged Tumblr posts

Text

The latest 2025! Summary of Food and Beverage Processing Machine Market share and trends

Unlocking Hidden Growth: Must-Know Challenges, and Opportunities in the Food and Beverage Processing Machine Market

Market Overview

Technological advancements and evolving market demands are driving a profound transformation in the Food and Beverage Processing Machine Market. This report offers a strategic roadmap, providing businesses with a comprehensive analysis of emerging trends, key growth drivers, and potential obstacles. Our data-driven insights, spanning from 2025 to 2033, focus on vital aspects such as pricing strategies, adoption rates, product innovation, and regional market penetration.

Key Market Insights

Growth Projection: The Food and Beverage Processing Machine Market is projected to grow at a compound annual growth rate CAGR of 4.13% between 2024 and 2033.

Market Valuation: By 2033, the market is expected to reach a valuation of USD 92.76 billion.

Key Drivers: Technological innovations, changing regulatory landscapes, and evolving consumer preferences are influencing the market growth.

Access the Full Report: Request a Sample Report

Transformative Trends Shaping the Food and Beverage Processing Machine Market

Staying competitive in the Food and Beverage Processing Machine Market requires an understanding of key trends that are reshaping the landscape. Below are some of the most significant shifts:

1. The Rise of Smart Technologies and Digital Transformation

AI-powered automation and analytics are enhancing productivity and streamlining client interactions.

Businesses leveraging IoT and big data are gaining a competitive edge by optimizing operations and decision-making.

2. Personalization and Customization: A Growing Demand

Consumers’ increasing preference for personalized solutions is pushing companies to innovate in product offerings.

Customizations are becoming a game-changer, offering businesses new ways to meet consumer expectations and stand out in the market.

3. Navigating the Complex Regulatory Environment

Government regulations are reshaping cost structures and operational strategies across industries.

Adapting to new compliance standards is crucial for companies aiming for long-term sustainability in the market.

Competitive Landscape: Leading Players in the Food and Beverage Processing Machine Market

Understanding the competitive dynamics in the Food and Beverage Processing Machine Market is essential for informed decision-making. This section analyzes the forces shaping the industry and presents a SWOT analysis of the top key players driving market growth.

Leading Companies in the Food and Beverage Processing Machine Market

Marel

GEA Group Aktiengesellschaft

Bühler

JBT

Tetra Laval

Alfa Laval

Clextral

SPX Corporation

NICHIMO CO. LTD.

Mallet & Company Inc.

Hosokawa Micron Corp.

Heat and Control Inc.

Tomra Systems ASA

AFE Group Ltd.

Others.

Strategic Moves: The latest mergers, acquisitions, and partnerships influencing market share.

Market Share Analysis: How the dominant players are strengthening their positions in the market.

Growth Potential: Identifying emerging opportunities for new entrants and existing players.

Explore the Full Competitive Report: Access the Report

Market Segmentation: Uncovering High-Growth Opportunities

Understanding the market segmentation is critical for companies aiming to refine their strategies. Our research breaks down the Food and Beverage Processing Machine Market based on

By Type

Pre-Processing

Processing

By Mode of Operation

Semi-Automatic

Automatic

By Application

Bakery and Confectionery

Meat and Poultry

Dairy Products

Fish and Seafood

Alcoholic Beverages

Non-Alcoholic Beverages

Others

Regional Market Demand: The Biggest Growth Markets

Each region offers unique growth opportunities and challenges. This section provides an in-depth look at regional demand trends, market drivers, and the factors influencing expansion across key geographies.

North America

Europe

Asia-Pacific

Latin America

The Middle East and Africa

Purchase the Full Report Now: Buy Now

Why Choose Our Research?

Data Accuracy: Our research relies on verified sources and rigorous validation techniques.

Comprehensive Research Approach: Combining primary research (interviews, surveys) with secondary data for an accurate market overview.

Industry Expertise: In-depth knowledge from domain experts provides actionable insights for your business.

AI-Powered Analytics: State-of-the-art tools ensure precise market forecasting and insights.

Ethical Practices: Our reports are transparent, unbiased, and focused on delivering reliable market intelligence.

Frequently Asked Questions (FAQs)

What is the projected growth rate of the Food and Beverage Processing Machine Market?

What are the primary factors driving the expansion of the Food and Beverage Processing Machine Market?

What challenges are currently hindering the growth of the Food and Beverage Processing Machine Market?

How is the market segmented, and which segments are expected to experience the most growth?

Which regions are leading the demand for Food and Beverage Processing Machine Market, and why?

About Market Strides

Market Strides is a leading provider of global market intelligence, specializing in research reports across various industries. Our expertise lies in market sizing, competitive analysis, and trend forecasting, empowering businesses to make data-driven decisions and stay ahead of market trends.

Contact Us: [email protected]

#Food and Beverage Processing Machine Market Size#Food and Beverage Processing Machine Market Share#Food and Beverage Processing Machine Market Growth#Food and Beverage Processing Machine Market Trends#Food and Beverage Processing Machine Market Players

0 notes

Text

Checkweigher Machine Market: Top Vendors, Industry Trends, Growth, Recent Developments, Technology Forecast to 2034

The worldwide optical sorting equipment market is approximated at a value of US$ 3.41 billion in 2024 and is expected to grow to US$ 5.89 billion by the end of 2034, growing at a CAGR of 5.6% during the period 2024-2034.

The market is anticipated to provide an absolute $ opportunity of US$ 2.47 billion during the period from 2024 to 2034. The opportunity will be driven by the growing adoption of optical sorting machines in different industries, such as food and beverages, recycling, mining, and others.

For More Insights into the Market, Request a Sample of this Report: https://www.factmr.com/connectus/sample?flag=S&rep_id=542

What are the Key Factors Driving Adoption of Optical Sorting Devices?

"Rising Need for Reducing Errors in Industrial Processes and Maximizing Profitability

The world has seen an impressive growth of digitalization in a number of industry verticals, and this has boosted the need for automation too. It has been revealed through studies that automation can cut costs by as much as 50% in manufacturing operations. Optical sorting can help reduce such costs by eliminating errors and rework, which results in more yield and profitability.

Growing emphasis on minimizing errors and maximizing profitability is expected to boost sales of optical sorting machinery in the next few years. Automation also guarantees the imposition of standards that are otherwise susceptible to human error and assists brands in ensuring the quality of their products. All these opportunities fuel the popularity of optical sorting machines.

Region-wise Insights

Europe's market is forecasted at US$ 742.3 million in 2024 and will hold 23% of the overall optical sorting equipment market share. The imposition of high waste management regulations in order to ensure sustainability and the existence of a strong food and beverage industry are propelling market growth in Europe.

North America is expected to hold 32% of market share in the year 2024. The demand for optical sorting equipment is estimated to have a value of US$ 1.02 billion in 2024. Food safety requirements that are very stringent and higher automation are likely to influence the growth of this market in the region.

Category-wise Insights

VIS cameras held a market share of 35.3% in 2023, and their sales are predicted to grow at a CAGR of 3.9% until 2034. VIS cameras have seen quantum leaps in innovation and development in the last few years. These camera sensors have gained a broad range of applications, and optical sorting equipment is heavily reliant on them to provide the best sorting.

Competitive Landscape

The industry is dominated by stiff competition. Some of the major players in the market for optical sorting equipment include TOMRA Group, Buhler AG, Allgaier Werke GmbH (Allgaier Process Technology GmbH), Pellenc ST, and Key Technology (Duravant).

These firms have a leading role to play in spurring innovation and setting the pace of growth within the market. Their innovations and strategies not only advance the technology involved in sorting but also have the capacity to usher in additional investment in the sector as it reflects the growing interest and confidence in the potential of the market.

Competition within these mature companies creates a culture of ongoing improvement and technological advancement, ultimately serving the industry as a whole. Their advancements in product innovation, strategic alliances, and global expansion have a long-term effect on the development of optical sorting equipment, pushing the industry forward and addressing the changing demands of various industries, such as food processing, recycling, mining, and beyond.

As these dominant players continue to unveil new technologies, diversify product portfolios, and increase global outreach, they are expected to determine the course of the market, dictating industry standards and best practices.

TOMRA launched in November 2023 the INNOSORT™ FLAKE, a new sorting machine that is capable of sorting plastic flakes by color, polymer, and transparency. It can produce high-quality recycled plastic flakes from dirty waste. The machine is also flexible and can be configured to sort for alternate colors and polymers on different occasions. In October 2020, Satake USA, a top food processing equipment maker, released information on its new optical sorter. The new FMSR-IR series is a one-stop machine featuring the company's newest RGB technology.

Browse Full Report: https://www.factmr.com/report/542/optical-sorting-equipment-market

Segmentation of Optical Sorting Equipment Market Research

By Technology :

VIS Cameras

Lasers

Near-Infrared (NIR)

X-rays

Hyperspectral Imaging (HSI)

By Sorting Platform :

Belt

Freefall

Chute-fed

By Capacity (Object/Hr) :

Low Capacity (Less Than 6 Metric Tons)

Medium Capacity (6 to 25 Metric Tons)

High Capacity (More Than 25 Metric Tons)

By Application :

Food Industry

Recycling Industry

Mining Industry

Pharmaceutical Industry

Postal and Logistics Industry

Automotive Industry

Beverages Industry

Cosmetics and Personal Care Industry

Glass Industry

Rubber & Plastic Industry

Others

By Region :

North America

Latin America

Europe

East Asia

South Asia

Oceania

Middle East & Africa

𝐂𝐨𝐧𝐭𝐚𝐜𝐭:

US Sales Office 11140 Rockville Pike Suite 400 Rockville, MD 20852 United States Tel: +1 (628) 251-1583, +353-1-4434-232 Email: [email protected]

1 note

·

View note

Text

Industrial Food Slicers Market Size, Share & Growth Analysis 2034: Slicing Towards Smart Automation

Industrial Food Slicers Market is witnessing a transformative phase driven by rising demand for processed and ready-to-eat food across the globe. With a focus on efficiency, hygiene, and consistency, industrial food slicers are becoming essential tools in commercial food production. These machines are designed to slice meats, cheese, fruits, vegetables, and bakery items with precision, ensuring uniformity and minimizing waste. The integration of automation and smart technology has further revolutionized operations in food processing plants, making food slicers indispensable in the industry.

Click to Request a Sample of this Report for Additional Market Insights: https://www.globalinsightservices.com/request-sample/?id=GIS23699

Market Size, Share & Demand Analysis

Valued at $3.5 billion in 2024, the Industrial Food Slicers Market is expected to reach $5.8 billion by 2034, registering a steady CAGR of 5.2%. Volume-wise, the market is projected to grow from 1.2 million units in 2024 to 1.8 million units by 2028, reflecting a significant rise in demand. Automatic slicers currently dominate the market, holding approximately 45% market share, followed by manual and semi-automatic slicers. The demand is being led by food processing giants and large-scale commercial kitchens aiming to meet growing consumer expectations for consistency and food safety.

Market Dynamics

The Industrial Food Slicers Market is being driven by several critical factors. The increasing global consumption of processed food, especially in urban areas, is pushing food manufacturers to adopt high-capacity, precision slicing equipment. Automation is playing a key role in streamlining slicing processes, reducing manual labor, and enhancing speed and hygiene. Additionally, strict regulatory standards from organizations like the FDA and EU are compelling companies to invest in equipment that meets food safety protocols. However, high initial investments and the need for skilled operators remain key challenges. Innovations focusing on energy efficiency, sustainability, and the ability to handle plant-based food textures are setting new trends in this evolving market.

Key Players Analysis

Leading the Industrial Food Slicers Market are established brands such as Bizerba, Hobart, and Berkel, who are leveraging digital technologies and energy-efficient solutions to maintain their competitive edge. Companies like Urschel Laboratories, FAM, and Magurit Gefrierschneider are expanding their product lines to cater to diverse applications. Emerging players such as Slice Tech Innovations and Gastro Slice Systems are also entering the scene with specialized, adaptive slicers for new-age food requirements. Innovation, pricing strategies, and after-sales service are key differentiators for these players.

Browse Full Report : https://www.globalinsightservices.com/reports/industrial-food-slicers-market/

Regional Analysis

Regionally, North America dominates the Industrial Food Slicers Market, led by the U.S., owing to its advanced food processing infrastructure and high adoption of automation. Europe follows closely, with Germany and France focusing on precision engineering and adherence to strict food safety norms. The Asia-Pacific region is emerging rapidly, driven by urbanization, changing dietary habits, and increasing investments in food processing in countries like China and India. Latin America and the Middle East & Africa are gradually catching up, supported by growing food and beverage sectors and shifting consumer preferences toward packaged foods.

Recent News & Developments

The Industrial Food Slicers Market has recently seen a surge in the integration of IoT and AI for enhanced performance monitoring. Companies like Weber Maschinenbau and Marel are pioneering smart slicers that offer real-time diagnostics and predictive maintenance. Additionally, the industry is experiencing shifts in sourcing strategies due to global supply chain disruptions, encouraging localized manufacturing. Pricing remains dynamic, ranging between $500 and $5,000 depending on customization and functionality. The focus on compliance with hygiene standards and sustainability goals is pushing manufacturers toward innovation in slicer design and materials used.

Scope of the Report

The scope of this report on the Industrial Food Slicers Market encompasses a comprehensive analysis of market trends, segmentation, and regional performance. It includes qualitative and quantitative assessments, competitive landscape evaluations, and insights into technological innovations. Market segments analyzed include slicer type (manual, automatic, semi-automatic), application (meat, cheese, bakery, fruits and vegetables), and technology (electric, hydraulic, pneumatic). The report also considers materials (stainless steel, aluminum, plastic), installation types (portable, fixed), and end-user categories such as food processing plants, restaurants, and supermarkets.

In conclusion, the Industrial Food Slicers Market is poised for sustained growth driven by automation, consumer demand for convenience foods, and global food safety standards. With evolving food consumption trends and continuous technological advancements, the market offers vast opportunities for both established players and emerging innovators.

Discover Additional Market Insights from Global Insight Services:

Chinese Takeout Market : https://linkewire.com/2025/06/24/chinese-takeout-market/

Cashew Milk Market : https://linkewire.com/2025/06/24/cashew-milk-market-size-share-demand-global-growth-insights-2034/

Canned Soup Market : https://linkewire.com/2025/06/24/canned-soup-market/

Brilliant Black BN Colors Market : https://linkewire.com/2025/06/24/brilliant-black-bn-colors-market/

Caraway Seeds Market : https://linkewire.com/2025/06/24/caraway-seeds-market/

About Us:

Global Insight Services (GIS) is a leading multi-industry market research firm headquartered in Delaware, US. We are committed to providing our clients with highest quality data, analysis, and tools to meet all their market research needs. With GIS, you can be assured of the quality of the deliverables, robust & transparent research methodology, and superior service.

Contact Us:

Global Insight Services LLC 16192, Coastal Highway, Lewes DE 19958 E-mail: [email protected] Phone: +1��833–761–1700 Website: https://www.globalinsightservices.com/

0 notes

Text

🧴 Bottle Filling Machine Market to Reach $6.31 Billion by 2032 – Driven by Food, Pharma & Cosmetics Boom! 🚀

📊 The global bottle filling machine market was valued at USD 3.81 billion in 2018 and is projected to climb to USD 6.31 billion by 2032, growing at a steady CAGR of 3.4%.

🌏 Asia Pacific led the global market with a 35.17% share in 2018, attributed to the region’s expanding food & beverage and pharmaceutical industries, along with growing automation in manufacturing.

🏭 Market Overview:

Bottle filling machines are extensively used across:

🥤 Food & Beverages

💊 Chemicals & Pharmaceuticals

💄 Cosmetics

They enable high-speed, contamination-free filling of PET, glass, and other bottle types, addressing industry demands for efficiency, hygiene, and customization.

🧩 By Bottle Type:

PET Bottles

Glass Bottles

Others

🧪 By Application:

Food Products

Beverages

Chemicals & Pharmaceuticals

Cosmetics

🏢 Key Companies Profiled:

Syntegon Technology GmbH (Bosch Packaging Technology)

GEA Group Aktiengesellschaft

JBT Corporation

Tetra Laval

KHS GmbH

Krone Group AG

Coesia Group SpA

Ave Technologies

E-PAK Machinery

Pacific Packaging Machinery Inc.

ProMatch

KB Associates

🔧 Key Industry Developments:

✅ Bosch Packaging Technology won the German Packaging Award for its ALF 5000 Series, a high-tech solution for filling ampoules and vials, especially in the pharma sector.

✅ JBT Corporation acquired Proseal UK Limited for USD 280 million, enhancing its sealing solutions in the food packaging segment.

✅ Ave Technologies launched a versatile bottling machine at PPMA Total Show, capable of handling multiple bottle substrates and customizable capping options—enhancing adaptability across sectors.

💡 Growth Drivers:

🌍 Rising demand for processed food and beverages

🏭 Surge in automated and hygienic production lines

💉 Expansion of pharma manufacturing

🌿 Shift towards eco-friendly and non-plastic packaging

With a global push for automation, hygiene, and speed, the bottle filling machine market is set to play a vital role in modern production ecosystems.

📎 Explore Full Report Here: 👉 https://www.fortunebusinessinsights.com/bottle-filling-machine-market-10264

#BottleFillingMachines#PackagingAutomation#FillingTechnology#PETandGlassBottles#FoodProcessing#PharmaPackaging#PackagingInnovation#MachineryMarket#ManufacturingAutomation#CAGR2032#BoschPackaging#JBTCorporation#AveTechnologies#IndustrialMachineryGrowth

0 notes

Text

Industrial Microbiology Industry Trends: What’s Driving Growth

United States of America – The Insight Partners is delighted to release its new market intelligence report entitled, "INDUSTRIAL MICROBIOLOGY Market – Global Industry Trends, Share, Size, Growth, Opportunity, and Forecast Period." The detailed report provides a critical examination of the market, providing a clear understanding of the existing scenario, upcoming trends, and long-term growth estimates.

Overview

The INDUSTRIAL MICROBIOLOGY market has experienced immense change over the past few years. Changes in demand, fast-paced technological advancements, changing rules and regulations, and consumer trends are redefining the market. This report delves deeper into these trends and reveals the driving forces behind market growth and the stumbling blocks that are hampering it.

Key Findings and Insights

Market Size and Growth

Historical Data and Forecast: Industrial Microbiology Market is anticipated to have a CAGR of 7.5% during forecast period.

Key Growth Drivers:

Increasing demand for microbial testing of quality in pharmaceutical and food sectors.

Greater focus on industrial fermentation for the production of enzymes and biofuels.

Growing biotechnology and biopharmaceutical industries.

Greater R&D and innovation investments in microbial technologies.

Get Sample Report: https://www.theinsightpartners.com/sample/TIPRE00005911

Market Segmentation

By Product

Equipment and Systems

Consumables

Laboratory Supply

By Test Type

Sterility Testing

Microbial Limits Testing

Bio-Burden Testing

Water and Environmental Testing

By Application

Pharmaceuticals and Biotechnology

Food and Beverage Industry

Environmental Industry

Agricultural Industry

Identifying Emerging Trends

Technological Innovations

Automation in microbial testing processes

Use of AI and machine learning in microbial analytics

Evolution of next-generation sequencing (NGS) for microbial identification

Application of biosensors and advanced bioprocess monitoring tools

Shift in Consumer Preferences

Growing emphasis on product safety and hygiene

Need for sustainable and eco-friendly industrial processes

Preference for rapid, accurate, and high-throughput testing solutions

Regulatory Changes

Strict regulatory policies by FDA, EPA, and EFSA for microbial testing

Compliance demands for the pharmaceutical and food industries

Stricter guidelines for good manufacturing practices (GMP) and cleanroom validation

Opportunities for Growth

Emerging Markets: Hitherto untapped markets in Asia-Pacific, Latin America, and Africa are increasingly interested in industrial microbial applications.

Biotech Startups' Expansion: Favorable funding and partnering frameworks for biotech small and medium businesses.

Sustainability Efforts: Increased adoption of microbial technologies for waste treatment, bioremediation, and green chemistry.

Personalized Solutions: Growing need for personalized testing kits and microbial services developed for specialty uses.

Conclusion

The INDUSTRIAL MICROBIOLOGY Market: Global Industry Trends, Share, Size, Growth, Opportunity, and Forecast Period report provides businesses with the information necessary to ride the changing tide. It provides a detailed analysis of market trends, competitive forces, and regulatory effects, which enables stakeholders to make informed decisions and tap into untapped business potential within the space.

About The Insight Partners

The Insight Partners is among the leading market research and consulting firms in the world. We take pride in delivering exclusive reports along with sophisticated strategic and tactical insights into the industry. Reports are generated through a combination of primary and secondary research, solely aimed at giving our clientele a knowledge-based insight into the market and domain. This is done to assist clients in making wiser business decisions. A holistic perspective in every study undertaken forms an integral part of our research methodology and makes the report unique and reliable.

0 notes

Text

AI In Food & Beverages Market: Driving Sustainability and Waste Reduction

The global AI in food & beverages market was valued at USD 8.45 billion in 2023 and is projected to reach USD 84.75 billion by 2030, with a compound annual growth rate (CAGR) of 39.1% from 2024 to 2030. AI is transforming the food and beverages industry by improving efficiency and automation in processing, sorting, and packaging, which helps reduce errors and meet global food demands.

The importance of AI in maintaining stringent quality control and ensuring safety compliance is growing due to heightened consumer awareness and regulatory pressures. Furthermore, AI enhances personalized consumer engagement and marketing while optimizing supply chains to minimize waste and manage inventory effectively. Technological advancements, particularly the integration of AI with IoT and big data, are expanding its applications and impact across the sector.

AI is reshaping the food and beverage industry by facilitating the creation of personalized food products tailored to individual preferences and dietary needs, appealing to health-conscious consumers. Predictive analytics powered by AI enables companies to forecast demand more accurately, reducing overproduction and waste, particularly for perishable items. Sustainability initiatives are bolstered by AI’s ability to optimize resource usage, decrease food waste, and enhance energy efficiency, aligning with global environmental goals. Additionally, AI-driven technologies like blockchain are improving food traceability, ensuring safety standards, and increasing consumer trust through enhanced transparency.

Key Market Trends & Insights

• North America AI in food & beverages market represented a significant market share of over 32.0% in 2023 due to its advanced technological infrastructure, including robust IT systems, high-speed internet, and data centers that support AI adoption. • AI in food & beverages market in the U.S. is expected to grow significantly over the forecast period, driven by the country's technological leadership and substantial investments in AI research and infrastructure. U.S. technology companies and startups are leading innovation in AI applications, enhancing efficiency, quality, and customer experience in the food and beverages industry. • By deployment, the cloud segment led the AI in the food & beverages industry in 2023 due to its scalability, cost efficiency, and ability to handle large volumes of data generated by AI systems. Cloud computing offers a flexible, pay-as-you-go model that reduces capital expenses and supports extensive data integration from various sources, enhancing AI analytics and decision-making. • By application, the quality control and safety compliance segment accounted for the largest market revenue share in 2023. AI technologies, such as machine learning and computer vision, offer highly accurate and consistent quality control by detecting defects, contaminants, and deviations more precisely than manual methods. • By end-use, the food processing segment accounted for the largest market revenue share in 2023 due to AI technologies that enhance efficiency by automating tasks such as sorting, grading, and blending, which speeds up production cycles and reduces manual labor.

Order a free sample PDF of the AI In Food & Beverages Market Intelligence Study, published by Grand View Research.

Market Size & Forecast

• 2023 Market Size: USD 8.45 Billion • 2030 Projected Market Size: USD 84.75 Billion • CAGR (2024-2030): 39.1% • North America: Largest market in 2023

Key Companies & Market Share Insights

Key players in the industry have bolstered their market presence through a strategic combination of product launches, expansions, mergers and acquisitions, contracts, partnerships, and collaborations. These initiatives are essential for enhancing market penetration and reinforcing their competitive advantage. For instance, in January 2024, ITC Limited implemented AI technologies to enhance quality control in dairy and beverage production. By utilizing visual inspection systems and real-time monitoring, the company ensured high product quality, reflecting the increasing adoption of AI in the food sector.

Key Players

• ABB • Honeywell International Inc. • IBM Corporation • Key Technology • NVIDIA Corporation • Rockwell Automation • Sesotec GmbH • Sight Machine • Siemens • TOMRA Systems ASA

Conclusion

The rapid growth of the AI in food and beverages market signifies a transformative shift in how the industry operates. By enhancing efficiency, personalization, and sustainability, AI not only addresses current challenges but also aligns with the increasing demands of consumers and regulatory bodies. As technology continues to evolve, the integration of AI will be crucial for businesses aiming to thrive in this dynamic environment.

Explore Horizon Databook – The world's most expansive market intelligence platform developed by Grand View Research.

#AI In Food & Beverages Market#AI In Food & Beverages Industry#AI In Food & Beverages Market Growth#AI In Food & Beverages Market Analysis#AI In Food & Beverages Market Forecast#AI In Food & Beverages Market Size

0 notes

Text

Meticulous Research®—a leading global market research company, published a research report titled, ‘South East Asia Food Processing Equipment Market by Type (Meat Processing Equipment, Beverage Processing Equipment, Dairy Processing Equipment, Fruit and Vegetable Processing Equipment), Mode of Operation (Semi-Automatic, Automatic), and Geography—Forecast to 2031.’What's Fueling the Growth Engine?

The numbers tell an impressive story. The global food processing equipment market is projected to reach $103.82 billion by 2031, at a CAGR of 5.6% during the forecast period. But what's behind these impressive figures?

Think about it – we're adding nearly 2 billion more people to the planet by 2050. That's a lot more mouths to feed, and traditional farming alone won't cut it. We need smarter, more efficient ways to process food, which means investing in better equipment.

But population growth is just part of the story. Walk through any major city today, and you'll see the real driver: urban lifestyles. More people are living in cities, working longer hours, and relying on processed foods for convenience. Families have less time to cook from scratch, and working professionals want quick, reliable meal solutions.

This shift is particularly dramatic in developing countries. The global consumption of processed foods has seen a significant uptick in recent decades, driven by urbanization, changing family structures, and women entering the workforce in greater numbers. When you combine this with rising disposable incomes, you get a recipe for sustained equipment demand.

Food safety has also become non-negotiable. Today's consumers expect their food to be safe, consistent, and traceable. This means food processors need equipment that can maintain strict hygiene standards while meeting regulatory requirements. It's not just about making food anymore – it's about making it safely and reliably.

The Automation Revolution

Here's where things get really interesting. While the semi-automatic segment is expected to account for the larger share of 60.3% of the global Food Processing Equipment market today, automation is rapidly gaining ground. The automatic segment is projected to register the higher CAGR of 6.4% during the forecast period of 2024–2031.

Why the shift? Automated systems offer something semi-automatic equipment can't match: consistency and safety. Machines don't get tired, don't make mistakes, and don't spread diseases. They can monitor production continuously, track individual batches, and maintain perfect cleaning protocols.

The productivity gains are substantial too. Automated systems can increase output by 25% while handling complex tasks like loading, unloading, and packaging more efficiently than human workers. For food processors dealing with tight margins and growing demand, these advantages are compelling.

But automation isn't just about replacing workers – it's about enabling new capabilities. Modern automated systems can handle multiple product variations, adapt to changing recipes, and integrate with broader supply chain systems. This flexibility has become essential as consumer preferences evolve rapidly.

Why Bakery Equipment Rules the Market

One segment consistently outperforms others: bakery and confectionery equipment. By application, the bakery & confectionery products segment contributed more than 22% of revenue share in 2023 and is predicted to have the largest market share by 2034.

There's something universally appealing about baked goods. Unlike other food categories that might be seasonal or culturally specific, bread, cakes, and confectionery products have consistent demand across all demographics and regions. Whether it's artisanal sourdough in San Francisco or mass-produced cookies in Mumbai, people always want baked goods.

The technical requirements also drive higher equipment values. Baking demands precise temperature control, exact timing, and specialized mixing technologies. These aren't simple machines – they're sophisticated systems that command premium prices and require regular upgrades as technology advances.

Innovation keeps this segment fresh too. Modern bakery processors need equipment that can handle organic ingredients, create gluten-free options, and adapt to health-conscious trends. Each new consumer preference creates opportunities for equipment manufacturers to develop specialized solutions.

How COVID-19 Changed Everything

The pandemic didn't just disrupt the food industry – it fundamentally transformed it. Supply chains broke down, workers got sick, and suddenly everyone realized how vulnerable our food system really was.

The response was swift and decisive: accelerate automation. As one industry expert noted, "Automated equipment does not catch or spread the flu, does not sneeze on the product coming down the packaging line or spread COVID-19." This harsh reality made automation investments essential for maintaining food safety and operational continuity.

But COVID-19 did more than just speed up automation adoption. It forced manufacturers to think differently about flexibility and resilience. Equipment that could quickly switch between products, adapt to new supply chains, and maintain strict hygiene standards became invaluable.

The pandemic also highlighted the importance of contactless technologies and enhanced sanitation capabilities. Equipment manufacturers responded by developing solutions that could provide end-to-end automation while maintaining the highest hygiene standards.

Asia Pacific: The Growth Engine

If you want to understand the future of food processing equipment, look east. Asia-Pacific is expected to account for the largest share of 43.0% of the global food processing equipment market, followed by Europe and North America. The region's market is already substantial – Asia-Pacific's food processing equipment market is estimated to be worth USD 30.38 billion in 2024.

But here's the kicker: this region is projected to register the highest CAGR of 6.1% during the forecast period, making it the fastest-growing market globally. The reasons are compelling: rapid urbanization, growing health awareness, and rising disposable income levels are creating perfect conditions for equipment demand.

Asian consumers are becoming increasingly sophisticated. They want international quality standards but with local flavors and preferences. This creates unique challenges for equipment manufacturers who must develop flexible systems capable of handling diverse ingredients and production methods.

The plant-based food trend is particularly strong in Asia Pacific, where environmental consciousness meets traditional dietary preferences. The rapidly growing plant-based foods market is expected to offer growth opportunities for the players operating in the food processing equipment market, requiring specialized processing capabilities and innovative equipment solutions.

Looking Ahead

The food processing equipment market until 2034 will be shaped by these powerful forces: growing populations, urbanization, automation, safety requirements, and evolving consumer preferences. Success will require understanding regional dynamics, particularly the Asia Pacific growth engine, while addressing universal trends toward automation, food safety, and sustainable processing solutions.

Download Sample Report Here @Download Sample Report Here @ https://www.meticulousresearch.com/download-sample-report/cp_id=4194

Contact Us: Meticulous Research® Email- [email protected] Contact Sales- +1-646-781-8004 Connect with us on LinkedIn- https://www.linkedin.com/company/meticulous-research

0 notes

Text

South East Asia Food Processing Equipment Market Analysis and Forecast

Meticulous Research®—a leading global market research company, published a research report titled, ‘South East Asia Food Processing Equipment Market by Type (Meat Processing Equipment, Beverage Processing Equipment, Dairy Processing Equipment, Fruit and Vegetable Processing Equipment), Mode of Operation (Semi-Automatic, Automatic), and Geography—Forecast to 2031.’What's Fueling the Growth Engine?

The numbers tell an impressive story. The global food processing equipment market is projected to reach $103.82 billion by 2031, at a CAGR of 5.6% during the forecast period. But what's behind these impressive figures?

Think about it – we're adding nearly 2 billion more people to the planet by 2050. That's a lot more mouths to feed, and traditional farming alone won't cut it. We need smarter, more efficient ways to process food, which means investing in better equipment.

But population growth is just part of the story. Walk through any major city today, and you'll see the real driver: urban lifestyles. More people are living in cities, working longer hours, and relying on processed foods for convenience. Families have less time to cook from scratch, and working professionals want quick, reliable meal solutions.

This shift is particularly dramatic in developing countries. The global consumption of processed foods has seen a significant uptick in recent decades, driven by urbanization, changing family structures, and women entering the workforce in greater numbers. When you combine this with rising disposable incomes, you get a recipe for sustained equipment demand.

Food safety has also become non-negotiable. Today's consumers expect their food to be safe, consistent, and traceable. This means food processors need equipment that can maintain strict hygiene standards while meeting regulatory requirements. It's not just about making food anymore – it's about making it safely and reliably.

The Automation Revolution

Here's where things get really interesting. While the semi-automatic segment is expected to account for the larger share of 60.3% of the global Food Processing Equipment market today, automation is rapidly gaining ground. The automatic segment is projected to register the higher CAGR of 6.4% during the forecast period of 2024–2031.

Why the shift? Automated systems offer something semi-automatic equipment can't match: consistency and safety. Machines don't get tired, don't make mistakes, and don't spread diseases. They can monitor production continuously, track individual batches, and maintain perfect cleaning protocols.

The productivity gains are substantial too. Automated systems can increase output by 25% while handling complex tasks like loading, unloading, and packaging more efficiently than human workers. For food processors dealing with tight margins and growing demand, these advantages are compelling.

But automation isn't just about replacing workers – it's about enabling new capabilities. Modern automated systems can handle multiple product variations, adapt to changing recipes, and integrate with broader supply chain systems. This flexibility has become essential as consumer preferences evolve rapidly.

Why Bakery Equipment Rules the Market

One segment consistently outperforms others: bakery and confectionery equipment. By application, the bakery & confectionery products segment contributed more than 22% of revenue share in 2023 and is predicted to have the largest market share by 2034.

There's something universally appealing about baked goods. Unlike other food categories that might be seasonal or culturally specific, bread, cakes, and confectionery products have consistent demand across all demographics and regions. Whether it's artisanal sourdough in San Francisco or mass-produced cookies in Mumbai, people always want baked goods.

The technical requirements also drive higher equipment values. Baking demands precise temperature control, exact timing, and specialized mixing technologies. These aren't simple machines – they're sophisticated systems that command premium prices and require regular upgrades as technology advances.

Innovation keeps this segment fresh too. Modern bakery processors need equipment that can handle organic ingredients, create gluten-free options, and adapt to health-conscious trends. Each new consumer preference creates opportunities for equipment manufacturers to develop specialized solutions.

How COVID-19 Changed Everything

The pandemic didn't just disrupt the food industry – it fundamentally transformed it. Supply chains broke down, workers got sick, and suddenly everyone realized how vulnerable our food system really was.

The response was swift and decisive: accelerate automation. As one industry expert noted, "Automated equipment does not catch or spread the flu, does not sneeze on the product coming down the packaging line or spread COVID-19." This harsh reality made automation investments essential for maintaining food safety and operational continuity.

But COVID-19 did more than just speed up automation adoption. It forced manufacturers to think differently about flexibility and resilience. Equipment that could quickly switch between products, adapt to new supply chains, and maintain strict hygiene standards became invaluable.

The pandemic also highlighted the importance of contactless technologies and enhanced sanitation capabilities. Equipment manufacturers responded by developing solutions that could provide end-to-end automation while maintaining the highest hygiene standards.

Asia Pacific: The Growth Engine

If you want to understand the future of food processing equipment, look east. Asia-Pacific is expected to account for the largest share of 43.0% of the global food processing equipment market, followed by Europe and North America. The region's market is already substantial – Asia-Pacific's food processing equipment market is estimated to be worth USD 30.38 billion in 2024.

But here's the kicker: this region is projected to register the highest CAGR of 6.1% during the forecast period, making it the fastest-growing market globally. The reasons are compelling: rapid urbanization, growing health awareness, and rising disposable income levels are creating perfect conditions for equipment demand.

Asian consumers are becoming increasingly sophisticated. They want international quality standards but with local flavors and preferences. This creates unique challenges for equipment manufacturers who must develop flexible systems capable of handling diverse ingredients and production methods.

The plant-based food trend is particularly strong in Asia Pacific, where environmental consciousness meets traditional dietary preferences. The rapidly growing plant-based foods market is expected to offer growth opportunities for the players operating in the food processing equipment market, requiring specialized processing capabilities and innovative equipment solutions.

Looking Ahead

The food processing equipment market until 2034 will be shaped by these powerful forces: growing populations, urbanization, automation, safety requirements, and evolving consumer preferences. Success will require understanding regional dynamics, particularly the Asia Pacific growth engine, while addressing universal trends toward automation, food safety, and sustainable processing solutions.

Download Sample Report Here @Download Sample Report Here @ https://www.meticulousresearch.com/download-sample-report/cp_id=4194

Contact Us: Meticulous Research® Email- [email protected] Contact Sales- +1-646-781-8004 Connect with us on LinkedIn- https://www.linkedin.com/company/meticulous-research

#FoodProcessingEquipment#SouthEastAsia#ProcessedFood#MarketResearch#FoodIndustry#FoodTech#GrowthForecast#MarketTrends#IndustrialMachinery#SEAeconomy

0 notes

Text

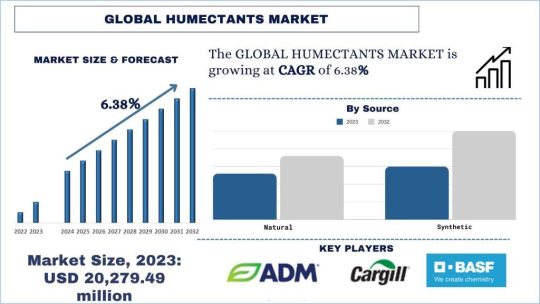

Humectants Market Report, Size, Share, Trends & Analysis 2032

The global Humectants Market has witnessed remarkable growth in recent years, fueled by the increasing demand for natural, sustainable, and clean-label ingredients across various industries. Manufacturers embrace technological advancements and innovative solutions to meet evolving consumer preferences and regulatory requirements.

Adapting to Evolving Consumer Demands

Consumers are becoming increasingly conscious of the ingredients in their products, driving a shift towards natural and plant-based alternatives. This trend has been particularly prevalent in the food and beverage, personal care, and pharmaceutical sectors, where humectants are crucial in maintaining moisture, texture, and shelf-life.

· Cargill, a leading provider of food and beverage ingredients, introduced EverSweet™, a new line of plant-based humectants derived from renewable sources. This innovative product line caters to the growing demand for clean labels and natural ingredients, offering a sustainable and environmentally friendly alternative to traditional humectants.

· Inolex, a prominent personal care ingredient manufacturer, launched a range of natural humectants derived from vegetable sources, aligning with the clean beauty movement and the increasing consumer demand for natural and sustainable personal care products.

Emphasis on Sustainability and Regulatory Compliance

As consumer awareness and environmental concerns continue to rise, regulatory bodies and industry organizations are implementing stricter guidelines and labeling requirements for products containing synthetic ingredients. Manufacturers actively pursue sustainability initiatives and eco-friendly practices throughout their supply chains to comply with these evolving regulations and meet consumer expectations.

· Corbion unveiled its new sustainable humectant line derived from bio-based sources and produced through a carbon-neutral process, targeting the food and personal care industries. This development demonstrates the company's commitment to environmental responsibility and aligns with the broader industry trend towards sustainable and eco-friendly solutions.

· In 2022, the European Chemicals Agency (ECHA) issued updated guidelines for using certain humectants in consumer products, prompting manufacturers to re-evaluate their formulations and adhere to the new safety standards.

Access sample report (including graphs, charts, and figures): https://univdatos.com/reports/humectants-market?popup=report-enquiry

Technological Advancements and Investments

The humectants market is witnessing rapid technological advancements and significant investments from leading companies to develop innovative and efficient solutions. One notable trend is the integration of artificial intelligence (AI) and machine learning (ML) algorithms in humectant formulations.

· DuPont Nutrition & Biosciences unveiled its AI-powered "Humectant Intelligence" platform. This platform leverages predictive analytics to optimize humectant blends for specific applications, improving functionality and cost-effectiveness.

· Additionally, companies actively invest in research and development to identify novel plant sources and sustainable extraction methods for natural humectants. In November 2022, Cargill announced a strategic partnership with a leading biotechnology firm to develop bio-based humectants derived from renewable plant sources.

Conclusion

The global humectants market is experiencing a transformative phase, driven by the increasing demand for natural, sustainable, and clean-label solutions. As consumer preferences evolve and regulatory frameworks tighten, manufacturers embrace technological advancements, invest in research and development, and form strategic partnerships to meet these changing demands.

Key Offerings of the Report

Market Size, Trends, & Forecast by Revenue | 2024−2032.

Market Dynamics – Leading Trends, Growth Drivers, Restraints, and Investment Opportunities

Market Segmentation – A detailed analysis by Source and Application

Competitive Landscape – Top Key Vendors and Other Prominent Vendors

Contact Us:

UnivDatos

Contact Number - +1 978 733 0253

Email - [email protected]

Website - https://univdatos.com/

Linkedin- https://www.linkedin.com/company/univ-datos-market-insight/mycompany/

0 notes

Text

Checkweigher Machine Market Size, Demand, Share, Trends and Forecast -2034

The size of the checkweigher machine market is expected to grow to US$ 629.2 million by 2024. The market is slated to grow with a consistent compound annual growth rate (CAGR) of 2.6% until 2034. This growth is expected to see the market growing to a size of US$ 813.3 million by 2034.

What are the Key Drivers Driving the Growth of the Checkweigher Machine Market?

"Checkweigher Machines Get Popular in Pharmaceuticals and Food & Beverage Sectors"

The explosive growth in demand for automatic checkweigher machines is due to their extensive usage across various sectors like chemicals, pharmaceuticals, and food & beverage. End-use industries such as chemicals, pharmaceuticals, food and beverage, and others are driving demand for automatic checkweigher machines. To measure bottles, cans, sachets, sticks, capsules, standing pouches, and more, the fast-growing international pharmaceutical industry requires the use of checkweigher machines. In the food and beverage sector, checkweigher machines are increasingly becoming popular.

For More Insights into the Market, Request a Sample of this Report: https://www.factmr.com/connectus/sample?flag=S&rep_id=9706

Country-wise Insights

The East Asia checkweigher machine market is set to advance steadily, looking towards a sluggish 2.3% CAGR through to 2034. The expanding food processing industry's need for automation, along with the rising consumer awareness regarding food product packaging and labeling and the demand for packaged foods and the growing packaging industry, all drive the growth of the market. Additionally, since they are the leading exporters of automatic checkweigher machines in the market, China and Japan are the major consumers of the devices. In this region, China will most likely hog the limelight as a dominant player in the checkweigher machine market with a significant share of 58.4% in 2024.

The North America checkweigher machine industry is gearing up for consistent growth, foreseeing a CAGR of 2.9% through 2034. The primary driver of this expansion is an increase in demand for automatic checkweighers in industrial automation systems to boost efficiency. By collaborating with other revolutionary, integrated technologies to minimize expenses throughout the production process, automatic checkweighers also enhance the quality and rate of packing. The United States checkweigher machine market is projected to dominate in 2024, holding an estimated value of 71.6%.

Category-wise Insights

In 2024, the 12 to 60 kg checkweigher machines segment shall be leading with a huge share of 49.5% market share. Conversely, the food and beverages industry segment is expected to prove its dominance within the Checkweigher Machine business, holding an impressive 45.2% market share during 2024.

Competitive Landscape

Prominent players in the checkweigher machine industry are Thermo Fisher Scientific Inc., Mettler Toledo, R.S. Bilance S.r.l., SF Engineering, VBS, Inc., VARPE CONTROL DE PESO S.A., Soc. Coop. Bilanciai Campogalliano, Teraoka Seiko Co., Ltd., ACG, Anritsu, Bizerba, Cassel Inspection, Dibal, Espera-Werke, Idecon, iXAPACK GLOBAL, LOMA SYSTEM, Marel, Minebea Intec, NEMESIS, OCS-WIPOTEC, Packital S.R.L., Prisma Industriale, and Mettler Toledo. These rival companies use multifarious strategies in order to come out on top.

For others, innovation is the top priority, and they invest heavily in state-of-the-art technology to remain ahead of the curve. A key objective is to differentiate by providing tailored features and applications that address specific industry requirements. For companies that want to appeal to customers on a shoestring budget, price positioning becomes a war. In addition, some competitors prioritize sustainability more, aligning their products with eco-friendly trends.

Recent Developments

In November 2023, Fortress Technology made a breakthrough in the checkweigher machine industry with the release of its slimline Raptor design. The Raptor weight sensors make real-time accurate and fast individual pack weight evaluation possible, reset rapidly. Furthermore, the Raptor Checkweigher software incorporates defined tolerance tables to ensure that there is automatic compliance with regional statutory weight limits.

In November 2022, Mettler-Toledo Product Inspection launched a new Track & Trace and Checkweighing combined solution with small and mid-market businesses in the cosmetics and pharmaceutical industries in focus. With the Mettler-Toledo CT33 system, customers can achieve supply chain accountability, legal compliance, enhanced brand security, and quality assurance due to an extreme level of integration between Mark & Verify, serialization, and accuracy weighing options.

Browse Full Report: https://www.factmr.com/report/checkweigher-machine-market

Segmentation of Checkweigher Machine Market Analysis

By Capacity :

Up to 12 kg Checkweigher Machines

12 to 60 kg Checkweigher Machines

Above 60 kg Checkweigher Machines

By End Use :

Food and Beverage

Logistics and Packaging

Personal Care Products

Pharmaceutical Use

By Region :

North America

Latin America

East Asia

South Asia and Pacific

Western Europe

Eastern Europe

Middle East and Africa

𝐂𝐨𝐧𝐭𝐚𝐜𝐭:

US Sales Office 11140 Rockville Pike Suite 400 Rockville, MD 20852 United States Tel: +1 (628) 251-1583, +353-1-4434-232 Email: [email protected]

1 note

·

View note

Text

North America Ultrasonic Sensor Market, Size, Segment and Growth by Forecast Period: (2019-2027)

The ultrasonic sensor market in North America is projected to grow from US$ 1.16 billion in 2018 to US$ 2.20 billion by 2027, registering a CAGR of 7.3% from 2019 to 2027. 📚Download Full PDF Sample Copy of Market Report @ https://wwcw.businessmarketinsights.com/sample/TIPRE00008342

Ultrasonic sensors operate by emitting ultrasonic waves and measuring the time it takes for the reflected waves to return after hitting a target. This time delay is used to calculate the distance between the sensor and the object. These sensors are widely deployed across numerous industries, including food & beverage, chemicals, medical, automotive, agriculture, process control, and wastewater management. Typical applications include conveyor belt monitoring, smart parking systems, vehicle detection in car washes, pallet detection in forklifts, medical diagnostics, liquid level sensing, trash level monitoring, and production line automation.

Ultrasonic technology offers several key advantages: process intensification, low power consumption, cost-effectiveness, user-friendliness, adaptability to specific applications, and environmental safety. These benefits contribute to its reputation as a reliable solution for high-quality outcomes. The growing adoption of automation and Industry 4.0 technologies across manufacturing and other sectors is a major driver for market growth.

In the automotive sector, ultrasonic sensors are increasingly used in autonomous and advanced driver-assistance systems (ADAS), particularly for functions like parking range detection. This expanding role in vehicle technology presents significant growth opportunities for the market. However, the availability of alternative technologies such as optical sensors for distance measurement may pose a challenge to market expansion.

The United States currently leads the North American ultrasonic sensor market in terms of installations. With manufacturing contributing approximately 11.15% to the nation's GDP, the country benefits from a strong industrial base. Major US-based manufacturers such as Exxon Mobil Corp, Apple Inc., General Motors Co., and Chevron Corp are actively investing in technological advancements including AI, Industrial IoT (IIoT), machine-to-machine communication, and advanced automation. Given the high demand for ultrasonic sensors in both the manufacturing and automotive industries, the presence of these industrial and automotive giants is expected to significantly support market growth.

The chart below illustrates Mexico’s revenue share in the North American ultrasonic sensor market over the forecast period:

North America Ultrasonic Sensor Strategic Insights

Strategic insights for the North America Ultrasonic Sensor provides data-driven analysis of the industry landscape, including current trends, key players, and regional nuances. These insights offer actionable recommendations, enabling readers to differentiate themselves from competitors by identifying untapped segments or developing unique value propositions. Leveraging data analytics, these insights help industry players anticipate the market shifts, whether investors, manufacturers, or other stakeholders. A future-oriented perspective is essential, helping stakeholders anticipate market shifts and position themselves for long-term success in this dynamic region. Ultimately, effective strategic insights empower readers to make informed decisions that drive profitability and achieve their business objectives within the market.

Market leaders and key company profiles Balluff Inc.

Baumer Group

Honeywell International, Inc.

Migatron Corporation

Keyence Corporation

Murata Manufacturing Co. Ltd.

Omron Corporation

Pepperl+Fuchs AG

Rockwell Automation, Inc.

Siemens AG North America Ultrasonic Sensor – Regional Insights

The regional landscape of the North America Ultrasonic Sensor market highlights the specific territories where companies operate and compete. Success in this market hinges on recognizing local variations—such as consumer preferences for plug types or battery backup options—as well as differing economic conditions and regulatory frameworks. Tailoring strategies to these regional nuances enables businesses to identify underserved markets and customize offerings to meet local needs. This localized approach ensures more efficient resource allocation, sharper marketing strategies, and stronger competitive positioning, ultimately fueling market expansion and growth within key geographic segments. About Us: Business Market Insights is a market research platform that provides subscription service for industry and company reports. Our research team has extensive professional expertise in domains such as Electronics & Semiconductor; Aerospace & Défense; Automotive & Transportation; Energy & Power; Healthcare; Manufacturing & Construction; Food & Beverages; Chemicals & Materials; and Technology, Media, & Telecommunications Author's Bio Akshay Senior Market Research Expert at Business Market Insights

0 notes

Text

Factory Automation Market: Key Technologies & Forecast Insights

Market Size & Forecast

Estimates for the global factory automation market project strong growth ahead:

Forecasts range from USD 181.5 billion in 2023 to USD 340.8 billion by 2031, at a CAGR of 8.2%.

While estimates vary, the consensus is clear: the factory automation market is poised for robust double-digit growth, driven by Industry 4.0 adoption.

Introduction & Definition

Market Drivers & Restraints

Key Drivers

Operational Efficiency & Productivity: Automation enables round-the-clock operations, minimizes downtime, and reduces labor costs. Some case studies report up to a 250% increase in production and 80% defect reduction after robotic integration.

Industry 4.0 Integration: IIoT, AI, machine vision, digital twins, and edge computing are transforming manufacturing management and maintenance.

Smart Factory Investment: Especially in Asia-Pacific, countries are rapidly adopting smart technologies through government and private sector initiatives.

Primary Restraints

High Capital Requirements: Advanced automation systems, particularly integrated and flexible ones, require significant upfront investments.

Skill Gaps: Many firms struggle with hiring and training skilled workers who can operate and maintain complex automated systems. To get a free sample report, click on https://www.datamintelligence.com/download-sample/factory-automation-market

Segmentation Analysis

By Component: Hardware leads the market in revenue share (~62%), while software and services—especially analytics and consulting—are growing fastest.

By System Type: Fixed automation dominates in high-volume manufacturing, while flexible and programmable systems are gaining traction in industries like automotive and electronics.

By Technology: PLC and DCS are the backbone of control systems; SCADA, MES, and HMIs enhance real-time oversight. IIoT and digital twins are being adopted to improve simulation and predictive capabilities.

By End-User: Automotive remains the largest industry segment (~27%), followed by pharmaceuticals and food & beverage due to strict quality control and hygiene needs. To get a unlimited market intelligence, subscribe to https://www.datamintelligence.com/reports-subscription

Geographical Insights

Asia-Pacific is the dominant region, accounting for nearly 39% of the market, with China and India as the fastest-growing markets.

North America holds about 27% of the global share, driven by large-scale adoption in the U.S. and Canada.

Europe sees steady demand supported by strict regulatory compliance and advancements in robotics and AI.

Latin America and the Middle East & Africa are emerging as new frontiers for automation in resource-heavy and industrial applications.

Latest News & Industry Trends

Robotics in the U.S.: Over 44,000 industrial robots were installed in the U.S. in 2023 alone, with AI integration transforming capabilities in automotive and electronics industries.

Smart Factories in Asia: Investments in smart manufacturing facilities in Asia-Pacific are projected to push the regional market to nearly USD 488 billion by 2030.

AI & Digital Twins: Advanced manufacturing environments are increasingly relying on AI-driven systems and digital twins for simulation, predictive maintenance, and real-time monitoring.

Edge Analytics: Edge computing is enabling localized data processing, making systems faster, more secure, and responsive.

Competitive Landscape

Major players dominating the global factory automation market include:

ABB

Siemens

Schneider Electric

Mitsubishi Electric

General Electric

Rockwell Automation

These companies are investing in R&D, smart factory solutions, and M&A strategies to strengthen their technological capabilities and global reach. Smaller players are entering niche segments such as industrial vision, modular robotics, and advanced analytics.

Key Developments

AI-powered Robotics: Leading manufacturers are integrating AI into robotic platforms for greater precision and adaptability.

Green Automation: Sustainability is emerging as a key theme, with automation solutions increasingly designed to reduce energy and material waste.

Global Partnerships: Strategic collaborations between tech firms and manufacturers are accelerating innovation and global expansion.

Reshoring of Manufacturing: Countries are investing in automation to reduce dependency on offshore production, especially in critical sectors like electronics and healthcare.

Report Features & Coverage

The Factory Automation Market Report offers:

Market size and forecast analysis from 2023 to 2031

Detailed segmentation by component, technology, end-use, and region

Competitive landscape and market share breakdown

Key trends in smart factories, robotics, digital transformation, and energy-efficient automation

Regulatory and geopolitical insights, along with supply chain analysis

About Us

DataM Intelligence is a global market intelligence and consulting firm headquartered in Hyderabad, India. We specialize in delivering high-quality market research across industries such as manufacturing, technology, energy, chemicals, healthcare, and more. Our reports empower decision-makers with strategic insights backed by data, enabling growth in dynamic markets.

Contact Us

📞 Mobile: +1 877 441 4866 📧 Email: [email protected]

0 notes

Text

Vibrating Sifter Machine Market Top Manufacturers, Global Opportunities by Regions 2032

The Reports and Insights, a leading market research company, has recently releases report titled “Vibrating Sifter Machine Market: Global Industry Trends, Share, Size, Growth, Opportunity and Forecast 2024-2032.” The study provides a detailed analysis of the industry, including the global Vibrating Sifter Machine Market share, size, trends, and growth forecasts. The report also includes competitor and regional analysis and highlights the latest advancements in the market.

Report Highlights:

How big is the Vibrating Sifter Machine Market?

The vibrating sifter machine market is expected to grow at a CAGR of 5.3% during the forecast period of 2024 to 2032.

What are Vibrating Sifter Machine?

A vibrating sifter machine is a tool that segregates and categorizes materials like powders, liquids, and solids. It uses vibration to guide materials through a mesh screen, separating them based on their particle sizes. This machine's vibrating action aids in efficiently sifting and isolating materials, making it valuable in industries such as food processing, pharmaceuticals, and chemicals. Designed to boost efficiency and precision in material sorting and classification, the vibrating sifter machine enhances overall production processes.

Request for a sample copy with detail analysis: https://www.reportsandinsights.com/sample-request/1940

What are the growth prospects and trends in the Vibrating Sifter Machine industry?

The vibrating sifter machine market growth is driven by various factors. The global market for vibrating sifter machines is experiencing significant growth, primarily due to the rising demand for efficient and automated sieving equipment in industries such as food and beverage, pharmaceuticals, and chemicals. These machines are known for their high throughput, improved accuracy, and reduced downtime, which collectively enhance overall productivity. Moreover, technological advancements, such as the incorporation of sensors and digital controls, are further driving market expansion. The Asia-Pacific region is expected to lead the market, driven by rapid industrialization and the increasing adoption of automated solutions in countries like China and India. However, challenges such as high initial costs and maintenance requirements may impede market growth to some extent. Hence, all these factors contribute to vibrating sifter machine market growth

What is included in market segmentation?

The report has segmented the market into the following categories:

By Product Type:

Rotary Vibrating Sifter Machine

Circular Vibrating Sifter Machine

Linear Vibrating Sifter Machine

Tumbler Vibrating Sifter Machine

By Operation Mode:

Manual Vibrating Sifter Machine

Semi-automatic Vibrating Sifter Machine

Automatic Vibrating Sifter Machine

By End User:

Food and Beverage Industry

Pharmaceutical Industry

Chemical Industry

Mining and Metallurgy Industry

Cosmetics and Personal Care Industry

Others

By Region:

North America

Latin America

Asia Pacific

Europe

Middle East & Africa

Who are the key players operating in the industry?

The report covers the major market players including:

Russell Finex Ltd.

VibraScreener Inc.

SWECO, a business unit of M-I LLC

Kason Corporation

Gough Engineering Ltd.

Rotex Global LLC

Elcan Industries Inc.

Eversun Machinery (Henan) Co., Ltd.

Midwestern Industries Inc.

Xinxiang Dayong Vibration Equipment Co., Ltd.

Xinxiang Gaofu Machinery Co., Ltd.

Virto-Cuccolini S.r.l.

Others

View Full Report: https://www.reportsandinsights.com/report/Vibrating Sifter Machine-market

If you require any specific information that is not covered currently within the scope of the report, we will provide the same as a part of the customization.

About Us:

Reports and Insights consistently mееt international benchmarks in the market research industry and maintain a kееn focus on providing only the highest quality of reports and analysis outlooks across markets, industries, domains, sectors, and verticals. We have bееn catering to varying market nееds and do not compromise on quality and research efforts in our objective to deliver only the very best to our clients globally.

Our offerings include comprehensive market intelligence in the form of research reports, production cost reports, feasibility studies, and consulting services. Our team, which includes experienced researchers and analysts from various industries, is dedicated to providing high-quality data and insights to our clientele, ranging from small and medium businesses to Fortune 1000 corporations.

Contact Us:

Reports and Insights Business Research Pvt. Ltd. 1820 Avenue M, Brooklyn, NY, 11230, United States Contact No: +1-(347)-748-1518 Email: [email protected] Website: https://www.reportsandinsights.com/ Follow us on LinkedIn: https://www.linkedin.com/company/report-and-insights/ Follow us on twitter: https://twitter.com/ReportsandInsi1

#Vibrating Sifter Machine Market trends#Vibrating Sifter Machine Market Size#Vibrating Sifter Machine Market Forecast

0 notes

Text

Warehouse Robotics Market Size, Share, Industry Trends 2032

Meticulous Research®, a leading global market research company, published a report titled ‘Warehouse Robotics Market—Global Opportunity Analysis and Industry Forecast (2025-2032)’. According to this latest publication, the warehouse robotics market is expected to reach $15.1 billion by 2032, at a CAGR of 14.4% from 2025 to 2032.

The growth of the warehouse robotics market is primarily driven by an increasing focus on optimizing warehouse operations for faster product delivery, the rising use of autonomous mobile robots, and the growing popularity of e-commerce shopping platforms. However, the high costs associated with warehouse setup and infrastructure development could constrain the market's growth.

Additionally, rapid advancements in robotics, AI, and machine learning technologies are expected to create significant growth opportunities for players in this market. However, the security risks associated with connected autonomous robots present challenges that could impact the growth of the warehouse robotics market.

The warehouse robotics market is segmented by product type, function, payload capacity, and end user. The report evaluates industry competitors and analyzes the market at the regional and country levels.

Among the product types studied in this report, the autonomous mobile robots segment is anticipated to hold the dominant position, with over 29% of the market share in 2025. The segment's dominance is driven by the rising demand for warehouse automation, the exponential growth of the e-commerce industry, and the increasing need for high-efficiency autonomous mobile robots to enhance industrial productivity. Additionally, the demand for customized AMRs designed to meet specific industry requirements, such as handling fragile goods, further contributes to this segment's dominance.

Among the functions studied in this report, the picking and placing segment is anticipated to hold the dominant position, with over 34% of the market share in 2025. The segment's dominance is attributed to the increasing need to optimize the picking process and maximize overall throughput in warehouses and distribution centers. Additionally, the growing emphasis on accurate inventory tracking, efficient replenishment, and timely reordering to prevent stockouts and backorders plays a significant role in this large market share.

Among the payload capacities studied in this report, the Below 20 Kg segment is anticipated to hold the dominant position, with over 26% of the market share in 2025. The segment's dominance is driven by the increased adoption of lower payload capacity robots in the consumer electronics and food and beverage industries, along with the rising popularity of e-commerce shopping. Additionally, the growing volume of lightweight and small packages that need to be managed in distribution centers further contributes to this large market share.

Among the end users studied in this report, the retail & e-commerce segment is anticipated to hold the dominant position, with over 22% of the market share in 2025. The segment's dominance is attributed to the increasing preference for online shopping, a growing demand for fast and efficient order fulfillment, and the need to enhance picking speed and order accuracy.

Among the geographies studied in this report, Asia-Pacific is anticipated to hold the dominant position, with over 52.7% of the market share in 2025. The presence of major warehouse robotics players, such as Daifuku Co., Ltd. (Japan), FANUC Corporation (Japan), Hikrobot Co., Ltd. (China), and Omron Corporation (Japan), is anticipated to significantly contribute to the high revenue share of this region. Additionally, the surge in e-commerce, an increased focus on optimizing warehouse operations for faster product delivery, technological advancements, and the growing adoption of warehouse robotics in the semiconductor, electronics, and automotive sectors are key factors driving the region's dominance.

Key Players

Some of the major players studied in this report are Daifuku Co., Ltd. (Japan), KUKA AG (Germany), ABB Ltd. (Switzerland), FUNUC Corporation (Japan), Toyota Material Handling India Pvt. Ltd.(India), Omron Corporation (Japan), Honeywell International Inc. (U.S.), Yaskawa Electric Corporation (Japan), Onward Robotics (U.S.), Zebra Technologies Corporation (U.S.), Hikrobot Co., Ltd. (China), SSI SCHÄFER - Fritz Schäfer GmbH (Germany), Onward Robotics (U.S.), TGW Logistics Group (Austria), and Addverb Technologies Limited. (India).

Download Sample Report Here @ https://www.meticulousresearch.com/download-sample-report/cp_id=6027

Key Questions Answered in the Report-

What is the value of revenue generated by the sale of warehouse robotics?

At what rate is the global demand for warehouse robotics projected to grow for the next five to seven years?

What is the historical market size and growth rate for the warehouse robotics market?

What are the major factors impacting the growth of this market at global and regional levels?

What are the major opportunities for existing players and new entrants in the market?

Which product type, function, payload capacity, and end user segments create major traction in this market?

What are the key geographical trends in this market? Which regions/countries are expected to offer significant growth opportunities for the manufacturers operating in the warehouse robotics market?

Who are the major players in the warehouse robotics market? What are their specific product offerings in this market?

What recent developments have taken place in the warehouse robotics market? What impact have these strategic developments created on the market?

Contact Us: Meticulous Research® Email- [email protected] Contact Sales- +1-646-781-8004 Connect with us on LinkedIn- https://www.linkedin.com/company/meticulous-research

#Warehouse Robotics#Autonomous Mobile Robots#Automated Guided Vehicles#Articulated Robots#Collaborative Robots#SCARA Robots#Warehouse Robotics Market

0 notes

Text