#Geotextiles and Geomembranes

Explore tagged Tumblr posts

Text

What is the Breaking Strength of Geotextiles Made From Filament?

The geotextile fabric manufacturers offer filament geotextiles primarily used as a drainage system and reinforcement and geotextiles made of filament have a variety of characteristics, making it normal for them to become widely utilized. For more information visit our blog.

#geotextile filaments#Geotextiles made of filament#Geotextiles and Geomembranes#geotextile fabric manufacturers#filter cloth manufacturers#geotextile in road

0 notes

Text

Significance of BIS Approved Geomembranes and their Applications in Modern Construction

Environmental protection and sustainable development are the most evident problems that the construction sector in general and engineers in particular are confronted with today. In the vast category of materials used in constructions, geomembrane have a great deal to offer towards a vast range of applications ranging from waste containment to dam liners. We would highlight here in this paper the significance of BIS approved geomembrane, the role played by geomembrane manufacturers, and the role played by geotextiles as reinforcing material to geomembranes for application such as dam construction.

What are Geomembranes?

A geomembrane is a man-made, impermeable sheet utilized to prevent water, gases, and liquids from flowing in civil and environmental engineering. They are durable sheets and are typically composed of polymers like high-density polyethylene (HDPE), low-density polyethylene (LDPE), and polypropylene. Geomembranes are applied on sites where they serve as a containment and shield barrier so that material like toxic waste or water does not seep into the environment.

Why BIS approved Geomembranes are important

BIS approval comes under the reliability and quality of construction and civil engineering materials in India. Geomembranes BIS approved are tested under very stringent testing and efficiency criteria that decide their long term quality, environmental durability, and application for a specific purpose.

After a geomembrane is BIS approved, that would mean that the geomembrane has been tested for the most important properties like:

- Chemical and water impermeability.

- UV resistance to allow exposure to severe outdoor climatic conditions.

- Chemical resistance to inhibit damage through chemical exposure.

To contractors and engineers, using BIS approved geomembranes is using material of the best quality, and they provide efficient and secure solutions for risky infrastructure projects.

Role of Geomembrane Producers

Geomembrane manufacturers are accountable for supply and quality of such vital supplies. They specialize in planning and producing geomembranes of various types, e.g., reinforced, smooth, and textured, based on the needs of a project.

As the technology itself has developed further, geomembrane manufacturer have developed products for a particular use, be it a landfill, a wastewater treatment facility, or dams. Through the development of geomembranes in close coordination with engineers under an exclusive agreement, the manufacturers guarantee that geomembranes made by them bear the specifications of tensile strength, flexibility, and long-term performance.

Apart from the high demand for green solutions, geomembrane manufacturers are also keen on green manufacturing processes and the production of geomembranes with lower environmental impact.

The Supportive Role of Geotextiles

While geomembranes are at the center of impermeable layer construction, they are usually protected by geotextile to ensure overall success in a project. Geotextiles are man-made fibers produced for filtering, reinforcement, or separation of layers in construction works.

Geotextiles, when used in conjunction with geomembranes, provide several benefits including:

1. Separation: Geotextiles provide separation between dissimilar layers of soil and structural support to the foundation.

2. Reinforcement: Geotextiles provide strength and stability to the underlying soil, especially in the event of erosion or water pressure.

3. Filtration: Geotextiles permit free passage of water but filter out finer particles to prevent clogging of drain pipes.

Geomembranes and geotextiles are together a composite material for management of water flow, erosion control, and strengthening of structures for civil engineering purposes.

Application of Geomembranes in Dam Construction: Water Tightness Maintenance

geomembrane for dams possess one of their most significant applications in dam construction. Application of geomembranes by dams is suitable for developing a surface which is water proof so that leakage of water to the maximum extent can be avoided, ensuring stability and safety of the dam.

Geomembranes are even employed for lining dams, ponds, and even lining the interior of dams during construction. Geomembranes are physically and chemically durable and can withstand the aggressive conditions of water storage and prolonged exposure to fluctuating water levels.

Using geomembranes, engineers can:

- Prevention of water seepage: Stability to the dam must be established and the area around it must not be ruined.

- Cost of repair or replacement reduced: Quality barrier equates to reduced cost of repair or replacement.

- Protection against environment: Because they lessen water body contamination in the vicinity, regional environments are protected by geomembranes.

Conclusion

Geomembrane production service and application and BIS compliant geomembranes are part of the essential development activity of the infrastructure today. In dam development by waste dump closure and enviro cover, the product extends maximum protection for water and chemical flow. The product with geomembranes applied along with geotextiles helps to allow engineers and construction builders an opportunity to make activities sustainable and perpetual endeavors.

As expansion and growth of the construction sector occur, the demand for green, quality, and durable materials will increase. BIS-approved geomembranes will facilitate such growth and lead the way in providing required protection and security to infrastructural projects that are needed at an international level.

1 note

·

View note

Text

Geosynthetics in Geotechnical Engineering: Types and Applications

Introduction Geotechnical engineering is at the core of building a solid foundation for modern infrastructure. However, achieving stability, sustainability, and cost-efficiency in construction can be a challenging task. Enter geosynthetics, a group of engineered materials revolutionizing the field. In this article, we’ll explore the types of geosynthetics and their myriad applications, shedding…

View On WordPress

#erosion control#Geocell#Geofoam#Geogrid#Geomembrane#Geosynthetic Clay Liner#Geosynthetics#Geotechnical engineering#Geotextile#Slope Protection#Sustainability

0 notes

Text

Separation Geotextile Sci-Tech Meets Geomechanics

Separation Geotextiles: Where Technology Meets Geomechanics

Beneath highway subgrades and railway ballast layers lies a little-known yet critical material—separation geotextile. This synthetic fabric, crafted from polypropylene or polyester fibers, is revolutionizing modern geotechnical engineering through its precisely engineered physical properties.

Microstructure Defines Macro-Functionality

The core value of separation geotextiles stems from their three-dimensional网状 structure. Weighing 100-300 grams per square meter, non-woven fabrics feature randomly oriented fibers forming millions of micropores (typically 60-120 microns). These meticulously designed apertures block soil particles larger than 0.075mm while allowing water permeability. Laboratory data indicates that high-quality separation geotextiles require a gradient ratio (GR value) below 3.0—a key metric for sustained filtration performance.

Multi-Protective Mechanisms in Engineering

Interface Stabilization System: In soft soil foundations, the tensile strength (typically 20-60kN/m) of separation geotextiles disperses load stress, increasing bearing capacity by 30-50%. During Beijing Daxing International Airport's construction, over 2 million square meters were deployed to treat marshland foundations.

Dynamic Isolation Layer: For railways, it prevents ballast颗粒 penetration into subgrades, reducing maintenance频率. Deutsche Bahn studies show it extends track bed service life by 8-12 years.

Chemical Barrier: Carbon-black-modified geotextiles resist chemical erosion (pH 3-11), proving vital in landfill liner systems.

Sustainability's Silent Ally

Modern separation geotextiles now incorporate recycled polyester fibers (rPET)—a single highway project can repurpose 3 million plastic bottles. With a service life exceeding 50 years and recyclability post-retirement, they enable closed-loop material cycles. In the Dutch Delta Works, geotextiles synergized with plant roots to pioneer eco-slope stabilization.

As smart materials advance,新一代 geotextiles embedded with fiber-optic sensors are undergoing trials, promising real-time foundation health monitoring. This deceptively simple material is redefining contemporary geotechnical paradigms.

-Aohong - Your Trusted Supply Chain Partner in China!

#Geotextiles

0 notes

Text

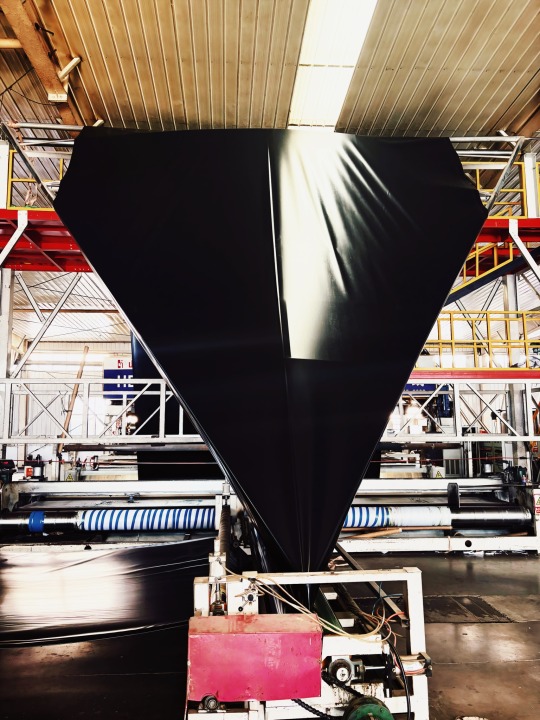

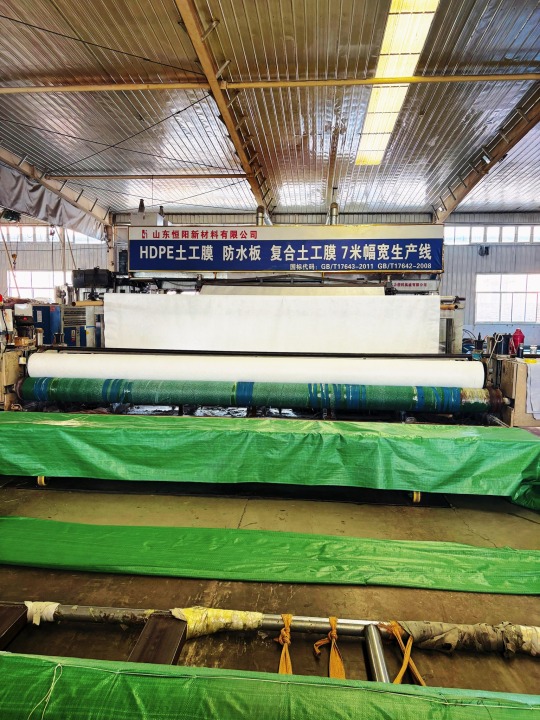

I am a manufacturer of geotextile and geomembrane, looking for customers in need

The main function of HDPE geomembrane is to isolate and prevent seepage. It is mainly used in landfills, reservoirs, artificial lakes, fish ponds, etc., effectively preventing water infiltration and improving water resource utilization efficiency。

1 note

·

View note

Text

Global Trends in the Geosynthetic Manufacturing Industry

In recent years, the geosynthetic manufacturing industry has experienced a remarkable transformation, driven by advances in materials science, growing environmental awareness, and increased demand for sustainable infrastructure. As construction projects across the globe become more complex and environmentally regulated, the role of the geosynthetic manufacturer has become more critical than ever. From roadways and landfills to mining and coastal defense, geosynthetics are reshaping the future of civil engineering.

Growing Demand for Infrastructure Development

One of the most significant drivers of growth for the geosynthetic manufacturer sector is the rising global demand for infrastructure. Developing countries in Asia, Africa, and South America are investing heavily in roads, bridges, and water management systems. Geosynthetics offer cost-effective and durable solutions for soil stabilization, drainage, and erosion control — making them indispensable in large-scale infrastructure projects.

In particular, countries like India and China have seen a surge in the use of geotextiles and geomembranes in highway and railway construction. This trend is pushing manufacturers to scale up production and innovate in order to meet the growing demand.

Shift Toward Sustainable Construction Practices

With environmental regulations becoming stricter, sustainability has taken center stage. A modern geosynthetic manufacturer must now focus not only on performance but also on the environmental impact of their products. The use of recycled polymers, biodegradable materials, and energy-efficient manufacturing processes is becoming a standard in the industry.

Geosynthetics themselves contribute to sustainability by extending the life of infrastructure, reducing the need for raw materials like sand and gravel, and minimizing environmental degradation. Their role in landfill liners and leachate collection systems also helps in containing waste and protecting groundwater.

Technological Innovations in Materials and Design

Innovation is another defining trend in the industry. The development of high-performance geogrids, composite geomembranes, and smart textiles with sensor capabilities is revolutionizing how geosynthetics are used. A forward-thinking geosynthetic manufacturer is likely investing in research and development to create next-generation products that can withstand extreme environmental conditions.

Nanotechnology, for example, is being explored to enhance the strength and permeability of geosynthetics. Meanwhile, digital tools and simulation software are helping manufacturers and engineers to better design and test geosynthetic applications before field deployment.

Increasing Adoption in Mining and Energy Sectors

Another trend reshaping the industry is the expanded use of geosynthetics in the mining and energy sectors. Geosynthetic liners and covers are essential for tailings management, heap leach pads, and reservoir containment. In renewable energy projects, such as solar and wind farms, geosynthetics play a role in slope reinforcement and erosion control.

A geosynthetic manufacturer catering to these sectors must comply with rigorous safety and chemical resistance standards. Customization and adaptability to site-specific requirements have become key differentiators in a highly competitive market.

Regional Expansion and Market Consolidation

With the global demand for geosynthetics rising, manufacturers are expanding their presence across new geographies. Many companies are establishing production plants and distribution networks closer to high-growth regions to reduce logistics costs and delivery times.

At the same time, mergers and acquisitions are shaping the competitive landscape. Large players are acquiring smaller, specialized firms to diversify their product offerings and gain technological edge. This consolidation trend is likely to continue, leading to a more integrated and capable industry.

Final Thoughts

The global geosynthetic manufacturing industry is poised for continued growth and innovation. For any geosynthetic manufacturer, the future lies in sustainable production, advanced materials, and adaptability to the changing demands of infrastructure and environmental protection. As governments and private sectors invest more in resilient infrastructure, the importance of reliable geosynthetic solutions will only grow.

Now is the time for manufacturers to align with global trends, invest in technology, and embrace sustainability — ensuring their relevance and competitiveness in an evolving global market.

0 notes

Text

Global Geocomposites Market: Key Drivers, Challenges, and Opportunities

Rising Infrastructure Development and Environmental Protection Efforts Propel Growth in the Geocomposites Market.

The Geocomposites Market Size was valued at USD 445.3 million in 2023, and is expected to reach USD 776.0 million by 2032, and grow at a CAGR of 6.4% over the forecast period 2024-2032.

The Geocomposites Market is fueled by increasing demand for cost-effective, durable, and sustainable solutions in construction, transportation, and environmental applications. Geocomposites, which are a combination of geotextiles, geogrids, geomembranes, and other geosynthetic materials, provide enhanced drainage, reinforcement, filtration, and barrier functions. With rising investments in infrastructure projects, road construction, and waste management, the demand for high-performance geocomposites is surging globally.

Key Players

ABG Limited

Atarfil

BASF

BOSTD Geosynthetics

Freudenberg Performance Materials

Geomembranes & Geotextiles

Geosynthetics

GSE Environmental

HUESKER

L & M Construction Chemicals

Emerging Trends and Future Scope

The Geocomposites Market is evolving with increased adoption in smart infrastructure projects and sustainable construction. Government regulations promoting environmental protection are driving the use of geocomposites in landfill management, water containment, and erosion control. The demand for lightweight and high-strength geocomposites is also rising in railway stabilization, road widening, and tunneling projects.

Additionally, advancements in bio-based and recyclable geocomposites are gaining momentum as industries seek eco-friendly alternatives to traditional materials. The expansion of geocomposites in offshore and marine applications, such as coastal protection and oil spill containment, further broadens the market scope. With increasing focus on climate-resilient infrastructure, geocomposites are playing a critical role in flood mitigation, stormwater management, and soil stabilization.

Key Market Points

Growing demand for geocomposites in construction, transportation, and waste management

Rising investments in smart infrastructure and climate-resilient projects

Advancements in eco-friendly and recyclable geocomposite materials

Increasing use of geocomposites in railways, roads, and tunneling applications

Government regulations supporting geocomposites for environmental sustainability

Conclusion

The Geocomposites Market is poised for significant expansion as industries and governments prioritize durability, sustainability, and cost-efficiency in infrastructure development. With the increasing adoption of advanced geosynthetics for environmental protection, road stabilization, and water management, the market is expected to grow steadily. Companies investing in innovative, high-performance, and eco-friendly geocomposites will shape the future of civil engineering and sustainable construction.

Read Full Report: https://www.snsinsider.com/reports/geocomposites-market-3057

Contact Us:

Jagney Dave — Vice President of Client Engagement

Phone: +1–315 636 4242 (US) | +44- 20 3290 5010 (UK)

#Geocomposites Market#Geocomposites Market Size#Geocomposites Market Share#Geocomposites Market Report#Geocomposites Market Forecast

0 notes

Text

0 notes

Text

Black Masterbatch for Geosynthetics

In this blog we shares the Role of Black Masterbatch for Geosynthetics- Geotextiles, Geomembranes & Geogrids. Like, High UV Absorption Capacity (Black Masterbatch with UV), Thermal Stabilization (Black Masterbatch with Antioxidant), etc. For black masterbatch manufacturers contact PCPPL today!

0 notes

Text

Uses Of Geomembranes in Road Construction for Better Drainage and Longevity

Road construction is a crucial element of infrastructure development, requiring materials and techniques that ensure durability, safety, and cost-effectiveness. One of the key challenges in road construction is managing water infiltration, which can lead to structural failures such as erosion, cracking, and potholes. To mitigate these issues, geomembranes are increasingly being used to enhance drainage and extend the longevity of roads. These synthetic materials provide a waterproof barrier, preventing moisture infiltration while improving overall structural integrity.

What Are Geomembranes?

Geomembranes are impermeable synthetic sheets made from materials such as high-density polyethylene (HDPE), low-density polyethylene (LDPE), polyvinyl chloride (PVC), and ethylene propylene diene monomer (EPDM). They are used in various civil engineering applications, including road construction, to serve as barriers against water, contaminants, and gases. Their flexibility, durability, and resistance to environmental factors make them ideal for enhancing the lifespan of roads.

Role of Geomembranes in Road Construction

The inclusion of geomembranes in road construction primarily aims to improve drainage and prevent water-related damage. Below are key ways in which geomembranes contribute to road longevity:

1. Preventing Water Infiltration

One of the most common causes of road deterioration is water penetration. When water seeps into the roadbed, it weakens the underlying soil and pavement layers, leading to cracks, potholes, and settlement. Geomembranes act as an impermeable barrier, preventing water from reaching the subgrade and thus preserving the structural integrity of the road.

2. Enhancing Drainage Efficiency

Proper drainage is vital to road durability. Geomembranes, when used in conjunction with geotextiles and drainage pipes, help channel water away from the road structure. They can be strategically placed to redirect water flow and prevent accumulation in critical areas, reducing the risk of waterlogging and frost heave in cold regions.

3. Strengthening Road Foundations

Weak subgrades and unstable soils can significantly reduce road lifespan. Geomembranes help stabilize these foundations by acting as a protective layer between the road surface and the underlying soil. This ensures load distribution is even, reducing the likelihood of settlement and deformation over time.

4. Preventing Erosion and Soil Contamination

Erosion control is another crucial aspect of road construction. Geomembranes help prevent the movement of fine soil particles, which can weaken the road structure. Additionally, they act as a barrier against contaminants such as chemicals, oil, and hazardous materials, ensuring the long-term performance of the road.

5. Reducing Maintenance Costs

By preventing water damage and soil movement, geomembranes contribute to the overall durability of roads, significantly reducing maintenance and repair costs. Roads constructed with geomembrane protection require fewer interventions, resulting in long-term cost savings for governments and infrastructure developers.

Types of Geomembranes Used in Road Construction

Different types of geomembranes are available, each with unique properties suited for specific applications. Below are the most commonly used types in road construction:

High-Density Polyethylene (HDPE) Geomembranes: Known for their chemical resistance, strength, and durability, HDPE geomembranes are widely used in road construction projects where environmental protection is a concern.

Low-Density Polyethylene (LDPE) Geomembranes: These offer greater flexibility than HDPE and are used in applications requiring adaptability to varying terrain.

Polyvinyl Chloride (PVC) Geomembranes: PVC geomembranes are flexible and easy to install, making them a preferred choice for projects that require quick deployment.

Ethylene Propylene Diene Monomer (EPDM) Geomembranes: EPDM membranes are highly elastic and resistant to UV exposure, making them ideal for long-term applications in various climates.

Applications of Geomembranes in Road Construction

Geomembranes are used in different ways in road construction projects, including:

As a Moisture Barrier in Pavement Systems: Installed beneath asphalt or concrete layers to prevent capillary rise of water from subgrade soils.

Underneath Bridge Decks: To protect structural components from water infiltration and corrosion.

In Tunnel and Underground Roadway Construction: Providing waterproofing for tunnels and underpasses to prevent leakage and structural damage.

In Landfills and Roadside Drainage Systems: Controlling leachate movement in roads built near landfills or industrial zones.

For Slope Protection and Retaining Walls: Used in conjunction with geogrids and geotextiles to prevent soil erosion on road embankments.

Installation and Best Practices

For optimal performance, geomembranes should be installed following specific guidelines:

Surface Preparation: The subgrade should be smooth, free of sharp objects, and properly compacted before laying the geomembrane.

Seam Welding: Overlapping edges should be welded or taped to ensure a continuous barrier against water.

Proper Drainage Design: Geomembranes should be integrated with drainage pipes and geotextiles to ensure effective water management.

UV Protection: In cases where geomembranes are exposed, UV-resistant coatings should be used to prolong their lifespan.

Regular Inspection and Maintenance: Periodic checks should be conducted to identify any damages or displacements that could compromise the membrane’s effectiveness.

Environmental and Economic Benefits

The use of geomembranes in road construction not only enhances performance but also offers environmental and economic advantages:

Sustainability: Geomembranes help minimize road repairs and reconstruction, reducing the environmental impact of material usage and construction activities.

Waste Reduction: By preventing soil contamination and erosion, geomembranes contribute to sustainable land use.

Cost Savings: The long-term reduction in maintenance expenses and extended road lifespan result in significant financial benefits for road authorities and taxpayers.

Geomembranes play a vital role in modern road construction, offering superior drainage solutions and ensuring longevity. Their ability to prevent water infiltration, enhance drainage, strengthen foundations, and reduce maintenance costs makes them an essential component in infrastructure projects. With advancements in material technology, geomembranes will continue to revolutionize road construction, providing safer, more durable, and cost-effective transportation networks worldwide. As more engineers and developers recognize their benefits, the adoption of geomembranes will undoubtedly become a standard practice in road-building projects.

0 notes

Text

Geosynthetics in Mining: Enhancing Safety and Environmental Protection

Mining operations are essential for global industrial growth, but they also pose significant challenges related to safety and environmental sustainability. The extraction of minerals and metals generates massive amounts of waste, soil instability, and water contamination risks. Geosynthetics have emerged as a crucial solution to these challenges, improving mine safety, controlling erosion, and minimizing ecological impact. A trusted geosynthetic manufacturer provides a range of innovative products that enhance the structural integrity of mining infrastructure while protecting the environment.

1. The Role of Geosynthetics in Mining

Mining sites involve extensive land excavation, tailings management, and waste containment, all of which require durable and reliable materials to prevent soil erosion and contamination. Geosynthetics, including geotextiles, geomembranes, geogrids, and geosynthetic clay liners (GCLs), provide reinforcement, filtration, and containment functions critical to mining operations.

By incorporating geosynthetics, mining companies can enhance site stability, improve safety, and comply with environmental regulations, making these materials indispensable for modern mining practices.

2. Key Geosynthetic Applications in Mining

a. Tailings Management and Waste Containment

Mining activities generate large volumes of tailings—fine waste materials left after mineral extraction. Without proper containment, tailings can contaminate water sources and lead to hazardous environmental consequences. Geomembranes and GCLs act as impermeable barriers that prevent leakage, protecting groundwater and surrounding ecosystems.

b. Heap Leach Pads for Metal Recovery

Heap leaching is a widely used process for extracting metals like gold, silver, and copper from ore piles. Geosynthetics such as high-density polyethylene (HDPE) geomembranes create leak-proof barriers that prevent toxic leachate from seeping into the ground. This ensures efficient metal recovery while safeguarding the environment.

c. Slope and Soil Stabilization

Mining operations often involve excavation in unstable terrains, increasing the risk of landslides and erosion. Geogrids and geotextiles reinforce weak soils, providing stability to mining roads, embankments, and tailings dams. These materials enhance load-bearing capacity and prevent ground failure, improving worker safety.

d. Water Management and Drainage Systems

Water accumulation in mining pits and processing facilities can lead to operational disruptions and safety hazards. Drainage geocomposites and geonets facilitate efficient water management by redirecting excess water and preventing soil saturation. This reduces risks related to flooding and structural failures.

e. Dust and Erosion Control

Dust pollution is a major concern in mining areas, affecting air quality and worker health. Geotextiles and erosion control blankets prevent dust dispersion and stabilize exposed soil surfaces, reducing environmental impact and maintaining regulatory compliance.

3. How Geosynthetics Improve Safety in Mining

Mining sites present various safety hazards, including ground instability, tailings dam failures, and exposure to hazardous materials. Geosynthetics mitigate these risks by:

Preventing soil and slope failures: Geogrids reinforce embankments, reducing landslide risks.

Containing hazardous materials: Geomembranes prevent toxic seepage into the environment.

Reducing dust inhalation: Geotextile covers limit airborne contaminants.

Enhancing road durability: Geosynthetics improve load distribution on haul roads, minimizing wear and tear.

By using geosynthetics, mining companies can create a safer work environment and reduce accident-related liabilities.

4. Environmental Benefits of Geosynthetics in Mining

Environmental sustainability is a growing priority in the mining industry. Geosynthetics help mining companies minimize their ecological footprint through:

Leak-proof containment systems that protect water bodies from toxic waste.

Erosion control measures that preserve surrounding landscapes.

Efficient water management that prevents contamination and wastage.

Reduced reliance on natural resources, as geosynthetics replace traditional construction materials like gravel and clay.

A geosynthetic manufacturer specializing in mining applications provides customized solutions that align with environmental regulations and promote sustainable mining practices.

5. Choosing the Right Geosynthetic Manufacturer for Mining Applications

Selecting a reliable geosynthetic manufacturer is crucial for ensuring high-performance materials that withstand harsh mining conditions. When evaluating manufacturers, consider:

Material quality and certifications to meet industry standards.

Customization options tailored to specific mining site requirements.

Expertise in mining applications to provide proven solutions.

Technical support and consultation for proper material selection and installation.

Investing in high-quality geosynthetics from a trusted manufacturer ensures long-term durability, operational efficiency, and environmental protection.

Conclusion

Geosynthetics have revolutionized the mining industry by enhancing safety, improving waste containment, and promoting environmental sustainability. Whether stabilizing slopes, preventing toxic leaks, or managing water resources, these materials play an essential role in modern mining operations. Partnering with a leading geosynthetic manufacturer ensures access to advanced solutions that optimize mining infrastructure while minimizing ecological impact. As the mining industry continues to evolve, geosynthetics will remain a key component in building a safer and more sustainable future.

0 notes

Text

Why Ground Improvement is Essential for Sustainable Construction

Sustainable construction is gaining momentum as the world moves towards eco-friendly and long-lasting infrastructure solutions. A crucial aspect of sustainable construction is Ground Improvement, a technique used to enhance soil properties for better stability, strength, and load-bearing capacity. Without proper ground enhancement, structures can suffer from settlement issues, foundation failures, and environmental damage. This article explores why Ground Improvement is essential for sustainable construction and how it contributes to building resilient infrastructure.

1. Understanding Ground Improvement

Ground Improvement refers to the modification of soil properties to make them more suitable for construction. This is done through various mechanical, chemical, and biological methods. These techniques improve soil strength, reduce compressibility, and increase durability, ensuring that structures built on them remain stable over time.

2. The Need for Ground Improvement in Construction

Many construction projects are built on weak or problematic soils that cannot support heavy structures. If left unaddressed, poor soil conditions can lead to:

Uneven settlement of buildings

Cracks in walls and foundations

Structural instability and potential failure

Increased maintenance costs and environmental hazards

By implementing Ground Improvement techniques, engineers can create a stronger foundation, reducing the risk of these issues.

3. Contribution to Sustainable Construction

a) Reducing Material Wastage

Traditional construction methods often involve removing poor-quality soil and replacing it with better material, which is both expensive and environmentally damaging. Ground Improvement techniques allow the in-situ soil to be enhanced, reducing the need for excavation and landfill disposal.

b) Lowering Carbon Footprint

By stabilizing soil on-site instead of transporting new materials, Ground Improvement reduces the carbon emissions associated with transportation and heavy machinery usage. Sustainable construction depends on reducing environmental impact, and soil enhancement plays a crucial role in achieving this.

c) Enhancing Structural Longevity

Buildings constructed on well-improved ground experience fewer foundation issues, reducing the need for repairs and maintenance. This extends the lifespan of structures, minimizing material consumption over time and contributing to sustainability.

d) Preventing Soil Erosion and Land Degradation

Unstable ground can lead to soil erosion, which not only affects the structure but also harms the surrounding environment. Ground Improvement stabilizes the soil, preventing erosion and reducing negative ecological effects.

4. Common Ground Improvement Techniques

Various Ground Improvement methods are used in sustainable construction, including:

a) Soil Stabilization

Uses lime, cement, or fly ash to enhance soil strength

Reduces permeability and increases durability

b) Vibro Compaction and Vibro Replacement

Improves loose granular soils using vibration

Strengthens the soil by introducing stone columns

c) Deep Soil Mixing

Involves mixing soil with a binder (cement or lime)

Enhances soil strength and stiffness

d) Grouting

Injecting cement or chemical solutions to fill voids in soil

Improves load-bearing capacity

e) Geosynthetics

Use of geotextiles, geogrids, and geomembranes

Enhances soil stability and drainage

Each of these methods contributes to making construction projects more sustainable by reinforcing the ground and reducing environmental impact.

5. Applications of Ground Improvement in Sustainable Construction

a) Infrastructure Development

Roads, bridges, and railway projects require Ground Improvement to ensure long-term stability. Weak soil conditions can lead to structural failures, making soil enhancement crucial for infrastructure longevity.

b) Residential and Commercial Buildings

Skyscrapers and heavy structures require a strong foundation. Ground Improvement techniques prevent uneven settlements and foundation cracks, ensuring long-lasting stability.

c) Renewable Energy Projects

Wind farms and solar power plants are often constructed on vast, uneven terrain. Ground Improvement helps stabilize these areas, allowing for the secure installation of turbines and panels.

d) Coastal and Flood-Prone Areas

In regions vulnerable to flooding, Ground Improvement methods like soil stabilization and deep mixing help prevent water ingress and soil erosion, making structures more resilient.

6. Cost-Effectiveness and Economic Benefits

While Ground Improvement may seem like an additional expense, it ultimately leads to cost savings in the long run. By preventing structural failures, reducing maintenance costs, and minimizing environmental damage, these techniques make construction more economically viable. Governments and developers are increasingly recognizing the importance of soil enhancement in sustainable infrastructure planning.

Conclusion

Ground Improvement is a fundamental element of sustainable construction. It strengthens soil, enhances structural stability, minimizes environmental impact, and promotes long-term resilience. With advancements in soil enhancement technologies, construction can become more eco-friendly, cost-effective, and durable. As sustainable development becomes a global priority, Ground Improvement will continue to play a crucial role in shaping the future of construction.

0 notes

Text

Mountlaser proudly offers a wide range of GEO Material products designed to meet the needs of diverse industries.

These products play an important role in fields such as civil engineering, environmental protection, agriculture, and infrastructure construction.

Mountlaser GEO Material includes Geotextile, Geocell, Geomembrane, etc.

Geotextile: used for soil stabilization, drainage and filtration, enhancing the durability and stability of the structure.

Geocell: provides a powerful soil enhancement solution for slope protection and ground reinforcement.

3D Geomat: specially designed for erosion control and greening, promoting vegetation growth and protecting soil.

Geomembrane: effectively prevents liquid leakage and is widely used in landfills, reservoirs and chemical plants.

Geosynthetic Clay Liner: provides economical and efficient waterproofing solutions for various environmental engineering projects.

0 notes

Text

Hello I am a manufacturer of geotextile and geomembrane, looking for customers in need

1 note

·

View note

Text

Future of U.S. Geosynthetics Market: Insights from Industry Experts

The U.S. geosynthetics market size was estimated at USD 3.08 billion in 2023 and is expected to grow at a CAGR of 5.8% from 2024 to 2030. The U.S. is expected to account for a significant market share of the total shale gas consumption in the future on account of increasing drilling activities for shale gas and tight oil supply conditions. This is projected to positively drive the geosynthetics market in the country over the forecast period.

Geosynthetics are used for base reinforcement, separation, and stabilization of roads and pavements. Furthermore, these products also find their application in subsurface drainage systems for dewatering, road base, and structure drainage. Geotextiles are used in the strengthening of industrial units, car parks, and new roadways. The incorporation of geosynthetics entails sustainable development, a small volume of earthwork, low carbon footprint, and an increased rate of construction. The growth of the construction industry around the world, including the U.S., is expected to remain one of the key market drivers for the global geosynthetics market, further boosting the market in the U.S.

Gather more insights about the market drivers, restrains and growth of the U.S. Geosynthetics Market

Key U.S. Geosynthetics Company Insights

The market is majorly run by petrochemical manufacturers across the U.S. The competition in the market is also high due to the presence of a large number of manufacturers. Market players have established strategic partnerships with the distributors to supply their product offerings. Stringent government regulations and depleting petroleum feedstock have contributed to shifting the focus of manufacturers on renewable energy sources and prompted extensive research and development of bio-based raw materials.

Some of the prominent players in the U.S. geosynthetics market are TenCate Geosynthetics Americas; Maccaferri; Concrete Canvas Ltd.; NAUE GmbH & Co. KG; and Propex Operating Company, LLC

• NAUE GmbH & Co. KG, formerly known as Naue Fasertechnik GmbH & Co. KG, was established in 1967. It changed its name to NAUE GmbH & Co. KG in 2005. The company has its headquarters in Germany, with a global presence across North America, Asia, Europe, Australia, South America, and the Middle East & Africa.

• Maccaferri provides advanced solutions for problems related to erosion control, soil reinforcement, stabilization of the soil, and infrastructure development in application areas such as roads, railways, canals, rivers, coastal defenses, and landfills. It owns over 70 subsidiaries in over 100 countries. As of 2018, the company employed over 3,000 individuals globally.

• TENAX Group was established in 1960 and headquartered in Viganò, Italy. The company majorly specializes in extruding thermoplastic polymers. Its product range includes fences, screens, plastic nets, geogrids, and geosynthetics, which find applications in areas such as pipeline, packaging, industrial, geotechnical, gardening, fencing, construction, and agriculture.

U.S. Geosynthetics Market Report Segmentation

This report forecasts market share and revenue growth at country levels and provides an analysis of industry trends in each of the sub-segments from 2018 to 2030. For the purpose of this study, Grand View Research has segmented the U.S. geosynthetics market report based on product:

Product Outlook (Volume, Million Square Meters; Revenue, USD Billion, 2018 - 2030)

• Geotextiles

o By Raw Material

o By Product

o By Application

• Geomembranes

o By Raw Material

o By Application

o By Technology

• Geogrids

o By Raw Material

o By Application

o By Product

• Geonets

o By Raw Material

o By Application

• Geocells

o By Raw Material

o By Application

Order a free sample PDF of the U.S. Geosynthetics Market Intelligence Study, published by Grand View Research.

#U.S. Geosynthetics Market#U.S. Geosynthetics Market Size#U.S. Geosynthetics Market Share#U.S. Geosynthetics Market Analysis#U.S. Geosynthetics Market Growth

0 notes

Text

Geomembrane Solutions by D L Millar And Company Limited

If you are looking for strong and high-quality geomembrane and geotextile products, D L Millar And Company Limited is here to help. We are proud to be one of the top geomembrane sheet manufacturers, offering reliable solutions for many industries. Our products are designed to protect the environment, ensure safety, and improve construction projects.

What Are Geomembranes?

What Are Geotextiles?

Geotextiles are fabric-like materials used in construction. They are strong and help improve soil, control erosion, and strengthen structures. When combined with geomembranes, geotextile provide extra strength and protection. Why Choose D L Millar And Company Limited? At D L Millar And Company Limited, we are committed to providing the best geomembrane and geotextile products. As experienced geomembrane manufacturers, we ensure our products meet international standards.

Our products are ideal for a wide range of applications, including:

1. Geomembrane for Dams : Our geomembrane sheets are the best option for dam lining. They prevent water loss, leak protection, and maintain the strength of the dam over time.

2. Geomembrane for Roads : We have geomembranes that improve road durability. They prevent water damage and maintain the structure of the road, even in heavy traffic.

3. Canal Lining Geomembrane : geomembrane for canal lining of canals stops water seepage. This enhances water flow and helps canals last longer.

4. Pond Liner Geomembrane : Our geomembrane pond liner are sturdy and long-lasting. They are good for fish ponds, ornamental ponds, and reservoirs meant for water storage.

Why Are Geomembranes and Geotextiles Important?

- Environmental Protection : Geomembranes prevent harmful chemicals and wastes from penetrating into the soil and water.

- Cost Savings : With leak prevention and less damage, the materials help one save money on repair and maintenance.

- Long Life Span: The geomembranes and geotextile last for many years.

- Versatility : They can be used in any kind of project, whether small ponds or large dams and highways.

Trust D L Millar And Company Limited for Quality

We are one of the leading manufacturers of geomembrane sheets. We are providing you with strong and reliable products. D L Millar And Company Limited has the right solution for you whether you need geomembrane for dams, roads, canal lining, or pond liners.

Contact Us Today!

Geomembranes or geotextile are needed, come to D L Millar And Company Limited for you. Your perfect selection and find-out is always available from us. Keep your projects protected with our premium quality solutions!

1 note

·

View note