#IPC-A-610 Training

Explore tagged Tumblr posts

Text

How to Choose the Right EMS Provider in India for Quality and Faster Time-to-Market

Choosing the right Electronics Manufacturing Services provider in India can significantly impact your product quality, production efficiency, and speed to market. With India's growing reputation as a global electronics manufacturing hub, thanks to initiatives such as Make in India and robust infrastructure development, more businesses are turning to Indian EMS partners for their end-to-end electronic assembly needs.

In this answer, I’ll walk you through the key aspects to consider when selecting an EMS provider in India and how a trusted partner like Resolute GOC can help you accelerate innovation while maintaining high standards.

Why India for Electronics Manufacturing Services?

India has rapidly evolved into a preferred destination for electronics manufacturing for several reasons:

Cost Efficiency: Lower labor and operational costs make Indian EMS providers globally competitive.

Skilled Workforce: A large pool of engineering talent and trained technicians ensures production precision.

Government Support: Policies such as the PLI (Production Linked Incentive) scheme have incentivized electronics production.

Geopolitical Stability: Compared to some other Asian countries, India offers a more stable business environment.

What Should You Look for in an EMS Provider?

When evaluating an Electronics Manufacturing Services provider in India, consider the following factors:

1) Technical Capabilities: Look for a provider with extensive experience in Surface Mount Technology (SMT), Through-Hole Technology (THT), box builds, printed circuit board (PCB) assembly, testing, and final packaging. The more technically diverse the provider is, the more they can support your growth.

2) Quality Certifications: Your EMS partner should comply with international quality standards, such as ISO 9001, ISO 14001, IATF 16949 (for the automotive industry), and IPC-A-610. These certifications ensure that the manufacturer adheres to global quality benchmarks.

3) Design and Engineering Support: An ideal EMS partner should offer Design for Manufacturability (DFM) and Design for Testing (DFT) services to optimize your product from the early stages. Engineering support helps avoid costly mistakes later in the production cycle.

4) Scalability and Flexibility: Can the provider handle your volume requirements as you scale? Whether you're a startup launching a new product or an enterprise managing large-scale production, the ability to ramp up or down without compromising quality is critical.

5) Turnaround Time and Supply Chain: Efficient supply chain management and faster turnaround times will reduce your time-to-market. Look for a provider that maintains strong relationships with component suppliers and demonstrates expertise in managing supply chain risks.

6) Testing and Quality Assurance: A strong EMS partner will have automated and manual testing capabilities, including in-circuit testing, functional testing, burn-in testing, and environmental stress screening. This ensures product reliability and performance.

7) Aftermarket Services: Support doesn’t end with assembly. Services like repair, rework, and reverse logistics demonstrate a provider’s commitment to the entire product lifecycle.

How the Right EMS Partner Can Transform Your Business

Choosing a reliable EMS provider isn’t just about outsourcing production; it’s about establishing a strategic partnership that supports innovation and growth. Here's how:

Improved Product Quality: High-precision assembly processes, real-time monitoring systems, and rigorous quality assurance protocols ensure consistently high-quality output. This results in fewer returns, lower defect rates, and better customer satisfaction.

Faster Time to Market: A full-service EMS provider accelerates the design-to-delivery process. Their expertise in prototyping, tooling, and rapid manufacturing enables you to launch new products more quickly than if you were managing everything in-house.

Cost Reduction: From minimizing BOM (Bill of Materials) costs to reducing labor and operational expenses, EMS companies in India offer significant cost advantages without compromising quality.

Innovation Enablement: Providers like Resolute GOC support innovation with integrated services, including prototyping, product development, and scalable production. This means more time and resources for your team to focus on design and market strategy.

Why Consider Resolute GOC?

Resolute GOC is one of the leading Electronics Manufacturing Services providers in India, offering comprehensive solutions for companies across various sectors, including automotive, industrial, medical, telecom, and consumer electronics. Here’s what sets them apart:

Comprehensive Capabilities: SMT, PCB assembly, product design, and system integration under one roof.

State-of-the-Art Infrastructure: Modern facilities equipped with high-speed pick-and-place machines, AOI, X-ray inspection, and automated testing systems.

Scalability: From low-volume prototypes to high-volume production, Resolute GOC adapts to your needs.

Strong Engineering Backbone: Their engineering team offers DFM and DFT support to improve manufacturability and reliability.

Quality First Approach: Stringent quality control measures and internationally certified processes ensure consistency and compliance.

Whether you’re a startup looking to bring a prototype to life or an OEM seeking volume production, Resolute GOC can serve as a reliable partner throughout your product lifecycle.

Conclusion

Selecting the right Electronics Manufacturing Services provider in India is a strategic decision that influences your product’s success, your brand’s credibility, and your company’s bottom line. By focusing on capabilities, quality, scalability, and reliability, you can find a partner that not only meets your current manufacturing needs but also evolves with you.

As Indian EMS companies continue to invest in advanced technologies and quality frameworks, the opportunity to build globally competitive products has never been more accessible. Explore providers like Resolute GOC, who are well-positioned to deliver innovative, efficient, and scalable solutions tailored to your specific requirements.

If you’re looking to optimize your electronics manufacturing strategy and expand your reach, India’s EMS landscape is ready; the only question is, are you?

0 notes

Text

In-Depth Analysis of Toggle Switch Terminal Connection Methods: Technical Selection and Scenario Adaptation for Soldered, Plug-In, and PCB-Mounted Designs

Introduction

In B2B applications such as industrial control, automotive electronics, and medical equipment, the terminal connection method of a toggle switch is a critical factor determining product reliability, installation efficiency, and long-term maintenance costs. Soldered, plug-in, and PCB-mounted designs each have unique advantages and limitations, requiring a comprehensive evaluation of electrical performance, environmental resistance, and production automation. This article analyzes structural design, application scenarios, and compatibility challenges, supported by industry cases (e.g., automotive ECU controls, industrial PLC modules) and emerging trends (e.g., high-density PCB integration), to provide engineers and procurement decision-makers with a systematic selection guide.

1. Soldered Terminal Connections: The "Permanent Bond" for High Reliability

Structure & Process

Physical Connection: Permanently fixes switch terminals to PCBs or wires via soldering (solder or reflow).

Terminal Type: Through-hole pins (0.6–1.2mm diameter), typically made of tin-plated or gold-plated phosphor bronze.

Key Standard: Compliant with IPC-A-610 to avoid cold joints or voids.

Applications & Cases

High-Vibration Environments: Siemens’ train control panels use soldered toggle switches validated for 10-year maintenance-free operation under EN 61373.

High-Current Loads: ABB frequency converters employ soldered emergency stop switches to withstand 50A short-circuit currents.

Pros & Cons

Advantages: Stable contact resistance (<5mΩ), superior vibration resistance (passes MIL-STD-202G), low cost (no connectors required).

Limitations: Difficult repairs (thermal desoldering needed), limited flexibility in automated production.

Innovations

Hybrid solder-crimp terminals (e.g., TE Connectivity’s DUOBILIT) balance reliability and removability.

High-temperature solder (Sn96.5Ag3Cu0.5) extends lifespan in automotive engine compartments.

2. Plug-In Terminals: Modular Flexibility for Easy Maintenance

Structure & Standards

Connection Types: Tab terminals, receptacles, or spring cages with 5–20N insertion force (UL 310).

Common Sizes: 2.8mm (automotive) or 4.8mm (industrial) tab widths.

Applications & Cases

Medical Equipment: GE MRI control switches use gold-plated tabs for <3mΩ contact resistance and 10,000-cycle durability.

Smart Home Gateways: C&K’s T-series plug-in terminals enable cross-device compatibility.

Pros & Cons

Advantages: Tool-free installation, hot-swappable (e.g., data center PDUs), space-efficient (2.54mm pitch).

Limitations: Higher contact resistance (+10–30% vs. soldered), vibration-induced loosening (requires locking mechanisms).

Innovations

Foolproof designs (e.g., AMP’s Mate-N-Lok asymmetric tabs).

Self-cleaning multi-point contacts (e.g., JST PA series).

3. PCB-Mounted Terminals: Miniaturization for High-Density Integration

Structure & Process

Mounting Types: Through-hole (THT) or surface-mount (SMT) with L/J-shaped leads.

Typical Dimensions: THT pins (3–5mm length), SMT packages (60% smaller than THT).

Applications & Cases

Consumer Electronics: ALPS SSSS series SMT toggle switches (2.3mm thickness) in TWS earphone cases.

Robotics: SMT switches integrated with FPGAs on 0.5mm-pitch PCBs.

Pros & Cons

Advantages: Ultra-compact, automated production-friendly (>20,000 CPH), low EMI.

Limitations: Vulnerable to PCB flexing, limited heat dissipation.

Innovations

Hybrid SMT-THT designs (e.g., E-Switch TL series).

Flexible PCB-compatible curved pins (Würth Elektronik WM series).

4. Compatibility Challenges & Solutions

Cross-Platform Adaptation: Phoenix Contact’s COMBICON modular terminals switch between THT and plug-in modes.

Moisture Resistance: 3M Parylene coating + O-rings prevent dendrite growth.

High-Frequency Noise: C&K KSC series with shielded pins and Rogers RO4003 substrates.

5. Industry Trends & Selection Guide

Smart Integration: LEM GoSwitch series with current sensors and I²C interfaces.

Green Manufacturing: DSM EcoPaXX halogen-free materials for RoHS 3.0 compliance.

en.dghongju.com

0 notes

Text

Unlocking Excellence: The Journey to Become a Certified IPC Trainer (CIT)

From the world of fine craftsmanship and accuracy in electronics manufacturing! The IPC certification Trainee (CIT) credential is a must-have for anyone looking to advance their career and make a positive impact on the dynamic electronics industry. It is only offered by IPC-approved training facilities like Blackfox.

We'll explore the value of CIT soldering certification, the training requirements, and the advantages it offers to individuals and businesses in this blog.

Why Select Certification in CIT?

The electronics sector requires highly qualified workers to guarantee the dependability and quality of electronic assemblies. The purpose of the CIT certification is to empower employees in businesses, self-employed consultants, and instructors at colleges and universities. Let's examine the main justifications for CIT certification among prospective professionals:

Industry Recognition: In the electronics manufacturing sector, the CIT certification is well-known. It is evidence of a person's skill and dedication to upholding standards of excellence.

Program for "Training the Trainer": The IPC certification is basically a "train-the-trainer" initiative. After passing the exam, candidates will have the information and abilities needed to instruct other people in their company or at a school as Certified IPC Specialists (CIS).

Comprehensive Training Materials: CITs can conduct application-level (CIS) IPC training with the IPC materials that Blackfox, an IPC-authorized training center, provides. This includes current details on soldering methods, industry standards, and best practices for electronic assembly.

The Process of CIT Training

The path to becoming a Certified IPC Trainer is demanding but worthwhile. Let's go over the main stages of the CIT training procedure:

1. Prerequisite Knowledge: Before beginning the CIT certification process, candidates usually have a strong background in electronics and soldering procedures.

CIT candidates receive instruction in the IPC-A-610 standard, which outlines the requirements for acceptable electronic assemblies. This training ensures a thorough understanding of industry standards and requirements.

2. Assessment of Hands-On Skills: Practical application is a key component of the CIT certification. Candidates participate in a practical skills evaluation where they demonstrate their soldering abilities and application of IPC standards.

3. Certification Exam: An extensive test covering the IPC-A-610 standard is the last obstacle. Succeeding candidates exhibit their command of the subject and dedication to upholding standards in the production of electronics.3

Advantages of Certification in CIT

Getting certified as a CIT opens doors to a lot of advantages for people and their companies:

Enhancement of Skill: CITs' overall skill set is improved by their increased understanding of soldering methods, electronic assembly procedures, and IPC standards.

Credibility in the Industry: The CIT certification is a symbol of excellence that gives professionals in the electronics manufacturing sector respect and credibility.

Cost savings: Having in-house trainers helps organizations cut costs related to errors and rework, as well as the need for outside training services.

Constant Learning: To keep CITs abreast of the latest developments in technology and industry best practices, they are provided with regular updates on industry standards.

Joining Blackfox as a Certified IPC Trainer is more than just obtaining a credential—it's a pledge to excellence in the electronics manufacturing industry. Whether you work in the industry as a professional or as an instructor, earning your soldering certification and CIT certification guarantees that you contribute significantly to upholding the highest standards in electronic assembly and opens doors to new opportunities.

Visit Blackfox's IPC-authorized training facility in Delaware to start your journey toward CIT certification and discover your potential as a leader and educator in the exciting field of electronics.

0 notes

Text

In the forefront of #ElectronicsManufacturing, Avalon Best EMS Company stands out with its exemplary #PCBAssembly processes. We’re excited to share insights into Avalon's dedicated approach to manufacturing that not only ensures #QualityAssurance but also streamlines rapid prototyping and volume manufacturing to meet today’s dynamic market demands. Understanding PCB Assembly: Printed Circuit Board assembly is the heart of functional electronic circuits. It's not just about soldering components; it's about ensuring lasting connectivity and performance. The Importance of High-Quality Assurance: Reliable electronic products hinge on stringent quality control. Avalon's robust measures are the bulwark against defects, guaranteeing customer satisfaction and #BusinessSuccess. Avalon’s Capabilities: Swift chip mounting for #RapidPrototyping. Flexible production lines for any volume. Advanced SMT lines for complex assemblies. Ensuring Excellence: State-of-the-art AOI and X-ray inspections. Rigorous quality control from start to finish. A highly skilled workforce trained in cutting-edge assembly techniques. Avalon holds prestigious ISO 9001:2015 and IPC-A-610 certifications, reflecting a relentless pursuit of quality. By choosing Avalon, you choose a partner dedicated to excellence. Save time, cut costs, and ensure your products stand out in the market. Join the ranks of satisfied clients who trust Avalon for their PCB assembly needs. Visit https://lnkd.in/gbEj6nz6 for more information. https://www.avalontec.com/contact/ https://www.avalontec.com/blog/pcb-assembly/

#AvalonEMS#Electronics#ManufacturingExcellence#QualityControl#PCBManufacturing#Innovation#TechIndustry#electronics#electronicsindustry#electronicmanufacturing Avalon Technologies Limited Sienna Corporation Sienna ECAD Technologies Private Limited

0 notes

Text

youtube

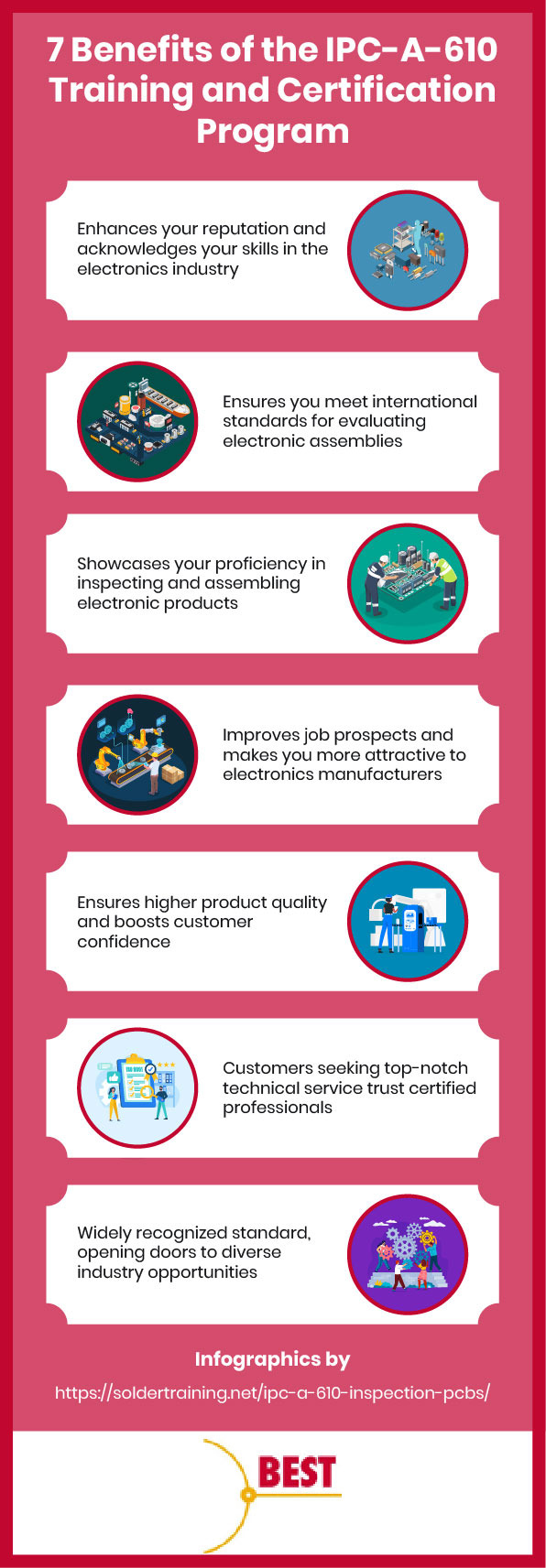

BEST Inc.'s training methods align with industry standards. The electronics company provides technicians with wide-ranging certification courses. Their IPC-A-610 certification program is an industry-consensus program that includes training, certification, and instructional materials that align with IPC-A-610 criteria. This training and certification program is well-known in the electronics industry. Those that want to join IPC A-610 training can contact BEST Inc. To know more, watch this video or visit their website: https://soldertraining.net/ipc-a-610-inspection-pcbs/.

0 notes

Text

BEST Inc. Offers Certification Training for IPC-A-610 and IPC-A-620 Standards

http://dlvr.it/SwVQGx

0 notes

Text

BEST Inc. Offers Certification Training for IPC-A-610 and IPC-A-620 Standards

http://dlvr.it/SwVHXk

0 notes

Text

BEST Inc. Offers Certification Training for IPC-A-610 and IPC-A-620 Standards

http://dlvr.it/SwVGQB

0 notes

Text

BEST Inc. is an ISO registered company who understands quality standards as well as the IPC electronic assembly standards. They have staff trained to the latest IPC-610 inspection criteria standards, the latest J-STD-001 assembly standards and the most recent wire harness inspection standards in the IPC-A-620. BEST Inc. can be your knowledgeable resource for electronic sorting, EST Inc. can arrange for the transport of the material, as well as unpacking and repacking. To learn more about it you can visit https://www.solder.net/services/electronics-sorting/

0 notes

Photo

The IPC-A-610 standard is the most widely recognized and accepted standard ever published by the IPC for the PCB assembly industry. After your trainers are certified to this specification, they will be qualified to teach and certify individuals in the IPC-A-610 standard. This training program provides comprehensive accept/defect criteria for all three classes of assembly production. Check here the course outline for the IPC-A-610 instructor class at BEST.

1 note

·

View note

Text

What is IPC A-610 and J-STD-001 Certification in PCB Assembly?

BEST Inc is a fully authorised and certified center for IPC A-610 and J-STD-001 Certification and Training in PCB Assembly. IPC A-610 and J-STD-001 standards especially emphasize process control and provide an industry-level standard for a broad range of electronic products. The standards are now updated to the “H” version with several significant changes. Read this article for additional information.

0 notes

Link

IPC’s J-Std-001 Training and Certification Program provides individuals with a valuable, portable credential that recognizes their understanding of the J-Std-001. It’s a multi-tiered training program built on a train-the-trainer instructional model that describes methods, materials as well as verification criteria. To know more read this blog…

0 notes

Link

Watch this PPT for information about IPC training and solder certification courses for courses like IPC-A-610, IPC J-STD-001, IPC-A-600, IPC/WHMA-A-620, and IPC 7711/7721 to all Instructors and specialists..

0 notes

Link

Join the IPC A-610 Certification and Training program offered by BEST Inc where certified IPC trainers provide training with world-class training materials and detailed plans for training application specialists (CIS). Thousands of individuals have been trained to be IPC-A-610 Certified IPC Trainers. It is a comprehensive and technically accurate program which provides Certified IPC Trainers with high-quality materials and detailed instructional plans for training Application Specialists at all levels. In IPC 610 class, there are numerous topics to be covered such as Roles and Responsibilities of IPC Registered Instructors, Terms and Definitions etc and much more that takes 4 days to administer and test out. Click the above link for more or visit https://goo.gl/jK3ajS

1 note

·

View note

Photo

Importance Of IPC Training And Certification | IPC-610 Certification

IPC A-610 certification program is an industry developed and approved program most widely used inspection for the PWB assembly industry.. BEST is an authorized IPC Training Center and offers the IPC A-610 for both CITs and CIS which is based purely on IPC A-610 doc. Read our blog for more info.

0 notes

Text

IPC-A-610 certification is an industry-standard document published by the Association of Connecting Electronics Industries (IPC). This widely recognized standard establishes the acceptability criteria for the assembly of electronic components, defining what is acceptable and what is not in terms of their artistry. To know more read this infographic: https://soldertraining.net/blog/benefits-of-ipca610-training-certification-program/.

0 notes