#IS code TMT

Explore tagged Tumblr posts

Text

What Every TMT Saria Manufacturer Wants You to Know About TMT Bar Standards

Introduction

Every tmt saria manufacturer understands that the credibility of a construction project hinges on the strength and consistency of the materials used. Whether the structure is a towering commercial complex or a simple residential building, the standards applied to a tmt saria bar make all the difference in ensuring long-term durability. With so many tmt bar manufacturers in the market, the need for clarity, performance, and trust has never been greater.

Standards aren’t simply formalities—they’re safeguards. They provide engineers and contractors with confidence that the steel being used has been tested, validated, and optimized for performance. And while glossy brochures can sell a brand, it's the internal metallurgical quality and consistency that determine real-world performance on-site.

Why Standards in TMT Bars Matter

TMT bars aren’t just another commodity; they’re foundational to structural safety. When subjected to stress—be it load-bearing tension, sudden impact, or seismic shifts—only a standard-compliant bar can ensure that the structure remains resilient.

National and regional codes such as IS:1786 define the physical and chemical properties a TMT bar must meet. These include elongation percentage, yield strength, tensile strength, and bend/rebend capacity. Without adherence to these norms, the performance of the bar in critical applications is left to chance.

Substandard products may save costs upfront, but the consequences can be catastrophic. Project delays, structural failures, and legal liabilities all stem from materials that fail to meet basic benchmarks.

What to Look for in a Reliable TMT Saria Bar

Every tmt saria bar must strike a balance between strength and ductility. Visual inspection is not enough. Performance lies in the grain structure of the steel, which can only be achieved through modern processes like the Quenching and Self-Tempering (QST) method.

This process imparts a tough outer layer for strength while retaining a softer core for flexibility—ideal for absorbing stress during earthquakes or wind loads. Apart from the manufacturing process, buyers should look for uniform rib patterns, accurate weight-to-length ratios, and clean surface finishes.

Flexibility also matters during fabrication. A good bar should resist breakage during bending, welding, and cutting operations on-site. Poor-quality bars often fail during these steps, affecting timelines and increasing labor fatigue.

Role of TMT Saria Manufacturers in Quality Assurance

A responsible tmt saria manufacturer doesn’t just produce steel—they control quality at every touchpoint. From selecting virgin raw materials to final packaging, each step should be supported by rigorous checks. In-house testing labs, third-party certifications, and automated production systems are indicators of a company’s seriousness toward quality.

Leading tmt bar manufacturers conduct tests like chemical composition analysis, tensile testing, bend/rebend trials, and elongation testing on every batch. These aren’t just routine—they’re requirements that ensure buyers receive consistent performance, batch after batch.

Manufacturers also contribute to the industry ecosystem by providing educational content, usage guides, and on-site training sessions for dealers, masons, and site supervisors. This reinforces trust while ensuring correct handling and application.

Final Considerations Before Choosing a TMT Brand

Before shortlisting a brand or supplier, it’s essential to review their certifications, product history, and technical capabilities. Does the tmt saria manufacturer comply with BIS norms? Are their bars used in high-profile or government projects? These indicators speak volumes about reliability.

Cost should not be the only deciding factor. Value is found in quality that lasts, service that supports, and standards that protect. Builders, developers, and procurement heads are increasingly prioritizing long-term performance over short-term savings.

As the market becomes more competitive, tmt bar manufacturers who lead with transparency, third-party validation, and customer education will continue to stand out. It’s not just about selling a bar—it’s about selling peace of mind.

#TMT bar guide#Saria standards#TMT bar quality#TMT Saria info#Best TMT bars#TMT bar specs#IS code TMT#Steel bar tips#TMT strength#Saria grades#TMT bar types#TMT bar uses#TMT for homes#TMT bar ISI#Fe 500 vs 550#TMT bar safety#TMT steel guide#Saria buying tips#TMT bar norms#TMT basics

0 notes

Text

Sketch a Day 2715-Wally and Kuki- 7/2/23

redraw: https://tmblr.co/ZiVmYs2Fbs_Ym

31 notes

·

View notes

Text

㊗️Today, January 27th,

🎧25:00, Night Code. 💻

🎉🎂 Asahina Mafuyu's birthday 🎂🎉

The birthday illustration was done by tmt (@t0mat0juice) ✨

#project sekai#project sekai colorful stage#hatsune miku colorful stage#pjsk#25 ji nightcord de#project sekai mafuyu#asahina mafuyu#mafuyu project sekai#mafuyu asahina#25ji mafuyu#n25 mafuyu#niigo mafuyu#pjsk mafuyu

71 notes

·

View notes

Text

Just some more of scrunkly will wood coded energy vampire sexyman :) 2nd is render test for my animation, but i had to delay the production because of publishers who knocked in my door and said MAKE A COMIC. NOW. TmT i couldnt resist

I feel so sorry for him 😢 love my man

52 notes

·

View notes

Text

Basic JDownloader 2 Tutorial

With the world realizing that media on the internet can be lost with a snap, I thought it would be a good idea to show you how to download media, either music, videos, pictures, and text in bulk. (LONG POST WARNING)

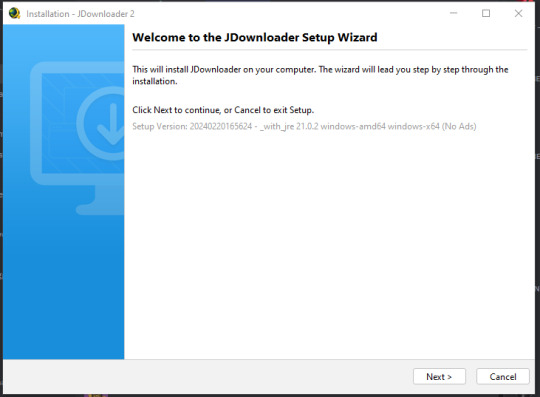

I. Downloading the Program

Behold, the download page, is this safe? There is a pretty high chance that the software is safe, as it is open-source, meaning anyone can look at the programs code and/or modify it. However if you still don't feel safe installing the file, that's okay! I don't have any alternatives however TmT.

I will be downloading the windows version since that's the OS I run, however I'm sure the other downloads work just as fine.

You should get either the top one or the bottom one, if one doesn't work then try the other, the other versions on the website I believe are for older computers.

Double click on the file it downloaded and wait for the installer to load.

Go though the installation and wait for it to install. Once it's done downloading click finish and JDownloader 2 should open automatically (or if you disabled that int he installation, you can just open it there.)

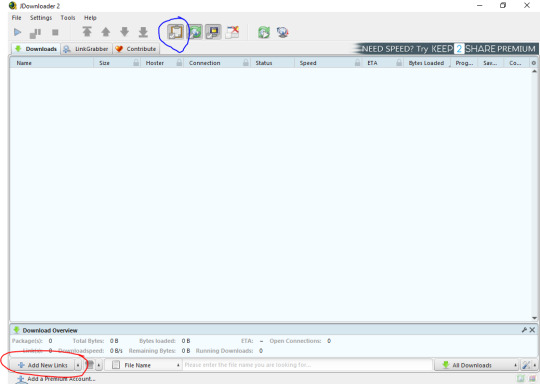

II. What the Heck am I Doing?

What do you do? The program is a bit confusing at first, however it's rather simple to understand. See that button circled in red? That's how to add items to download, click it. However, if you look at the top of the image and locate the clipboard circled in blue, that makes is so anything you copy, links, images, etc, will automatically be added to the program, if you think this will be annoying then disable it.

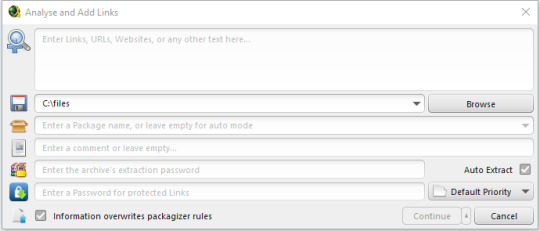

Once you click the "Add New Links" button, this window should appear. Everything here looks pretty scary, however you only need the two that are circled, the rest is for more advanced searching. Simply copy and paste a link that has any content supported by JDownloader 2. (NOTE: Youtube is fully supported by JDownload 2).

(Just if your looking for the continuation!)

7 notes

·

View notes

Text

⸻ get to know the stay ! 🥨🫙 ( thank you for tagging me @hanjsquokka )

1. what’s your current bias line?

seungmin, han, and lee know.

2. who’s the one that made you stan?

han, he’s the first one who indulged me into the group but i knew hyunjin and felix even before i decided to stan.

3. what song was your first?

hellevator!! 👑

4. what’s your current favorite song?

falling up (from tower of god) and come play (from arcane) !!

5. what members personally resembles yours the most?

my friends would say i resemble han the most and a bit of seungmin.

6. if you had to pick a specific racha which would you choose?

paboracha ofc i’m dumb as well 🤷🏻♀️🙈

7. what’s one attribute of the members do you like the most? (example: chan's dimples)

i love seungmin’s eyes and his smile, and han and hyunjin’s laugh.

8. what’s your favorite album?

damn... uhm, levanter and ATE. special mention to 5-STAR, NOEASY, GO LIVE, I AM NOT and IN LIFE.

9. do you have any albums?

tons!! from i am you, miroh and levanter to ATE. i just pre-ordered HOP!!

10. have you been to a concert?

yes, during maniac tour in manila. they came to the philippines recently but i wasn’t able to attend.

11. who’s your favorite duo?

seungsung (they’re underrated) and 2min.

12. favorite cover/solo songs:

love again and you were beautiful by seungmin, congratulations by han and seungmin, stars and raindrops and as we are from seungmin, and close and 13 from han.

13. favorite skzoo?

puppym, hanquokka and leebit!

14. if you had a day with one member what would you wanna do with them?

i would love to go around and explore places with them, have coffee (or drink) at a local café, talk about life, play at the arcade, or just walk by the beach.

15. who’s your favorite singing voice?

seungsung 🫶🏻✨

16. who’s your favorite to watch dance?

not to be biased but han and seungmin are both underrated dancers and yet they both move smoothly. special mention, lee know.

17. do you have a favorite skz code?

ep. 6-7, ep. 16-17, ep. 20-24, ep. 39-40, ep. 55-56, ep. 59-60, and ep. 63 (still waiting for the next ep. in australia)

18. favorite mv?

as we are (even tho it’s not released yet), the view, insomnia (they were in new york here), tmt, give me your tmi, freeze, megaverse, chk chk boom, and ex.

19. who do you think you’d be best friends with?

i think hyunjin and felix, yes, also han. the rest are brother material, except seungmin, he’s like THE boyfriend.

20. let’s feed those delusions, who are you picking for a date and what are you doing?

seungmin! i would love to watch him play baseball, go to a bookshop and read together, maybe exchange book recommendations, listen to music together at a music store, watch the sunset together as we play on a picnic mat, eat our favorite deserts together and stay up late just to watch the stars and talk about our plans in the future.. yep (i suddenly miss him thank you so much)

no pressure tags : @starseungs @lix-ables @hyunverse @hyunebunx @starlostastronaut @stayconnecteed @arrasuh @lixies-favorite-cookie + those who wanted to do this ⭐🌈

4 notes

·

View notes

Note

I'm so curious about Cutlass 👀👀 but this question has been swirling around my head for a bit. Does Cutlass have a few morals? As in like if she sees a sparkling/youngling she won't do anything to them or not purposefully?

One form of torture she’ll reframe from is solitude, though in Oardivia nearly every individual (aside from the TMT) fears being completely alone, as if it’s ‘coded’ in them, or perhaps even inherited from Tectonichus.

This is less of a moral thing, and more of a natural primal fear she and other Oardivians just have. Though she has often considered trying it, for science.(she’s not a scientist)

As for sparklings/young ones… (potential tw, just to be safe)

Sparklings haven’t been much of a thing in recent years, as Tec’s birthing pool has not been producing many viable buds for a while, meaning there hasn’t been any recent opportunities for a youngster to be in a position to be harmed by Cutlass or her crew.

However, it is likely that youngsters have been harmed and even murdered by Cutlass and her goons.

Say someone has somehow gotten the attention of Cutlass, got on her bad side, or owes her money. One way to threaten them into keeping quiet or paying up is to get a loved one, kidnapping them. The longer the captured mech remains with Cutlass, the higher the chances are that she’ll start sending back bits and pieces that have been cut away from their living frame, each piece a warning. It would start from harmless cuttings of armor, then to things like fingers, eyes, noses and tongues, until finally they are given the empty spark casing of their captured loved one.

Ultimately, Cutlass cares only for herself and what she wants. So if she has to punt a baby like a football to get something she wants, she won’t even bat an eye.

10 notes

·

View notes

Text

Building Strong: A Guide to Choosing the Right TMT Bars for Your Project

The towering skyscrapers that define modern cities, the bridges that span rivers, and the homes that shelter families – all of them share a crucial foundation: the strength and resilience of TMT bars. Choosing the right type of TMT bar for your construction project isn't just about picking metal rods; it's about laying the groundwork for a structure that will endure.

Navigating the Maze of Options:

With an array of TMT bars available, each with its own unique properties, the selection process can seem daunting. But fear not! This guide will equip you with the knowledge to navigate the labyrinth of options and confidently choose the bars that will be the unsung heroes of your building.

Unveiling the Grades:

Understanding TMT bar grades is your first step to success. These grades, denoted by numbers like Fe415 or Fe500, represent the minimum yield strength of the bar. Simply put, the higher the grade, the stronger the bar. But this isn't a one-size-fits-all equation. A high-rise needs different muscle than a small bungalow. Carefully consider the load-bearing requirements of your project and consult structural engineers to determine the ideal grade for each element.

The Strength Equation: Tensile Power and Ductile Grace:

Tensile strength is the champion of load resistance, making your structure stand tall against gravity and external forces. But true strength lies in balance. Ductility, the ability to bend without breaking, is equally crucial, allowing the bars to absorb stress and prevent sudden fractures. Finding the sweet spot between these two properties is vital, ensuring both resilience and adaptability.

Weathering the Storm: The Corrosion Challenge:

No structure is an island. It faces the relentless assault of sun, rain, and wind. This is where corrosion resistance takes center stage. Choose TMT bars with effective anti-corrosion measures, be it chemical additives or a well-designed ribbed surface, to shield your building from the ravages of time and the elements.

Shaping Dreams: Bendability and Weldability:

Construction is not a rigid art form. The ability to bend TMT bars to your will is essential for creating arches, columns, and intricate architectural details. Weldability, too, plays a crucial role in seamlessly joining bars, ensuring a unified and sturdy skeleton for your project.

Finding the Perfect Fit: Size and Dimensions Matter:

Think of TMT bars as the veins of your structure. Their thickness and spacing determine the flow of forces within the concrete. Choosing the right sizes and dimensions is key to ensuring uniform load distribution and structural stability. Consult experts and follow building codes to select the perfect diameter and spacing for each element of your project.

Quality Beyond Compromise: Certifications and Standards:

Don't let the allure of a bargain blind you to quality. Always choose TMT bars that comply with recognized industry standards and certifications. These ensure stringent manufacturing processes and material testing, giving you peace of mind and a guarantee of long-lasting performance.

Investing in Strength: Balancing Cost and Value:

While cost is a factor, remember that cheap bars can turn into expensive repairs down the line. Choose TMT bars that offer optimal value for money, striking a balance between upfront cost and long-term durability. Think of it as an investment in the future of your structure.

Building With Confidence:

Now, armed with this knowledge, you can enter the world of TMT bars with confidence. By considering these key factors – grades, strength, corrosion resistance, bendability, size, certifications, and cost – you can select the bars that will become the silent heroes of your project, ensuring its strength, resilience, and beauty for years to come.

2 notes

·

View notes

Text

High-Quality Construction Materials in Qatar: Building the Nation with Strength and Reliability

Qatar is a rapidly developing country known for its world-class infrastructure, innovative architecture, and ambitious development projects. From state-of-the-art stadiums built for the FIFA World Cup 2022 to luxurious commercial and residential spaces, the demand for high-quality construction materials in Qatar has never been greater. Quality construction materials are the backbone of every durable structure, and in Qatar’s competitive and challenging environment, ensuring strength, durability, and efficiency is crucial.

Importance of High-Quality Construction Materials

In any construction project, the longevity, safety, and performance of the final structure heavily depend on the quality of materials used. Using substandard materials can lead to structural weaknesses, high maintenance costs, and even safety hazards. In Qatar’s harsh climatic conditions—marked by high temperatures, humidity, and occasional sandstorms—materials need to be especially resilient to corrosion, heat, and wear. Therefore, contractors and developers in Qatar prioritize sourcing top-grade materials that meet international standards.

Types of High-Quality Construction Materials in Demand

Cement and Concrete Products High-performance cement and ready-mix concrete are essential for foundations, columns, and other structural components. These materials must offer superior compressive strength, workability, and durability to withstand environmental stresses.

Steel and Rebar Reinforced steel bars (rebar) are vital for adding tensile strength to concrete. In Qatar, corrosion-resistant and thermo-mechanically treated (TMT) steel is highly preferred for major infrastructure and commercial projects.

Aggregates and Sand Clean, well-graded aggregates and high-quality sand are important for concrete mixes, drainage layers, and landscaping. Their consistent sizing and chemical composition ensure better bonding in concrete and reduce wear.

Insulation and Waterproofing Materials Due to extreme heat, buildings in Qatar require thermal insulation materials like polyurethane foam, rock wool, and reflective coatings. Waterproofing membranes and chemicals also play a crucial role in protecting buildings from moisture infiltration.

Pipes and Fittings Durable and leak-proof pipes are necessary for water supply, drainage, and HVAC systems. Materials such as PVC, HDPE, and PPR are widely used for their durability and resistance to corrosion and heat.

Finishing Materials High-quality tiles, paints, gypsum boards, and aluminum cladding enhance both the aesthetic and functional value of buildings. These materials must also be easy to maintain and long-lasting in Qatar’s climate.

Reliable Suppliers and Global Standards

Qatar hosts many trusted suppliers and distributors who offer internationally certified materials that comply with Qatar Construction Standards (QCS). Companies often import from reputed global brands while also supporting local manufacturing, ensuring availability, competitive pricing, and quality assurance.

Conclusion

As Qatar continues to expand its skyline and infrastructure footprint, the role of high-quality construction materials becomes even more significant. Developers and contractors must continue to prioritize materials that offer durability, efficiency, and sustainability. With strict building codes, modern construction technology, and a strong focus on quality, Qatar is well-equipped to build a future that stands strong for generations to come.

0 notes

Text

TMT Saria – Backbone of Strong Construction

TMT Saria, or Thermo Mechanical Treatment bars, is vital in modern construction, due to its high tensile strength, ductility, and resistance to earthquakes and corrosion. Indostar TMT not only support residential units but also bridges and high-rise towers, providing the integrity that is necessary for every construction project.

Why you should consider TMT Saria?

✅ High Strength & Ductility

✅ Resists Earthquakes

✅ Resists Corrosion

✅ Best Bonding with Concrete

✅ Cost Effective & Long LastingTMT Saria is classified for its grade including Fe 500, Fe 550, and Fe 550D and is determined by code requirements and structural needs of safety and endurance in all infrastructures. When choosing TMT Saria it comes down to the trust & brand a manufacturer delivers to the construction industry, with certified product quality from reliable producers.

#TMTSaria#TMTBarsinUttarakhand#TMTSteelmanufacturersinIndia#TMTBarsmanufacturersinIndia#TMTSteelBarsinIndia#TopTMTSteelindustriesinIndia#BestTMTinIndia#QualityTMTinIndia#FireresistanceTMTinIndia#BISCertifiedTMTBarsSteel#TMTBars#CorrosionResistanceTMT#ReliableTMTInIndia#EarthquakeresistanceTMTinIndia

0 notes

Text

The Role of TMT Bars in Road and Highway Projects

In modern infrastructure development, TMT bars (Thermo-Mechanically Treated bars) play a critical role in ensuring strength, durability, and safety. Among the various components used in road and highway construction, TMT bars are often overlooked, but they form the backbone of bridges, culverts, underpasses, retaining walls, and supporting structures that connect our cities.

With the expansion of national highways, expressways, and smart road projects across India, choosing the right TMT bars is more important than ever. And when it comes to reliability and strength, opting for one of the top ten TMT bar brands ensures long-term performance and compliance with national standards.

Why TMT Bars Are Essential in Road and Highway Infrastructure

While asphalt, concrete, and aggregate form the visible layers of a road, it's the steel reinforcement inside that provides structural stability. TMT bars are used in:

Bridge piers and decks

Flyovers and underpasses

Culverts and drainage systems

Retaining and boundary walls

Toll plaza foundations

Crash barrier supports

Key Benefits of TMT Bars in Road Projects

1. High Tensile Strength

TMT bars are known for their excellent tensile-to-yield ratio, which is vital for large structures that bear dynamic loads such as traffic pressure and vibrations.

2. Ductility for Earthquake Zones

Roads and highways in seismic-prone regions require ductile reinforcement. TMT bars, especially Fe 500D or Fe 550D grades, provide flexibility without compromising strength, reducing the risk of sudden failure.

3. Corrosion Resistance

TMT bars are engineered to resist corrosion, making them suitable for coastal highways, flyovers in humid zones, and structures exposed to water and pollutants.

4. Thermal Resistance

During hot bitumen laying or fire accidents, TMT bars can withstand temperatures up to 600°C, offering safety to critical road infrastructure.

5. Longevity

TMT-reinforced road structures have a longer life cycle with reduced maintenance, especially in bridges and high-traffic flyovers.

Top Ten TMT Bar Brands Used in Infrastructure Projects

Choosing a trusted brand is key to ensuring compliance with BIS standards and project durability. Here are 10 of the top TMT bar brands in India, frequently used in road and highway construction:

TATA Tiscon – Known for high consistency and nationwide availability

JSW Neosteel – Popular in large-scale infrastructure and metro projects

SAIL TMT – Government-backed and trusted for public projects

Vizag Steel (RINL) – Excellent for high-stress structures

Jindal Panther – Preferred in premium residential and commercial structures

SRMB Steel – Used in several road and flyover projects in East India

Kamdhenu TMT – Wide distribution and strong corrosion resistance

Shyam Steel – BIS-certified, strong in Eastern and North-Eastern zones

Essar TMT – Known for ductility and consistent quality

Electrotherm TMT (Thermex) – Innovative steel for earthquake zones

These brands offer Fe 500, Fe 550, and even Fe 600 grades, which are ideal for demanding road and bridge projects.

Government Standards and Project Compliance

Public works departments (PWDs) and national agencies like NHAI (National Highways Authority of India) mandate the use of TMT bars that meet specific standards such as:

IS:1786 – The Indian Standard code for high-strength deformed steel bars

BIS Certification – Bureau of Indian Standards approval

Third-party quality tests – For infrastructure tenders and contracts

Using TMT bars from top brands ensures easier project approval, fewer delays, and longer-lasting road infrastructure.

Case Study: Expressway Development Using Premium TMT Bars

In projects like the Delhi-Mumbai Expressway, Eastern Peripheral Expressway, and Mumbai Trans Harbour Link, top-tier TMT bars were used to:

Build earthquake-resistant pillars

Ensure long-span bridges remain stable under constant vehicle load

Resist corrosion in humid and saline zones

Final Thoughts

TMT bars may not be visible once the construction is done, but their role in road and highway durability is irreplaceable. When working on infrastructure that’s built to last 50–100 years, using high-quality TMT bars is non-negotiable.

Choosing from the top ten TMT bar brands ensures:

Long-term safety

Structural integrity

Regulatory compliance

Peace of mind

Need Help Selecting the Right TMT Bar Brand?

Whether you're a contractor, architect, or government vendor, consult with a certified distributor to source premium TMT bars for road and highway projects that meet every safety and durability standard.

0 notes

Text

How Kapila Steel’s Dowel Bar Standards Align with Global Construction Codes

Dowel bars have left a vital detail in civil engineering, mainly for pavements and urban slabs. These unassuming metal rods silently deliver the responsibility of transferring hundreds between adjoining slabs, minimizing joint deflection and stopping cracking. Their performance plays an instantaneous role in determining the energy, durability, and lifespan of a concrete structure. As construction standards tighten globally, so does the scrutiny over bar dowel satisfactory and compliance. This is where the role of reliable TMT bar manufacturers, like Kapila Steel, becomes critically important.

The moment any infrastructure project begins to scale, consistency in material strength and code alignment becomes non-negotiable. Dowel bars aren't just metal pieces—they’re precision-engineered elements that must meet exact tolerances. The early-stage selection of bar dowel products can influence the long-term success of pavements, industrial floors, and airport runways. In this scenario, engineers seek not just suppliers, but dependable allies.

Raising the Bar in Dowel Precision

Kapila Steel manufactures dowel bars with consistent diameter, length, and finish, ensuring seamless load transfer and preventing pavement distress. These bars are fabricated with exacting standards that reflect internationally recognized norms. Whether it's ASTM A615/A615M or BS 4449, Kapila’s production process mirrors the rigorous checks and balances that top global construction codes demand.

A Focus on Metallurgical Integrity

Material science lies at the heart of performance. Kapila Steel’s dowel bars are manufactured using advanced metallurgical techniques that ensure high tensile strength and ductility. Through controlled heat treatment and chemical balancing, the bars can endure cyclic loading, impact pressure, and even harsh weathering without fatigue.

Such attributes are crucial when aligning with Eurocode 2 or Indian IRC specifications. These standards emphasize not only physical dimensions but also fatigue resistance, corrosion tolerance, and load-sharing effectiveness. Kapila’s production plant adheres to these principles without compromise.

TMT Bar Manufacturers Who Think Globally, Deliver Locally

While the spotlight is on dowel bars, it’s important to understand that TMT bar manufacturers who get the details right here tend to apply the same ethos across all products. This is evident in how Kapila Steel handles their entire TMT lineup—built for resilience, earthquake resistance, and superior bonding with concrete. The global codes they follow for dowel bar production echo across their TMT bar solutions, creating a consistent reliability engineers can count on.

When Standards Meet Supply Chain Reliability

It's one thing to manufacture dowel bars that meet global standards. It's another to deliver them reliably, on time, and at scale. Kapila Steel operates with supply chain agility, enabling project managers to meet their construction timelines without compromising on material compliance.

The availability of bar dowel products, backed by thorough documentation and certificates of compliance, brings peace of mind to stakeholders who cannot afford risks in large-scale construction projects. It’s this harmony between engineering discipline and logistic efficiency that gives Kapila its industry edge.

A Smarter Choice for Builders and Engineers

In the end, aligning with global construction codes isn’t about ticking boxes—it’s about instilling confidence. Whether it's highway expansion, industrial floors, or mass housing projects, the quality of dowel bars can define the success or failure of the structure over time.

Kapila Steel stands as a quiet partner in this journey—through dowel bars that meet international standards and through a commitment to precision that’s visible in every delivery.

Conclusion

Global construction codes exist to ensure durability, safety, and structural integrity. Kapila Steel’s dowel bars don’t just comply—they contribute. Through manufacturing excellence, rigorous quality checks, and a mindset aligned with international engineering demands, Kapila Steel offers much more than metal rods. It delivers the foundation for lasting trust and construction that endures.

#Dowel Bar Specs#Global Codes Fit#Kapila Steel Bars#Bar Strength Test#Concrete Dowels#Code-Ready Steel#Global Bar Norms#Bar Quality Check#Steel Bar Grade#Kapila Bar Tech#Dowel Fit Guide#Bar Code Match#ISO Steel Bars#Bar Design Code#Durable Dowels#Code Safe Bars#Global Build Fit#Bar Spec Sheet#Dowel Compliance#Steel Code Align

0 notes

Text

Associate / Vice President, Investment Banking (TMT Sector)

Job responsibilities:Execute a full spectrum of corporate finance assignments, with a particular focus on IPOs and related transactions, including Listing Rules and/or Takeovers Code related transactions, M&A and fund-raising exercises and other finance advisory transactions;Assist in potential deal pitching, including preparing pitch books, business proposals, market research and valuation…

0 notes

Text

The Rise of Eco-Friendly TMT Bars: A Sustainable Shift in Indian Construction

As India races towards urbanization, sustainable construction practices have become more than just a trend—they're a necessity. Among the various innovations steering this shift, Thermo Mechanical Treated Steel (TMT steel) bars have emerged as a cornerstone of modern construction. These bars not only provide superior strength and durability but are now being developed with a strong focus on environmental sustainability.

In regions like West Bengal, manufacturers such as Maan Shakti are pioneering this green revolution.

Understanding Thermo-Mechanical Treated Steel

What Are TMT Bars?

TMT bars, or Thermo Mechanical Treated Steel bars, undergo a rigorous manufacturing process that combines thermal and mechanical treatment. This process imparts a hard outer surface and a softer core, making them ideal for high-stress construction environments like bridges, high-rise buildings, and industrial structures.

Key Benefits

High Strength and Ductility: Ideal for earthquake-resistant construction.

Corrosion Resistance: Enhanced longevity in humid and coastal areas.

Weldability and Bendability: Reduces structural vulnerability.

The Environmental Impact of Traditional Construction Materials

Historically, construction has been one of the most resource-intensive sectors, contributing significantly to carbon emissions, deforestation, and land degradation. Traditional steel production is energy-heavy and often involves the release of large amounts of greenhouse gases. As India commits to its net-zero goals, the construction sector is under pressure to adopt eco-friendlier alternatives.

The Shift Toward Eco-Friendly TMT Bars

What Makes TMT Bars Eco-Friendly?

Today’s advanced Thermo Mechanical Treated Steel bars are manufactured using:

Energy-Efficient Processes: Reduced carbon footprints due to less energy consumption.

Recyclable Materials: Most TMT bars are fully recyclable, lowering the demand for virgin raw materials.

Low Emissions Technology: Use of cleaner fuels and emission control systems.

Government Push and Green Building Initiatives

With government initiatives like the Energy Conservation Building Code (ECBC) and incentives for green-certified buildings, there's a growing demand for sustainable materials, including eco-friendly TMT bars.

Maan Shakti: Leading the Green Revolution in Steel Manufacturing

A Brand Committed to Sustainability

When discussing Best TMT Steel Manufacturers in West Bengal, Maan Shakti consistently ranks among the top. With a reputation built on quality and responsibility, Maan Shakti has taken bold steps to align its production with sustainable practices.

Eco-Conscious Manufacturing Techniques

Maan Shakti utilizes:

Waste Heat Recovery Systems

Energy-Efficient Rolling Mills

Rainwater Harvesting & Water Recycling

Zero Effluent Discharge Systems

These innovations not only conserve resources but also significantly reduce the environmental impact of steel production.

Why Eco-Friendly TMT Bars Are the Future of Indian Construction

Rising Awareness Among Builders and Consumers

Builders are now more conscious about the environmental impact of their materials. Consumers, too, are demanding sustainable solutions, especially in residential and commercial developments.

Cost Efficiency in the Long Run

While eco-friendly TMT bars may have a slightly higher upfront cost, their durability and low maintenance requirements make them more economical over a structure's lifecycle.

Compliance and Certification

Using sustainable materials helps builders easily meet green building certifications like IGBC (Indian Green Building Council) and LEED (Leadership in Energy and Environmental Design), which can add value and credibility to their projects.

Conclusion

The construction landscape in India is undergoing a transformative shift, driven by sustainability and innovation. Thermomechanically treated Steel bars have emerged not just as structural necessities but as environmentally responsible choices. As one of the Best TMT Steel Manufacturers in West Bengal, Maan Shakti is setting a strong example in eco-friendly steel production, proving that strength and sustainability can go hand in hand.

By choosing manufacturers who prioritize green practices, the industry can build a stronger, more sustainable India, one TMT bar at a time.

0 notes

Text

Rathi Steel and Power Secures BIS Certification for Fe 500 Reinforcement Bars, Marking a New Chapter in Product Excellence

In a significant milestone that underscores its commitment to quality and national standards, Rathi Steel and Power Limited has announced the successful grant of a Bureau of Indian Standards (BIS) license to use the standard mark on its Fe 500 Reinforcement Bars. This move reaffirms the company’s ongoing efforts to strengthen its market presence and expand its product portfolio while adhering to the highest levels of compliance and technical standards.

The license, bearing number CM/L – 8700195219, was officially granted on May 9, 2025, by the Bureau of Indian Standards, the National Standards Body of India. It authorizes Rathi Steel and Power to use the BIS hallmark on a specified range of TMT bars categorized under the title “High Strength Deformed Steel Bars and Wires for Concrete Reinforcement.” These include nominal diameters of 8 mm, 10 mm, 12 mm, 16 mm, 20 mm, and 25 mm—standard sizes widely used across infrastructure and construction projects throughout India.

This development is not merely regulatory compliance; it is a strategic enabler for the company’s broader vision. The BIS certification allows Rathi Steel and Power to fully leverage its manufacturing facilities for both the production and rigorous testing of its Fe 500 Reinforcement Bars. The company now stands equipped to meet the growing demand in the construction sector, which increasingly prioritizes structural integrity, durability, and compliance with Indian and global standards. The grant of this license also enhances operational efficiency, enabling optimal utilization of the company’s existing capacity while expanding its addressable market with a certified and trusted product line.

Shobhita Singh, Company Secretary and Compliance Officer of Rathi Steel and Power, shared the news in an official communication to the BSE Limited (Scrip Code: 504903), highlighting the relevance and impact of this achievement. She confirmed that the license will remain valid until May 8, 2026, and clarified that there has been no instance of suspension, withdrawal, or cancellation—emphasizing the company’s clean and proactive regulatory standing.

This certification also aligns with the broader strategic goals of the company, which has consistently worked to elevate its product standards, manufacturing capabilities, and stakeholder trust. By acquiring BIS certification, Rathi Steel and Power Limited not only meets a key regulatory benchmark but also positions itself more strongly within a competitive and rapidly expanding market. This approval will further empower the company to cater to developers, infrastructure firms, and contractors seeking reliable, high-strength reinforcement solutions.

Rathi Steel and Power has long maintained a reputation for integrity, innovation, and industrial resilience. With this license now in hand, the company is poised to scale new heights in operational performance and market responsiveness. As India continues to modernize its infrastructure and urban landscape, certified, high-quality materials such as those produced by Rathi will play a critical role in shaping the future.

This latest development represents another step forward in the company’s journey—one rooted in quality assurance, engineering excellence, and national growth. The company has reiterated its dedication to creating lasting value for its stakeholders while supporting India’s broader infrastructure mission with materials that are safe, reliable, and certified by the country's highest standardization authority.

0 notes

Text

Why Bar Dowels Are Becoming the Standard for Smart Construction

Bar dowel technology has silently revolutionized creation practices throughout the globe, reworking how structural engineers approach concrete connections. This apparently easy innovation grants profound upgrades in structural integrity, construction performance, and long-term performance—factors that have positioned these specialized structures as the favored preference for forward-questioning developers and developers.

The construction industry's evolution closer to smarter, extra-efficient strategies has extended adoption of these specialized connectors. Progressive developers recognize that while traditional approaches served adequately in the past, modern building demands require sophisticated solutions that Bar Dowel systems uniquely provide.

How These Connectors Transform Structural Performance

Structural engineers increasingly specify these connections because they allow controlled movement between concrete elements while maintaining load transfer capabilities. This dual functionality prevents common structural issues like cracking and spalling that plague conventional rigid connections. For manufacturers of TMT Steel, this trend represents both a challenge and an opportunity—requiring adaptation to new installation methods while opening markets for specialty products.

When concrete elements expand, contract, or settle differently, rigid connections create stress concentration points that eventually fail. Bar Dowel systems, by contrast, accommodate this movement while maintaining structural continuity. This performance advantage explains why leading TMT Bars producers have developed specialized variants specifically designed for dowel applications.

Efficiency Gains in Modern Construction

Construction timelines benefit tremendously from this approach. Traditional connection methods often involve:

Complex formwork

Extensive rebar tying

Careful staging that slows progress

Bar Dowel systems simplify these processes dramatically, allowing for faster concrete placement and reducing labor requirements. The resulting efficiency gains have prompted many a Steel Pipe Company to develop complementary products designed to work seamlessly with these connections.

Superior Durability and Longevity Benefits

Concrete structures utilizing properly designed systems demonstrate superior durability in challenging environments, including:

Seismic zones

Areas with extreme temperature variations

Locations with significant settlement concerns

This performance advantage translates directly to reduced maintenance costs and extended service life—factors increasingly important to project owners concerned with lifetime value rather than just initial construction costs.

Material Supply Chain Evolution

Material suppliers—particularly TMT Bars manufacturers—have recognized this shift and responded with specialized product lines. These purpose-designed bars feature precise dimensional tolerances and specialized coatings that enhance performance in dowel applications.

The distribution network has likewise adapted to this market evolution. The typical Steel Pipe Company now stocks specialized sleeve components that complement Bar Dowel installations, creating valuable cross-selling opportunities. This system approach to construction materials distribution has strengthened relationships between suppliers and contractors.

Regulatory Support and Market Projections

Building codes increasingly recognize these systems as preferred solutions for specific structural applications, particularly in infrastructure projects where long-term performance is paramount. This regulatory endorsement provides additional confidence for specifiers considering these systems.

Market projections suggest double-digit growth for specialized TMT Bars designed for dowel applications over the next five years. This growth opportunity has prompted forward-thinking producers to invest in manufacturing capabilities specifically tailored to these products.

Strategic Positioning for Material Suppliers

The competitive landscape for construction materials suppliers continues shifting in response to these trends. Progressive Steel Pipe Company leaders have expanded product portfolios to include complementary components that enhance Bar Dowel performance, creating valuable system solutions rather than merely supplying commodity products.

As creation practices preserve evolving in the direction of smarter, more efficient strategies, Bar Dowel generation stands as a prime instance of how seemingly incremental improvements can power extensive enhancements in building performance, performance, and sturdiness. For cloth providers all through the construction surroundings, this evolution represents a substantial possibility to broaden specialized merchandise that supplies premium fees while addressing proper marketplace wishes.

#Bar Dowels Use#Dowels in RCC#Smart Construction#Joint Stability#Dowel Bar Role#Load Transfer Tech#Concrete Dowels#RCC Bar Trends#Steel Dowels Use#Bar Joint System#Dowels in Roads#RCC Joint Tech#Bar Dowel Benefits#Smart RCC Bars#Rebar Dowel Tips#Dowel in Pavement#Dowel Rods Use#Modern RCC Build#RCC Steel Joints#Dowel Steel Bars

0 notes