#Industrial Automation Control

Explore tagged Tumblr posts

Text

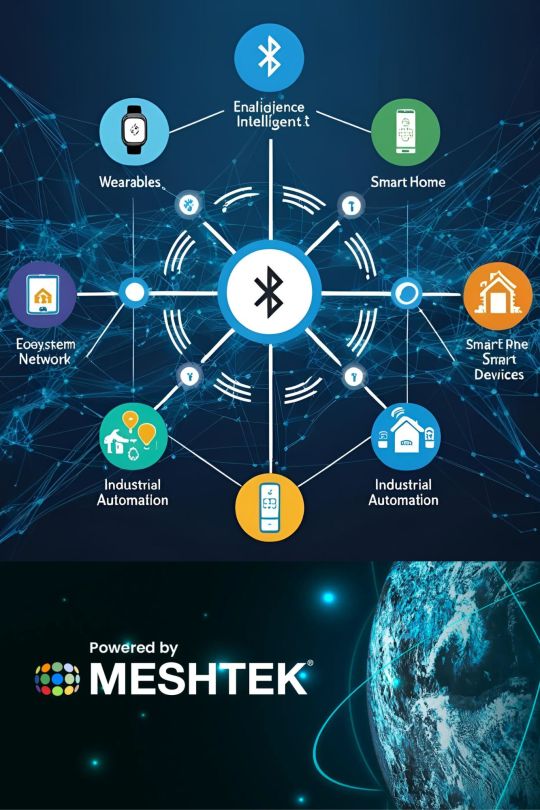

MeshTek’s Vision: Empowering IoT with Bluetooth Mesh Networking

MeshTek’s robust Bluetooth Mesh Networking ecosystem—seamlessly linking smart homes, wearables, industrial automation, and connected devices into one intelligent grid. It illustrates how MeshTek empowers secure, low-energy, and scalable communication across complex environments, enabling real-time control, optimized performance, and unmatched flexibility. Built to support everything from smart devices to enterprise-level automation, MeshTek’s platform is at the heart of next-gen IoT transformation.

#Bluetooth Mesh Networking#MeshTek#smart automation#connected devices#industrial IoT#IoT ecosystem#smart home network#IoT infrastructure#wearable integration#scalable IoT platform#low-energy communication#real-time control#IoT app development#MeshTek technology#intelligent automation

1 note

·

View note

Text

Understanding the meaning, applications, and advantages of control valves.

Control valves are devices that play an essential role in controlling and regulating the flow, pressure, and temperature in industrial processes and control systems. It is installed in the field-level area of the automation pyramid and connected to the control system and PLC through the PLC’s hardware. The global control valve consists of the body, actuator, Positioner, Valve trim, stem, and bonnet to prevent leakage. There are also the Gaskets and seals that are used when connecting the valve with other mechanical parts.

Control valves have many advantages such as Accurate Control of Process Parameters, Easy Automation Compatibility by integrating these items with the main Control systems (DCS and PLC), Energy saving and energy efficiency by optimizing the process condition and minimizing waste, maintaining safe operating conditions and increase process safety factors, Improve Process Efficiency and Increase Product Quality.

Control valves are used in many applications such as the Automotive Industry, Cement and steel, and Oil and Gas Industry, especially in gas valve trains, Renewable Energy, and HVAC Systems.

For full article check the following link:

For more articles about Renewable, Automation and Instrumentation, check the following link:

www.ecaico.com

#automation#instrumentation#renewable#control system#plc#sensors#pressure#gas valve#industrial valves

2 notes

·

View notes

Text

Unveiling the Power of Position Velocity Feedback Transmitter Systems in Modern Industries

Introduction: The Importance of Position and Velocity Feedback Systems in Precision Control

Position and velocity feedback transmitter systems are integral to industries that demand high-precision control and motion tracking. These systems are employed to monitor the position and velocity of moving objects in real-time, providing critical data for automated operations. The evolution of these systems has been significant, with advancements in technology enabling more compact, accurate, and reliable feedback mechanisms that drive automation, robotics, aerospace, automotive, and healthcare applications.

With the global shift towards increased automation, the demand for such systems is on the rise. Industries across the board require precise control of machinery, vehicles, and robots to enhance performance, improve safety, and optimize productivity. The growing need for smart manufacturing, autonomous vehicles, and medical robotics underscores the vital role these systems play in modern industries. Despite some challenges, such as high upfront costs and integration complexities, the long-term benefits of precision, efficiency, and reliability outweigh these hurdles.

Request Sample Report PDF (including TOC, Graphs & Tables): https://www.statsandresearch.com/request-sample/40604-global-position-velocity-feedback-transmitter-systems-market

Position Velocity Feedback Transmitter Systems Market Dynamics: Drivers, Challenges, and Opportunities

Drivers of Growth

The Position Velocity Feedback Transmitter Systems market is experiencing robust growth driven by several key factors:

Advancements in Automation and Robotics: Industries across manufacturing, automotive, and aerospace are increasingly adopting automation technologies. These systems allow for faster, more accurate control, driving the need for precise position and velocity feedback.

Technological Advancements in Sensors: Innovations in sensor technology, particularly in digital systems, are facilitating the development of more accurate and miniaturized position velocity feedback systems. The integration of Internet of Things (IoT) technologies is making these systems smarter and more adaptable, driving their adoption in industries such as healthcare, smart manufacturing, and autonomous vehicles.

The Rise of Industry 4.0: Industry 4.0 technologies are revolutionizing production lines, with automation and data-driven decisions at their core. Position velocity feedback systems play a critical role in enabling smarter, more efficient manufacturing processes.

Emerging Applications in Healthcare and Autonomous Vehicles: In healthcare, robotic surgeries and diagnostics systems demand highly accurate motion control, while autonomous vehicles require precise feedback systems for safe operation. Both sectors are driving significant demand for position and velocity feedback systems.

Get up to 30% Discount: https://www.statsandresearch.com/check-discount/40604-global-position-velocity-feedback-transmitter-systems-market

Challenges to Position Velocity Feedback Transmitter Systems Market Adoption

Despite the promising growth, several barriers could slow the widespread adoption of position velocity feedback transmitter systems:

High Initial Investment Costs: The cost of acquiring and integrating high-precision position velocity feedback systems can be prohibitive, especially for small and medium-sized enterprises (SMEs). High upfront costs can deter organizations from upgrading or adopting these systems, limiting market expansion.

Complexity of System Integration: Integrating new feedback systems with existing infrastructure and machinery can be complex and time-consuming, especially in industries that have legacy systems. This complexity increases the time to market and may discourage immediate adoption.

Specialized Training Requirements: The operation, calibration, and maintenance of advanced position velocity feedback systems require highly specialized knowledge and skills. The shortage of skilled labor in these fields may hinder growth, particularly in developing regions.

Key Opportunities

Several emerging trends present substantial opportunities for the growth of the position velocity feedback transmitter systems market:

Smart Manufacturing: As manufacturing processes become increasingly automated, there is a growing demand for position velocity feedback systems to enhance productivity and reduce human error. These systems are integral to improving the efficiency of production lines and ensuring consistent product quality.

Healthcare Robotics: Surgical robots, diagnostic devices, and rehabilitation technologies require real-time motion control. The healthcare sector’s increasing reliance on these technologies provides a substantial opportunity for the growth of high-precision position feedback systems.

Autonomous Vehicles: The rapid development of autonomous vehicles (AVs) hinges on accurate motion tracking and feedback systems for safe navigation. As the demand for AVs increases, so too will the demand for position and velocity feedback transmitters that ensure precise vehicle control.

Position Velocity Feedback Transmitter Systems Market Segmentation and Analysis

By Type

The position velocity feedback transmitter systems market can be divided into two key types:

Position Feedback Transmitter: This sub-segment is expected to dominate the market, driven by the increasing demand for precision in industrial automation applications. Position feedback transmitters provide accurate location tracking, ensuring the correct placement of components in automated systems.

Velocity Feedback Transmitter: While this segment is smaller, it is growing rapidly due to the need for precise speed control in applications such as robotics, aerospace, and automotive industries.

By Technology

Analog Systems: While still in use, analog systems are being increasingly replaced by more sophisticated digital feedback systems that offer greater accuracy and scalability.

Digital Systems: Dominating the market, digital systems provide real-time, highly accurate feedback for a range of applications, particularly in industries like automotive, aerospace, and healthcare. The continued innovation in sensor technology and integration with IoT is expected to fuel further growth in this segment.

By Application

The demand for position and velocity feedback systems spans a variety of industries:

Industrial Automation: Expected to maintain the largest market share, industrial automation continues to be the leading driver of demand for precise motion control systems. These systems are integral to ensuring the accuracy and speed of machinery in sectors such as manufacturing and material handling.

Aerospace and Defense: Aerospace applications require high-precision feedback systems for tasks such as flight control, navigation, and satellite positioning.

Automotive: As automotive systems become more automated, the demand for position and velocity feedback systems grows. These systems ensure precise vehicle control in autonomous and semi-autonomous driving technologies.

Energy: The energy sector, particularly in renewable energy systems, requires high-performance motion control to optimize energy production and distribution.

By Region

The market is geographically diverse, with distinct growth patterns across various regions:

North America: Dominating the market, North America is poised to continue leading the position velocity feedback transmitter systems market due to its advanced industrial sectors, including aerospace and automotive.

Asia-Pacific: The Asia-Pacific region is expected to witness the highest growth rate, driven by rapid industrialization and the increasing adoption of automation technologies in countries like China and India.

Europe: Europe’s strong automotive and industrial automation sectors will continue to contribute to the growth of this market.

Latin America and Middle East & Africa: While smaller markets, the demand for these systems is expected to rise as industries in these regions embrace automation and robotics.

Position Velocity Feedback Transmitter Systems Market Competitive Landscape

Key Players

The market for position velocity feedback transmitters is highly competitive, with several industry leaders at the forefront:

Pepperl+Fuchs: Known for its next-generation sensors, Pepperl+Fuchs continues to innovate with solutions tailored to the needs of the automotive and industrial automation sectors. The company launched new high-performance sensors aimed at enhancing precision in harsh industrial environments in 2024.

Temposonics: Specializing in digital feedback systems, Temposonics has made significant strides in the robotics and aerospace sectors. Their advanced systems offer real-time position and velocity tracking, catering to industries that demand high-speed and high-accuracy solutions.

Other Key Players: Other companies in this market include Balluff, Siemens, and Honeywell, each offering various solutions across different applications, from industrial automation to healthcare.

Emerging Trends in Competition

Integration of IoT: Manufacturers are increasingly integrating IoT technologies into their position velocity feedback systems to enhance data collection, improve connectivity, and enable predictive maintenance.

Customization and Tailored Solutions: Companies are focusing on providing customized solutions for specific industries to cater to the unique needs of sectors such as automotive, aerospace, and healthcare.

Sustainability Initiatives: With growing environmental concerns, companies are developing energy-efficient systems that not only meet performance requirements but also adhere to sustainable production practices.

Purchase Exclusive Report: https://www.statsandresearch.com/enquire-before/40604-global-position-velocity-feedback-transmitter-systems-market

Conclusion:

The Position Velocity Feedback Transmitter Systems Market is on a rapid growth trajectory, driven by advancements in automation, robotics, and sensor technologies. The demand for high-precision motion control systems is intensifying as industries seek to improve efficiency, safety, and productivity. Despite challenges such as high initial costs and integration complexities, the opportunities presented by emerging applications in healthcare, autonomous vehicles, and smart manufacturing are substantial.

With continued innovation and a focus on integration with IoT and digital technologies, the market is well-positioned for long-term expansion. As the industrial landscape continues to evolve, the role of position and velocity feedback systems will be pivotal in shaping the future of automation and precision control across various sectors.

Our Services:

On-Demand Reports: https://www.statsandresearch.com/on-demand-reports

Subscription Plans: https://www.statsandresearch.com/subscription-plans

Consulting Services: https://www.statsandresearch.com/consulting-services

ESG Solutions: https://www.statsandresearch.com/esg-solutions

Contact Us:

Stats and Research

Email: [email protected]

Phone: +91 8530698844

Website: https://www.statsandresearch.com

#Position Velocity Feedback Transmitter Systems Market#Position Feedback Systems#Velocity Feedback Transmitters#Automation#Industrial Automation#Motion Control Systems#Precision Motion Tracking#Position and Velocity Sensors#Digital Feedback Systems#Robotics#Aerospace Industry#Autonomous Vehicles#Healthcare Robotics#Smart Manufacturing#Industrial Robotics#Sensor Technology#Motion Control#Market Growth#Industry 4.0#Digital Position Sensors#Automotive Automation#IoT-enabled Feedback Systems#High-Precision Transmitters#Real-time Position Feedback#Aerospace Sensors#Automation Trends#Smart Manufacturing Systems#Position Velocity Sensors#Market Analysis#Precision Control Systems

1 note

·

View note

Video

youtube

Controlling Plastic Injection Machine Nozzle Movement with a Digital Las...

#youtube#Plastic Injection Machine#Nozzle Movement#Digital Laser Ruler#Arduino Project#Wemos D1 Mini#Stepper Motor#3D Printing#Industrial Automation#DIY Electronics#Tutorial#Arduino#Digital Control#Laser Ruler#DIY#VL53L0X#ULN2003#Maker Community

6 notes

·

View notes

Text

pvc electric red and blue wire #smartratework#tumblr

#flowers#aesthetic#alternative#grunge#1950s#cute#japan#60s#70s#80s#|| Smart Rate Work#Manufacturing encompasses a diverse array of processes and technologies aimed at producing a wide range of products#from everyday essentials to specialized components. Take wires#for instance: these are typically manufactured through drawing processes#where metal rods or strips are pulled through dies to reduce their diameter and achieve the desired thickness. This method ensures uniformi#crucial for applications in electronics#construction#and industrial settings.#On the other hand#the production of bottles involves molding techniques such as blow molding or injection molding. Blow molding heats plastic resin into a mo#used extensively for beverage containers and packaging. Injection molding#meanwhile#injects molten plastic into a mold under high pressure#ideal for producing intricate shapes with precision#like medical vials or automotive parts.#Both wire and bottle manufacturing rely heavily on materials science#engineering precision#and quality control measures to meet stringent specifications. Advances in automation#robotics#and sustainability practices are transforming these industries

2 notes

·

View notes

Text

Streamlining Innovation: Unveiling the Engineering Process with our ERP Module

Call us for free Demo : +91-9825056355 www.sterpsoftware.com

#sterp#sterperp#Sterpsoftware#Erpsoftwaresolutions#Marketing#Erpsoftware#Technology#Erpsystem#Clouderp#Erpsolutions#Erpsoftwareforengineering#Softwaredevelopment#Industry#Communication#Control#Productive#Manufacturers#Automation#Solutions#Experience#Accounting#Engineeringerp#Businessprocess#Managementsoftware#Businessandmanagement#Businessanalytics#Businessanalyst#Business#Engineering#Engineeringservices

4 notes

·

View notes

Text

For those seeking a reputable industrial automation parts supplier that can save customers time and money while presenting optimal fulfillment solutions, look no further than Buy Automation Spare Parts. Owned and operated by ASAP Semiconductor, customers perusing Buy Automation Spare Parts’ website will be treated to a selection of over 2 billion items that range from factory-new condition to obsolete status.

2 notes

·

View notes

Text

Discover reliable performance with the ABB 3BHT310086 R60, 3BHT310510 R40, 3BHT310515 R40, and 3BHB000295R20 PLC Controllers, available at Auto2mation. These ABB PLC units are designed to deliver high-speed processing, precise control, and seamless integration for industrial automation systems. Ideal for various applications, they ensure dependable operation and improved system efficiency. Built with advanced technology and robust components, ABB PLC Controllers help streamline processes and reduce downtime. Whether upgrading or building a new system, these controllers offer the reliability and scalability you need. Choose Auto2mation for authentic ABB automation products that power performance and productivity in every industrial environment.

#industrial automation#industrial equipment#industrial spare parts#industrial#automation#industrial and marine automation#industrial parts supplier#industrial innovation#automation solutions#Marine Automation#marine equipment#marine spare parts#auto2mation#Abb#Plc#Controller

0 notes

Text

AHU PLC BASED CONTROL SYSTEM I AHU controllers i NX-ERA JET PLC

#AHU CONTROLLER#AHU PLC CONTROLLER SYSTEM#NX-ERA JET PLC#COMPACT PLC#MICRO PLC#IEC 61131-3 standards PLC#MODULAR PLC#PLC control systems#programmable logic controller#Messung’s PLC-based AHU systems#NX-ERA JET#PLC#industrial automation#plc controller#plc automation#industry 4.0#messung plc

0 notes

Text

How Does a Mitsubishi Servo Drive Supplier Empower Precision?

A Mitsubishi Servo Drive Supplier in kuwait delivers high-performance motion control solutions for industries that demand accuracy and reliability. With advanced servo drives, you can achieve precise speed, torque, and positioning in your automation systems. Upgrade your machinery and experience seamless operations with our expert support. Explore our range and contact us today for tailored servo drive solutions!

0 notes

Text

Liebherr PCB Card 925086914 0002555 0601004 | High-Quality Control PCB Board | Ram Automations

Enhance your machinery’s performance with the Liebherr PCB Card 925086914 0002555 0601004, available now at Ram Automations. This high-quality Printed Circuit Board (PCB) offers exceptional reliability, precision engineering, and durability for a wide range of industrial and marine applications.

Designed for maximum performance and efficiency, this Liebherr PCB Card ensures seamless integration with complex control systems, making it ideal for critical automation environments and high-demand applications.

🛒 Buy Now from Ram Automations 👉 https://ramautomations.com/products/pcb-card-925086914-0002555-0601004-liebherr-new

🌐 Explore 1000+ Genuine Automation Components 👉 https://ramautomations.com

🧩 Product Specifications

• 🔹 Brand: Liebherr • 🔹 Model: 925086914 / 0002555 / 0601004 • 🔹 Type: PCB Card • 🔹 Category: PCB Card / Industrial Electronics / Automation PCB • 🔹 Application: Industrial Automation, Marine Systems, Control Panels, Process Systems

✅ Key Features

✔️ Precision-engineered PCB for reliable performance ✔️ Seamless integration with industrial systems ✔️ High-quality materials and craftsmanship ✔️ Essential for complex machinery and automation units ✔️ Ideal for industrial, marine, and manufacturing environments

💡 Typical Applications

• Marine Electronic Control Systems • Industrial Automation Panels • SCADA and HMI System Boards • Heavy Equipment Automation • Process Automation Systems • Robotics Control Panels • Industrial Machinery Systems

🌟 Why Choose Ram Automations?

✅ 100% Genuine Products Only ✅ Best Prices with Worldwide Delivery ✅ Trusted Industrial Automation Supplier ✅ Large Inventory of Hard-to-Find Components

🛍️ Visit Us: https://ramautomations.com

In This Video You Will Discover:

🔎 Close-up View of Liebherr PCB Card 🔧 How It Integrates with Complex Systems 💡 Importance of High-Quality PCBs in Industrial Automation 🌐 Why Ram Automations is the Go-To Source for Industrial Parts

📣 Get Involved!

🔔 Subscribe for Automation & Electronics Updates 👍 Like to Show Support for Quality Electronics 💬 Comment Your Queries — We’re Happy to Help! 🛒 Visit our Online Store: https://ramautomations.com

#Liebherr PCB Card#PCB Card for Automation#Industrial PCB Card#Automation PCB Card#Marine Control PCB#Automation System Board#Ram Automations#Control Panel PCB Card#Process Control PCB#Marine Automation Electronics#Industrial Electronic PCB#Automation Equipment PCB Card#Marine Systems PCB Card#Factory Automation Parts#Robotics Control Panel Card#Data Transmission PCB Card#PLC Control PCB Card#High Quality PCB Card#SCADA System PCB Card#Electronic Connectivity PCB Board

1 note

·

View note

Text

Connected Intelligence: Powering Tomorrow with Bluetooth Mesh

MeshTek’s advanced Bluetooth Mesh Networking seamlessly integrates across diverse sectors — from industrial automation and AI-driven operations to smart agriculture and urban lighting. Real-time data flow, secure communication, and synchronized control across a decentralized, energy-efficient IoT network. Designed for scalability and precision, MeshTek’s platform enables smarter environments through robust, low-latency connectivity.

#Bluetooth Mesh Networking#Smart Lighting#Industrial Automation#AI Connectivity#Smart Agriculture#MeshTek IoT#Edge Devices#Real-Time IoT Control#Scalable Mesh Network#IoT Infrastructure

1 note

·

View note

Text

0 notes

Text

Technological Advancements in Welding Technology & Training | PTTI Insights

Discover the latest technological advancements transforming welding—from automated welding systems and robotics to virtual training, augmented reality, and AI-powered quality control. Learn how PTTI integrates these cutting-edge tools into its welding curriculum to equip students with modern skills demanded by industry. Stay ahead with hands-on experience in the most advanced welding techniques and technologies shaping the future of manufacturing and construction.

Related Tags : welding technology advancements, welding training technology, automated welding systems, welding robotics, AR welding training, virtual welding simulator, AI quality control welding, PTTI welding tech, advanced welding techniques, industry 4.0 welding

#welding technology advancements#welding training technology#automated welding systems#welding robotics#AR welding training#virtual welding simulator#AI quality control welding#PTTI welding tech#advanced welding techniques#industry 4.0 welding

0 notes

Text

🚨 Why 4–20 mA? What makes it the gold standard in industrial automation?

📄 [PDF link Attached]

#automation#trending#tumblr trends#viral#bestdeals#viralpost#trendingnow#Solution#linkdin#linkdinpost#industrial applications#industrial automation#industrial equipment#industrial control

1 note

·

View note

Text

0 notes