#Real-Time IoT Control

Explore tagged Tumblr posts

Text

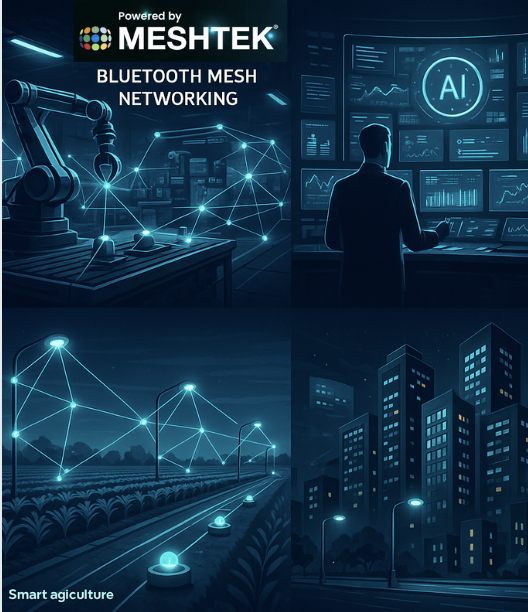

Connected Intelligence: Powering Tomorrow with Bluetooth Mesh

MeshTek’s advanced Bluetooth Mesh Networking seamlessly integrates across diverse sectors — from industrial automation and AI-driven operations to smart agriculture and urban lighting. Real-time data flow, secure communication, and synchronized control across a decentralized, energy-efficient IoT network. Designed for scalability and precision, MeshTek’s platform enables smarter environments through robust, low-latency connectivity.

#Bluetooth Mesh Networking#Smart Lighting#Industrial Automation#AI Connectivity#Smart Agriculture#MeshTek IoT#Edge Devices#Real-Time IoT Control#Scalable Mesh Network#IoT Infrastructure

1 note

·

View note

Text

Unveiling the Power of Position Velocity Feedback Transmitter Systems in Modern Industries

Introduction: The Importance of Position and Velocity Feedback Systems in Precision Control

Position and velocity feedback transmitter systems are integral to industries that demand high-precision control and motion tracking. These systems are employed to monitor the position and velocity of moving objects in real-time, providing critical data for automated operations. The evolution of these systems has been significant, with advancements in technology enabling more compact, accurate, and reliable feedback mechanisms that drive automation, robotics, aerospace, automotive, and healthcare applications.

With the global shift towards increased automation, the demand for such systems is on the rise. Industries across the board require precise control of machinery, vehicles, and robots to enhance performance, improve safety, and optimize productivity. The growing need for smart manufacturing, autonomous vehicles, and medical robotics underscores the vital role these systems play in modern industries. Despite some challenges, such as high upfront costs and integration complexities, the long-term benefits of precision, efficiency, and reliability outweigh these hurdles.

Request Sample Report PDF (including TOC, Graphs & Tables): https://www.statsandresearch.com/request-sample/40604-global-position-velocity-feedback-transmitter-systems-market

Position Velocity Feedback Transmitter Systems Market Dynamics: Drivers, Challenges, and Opportunities

Drivers of Growth

The Position Velocity Feedback Transmitter Systems market is experiencing robust growth driven by several key factors:

Advancements in Automation and Robotics: Industries across manufacturing, automotive, and aerospace are increasingly adopting automation technologies. These systems allow for faster, more accurate control, driving the need for precise position and velocity feedback.

Technological Advancements in Sensors: Innovations in sensor technology, particularly in digital systems, are facilitating the development of more accurate and miniaturized position velocity feedback systems. The integration of Internet of Things (IoT) technologies is making these systems smarter and more adaptable, driving their adoption in industries such as healthcare, smart manufacturing, and autonomous vehicles.

The Rise of Industry 4.0: Industry 4.0 technologies are revolutionizing production lines, with automation and data-driven decisions at their core. Position velocity feedback systems play a critical role in enabling smarter, more efficient manufacturing processes.

Emerging Applications in Healthcare and Autonomous Vehicles: In healthcare, robotic surgeries and diagnostics systems demand highly accurate motion control, while autonomous vehicles require precise feedback systems for safe operation. Both sectors are driving significant demand for position and velocity feedback systems.

Get up to 30% Discount: https://www.statsandresearch.com/check-discount/40604-global-position-velocity-feedback-transmitter-systems-market

Challenges to Position Velocity Feedback Transmitter Systems Market Adoption

Despite the promising growth, several barriers could slow the widespread adoption of position velocity feedback transmitter systems:

High Initial Investment Costs: The cost of acquiring and integrating high-precision position velocity feedback systems can be prohibitive, especially for small and medium-sized enterprises (SMEs). High upfront costs can deter organizations from upgrading or adopting these systems, limiting market expansion.

Complexity of System Integration: Integrating new feedback systems with existing infrastructure and machinery can be complex and time-consuming, especially in industries that have legacy systems. This complexity increases the time to market and may discourage immediate adoption.

Specialized Training Requirements: The operation, calibration, and maintenance of advanced position velocity feedback systems require highly specialized knowledge and skills. The shortage of skilled labor in these fields may hinder growth, particularly in developing regions.

Key Opportunities

Several emerging trends present substantial opportunities for the growth of the position velocity feedback transmitter systems market:

Smart Manufacturing: As manufacturing processes become increasingly automated, there is a growing demand for position velocity feedback systems to enhance productivity and reduce human error. These systems are integral to improving the efficiency of production lines and ensuring consistent product quality.

Healthcare Robotics: Surgical robots, diagnostic devices, and rehabilitation technologies require real-time motion control. The healthcare sector’s increasing reliance on these technologies provides a substantial opportunity for the growth of high-precision position feedback systems.

Autonomous Vehicles: The rapid development of autonomous vehicles (AVs) hinges on accurate motion tracking and feedback systems for safe navigation. As the demand for AVs increases, so too will the demand for position and velocity feedback transmitters that ensure precise vehicle control.

Position Velocity Feedback Transmitter Systems Market Segmentation and Analysis

By Type

The position velocity feedback transmitter systems market can be divided into two key types:

Position Feedback Transmitter: This sub-segment is expected to dominate the market, driven by the increasing demand for precision in industrial automation applications. Position feedback transmitters provide accurate location tracking, ensuring the correct placement of components in automated systems.

Velocity Feedback Transmitter: While this segment is smaller, it is growing rapidly due to the need for precise speed control in applications such as robotics, aerospace, and automotive industries.

By Technology

Analog Systems: While still in use, analog systems are being increasingly replaced by more sophisticated digital feedback systems that offer greater accuracy and scalability.

Digital Systems: Dominating the market, digital systems provide real-time, highly accurate feedback for a range of applications, particularly in industries like automotive, aerospace, and healthcare. The continued innovation in sensor technology and integration with IoT is expected to fuel further growth in this segment.

By Application

The demand for position and velocity feedback systems spans a variety of industries:

Industrial Automation: Expected to maintain the largest market share, industrial automation continues to be the leading driver of demand for precise motion control systems. These systems are integral to ensuring the accuracy and speed of machinery in sectors such as manufacturing and material handling.

Aerospace and Defense: Aerospace applications require high-precision feedback systems for tasks such as flight control, navigation, and satellite positioning.

Automotive: As automotive systems become more automated, the demand for position and velocity feedback systems grows. These systems ensure precise vehicle control in autonomous and semi-autonomous driving technologies.

Energy: The energy sector, particularly in renewable energy systems, requires high-performance motion control to optimize energy production and distribution.

By Region

The market is geographically diverse, with distinct growth patterns across various regions:

North America: Dominating the market, North America is poised to continue leading the position velocity feedback transmitter systems market due to its advanced industrial sectors, including aerospace and automotive.

Asia-Pacific: The Asia-Pacific region is expected to witness the highest growth rate, driven by rapid industrialization and the increasing adoption of automation technologies in countries like China and India.

Europe: Europe’s strong automotive and industrial automation sectors will continue to contribute to the growth of this market.

Latin America and Middle East & Africa: While smaller markets, the demand for these systems is expected to rise as industries in these regions embrace automation and robotics.

Position Velocity Feedback Transmitter Systems Market Competitive Landscape

Key Players

The market for position velocity feedback transmitters is highly competitive, with several industry leaders at the forefront:

Pepperl+Fuchs: Known for its next-generation sensors, Pepperl+Fuchs continues to innovate with solutions tailored to the needs of the automotive and industrial automation sectors. The company launched new high-performance sensors aimed at enhancing precision in harsh industrial environments in 2024.

Temposonics: Specializing in digital feedback systems, Temposonics has made significant strides in the robotics and aerospace sectors. Their advanced systems offer real-time position and velocity tracking, catering to industries that demand high-speed and high-accuracy solutions.

Other Key Players: Other companies in this market include Balluff, Siemens, and Honeywell, each offering various solutions across different applications, from industrial automation to healthcare.

Emerging Trends in Competition

Integration of IoT: Manufacturers are increasingly integrating IoT technologies into their position velocity feedback systems to enhance data collection, improve connectivity, and enable predictive maintenance.

Customization and Tailored Solutions: Companies are focusing on providing customized solutions for specific industries to cater to the unique needs of sectors such as automotive, aerospace, and healthcare.

Sustainability Initiatives: With growing environmental concerns, companies are developing energy-efficient systems that not only meet performance requirements but also adhere to sustainable production practices.

Purchase Exclusive Report: https://www.statsandresearch.com/enquire-before/40604-global-position-velocity-feedback-transmitter-systems-market

Conclusion:

The Position Velocity Feedback Transmitter Systems Market is on a rapid growth trajectory, driven by advancements in automation, robotics, and sensor technologies. The demand for high-precision motion control systems is intensifying as industries seek to improve efficiency, safety, and productivity. Despite challenges such as high initial costs and integration complexities, the opportunities presented by emerging applications in healthcare, autonomous vehicles, and smart manufacturing are substantial.

With continued innovation and a focus on integration with IoT and digital technologies, the market is well-positioned for long-term expansion. As the industrial landscape continues to evolve, the role of position and velocity feedback systems will be pivotal in shaping the future of automation and precision control across various sectors.

Our Services:

On-Demand Reports: https://www.statsandresearch.com/on-demand-reports

Subscription Plans: https://www.statsandresearch.com/subscription-plans

Consulting Services: https://www.statsandresearch.com/consulting-services

ESG Solutions: https://www.statsandresearch.com/esg-solutions

Contact Us:

Stats and Research

Email: [email protected]

Phone: +91 8530698844

Website: https://www.statsandresearch.com

#Position Velocity Feedback Transmitter Systems Market#Position Feedback Systems#Velocity Feedback Transmitters#Automation#Industrial Automation#Motion Control Systems#Precision Motion Tracking#Position and Velocity Sensors#Digital Feedback Systems#Robotics#Aerospace Industry#Autonomous Vehicles#Healthcare Robotics#Smart Manufacturing#Industrial Robotics#Sensor Technology#Motion Control#Market Growth#Industry 4.0#Digital Position Sensors#Automotive Automation#IoT-enabled Feedback Systems#High-Precision Transmitters#Real-time Position Feedback#Aerospace Sensors#Automation Trends#Smart Manufacturing Systems#Position Velocity Sensors#Market Analysis#Precision Control Systems

1 note

·

View note

Text

Top 5 Industrial Automation Low-Voltage Switchgear Accessories You Need to Utilize

Stable and proper electrical systems are most important in industrial automation, and low-voltage switchgear is one of the most important elements that connects these systems. However, to reach the best performance, safety, and lifespan, the correct accessories for low-voltage switchgear need to be selected.

In this article, we will discuss the 5 must-have low-voltage switchgear accessories that industrial automation requires to run at its optimum and be less down.

1. Circuit Breakers – Protection and Safety from Overloading

Circuit breakers are the most important devices of low-voltage switchgear equipment. Circuit breakers safeguard electric circuits from problems like short circuits, overloads, and faults by breaking power supply to the circuit when they detect abnormal conditions.

Why They Are Important?

- Protect equipment from electrical fire and damage.

- Comply with industry safety standards.

- Recover quickly from a fault.

Recommendation: Use high-level circuit breakers with remote monitoring and diagnostic capabilities to improve automation efficiency.

2. Surge Protection Devices (SPDs) – Voltage Spike Protection

Voltage spikes and transients destroy electrical equipment in automation systems. SPDs function by absorbing excess voltage, thereby safeguarding sensitive hardware.

Why They Are Important?

- Reduce electrical surge downtime.

- Protect the automatic equipment and control panel from damage.

- Extend the life of electrical equipment.

Pro Tip: Install SPDs with real-time sensing sensors. That way, you can detect and fix voltage problems as they occur.

3. Busbar Systems – More Efficient Power Distribution

A busbar system is important since it allows the transmission of electrical energy more efficiently in switchgear setups. Busbars conduct better, lose less energy, and work better with systems than regular wiring.

Why They Matter?

- Simplified and less costly wiring installation.

- Minimization of energy losses by reducing the power loss.

- Simple extension to and integration with automated systems.

It is suggested that insulated busbar systems shall be employed for safety and to prevent accidental short circuits.

4. Motor Protection Relays – Intelligent Monitoring for Motors

Electric motors are a fundamental component of industrial automation. Motor protection relays safeguard motors against overloading, phase imbalance, and overheating to enable motors to run faultlessly and continuously.

Why Are They Important?

- Prevent costly motor failure and operational downtime.

- Allow remote monitoring for easy predictive maintenance. - Improve operational efficiency with auto-reset.

Tip: Incorporate programmable motor protection relays with automation systems for real-time monitoring and control.

5. Remote Monitoring and Control Devices – Increasing Automation Scope

New businesses must monitor switchgear remotely to be efficient and have low maintenance costs.

Remote monitoring devices allow operators to monitor voltage levels, power consumption, and system status from a distance.

Why Are They Important?

- Perform routine maintenance to avoid unexpected breakdowns.

- Require fewer resources and time to reduce manual inspections.

- Increase system reliability with real-time fault notifications.

Pro Tip: Implement IoT-enabled remote monitoring systems for easy integration with industrial automation systems.

Final Thoughts:

Buy good quality low-voltage switchgear accessories when you purchase them for safety, performance, and efficiency in industrial automation.

Circuit breakers, surge protective devices, busbar systems, motor protection relays, and remote monitoring systems will help you to ensure a healthy and strong electrical system.

10 notes

·

View notes

Text

Cost vs. Quality: What to Consider When Investing in Switchgear

In today’s energy-intensive world, switchgear plays a critical role in managing power distribution safely and efficiently. Whether you’re upgrading your industrial facility, building a commercial plant, or powering a large infrastructure project, choosing the right switchgear is not just a technical decision — it’s a strategic investment. One of the most common dilemmas buyers face is balancing cost vs. quality. So, how do you decide?

Understanding Switchgear: The Heart of Electrical Safety

Switchgear is a combination of electrical disconnect switches, fuses, or circuit breakers used to control, protect, and isolate electrical equipment. Its primary role is to ensure the reliability and safety of your power system.

Types of switchgear include:

· Low-voltage switchgear (for commercial and residential use)

· Medium-voltage switchgear (typically for industrial applications)

· High-voltage switchgear (used in power transmission)

Investing in the right switchgear directly impacts operational continuity, personnel safety, and overall infrastructure reliability.

The True Cost of Cheap Switchgear:

While it’s tempting to opt for budget-friendly solutions, low-cost switchgear often comes with hidden risks and long-term expenses.

Inferior Material Quality

Cheaper models often use substandard materials that degrade faster, leading to frequent maintenance or early replacement.

Safety Hazards

Low-quality switchgear can result in arc faults, insulation failure, or overheating — putting workers and equipment at risk.

Increased Lifecycle Costs

Although the initial price may be low, the total cost of ownership (including downtime, repair, and energy inefficiency) is usually higher.

Limited Scalability and Customization

Budget systems are often rigid and harder to scale as your facility grows or needs change.

Why Quality Switchgear Pays Off

When you invest in premium switchgear, you’re not just buying a product — you’re buying peace of mind.

Enhanced Reliability

High-quality switchgear is engineered to perform in extreme conditions and handle high fault levels without compromising performance.

Superior Safety Standards

Reputable brands comply with international standards such as IEC, ANSI, or UL, reducing liability and improving workplace safety.

Ease of Maintenance

Well-built switchgear is modular and user-friendly, simplifying diagnostics and minimizing downtime during maintenance.

Energy Efficiency & Smart Capabilities

Modern switchgear includes IoT sensors, real-time monitoring, and predictive maintenance features, ensuring optimal energy use and proactive problem resolution.

Key Factors to Consider When Choosing Switchgear

When evaluating switchgear options, balance cost and quality by focusing on the following:

1. Application Requirements

Understand your voltage class, load types, and fault current ratings. Quality should match your operational demands.

2. Brand Reputation & Certification

Look for trusted brands with certifications like ISO 9001, CE, or IEC 62271. Positive reviews and case studies add credibility.

3. Lifecycle Costs

Don’t just compare sticker prices — consider maintenance, service availability, spare part costs, and expected lifespan.

4. Customization & Flexibility

Choose systems that can evolve with your operation. Modular designs support upgrades and expansions more efficiently.

5. Support and Service

Ensure the manufacturer provides robust after-sales support, technical training, and warranty services.

Cost vs. Quality: The Bottom Line

When it comes to switchgear, cheap is rarely cheerful. Cutting corners today can lead to outages, hazards, and hefty repair bills tomorrow. On the other hand, investing in high-quality switchgear ensures operational resilience, safety, and long-term savings.

The smartest strategy? Aim for value, not just price. Evaluate switchgear as a long-term asset, not just a one-time purchase.

Trending Tip: Think Smart and Sustainable

With rising energy demands and climate-conscious regulations, smart and sustainable switchgear is trending. Look for:

· Eco-friendly insulation (like SF₆-free switchgear)

· Energy management features

· Digital monitoring systems

Investing in such features not only future-proofs your infrastructure but can also help you qualify for green certifications and incentives.

Final Thoughts

Balancing cost and quality in switchgear selection is about understanding your long-term operational goals. By focusing on durability, safety, and lifecycle value, you can make a decision that protects both your budget and your business.

8 notes

·

View notes

Text

Switchgear Solutions for Solar and Wind Energy Systems

Why Switchgear Matters in Solar and Wind Systems

Switchgear plays a central role in controlling, isolating, and protecting electrical equipment. In renewable energy applications, it helps:

· Manage power flow from variable energy sources.

· Protect systems from faults or overloads.

· Ensure seamless grid integration and disconnection when needed.

Unlike traditional power plants, solar and wind systems generate intermittent power, requiring switchgear that can handle dynamic loads and frequent switching.

Challenges in Renewable Energy Applications

Here are some of the unique challenges renewable energy systems face — and how they impact switchgear selection:

1. Variable Output

Solar and wind energy production fluctuates based on weather and time of day. This demands switchgear that can:

· Handle frequent load changes.

· Operate reliably under fluctuating voltages and currents.

2. Decentralized Generation

Unlike centralized grids, solar and wind systems are often spread out across multiple locations.

· Modular, compact switchgear is preferred for such installations.

· Smart monitoring becomes critical to manage performance remotely.

3. Harsh Environments

Wind turbines operate at high altitudes, and solar farms are often exposed to heat, dust, or salt.

· Switchgear needs to be rugged, weather-resistant, and have high IP ratings.

· Outdoor switchgear enclosures and temperature management are essential.

Key Features of Switchgear for Solar & Wind

When designing or upgrading renewable energy systems, look for switchgear that offers:

1. Remote Monitoring and Control

Smart switchgear integrated with IoT technology allows operators to track real-time data, detect faults early, and optimize system performance.

2. High Interruption Capacity

Wind and solar systems may experience voltage spikes. Modern switchgear provides high breaking capacities to safely interrupt fault currents.

3. Modular Design

Allows for easy upgrades and maintenance — crucial for scaling renewable installations.

4. Eco-Friendly Design

Look for SF₆-free switchgear that uses clean air or other sustainable alternatives to reduce environmental impact.

5. Hybrid Capabilities

Switchgear that can connect both AC and DC sources is increasingly valuable in mixed-source grids.

LV, MV, and HV Switchgear for Renewables

· Low Voltage (LV) Switchgear: Used in residential or small-scale solar systems. Compact, safe, and cost-effective.

· Medium Voltage (MV) Switchgear: Ideal for commercial and industrial solar/wind applications.

· High Voltage (HV) Switchgear: Essential for utility-scale wind farms or solar plants feeding into the national grid.

Each type requires specific protection, metering, and automation components tailored to its load and system requirements.

Final Thoughts

Switchgear is the backbone of any successful solar or wind energy system. As these technologies become more mainstream, the demand for resilient, intelligent, and environmentally friendly switchgear solutions will continue to rise.

Whether you’re an energy consultant, project developer, or facility manager, choosing the right switchgear today will set the stage for long-term efficiency, safety, and scalability.

8 notes

·

View notes

Text

The Growing Importance of Cargo Handling Services in India

With India's economy expanding rapidly and trade volumes increasing, the demand for reliable cargo handling services in India has become more critical than ever. These services are the backbone of supply chain operations, ensuring that cargo is moved, stored, and delivered efficiently and securely across various locations and modes of transport.

Understanding Cargo Handling

Cargo handling refers to all operations involved in the movement of goods — including loading, unloading, packaging, inspection, and storage. These tasks must be performed with precision and speed to maintain the integrity of the cargo and ensure timely delivery. In India, with its diverse geography and complex trade routes, effective cargo handling requires a combination of technology, infrastructure, and skilled personnel.

Major Types of Cargo Handling Services

1. Air Cargo Services

Airports in major cities like Mumbai, Delhi, Bengaluru, and Hyderabad handle large volumes of cargo every day. Air cargo handling involves high-speed processing of express shipments, including fragile, perishable, and high-value goods. Services include temperature-controlled storage, cargo sorting, customs clearance, and loading/unloading using modern conveyor systems and ground-handling equipment.

2. Port and Marine Cargo Handling

India’s maritime network includes major and minor ports across its extensive coastline. Ports such as Mundra, Chennai, and Visakhapatnam are equipped with container terminals, gantry cranes, and automated tracking systems. Port handling services manage the transfer of cargo between ships and shore, storage in port warehouses, and container yard logistics.

3. Rail and Road Transport Handling

The Indian railway system, one of the largest in the world, plays a vital role in cargo movement. Alongside rail, the country's expansive road network supports door-to-door cargo delivery. Cargo handling in this sector includes loading goods into containers or trucks, managing freight stations, and handling multimodal transfers.

4. Cold Chain Logistics

For goods that require temperature regulation — such as pharmaceuticals, dairy, seafood, and fresh produce — cold chain cargo handling is crucial. This includes refrigerated warehousing, insulated containers, temperature monitoring, and rapid handling to prevent spoilage. The cold chain sector in India is witnessing rapid investment and technological upgrades.

Advantages of Professional Cargo Handling

Minimized Cargo Damage: With trained workers and appropriate machinery, the risk of breakage or spoilage is greatly reduced.

Operational Efficiency: Quick turnaround times at terminals and distribution points help avoid costly delays.

Compliance and Safety: Cargo handling providers ensure adherence to domestic and international shipping regulations.

Improved Customer Satisfaction: Reliable service enhances delivery performance and builds trust with end customers.

Challenges in the Indian Cargo Handling Sector

Despite growth, the industry faces several hurdles:

Infrastructure Gaps: Some regions lack modern handling facilities and equipment.

Labor Shortages: There is a growing need for skilled workers trained in modern logistics tools.

Regulatory Delays: Clearance and documentation processes can slow down cargo movement, particularly at ports.

Future Outlook and Innovations

The cargo handling industry in India is evolving quickly, thanks to digitization and infrastructure development. Emerging trends include:

AI-powered cargo management systems

Real-time cargo tracking via GPS and IoT

Drone-based warehouse inspections

Integration of blockchain for transparent and tamper-proof documentation

Conclusion

The role of cargo handling services in India is more significant than ever in supporting the country’s logistics and supply chain systems. As global trade continues to expand and customer expectations rise, businesses must rely on efficient and technology-driven cargo handling partners. Whether it’s air, sea, rail, or road transport, professional handling services help minimize losses, reduce delivery times, and improve overall supply chain efficiency — all of which are vital to succeeding in today’s competitive business environment.

4 notes

·

View notes

Text

The Rise of 5G and Its Impact on Mobile App Development

5G isn’t just about faster internet — it’s opening up a whole new era for Mobile App Development. With dramatically higher speeds, ultra-low latency, and the ability to connect millions of devices seamlessly, 5G is transforming how developers think about building apps. From richer experiences to smarter services, let's explore how 5G is already reshaping the mobile app landscape in 2025 and beyond.

1. Lightning-Fast Data Transfer

One of the biggest promises of 5G is incredibly fast data transfer — we're talking about speeds up to 100 times faster than 4G. For mobile apps, this means that large files, high-resolution images, and HD or even 4K video content can be downloaded or streamed instantly. Apps that once needed to compress their data heavily or restrict features due to bandwidth limits can now offer fuller, richer experiences without worrying about lag.

2. Seamless Real-Time Experiences

5G dramatically reduces latency, meaning the time between a user action and the app’s response is almost instant. This will revolutionize apps that rely on real-time communication, such as video conferencing, live-streaming platforms, and online gaming. Developers can create much more responsive apps, allowing users to interact with data, people, and services with zero noticeable delay.

3. The Growth of AR and VR Mobile Applications

Augmented Reality (AR) and Virtual Reality (VR) apps have been growing, but 5G takes them to another level. Because of the high bandwidth and low latency, developers can now build more complex, interactive, and immersive AR/VR experiences without requiring bulky hardware. Imagine trying on clothes virtually in real-time or exploring a vacation destination through your phone — 5G is making this possible within Mobile App Development.

4. Smarter IoT-Connected Apps

The Internet of Things (IoT) will thrive even more in a 5G environment. Smart home apps, connected car apps, fitness trackers, and other IoT applications will be able to sync and update faster and more reliably. Developers can now integrate complex IoT ecosystems into mobile apps with minimal worries about network congestion or instability.

5. Enhanced Mobile Cloud Computing

Thanks to 5G, mobile cloud computing becomes much more viable. Instead of relying solely on local device storage and processing, apps can now store large amounts of data and execute processes directly in the cloud without latency issues. This allows users with even mid-range smartphones to experience high-performance features without the need for powerful hardware.

6. Revolutionizing Mobile Commerce

E-commerce apps are set to benefit greatly from 5G. Instant-loading product pages, real-time customer support, virtual product previews through AR, and lightning-fast payment gateways will enhance user experience dramatically. This could lead to higher conversion rates, reduced cart abandonment, and greater user loyalty in shopping apps.

7. Opportunities for New App Categories

With the technical limitations of mobile networks reduced, a whole new range of apps becomes possible. Real-time remote surgeries, autonomous vehicles controlled via mobile apps, and highly advanced telemedicine solutions are just a few examples. The doors are open for mobile developers to innovate and create applications that were previously impossible.

8. Better Security Requirements

With 5G’s mass connectivity also comes a bigger responsibility for security. As mobile apps become more connected and complex, developers must prioritize data protection, encryption, and secure authentication methods. Building security deeply into Mobile App Development workflows will be critical to maintain user trust.

9. More Demanding User Expectations

As 5G rolls out globally, users will expect every app to be faster, smoother, and more capable. Apps that fail to leverage the benefits of 5G may seem outdated or sluggish. This shift will push developers to continually optimize their apps to take advantage of higher speeds and smarter networking capabilities.

10. Preparing for the 5G Future

Whether you’re building entertainment apps, business solutions, healthcare tools, or gaming platforms, now is the time to adapt to 5G. Developers must start thinking about how faster speeds, greater device connections, and cloud capabilities can improve their mobile applications. Partnering with experts in Mobile App Development who understand the full potential of 5G will be key to staying ahead in a rapidly evolving digital world.

3 notes

·

View notes

Text

From Circuits to Solutions: Practical Projects to Elevate Your EE Skills

From Breadboards to Breakthroughs” encapsulates the journey of an aspiring electrical engineer as they evolve from basic circuit experiments to advanced, real-world engineering projects. Hands-on projects are essential for building practical skills, reinforcing theoretical knowledge, and preparing for professional challenges. Below is a guide to project-based learning that can help you improve your electrical engineering (EE) skills at every stage.

Beginner Projects: Building Foundations

Simple LED Circuit

What you learn: Basic circuit design, current and voltage concepts, use of resistors and LEDs.

Tools: Breadboard, jumper wires, resistors, LEDs, battery.

Battery Tester

What you learn: Measuring voltage and current, basic instrumentation, and safety practices.

Water Level Indicator

What you learn: Sensor integration, simple logic circuits, and practical applications.

Logic Gates and Digital Circuits

What you learn: Boolean logic, digital circuit fundamentals, and troubleshooting.

DIY Switch Circuits

What you learn: Circuit switching, input/output devices, and practical wiring.

Intermediate Projects: Expanding Your Skills

Infrared Security System

What you learn: Sensor-based security, signal processing, and system integration.

Digital Voltmeter

What you learn: Instrumentation, analog-to-digital conversion, and measurement accuracy.

Solar Charger

What you learn: Renewable energy concepts, power management, and circuit protection.

Motor Control Circuits

What you learn: Driving motors, pulse-width modulation (PWM), and power electronics.

Heart Rate Monitor

What you learn: Biomedical instrumentation, sensor interfacing, and signal filtering.

Advanced Projects: Real-World Breakthroughs

Smart Home Automation System

What you learn: IoT, wireless communication (Bluetooth, Wi-Fi), and system integration.

Wireless Power Transfer System

What you learn: Inductive coupling, resonant circuits, and energy efficiency.

Dual Axis Solar Power Tracker

What you learn: Mechatronics, sensor feedback, and renewable energy optimization.

Smart Energy Meter

What you learn: Real-time data monitoring, wireless communication, and energy management.

DIY Quadcopter or Drone

What you learn: Embedded systems, motor control, wireless communication, and robotics.

Why Hands-On Projects Matter

Resume Building: Practical projects demonstrate your skills to potential employers and can help you land internships or jobs

Theory Application: Projects bridge the gap between classroom learning and real-world engineering challenges.

Skill Discovery: Experimenting with different projects helps you identify your interests and strengths.

How to Get Started

Gather Basic Tools: Invest in a quality breadboard, jumper wires, resistors, capacitors, LEDs, and a multimeter.

Start Simple: Begin with basic circuits and gradually tackle more complex projects as your confidence grows.

Use Online Resources: Take advantage of tutorials, simulation tools, and open-source project guides.

Join Maker Communities: Engage with online forums, local maker spaces, and engineering clubs for support and inspiration.

Document Your Work: Keep a project journal, take photos, and share your progress on platforms like GitHub or LinkedIn.

Conclusion

Arya College of Engineering & I.T. is one of the best colleges of Jaipur, which is progressing from breadboard experiments to advanced engineering projects is a transformative process that builds both technical expertise and problem-solving confidence. By systematically advancing through beginner, intermediate, and advanced projects, you will develop a robust skill set that prepares you for the challenges and opportunities of a career in electrical engineering.

2 notes

·

View notes

Text

Comprehensive Industrial Solutions by AxisValence: Advancing Productivity, Safety, and Efficiency

In today’s fast-paced manufacturing world, industrial productivity is driven by precision, consistency, safety, and compliance. Whether it’s printing, packaging, converting, textiles, plastics, or pharmaceuticals—modern production lines demand advanced electro-mechanical systems that minimize waste, ensure operational safety, and improve overall efficiency.

AxisValence, a business unit of A.T.E. India, addresses this demand with a complete range of industrial automation and enhancement products. From static elimination to print quality assurance, ink management, and solvent recovery, AxisValence solutions are engineered to optimize each critical point in the production cycle.

This article provides an overview of the key technologies and systems offered by AxisValence across its diverse portfolio:

Electrostatics: Managing Static for Quality and Safety

Electrostatics can compromise product quality, disrupt operations, and pose serious safety hazards, especially in high-speed processes involving films, paper, textiles, or volatile solvents. AxisValence offers a complete suite of static control solutions:

ATEX AC Static Eliminators: Certified for use in explosive or solvent-heavy environments such as rotogravure or flexo printing lines.

AC and DC Static Eliminators: Designed for long-range or close-range static charge neutralization across a range of substrates.

Passive Static Dischargers: Cost-effective, maintenance-free brushes for light-duty static elimination where power isn't available.

Air-based Static Eliminators / Ionisers: Use ionized air streams for dust blow-off and static removal, ideal for hard-to-reach areas.

Static Measurement & Online Monitoring: Includes handheld meters and IoT-enabled monitoring systems for real-time control and diagnostics.

Electrostatic Charging Systems: Generate controlled static charges for bonding or pinning applications in laminating or packaging lines.

Electrostatic Print Assist (ESA): Enhances ink transfer in rotogravure printing by improving ink pickup and registration.

Camera-Based Web Videos for Print Viewing: Real-Time Visual Inspection

High-speed printing applications require instant visibility into print quality. AxisValence’s ViewAXIS systems are high-performance, camera-based web viewing solutions:

ViewAXIS Mega: Entry-level system with high-resolution imaging for real-time visual inspection.

ViewAXIS Giga: Equipped with 14x optical zoom and X-ray vision for deeper inspection of layered prints.

ViewAXIS Tera: Full repeat system with a 55” display, allowing operators to monitor and inspect the complete print layout in real-time.

Camera-Based Web Videos for Print Viewing systems help identify print errors like registration issues, smudging, or color inconsistencies early in the production run—minimizing rework and improving efficiency.

100% Inspection Systems: Intelligent Defect Detection

Modern converters and packaging companies require automated systems that can identify microscopic flaws at high speeds. AxisValence’s DetectAXIS systems use AI-based image processing and line scan cameras for 100% inspection:

DetectAXIS Print: Identifies printing defects such as streaks, misregistration, color deviation, and missing text at speeds up to 750 m/min.

DetectAXIS Surface: Designed for detecting surface anomalies—scratches, gels, holes, fish-eyes—on films, textiles, and nonwovens.

Real-time alerts, digital roll-maps, and adaptive detection improve quality control while reducing material waste and production downtime.

Ink Handling Systems: Consistent Ink Quality and Reduced Waste

Stable ink flow and temperature directly impact print quality and solvent consumption. AxisValence’s Valflow range ensures optimal ink conditioning through:

Ink Filters: Eliminate contaminants like metallic particles, fibers, and dried pigments that can damage cylinders or cause print defects.

Ink Pumps & Tanks: Efficient centrifugal pumps and round stainless-steel tanks designed for continuous ink circulation and minimal ink residue.

Ink Temperature Stabilisers (ITS): Automatically control ink temperature to prevent viscosity drift and reduce solvent evaporation—delivering consistent print shade and odor-free operation.

Valflow Ink handling solutions are ideal for gravure and flexographic printing applications.

Print Register Control Systems: Precision Alignment in Every Print

Maintaining precise print registration control systemis critical in multi-color printing processes. AxisValence offers two specialized systems:

AlygnAXIS: For rotogravure presses, using fiber optic sensors and adaptive algorithms to deliver real-time register accuracy.

UniAXIS: A versatile controller for print-to-mark, coat-to-mark, and cut-to-mark applications—both inline and offline.

These controllers reduce waste, enhance print alignment, and speed up setup during job changes.

Safety and Heat Recovery Systems: Energy Efficiency and Explosion Prevention

Solvent-based processes require strict monitoring of air quality and heat management to meet compliance and reduce operational costs. AxisValence provides:

NIRA Residual Solvent Analyser: Lab-based gas chromatography system for quick analysis of residual solvents in films.

Air-to-Air Heat Exchangers (Lamiflow): Recover and reuse waste heat from drying processes—improving energy efficiency.

LEL Monitoring and Recirculation Systems: Ensure solvent vapor concentrations stay within safe limits in enclosed dryers using flame ionization or infrared detection.

Together, safety and heat recovery systems ensure both environmental safety and process optimization.

Surface Cleaning Systems: Contaminant-Free Production Lines

Particulate contamination can ruin coating, lamination, and printing jobs. AxisValence offers contactless surface cleaning systems that combine airflow and static control:

Non-Contact Web Cleaners: Use air curtains and vacuum to remove dust from moving substrates without physical contact.

Ionising Air Knives: High-velocity ionized air streams neutralize static and clean surfaces entering finishing zones.

Ionising Air Blowers: Cover larger surfaces with ionized air to eliminate static and debris.

Ionising Nozzles & Guns: Handheld or fixed, these tools offer targeted static and dust elimination at workstations.

Waste Solvent Recovery: Sustainable Ink and Solvent Reuse

Reducing solvent consumption and improving environmental compliance is critical for modern converters. AxisValence partners with IRAC (Italy) to offer:

Solvent Distillation Systems: Recover usable solvents from spent ink mixtures, reducing hazardous waste and cutting costs.

Parts Washers: Clean anilox rolls, gravure cylinders, and components through high-pressure, ultrasonic, or brush-based systems.

Waste solvent recovery systems offer a quick ROI and support zero-waste manufacturing goals.

Why Choose AxisValence?

AxisValence combines decades of industrial expertise with innovative product design to deliver reliable, safe, and efficient solutions for manufacturing processes. With a product portfolio spanning:

Electrostatics & Static Control Systems

Web Viewing & Print Inspection Solutions

Ink Handling and Conditioning Equipment

Register Control and Print Automation

Heat Recovery and Air Quality Monitoring

Surface Cleaning Technologies

Waste Solvent Management

…AxisValence serves diverse industries including printing, packaging, plastic and rubber, textile, pharma, and automotive.

From single-device retrofits to complete system integration, AxisValence enables manufacturers to improve output quality, reduce waste, meet safety norms, and gain a competitive edge.

Explore our full product range at www.axisvalence.com or contact our sales network for a customized consultation tailored to your industrial needs.

youtube

2 notes

·

View notes

Text

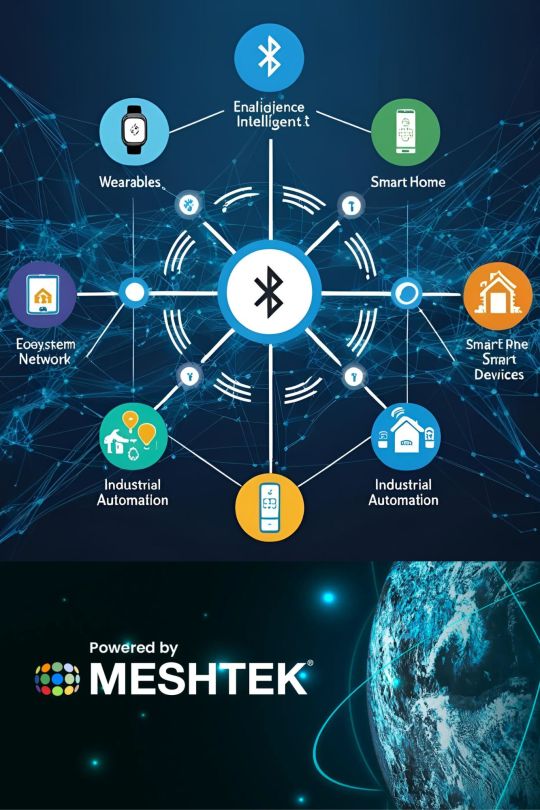

MeshTek’s Vision: Empowering IoT with Bluetooth Mesh Networking

MeshTek’s robust Bluetooth Mesh Networking ecosystem—seamlessly linking smart homes, wearables, industrial automation, and connected devices into one intelligent grid. It illustrates how MeshTek empowers secure, low-energy, and scalable communication across complex environments, enabling real-time control, optimized performance, and unmatched flexibility. Built to support everything from smart devices to enterprise-level automation, MeshTek’s platform is at the heart of next-gen IoT transformation.

#Bluetooth Mesh Networking#MeshTek#smart automation#connected devices#industrial IoT#IoT ecosystem#smart home network#IoT infrastructure#wearable integration#scalable IoT platform#low-energy communication#real-time control#IoT app development#MeshTek technology#intelligent automation

1 note

·

View note

Text

GRANDPACK CELEBRATES OVER A DECADE OF EXCELLENCE IN PHARMACEUTICAL PACKAGING SOLUTIONS

Grandpack is a leading supplier of complete solutions for pharmaceutical packaging.

Grandpack, a leading pharmaceutical machinery manufacturer & supplier from China, proudly marks over ten years of delivering comprehensive technical solutions for pharmaceutical packaging. With a steadfast commitment to quality and innovation, the company has become a trusted partner for industries worldwide.

Leveraging Computer Science to Increase Efficiency and Improve Safety

The integration of computer science into pharmaceutical packaging machinery is subtly transforming the industry, enhancing operational efficiencies, and setting new standards for production safety. Grandpack has equipped itself with smarter technologies by adopting the high standards of Industry 4.0 and IoT. Machine learning and data analytics enable Grandpack to monitor packaging lines in real time and implement predictive maintenance strategies, reducing equipment downtime by approximately 25% and improving overall production efficiency and safety.

Product Line-up of Grandpack: A Brief Overview

Grandpack is a leading company that provides effective solutions in the pharmaceutical packaging sector and offers innovative solutions that enhance productivity, accuracy, and compliance with the requirements. The company specializes in providing high-quality machines for tube filling, vial filling, and solid preparation granulation, all this with a view to automation and precision as the key goals.

The Tube Filling Machines from Grand Pack Machine cater to a wide range of industries, including pharmaceuticals, cosmetics, and food. With models offering semi-automatic and fully automatic operations, these machines ensure high-speed, precise filling and sealing, significantly reducing manual labor and production inefficiencies.

For vial filling, Grandpack provides advanced aseptic filling solutions designed for pharmaceuticals, cosmetics, and food industries. These machines ensure hygienic, high-speed liquid filling, with integrated capping and labeling options to streamline the packaging process while maintaining strict quality standards.

The Solid Preparation Granulation Line offers a fully automated solution for pharmaceutical manufacturing, minimizing human error and maximizing efficiency. With a strong focus on GMP compliance and contamination control, this system is ideal for large-scale tablet and capsule production, ensuring consistency and regulatory adherence.

With its precision-engineered packaging solutions, Grandpack continues to empower businesses with cutting-edge technology that enhances production efficiency and product integrity.

Key Advantages of Choosing Grandpack for Pharmaceutical Packaging

Proven Experience: More than ten years in pharmaceutical packaging.

Compliance with GMP & ISO 9001:2015: Guaranteeing top-tier quality standards.

Tailored Solutions: personalized options designed to fulfill unique production requirements.

Worldwide Impact: Endorsed by over 3,000 clients in more than 100 countries.

Unmatched Precision & Efficiency: Our machines are engineered for exceptional accuracy and rapid performance.

3 notes

·

View notes

Text

Pest Control Market Insights Health and Hygiene Awareness Driving Preventive Solutions

The pest control market is a dynamic industry influenced by evolving consumer demands, regulatory frameworks, and technological advancements. This article delves into key insights about the pest control market, highlighting factors driving growth, challenges, and opportunities for innovation.

Pest Control Market Insights: Urbanization Driving Demand

Rapid urbanization has led to increased pest infestations in cities, requiring effective management strategies. Dense housing developments and waste mismanagement provide fertile grounds for pests, pushing urban consumers and municipalities to seek professional pest control services.

Pest Control Market Insights: Focus on Sustainable Solutions

Consumers and businesses are increasingly favoring environmentally friendly pest control options. The demand for biopesticides, organic repellents, and integrated pest management (IPM) techniques has surged, reflecting a shift toward sustainability within the industry.

Pest Control Market Insights: Technological Advancements in Pest Control

Technology is transforming pest control methods. Innovations such as AI-powered pest monitoring, IoT devices for real-time detection, and drone-based pest spraying systems are enhancing efficiency and precision, catering to both residential and industrial needs.

Pest Control Market Insights: Agriculture Sector and Pest Management

Agricultural pest control is critical for ensuring food security and maximizing crop yields. Precision agriculture, biological pest control methods, and automated pest monitoring systems are becoming integral to managing pests in farming.

Pest Control Market Insights: Commercial Sector Expansion

The commercial pest control market is growing significantly as industries like hospitality, food processing, and healthcare prioritize pest management for regulatory compliance and customer safety. Commercial facilities are investing heavily in regular pest inspections and preventive measures.

Pest Control Market Insights: Health and Hygiene Awareness

Heightened awareness about health risks associated with pests, such as disease transmission and allergic reactions, is driving consumers to opt for preventive pest control measures. The focus on hygiene has intensified in the wake of global pandemics.

Pest Control Market Insights: Challenges in Rural Areas

While urban areas have easy access to pest control services, rural regions face challenges such as limited service providers and lack of awareness. Addressing these gaps presents a significant growth opportunity for the pest control market.

Pest Control Market Insights: Regulatory Landscape and Compliance

Strict regulations governing pesticide use and environmental protection are reshaping the pest control industry. Companies must invest in compliance and innovation to meet regulatory standards while delivering effective solutions.

Pest Control Market Insights: Mergers and Strategic Alliances

Mergers, acquisitions, and collaborations among pest control companies are driving market consolidation. Strategic alliances help businesses expand their service offerings, adopt new technologies, and enhance their market presence.

Conclusion: Unlocking Potential in the Pest Control Market

The pest control market offers immense growth opportunities, driven by urbanization, health awareness, and technological advancements. However, addressing challenges such as sustainability, rural access, and regulatory compliance is essential. By focusing on innovation, eco-friendly solutions, and strategic collaborations, the pest control industry can achieve long-term growth and success.

#Pest Control Market#Pest Control Market trends#Pest Control#pest control company#pest regretevator#pest control services

4 notes

·

View notes

Text

Innovations in Electrical Switchgear: What’s New in 2025?

The electrical switchgear industry is undergoing a dynamic transformation in 2025, fueled by the rapid integration of smart technologies, sustainability goals, and the growing demand for reliable power distribution systems. As a key player in modern infrastructure — whether in industrial plants, commercial facilities, or utilities — switchgear systems are becoming more intelligent, efficient, and future-ready.

At Almond Enterprise, we stay ahead of the curve by adapting to the latest industry innovations. In this blog, we’ll explore the most exciting developments in electrical switchgear in 2025 and what they mean for businesses, contractors, and project engineers.

Rise of Smart Switchgear

Smart switchgear is no longer a futuristic concept — it’s a necessity in 2025. These systems come equipped with:

IoT-based sensors

Real-time data monitoring

Remote diagnostics and control

Predictive maintenance alerts

This technology allows for remote management, helping facility managers reduce downtime, minimize energy losses, and detect issues before they become critical. At Almond Enterprise, we supply and support the integration of smart switchgear systems that align with Industry 4.0 standards.

2. Focus on Eco-Friendly and SF6-Free Alternatives

Traditional switchgear often relies on SF₆ gas for insulation, which is a potent greenhouse gas. In 2025, there’s a significant shift toward sustainable switchgear, including:

Vacuum Interrupter technology

Air-insulated switchgear (AIS)

Eco-efficient gas alternatives like g³ (Green Gas for Grid)

These options help organizations meet green building codes and corporate sustainability goals without compromising on performance.

3. Wireless Monitoring & Cloud Integration

Cloud-based platforms are transforming how switchgear systems are managed. The latest innovation includes:

Wireless communication protocols like LoRaWAN and Zigbee

Cloud dashboards for real-time visualization

Integration with Building Management Systems (BMS)

This connectivity enhances control, ensures quicker fault detection, and enables comprehensive energy analytics for large installations

4. AI and Machine Learning for Predictive Maintenance

Artificial Intelligence is revolutionizing maintenance practices. Switchgear in 2025 uses AI algorithms to:

Predict component failure

Optimize load distribution

Suggest optimal switchgear settings

This reduces unplanned outages, increases safety, and extends equipment life — particularly critical for mission-critical facilities like hospitals and data centers.

5. Enhanced Safety Features and Arc Flash Protection

With increasing focus on workplace safety, modern switchgear includes:

Advanced arc flash mitigation systems

Thermal imaging sensors

Remote racking and switching capabilities

These improvements ensure safer maintenance and operation, protecting personnel from high-voltage hazards.

6. Modular & Scalable Designs

Gone are the days of bulky, rigid designs. In 2025, switchgear units are:

Compact and modular

Easier to install and expand

Customizable based on load requirements

Almond Enterprise supplies modular switchgear tailored to your site’s unique needs, making it ideal for fast-paced infrastructure developments and industrial expansions.

7. Global Standardization and Compliance

As global standards evolve, modern switchgear must meet new IEC and IEEE guidelines. Innovations include:

Improved fault current limiting technologies

Higher voltage and current ratings with compact dimensions

Compliance with ISO 14001 for environmental management

Our team ensures all equipment adheres to the latest international regulations, providing peace of mind for consultants and project managers.

Final Thoughts: The Future is Electric

The switchgear industry in 2025 is smarter, safer, and more sustainable than ever. For companies looking to upgrade or design new power distribution systems, these innovations offer unmatched value.

At Almond Enterprise, we don’t just supply electrical switchgear — we provide expert solutions tailored to tomorrow’s energy challenges. Contact us today to learn how our cutting-edge switchgear offerings can power your future projects.

6 notes

·

View notes

Text

ARMxy Series Industrial Embeddedd Controller with Python for Industrial Automation

Case Details

1. Introduction

In modern industrial automation, embedded computing devices are widely used for production monitoring, equipment control, and data acquisition. ARM-based Industrial Embeddedd Controller, known for their low power consumption, high performance, and rich industrial interfaces, have become key components in smart manufacturing and Industrial IoT (IIoT). Python, as an efficient and easy-to-use programming language, provides a powerful ecosystem and extensive libraries, making industrial automation system development more convenient and efficient.

This article explores the typical applications of ARM Industrial Embeddedd Controller combined with Python in industrial automation, including device control, data acquisition, edge computing, and remote monitoring.

2. Advantages of ARM Industrial Embeddedd Controller in Industrial Automation

2.1 Low Power Consumption and High Reliability

Compared to x86-based industrial computers, ARM processors consume less power, making them ideal for long-term operation in industrial environments. Additionally, they support fanless designs, improving system stability.

2.2 Rich Industrial Interfaces

Industrial Embeddedd Controllerxy integrate GPIO, RS485/232, CAN, DIN/DO/AIN/AO/RTD/TC and other interfaces, allowing direct connection to various sensors, actuators, and industrial equipment without additional adapters.

2.3 Strong Compatibility with Linux and Python

Most ARM Industrial Embeddedd Controller run embedded Linux systems such as Ubuntu, Debian, or Yocto. Python has broad support in these environments, providing flexibility in development.

3. Python Applications in Industrial Automation

3.1 Device Control

On automated production lines, Python can be used to control relays, motors, conveyor belts, and other equipment, enabling precise logical control. For example, it can use GPIO to control industrial robotic arms or automation line actuators.

Example: Controlling a Relay-Driven Motor via GPIO

import RPi.GPIO as GPIO import time

# Set GPIO mode GPIO.setmode(GPIO.BCM) motor_pin = 18 GPIO.setup(motor_pin, GPIO.OUT)

# Control motor operation try: while True: GPIO.output(motor_pin, GPIO.HIGH) # Start motor time.sleep(5) # Run for 5 seconds GPIO.output(motor_pin, GPIO.LOW) # Stop motor time.sleep(5) except KeyboardInterrupt: GPIO.cleanup()

3.2 Sensor Data Acquisition and Processing

Python can acquire data from industrial sensors, such as temperature, humidity, pressure, and vibration, for local processing or uploading to a server for analysis.

Example: Reading Data from a Temperature and Humidity Sensor

import Adafruit_DHT

sensor = Adafruit_DHT.DHT22 pin = 4 # GPIO pin connected to the sensor

humidity, temperature = Adafruit_DHT.read_retry(sensor, pin) print(f"Temperature: {temperature:.2f}°C, Humidity: {humidity:.2f}%")

3.3 Edge Computing and AI Inference

In industrial automation, edge computing reduces reliance on cloud computing, lowers latency, and improves real-time response. ARM industrial computers can use Python with TensorFlow Lite or OpenCV for defect detection, object recognition, and other AI tasks.

Example: Real-Time Image Processing with OpenCV

import cv2

cap = cv2.VideoCapture(0) # Open camera

while True: ret, frame = cap.read() gray = cv2.cvtColor(frame, cv2.COLOR_BGR2GRAY) # Convert to grayscale cv2.imshow("Gray Frame", gray)

if cv2.waitKey(1) & 0xFF == ord('q'): break

cap.release() cv2.destroyAllWindows()

3.4 Remote Monitoring and Industrial IoT (IIoT)

ARM industrial computers can use Python for remote monitoring by leveraging MQTT, Modbus, HTTP, and other protocols to transmit real-time equipment status and production data to the cloud or build a private industrial IoT platform.

Example: Using MQTT to Send Sensor Data to the Cloud

import paho.mqtt.client as mqtt import json

def on_connect(client, userdata, flags, rc): print(f"Connected with result code {rc}")

client = mqtt.Client() client.on_connect = on_connect client.connect("broker.hivemq.com", 1883, 60) # Connect to public MQTT broker

data = {"temperature": 25.5, "humidity": 60} client.publish("industrial/data", json.dumps(data)) # Send data client.loop_forever()

3.5 Production Data Analysis and Visualization

Python can be used for industrial data analysis and visualization. With Pandas and Matplotlib, it can store data, perform trend analysis, detect anomalies, and improve production management efficiency.

Example: Using Matplotlib to Plot Sensor Data Trends

import matplotlib.pyplot as plt

# Simulated data time_stamps = list(range(10)) temperature_data = [22.5, 23.0, 22.8, 23.1, 23.3, 23.0, 22.7, 23.2, 23.4, 23.1]

plt.plot(time_stamps, temperature_data, marker='o', linestyle='-') plt.xlabel("Time (min)") plt.ylabel("Temperature (°C)") plt.title("Temperature Trend") plt.grid(True) plt.show()

4. Conclusion

The combination of ARM Industrial Embeddedd Controller and Python provides an efficient and flexible solution for industrial automation. From device control and data acquisition to edge computing and remote monitoring, Python's extensive library support and strong development capabilities enable industrial systems to become more intelligent and automated. As Industry 4.0 and IoT technologies continue to evolve, the ARMxy + Python combination will play an increasingly important role in industrial automation.

2 notes

·

View notes

Text

Building Safer Cities: How Advanced Switchgear Is Powering the Future

Switchgear refers to the combination of electrical disconnect switches, fuses, and circuit breakers used to control, protect, and isolate electrical equipment. In simple words: it’s the shield that protects the power network from overloads, faults, and blackouts.

Without high-quality switchgear, cities would face:

· Frequent power failures

· Increased risk of electrical fires

· Equipment damage

· Unsafe environments for residents and businesses

In today’s urban landscape, switchgear isn’t just an accessory — it’s a critical lifeline for energy security and public safety.

How Advanced Switchgear is Shaping Safer Cities

Thanks to major technological advancements, switchgear is no longer static and reactive. Modern switchgear systems are smart, dynamic, and preventative. Here’s how they are transforming cities:

1. Real-Time Monitoring and Fault Detection

Smart switchgear comes equipped with IoT sensors and digital monitoring systems that detect faults in real time. Instead of waiting for a catastrophic failure, the system identifies weak points early — enabling quick, preventive maintenance.

Impact: Reduced blackouts, faster repair times, safer living and working environments.

2. Automated Shutdowns During Emergencies

In critical events like fires, short circuits, or system overloads, automated switchgear can instantly isolate the affected section. This targeted shutdown prevents the spread of danger and keeps the rest of the city powered.

👉 Impact: Enhanced public safety, minimized risk of widespread outages.

3. Supporting Renewable Energy Integration

As cities shift toward renewable energy sources (solar, wind, hydro), modern switchgear is designed to handle these variable inputs seamlessly. It balances load fluctuations and ensures grid stability, even when energy production varies hour by hour.

👉 Impact: Cleaner cities without sacrificing reliability.

4. Enhanced Energy Efficiency

Advanced switchgear minimizes energy losses during transmission and distribution. With features like optimized load management and energy analytics, cities can operate their power grids more sustainably and economically.

👉 Impact: Lower energy costs, greener urban spaces.

Why Upgrading Switchgear is Essential for the Cities of Tomorrow

The future city will be:

· More populated

· More digitalized

· More energy-demanding

Legacy power systems cannot keep up with this growth. Old switchgear is more vulnerable to faults, inefficiency, and even cyberattacks. Modern, advanced switchgear not only provides higher protection but also future-proofs cities against evolving challenges.

Investing in advanced switchgear means investing in:

· Public safety

· Economic stability

· Environmental responsibility

· Smart infrastructure development

Conclusion: Powering a Safer, Smarter Future

As we envision smarter, greener, and safer cities, we must pay attention to the systems that keep the lights on — and keep people safe. Advanced switchgear stands at the front line of this transformation, quietly ensuring that progress doesn’t come at the cost of safety.

Whether you’re an urban planner, an electrical engineer, or a business owner — prioritizing the right switchgear solutions is key to building cities ready for the challenges of tomorrow.

Looking for world-class switchgear products and accessories? Al Taqwa Electrical and Building Materials offers cutting-edge solutions trusted by industries across the world.

#electrical#electrical equipment#electrical supplies#building#building materials#oman#muscat#switchgear

3 notes

·

View notes

Text

Cloud Migration and Integration A Strategic Shift Toward Scalable Infrastructure

In today’s digital-first business environment, cloud computing is no longer just a technology trend—it’s a foundational element of enterprise strategy. As organizations seek greater agility, scalability, and cost-efficiency, cloud migration and integration have emerged as critical initiatives. However, transitioning to the cloud is far from a lift-and-shift process; it requires thoughtful planning, seamless integration, and a clear understanding of long-term business objectives.

What is Cloud Migration and Why Does It Matter

Cloud migration involves moving data, applications, and IT processes from on-premises infrastructure or legacy systems to cloud-based environments. These environments can be public, private, or hybrid, depending on the organization’s needs. While the move offers benefits such as cost reduction, improved performance, and on-demand scalability, the true value lies in enabling innovation through flexible technology infrastructure.

But migration is only the first step. Cloud integration—the process of configuring applications and systems to work cohesively within the cloud—is equally essential. Without integration, businesses may face operational silos, inconsistent data flows, and reduced productivity, undermining the very purpose of migration.

Key Considerations in Cloud Migration

A successful cloud migration depends on more than just transferring workloads. It involves analyzing current infrastructure, defining the desired end state, and selecting the right cloud model and service providers. Critical factors include:

Application suitability: Not all applications are cloud-ready. Some legacy systems may need reengineering or replacement.

Data governance: Moving sensitive data to the cloud demands a strong focus on compliance, encryption, and access controls.

Downtime management: Minimizing disruption during the migration process is essential for business continuity.

Security architecture: Ensuring that cloud environments are resilient against threats is a non-negotiable part of migration planning.

Integration for a Unified Ecosystem

Once in the cloud, seamless integration becomes the linchpin for realizing operational efficiency. Organizations must ensure that their applications, databases, and platforms communicate efficiently in real time. This includes integrating APIs, aligning with enterprise resource planning (ERP) systems, and enabling data exchange across multiple cloud platforms.

Hybrid and Multi-Cloud Strategies

Cloud strategies have evolved beyond single-provider solutions. Many organizations now adopt hybrid (combining on-premise and cloud infrastructure) or multi-cloud (using services from multiple cloud providers) approaches. While this enhances flexibility and avoids vendor lock-in, it adds complexity to integration and governance.

To address this, organizations need a unified approach to infrastructure orchestration, monitoring, and automation. Strong integration frameworks and middleware platforms become essential in stitching together a cohesive IT ecosystem.

Long-Term Value of Cloud Transformation

Cloud migration and integration are not one-time projects—they are ongoing transformations. As business needs evolve, cloud infrastructure must adapt through continuous optimization, cost management, and performance tuning.

Moreover, integrated cloud environments serve as the foundation for emerging technologies like artificial intelligence, data analytics, and Internet of Things (IoT), enabling businesses to innovate faster and more efficiently.

By treating cloud migration and integration as strategic investments rather than tactical moves, organizations position themselves to stay competitive, agile, and future-ready.

#CloudMigration#CloudIntegration#DigitalTransformation#HybridCloud#MultiCloud#CloudComputing#InfrastructureModernization#ITStrategy#BusinessContinuity

2 notes

·

View notes