#Insulating Firebrick

Explore tagged Tumblr posts

Text

The technology involves assembling heat-absorbing bricks in an insulated container, where they can store heat generated by solar or wind power for later use at the temperatures required for industrial processes. The heat can then be released when needed by passing air through channels in the stacks of "firebricks," thus allowing cement, steel, glass, and paper factories to run on renewable energy even when wind and sunshine are unavailable.

These systems, which several companies have recently begun to commercialize for industrial heat storage, are a form of thermal energy storage. The bricks are made from the same materials as the insulating bricks that lined primitive kilns and iron-making furnaces thousands of years ago. To optimize for heat storage instead of insulation, the materials are combined in different amounts.

Batteries can store electricity from renewable sources and provide electricity to generate heat on demand. "The difference between firebrick storage and battery storage is that the firebricks store heat rather than electricity and are one-tenth the cost of batteries," said lead study author Mark Z. Jacobson, a professor of civil and environmental engineering in the Stanford Doerr School of Sustainability and School of Engineering. "The materials are much simpler too. They are basically just the components of dirt."

#good news#environmentalism#science#environment#nature#energy efficiency#energy storage#bronze age#green technology#technology#batteries#geothermal power#firebricks#climate crisis#climate change

28 notes

·

View notes

Text

Excerpt from this story from Inside Climate News:

Inside a cinder block office building perhaps best known for the Hindu temple and table tennis club next door, a startup company is testing what may be one of the hottest new developments in clean energy technology.

At the back of a small warehouse laboratory buzzing with fans and motors, an MIT spinoff company called Electrified Thermal Solutions is operating something its founders call the Joule Hive, a thermal battery the size of an elevator.

The Hive is a large, insulated metal box loaded with dozens of white-hot ceramic bricks that convert electricity to heat at temperatures up to 1800 degrees Celsius—well beyond the melting point of steel—and with enough thermal mass to hold the heat for days.

As the price of renewable energy continues to plummet, one of the biggest challenges for the clean energy transition is finding a way to convert electricity to high temperature heat so societies don’t have to continue burning coal or natural gas to power heavy industries. Another thorny issue is finding a way to store energy—in this case heat—for when the sun doesn’t shine and the wind doesn’t blow.

“If you are running an industrial plant where you’re making cement or steel or glass or ceramics or chemicals or even food or beverage products, you burn a lot of fossil fuels,” Daniel Stack, chief executive of Electrified Thermal Solutions, said. “Our mission is to decarbonize industry with electrified heat.”

The industrial sector accounts for nearly one-fourth of all direct greenhouse gas emissions in the U.S., which drive climate change, according to the EPA. Thermal batteries powered by renewable energy could reduce roughly half of industry’s emissions, according to a 2023 report by the Center for Climate and Energy Solutions, a nonprofit, and its affiliated Renewable Thermal Collaborative.

Additional emissions come from chemical reactions, such as carbon dioxide that is formed as an unwanted byproduct during cement production, and from methane that leaks or is intentionally vented from natural gas pipes and other equipment.

The challenge to replacing fossil fuel combustion as the go to source for heat, is that there aren’t a lot of good options available to produce high temperature heat from electricity, Stack said. Electric heaters, like the wires that turn red hot in a toaster, work well at low temperatures but quickly burn out at higher temperatures. Other, less common materials like molybdenum and silicon carbide heaters can withstand higher temperatures, but are prohibitively expensive.

As a grad student at MIT, Stack wondered if firebricks, the bricks commonly used in residential fireplaces and industrial kilns, could be a less expensive, more durable solution. Bricks do not typically conduct electricity, but by slightly altering the recipe of the metal oxides used to make them, he and ETS co-founder Joey Kabel were able to create bricks that could essentially take the place of wires to conduct electricity and generate heat.

“There’s no exotic metals in here, there’s nothing that’ll burn out,” Stack said standing next to shelves lined with small samples, or “coupons,” of brick that he and his team have tested to find the ones with the best heating properties.

5 notes

·

View notes

Text

0 notes

Text

Choosing the Right Refractory Bricks: A Guide by RefShape

In industries where high temperatures are part of daily operations—such as steel manufacturing, glass production, or cement kilns—selecting the right refractory bricks is crucial. These heat-resistant bricks are engineered to withstand extreme conditions, providing both insulation and structural integrity. At RefShape, we specialize in high-performance refractory solutions tailored to your operational needs. If you’re looking for refractory bricks for sale, here’s what you need to know to make the right choice.

What Are Refractory Bricks?

Refractory bricks, also known as firebricks, are specially designed materials that can tolerate high heat, pressure, and chemical wear. Unlike regular bricks, they retain their strength and stability even under intense thermal conditions. They are essential in furnaces, kilns, incinerators, and reactors where temperatures can soar above 1000°C.

Types of Refractory Bricks Offered by RefShape

At RefShape, we provide a wide range of refractory bricks to meet the demands of different industrial applications:

Fire Clay Bricks – Affordable and widely used, ideal for general-purpose lining.

High Alumina Bricks – Withstand higher temperatures, great for cement and steel industries.

Silica Bricks – Suitable for coke ovens and glass furnaces.

Magnesia Bricks – Best for environments exposed to basic slags.

Insulating Fire Bricks – Lightweight, used where thermal insulation is key.

Each type of brick serves a unique function, and our experts at RefShape are here to help you select the most suitable product based on your specific requirements.

Why Choose RefShape for Your Refractory Needs?

When searching for refractory bricks for sale, it's not just about finding a product—it's about finding a reliable partner. Here’s why RefShape is a trusted name across industries:

Quality Assurance: We adhere to strict manufacturing standards to ensure durability and thermal resistance.

Custom Solutions: From standard sizes to customized shapes, we offer tailored products to match your furnace design.

Competitive Pricing: Top-tier performance without the premium price tag.

Technical Support: Our in-house experts provide consultation on product selection, installation, and maintenance.

Applications of RefShape Refractory Bricks

Our bricks are trusted across a wide range of sectors, including:

Steel and iron manufacturing

Cement and lime kilns

Glass production furnaces

Petrochemical plants

Incinerators and crematoriums

Whether you’re building a new plant or refurbishing an old one, RefShape has the experience and inventory to meet your needs.

Conclusion

Durability, efficiency, and safety begin with the right materials. With RefShape’s high-quality refractory bricks, you can ensure peak performance and long-lasting results, no matter the heat or pressure.

If you’re looking for refractory bricks for sale, contact RefShape today to explore our complete product range and get expert guidance on the best solution for your operation.

Visit Us https://refshape.com/blogs/refractory-shapes-redefining-excellence-as-a-leading-fire-brick-manufacturer/

0 notes

Text

How Old Fireplaces Can Be Made Safe and Efficient Again

There’s nothing quite like the warmth and ambiance of a traditional fireplace. But if your home has an old, unused, or neglected fireplace, it could be doing more harm than good — from safety hazards to energy loss. Fortunately, with proper Fireplace Restoration in Toronto, you can bring these aging architectural features back to life.

For homeowners in Toronto, where many homes boast beautiful but aging fireplaces, restoration is not only about preserving character — it’s also about ensuring safety, efficiency, and modern compliance.

Why Old Fireplaces Can Be Unsafe or Inefficient

Older fireplaces, especially those in homes built decades ago, may be:

Structurally compromised (loose bricks, deteriorating mortar)

Lacking modern chimney liners or flue systems

Not up to current building codes

Drafty, pulling warm air out in winter or letting in cold air

Inefficient, wasting more energy than they provide

Simply put, they were built for a different time — and need upgrades to perform safely and efficiently today.

Key Steps to Make an Old Fireplace Safe Again

1. Chimney Inspection and Cleaning

Start with a certified chimney inspection to check for:

Blockages or creosote buildup

Cracked or missing flue liners

Deteriorated chimney caps or crowns

A full cleaning and structural assessment will identify what needs to be repaired or replaced.

🔧 In Toronto, fireplace restoration professionals can use advanced tools like video chimney scans to spot hidden issues.

2. Structural Repairs

Loose bricks, cracked fireboxes, or crumbling mortar can all be safety hazards. Common repairs include:

Tuckpointing to restore weakened mortar joints

Replacing damaged firebricks

Reinforcing the smoke chamber or damper area

These repairs not only improve safety but also prevent further deterioration.

3. Install or Upgrade the Chimney Liner

A properly fitted chimney liner:

Improves heat resistance

Prevents toxic gas leaks

Enhances energy efficiency

Helps meet modern building codes

Many old fireplaces in Toronto homes either lack a liner entirely or have one that’s outdated or damaged.

4. Consider a Fireplace Insert

For maximum efficiency, consider installing a gas, electric, or wood-burning insert. These units fit directly into your existing fireplace opening and offer:

Increased heat output

Reduced emissions

Easy operation and maintenance

Modern inserts are especially beneficial in older Toronto homes, where retrofitting a full heating system may be costly or complex.

5. Seal and Insulate the Surrounding Areas

Many old fireplaces are notorious for heat loss. Restorers can:

Add insulation behind and around the firebox

Seal air leaks at the chimney base or damper

Improve the overall energy performance of your living space

Why Choose Professional Fireplace Restoration in Toronto?

Toronto’s housing stock includes many historic and character homes. While these fireplaces add charm, they often require specialized restoration techniques. Local experts understand:

Heritage building guidelines

Ontario fire codes

The specific materials and styles used in older Toronto homes

Whether you're restoring a red-brick hearth in a century home or converting a wood-burning fireplace in a downtown condo, professional help ensures safety, compliance, and lasting results.

Final Thoughts

An old fireplace doesn’t have to stay cold, drafty, or dangerous. With a thoughtful approach to Fireplace Restoration in Toronto, you can transform it into a safe, efficient, and beautiful focal point once again.

If you’re in the Toronto area and your fireplace needs some love, contact a trusted Fireplace Restoration in Toronto. They’ll assess the condition, explain your options, and guide you through every step of the process — from safety improvements to style upgrades.

0 notes

Text

The Ultimate Guide to 2KG Melting Furnaces with Graphite Crucibles for Jewelry Making

2KG Melting Furnace with Graphite Crucible, Gold, Silver, Copper, & Aluminum Melting Furnace for Casting Jewelry Making Equipment

👍👍Buy now: https://youtu.be/MwfpaLfn_w8

🔥🔥 DISCOUNT: 30% 🔥🔥

Melting metals like gold, silver, copper, and aluminum is an essential process for jewelry makers, metalworkers, and hobbyists. A 2KG melting furnace with a graphite crucible is a versatile and efficient tool that allows for precise and safe metal casting. Whether you're a professional jeweler or a DIY enthusiast, this guide will explore the benefits, features, and best practices for using a 2KG melting furnace with a graphite crucible.

Why Choose a 2KG Melting Furnace with a Graphite Crucible? A 2KG capacity melting furnace is ideal for small to medium-scale metal casting projects. Here’s why it’s a great choice:

Perfect for Jewelry Making – Melting gold, silver, and copper requires precision, and a 2KG furnace provides the right balance between capacity and control 113.

Efficient & Fast Melting – Graphite crucibles have excellent thermal conductivity, reducing melting time and energy consumption 510.

Durable & Long-Lasting – High-quality graphite crucibles resist cracking and corrosion, ensuring multiple uses before replacement 57.

Safe & User-Friendly – Many kits come with protective gloves, tongs, and safety features to prevent burns 416.

Versatile Applications – Suitable for melting gold, silver, copper, aluminum, brass, and bronze 413.

Key Features of a 2KG Melting Furnace with Graphite Crucible

High-Quality Graphite Crucible Made from 99.9% high-purity graphite, ensuring minimal contamination of precious metals 5.

Excellent thermal conductivity for faster melting and energy efficiency 10.

High heat resistance (up to 2642°F / 1450°C), making it suitable for gold, silver, and copper 16.

Grooved design for easy pouring and handling 7.

Efficient Heating System Electric or propane-powered options available 1316.

Rapid heating (melting gold in 10-15 minutes) with adjustable temperature controls 13.

3D heating technology ensures even heat distribution for consistent melting 4.

Complete Melting Kit Many 2KG furnace kits include:

Graphite crucible & ingot mold 16.

Crucible tongs & protective gloves 4.

Adjustable propane regulator (for gas furnaces) 16.

Firebrick insulation for heat retention 4.

Safety & Durability Heat-resistant ceramic fiber insulation prevents external burns 16.

Sturdy construction (cold-rolled steel or refractory materials) 4.

Automatic shut-off features in electric models for overheat protection 13.

How to Use a 2KG Melting Furnace with Graphite Crucible Step 1: Preparing the Crucible First-time seasoning: Heat the crucible to 500°C (932°F) for 15-20 minutes, then gradually increase to 900°C (1652°F) to prevent cracking 5.

Avoid sudden temperature changes—allow it to cool slowly after use 8.

Step 2: Loading & Melting Metal Fill the crucible to ¾ capacity to prevent spills 5.

Use flux (for gold/silver) to remove impurities, but avoid excessive borax, which can degrade graphite 8.

Stir gently with a graphite rod for even melting 8.

Step 3: Pouring & Casting Preheat molds to prevent thermal shock 8.

Pour quickly and steadily to avoid premature solidification 8.

Use protective gear (gloves, face shield) to prevent burns 16.

Step 4: Maintenance & Storage Clean the crucible after each use to prevent residue buildup 5.

Store in a dry place to avoid moisture damage 7.

Monitor crucible wear—replace if cracks or thinning occur 10.

Best 2KG Melting Furnace Kits in 2025

VEVOR Propane Melting Furnace (2KG) 16 Pros: Complete kit (includes tongs, gloves, regulator), reaches 2462°F (1450°C), durable clay-graphite crucible.

Cons: Some users report assembly issues with propane fittings.

ZHLINGQ Electric Melting Furnace (2KG) 13 Pros: PID temperature control, fast heating (up to 2102°F / 1150°C), includes safety mesh guard.

Cons: Limited to metals with melting points below 1150°C.

Proops Brothers Graphite Crucible (2KG) 1 Pros: High-quality graphite, precise dimensions, fits most electric furnaces.

Cons: Sold separately (furnace not included).

Common Mistakes to Avoid Overfilling the Crucible – Can lead to spills and dangerous molten metal leaks 5.

Skipping Preheating – Causes thermal shock, leading to cracks 8.

Using the Wrong Flux – Borax can degrade graphite over time 8.

Ignoring Safety Gear – Molten metal can cause severe burns 16.

Conclusion A 2KG melting furnace with a graphite crucible is an excellent investment for jewelers, metal casters, and hobbyists. Its efficiency, durability, and safety features make it ideal for melting gold, silver, copper, and aluminum. By following proper usage and maintenance tips, you can maximize its lifespan and achieve professional-quality results.

Whether you choose a propane or electric model, ensure it meets your project needs. Ready to start casting? Check out the top-rated VEVOR and ZHLINGQ furnaces for a seamless melting experience!

Would you like recommendations based on your specific metalworking needs? Let us know in the comments!

0 notes

Text

"High Temperature Insulation Materials: Powering Efficiency and Safety in Extreme Environments – 2025 Spotlight"

High temperature insulation materials are critical components in industries that operate under extreme heat—such as aerospace, metallurgy, power generation, and petrochemicals. These advanced materials, including ceramic fibers, aerogels, and insulating firebricks, are engineered to withstand temperatures exceeding 1000°C while minimizing heat loss, boosting energy efficiency, and enhancing operational safety. In 2025, with a strong push for energy conservation and sustainability, demand for lightweight, eco-friendly, and high-performance insulation solutions is at an all-time high. Innovations are also focusing on recyclable and low-carbon insulation alternatives that align with global green mandates. These materials not only protect equipment and personnel but also play a key role in reducing emissions across high-heat industries.

#HighTempInsulation#ThermalProtection#EnergyEfficiency2025#IndustrialInnovation#HeatResistance#SustainableEngineering#AdvancedMaterials#GreenIndustry#AerospaceTech#SmartManufacturing

0 notes

Text

The Revolutionary Crucible Kamado Firebox: A Breakthrough in Grilling and Smoking

When it comes to mastering the art of grilling and smoking, enthusiasts know the importance of investing in a high-quality Kamado firebox. The Saffire Crucible Kamado Firebox sets a new standard in durability, efficiency, and convenience, making it a game-changer for any barbecue aficionado.

The Science Behind the Saffire Crucible Kamado Firebox

The insulating and radiant heating qualities of ceramics have long been celebrated for creating the perfect environment for cooking and smoking all types of food. However, traditional Kamado grill fireboxes are often prone to structural failure under extreme temperatures, especially when charcoal burns at a staggering 2,000°F or higher. Saffire’s patent-pending Crucible Kamado Firebox not only overcomes this limitation but also exceeds expectations with its remarkable features and performance.

Exceptional Heat Resistance

Rated up to 2,700°F, the Crucible Kamado Firebox offers a heat resistance 1,000° higher than any other Kamado ceramic firebox on the market. This enhanced capacity ensures reliability even during high-intensity cooking sessions, providing peace of mind for avid grillers.

Ingenious 12-Brick Design

The firebox’s 12-brick design is revolutionary. It effectively relieves thermal stress, eliminating breakage common in conventional models. Even if a brick were to crack, the aluminized steel shell holds it securely in place, preventing air leakage. Furthermore, these individual bricks can be easily replaced, ensuring that your investment remains functional for years to come.

Unparalleled Features for a Superior Cooking Experience

Saffire’s Crucible Kamado Firebox is designed with precision to enhance every aspect of grilling and smoking. Here are some of its standout features:

Massive Charcoal and Ash Capacity

The enlarged shape of the firebox allows for increased charcoal capacity, enabling longer cooking times without the need for constant refueling. Additionally, its huge ash capacity means you can enjoy multiple cooking sessions before needing to clean out the ashes.

Double Grate Area for Efficiency

The Crucible Kamado Firebox features a double-sized grate area, which:

Facilitates faster starting of a large bed of coals.

Enhances airflow across the entire bed of charcoal.

Makes ash cleaning effortless with a quick shake of the stainless steel charcoal basket.

Innovative Charcoal Basket and Divider

Included with the Platinum Crucible Firebox, the 304 stainless steel charcoal basket is a versatile addition. It holds charcoal securely, allowing users to drop ash into the pan below with minimal effort. The removable divider lets you arrange charcoal on one side for indirect cooking, making it ideal for smoking delicate foods.

Quick and Convenient Ash Removal

One of the standout features of the Crucible Kamado Firebox is its industry-leading lift-out ash pan. With a 12.5-inch diameter and 3-inch height, this enormous ash pan eliminates the hassle of raking ash through a fire grate. Instead, you can simply lift out the pan and dispose of the ash quickly and easily.

Why Choose the Saffire Crucible Kamado Firebox?

Whether you are an occasional griller or a seasoned pitmaster, the Saffire Crucible Kamado Firebox offers several advantages that make it an essential upgrade for your Kamado grill:

Durability That Lasts The combination of high-temperature-rated refractory firebrick and aluminized steel ensures unmatched durability and thermal resistance. The insulating air gaps further enhance efficiency while keeping external temperatures safe.

Ease of Maintenance Say goodbye to tedious cleaning routines. The double-sized grate and lift-out ash pan simplify charcoal and ash management, so you can focus on enjoying the cooking process.

Customizable and Versatile The modular design of the firebox allows you to upgrade components like the charcoal basket and ash pan over time. This ensures that your Saffire Kamado Grill Firebox adapts to your evolving grilling needs.

The Bronze Series: Durability at a Lower Price Point

For those seeking the same long-lasting durability at a more affordable price, Saffire offers the Bronze Crucible Kamado Firebox. It includes a large cast-iron fire grate for easy ash cleaning and a huge ash area, reducing cleaning frequency. Users can later upgrade to the platinum series by adding a charcoal basket and ash pan, providing flexibility for all budgets.

Elevating the Grilling Experience

The Saffire Crucible Kamado Firebox is not just a component; it is the heart of a transformative cooking experience. Its advanced design and features cater to both efficiency and ease of use, ensuring consistent and flavorful results every time.

Whether you’re slow-smoking ribs, searing steaks, or baking pizzas, the Crucible Kamado Firebox’s superior performance and durability will redefine your grilling journey.

Why Saffire Grills Are the Ultimate Choice

At the forefront of innovation, Saffire Grills has consistently delivered premium-quality products that combine cutting-edge technology with exceptional craftsmanship. The Crucible Kamado Firebox is a testament to their commitment to enhancing the grilling experience for enthusiasts worldwide.

Invest in a Saffire Kamado Grill Firebox today and discover the unparalleled joy of grilling and smoking with the most advanced firebox in the industry. With Saffire, every meal becomes a masterpiece, and every grilling session, a celebration. For more information on the revolutionary Crucible Kamado Firebox and other Saffire products, visit our website and experience the future of grilling today!

0 notes

Text

Buy High Quality Wood Oven In Cyprus

Lambros Christoforou Ltd wood fire ovens are made from refractory materials. Cast refractory firebricks, high-temperature cement, and insulated with materials for fast heat-up time. We provide the best quality wood fire ovens. For more details, visit our online store!

Buy High Quality Wood Oven In Cyprus

0 notes

Text

Decarbonizing heavy industry with thermal batteries

New Post has been published on https://thedigitalinsider.com/decarbonizing-heavy-industry-with-thermal-batteries/

Decarbonizing heavy industry with thermal batteries

Whether you’re manufacturing cement, steel, chemicals, or paper, you need a large amount of heat. Almost without exception, manufacturers around the world create that heat by burning fossil fuels.

In an effort to clean up the industrial sector, some startups are changing manufacturing processes for specific materials. Some are even changing the materials themselves. Daniel Stack SM ’17, PhD ’21 is trying to address industrial emissions across the board by replacing the heat source.

Since coming to MIT in 2014, Stack has worked to develop thermal batteries that use electricity to heat up a conductive version of ceramic firebricks, which have been used as heat stores and insulators for centuries. In 2021, Stack co-founded Electrified Thermal Solutions, which has since demonstrated that its firebricks can store heat efficiently for hours and discharge it by heating air or gas up to 3,272 degrees Fahrenheit — hot enough to power the most demanding industrial applications.

Achieving temperatures north of 3,000 F represents a breakthrough for the electric heating industry, as it enables some of the world’s hardest-to-decarbonize sectors to utilize renewable energy for the first time. It also unlocks a new, low-cost model for using electricity when it’s at its cheapest and cleanest.

“We have a global perspective at Electrified Thermal, but in the U.S. over the last five years, we’ve seen an incredible opportunity emerge in energy prices that favors flexible offtake of electricity,” Stack says. “Throughout the middle of the country, especially in the wind belt, electricity prices in many places are negative for more than 20 percent of the year, and the trend toward decreasing electricity pricing during off-peak hours is a nationwide phenomenon. Technologies like our Joule Hive Thermal Battery will enable us to access this inexpensive, clean electricity and compete head to head with fossil fuels on price for industrial heating needs, without even factoring in the positive climate impact.”

A new approach to an old technology

Stack’s research plans changed quickly when he joined MIT’s Department of Nuclear Science and Engineering as a master’s student in 2014.

“I went to MIT excited to work on the next generation of nuclear reactors, but what I focused on almost from day one was how to heat up bricks,” Stack says. “It wasn’t what I expected, but when I talked to my advisor, [Principal Research Scientist] Charles Forsberg, about energy storage and why it was valuable to not just nuclear power but the entire energy transition, I realized there was no project I would rather work on.”

Firebricks are ubiquitous, inexpensive clay bricks that have been used for millennia in fireplaces and ovens. In 2017, Forsberg and Stack co-authored a paper showing firebricks’ potential to store heat from renewable resources, but the system still used electric resistance heaters — like the metal coils in toasters and space heaters — which limited its temperature output.

For his doctoral work, Stack worked with Forsberg to make firebricks that were electrically conductive, replacing the resistance heaters so the bricks produced the heat directly.

“Electric heaters are your biggest limiter: They burn out too fast, they break down, they don’t get hot enough,” Stack explains. “The idea was to skip the heaters because firebricks themselves are really cheap, abundant materials that can go to flame-like temperatures and hang out there for days.”

Forsberg and Stacks were able to create conductive firebricks by tweaking the chemical composition of traditional firebricks. Electrified Thermal’s bricks are 98 percent similar to existing firebricks and are produced using the same processes, allowing existing manufacturers to make them inexpensively.

Toward the end of his PhD program, Stack realized the invention could be commercialized. He started taking classes at the MIT Sloan School of Management and spending time at the Martin Trust Center for MIT Entrepreneurship. He also entered the StartMIT program and the I-Corps program, and received support from the U.S. Department of Energy and MIT’s Venture Mentoring Service (VMS).

“Through the Boston ecosystem, the MIT ecosystem, and with help from the Department of Energy, we were able to launch this from the lab at MIT,” Stack says. “What we spun out was an electrically conductive firebrick, or what we refer to as an e-Brick.”

Electrified Thermal contains its firebrick arrays in insulated, off-the-shelf metal boxes. Although the system is highly configurable depending on the end use, the company’s standard system can collect and release about 5 megawatts of energy and store about 25 megawatt-hours.

The company has demonstrated its system’s ability to produce high temperatures and has been cycling its system at its headquarters in Medford, Massachusetts. That work has collectively earned Electrified Thermal $40 million from various the Department of Energy offices to scale the technology and work with manufacturers.

“Compared to other electric heating, we can run hotter and last longer than any other solution on the market,” Stack says. “That means replacing fossil fuels at a lot of industrial sites that couldn’t otherwise decarbonize.”

Scaling to solve a global problem

Electrified Thermal is engaging with hundreds of industrial companies, including manufacturers of cement, steel, glass, basic and specialty chemicals, food and beverage, and pulp and paper.

“The industrial heating challenge affects everyone under the sun,” Stack says. “They all have fundamentally the same problem, which is getting their heat in a way that is affordable and zero carbon for the energy transition.”

The company is currently building a megawatt-scale commercial version of its system, which it expects to be operational in the next seven months.

“Next year will be a huge proof point to the industry,” Stack says. “We’ll be using the commercial system to showcase a variety of operating points that customers need to see, and we’re hoping to be running systems on customer sites by the end of the year. It’ll be a huge achievement and a first for electric heating because no other solution in the market can put out the kind of temperatures that we can put out.”

By working with manufacturers to produce its firebricks and casings, Electrified Thermal hopes to be able to deploy its systems rapidly and at low cost across a massive industry.

“From the very beginning, we engineered these e-bricks to be rapidly scalable and rapidly producible within existing supply chains and manufacturing processes,” Stack says. “If you want to decarbonize heavy industry, there will be no cheaper way than turning electricity into heat from zero-carbon electricity assets. We’re seeking to be the premier technology that unlocks those capabilities, with double digit percentages of global energy flowing through our system as we accomplish the energy transition.”

#000#air#Alternative energy#Alumni/ae#applications#approach#Arrays#assets#batteries#battery#board#Building#carbon#cement#challenge#chemical#chemicals#classes#Cleaner industry#climate#climate change#Companies#Composition#digit#double#electricity#Emissions#energy#energy storage#engineering

0 notes

Text

Heat-Resistant Materials Market: Growth, Trends, and Opportunities

The Heat-Resistant Materials Market is essential for industries such as steel, cement, and glass, where extreme temperatures are a constant challenge. The Refractories Market is driving innovation by providing materials that withstand high temperatures and improve operational efficiency.

The Heat-Resistant Materials Market ,is anticipated to experience growth, with significant developments expected over the forecast period, leading to substantial value projections by the end of this decade.

Market Growth

The Heat-Resistant Materials Market is expanding rapidly due to growing industrialization and demand from sectors like steel manufacturing and petrochemicals. The Refractories Market is benefiting from innovations in heat-resistant materials that improve performance and durability.

Download Complete TOC of the Heat-Resistant Materials Market

Key Technologies

Fireclay Bricks: Widely used in industries requiring resistance to high temperatures and corrosion.

Monolithic Refractories: Known for their versatility and ease of installation in various industrial applications.

Insulating Refractories: These materials provide thermal insulation, reducing energy consumption in high-temperature processes.

Demand Drivers

Steel Industry Growth: The steel industry is the largest consumer of refractories, driving demand for heat-resistant materials.

Energy Efficiency: Refractories that reduce heat loss and improve energy efficiency are increasingly in demand.

Industrial Expansion: As industrialization grows in developing regions, the demand for refractories continues to rise.

Castable and Mortar Products to Lead the Heat-Resistant Materials Market

In the refractories market, castable and mortar products are dominating due to their versatility and ease of installation. Castables offer excellent thermal resistance and can be tailored for various applications, while mortars provide essential bonding and sealing capabilities, ensuring durability and performance in high-temperature environments. This combination makes them preferred choices for industries requiring reliable and efficient refractory solutions.

Get more market insights for Advanced materials chemicals

Conclusion

The Heat-Resistant Materials Market is set for substantial growth, driven by industrial expansion and innovations in heat-resistant technologies. The Refractories Market will remain critical to high-temperature industrial processes. As companies continue to invest in innovative materials, the market will see increased adoption of advanced, eco-friendly products, positioning firebricks as a cornerstone of industrial efficiency and sustainability.

0 notes

Text

TRL Krosaki: A Pioneer in Flow Control Plant Refractories

Flow control plants, essential components of steelmaking and other industrial processes, require specialized refractory materials to withstand the harsh conditions they encounter. TRL Krosaki, a leading refractories provider, has been a pioneer in developing and supplying high-quality refractory solutions for flow control plants in India.

The Role of Refractories in Flow Control Plants

In flow control plants, such as ladle furnaces, tundish, and caster, refractories play a critical role in:

Heat Insulation: Preventing heat loss and maintaining optimal operating temperatures.

Erosion Resistance: Protecting against the abrasive forces of molten metal and slag.

Corrosion Resistance: Withstanding the corrosive effects of chemicals and slag.

Thermal Shock Resistance: Handling rapid temperature fluctuations.

TRL Krosaki's Expertise

TRL Krosaki has a deep understanding of the unique requirements of flow control plants and has developed a range of specialized refractory products to meet these needs. Their expertise includes:

Ladle Refractories: Ladle linings must be durable, resistant to thermal shock, and able to withstand the high temperatures and corrosive nature of molten steel. TRL Krosaki offers a variety of ladle refractory materials, including firebricks, castables, and ramming mixes.

Tundish Refractories: Tundish linings are subjected to intense heat, erosion, and slag attack. TRL Krosaki provides high-quality tundish refractories that can withstand these harsh conditions and ensure smooth flow of molten steel.

Caster Refractories: Caster refractories must be able to withstand the abrasive forces of molten steel and the high temperatures of the casting process. TRL Krosaki offers specialized caster refractories that meet these demanding requirements.

Key Features of TRL Krosaki Refractories

High Temperature Resistance: TRL Krosaki refractories can withstand extreme temperatures, ensuring the efficient operation of flow control plants.

Durability: Their products are designed to be durable and long-lasting, reducing maintenance costs and downtime.

Corrosion Resistance: TRL Krosaki refractories are resistant to corrosion, preventing damage and ensuring the longevity of flow control plant components.

Thermal Shock Resistance: They can withstand rapid temperature fluctuations, which is essential for smooth operation.

Benefits of Using TRL Krosaki Refractories

Increased Efficiency: TRL Krosaki refractories can help improve the efficiency of flow control plants by reducing heat loss and downtime.

Reduced Costs: By providing durable and long-lasting refractories, TRL Krosaki can help reduce maintenance costs and improve overall profitability.

Improved Product Quality: High-quality refractories can contribute to the production of higher-quality steel products.

Conclusion

TRL Krosaki has established itself as a leading provider of refractory solutions for flow control plants in India. Their expertise, coupled with their high-quality products, has made them a trusted partner for many steelmakers. By using TRL Krosaki refractories, flow control plants can enhance their efficiency, reduce costs, and improve product quality.

0 notes

Photo

Brazilian Charcoal Grill for BBQ 38 Skewers - NSF Certified - Professional Grade

BRAZILIAN CHARCOAL GRILL FOR BBQ

NSF Certified

38 Skewers / 3 Galleries

Professional Grill

Bring the authentic Brazilian BBQ experience to

your customers with this top-notch grill!

A wonderful tool for cooking a variety of dishes and is ideal for

those who appreciate the traditional grilling method.

Specification & Standard Features

•Grill manufactured in coated stainless steel and firebox

insulated with special firebricks and rock wool

• Rotisserie system with 3 galleries, plus rest bar

•Removable front bars, for easy access to the rotisserie system

and very handy for cleaning, to put or remove charcoal

•Ready to use, Easy to clean, Easy to move!

•Ash Tray

•Skewers are included.

Mechanical System

• ¼ HP engine, 110V/220 V - 60 Hz (6,0 Amp);

• Speed reducer 1 x 50 – Cast iron gears fixed on solid round iron bar 1 ¼”

• Double bronze (TM-23) axle bushings;

• Galvanized covering for the wires and electrical system;

• Bicycle chain (resistant and easier to replace);

Weight

1100 Pounds /500 Kilos

Dimensions

63" L x 34" W x 63" H (inches)

160 L x 85 W x 165 H (centimeters)

It is a very sturdy piece that lasts a lifetime.

Production lead time

3–4 weeks

Payment Condition

50% when placed the order and 50% before shipping by Zelle, deposit, credit card or PayPal.

Financing also available.

Warranty Policy

12 months against manufacturing defect.

We Ship Worldwide

For more information regarding this item, please contact us prior to purchasing.

We accept customized orders and special projects.

0 notes

Text

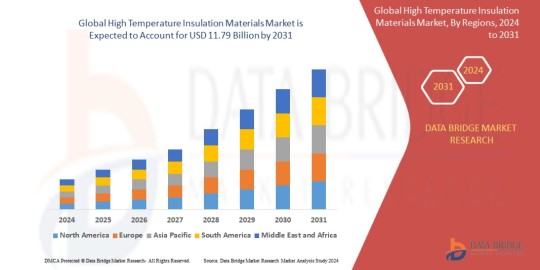

High Temperature Insulation Materials Market Size, Share, Trends, Demand, Growth, Challenges and Competitive Outlook

"High Temperature Insulation Materials Market Report involves the drivers and restraints for the market that are derived from SWOT analysis, and also shows what all the recent developments, product launches, joint ventures, mergers, and acquisitions by the several key players and brands that are driving the market are by systemic company profiles. In this document, intricate market insights are turned into simpler version by using the proven tools and techniques to provide it to the end users.

Global High Temperature Insulation Materials Market, By Material Type (Ceramic Fiber, Insulating Firebrick, Calcium Silicate, and Others), Temperature Range (600°C-1100°C, 1100°C-1500°C, 1500°C-1700°C, and 1700°C and Above), Application (Insulation, Industrial Equipment, and Others), End User (Petrochemicals, Ceramics, Glass, Cement, Iron and Steel, Refractory, Powder Metallurgy, Aluminum, and Others) - Industry Trends and Forecast to 2031.

Access Full 350 Pages PDF Report @

https://www.databridgemarketresearch.com/reports/global-high-temperature-insulation-materials-market

The global high temperature insulation materials market size was valued at USD 7.18 billion in 2023, is projected to reach USD 11.79 billion by 2031, with a CAGR of 6.40% during the forecast period 2024 to 2031. In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include in-depth expert analysis, geographically represented company-wise production and capacity, network layouts of distributors and partners, detailed and updated price trend analysis and deficit analysis of supply chain and demand.

Market Players Covered:

Some of the major players operating in the market are:

Morgan Advanced Materials (U.K.) Luyang Energy-saving Materials Co., Ltd. (China) RHI Magnesita GmbH (Austria) Mitsubishi Chemical Group Corporation (Japan) 3M (U.S.) Isolite Insulating Products Co., Ltd. (Japan) Etex Group (Belgium) Unifrax (U.S.) BNZ Materials (U.S.) Pyrotek (U.S.) Tmax Germany GmbH (Germany) Insulcon B.V. (Netherlands) PAR Group (U.K.) ADL INSULFLEX INC. (Canada) M.E. SCHUPP Industriekeramik GmbH (Germany) Owens Corning (U.S.) IBIDEN (Japan) Pacor, Inc. (U.S.) BASF SE (Germany) Saint-Gobain (France)

Global High Temperature Insulation Materials Market survey report analyses the general market conditions such as product price, profit, capacity, production, supply, demand, and market growth rate which supports businesses on deciding upon several strategies. Furthermore, big sample sizes have been utilized for the data collection in this business report which suits the necessities of small, medium as well as large size of businesses. The report explains the moves of top market players and brands that range from developments, products launches, acquisitions, mergers, joint ventures, trending innovation and business policies.

The report provides insights on the following pointers:

Market Penetration: Comprehensive information on the product portfolios of the top players in the High Temperature Insulation Materials Market.

Product Development/Innovation: Detailed insights on the upcoming technologies, R&D activities, and product launches in the market.

Competitive Assessment: In-depth assessment of the market strategies, geographic and business segments of the leading players in the market.

Market Development: Comprehensive information about emerging markets. This report analyzes the market for various segments across geographies.

Market Diversification: Exhaustive information about new products, untapped geographies, recent developments, and investments in the High Temperature Insulation Materials Market.

The following are the regions covered in this report.

North America [U.S., Canada, Mexico]

Europe [Germany, UK, France, Italy, Rest of Europe]

Asia-Pacific [China, India, Japan, South Korea, Southeast Asia, Australia, Rest of Asia Pacific]

South America [Brazil, Argentina, Rest of Latin America]

The Middle East & Africa [GCC, North Africa, South Africa, Rest of the Middle East and Africa]

Browse Trending Reports:

Multifunctional Food Ingredients Market Refractory Ceramic Fiber Rcf Market Packaged Water Treatment Market Employment Screening Services Market Irrigation Controller For Agriculture Market High Temperature Insulation Materials Market Angiographic Catheter Market Perfusion Systems Market Customized Wound Care Biologics Market Bathroom Toilet Assist Devices Market Protective Cultures Market Laser Eyewear Market Automotive Rain Sensor Market Uveitis Drug Market Nephrostomy Devices Market Battery Powered Electronic Control Unit Market Eye Melanoma Drug Market Eyelid Surgery Market Apraxia Drug Market Ethernet Storage Fabric Market

About Data Bridge Market Research:

Data Bridge set forth itself as an unconventional and neoteric Market research and consulting firm with unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market. Data Bridge endeavors to provide appropriate solutions to the complex business challenges and initiates an effortless decision-making process.

Contact Us:

Data Bridge Market Research

US: +1 614 591 3140

UK: +44 845 154 9652

Hong Kong: +852 8192 7475

Email: [email protected]"

0 notes

Text

Which type of material is used in muffle furnace?

1. Refractory Materials:

Refractory materials are the backbone of muffle furnaces, providing the necessary heat resistance and durability. Commonly used refractories include alumina, zirconia, and silicon carbide. Alumina is valued for its high melting point and thermal stability, making it ideal for furnaces operating at temperatures up to 1700°C. Zirconia is another excellent refractory material known for its low thermal conductivity and high resistance to thermal shock. Silicon carbide, with its exceptional thermal conductivity and ability to withstand temperatures up to 1600°C, is often used for muffle furnace linings and heating elements.

2. Insulation Materials:

Proper insulation is crucial to minimize heat loss and improve energy efficiency in muffle furnaces. Insulating materials such as ceramic fibers, insulating firebricks, and microporous boards are commonly used. Ceramic fibers offer low thermal conductivity and high-temperature stability, making them ideal for lining furnace walls. Insulating firebricks are lightweight and provide excellent thermal insulation, while microporous boards are known for their superior thermal performance and low thermal conductivity.

3. Heating Elements:

The heating elements in muffle furnaces are typically made from materials that can withstand high temperatures while providing consistent and efficient heating. Kanthal (iron-chromium-aluminum alloy) and Nichrome (nickel-chromium alloy) are widely used for heating elements due to their excellent electrical resistance and ability to operate at elevated temperatures. Molybdenum disilicide (MoSi2) is another material used in heating elements for furnaces requiring temperatures above 1800°C.

4. Structural Materials:

The external structure of muffle furnaces is usually constructed from stainless steel or mild steel, ensuring strength and durability. These materials provide structural support and protect the internal components from external environmental factors.

In summary, muffle furnaces rely on a combination of refractory materials, insulation, heating elements, and structural materials to achieve optimal performance and longevity. The careful selection and combination of these materials ensure the furnace can operate efficiently at high temperatures while maintaining safety and reliability.

Related Products:- High Temperature Furnace Muffle Furnace Programmable Furnace

For more Information:- Contact us:-+91–9278334734 Email:- [email protected] Address:- House №210, 1st Floor, Block-I, SDV Lakkarpur, Pole Factory, Faridabad, Haryana-121009, India.

#muffle furnace#muffle furnace manufacturer#muffle furnace manufacturer in india#muffle furnace supplier in india

0 notes