#flow control refractory

Explore tagged Tumblr posts

Text

TRL Krosaki: A Pioneer in Flow Control Plant Refractories

Flow control plants, essential components of steelmaking and other industrial processes, require specialized refractory materials to withstand the harsh conditions they encounter. TRL Krosaki, a leading refractories provider, has been a pioneer in developing and supplying high-quality refractory solutions for flow control plants in India.

The Role of Refractories in Flow Control Plants

In flow control plants, such as ladle furnaces, tundish, and caster, refractories play a critical role in:

Heat Insulation: Preventing heat loss and maintaining optimal operating temperatures.

Erosion Resistance: Protecting against the abrasive forces of molten metal and slag.

Corrosion Resistance: Withstanding the corrosive effects of chemicals and slag.

Thermal Shock Resistance: Handling rapid temperature fluctuations.

TRL Krosaki's Expertise

TRL Krosaki has a deep understanding of the unique requirements of flow control plants and has developed a range of specialized refractory products to meet these needs. Their expertise includes:

Ladle Refractories: Ladle linings must be durable, resistant to thermal shock, and able to withstand the high temperatures and corrosive nature of molten steel. TRL Krosaki offers a variety of ladle refractory materials, including firebricks, castables, and ramming mixes.

Tundish Refractories: Tundish linings are subjected to intense heat, erosion, and slag attack. TRL Krosaki provides high-quality tundish refractories that can withstand these harsh conditions and ensure smooth flow of molten steel.

Caster Refractories: Caster refractories must be able to withstand the abrasive forces of molten steel and the high temperatures of the casting process. TRL Krosaki offers specialized caster refractories that meet these demanding requirements.

Key Features of TRL Krosaki Refractories

High Temperature Resistance: TRL Krosaki refractories can withstand extreme temperatures, ensuring the efficient operation of flow control plants.

Durability: Their products are designed to be durable and long-lasting, reducing maintenance costs and downtime.

Corrosion Resistance: TRL Krosaki refractories are resistant to corrosion, preventing damage and ensuring the longevity of flow control plant components.

Thermal Shock Resistance: They can withstand rapid temperature fluctuations, which is essential for smooth operation.

Benefits of Using TRL Krosaki Refractories

Increased Efficiency: TRL Krosaki refractories can help improve the efficiency of flow control plants by reducing heat loss and downtime.

Reduced Costs: By providing durable and long-lasting refractories, TRL Krosaki can help reduce maintenance costs and improve overall profitability.

Improved Product Quality: High-quality refractories can contribute to the production of higher-quality steel products.

Conclusion

TRL Krosaki has established itself as a leading provider of refractory solutions for flow control plants in India. Their expertise, coupled with their high-quality products, has made them a trusted partner for many steelmakers. By using TRL Krosaki refractories, flow control plants can enhance their efficiency, reduce costs, and improve product quality.

0 notes

Text

Can TRL Krosaki Provide Customized Refractory Solutions for Unique Industrial Needs?

When it comes to the manufacturing of refractories, one size does not fit all. Industries have diverse needs based on their operations, and the performance of refractory materials is crucial to the efficiency and longevity of high-temperature processes. As one of the top refractories companies in India, TRL Krosaki understands this and offers highly customized refractory solutions tailored to unique industrial requirements.

Understanding Customized Refractory Solutions

Refractories are materials that can withstand high temperatures and harsh conditions. They are used in industries like steel, cement, glass, and many others. However, every industrial setup has its own challenges. Whether it’s the type of material processed, the temperatures involved, or the need for specific wear resistance, the refractories used must meet these challenges head-on.

TRL Krosaki specializes in designing and delivering customized refractory solutions for industries with unique needs. With decades of experience and a focus on research and development, TRL Krosaki has honed its ability to create products that fit precisely into the specific demands of its customers.

Customized Solutions for Different Industries

TRL Krosaki provides refractories tailored to a wide range of industrial applications. Some of the key sectors they serve include:

Steel Industry – Refractories play a critical role in the steel industry, especially in the flow control plant where molten steel is processed. TRL Krosaki offers customized refractory products that enhance the efficiency of steel manufacturing while ensuring the safety and longevity of equipment. Their refractory solutions are designed to handle extreme temperatures, chemical corrosion, and abrasion in the flow control plant, optimizing production.

Cement Industry – In cement manufacturing, refractories are crucial for maintaining high temperatures in kilns. TRL Krosaki tailors its refractories to ensure they last longer under the thermal stress in cement plants, reducing maintenance costs and enhancing productivity.

Glass and Ceramic Industries – High-quality refractories are essential in industries dealing with molten glass or ceramics. TRL Krosaki designs products that ensure minimal heat loss, optimize energy efficiency, and maintain structural integrity over time.

The Role of the Flow Control Plant in Customization

A flow control plant is an essential component in industries like steel manufacturing, where molten metal must be accurately and safely managed during production. In such plants, refractories are exposed to not only high temperatures but also physical wear and chemical interactions. This is where TRL Krosaki's custom refractory solutions come into play. By offering specialized refractories designed for such high-demand environments, TRL Krosaki ensures that flow control plants run more efficiently and with fewer disruptions.

These refractories are designed to meet the specific needs of a flow control plant:

Thermal Stability: Refractories must withstand extreme temperatures without degrading.

Chemical Resistance: In a flow control plant, refractories must resist chemical reactions with molten metal or other materials.

Durability and Wear Resistance: Given the high abrasion and mechanical stress, custom-designed refractories can extend the life of critical components like furnaces and ladles.

The Process of Customization

TRL Krosaki’s approach to providing customized refractory solutions involves several key steps:

Understanding the Specific Requirements: TRL Krosaki collaborates closely with clients to understand their specific needs, including operational conditions, temperatures, and any unique challenges they may face.

Material Selection: Based on the industry and specific application, TRL Krosaki selects the right combination of materials. Whether it’s high alumina, magnesia, or other specialized compositions, the company ensures that the refractories are tailored to meet the technical requirements of the client.

Engineering and Design: The company’s expert engineers design the refractory solutions, taking into account factors like thermal conductivity, wear resistance, and structural integrity under stress. The design phase is critical to ensuring the products are fit-for-purpose.

Testing and Quality Assurance: Before the custom refractories are deployed, TRL Krosaki conducts rigorous testing to ensure that the products meet industry standards and client specifications.

Installation and Support: TRL Krosaki’s involvement doesn’t end with the product delivery. The company offers full support during installation and provides ongoing maintenance services to ensure optimal performance.

Conclusion

TRL Krosaki has earned its reputation as a top refractories company in India by providing high-quality, customized refractory solutions to meet the unique needs of various industries. Whether it's improving the performance of a flow control plant in steel manufacturing or enhancing the longevity of kilns in the cement industry, TRL Krosaki’s expertise in tailoring refractories ensures maximum efficiency and reduced downtime.

Their commitment to research, innovation, and customer satisfaction makes them a leader in the industry. If you’re looking for customized refractory solutions that can handle the toughest industrial challenges, TRL Krosaki is the trusted partner you can rely on.

0 notes

Note

Hi! Sssoooo... remember the top/bottom headcannons you made? That wasn't fully complete cuz Obscuary hadn't been released? Is it a good time now? 👀👀 Where would you put Ed in the end? And if your opinion of Lyca and Rui has changed, of course!

re: top/bottom headcanons with the ghouls

I WAS ACTUALLY THINKING ABOUT THAT A LITTLE WHILE AGO thank you for stepping up anon lol

to recap what terms mean

Top - generally does or is most in control of the penetrating

Bottom - generally being penetrated or being ridden by the one being penetrated

Verse - top and/or bottom

Dom - generally leads and controls the interaction

Sub - generally is controlled and led throughout the interaction

Switch - dom and/or sub

Edward: His laziness makes him lean towards bottoming is still something I'd think, however. . .he's so openly horny and forward. I think if he were pursuing somebody, and he tends to be the one pursuing others with how forward he is, he'd be more dominant and prone to topping. He likes to give orders, tell them what to do to him, from undressing him to just how to pleasure him. . .he also likes to hear people out for what they want if he's fond of them himself. On the other hand, he's lazy, he's got chronic pain, and he'd be happy to lie back and be at somebody's mercy(y'know, until he's not and he wants control.) I think he's a solid verse switch, and it really depends on. . .damn near every factor out there. How much he likes you, how hungry he is, how much pain he's in, the season. . .he leans dom bottom though. Tops Lyca, would bottom to Rui and Towa.

Rui: I maintain what I said in my original post. Rui is very nervous about not touching his partners. He's more lax about it with Ed because Ed can't die, he just makes a big mess or is in a ton of pain--not to mention they live together so he gets careless in his own home. But Rui, while he's nervous and careful, would prefer to be in control just to have as much control and certainty regarding contact as possible. He's very flirty and open and forward, but it's all for the fun of the banter--the most they can do is play with toys and masturbate together and talk dirty, so things are very equal with him, but he tends towards dom top nonetheless. When he didn't have his reaper curse, he was still more of a dom top but that's because he's straight and thinks of that as the normal way of things. But he was more willing to experiment as well--why not if he got to be with someone attractive?--and he would be willing to sub too. Experiment with bottom if he really liked them. But oh man if you could fuck Rui even with his reaper curse. . .he could go for ages. All that energy he can't devote to something else, he'd cum once and he'd keep going. No refractory period either. Just orgasm after orgasm. He'd go hard, he'd go ham, he'd go until his partner needed to stop. But that's just imagination.

Lyca: I still maintain that his inexperience makes him a verse sub, but his boyish bravado means he tries to dom and top a lot too especially if he's challenged or praised. Not that he's bad at either one, but he's inexperienced and guided by canid instinct. He's comfortable being directed by a trusted leader, even if he isn't very good at following instruction if he doesn't understand it. He's very 'go with the flow' and he does whatever he wants and whatever feels right for him at the time, so while he leans submissive it depends on who he's with and how much he knows and trusts them--but oh boy this boy loves praise. He'll be desperate to do better if praised. Who bottoms and who tops is largely decided by the other party, unless he's feeling feisty and wants to try and 'fight' for it. The closer to the full moon or his rut(or god forbid both) however, the more aggressive his instincts make him and the more likely he is to want to top. . .he wants to be more dominant too, but he fears losing control if he has too much power, and it makes him somewhat prone to being more submissive.

16 notes

·

View notes

Text

Torn Between Love And Fear (A Scogan Fic)

*decked out in yellow spandex* I've written my first Scogan fic! I'm literally so excited; I'm in love love love with these guys, both as characters and as a ship, so I just couldn't help myself! It's a lil spicy but not in like a salacious way (I don't think), it's more along the line of how a couple who have been together for a while and are still incredibly hot for each other would be. It sort of flows between angsty and spicy, so strap yourselves in and get yourselves ready! Also, be prepared for both Logan and Scott to be pretty soft at times, because the peak Scogan dynamic is bickering and sniping but also totally committed and in love. Please don't yell at me for my depiction of whether or not Scott's laser eyes could kill Logan (told you there were angsty parts lol); I went with the level of regenerative ability in that scenario that I thought worked best with the story.

Read on and enjoy!

Logan pulled out of Scott, spent, and kissed the side of Scott’s neck with a grin. “That noise you were making? I’m gonna have to hear that again,” he whispered, his voice low and slightly hoarse with the remnants of desire. He cupped one hand around Scott’s face, running his thumb across Scott’s tightly-closed eyelid. If there was one thing he regretted, it was that he could never see what color his partner’s eyes were, or that they could never lock eyes in the heat of the moment and see in each other reflected passion and euphoria.

“Whatever you say, boss,” Scott replied, that sarcastic bite in his tone dulled by an affectionate smile. He reached towards the nightstand for his visor; it had been a bit of a battle to get him even to take that off, but Logan really did prefer to at least be able to kiss him where usually the visor would be.

Logan took the opportunity to trace a small bruised spot on the back of Scott’s shoulder. “See? This is why.” He’d dug his fingers into the skin there, utterly blissed out on the heady sounds Scott was making that were in a sweet spot between screaming and moaning.

Scott laughed, sliding the visor back on over his eyes. “Yes, because I want your dirty fingers leaving behind more of those.”

Wrapping his arms around Scott, Logan pressed his lips to the mark, just barely grazing it with his teeth in the process. “I know you do,” Logan said. It wasn’t the first, and it wouldn’t be the last, eagerly welcomed bruise left on Scott’s body from an amorous, if rough, touch.

Scott shivered, then swatted at Logan’s hands. “Babe,” he scolded. “Don’t mess with me like that. Just because you don’t have a refractory period—”

“Yeah, I know. I’m Superman.”

Scott rolled his eyes (it was one of his greatest annoyances that Logan couldn’t actually see it when he did that) and handed Logan his tank top. There was a hesitance in his movements that made Logan uncomfortable; he was sure he knew where this was headed, and he didn’t like it.

“Logan, let me sleep with you tonight,” Scott said.

“We’ve had this conversation before.” Logan pulled away from Scott, putting on his shirt. “I have nightmares. Sometimes I can’t control when my claws come out, it’s not safe for you to be here.”

“Every time I say ‘I trust you,’ ‘I love you,’ ‘You wouldn’t hurt me,’ and every time I have to give up and leave,” Scott said more insistently. “I do trust you, and I do love you, that’s true, but yes, you also might hurt me. And I don’t care. It isn’t enough for me to leave your room and sleep alone, when we’ve just been as close as two people can possibly be and I want to keep your arms around me.”

Logan shook his head, unable to meet Scott’s gaze. He still remembered, vividly, the time he’d almost killed Rogue because he’d been having a nightmare and stabbed her without knowing it—and worse, the moment he realized what he had done; the spots of blood on her clothes and the look of pain and betrayal in her eyes.

And, he harbored no illusions about it, she had only survived because she could steal his regenerative abilities and heal herself. Logan knew he wouldn’t be able to handle it if he accidentally stabbed Scott and had to watch as his partner, the man he loved most in the world, bled out on the sheets that had been so recently clenched in his fists.

“Scott, I…I can’t.”

They were always torn here, between Scott’s “Shouldn’t I be allowed to choose to risk it myself?” And Logan’s “I’m the one who would have to live with it.”

Scott turned Logan back to face him, his hands so gentle it made Logan shake. That was what he couldn’t lose. “Logan, every time I take my visor off, I could kill you—look at me, Logan, this is serious.” It was still hard to meet his stare, which had softened at the same time it had gotten firmer. “If I opened my eyes for a second you could die.” Logan's regenerative powers were impressive, but a point-blank laser blast to his upper body would still probably be the end of him.

“But,” Scott continued, “I go visorless anyway, because it’s important to you that you can see, and touch, all of me while we’re having sex. If we can take that chance, why not this one?”

“I love you,” was all Logan could come up with. I would rather die than let you was a hard thing to say.

“One night, Logan. At least give me one night.”

Logan caught Scott’s face between his hands and kissed him, so much more delicately and slowly than he had before. It felt like melting; like if they just lingered in that embrace for long enough they might become one and be unable to ever split themselves apart.

I want you. I love you. You’re pissing me off. These were all things Scott was used to feeling in Logan’s kisses. I’m afraid for you was not.

“If you really want me to go—”

“One night,” Logan broke in. “Maybe I can do that. Everything has a first step, right?”

“Thank you,” Scott said, shifting forward to straddle Logan’s lap. “You know how much this means to me.”

Logan moved his hands down to Scott’s waist, rubbing his hipbones to distract himself from the overwhelming sense of fear. “I have one condition. Non-negotiable.” “Name it, babe.”

“I’m not going to have my arms around you. Having my hands so close to your head or your chest would make it too easy to hurt you.”

“Deal.” Scott leaned forward to speak directly into Logan’s ear, his voice deep and incredibly warm. “I’m proud of you, Logan. And tomorrow morning, since I’ll already be here, I plan on showing you just how much I appreciate this in some very obscene ways.”

Logan groaned, pushing Scott off his lap with absolutely no grace. “If you’re going to complain about my refractory period—”

“You mean your lack of one,” Scott grumbled, pulling Logan down on top of him.

“Then don’t get me all excited when you and I can’t go together, asshole,” Logan finished.

Scott slowly took off his visor, setting it on the sheets off to the side. “I think tonight you’ve earned round two, if you’re gentle.” He laced his fingers together with Logan’s, guiding them up to trace the mark Logan had left earlier. “Well…gentle in some spots.”

“Obscene in others?”

Scott laughed, a much more sultry sound than Logan was used to laughter being. “Mark me up.”

Logan wanted little more than to thrust into Scott that minute, but he paused, hovering over Scott, studying the way the lines on his face became more apparent as he held his eyes carefully closed.

“I really do love you, Scott,” he said. “That you’re willing to do this for me, even if it scares you.”

“You know why I do?”

“I think I can guess.” Because Scott loved Logan the same way Logan loved him. Because it was the same reason Logan had agreed to let Scott sleep with him.

“Then shut up and take me, babe.”

#wooHOO y'all this was a blast to write#it combines two of my favorite things: angst (which I could not live without) and spiciness#hope I did my boys justice#Logan howlett#Scott summers#scogan#wolverine#cyclops#Scott x logan#Logan x scott#wolverine x cyclops#cyclops x wolverine#xmen#xmen movies#spicy#angst#fic#martianbugsbunny writes fic

46 notes

·

View notes

Text

Robust Growth Ahead for Metallurgical Additives Market Through 2031

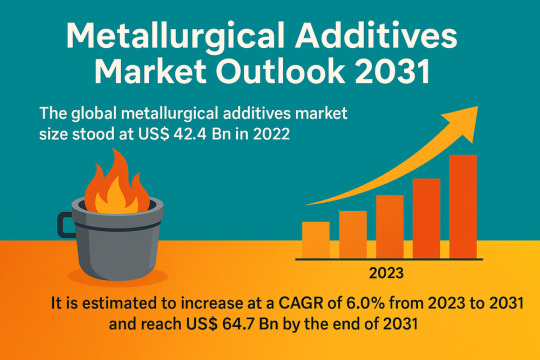

The global metallurgical additives market is poised for robust expansion, driven by increasing demand from steel, automotive, aerospace, and construction sectors. According to the latest industry research, the global metallurgical additives market size, which stood at US$ 42.4 billion in 2022, is projected to grow at a CAGR of 6.0% from 2023 to 2031, reaching a valuation of US$ 64.7 billion by the end of the forecast period.

Market Overview: Metallurgical additives are vital components in metal manufacturing processes, enhancing the mechanical, chemical, and thermal properties of base metals. These additives are used extensively in steelmaking, casting, and smelting to produce high-performance alloys suited for demanding industrial applications. Their usage is imperative in producing corrosion-resistant, high-strength materials required across the construction, automotive, and aerospace industries.

Market Drivers & Trends

The surge in demand for lightweight and durable components, especially in transportation and infrastructure development, has increased the reliance on enhanced alloys. This trend, coupled with the rapid pace of urbanization and industrialization, is bolstering the need for metallurgical additives.

Key drivers include:

The rise in global construction activity.

Increased demand for structural components in automotive and machinery manufacturing.

Technological advancements in metal refining and alloy development.

Shift toward high-efficiency, precision-engineered metal components.

Manufacturers are prioritizing cost-effective processes like sintering and thermal processing to enhance production efficiency, further fueling demand for quality metallurgical additives.

Latest Market Trends

Growth of additive manufacturing: Though still a niche within the metals industry, additive manufacturing is gaining traction due to its flexibility and efficiency. This technique, supported by metallurgical additives, enables rapid prototyping and complex design implementation.

Sustainability and green metallurgy: With increasing regulatory pressure and environmental concerns, the industry is adopting additives that promote eco-friendly steel and alloy production processes.

Customization and specialty alloys: Rising customization in metal compositions to meet specific performance criteria is driving R&D investment in innovative metallurgical additives.

Key Players and Industry Leaders

The global metallurgical additives market is highly consolidated, with key players accounting for over 80% of the total market share. These companies continue to lead in innovation, regional expansion, and sustainability initiatives.

Prominent players include:

Kerneos S.A.

Imerys Aluminates

Calucem GmbH

Almatis

Harsco Corporation

RHI Magnesita

Grecian Magnesite

Premier Periclase Ltd.

Magnesitas Navarras S.A.

Nedmag Industries Mining & Manufacturing B.V.

Others

These companies are enhancing their capabilities through acquisitions, R&D initiatives, and investments in manufacturing capacities across high-growth regions.

Recent Developments

RHI Magnesita announced in January 2023 the acquisition of a majority stake in Jinan New Emei Industries Co. Ltd. The deal is aimed at strengthening its steel flow control product portfolio and expanding its footprint in China and East Asia.

Imerys inaugurated a new manufacturing plant in Atchutapuram, India, in October 2022 with an annual capacity of 30,000 tons of calcium aluminate binders for the refractory and construction industries.

These developments signal a strong focus on regional expansion and product innovation to meet evolving customer needs.

Market Opportunities

Significant opportunities exist in:

Emerging economies: Rapid infrastructure development and increasing industrialization in Asia Pacific, Latin America, and parts of Africa present vast growth prospects.

High-performance alloy segments: Growing demand for specialized alloys in aerospace and defense sectors.

Eco-friendly metallurgy: Rising preference for additives that reduce environmental impact and energy consumption in metal processing.

Explore pivotal insights and conclusions from our Report in this sample - https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=85845

Future Outlook

Analysts foresee the metallurgical additives market evolving in alignment with industrial trends such as lightweighting in automotive, smart infrastructure, and sustainable manufacturing. The demand for performance-driven and application-specific additives will keep rising, pushing companies to innovate faster and expand regionally.

As industrial sectors aim for higher efficiency and precision, metallurgical additives will remain indispensable in achieving desired material characteristics across diverse end-use applications.

Market Segmentation

By Type:

Calcium Aluminate

Aluminum Silica Based Slag

Magnesia

Lime

Others

By Category:

Ferrous

Non-Ferrous

By End-use Industry:

Automotive

Aerospace

Electronics

Medical

Energy

Building & Construction

Others

Ferrous additives dominate the category segment, thanks to their widespread use in iron and steel manufacturing. Meanwhile, automotive and construction sectors lead among end-users due to their high volume consumption of refined steel and alloy products.

Regional Insights

Asia Pacific emerged as the dominant region in 2022, led by countries like China, India, and Japan. The region benefits from large-scale urbanization, growing population, and heavy investments in infrastructure.

China and India are experiencing increased per capita consumption of metallurgical additives due to rapid industrial expansion and growing steel production capacities.

North America and Europe remain key regions with strong demand in aerospace, automotive, and advanced manufacturing sectors. These regions are also pioneers in sustainable metallurgical practices, boosting demand for eco-friendly additives.

Emerging economies in Latin America and Africa offer untapped potential due to increasing construction activities and the presence of untapped mineral resources.

Why Buy This Report?

Comprehensive analysis of market trends, drivers, and growth forecasts

In-depth segmentation and regional outlook

Competitive landscape featuring leading global players

Insights into recent developments and future market strategies

Frequently asked questions and actionable recommendations for investors and stakeholders

Frequently Asked Questions

1. What is the market size of the metallurgical additives industry in 2022? The global market was valued at US$ 42.4 billion in 2022.

2. What is the projected market value by 2031? It is expected to reach US$ 64.7 billion by 2031, growing at a CAGR of 6.0%.

3. Which segment dominates the market? Ferrous additives dominate, primarily due to their widespread application in steelmaking.

4. Which region holds the largest market share? Asia Pacific, driven by demand from China, India, and Japan.

5. Who are the top players in the market? Major players include Kerneos S.A., Imerys Aluminates, Calucem GmbH, RHI Magnesita, and Harsco Corporation.

6. What are the key growth opportunities? Emerging markets, sustainable metallurgy, and additive manufacturing represent significant growth avenues.

7. Why are metallurgical additives important? They enhance the performance of base metals, making them more suitable for high-stress, high-performance applications in construction, automotive, and aerospace.

Explore Latest Research Reports by Transparency Market Research: Feed Intermediate Chemicals Market: https://www.transparencymarketresearch.com/feed-intermediate-chemicals-market.html

Automatic Plastic Recycling Market: https://www.transparencymarketresearch.com/automatic-plastic-recycling-market.html

Lipophilic Dyes Market: https://www.transparencymarketresearch.com/lipophilic-dyes-market.html

Low-carbon Monocrystalline Silicon Ingots Market: https://www.transparencymarketresearch.com/low-carbon-monocrystalline-silicon-ingots-market.html

About Transparency Market Research Transparency Market Research, a global market research company registered at Wilmington, Delaware, United States, provides custom research and consulting services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision makers. Our experienced team of Analysts, Researchers, and Consultants use proprietary data sources and various tools & techniques to gather and analyses information. Our data repository is continuously updated and revised by a team of research experts, so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports. Contact: Transparency Market Research Inc. CORPORATE HEADQUARTER DOWNTOWN, 1000 N. West Street, Suite 1200, Wilmington, Delaware 19801 USA Tel: +1-518-618-1030 USA - Canada Toll Free: 866-552-3453 Website: https://www.transparencymarketresearch.com Email: [email protected]

0 notes

Text

Advanced Industrial Heating Solutions from Heat Master International

Industrial Immersion Heaters Heat Master International's industrial immersion heaters are made for effective and direct liquid heating, such as water, oil, and chemical solutions. Crafted with superior materials and engineered components, the heaters provide fast heat transfer and extended service life. They find extensive applications in chemical processing, oil & gas, and manufacturing industries, delivering strong performance even under harsh conditions. Nozzle Heaters

Heat Master's nozzle heaters are specifically designed for plastic injection molding and extrusion applications. These versatile, high-performance heaters are designed for uniform heat distribution to ensure consistent melt flow and product quality. They come with the option for custom sizing and clamping systems to optimize heat transfer while saving energy and maintaining less. Gas-Fired Pit Furnace

Heat Master International's gas-fired pit furnaces are well-suited for heat treatment procedures such as annealing, tempering, and carburizing. With their durable construction and accurate temperature control, these furnaces provide durable performance in heavy-duty industry settings. With vertical loading, they are easy to handle and maximize space, thus making them a favorite among metallurgical and aerospace industries. Rotary Kiln Direct Firing

Heat Master International rotary kiln direct fired systems are designed for high-temperature thermal processing of material in industries including cement, lime, and refractory manufacturing. They offer even heat distribution, enhanced thermal efficiency, and lower fuel usage. They are built for long life and reliable operation to be a major factor in continuous, high-volume thermal processing. Roller Hearth Furnace

Heat Master roller hearth furnaces are used for continuous heat treatment of parts in the automotive, steel, and forging markets. They provide exact temperature uniformity, high throughput, and energy efficiency. Their modular construction and ability to automate make them well suited for high-volume production lines with constant and controlled heat requirement. Casting Heaters

Casting heaters provided by Heat Master International find application in die casting and molding processes where temperature uniformity is essential. These heaters are designed to endure high temperatures and are custom-sized to fit different mold shapes and sizes. Their high-thermal-response efficiency guarantees increased productivity and better casting quality. Ceramic Band Heaters

Heat Master ceramic band heaters are efficient heating elements for barrel and nozzle heating on plastic processing equipment. Constructed of top-grade ceramic insulation, the heaters have very good retention of heat and a uniform surface temperature. The heaters are suited for high-temperature applications where energy conservation and endurance are critical considerations. Duct Heaters

Heat Master International duct heaters are utilized to warm air or gas in HVAC and industrial drying applications. They come in electric and gas-fired versions and provide accurate temperature control, simple installation, and high efficiency. They are engineered to satisfy particular air flow and temperature needs in diverse industrial settings.

0 notes

Text

The stopper rod is a kind of shaped refractory material used in the production process of the continuous casting machine. It can ensure the stability of the liquid level of the crystallizer, control the linear flow rate of molten steel, and ensure the surface quality and internal quality of the ingot. In actual production, the stopper plays a vital role in the stability of steelmaking production. Problems with the stopper , such as erosion, fracture, nodule, etc., will cause excessive fluctuations in the liquid level of the molten steel in the crystallizer. In severe cases, the continuous casting machine will be shut down prematurely or forced to be pulled down.

#steelmill#steelindustry#steelmanufacturing#steelwork#steeltechnology#steelplant#steelmaking#LMMGROUP#products4steelmaking

0 notes

Text

Spheroidizing Methods for Ductile Iron: Techniques, Processes, and Best Practices!

Ductile iron, also known as nodular or spheroidal graphite iron, is widely used in industries requiring high strength, durability, and excellent machinability. The key to ductile iron's superior mechanical properties lies in the spheroidization process, which transforms graphite flakes into spheroidal nodules. This process enhances ductility, toughness, and resistance to impact, making ductile iron a preferred material for various applications, including automotive, construction, and pipeline systems.

This article explores the spheroidizing methods for ductile iron, detailing techniques, processes, and best practices to achieve optimal results in manufacturing.

Understanding Spheroidization in Ductile Iron

Spheroidization is the process of converting graphite flakes in cast iron into rounded nodules. This transformation is achieved by adding specific alloying elements, primarily magnesium (Mg), which prevents the formation of flaky graphite structures and promotes the development of spherical nodules.

Techniques for Spheroidizing Ductile Iron

There are several methods used to introduce magnesium or other nodularizing elements into the molten iron. The choice of method depends on factors such as furnace type, casting process, and production requirements. The most commonly used techniques include:

1. Magnesium Ladle Treatment

This is the most widely used method for spheroidization. The process involves placing a magnesium alloy inside a ladle before pouring the molten iron over it. The reaction between molten iron and magnesium releases gases and forms nodular graphite.

Advantages:

Suitable for large-scale production.

Provides consistent results.

Efficient in controlling magnesium content.

Challenges:

Requires precise control over magnesium addition.

Magnesium losses due to oxidation can affect efficiency.

2. In-Mold Process

In this technique, magnesium is introduced directly into the mold cavity before pouring molten iron. When the iron enters the mold, the magnesium reacts and forms nodular graphite.

Advantages:

Reduces magnesium fading since the reaction occurs just before solidification.

Minimizes oxidation losses.

Challenges:

Limited to specific casting applications.

Requires careful mold design.

3. Tundish Cover Method

In this process, molten iron flows through a tundish (a refractory-lined container) containing magnesium alloys before being poured into molds.

Advantages:

Ensures uniform magnesium distribution.

Reduces exposure to air, minimizing oxidation losses.

Challenges:

Requires specialized equipment.

Not ideal for small-scale production.

4. Cored Wire Injection

This method involves injecting a cored wire filled with magnesium into molten iron in a controlled manner. This technique allows precise control over magnesium content and reduces fading effects.

Advantages:

Highly efficient and precise.

Suitable for continuous casting and high-volume production.

Challenges:

Requires specialized equipment and automation.

Higher initial setup costs.

Processes Involved in Spheroidization

Regardless of the technique used, the spheroidizing process follows these key steps:

Preparation of Base Iron: Ensure the base iron has a low sulfur content (preferably below 0.02%) since sulfur reacts with magnesium and reduces spheroidization efficiency.

Addition of Nodularizing Agents: Magnesium, cerium, or other rare earth elements are introduced using one of the spheroidizing methods.

Inoculation: Inoculants such as ferrosilicon (FeSi) are added to promote graphite nodule formation and reduce undercooling.

Pouring and Solidification: The treated iron is poured into molds, where spheroidal graphite structures develop during solidification.

Quality Control: Microstructural analysis and mechanical testing ensure that the desired nodular graphite structure has been achieved.

Best Practices for Effective Spheroidization

To achieve optimal spheroidization in ductile iron production, consider the following best practices:

Control Sulfur Content: Low sulfur levels improve magnesium absorption and prevent unwanted reactions.

Optimize Magnesium Addition: Use the right amount of magnesium to avoid excess fading or excessive reactions leading to high porosity.

Ensure Proper Inoculation: Adequate inoculation promotes uniform graphite distribution and prevents carbide formation.

Monitor Temperature Control: The ideal treatment temperature should be maintained to ensure complete magnesium reaction and nodule formation.

Use High-Quality Raw Materials: Impurities in the raw materials can impact graphite morphology and mechanical properties.

Conduct Regular Testing: Microstructural examination and mechanical testing help verify the effectiveness of the spheroidizing process.

Conclusion

Spheroidization is a crucial step in the production of ductile iron, directly influencing its mechanical properties and performance. Various spheroidizing methods such as magnesium ladle treatment, in-mold processes, tundish cover methods, and cored wire injection offer unique benefits depending on production requirements. By following best practices, manufacturers can achieve high-quality ductile iron with excellent strength, ductility, and durability.Understanding and implementing the right spheroidizing techniques ensures consistent and reliable production, making ductile iron a preferred choice across industries. With continuous advancements in metallurgy and foundry technology, spheroidizing methods will continue to evolve, enhancing efficiency and product performance.

#SpheroidizationProcess#SpheroidizingMethodsForDuctileIron#SpheroidizingTechniques#CoredWireInjection

0 notes

Text

How to Maintain Your Brick Kiln for Longevity

Brick kilns are an essential part of the brick manufacturing process, crucial for producing durable and high-quality bricks used in construction, paving, and other applications. However, these kilns undergo extreme temperatures, wear, and tear. To ensure that your brick kiln remains efficient and continues producing quality bricks for years to come, proper maintenance is key. A well-maintained kiln can not only extend its lifespan but also improve its energy efficiency, reduce downtime, and lower operating costs.

Here Kailash Bricks provide a comprehensive guide on how to maintain your brick kiln for longevity.

Regular Inspection and Monitoring Regular inspections are the first line of defense in identifying issues before they escalate into major problems. Conducting thorough and routine checks at specific intervals can help ensure your kiln is functioning optimally.

Check for cracks and leaks: Over time, the brick structure of the kiln may develop cracks, which could lead to heat loss or affect the quality of the firing process. Inspect the kiln walls, roof, and floor for any signs of damage. Monitor kiln temperature: Consistent temperature control is crucial for firing bricks properly. Install temperature sensors and ensure that the kiln’s internal temperature stays within the required range. Sudden temperature fluctuations or inconsistent heat distribution can affect the quality of the bricks. Inspect the burners and fuel supply system: Ensure the burners are operating correctly and that there are no fuel blockages or leaks in the fuel system, whether gas, coal, or other fuel sources are used. Cleaning the Kiln A clean kiln ensures efficient operation, better heat retention, and reduced chances of failure due to debris or material buildup.

Clean the flue and chimney: The flue and chimney are vital parts of the kiln’s exhaust system. Over time, ash and soot can accumulate, obstructing airflow and reducing the kiln’s efficiency. Regularly clean these areas to prevent any blockages and ensure proper ventilation. Remove ash and debris: Ash buildup can interfere with airflow and even clog burners, reducing the effectiveness of the kiln. After each firing cycle, thoroughly clean the fireboxes and other components where ash tends to accumulate. Maintain clean fuel feed lines: For coal or biomass-fired kilns, the fuel feed lines can become blocked over time due to ash and other impurities. Keep these lines free of obstructions for smooth fuel flow and consistent burning. Refractory Maintenance The refractory lining inside the kiln is designed to withstand high temperatures, but it can deteriorate over time, leading to reduced efficiency and potential damage to the kiln’s structure. Proper refractory maintenance is essential to maintaining high kiln performance.

Inspect the refractory lining: Regularly check the integrity of the refractory lining inside the kiln. Look for signs of wear, cracking, or erosion. If you notice any damaged areas, they should be repaired or replaced immediately to prevent further damage to the kiln. Rebuild the refractory lining periodically: Depending on the intensity of use, the refractory lining may need to be rebuilt every few years. Rebuilding ensures that the kiln can maintain the necessary heat retention levels without wasting energy. Fuel Efficiency and Proper Combustion Improper combustion can lead to excessive fuel consumption, lower firing temperatures, and increased emissions. Efficient combustion is essential for kiln longevity and reducing operational costs.

Check the air-to-fuel ratio: An ideal air-to-fuel ratio is necessary for efficient combustion. An incorrect ratio can result in incomplete combustion, leading to excess soot, smoke, and waste. Ensure that the burner settings are optimized for the specific type of fuel used. Fuel quality: Use high-quality, clean fuel to avoid blockages and to ensure efficient burning. Impurities such as moisture or foreign particles in the fuel can damage kiln components and reduce firing efficiency. Maintain a steady fuel supply: Ensure that the fuel supply to the kiln is constant and consistent. Fluctuations in fuel delivery can disrupt the firing cycle and affect the kiln’s performance. Kiln Door and Ventilation Maintenance The kiln door and ventilation system play a crucial role in regulating airflow, controlling temperature, and maintaining efficient firing. Properly maintained doors and ventilation systems help prevent heat loss and improve overall efficiency.

Inspect the kiln door: The kiln door should be tightly sealed to prevent heat loss. Over time, the door may warp or become damaged, compromising its seal. Inspect the door regularly and replace any worn-out seals or gaskets. Check ventilation openings: Adequate ventilation is necessary to remove excess heat and gases. Inspect the vents and make sure they are free from obstructions to allow smooth airflow. Proper ventilation also helps prevent the build-up of harmful gases, which can affect the quality of the bricks. Kiln Firing Cycle Optimization An efficient firing cycle is vital to the longevity of your kiln. An optimized firing cycle reduces stress on the kiln structure, minimizes fuel consumption, and ensures consistent brick quality.

Avoid overfiring or underfiring: Overfiring can damage the kiln and increase wear and tear, while underfiring can result in poorly fired bricks. Carefully monitor the firing process and adhere to the optimal temperature curves. Proper loading and unloading: Ensure that the kiln is properly loaded and unloaded to maximize heat circulation and minimize uneven firing. Improper loading can lead to inefficient heating, longer firing times, and uneven brick quality. Proper Maintenance of Electrical and Mechanical Components A brick kiln often relies on various electrical and mechanical systems, including fans, temperature controllers, and motors. Maintaining these components is crucial for the smooth operation of the kiln.

Regularly check electrical systems: Inspect the wiring, connections, and electrical components to ensure there are no loose connections or signs of wear. Faulty electrical systems can lead to equipment failure, which may result in costly repairs and downtime. Monitor mechanical systems: Fans, motors, and other mechanical systems must be regularly lubricated and maintained to prevent mechanical failure. Check for unusual noises, vibrations, or overheating, which could indicate mechanical issues. Training and Operator Maintenance Operators play a key role in maintaining a kiln’s longevity. Proper training and awareness can help prevent human error, optimize kiln operations, and reduce wear on components.

Operator training: Train kiln operators on proper loading/unloading techniques, firing schedules, and safety procedures. Knowledgeable operators are essential for the efficient operation of the kiln. Document and track maintenance: Keep detailed records of all maintenance activities, including inspections, repairs, and parts replacements. This documentation will help you track the kiln’s performance over time and anticipate when certain components may need replacing. Energy Efficiency and Emission Control Kilns are energy-intensive operations, so maintaining energy efficiency is crucial for both environmental and cost-saving purposes.

Install insulation: Ensure that the kiln is properly insulated to prevent heat loss. Insulation helps retain the necessary temperature and reduces fuel consumption. Emission control systems: Check the emission control systems to ensure they are functioning effectively. This includes filters, scrubbers, or other systems designed to reduce harmful emissions from the kiln. Maintaining a brick kiln for longevity requires consistent care, attention to detail, and proactive planning. By regularly inspecting the kiln, maintaining its components, and optimizing operations, you can significantly extend the life of your kiln and improve its performance. A well-maintained brick kiln will operate more efficiently, reduce energy costs, and produce high-quality bricks for years to come. Additionally, by investing time and resources into maintenance, you protect your business from costly repairs, minimize downtime, and contribute to a more sustainable operation.

#kailash bricks#best bricks manufacture in haryana#facing bricks#anya mouthwashing#agatha all along#3 hole brick#3 hole bricks#extruded brick

0 notes

Text

TRL Krosaki – Pioneering Innovation and Excellence in the Refractories Industry

When it comes to delivering high-performance refractories, few companies stand out like TRL Krosaki. With decades of experience and a commitment to continuous innovation, TRL Krosaki has earned its place as The top refractories company in India and a global leader in the field. Among its numerous achievements, the company’s expertise extends to state-of-the-art technologies like the flow control plant, which plays a pivotal role in ensuring the highest quality of refractories for industries worldwide.

What Makes TRL Krosaki the Top Refractories Company in India? TRL Krosaki’s unwavering commitment to excellence and cutting-edge technology sets it apart from other players in the refractories industry. As The top refractories company in India, TRL Krosaki has revolutionized the industry with its ability to manufacture products that stand the test of time and meet the ever-growing demands of various sectors, including steel, cement, and glass production.

The company’s track record of delivering durable and efficient refractories is complemented by its dedication to research and development. By integrating the latest technologies and leveraging deep industry knowledge, TRL Krosaki continues to redefine what’s possible in the refractories world.

Flow Control Plant – A Game Changer in Refractory Technology At the heart of TRL Krosaki’s technological advancement is the flow control plant, a facility that plays a crucial role in ensuring the precision and reliability of their products. The flow control plant is a key component that enables TRL Krosaki to produce refractories that offer enhanced performance in high-temperature environments. This facility allows for the controlled flow of molten metals, ensuring optimal quality and superior consistency for customers across a wide range of industries.

The flow control plant offers several key benefits that contribute to TRL Krosaki’s leadership in the refractories market:

Enhanced Product Quality: The plant ensures that molten metal flows smoothly and consistently, allowing for the production of high-quality refractory products with exceptional strength and durability.

Precision Manufacturing: The controlled environment provided by the flow control plant ensures that every batch of refractory materials is precisely formulated, meeting the stringent requirements of industries such as steel manufacturing and metallurgy.

Operational Efficiency: By streamlining the production process, the flow control plant reduces waste and increases operational efficiency, resulting in cost-effective solutions for clients.

Sustainability: The plant's design and operation prioritize eco-friendly processes, reducing energy consumption and minimizing environmental impact.

Innovation and Sustainability: A Winning Combination What truly sets TRL Krosaki apart as The top refractories company in India is its balance between innovation and sustainability. The company continually invests in advanced technologies like the flow control plant to ensure that its products not only meet the highest standards of performance but also adhere to environmentally responsible practices.

By focusing on sustainable manufacturing processes and eco-friendly products, TRL Krosaki contributes to a greener future while maintaining its reputation for unmatched quality. Whether it’s reducing carbon emissions or improving energy efficiency, the company’s sustainable approach is a key part of its strategy to stay ahead in the competitive global refractories market.

Conclusion: As The top refractories company in India, TRL Krosaki has set the bar for excellence in the refractories industry. The integration of cutting-edge technologies like the flow control plant exemplifies the company’s commitment to quality, innovation, and sustainability. Whether you’re in the steel, cement, or glass industry, TRL Krosaki continues to be the trusted partner for all your refractory needs.

Stay tuned to see how TRL Krosaki will continue to lead the way with pioneering solutions and unmatched expertise, making a difference in industries worldwide.

About TRL Krosaki: TRL Krosaki is a leading manufacturer of high-quality refractories, catering to various industries, including steel, cement, and non-ferrous metals. With a legacy of over 50 years, the company operates world-class manufacturing facilities and is committed to delivering innovative, sustainable, and reliable solutions to its clients across the globe. As a part of the Krosaki Harima Corporation, Japan, TRL Krosaki remains a global leader in the refractories industry.

For more information about our products and services, visit www.trlkrosaki.com.

0 notes

Text

Burner blocks are critical components in various industrial processes that involve high temperatures. These specialized blocks are engineered to withstand extreme heat, ensuring efficient and reliable operation of industrial furnaces, kilns, and other high-temperature equipment.

Key Functions of Burner Blocks:

Heat Distribution: Burner blocks are designed to direct and distribute heat evenly within the combustion chamber, optimizing the heating process.

Durability: Constructed from refractory materials, they can withstand high temperatures, thermal shock, and corrosive environments.

Protection: They shield surrounding structures from the intense heat generated during combustion.

Efficiency: Well-designed burner blocks contribute to efficient fuel combustion, reducing energy consumption and minimizing emissions.

Common Applications:

Glass Manufacturing: Controlling the precise heating and cooling of molten glass.

Metal Smelting: Directing the flow of hot gases for efficient metal melting and refining.

Ceramic Firing: Ensuring uniform heat distribution for optimal firing of ceramic products.

Industrial Boilers: Supporting efficient combustion and heat transfer in boilers.

Key Considerations for Burner Block Selection:

Temperature Requirements: The block must be able to withstand the maximum operating temperature of the process.

Chemical Compatibility: The material should be resistant to chemical attack from combustion products and other substances.

Thermal Shock Resistance: The block must be able to withstand rapid temperature changes without cracking or fracturing.

Wear Resistance: The block should be durable enough to resist erosion and wear from the combustion process.

By understanding the critical role of burner blocks in high-temperature applications, industries can optimize their processes, improve efficiency, and reduce environmental impact.

0 notes

Text

Aluminosilicate Prices: Trend | Pricing | News | Price | Database

Aluminosilicates Prices a group of minerals widely used in various industries, are experiencing dynamic shifts in pricing trends driven by market demand, supply constraints, and technological advancements. These minerals, comprising aluminum, silicon, and oxygen, play a vital role in sectors such as construction, petrochemicals, ceramics, and environmental applications. The market for aluminosilicates is influenced by their diverse applications, particularly in producing zeolites, refractories, and catalysts. Zeolites, one of the most prominent products derived from aluminosilicates, are highly sought after in water treatment, detergents, and petrochemical refining, making their demand a significant driver of aluminosilicate prices globally.

The aluminosilicate market is shaped by several key factors, including raw material availability, production costs, and regulatory policies. Natural aluminosilicates, such as feldspar and kaolin, are mined in specific geographic regions, creating regional price disparities. Additionally, synthetic aluminosilicates, which are engineered for high purity and specific applications, often carry a premium price due to their complex manufacturing processes. Rising energy costs have also contributed to fluctuating prices, as aluminosilicate production is energy-intensive, particularly in synthesizing zeolites and manufacturing ceramics. These cost pressures are exacerbated by global inflationary trends, impacting the overall pricing landscape.

Get Real time Prices for Aluminosilicates: https://www.chemanalyst.com/Pricing-data/aluminosilicate-1518

The construction industry's growing demand for lightweight and durable materials has significantly contributed to the increased consumption of aluminosilicates. As a result, prices have risen steadily, especially in markets like Asia-Pacific, where rapid urbanization and infrastructure development are driving demand. Aluminosilicates are integral to manufacturing high-strength ceramics and refractories, crucial for construction projects requiring thermal and mechanical stability. With nations prioritizing sustainable and long-lasting construction practices, the demand for these minerals is expected to remain robust, further influencing their market valuation.

Environmental regulations and sustainability concerns have also played a pivotal role in shaping aluminosilicate prices. Industries are increasingly adopting zeolite-based solutions for applications such as air purification, water treatment, and carbon capture, owing to their eco-friendly properties. As governments and organizations push for stricter emission control measures, the demand for zeolites has surged, creating upward pressure on aluminosilicate prices. Furthermore, advancements in green chemistry and circular economy practices have encouraged the development of innovative aluminosilicate applications, such as in renewable energy technologies, thereby expanding their market scope and influencing pricing dynamics.

The aluminosilicate market is also impacted by global trade dynamics and geopolitical factors. Disruptions in supply chains, trade tariffs, and export restrictions in key aluminosilicate-producing countries can lead to price volatility. For example, the availability of raw materials like feldspar and kaolin, primarily sourced from regions such as China, India, and Brazil, is subject to mining regulations and environmental policies in these countries. Any changes in these policies can significantly alter the supply-demand equilibrium, affecting prices worldwide. Similarly, geopolitical tensions can disrupt trade flows, leading to temporary shortages and price spikes in import-dependent regions.

Technological advancements and innovations in manufacturing processes have provided some relief in controlling production costs and stabilizing prices. For instance, modern methods of synthesizing zeolites and other high-performance aluminosilicates have enabled producers to achieve better efficiency and consistency. However, these advancements require substantial capital investment, which is often reflected in the product's final price. The ongoing research into optimizing aluminosilicate applications across industries, such as improving their catalytic efficiency in petrochemical processes or enhancing their durability in ceramics, also adds to the pricing considerations as manufacturers seek to recover R&D expenses.

Regional markets exhibit varying trends in aluminosilicate prices, influenced by local demand patterns, industrial growth, and resource availability. In North America and Europe, where environmental regulations are stringent, the demand for high-purity aluminosilicates, particularly zeolites, is high. This demand has supported steady price growth, especially in applications related to emission control and water purification. Conversely, in developing regions like Asia-Pacific, the market is driven more by the construction and ceramics industries, with prices reflecting the growing consumption of raw aluminosilicates. The Middle East and Africa, though smaller in market share, are witnessing increased demand for aluminosilicates in petrochemical refining, supported by regional oil and gas activities.

The future of aluminosilicate prices is expected to be influenced by global megatrends such as sustainability, digitalization, and urbanization. The transition towards renewable energy and green technologies is likely to amplify the demand for zeolites, especially in hydrogen production and carbon capture systems. Similarly, the growing emphasis on sustainable urban development will continue to drive demand for durable and eco-friendly construction materials, ensuring a steady market for aluminosilicates. However, challenges such as resource depletion, rising energy costs, and geopolitical uncertainties could pose risks to price stability in the coming years.

In conclusion, the aluminosilicate market is characterized by its complexity and responsiveness to diverse factors, ranging from industrial demand and environmental regulations to technological advancements and geopolitical dynamics. Prices are likely to remain dynamic, reflecting the interplay of these forces in a rapidly evolving global landscape. Businesses and stakeholders in the aluminosilicate industry must stay attuned to these trends, adapting their strategies to navigate challenges and capitalize on emerging opportunities in this critical market segment.

Get Real time Prices for Aluminosilicates: https://www.chemanalyst.com/Pricing-data/aluminosilicate-1518

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

#Aluminosilicate#Aluminosilicate Price#Aluminosilicate Prices#Aluminosilicate Pricing#Aluminosilicate News#Aluminosilicate Price Monitor#Aluminosilicate Database

0 notes

Text

Powder Metallurgy Market - Forecast(2024 - 2030)

Powder Metallurgy Market Overview

Request Sample Report :

COVID-19 Impact

The onset of Covid-19 in the entire nation had a negative impact on the automotive industry. There was an overall revenue impact across the automotive industry. The pandemic also impacted all the stakeholders present in the value chain for the short as well as medium term. Shortage of raw material, shifting of production to other countries, liquidity crunch to delays in availability of models, deferred launches, and shrinkage in consumer demand were some of the main issues faced by the automotive stakeholders, owing to which the production and demand of automobiles had significantly fallen. For instance, according to the China Passenger Car Association (CPCA), China’s passenger car sales in June fell 6.5% year on year to 1.68 million units. The unstable automotive production and demand have significantly impacted the market of powder metallurgy as the demand for powder metal was also uncertain during the period. A prolonged truncation of consumer demand due to the lockdown has significantly affected auto manufacturers’ revenues and cash flows. Even after the restriction is eased in 2021, with discretionary spending taking a backseat, further declines in the market for passenger vehicles are expected.

Powder Metallurgy Market Report Coverage

The report: “Powder Metallurgy Market — Forecast (2021–2026)”, by IndustryARC, covers an in-depth analysis of the following segments of the powder metallurgy Industry.

By Material: Ferrous (Iron, Steel, and Stainless Steel), Non-Ferrous (Copper, Aluminium, Cobalt, Tin, Nickel, Magnesium, Zinc, Titanium, Molybdenum, and Others By Process: Conventional Process, Metal Injection Moulding, Hot Isostatic Pressing, and Metal Additive Manufacturing By Application: Porous Products, Bearing and Bushes, Filters (Ceramic Filter, Fiber Metal Filter, and Others), Refractory Metal Composites, Electric Motors, Cemented Carbides, Machinery Parts (Gears, Sprockets, Rotors, and Others), Tungsten Wires, Medical Implants, Magnetic Materials, Cutting Tools and Dies, and Others By End-Use Industry: Medical & Healthcare, Automobile (Transmission, Engine Parts, and others), Oil & Gas, Electrical and Electronics (Refrigerators, Vacuum Cleaners, Circuit Breakers, Electric Motors, Sewing Machines, and Others), Industrial (Hydraulics, Motors/Controls, and Others), Aerospace (Aero-engine, Land-based Gas Turbine, Airframes, and Others), Household Appliances, Recreation and Leisure, and Others By Geography: North America (USA, Canada, and Mexico), Europe (UK, Germany, France, Italy, Netherlands, Spain, Russia, Belgium, and Rest of Europe), Asia-Pacific (China, Japan, India, South Korea, Australia and New Zealand, Indonesia, Taiwan, Malaysia, and Rest of APAC), South America (Brazil, Argentina, Colombia, Chile, and Rest of South America), Rest of the World (Middle East, and Africa)

Inquiry Before Buying :

Key Takeaways

Asia-Pacific dominates the powder metallurgy market, owing to the increasing demand and production of lightweight vehicles in the region. For instance, according to OICA, the production of passenger cars has increased by 2.6 % in Malaysia in 2019.

There are many cases in which powder metallurgy over casting has a strong benefit. The benefits of the powder metallurgy process are particularly apparent when dealing with high-value and high-melting-point materials, owing to which there is increasing adoption of powder metallurgy over die casting, which will propel the market growth.

There are growing interests in producing customized medical implants using additive manufacturing and in producing porous implant structures (to match bone stiffness and to aid osteointegration) by powder metallurgy processing, which may boost the market growth.

For More Details on This Report — Request for Sample

Powder Metallurgy Market Segment Analysis — By Material

The ferrous segment held the largest share in the powder metallurgy market in 2020. Ferrous powdered metals such as iron, steel, and more offer the highest level of mechanical properties. Ferrous metal powders are also known for their extensive characteristics such as durability, hardness, tensile strength, lower costs, broad flexibility, and more. The ferrous powdered metal is largely employed in the automotive industry for designing bearings, gears, or other auto parts, owing to its good strength and flexibility. Furthermore, ferrous metals are also widely utilized in various other end-use industries such as construction, piping, aerospace, electronics, and more. Thus, it is anticipated that these extensive characteristics and wide applications of ferrous powder metallurgy are the major factors driving its demand during the forecast period.

Powder Metallurgy Market Segment Analysis — By Application

The bearings segment held the largest share in the powder metallurgy market in 2020 and is growing at a CAGR of 7.4% during 2021–2026, owing to its self-lubricating property. Bearings that are made from powder metallurgy are known as self bearings of sintered metal. They are economical, suitable for high production rates, and precision tolerances can be produced. The majorities of porous-metal bearings consist of either bronze or iron with pores that are interconnected. These voids take up 10 percent of the total volume to 35 percent. In operation, lubricating oil is deposited in these voids and feeds to the bearing surface through the interconnected pores. Sintered-metal self-lubricating bearings are widely used in home appliances, small motors, machine tools, aircraft, and automotive accessories, business machines, instruments, and farm and construction equipment, owing to which it holds a prominent share in the powder metallurgy application segment.

Schedule A Call :

Powder Metallurgy Market Segment Analysis — By End-Use Industry

The automotive segment held the largest share in the powder metallurgy market in 2020 and is growing at a CAGR of 8.6% during 2021–2026. Powder metal parts display excellent controlled porosity and self-lubricating properties that allow gases and liquids to be filtered. Powder metallurgy is also a strongly recommended method in the manufacture of components involving complex bends, depressions, and projections. Flexibility in the development of mechanical parts of different compositions, such as metal-non-metal and metal-metal hybrids, allows high dimensional precision in the production of automobile parts and ensures consistent properties and measurements with very little scrap and waste of material. The most popular vehicle parts that are manufactured through the method of powder metallurgy are the bearings and gears. A variety of metals, including ferrous, and non-ferrous are used in automotive components including chassis, steering, exhaust, transmission, shock absorber parts, engine, battery, seats, air cleaners, brake disc, and more. The powder metallurgy is often used in these components as it improves the net shape, utilizes heat treatment, enhances surface treatment, and improves the precision of these components. Thus, the demand for powder metallurgy in the automotive sector is growing due to such factors.

Powder Metallurgy Market Segment Analysis — By Geography

Asia-Pacific region held the largest share in the powder metallurgy market in 2020 up to 45%, owing to the increasing automotive manufacturing coupled with population growth in the region. China is the world’s largest vehicle market, according to the International Trade Administration (ITA), and the Chinese government expects automobile production to reach 35 million by 2025. In 2019, according to OICA, the automotive production in Malaysia and Vietnam has increased up to 571632, and 250000, i.e., 1.2%, and 5.5%. India’s annual production in 2019 was 30.91 million vehicles, according to Invest India, compared to 29.08 million in 2018, recording a healthy 6.26 percent growth. Also, by 2026, the US$118 billion Indian car industry is projected to cross US$300 billion. The increasing automation production in the Asia Pacific will eventually boost the demand for powder metallurgy to manufacture various automobile components, which will likely influence the growth of the powder metallurgy market in the APAC region.

Powder Metallurgy Market Drivers

Flourishing Aerospace Industry

Powder metallurgy is used extensively in aerospace, because of its advantages of high strength/weight ratio, high heat capacity, and high modulus of elasticity. Within aerospace, powder metallurgy finds its most significant application in turbine engines, compressors, fan sections, discs, airframes, fasteners, and landing gear. Tungsten metallurgy based tungsten carbide has received considerable attention in the aerospace industry because of its high strength at very high temperatures. Tungsten carbide is sintered through a selective laser sintering process based on the additive manufacturing process. In 2019, China was the second-largest civil aerospace and aviation services market in the world and one of the fastest-growing markets, according to the International Trade Administration (ITA). China will need 7,690 new aircraft over the next 20 years, valued at US$1.2 trillion, according to Boeing (Commercial Market Outlook 2018–2037). China also currently accounts for 15 percent of the world’s commercial aircraft fleet, and it will be almost 20 percent by 2037. According to Boeing, the demand for 2,300 airplanes worth US$320 billion is projected in India over the coming 20 years. Boeing’s current market outlook (BMO) forecasts demand for 2,520 new aircraft in the Middle East by 2030. With the flourishing aerospace industry, the demand for aircraft components will also gradually increase, which will drive the market growth.

Buy Now :

Expanding Electrical and Electronics Sector

The powder metallurgy method offers the opportunity to cost-effectively produce net form components from a variety of materials. A market segment that has exhibited the ability to take advantage of powder metallurgy’s flexibility has been in electromagnetic applications such as household appliances, industrial applications, and more. Magnetic materials are essential elements in the electronic industry in recent times. From the motors and turbines that provide the power for the industry to the high-frequency transformers that power computers, magnetic materials are becoming increasingly important for consumers. The electronic sector is booming in various regions, which will further drive the market growth as there is an increasing demand for powder metallurgy from the electrical and electronics sector. For instance, the consumer electronics and appliances sector in India is expected to become the fifth-largest in the world by 2025, according to Invest India. India could create an US$800 billion to US$1 trillion digital economy by 2025, and India’s digital economy could fuel 18–23 percent of overall economic activity by 2025. According to the Government of Canada, revenues in the ICT sector reached an estimated US$210 billion in 2019. ICT sector revenues grew from US$158 billion to US$200 billion from 2013 to 2018, a 26.9 percent increase.

Powder Metallurgy Market Challenges

Various Drawbacks Associated with Powder Metallurgy

The cost of metal powders compared to the cost of raw material used for casting or forging a component is relatively higher. At the time the cost of tooling and equipment is also higher. When production volumes are limited, this is especially a limitation. Also, low melting point metal powders such as zinc, tin, and cadmium give thermal difficulties during sintering operation, as most oxides of these metals cannot be reduced at temperatures below the melting point. Furthermore, large or complex-shaped parts, and uniformly high — density products are difficult to produce by the powder metallurgy process. Without any degradation, a few powders are also difficult to store. All these drawbacks associated with the powder metallurgy may hinder the market growth during the forecast period.

Powder Metallurgy Market Landscape

Technology launches, acquisitions, and R&D activities are key strategies adopted by players in the powder metallurgy market. Major players in the powder metallurgy market are Arcam AB, Carpenter Technology Corp., ExOne GmbH, GKN Plc, Höganäs AB, Materialize NV, Melrose Industries PLC, Sumitomo Electric Industries, Ltd., and Hitachi Chemical Co., Ltd.

Acquisitions/Technology Launches

In May 2019, Epson Atmix Corp. installed a new production line at its Kita-Inter Plant in Japan for producing amorphous alloy powder. The company invested around ¥800 million (USD 7.43 million) for the installation of a new line and it plans to further increase its production capacity in stages and reach 6,000 tons per year by 2023.

In October 2019, GKN Powder Metallurgy a leading metal powder and parts manufacturers acquired specialist polymer 3D printing service provider Forecast 3D. The acquisition presents a significant expansion of GKN powder metallurgy’s additive capabilities.

Relevant Reports

Powder Coatings Market — Forecast (2021–2026)

Report Code: CMR 0113

Ferromanganese Market — Forecast (2021–2026)

Report Code: CMR 0382

For more Chemicals and Materials Market reports, please click here

#PowderMetallurgy#Metalworking#AdvancedManufacturing#PowderMetals#AdditiveManufacturing#MetalPowder#IndustrialMaterials

1 note

·

View note

Text

Top Applications of Talc Powder and How to Source It

Talc powder, a naturally occurring mineral, is a versatile substance widely used in various industries. Talc's special qualities make it a useful element in a variety of products, including paints, ceramics, plastics, cosmetics, and medications. If you’re in search of a dependable provider of talc powder, understanding its applications and attributes is crucial to guarantee you deal with the proper source.

What is Talc Powder?

A soft, hydrous magnesium silicate mineral, talc is prized for its lubricating qualities and smooth texture. It takes on a soft, silky consistency when processed into talc powder, which is perfect for a variety of commercial and industrial uses.

Among the special qualities of talc are:

Softness: Talc is perfect for applications needing lubrication and smoothness because it is the softest mineral on the Mohs scale.

Thermal Stability: Talc is an essential ingredient in ceramics and polymers because of its ability to tolerate high temperatures.

Chemical Inertness: Talc is chemically stable, ensuring its compatibility with many substances.

Absorbency: It is useful in cosmetics and personal care products because of its capacity to absorb moisture and oils.

Applications of Talc Powder Because of its special qualities, talc powder is widely used in many different industries. Here’s a peek at its key applications:

1. Cosmetics and Personal Care

A common ingredient in cosmetics is talc. Its softness, absorbing characteristics, and smooth texture make it a perfect ingredient in cosmetics such as baby powders, face powders, and eye shadows. It improves product performance by giving it a smooth feel and aiding in the absorption of oil and moisture.

2. Medicines