#IoT in Factory Automation

Explore tagged Tumblr posts

Text

IoT in Factory Automation

IoT in Factory Automation is revolutionizing industrial operations by connecting machines, sensors, and systems to enable real-time data exchange and intelligent decision-making. By integrating the Internet of Things (IoT), factories can monitor production processes remotely, predict equipment failures, and optimize resource utilization. This leads to improved efficiency, reduced downtime, and enhanced overall productivity.

0 notes

Text

Smart Factories Need Smart Data: Leveraging Real-Time Analytics for Operational Excellence

Unlock the value of live data for faster decisions, smoother workflows, and a more responsive shop floor. Drowning in Data, Still Lacking Clarity? All of the machines, sensors, and control systems across your shop floor are generating data. That is not the problem. The actual problem? To take that constant, flowing stream and make it something your team can actually act upon—now. That’s…

#Factory Automation#Industrial IoT#Manufacturing Data#Operational Excellence#Secondary Keywords (Short-Tail): Smart Factory

0 notes

Text

Explore how manufacturing, electronics, and robotics have transformed mankind—from early automata and industrial machinery in the 1950s to today's smart factories, AI-powered robots, and space exploration. Learn how innovations like CNC machines, pick-and-place electronics robots, surgical bots, and Mars rovers increased productivity, safety, and scientific discovery, playing a pivotal role in human progress and future advancements.

#Manufacturing programs#Manufacturing Electronics History#The role of robots in human evolution#Industrial automation impact#CNC and robotics evolution#pick-and-place electronics robots#Smart factories IoT#Surgical robots' benefits#Mars rover robotics#Electronics and human progress

0 notes

Text

The ROI of IoT in Factory Automation: Is It Worth the Investment?

0 notes

Text

The Industrial IoT Revolution: Market Forecast and Leading Players to Watch in 2023–2031

Industrial IoT Market Report: Growth, Trends, and Future Outlook

The Industrial Internet of Things (IIoT) represents a transformative wave in industrial operations, leveraging the power of connected devices, sensors, and advanced analytics to optimize processes, improve efficiency, and unlock new business opportunities. IIoT connects machines, devices, sensors, and systems to collect and analyze data in real time, enabling industries to achieve smarter decision-making, reduce operational costs, and enhance productivity.

The global Industrial IoT (IIoT) market was valued at USD 334.53 billion in 2022 and is projected to reach USD 2,916.21 billion by 2031, growing at an impressive CAGR of 27.2% during the forecast period (2023–2031). This rapid growth highlights the increasing demand for IoT-enabled technologies across various industrial sectors, making IIoT a vital part of the digital transformation process in manufacturing, supply chains, and infrastructure.

Request a Free Sample (Free Executive Summary at Full Report Starting from USD 1850): https://straitsresearch.com/report/industrial-iot-market/request-sample

Key Trends in the Industrial IoT Market

Increased Adoption of Smart Manufacturing: Manufacturers are embracing IIoT for process automation, predictive maintenance, real-time monitoring, and supply chain optimization. This trend is expected to continue as more companies focus on reducing downtime and improving product quality through connected devices.

Advancements in Edge Computing and AI Integration: The rise of edge computing is reducing latency, enabling faster data processing at the source. Integrating AI and machine learning with IIoT systems allows industries to gain insights from real-time data, improving decision-making capabilities.

Focus on Cybersecurity: As the number of connected devices increases, so does the potential vulnerability to cyberattacks. Ensuring robust cybersecurity measures within IIoT systems is becoming a top priority for businesses.

5G Connectivity: The rollout of 5G technology is enhancing the capabilities of IIoT by offering faster and more reliable communication between connected devices. This enables applications that require low latency, such as autonomous vehicles and real-time remote monitoring.

Sustainability and Energy Efficiency: Industries are increasingly adopting IIoT technologies to improve energy efficiency, reduce emissions, and support sustainability goals. Sensors and data analytics enable more efficient resource management, leading to reduced waste and energy consumption.

Industrial IoT Market Size and Share

The IIoT market is witnessing substantial growth across various regions, driven by technological advancements, an increasing number of connected devices, and the need for automation. The major industrial sectors benefiting from IIoT include manufacturing, energy, automotive, pharmaceuticals, and more. Businesses are investing heavily in IIoT to streamline their operations, reduce operational costs, and ensure more efficient use of resources.

The market is also being driven by increasing government initiatives aimed at fostering smart city projects, digital infrastructure, and sustainable industrial practices. As industries continue to digitize their operations, the demand for IIoT solutions is poised to grow exponentially.

Buy Full Report (Exclusive Insights with In-Depth Data Supplement): https://straitsresearch.com/buy-now/industrial-iot-market

Industrial IoT Market Statistics

The global market value was USD 334.53 billion in 2022.

The market is expected to grow to USD 2,916.21 billion by 2031, with a CAGR of 27.2% during the forecast period (2023–2031).

North America holds a significant share of the market, driven by the adoption of advanced industrial technologies and the presence of key players like Cisco, IBM, and Honeywell.

Asia Pacific (APAC) is expected to witness the highest growth due to rapid industrialization, increasing investments in smart factories, and government support for smart manufacturing initiatives.

Regional Trends and Impact

North America: The North American region, particularly the United States and Canada, dominates the global IIoT market due to a robust manufacturing base, the presence of key technology companies, and early adoption of IoT-enabled technologies. The region’s focus on automation, smart factories, and energy efficiency has led to a high demand for IIoT solutions.

Asia Pacific (APAC): APAC is expected to witness the fastest growth in the IIoT market, primarily driven by the increasing industrialization in countries like China, Japan, and India. The region's push towards smart manufacturing, government initiatives supporting industrial automation, and rapid adoption of advanced technologies like AI, robotics, and 5G are propelling the growth of the IIoT market.

Europe: Europe is another key region for IIoT, driven by strong industrial sectors such as automotive, chemicals, and energy. The European Union’s focus on Industry 4.0 and digital transformation is increasing the demand for IIoT technologies across manufacturing, energy, and logistics.

LAMEA (Latin America, Middle East, and Africa): While still a developing market, the LAMEA region is showing significant potential for IIoT growth, especially in industries such as oil and gas, utilities, and agriculture. Increased investment in infrastructure and digitalization is expected to drive the demand for IIoT solutions in these regions.

Industrial IoT Market Segmentation

By Offering

Hardware:

Industrial Robots: These robots are essential for automating repetitive tasks in industries such as manufacturing and automotive, improving efficiency and reducing errors.

Industrial PC: Industrial PCs are used for data processing, monitoring, and control in industrial environments.

Industrial Sensors: Sensors play a critical role in collecting data from machines and devices to monitor conditions like temperature, pressure, and vibration.

Distributed Control System (DCS): DCS solutions enable centralized control of industrial processes, helping manage large-scale production systems.

Smart Meters: Smart meters are essential for monitoring and managing energy consumption in industries, contributing to energy efficiency.

Human Machine Interface (HMI): HMIs provide a visual interface for operators to interact with industrial control systems.

Control Devices: Devices that help regulate and control industrial processes, ensuring smooth operations.

Software: Software solutions in IIoT are used for data collection, processing, analytics, and visualization. These software tools enable industries to derive actionable insights from the vast amount of data generated by IIoT devices.

Services:

Training & Consulting Services: These services help organizations integrate IIoT technologies into their existing systems and operations.

Support and Maintenance Services: These services ensure that IIoT solutions continue to operate efficiently and without disruption.

By Connectivity

Wired Connectivity:

Ethernet: Provides high-speed, reliable data transmission for industrial applications.

Fieldbus: Used in process control systems for connecting field devices and control systems.

Wireless Connectivity:

Wi-Fi, Bluetooth, Cellular Connectivity, Satellite Connectivity: Wireless connectivity solutions offer flexibility and scalability for IIoT applications, especially in large industrial environments.

By End-use Industry

Aerospace and Defense

Automotive

Chemicals

Energy & Power

Food & Beverage

Metal and Mining

Oil & Gas

Pharmaceutical

Semiconductor & Electronics

Others (Healthcare, Water & Wastewater, etc.)

Each of these industries is increasingly adopting IIoT technologies to improve operational efficiency, ensure product quality, reduce costs, and enhance safety.

Market Segmentation with Insights-Driven Strategy Guide: https://straitsresearch.com/report/industrial-iot-market/segmentation

Top Players in the Industrial IoT Market

Several companies are leading the way in the IIoT market, providing innovative solutions and services:

Huawei Technology Co., Ltd.

Cisco

General Electric

Schneider Electric

Rockwell Automation

ABB

Texas Instruments

Honeywell

IBM

KUKA AG

NEC Corporation

Bosch

Siemens AG

SAP

Endress+Hauser

Accenture PLC

STMicroelectronics

These companies are at the forefront of developing and implementing IIoT solutions, helping industries to leverage IoT technologies for better efficiency, safety, and profitability.

Table of Contents for the Industrial IoT Market Report: https://straitsresearch.com/report/industrial-iot-market/toc

Conclusion

The Industrial IoT market is experiencing rapid growth as industries worldwide adopt connected devices, advanced analytics, and automation to enhance productivity, reduce costs, and improve decision-making. With significant investments in IIoT infrastructure, the market is poised to expand substantially in the coming years, especially in sectors such as manufacturing, energy, automotive, and pharmaceuticals. As technologies like AI, 5G, and edge computing continue to evolve, the potential for IIoT to drive industrial transformation will only increase, presenting enormous opportunities for businesses and industries to embrace the future of connected manufacturing and operations.

About Straits Research

Straits Research is a leading provider of market research and intelligence services. With a focus on high-quality research, analytics, and advisory, our team offers actionable insights tailored to clients’ strategic needs.

Contact Us Email: [email protected] Address: 825 3rd Avenue, New York, NY, USA, 10022 Tel: UK: +44 203 695 0070, USA: +1 646 905 0080

#Industrial IoT#IIoT#Industrial Internet of Things#Smart Manufacturing#IoT Market Growth#Industry 4.0#Automation#Connected Devices#Predictive Maintenance#Smart Sensors#Edge Computing#Industrial Robotics#Market Research#IoT Solutions#5G Connectivity#IIoT Market Trends#Global Market Forecast#Honeywell#Cisco#Siemens#IIoT Adoption#Digital Transformation#Smart Factories#Industrial Automation#Market Segmentation#Straits Research

0 notes

Text

Interwork Software Solutions provides comprehensive Industry 4.0 solutions, integrating advanced technologies like IoT, AI, blockchain, and data analytics to enhance operational efficiency, drive automation, and support digital transformation across industries, fostering sustainable, smart, and connected business ecosystems.

0 notes

Text

Why Industrial Edge Computing is Important for Building Maximally Efficient Factories

Industrial Edge computing ensures that data can be captured, managed, analyzed, and immediate decisions can be made in real time at a standalone device, and that data that is no longer needed can be discarded at the end of the process, or portions of the data can be transferred to the cloud for storage and analysis.

The key to smart factories is data integration and real-time communication, and edge computing simplifies the process of data collection, processing, and analysis, and enables rapid and controlled decision-making, making it the key to highly automated and maximally efficient smart factories.

What are the main benefits of edge computing in industrial applications?

Improve Process Efficiency

Low latency, high bandwidth edge computing speeds up the process of downloading and analyzing data, allowing each data point to process its own information. Data is available and actionable in real-time, EdgeCOM enables real-time decision making and immediate action, and the ability to optimize data and analyze complex data sources with the "always-on" EdgeCOM integration can take the quality of industrial processes to the next level.

Data Security

The proximity of edge computing and data sources reduces data risks during transmission and ensures strong network security. The data is partially processed in EdgeCOM, not all transferred to the cloud platform through the network. Cyber attacks will not have a chance to destroy the whole network, which ensures the system's stable operation to a certain extent.

Reduce Costs

Not all data needs to be sent to the cloud. Leaving some of the data at the edge and discarding it when it is finished being processed, and transmitting only a portion of it to the cloud, can reduce the costs associated with cloud servers and data transfer functions. Edge computing can also minimize network latency and make critical control applications more connected.

Flexible Management

Supports a variety of development tools and programs for customized functions and remote maintenance, allowing for more flexible management and processing of data.

#iot devices#iot solutions#industrial automation#datasecurity#Building Maximally Efficient Factories

0 notes

Text

CNC Press Brake Machine in India: Shaping the Future of Metal Bending

In the dynamic world of metal fabrication, CNC Press Brake Machines have become indispensable. These machines are critical in industries that demand precision bending and forming of sheet metal components. In India, the rising focus on infrastructure development, automotive manufacturing, and localized production has driven the adoption of CNC press brake technology across various sectors.

From small workshops to large-scale factories, CNC press brakes are revolutionizing how Indian manufacturers handle metal forming—efficiently, accurately, and consistently.

What is a CNC Press Brake Machine?

A CNC (Computer Numerical Control) Press Brake Machine is used to bend and shape metal sheets with precision. It uses a punch and die to perform various bends, guided by a CNC system that ensures exact specifications for angle, length, and repetition.

Modern CNC press brakes are far more advanced than traditional mechanical or hydraulic versions. They come with programmable controls, automated back gauges, and advanced sensors to deliver high-speed and high-precision bending.

Why CNC Press Brakes are Gaining Popularity in India

1. Precision and Consistency

In sectors like automotive, aerospace, and electronics, even minor deviations in part dimensions can lead to quality issues. CNC press brakes eliminate human error and ensure consistent output across batches.

2. Growing Industrialization

India’s expanding industrial base, especially in Tier 2 and Tier 3 cities, is fueling demand for reliable fabrication equipment. CNC press brakes allow businesses to scale up production without compromising on accuracy.

3. Labour Efficiency

With a skilled labor shortage and rising wages, automation is becoming more attractive. CNC press brakes require minimal human intervention, reducing labor costs and dependency on manual operators.

4. Government Incentives

Government initiatives like Make in India and Production Linked Incentive (PLI) Schemes are encouraging manufacturers to invest in advanced machinery, including CNC press brakes, for higher productivity.

Key Features of CNC Press Brake Machines in the Indian Market

High-Tonnage Capability: Machines ranging from 30 to 1000+ tons to suit various applications.

CNC Control Systems: Brands like Delem, ESA, and Cybelec offer intuitive interfaces for programming and automation.

Servo-Electric or Hydraulic Drive Systems: Depending on precision, energy efficiency, and speed requirements.

Multi-Axis Back Gauge: Enables complex bends and reduces setup time.

Automatic Tool Changers (ATC): For higher production environments.

Leading Indian and International Brands

India has a strong presence of both domestic and international CNC press brake manufacturers. Some notable names include:

Hindustan Hydraulics

Electropneumatics

Energy Mission

LVD India

Amada (Japan)

Durma (Turkey)

Yawei (China)

These companies offer machines tailored to the needs and budget of Indian manufacturers.

Applications in India

Automobile Body & Chassis Manufacturing

Kitchen Equipment Fabrication

Electrical Enclosures & Cabinets

Elevator and Escalator Components

Construction and Infrastructure Products

Railways and Defence Equipment

Challenges for Indian Buyers

High Initial Investment: CNC press brakes can be capital intensive, though the ROI is excellent over time.

Skill Development: Operators need training to use CNC systems effectively.

After-Sales Service: Choosing a vendor with reliable local support is crucial for maintenance and uptime.

The Road Ahead: Smart Factories & Industry 4.0

India is steadily moving towards smart manufacturing. CNC press brakes are now integrating with IoT, ERP systems, and robotic automation, enabling real-time monitoring, predictive maintenance, and remote troubleshooting. This evolution is making Indian factories more agile and globally competitive.

Conclusion

The CNC Press Brake Machine is no longer a luxury—it's a necessity in modern Indian manufacturing. With its unmatched accuracy, efficiency, and automation capabilities, it empowers businesses to meet rising customer expectations while optimizing operational costs.

As India continues to climb the global manufacturing ladder, CNC press brake machines will play a pivotal role in shaping the future—quite literally.

2 notes

·

View notes

Text

IoT in Factory Automation

The integration of IoT in Factory Automation is revolutionizing industrial operations by enabling real-time data collection, seamless communication, and intelligent decision-making. Oracle Robotics leverages IoT technology to enhance connectivity between machines, systems, and operators, ensuring optimized efficiency and predictive maintenance. With IoT-driven automation, factories can achieve smarter workflows, reduced downtime, and greater productivity. Trust Oracle Robotics to bring the power of IoT to your factory, paving the way for Industry 4.0 transformation.

1 note

·

View note

Text

Top 10 Pneumatic Actuator Brands In 2025

The pneumatic actuator market continues to thrive in 2025, driven by advancements in automation and industrial efficiency. Based on comprehensive evaluations by CN10/CNPP research departments, which integrate big data analytics, AI-driven insights, and market performance metrics, here are the leading brands shaping the industry.

1. SMC (SMC Corporation)

Performance & Reliability: As a global leader since 1959, SMC delivers over 10,000 pneumatic components, including high-precision cylinders, valves, and F.R.L. units. Its products are renowned for durability, energy efficiency, and adaptability to extreme industrial conditions. Industry Applications: Widely used in automotive manufacturing, semiconductor production, and robotics, SMC’s actuators ensure seamless automation across 80+ countries. Its China-based facilities, established in 1994, serve as a primary global production hub.

2. FESTO (Festo AG & Co. KG)

Performance & Reliability: With nearly a century of expertise, Festo combines innovative engineering with IoT-enabled solutions. Its actuators emphasize precision control, low maintenance, and compatibility with smart factory ecosystems. Industry Applications: Festo dominates sectors like pharmaceuticals, food processing, and renewable energy, offering customized automation systems that enhance productivity and sustainability.

Other Notable Brands In The 2025 Rankings

While SMC and Festo lead the list, the following brands also excel in specific niches:

Brand A: Specializes in compact actuators for medical devices.

Brand B: Focuses on heavy-duty applications in construction machinery.

Brand C: Pioneers eco-friendly designs with reduced carbon footprints.

Key Trends Driving Market Growth

Smart Automation: Integration of AI and real-time monitoring in actuator systems.

Sustainability: Energy-efficient designs aligned with global decarbonization goals.

Customization: Tailored solutions for niche industries like aerospace and biotechnology.

This ranking underscores the critical role of innovation and adaptability in maintaining competitive advantage. Brands that prioritize R&D and cross-industry collaboration are poised to lead the next decade of pneumatic automation.

If you want to learn more about low-priced products, please visit the following website: www.xm-valveactuator.com

2 notes

·

View notes

Text

𝐇𝐨𝐰 𝐀𝐈 𝐚𝐧𝐝 5𝐆 𝐀𝐫𝐞 𝐓𝐫𝐚𝐧𝐬𝐟𝐨𝐫𝐦𝐢𝐧𝐠 𝐁𝐮𝐬𝐢𝐧𝐞𝐬𝐬 𝐆𝐫𝐨𝐰𝐭𝐡 | 𝐓𝐡𝐞 𝐅𝐮𝐭𝐮𝐫𝐞 𝐨𝐟 𝐈𝐧𝐧𝐨𝐯𝐚𝐭𝐢𝐨𝐧

The fusion of AI and 5G is revolutionizing businesses worldwide. With ultra-fast connectivity and real-time data analytics, companies are unlocking new opportunities for efficiency, automation, and customer engagement.

Learn how AI and 5G work together to:

Enhance real-time decision-making

Improve IoT connectivity for smart industries

Power AI-driven automation and predictive analytics

Personalize customer experiences like never before

From smart factories to AI-powered healthcare, discover how these technologies are shaping the future of business. Don't miss out—watch now - https://youtu.be/w1nDoqzVj0g

Follow for more tech insights.

#ai#5g#businessgrowth#innovation#futuretech#iot#automation#digitaltransformation#smarttechnology#bigdata

2 notes

·

View notes

Text

How 5g Technology Change The World

The world is getting ready to a technological revolution, and on the coronary heart of this alteration is 5G era. As the 5th generation of mobile networks, 5G guarantees extremely-speedy speeds, low latency, and extraordinary connectivity. This advancement is ready to reshape industries, improve every day existence, and create new opportunities across more than one sectors. From healthcare and transportation to entertainment and clever towns, 5G isn't always simply an upgrade; it's miles a catalyst for a brand new virtual generation.

what is 5g and how it works

The Fundamentals of 5G Technology

5G era is designed to provide extensively faster information speeds than its predecessor, 4G LTE. It operates on three special spectrum bands:

Low-band spectrum – Provides broad coverage however with highly slower speeds.

Mid-band spectrum – Offers a balance between pace and insurance.

High-band spectrum (millimeter-wave) – Delivers extremely fast speeds but has confined range.

With information speeds attaining up to 10 Gbps, 5G networks will enable seamless connectivity, permitting gadgets to communicate in actual-time with minimum delay (latency as little as one millisecond). This bounce in community functionality will pave the manner for improvements that had been previously impossible.

Transforming Industries

1. Healthcare

5G technology is revolutionizing the healthcare industry through allowing faraway surgical procedures, telemedicine, and real-time affected person tracking. With ultra-low latency and high-speed connectivity, surgeons can perform robotic surgical procedures from different elements of the world, expanding get admission to to existence-saving techniques. Additionally, 5G allows for stepped forward records transfer between clinical devices, ensuring timely prognosis and higher affected person care.

2. Smart Cities and Infrastructure

5G is a key aspect inside the improvement of smart towns. By connecting billions of gadgets through the Internet of Things (IoT), 5G lets in for efficient visitors management, smart lighting, and waste management structures. Autonomous motors will gain from actual-time verbal exchange with traffic indicators and different cars, reducing injuries and improving traffic waft. Cities will become more sustainable, energy-green, and safer for citizens.

Three. Manufacturing and Automation

The manufacturing quarter is undergoing a transformation with the appearance of 5G. Smart factories prepared with AI-powered robots and IoT gadgets will operate with minimum human intervention. Predictive renovation powered by means of real-time records will reduce downtime and decorate productiveness. Augmented fact (AR) and virtual reality (VR) packages will streamline employee education and improve efficiency on manufacturing unit flooring.

4. Entertainment and Media

The enjoyment industry is also experiencing a shift with 5G generation. High-definition streaming, cloud gaming, and immersive AR/VR reviews becomes the norm. With minimal buffering and high-speed connectivity, customers can enjoy seamless content intake. Additionally, 5G allows real-time interaction in stay events and esports, offering a more engaging experience for audiences worldwide.

5. Education and Remote Work

5G is gambling a crucial function inside the evolution of schooling and far off work. Virtual lecture rooms, interactive gaining knowledge of modules, and terrific video conferencing are becoming greater accessible. Students in faraway regions can advantage from advanced internet connectivity, bridging the virtual divide. Businesses, however, can put into effect flexible paintings models with uninterrupted video calls and faster cloud get entry to, boosting productivity and performance.

The Impact of 5G on Everyday Life

Beyond industries, 5G will significantly enhance normal reviews. Smart houses prepared with 5G-enabled IoT devices will provide better safety, energy management, and comfort. Personal assistants, consisting of AI-powered voice assistants, will become extra responsive and intuitive. Augmented fact packages will remodel purchasing experiences with the aid of allowing consumers to visualise products earlier than buying.

Moreover, the gaming industry will see a shift in the direction of cloud gaming platforms, wherein high-cease gaming reports are handy with out the need for steeply-priced hardware. With decreased latency, multiplayer gaming will become smoother, allowing gamers to compete in real time with minimal disruptions.

Challenges and Concerns

While the advantages of 5G are plain, there also are demanding situations that need to be addressed. Some of the key concerns consist of:

Infrastructure Development – The deployment of 5G calls for a big funding in new infrastructure, including small cell towers and fiber-optic networks.

Security and Privacy – With accelerated connectivity comes the hazard of cyber threats. Ensuring sturdy safety features is essential to shield user statistics and prevent cyberattacks.

Health Concerns – There have been debates regarding the capability fitness risks associated with 5G radiation. However, clinical research have now not observed conclusive proof linking 5G to health troubles.

Digital Divide – While urban areas may enjoy fast 5G adoption, rural and underserved areas may additionally face delays in deployment, probably widening the virtual divide.

The Future of 5G

The destiny of 5G era seems promising as countries and agencies continue to invest in its improvement. With advancements in artificial intelligence, side computing, and quantum computing, 5G will release even more opportunities. The transition to 6G in the coming years will in addition push the limits of connectivity, making futuristic concepts consisting of holographic verbal exchange and brain-computer interfaces a fact.

Affordable smartphones with best camera reviews

2 notes

·

View notes

Text

The Need for Digitization in Manufacturing : Stay Competitive With Low-Code

Industry 4.0 is transforming manufacturing with smart factories, automation, and digital integration. Technologies like the Internet of Things (IoT), artificial intelligence (AI), and low-code applications are enabling manufacturers to streamline processes and develop customized solutions quickly. Low-code platforms empower manufacturers to adapt to global demands, driving efficiency and innovation.

Previously, cross-border transactions in manufacturing faced delays due to bureaucracy, complex payment mechanisms, and inconsistent regulations. These challenges led to inefficiency and increased costs. However, Industry 4.0 technologies, such as digital payments, smart contracts, and logistics tracking, have simplified international transactions, improving procurement processes.

Low-code applications are key in this transformation, enabling rapid development of secure solutions for payments, customs clearance, and regulatory compliance. These platforms reduce complexity, enhance transparency, and ensure cost-effective, secure global supply chains. This shift aligns with the demands of a connected global economy, enhancing productivity and competitiveness.

The Need for Digitization in Manufacturing

Digitization has become crucial for manufacturing to stay competitive, with new technologies and the need for automation driving the sector’s transformation. Key features include ERP systems for centralized management of inventory, finances, and operations; digital supply chain tools for visibility and disruption prediction; real-time data for performance monitoring; sustainability tracking; and IoT/RFID for better tracking, accuracy, and reduced waste.

Low-code applications play a pivotal role in digitization by enabling rapid development of tailored solutions for inventory management, supply chain optimization, and performance analytics. These platforms streamline processes, reduce manual work, and enhance agility, helping manufacturers implement digital transformations quickly and cost-effectively.

Upgrading Manufacturing Capabilities in the Era of Industry 4.0 with Low-code Solutions

Low-code applications are becoming essential for digital transformation in manufacturing, addressing operational challenges while managing increased production demands and a shortage of skilled staff. These platforms enable manufacturers to quickly develop tailored applications without needing specialized coding expertise, fostering faster, more flexible operations. By streamlining processes and aligning with modern consumer demands, low-code technology helps bridge the skills gap, empowering manufacturers to stay competitive and seize new opportunities in a rapidly evolving market.

Low-code Technology Benefits for Modern Industries

As digital transformation becomes increasingly crucial for manufacturing, many enterprises in the sector face challenges with outdated processes, legacy system limitations, customization challenges, and inadequate resources. Low-code applications offer a compelling solution, enabling manufacturers to streamline operations by eliminating paper-based processes and automating workflows across functions such as Production, Sales, Logistics, Finance, Procurement, Quality Assurance, Human Resources, Supply Chain, and IT Operations. Additionally, low-code platforms enhance compliance and safety standards through built-in automated tools.

These platforms deliver impressive results, including over 70% improvement in productivity and close to 95% improvement in output quality in specific scenarios. This is particularly evident in automating complex processes like order fulfillment—from receiving customer orders to delivering finished products and managing invoicing with customers. Use cases also include automating inventory management, enhancing predictive maintenance with real-time data, and optimizing supply chain operations. Low-code solutions make it easier for manufacturers to implement changes quickly, boosting agility and reducing time-to-market while improving overall operational efficiency.

Conclusion

Low-code platforms are driving digital transformation in manufacturing, addressing sector-specific challenges in industries like automotive, aviation, and oil & gas. With Industry 4.0 and smart manufacturing, iLeap’s low-code platform helps integrate IoT, advanced analytics, and end-to-end automation, leading to optimized workflows and real-time decision-making. By adopting agile development, manufacturers can quickly adapt to new technologies and market demands, making iLeap the ideal partner for digital transformation. Unlock the potential of Industry 4.0 with iLeap and turn challenges into growth opportunities.

3 notes

·

View notes

Text

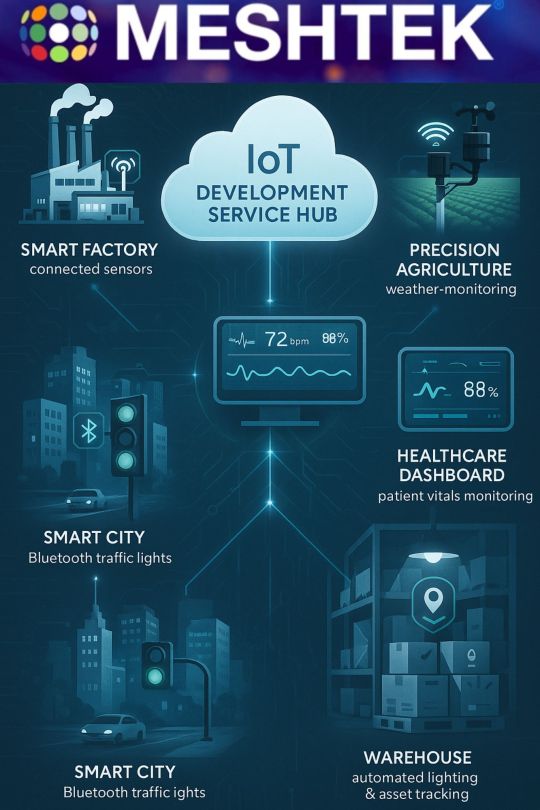

Unified IoT Development Services Powering Smart Infrastructure with MeshTek

Step into the future with MeshTek’s cutting-edge IoT development service that seamlessly connects and automates critical sectors. From precision agriculture and smart factories to Bluetooth-enabled smart cities, healthcare dashboards, and intelligent warehouses — this powerful cloud-based platform ensures everything is connected, efficient, and secure. Designed for scalability and real-time responsiveness, MeshTek delivers reliable IoT solutions for modern infrastructure needs.

#IoTDevelopmentService#MeshTek#SmartInfrastructure#IoTSolutions#BluetoothMeshNetworking#SmartCitySolutions#ConnectedDevices#IoTPlatform#IndustrialAutomation#PrecisionAgriculture#HealthcareIoT#WarehouseAutomation#SmartFactory#IoTInnovation#MeshNetworking

1 note

·

View note

Text

Edge Computing Market Disruption: 7 Startups to Watch

Edge Computing Market Valuation and Projections

The global edge computing market is undergoing a transformative evolution, with projections estimating an edge computing market size escalation from USD 15.96 billion in 2023 to approximately USD 216.76 billion by 2031, marking a compound annual growth rate (CAGR) of 33.6%. This unprecedented trajectory is being driven by rising demand for real-time data processing, the proliferation of Internet of Things (IoT) devices, and the deployment of 5G infrastructure worldwide.

Request Sample Report PDF (including TOC, Graphs & Tables): https://www.statsandresearch.com/request-sample/40540-global-edge-computing-market

Accelerated Demand for Real-Time Data Processing

Edge computing is revolutionizing the digital ecosystem by decentralizing data processing, shifting it from core data centers to the edge of the network—closer to the point of data generation. This architectural transformation is enabling instantaneous insights, reduced latency, and optimized bandwidth usage, which are critical in sectors requiring rapid decision-making.

Industries such as automotive, healthcare, telecommunications, and manufacturing are leading adopters of edge technologies to empower smart operations, autonomous functionality, and predictive systems.

Get up to 30%-40% Discount: https://www.statsandresearch.com/check-discount/40540-global-edge-computing-market

Edge Computing Market Segmentation Analysis:

By Component

Hardware

Edge computing hardware includes edge nodes, routers, micro data centers, servers, and networking gear. These devices are designed to endure harsh environmental conditions while delivering low-latency data processing capabilities. Companies are investing in high-performance edge servers equipped with AI accelerators to support intelligent workloads at the edge.

Software

Software solutions in edge environments include container orchestration tools, real-time analytics engines, AI inference models, and security frameworks. These tools enable seamless integration with cloud systems and support distributed data management, orchestration, and real-time insight generation.

Services

Edge services encompass consulting, deployment, integration, support, and maintenance. With businesses adopting hybrid cloud strategies, service providers are essential for ensuring compatibility, uptime, and scalability of edge deployments.

By Application

Industrial Internet of Things (IIoT)

Edge computing plays a vital role in smart manufacturing and Industry 4.0 initiatives. It facilitates predictive maintenance, asset tracking, process automation, and remote monitoring, ensuring enhanced efficiency and minimized downtime.

Smart Cities

Municipalities are leveraging edge computing to power traffic control systems, surveillance networks, waste management, and public safety infrastructure, enabling scalable and responsive urban development.

Content Delivery

In media and entertainment, edge solutions ensure low-latency content streaming, localized data caching, and real-time audience analytics, thereby optimizing user experience and reducing network congestion.

Remote Monitoring

Critical infrastructure sectors, including energy and utilities, employ edge computing for pipeline monitoring, grid analytics, and remote equipment diagnostics, allowing for proactive threat identification and response.

By Industry Vertical

Manufacturing

Edge solutions in manufacturing contribute to real-time production analytics, defect detection, and logistics automation. With AI-powered edge devices, factories are becoming increasingly autonomous and intelligent.

Healthcare

Hospitals and clinics implement edge computing to support real-time patient monitoring, diagnostic imaging processing, and point-of-care data analysis, enhancing treatment accuracy and responsiveness.

Transportation

The sector is utilizing edge technology in autonomous vehicle systems, smart fleet tracking, and intelligent traffic signals. These systems demand ultra-low latency data processing to function safely and efficiently.

Energy & Utilities

Edge computing enables smart grid optimization, renewable energy integration, and predictive fault detection, allowing utilities to manage resources with greater precision and sustainability.

Retail & Others

Retailers deploy edge devices for personalized marketing, real-time inventory management, and customer behavior analysis, enabling hyper-personalized and responsive shopping experiences.

Key Drivers Behind Edge Computing Market Growth:

1. IoT Proliferation and Data Deluge

With billions of connected devices transmitting real-time data, traditional cloud architectures cannot meet the bandwidth and latency demands. Edge computing solves this by processing data locally, eliminating unnecessary round trips to the cloud.

2. 5G Deployment

5G networks offer ultra-low latency and high throughput, both essential for edge applications. The synergy between 5G and edge computing is pivotal for real-time services like AR/VR, telemedicine, and autonomous navigation.

3. Hybrid and Multi-Cloud Strategies

Enterprises are embracing decentralized IT environments. Edge computing integrates with cloud-native applications to form hybrid infrastructures, offering agility, security, and location-specific computing.

4. Demand for Enhanced Security and Compliance

By localizing sensitive data processing, edge computing reduces exposure to cyber threats and supports data sovereignty in regulated industries like finance and healthcare.

Competitive Landscape

Leading Players Shaping the Edge Computing Market

Amazon Web Services (AWS) – Offers AWS Wavelength and Snowball Edge for low-latency, high-performance edge computing.

Microsoft Azure – Delivers Azure Stack Edge and Azure Percept for AI-powered edge analytics.

Google Cloud – Provides Anthos and Edge TPU for scalable, intelligent edge infrastructure.

IBM – Offers edge-enabled Red Hat OpenShift and hybrid edge computing solutions for enterprise deployment.

NVIDIA – Powers edge AI workloads with Jetson and EGX platforms.

Cisco Systems – Delivers Fog Computing and edge networking solutions tailored to enterprise-grade environments.

Dell Technologies – Supplies ruggedized edge gateways and scalable edge data center modules.

Hewlett Packard Enterprise (HPE) – Delivers HPE Edgeline and GreenLake edge services for data-intensive use cases.

FogHorn Systems & EdgeConneX – Innovators specializing in industrial edge analytics and data center edge infrastructure respectively.

Edge Computing Market Regional Insights

North America

A mature digital infrastructure, coupled with high IoT adoption and strong cloud vendor presence, makes North America the dominant regional edge computing market.

Asia-Pacific

Driven by rapid urbanization, smart city initiatives, and industrial automation in China, India, and Japan, Asia-Pacific is projected to experience the fastest CAGR during the forecast period.

Europe

The region benefits from strong government mandates around data localization, Industry 4.0 initiatives, and investments in telecom infrastructure.

Middle East and Africa

Emerging adoption is evident in smart energy systems, oilfield monitoring, and urban digital transformation projects.

South America

Growth in agritech, mining automation, and public safety systems is propelling the edge market in Brazil, Chile, and Argentina.

Purchase Exclusive Report: https://www.statsandresearch.com/enquire-before/40540-global-edge-computing-market

Edge Computing Market Outlook and Conclusion

Edge computing is not just an enabler but a strategic imperative for digital transformation in modern enterprises. As we move deeper into an AI-driven and hyperconnected world, the integration of edge computing with 5G, IoT, AI, and cloud ecosystems will redefine data management paradigms.

Businesses investing in edge infrastructure today are setting the foundation for resilient, intelligent, and real-time operations that will determine industry leadership in the years ahead. The edge is not the future—it is the present frontier of competitive advantage.

Our Services:

On-Demand Reports: https://www.statsandresearch.com/on-demand-reports

Subscription Plans: https://www.statsandresearch.com/subscription-plans

Consulting Services: https://www.statsandresearch.com/consulting-services

ESG Solutions: https://www.statsandresearch.com/esg-solutions

Contact Us:

Stats and Research

Email: [email protected]

Phone: +91 8530698844

Website: https://www.statsandresearch.com

1 note

·

View note

Text

BLIIoT OPC UA Distributed Ethernet IO Module BL205 Helps Digital Factory

Introduction

The digital factory is an important concept in today's industry, and it represents the future of manufacturing. In the realization of the digital factory, the collection, transmission and analysis of data become crucial. In this process, the OPC UA distributed IO module plays a key role, providing strong support and flexibility for the digital factory.

OPC UA is closely related to the digital factory because it can be used as a bridge connecting various components in the digital factory to realize real-time data transmission and sharing.

Introduction to OPC UA

OPC UA (Open Platform Communications Unified Architecture) is a communication protocol designed to enable data exchange and communication across different devices and systems. It provides a standardized method for connecting and managing devices and applications in industrial automation systems. Key advantages of OPC UA include cross-platform compatibility, high security and scalability.

OPC UA is closely related to the digital factory because it can be used as a bridge connecting various components in the digital factory to realize real-time data transmission and sharing.

Industrial Internet of Things Transformation

One of the challenges of IIoT transformation is how to seamlessly integrate existing OT systems into new IT systems.

OPC UA I/O to SCADA without gateway

Traditionally, most solutions utilize protocol gateways to convert remote I/O data to OPC UA, which requires additional configuration, and the software installed in the gateway's operating system increases the risk of the system being attacked by malware. To solve this problem, OPC UA Distributed Ethernet IO Module BL205 communicates directly via SCADA and OPC UA cloud without additional gateway, saving additional cost and integration work.

Application of OPC UA Distributed Ethernet IO Module BL205 in Digital Factory

Real-time data collection and transmission

A digital factory requires real-time production data in order to monitor the production process in real time and make timely decisions. OPC UA Distributed Ethernet IO Module BL205 can effectively collect data from sensors and devices and transmit it to a central database or cloud platform for use by factory managers and engineers.

Remote Monitoring and Control

The existence of OPC UA Distributed Ethernet IO Module BL205 makes remote monitoring and control possible. Factory managers can access production data from anywhere and remotely control it as needed, increasing work flexibility and efficiency.

Troubleshooting and Predictive Maintenance

Through real-time data analysis, digital factories can realize fault diagnosis and predictive maintenance. OPC UA Distributed Ethernet IO Module BL205 can collect health status data of equipment and help engineers predict when equipment needs to be maintained or replaced, thereby reducing downtime and maintenance costs.

Data analysis and optimization of production

A digital factory is not just about data collection, but also data analysis and optimizing production. OPC UA Distributed Ethernet IO Module BL205 provides real-time data, which can be used for optimization and improvement of the production process to improve production efficiency and quality.

Cost-effective: High I/O density and daisy-chain solutions save costs

With high I/O density and support for daisy chain connection, OPC UA Distributed Ethernet IO Module BL205 series is the most cost-effective solution to meet diverse needs. Users benefit from cost savings in I/O modules, switches, amount of wiring and space savings in the control cabinet.

In conclusion

OPC UA distributed IO modules are a key component of digital factories. They provide factories with real-time data and remote control capabilities, helping factories achieve higher production efficiency, quality and maintainability. With the development of the digital factory, we can expect to see more innovations and improvements to meet the changing needs of the manufacturing industry and push industrial production to new heights.

More information about the OPC UA Distributed Ethernet IO Module BL205 :https://www.bliiot.com/opc-ua-io-controller-opc-ua-i-o-controller-opc-ua-io-module-p00347p1.html

0 notes