#Labeling Machine Automation

Explore tagged Tumblr posts

Text

In today’s fast-paced industrial landscape, efficiency and precision are crucial for businesses looking to optimize production and maintain competitive advantage. Labeling is a fundamental aspect of packaging and product identification, making Labeling Machine Automation an essential investment for many industries. Selecting the right labeling machine automation system can streamline operations, reduce costs, and enhance product consistency.

0 notes

Video

youtube

Customized Packaging Line with 8 sets of vertical packing machines & Car...

Customized Packaging Line with 8 sets of vertical packing machines & Cartoning & Automatic Labeling This fully integrated packaging system combines 8 vertical form-fill-seal machines with manual cartoning and automatic labeling for complete end-to-end production. Line Configuration: • 8 independent VFFS units for continuous product packaging • Manual cartoning station for operator-assisted box loading • 90° belt turn modules (x2) for compact floorplan adaptation • Automatic labeling system for sticking at side of carton Design Advantages: ✓ Space-optimized layout designed around your facility ✓ Natural workflow between automated and manual processes ✓ Gentle product handling throughout all stages ✓ Adaptable components for various packaging formats

#youtube#packing machine#packaging line#manufacturing packaging#customized packaging#packaging solution#cartoning#labeling#automation#bestar packaging#bestar rachel

0 notes

Text

Automated Wrap Around Labeling Machine for Snus Packaging

Achieve flawless and consistent labeling for your snus cans with our advanced Wrap Around Labeling Machine For Snus cans, designed for unmatched precision and performance. Engineered to meet the high demands of the tobacco industry, this automated system ensures seamless label application around cylindrical containers, eliminating wrinkles and misalignments. Its robust construction guarantees long-term durability, while the high-speed operation boosts production efficiency without compromising on quality. Whether you're scaling up your manufacturing line or looking to enhance packaging aesthetics, this machine is the perfect solution for consistent results. Explore here: https://www.packnika.com/wrap-around-labeling-machine-for-snus-cans

#Wrap Around Labeling Machine For Snus cans#fully automated nicotine pouch packing machine#business#manufacturer#pouches#snus packing machine#filter tobacco packing machine#machinery#health

0 notes

Text

Automated Teller Machine Market to Witness Growth Owing to Digitalization

Global Automated Teller Machine Market is estimated to be valued at US$ 25.31 Bn in 2025 and is expected to exhibit a CAGR of 4.2% over the forecast period 2025 to 2032. Automated teller machines (ATMs) serve as critical touchpoints between banks and customers, offering cash withdrawals, balance inquiries, deposits and fund transfers without the need for branch visits. Enhanced by contactless interfaces, biometric authentication and real-time monitoring, modern ATMs improve customer convenience and security while reducing teller workloads. Financial institutions leverage these self-service kiosks to expand service networks, optimize operational efficiency and capture market share in both urban and rural areas. Automated Teller Machine Market Insights is growing adoption of omnichannel banking strategies and the demand for 24/7 access to cash and basic financial services are driving market growth. In addition, integration with digital wallets and mobile banking apps extends the ATM’s role from a simple cash dispenser to a multi-functional banking hub. Continuous innovation in hardware and software—such as modular designs, advanced sensors and cloud-based management—fuels industry trends toward smarter, more resilient ATM deployments. Get more insights on,Automated Teller Machine Market

#Coherent Market Insights#Automated Teller Machine Market#Automated Teller Machine#Automated Teller Machine Market Insights#Brown Label ATMs

0 notes

Text

Automatic Labeling Machine Market Drivers: Key Forces Fueling Global Industry Growth

The automatic labeling machine market is gaining momentum globally, driven by rapid industrial automation and the need for accurate, efficient, and high-speed labeling solutions. These machines, essential in industries such as food and beverage, pharmaceuticals, cosmetics, and logistics, are evolving in design and function to meet growing demands. With the global market expected to reach over USD 3.4 billion by 2030, understanding the key drivers behind this growth is crucial for businesses, investors, and industry professionals.

1. Rising Demand for Packaging Automation

One of the most influential drivers of the automatic labeling machine market is the increasing demand for automation in packaging processes. As manufacturers aim to enhance productivity and minimize human error, automated labeling systems offer an ideal solution. These machines streamline the labeling process, reduce labor costs, and improve overall operational efficiency. In industries with high-volume production, such as food and beverages or pharmaceuticals, automation has become a necessity rather than an option.

2. Expanding E-Commerce Sector

The explosive growth of e-commerce globally has significantly contributed to the demand for efficient labeling systems. Accurate product labeling ensures smooth logistics, helps in inventory management, and improves the customer experience. Automatic labeling machines facilitate the handling of large volumes of products by applying barcodes, shipping labels, and QR codes with high precision. As e-commerce continues to expand, especially in emerging markets, so does the need for reliable labeling solutions.

3. Stringent Labeling Regulations

Governments and regulatory bodies worldwide are enforcing stricter guidelines on product labeling, particularly in sensitive sectors like healthcare, pharmaceuticals, and food. These regulations aim to ensure consumer safety, product authenticity, and traceability. Automatic labeling machines help businesses comply with these requirements by producing consistent and tamper-proof labels. Their ability to integrate with traceability systems, such as serialization and anti-counterfeiting features, adds further value in regulated environments.

4. Technological Advancements and Smart Labeling

The adoption of smart technologies such as RFID (Radio Frequency Identification), IoT (Internet of Things), and AI (Artificial Intelligence) has transformed the labeling industry. Modern automatic labeling machines are now equipped with intelligent systems that offer real-time tracking, error detection, and remote operation capabilities. These advancements not only improve efficiency but also enable better decision-making and inventory control. Companies investing in smart labeling are gaining a competitive edge in terms of quality assurance and data analytics.

5. Growth in the Food and Beverage Industry

The food and beverage industry holds a significant share of the automatic labeling machine market. This sector demands fast, accurate, and hygienic labeling solutions to ensure compliance with food safety standards and consumer expectations. With the increasing consumption of packaged foods and beverages globally, manufacturers are upgrading to automatic labeling systems that support diverse packaging formats and label types. Product traceability, nutritional labeling, and expiration date accuracy are critical aspects driving this trend.

6. Pharmaceutical and Healthcare Applications

Pharmaceutical companies are among the early adopters of automatic labeling machines due to their need for precision and compliance. Labels on medicine bottles, vials, and cartons must contain critical information such as dosage, manufacturing date, batch number, and warnings. Given the strict regulations in the pharmaceutical industry, labeling errors can have serious consequences. Automatic machines ensure consistent and error-free application, making them indispensable in healthcare manufacturing units.

7. Sustainability and Eco-Friendly Labeling

Sustainability trends are shaping the automatic labeling machine market as companies aim to reduce their environmental impact. Eco-friendly label materials, recyclable packaging, and reduced waste in the labeling process are becoming standard expectations. Automatic labeling machines that support water-based adhesives, linerless labels, and energy-efficient operations are gaining popularity among environmentally conscious manufacturers. This shift is particularly strong in Europe and North America, where green initiatives are heavily promoted.

8. Regional Market Expansion

The Asia-Pacific region is currently leading the automatic labeling machine market, accounting for over 38% of the global share. Rapid industrialization, growing consumer markets, and government support for automation in countries like China, India, and Thailand are fueling this growth. Meanwhile, North America and Europe are experiencing steady demand due to their mature industrial infrastructure and focus on technological upgrades. Latin America and the Middle East are emerging markets with increasing investments in automation technologies.

Conclusion

The automatic labeling machine market is on a robust growth path, driven by a combination of industry needs, technological innovations, and regulatory frameworks. As businesses prioritize efficiency, accuracy, and compliance, the demand for automated labeling solutions will continue to rise. Understanding these key drivers allows companies to strategically invest in labeling technologies that not only enhance productivity but also support long-term growth and sustainability goals.

#Automatic Labeling Machine Market#Packaging Automation#Labeling Technology#Smart Labeling Solutions#Industrial Automation

0 notes

Text

Discover Different Sticker Labeling Machines for Industries

Labeling plays a crucial role in various industries, including pharmaceuticals, food and beverages, cosmetics, and chemicals. Proper labeling ensures compliance with regulations, enhances brand visibility, and improves efficiency in production lines. With the advancement of automation, sticker labeling machines have become an integral part of industrial packaging. These machines streamline the…

#Ampoule Labeling Machine#Automatic Labeling Machines#Double Side Labeling Machine#Food and Beverage Labeling#High-Speed Labeling Machines#Horizontal Sticker Labeling#Industrial Labeling Equipment#Labeling Machine Selection#Labeling Solutions for Industries#Packaging Automation#Pharmaceutical Labeling#Round Bottle Labeling#Semi-Automatic Labeling#Sticker labeling machines

0 notes

Text

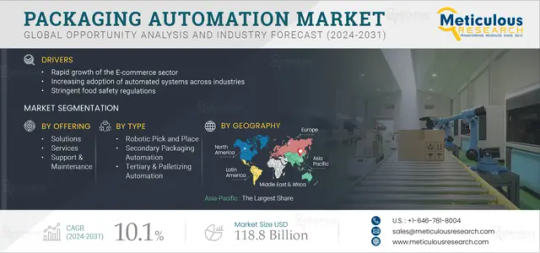

Packaging Automation Market Size, Share, Forecast, & Trends Analysis

Meticulous Research®—a leading global market research company, published a research report titled, ‘Packaging Automation Market by Offering (Solution, Services), Type, End-use Industry (Healthcare & Pharmaceuticals, E-commerce & Logistics, Food & Beverage, Chemical & Refinery, Aerospace & Defense), and Geography - Global Forecast to 2031.’

According to this latest publication from Meticulous Research®, the global packaging automation market is projected to reach $118.8 billion by 2031, at a CAGR of 10.1% during the forecast period. The growth of the packaging automation market is mainly attributed to the rapid growth of the E-commerce sector, the increasing adoption of automated systems across industries, and stringent food safety regulations. However, the high initial costs of installing automated systems restrain the market’s growth.

The high demand for packaging automation in the logistics industry and the increasing demand for sustainable and eco-friendly packaging are expected to create market growth opportunities. However, the shortage of skilled operators is a major challenge for the players in this market. Integration of advanced technologies and smart packaging are major trends in the packaging automation market.

The global packaging automation market is segmented by offering (solutions [case sealers & erectors, sleevers & cartoners, palletizers & depalletizers, strappers, markers & labelers, automated mailer systems, case packers, and other solutions], services [consulting, installation & training, and support & maintenance]), type (robotic pick & place, secondary packaging, and tertiary & palletizing), end-use industry (healthcare & pharmaceuticals [healthcare & pharmaceuticals manufacturing companies and contract manufacturing organizations], e-commerce & logistics [E-commerce, contract packaging, and logistics companies], food & beverage, automotive, chemical & refineries, aerospace & defense, and other end-use industries), and geography (Asia-Pacific, Europe, North America, Latin America, and the Middle East & Africa). The study also evaluates industry competitors and analyses the market at the country and regional levels.

Based on offering, the packaging automation market is segmented into solutions and services. Furthermore, the solutions segment is subsegmented into case sealers & erectors, sleevers & cartoners, palletizers & depalletizers, strappers, markers & labelers, automated mailer systems, case packers, and other solutions. The services segment is subsegmented into consulting, installation & training, and support & maintenance. In 2024, the solutions segment is expected to account for the larger share of the global packaging automation market. The segment’s large market share is mainly attributed to the need for increased manufacturing speed and ensuring products and workers’ safety. However, the services segment is projected to record the highest CAGR during the forecast period. The segment’s growth is driven by the increasing deployment of automation in various industries such as e-commerce, healthcare & pharmaceuticals, food & beverage, automotive, and chemical & refineries and the growing demand for packaging automation to speed up production, optimize warehouse space, and reduce reliance on labor to provide more value-added services to their customers.

Based on type, the packaging automation market is segmented into robotic pick & place, secondary packaging, and tertiary & palletizing. In 2024, the robotic pick & place segment is expected to account for the largest share of the global packaging automation market. The segment’s large market share is mainly attributed to rising demand for pick and place robots in various industries such as manufacturing, food & beverage, automotive, chemical & refineries, aerospace & defense, e-commerce & logistics, healthcare & pharmaceuticals, and the growing demand for automation from manufacturing companies to increase production rates. However, the secondary packaging segment is projected to record the highest CAGR during the forecast period. The segment’s growth is driven by the rising need to safely transport products during shipment and the growing demand for supplementary protection in the e-commerce and pharmaceutical sectors.

Based on end-use industry, the packaging automation market is segmented into healthcare & pharmaceuticals, E-commerce & logistics, food & beverage, automotive, chemical & refineries, aerospace & defense, and other end-use industries. Furthermore, the healthcare & pharmaceuticals segment is subsegmented into healthcare & pharmaceuticals manufacturing companies and contract manufacturing organizations. The E-commerce & logistics segment is subsegmented into E-commerce, contract packaging, and logistics companies. In 2024, the food & beverage segment is expected to account for the largest share of the global packaging automation market. The segment’s large market share is mainly attributed to shifting consumer tastes, high competition in the packaged food market, and a surge in demand for packaged food. However, the e-commerce & logistics segment is projected to record the highest CAGR during the forecast period. The segment’s growth is attributed to various factors, including the rise in online sales channels, the increase in online shopping among customers, the increasing adoption of automation in e-commerce & logistics to ensure timely delivery, and the rising consumer demand for convenience shopping.

Based on geography, the global packaging automation market is segmented into North America, Europe, Latin America, and the Middle East & Africa. In 2024, Asia-Pacific is expected to account for the largest share of the packaging automation market, followed by Europe, North America, Latin America, and the Middle East & Africa. Asia-Pacific’s significant market share is attributed to the increasing utilization of sustainable packaging in the food & beverage sector, supportive government initiatives aimed at promoting the adoption of automation and Industry 4.0 technologies to enhance manufacturing capabilities, the growing demand for eco-friendly packaging solutions, and the rapid expansion of the E-commerce sector in countries like China and India. Moreover, Asia-Pacific is also projected to register the highest CAGR over the forecast period.

Key Players

The key players operating in the global packaging automation market are ABB, Ltd. (Switzerland), Robert Bosch GmbH (Germany), Siemens AG (Germany), Fanuc Corporation(Japan), and Mitsubishi Electric Corporation (Japan), Swisslog Holding AG (Switzerland), Rockwell Automation, Inc. (U.S.), Schneider Electric SE (France), WestRock Company (U.S.), SATO Holdings Corporation (Japan), Krones AG (Germany), Automated Packaging Systems, Inc. (U.S.), Emerson Electric Co. (U.S.), Crawford Packaging (Canada), Fuji Machinery (Japan), Brenton LLC (U.S.), BEUMER Group GmbH & Co. KG(Germany), Barry-Wehmiller Group, Inc. (U.S.), KHS GmbH (Italy), MULTIVAC Sepp Haggenmüller SE & Co. KG (Germany), Omori Machinery Co., Ltd. (Japan), and Syntegon Technology GmbH (Germany).

Download Sample Report Here @ https://www.meticulousresearch.com/download-sample-report/cp_id=5324

Key Questions Answered in the Report:

Which are the high-growth market segments in terms of offering, type, and end-use industry?

What is the historical market for packaging automation across the globe?

What are the market forecasts and estimates for the period of 2024–2031?

What are the major drivers, restraints, opportunities, challenges, and trends in the global packaging automation market?

Who are the major players in the global packaging automation market, and what are their market shares?

What is the competitive landscape like?

What are the recent developments in the global packaging automation market?

What are the different strategies adopted by the major players in the market?

What are the geographic trends and high-growth countries?

Who are the emerging players in the global packaging automation market, and how do they compete with the other players?

Contact Us: Meticulous Research® Email- [email protected] Contact Sales- +1-646-781-8004 Connect with us on LinkedIn- https://www.linkedin.com/company/meticulous-research

#Packaging Automation Market#Packaging Automation#Smart Packaging#Automated Packaging Systems#Packaging & Processing Solutions#Portioning#Labeling#Marking#Inspection#Handling#Packaging Machines#Robotic Pick & Place#Secondary Packaging#Tertiary & Palletizing#Automation Solutions#Automated Equipment#Automated Bagging Systems#Transit Packaging#Food Packaging Equipment

0 notes

Text

When choosing the best automatic label printer and applicator for your business, several factors must be considered to ensure efficiency, quality, and cost-effectiveness.

Product & Labels information

Application information – Label location and photo

Transmission device and photo

Signal/Sensor

Maintenance and Support

Cost and Return on Investment (ROI)

#Label Printer and Applicator#Integrated Labeling Machine#Automated Labeling System#Labeling Equipment

0 notes

Text

360° No-dead-angle And No-bubble Labeling Solution

The core of the visual labeling machine lies in its highly integrated visual recognition system and advanced laminating technology. At present, many factories are manually laminating and manually positioning the auxiliary materials, but there are still bubbles and large laminating accuracy errors. In order to solve this industry pain point, the bubble-free laminating technology ensures the seamless connection between the label and the product surface, improving the overall aesthetics and market competitiveness of the product. The laminating accuracy is as high as ±0.05mm to ±0.15mm, which provides higher efficiency for labeling operations. Gosunm has developed a high-precision visual positioning auxiliary material laminating machine.

Featureds

360° no-dead-angle lamination

gosunm visual labeling machine can handle products of various complex shapes, and can achieve precise lamination no matter which part of the product needs to be labeled.

Bubble-free lamination

By precisely controlling the labeling process, ensure that the label is tightly attached to the product surface without bubbles or wrinkles, thus ensuring the labeling quality

Non-standard customization

In response to the special needs of different customers, gosunm visual labeling machine provides non-standard customization services to meet various specific production needs,

High-precision lamination

The lamination accuracy is as high as ±0.05mm to ±0.15mm, ensuring the high precision of labeling operations and meeting the industry standards with strict requirements on product quality.

Multiple advantages of visual labeling machine

◆Perfect combination of efficiency and precision

The Hardson visual labeling machine greatly improves production efficiency through automated processes. At the same time, its high-precision visual system ensures the accuracy of labeling position, meeting the dual needs of modern production for speed and quality.

◆Strong adaptability and high flexibility

Whether it is regular or irregular product shape, the Hardson visual labeling machine can quickly adapt to different labeling needs through software adjustment, greatly improving the flexibility and adaptability of production.

◆Reduce labor costs and improve safety

Automated visual labeling machines reduce the physical and mental requirements of operators, which not only reduces long-term labor costs, but also reduces errors and safety hazards that may be caused by manual operation.

Application fields and industry impact

Visual labeling machines are widely used in many fields, including but not limited to:

Consumer electronicsMainly used for labeling of structural shell accessories such as mobile phones, laptops, and tablets

Electronic componentsSuitable for laminating operations of electronic components such as cooling fans and foot pads

Emerging fieldsSuch as FPC wireless charging laminating operations, Hardson visual labeling machines meet the strict requirements of emerging technologies for labeling operations with their high precision and high efficiency

As a key component of intelligent manufacturing, the visual labeling machine has promoted the process of industrial automation. It not only significantly improves production efficiency, but also ensures the consistency and accuracy of product labeling, becoming an indispensable "precision eye" in modern manufacturing. With the continuous advancement of technology, we have every reason to believe that CCD visual labeling machines will play a more important role in intelligent production.

#visual labeling machine#gosunm#CCD visual labeling machines#visual positioning auxiliary material laminating machine#Automated visual labeling machine#visual inspection

0 notes

Text

A manufacturing line that includes a variety of equipment for cleaning, filling, capping, and labeling syrup bottles is known as a pharmaceutical syrup filling line. It’s interesting that it also has an automated syrup production facility. We are a well-known manufacturer of syrup filling lines with uses in the culinary, pharmaceutical, nutraceutical, and herbal industries. Our syrup suspension filling line, which has an elegant appearance, is furnished with state-of-the-art components for production, cleaning, filling, capping, and labeling tasks. The entire suspension fill line functions as a single, integrated system, streamlining the production process.

As one of the top exporters of oral suspension filling lines from India, Adinath has developed both fully automatic and semi-automated oral liquid filling lines. The manufacturing capacity of our filling lines ranges from 500 to 50,000 liters per day.

Let’s have a look on some of the key equipments of our syrup filling line:

Syrup Manufacturing Plant

The pharmaceutical business uses oral liquid manufacturing plants as the best instruments for producing oral liquids. It is specifically made to address two important issues that have a direct impact on the liquids’ quality. Minimal liquid handling by hand and efficient cleanliness throughout production.

youtube

Automatic Bottle Washing Machine

Our bottle washing machine, sometimes called a linear bottle washer, is widely utilized in the pharmaceutical business. It has an all-automatic setup that guarantees hassle-free vial loading on the stainless steel wire mesh conveyor. You can also push them manually from the feed table if you’re comfortable doing things that way. Use this automated machine to save a lot of labor, and you can even opt to have an automatic emptying mechanism when needed. The latter is not required.

youtube

Automatic Bottle Filling Machine

The pharmaceutical business frequently uses bottle filling machines, also referred to as bottle fillers, to pack various liquids into various bottle types. This adaptable device can be used to fill bottles, jars, and containers made of glass, plastic, aluminum, steel, copper, and PET, among other materials. It can also fill aqueous solutions, foamy liquid, and semi-viscous solutions. The machine’s essential components include feeding needles, a piston pump, a quality stainless steel slat conveyor belt, and a robust foundation structure.

youtube

Automatic Bottle Capping Machine

We provide bottle stoppers that are used to cap bottles in a variety of industries, including the manufacturing of chemicals, pharmaceuticals, food and beverage products, pesticides, and alcoholic beverages. Our bottle capping machine is constructed with an M.S. frame and stainless steel enclosures or cladding. An orientation-style cap feeder is included with our ROPP bottle cap sealing machine to ensure smooth cap feeding.

youtube

Bottle Visual Inspection Machine

Adinath International produces and exports a cGMP certified bottle inspection machine with a three track conveyor and hooded lighting configuration. Aside from an inspection table with an SS construction, there is a background that alternates between black and white for a perfect visual inspection. A slat chain made of stainless steel is also a part of it. This machine will last for many years because of its sturdy adjustable bolt support and stainless steel square pipes.

youtube

Automatic Bottle Sticker Labeling Machine

This machine is widely used for labeling PET, aluminum, glass, plastic, and copper bottles, cans, jars, and other containers. With the most advanced microprocessor control label dispensing mechanism available, this linear design machine can detect labels and items with maximum efficiency. Additionally, it features a specially created mechanical and electronic technology that is useful for quickly applying transparent labels on bottles. For the labeling of different bottle types, there are no sections that need to be changed.

youtube

#syrup suspension filling line#oral suspension filling lines#semi-automated oral liquid filling lines#oral liquid manufacturing plants#Automatic Bottle Washing Machine#Automatic Bottle Filling Machine#Automatic Bottle Capping Machine#Bottle Visual Inspection Machine#Automatic Bottle Sticker Labeling Machine#Youtube

0 notes

Text

Streamlining Your Business with Labelling Machines

Optimising productivity and efficiency is crucial for success in today’s fast-paced and competitive business landscape. One area where businesses can significantly improve their operations is in the labelling and decorating process. Traditional manual labelling methods are time-consuming and prone to human errors, which can lead to costly mistakes. Thankfully, labelling or decorating machines have emerged as a game-changer, revolutionising how businesses handle their labelling needs. This comprehensive guide will explore the benefits of labelling machines and how they can streamline your business operations while saving time and resources.

Understanding the Power of Labelling or Decorating Machines

Enhanced Productivity and Efficiency

Labelling machines are designed to automate the labelling process, eliminating the need for manual application. These machines can label products at a much higher speed and with greater precision than human workers. For example, a high-speed labelling machine can label hundreds of products per minute, while manual labelling may take considerable time and labour. With increased throughput, businesses can meet higher demands and efficiently handle larger order volumes, ultimately improving productivity.

Reduced Errors and Improved Accuracy

Human errors during labelling can significantly affect businesses, including wasted resources, product recalls, and dissatisfied customers. Labelling machines reduce the likelihood of errors by automating the application process and ensuring precise label placement on each product.

Some labelling machines have built-in sensors that detect product positioning and automatically adjust the label application to match the product’s size and shape. It minimises the risk of misaligned labels and ensures accurate placement every time. Furthermore, labelling machines can integrate with barcode and RFID systems, enhancing product traceability and inventory management, which further reduces the chances of errors and improves overall accuracy.

Cost Savings

While labelling machines require an initial investment, they are cost-effective in the long run. One of the primary cost-saving benefits is the reduction in material wastage. Manual labelling often leads to misprints, label misplacement, and label damage, which results in wasted labels and additional expenses. Labelling machines ensure minimal wastage by applying labels accurately and consistently, optimising the use of label rolls or sheets.

Flexibility and Versatility

Labelling machines are highly versatile and can accommodate various label sizes, shapes, and materials. Whether businesses require adhesive labels, shrink sleeves, wraparound labels, or heat-transfer labels, these machines can handle them all. Some labelling machines offer quick changeover capabilities, allowing businesses to swiftly switch between different products or label designs.

Streamlined Regulatory Compliance

In industries with strict regulatory requirements, compliance with labelling standards is essential. Labelling machines can be programmed to ensure compliance with specific regulations, such as ingredient listings, nutritional information, and hazard warnings. Businesses can avoid legal penalties, maintain consumer trust, and uphold their brand reputation by automating the compliance process.

Improved Branding and Aesthetics

In today’s competitive market, product branding is vital in attracting consumers and building brand recognition. Labelling machines can add decorative elements, brand logos, and appealing designs to product labels, making them more visually appealing to customers.

Adaptability to Industry Demands

Labelling machines cater to various industries, including food and beverage, pharmaceuticals, cosmetics, etc. Different industries have unique labelling requirements, and labelling machines can adapt to meet these specific needs.

Choosing the Right Labelling Machine for Your Business

Label Types and Sizes

Before selecting a labelling machine, businesses should identify the types of labels they need to apply and their sizes. Some labelling machines specialise in specific label types, such as self-adhesive labels. In contrast, others offer greater versatility, accommodating a variety of label materials, including shrink sleeves and in-mould labels.

Production Volume

The production volume is crucial in determining the appropriate labelling machine for a business. High-speed labelling machines are ideal for large-scale production facilities, where a high volume of products needs to be labelled quickly. Conversely, smaller businesses or those with lower production volumes may find more cost-effective solutions in mid-range or semi-automatic labelling machines.

Automation and Integration

Automation features are essential for optimising the labelling process and reducing manual intervention. Advanced labelling machines can feature auto-adjusting settings, label position correction, and label presence sensors. These functionalities ensure that labels are applied accurately and consistently, even when dealing with products of different shapes and sizes.

Maintenance and Support

When selecting a labelling machine, consider the ease of maintenance and the availability of technical support from the manufacturer or supplier. Regular maintenance is essential to keep the machine in optimal working condition and prevent unexpected breakdowns.

Conclusion

Plastics Processing Machinery in Australia have transformed how businesses handle their labelling needs, offering increased productivity, reduced errors, and improved efficiency. By investing in a suitable labelling machine that aligns with their business requirements, companies can streamline their operations, save valuable time and resources, and position themselves for success in today’s competitive market.

Automation and technology continue to shape the future of Plastics Processing Machinery in Australia with advancements in precision, speed, and integration capabilities. As businesses seek to optimise their labelling processes, staying informed about the latest trends and industry innovations is essential to remain competitive and meet consumer demands effectively. Embrace the power of labelling or decorating machines, and take your business to new heights of efficiency and success.

#Granulation Moulding Machines#World’s fastest Automatic Bagging Machines#High Quality Conveying Machines#ISBM Mould Injection Machines Supplier#Plastic Automation machine systems#Plastics Processing Machinery Australia#Labelling or Decorating Machines#Recycling Machines#inspection machines#injection moulding machines#Plastics Processing Machinery#Blow Moulding Machines

0 notes

Note

are there any critiques of AI art or maybe AI in general that you would agree with?

AI art makes it a lot easier to make bad art on a mass production scale which absolutely floods art platforms (sucks). LLMs make it a lot easier to make content slop on a mass production scale which absolutely floods search results (sucks and with much worse consequences). both will be integrated into production pipelines in ways that put people out of jobs or justify lower pay for existing jobs. most AI-produced stuff is bad. the loudest and most emphatic boosters of this shit are soulless venture capital guys with an obvious and profound disdain for the concept of art or creative expression. the current wave of hype around it means that machine learning is being incorporated into workflows and places where it provides no benefit and in fact makes services and production meaningfully worse. it is genuinely terrifying to see people looking to chatGPT for personal and professional advice. the process of training AIs and labelling datasets involves profound exploitation of workers in the global south. the ability of AI tech to automate biases while erasing accountability is chilling. seems unwise to put a lot of our technological eggs in a completely opaque black box basket (mixing my metaphors ab it with that one). bing ai wont let me generate 'tesla CEO meat mistake' because it hates fun

6K notes

·

View notes

Text

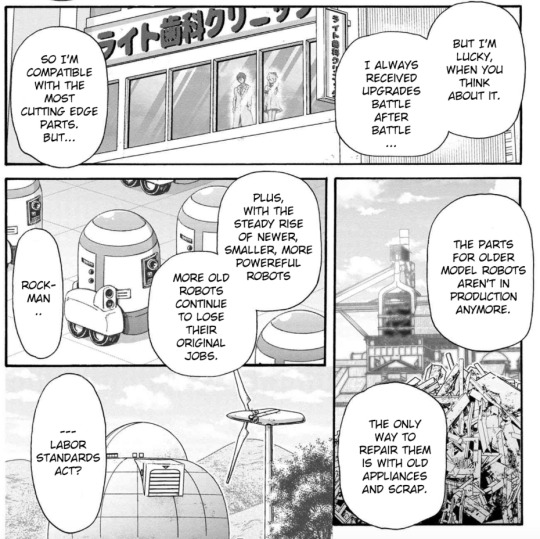

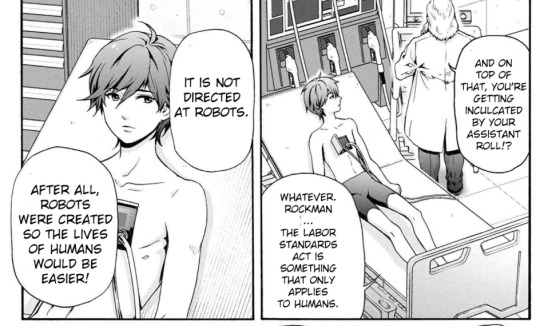

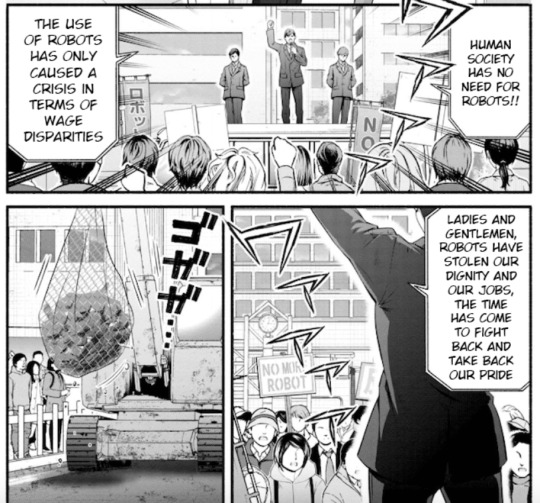

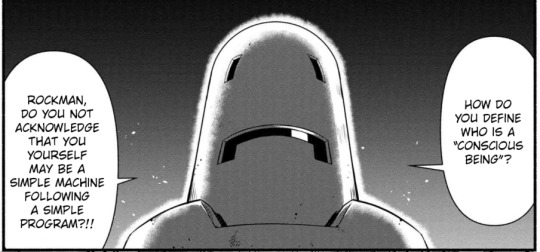

I saw a post talking about how media like Detroit Become Human that use robots as a metaphor for racism never quite hits the nail on the head because, well, robots aren't people and the fear of being replaced by automation is a legitimate one.

And it made me think about Rockman-san.

Which is coming out very soon as Mr. Megaman, in English, so might as well talk about it now!

For a gag comic, Rockman-san has a very melancholy tone to it. It often touches on concepts like deterioration, obsolescence, and... well...

Automation.

The original Robot Masters of the Rockman-san comic are sentient. They can think, they can feel, they can love. It's a staple of Rockman/Megaman media for its Robot Masters and Reploids to be self-determining, but Rockman-san takes that to its extreme and, without getting into spoilers, has a real blurring of what it means to be human and what it means to be a machine.

Their humanity is what labels them as "dangerous," and that type of robot is being phased out and replaced with robots that can't think or feel. Yup - AI took the AI's jobs. The RMs are largely struggling with employment - some are having difficulty holding down a job, while others have been pushed out of the industries they were made for and find the work they took up to survive unfulfilling, while others are finding fulfillment in repurposing their hardware and programming to a new career. They have a variety of ways they experience the hardships of the world that... honestly hit me pretty hard, my first time reading, because it was probably the first time I'd read a story that felt like it was really talking to my actual lived experience as an adult.

By including these more real world ai machines, it reminds the audience the RMs are fantastical and highlights what the narrative is trying to analyze - "what does it mean to be self-determining? what does it mean to be sentient? is it a blessing or a burden? what rights does a fully aware, self-determining, sentient being have if it is not human? when do they become a person? what do you have to strip away from a human to make them no longer a person?"

Rockman-san manages to balance a narrative of robot discrimination while acknowledging that the presence of robots in their world is harmful to humans. It acknowledges that, by making the robots sentient, the scientists have accidentally created an underclass of person - the robots are thinking, feeling people who have to work to survive, to pay for energy, pay for repairs, pay for a place to live, pay for recreation. Robots work longer hours for less pay and have no legal recourse.

Rockman-san hits the nail on the head that this benefits the wealthy and harms the working class. Capitalism rears its ugly head yet again. The sentient robots get exploited, abused, and tossed aside. The working class suffers and dies. The wealthy profit.

And the finger gets pointed to the exploited underclass rather than those in power, as it so often does. But then... how would one ethically close Pandora's box? What changes would allow humans and robots to coexist? Can they coexist?

Just, something about how Rockman-san handles its robot rights narrative resonates, y'know? It doesn't rely on cheap parallels that don't really work. It's mostly asking questions of Megaman's premise. There's a lot of varying life experiences and opinions expressed by the characters, and it doesn't really ask you to agree with any of them - not even Rock or Dr. Light. We're not trying to come to definite answers, just exploring what it means to be alive and how to live in a society, how it works and how it fails.

I dunno. I'm not about to say it's a perfect narrative, but there's something about it I like.

31 notes

·

View notes

Text

Today, the label luddite is an epithet for someone afraid of technology and the change it can bring. Merchant’s book makes clear that Luddites did not fear automation in the sense of being afraid of the machines or longing for an idyllic past. On the contrary, as Merchant points out, clothworkers were often themselves intimately engaged in improving the technology they used. Some of them proposed paying for job retraining by taxing factory owners who implemented the automating machines, earning the workers the title of “some of the earliest policy futurists,” according to Merchant. These efforts—to use official channels at the local and parliamentary levels—failed, however. With their futures rapidly foreclosing, the clothworkers invoked the fictional Ned Ludd (alternatively, Ludlam), an apprentice stocking-frame knitter in the late 1700s who, the story went, responded to his master whipping him by destroying the machine. Inspired by his act of sabotage against a cruel employer, the Luddites campaigned to halt the spread of the “obnoxious machines.” Soon factory owners found threatening letters signed by Captain Ludd or General Ludd or King Ludd. The letters also allude to another hero of working people from Nottingham, Robin Hood. Merchant argues that the mutability of Ned Ludd served as an organizing symbol akin to a playful but potent meme.

[...]

The Luddites used the tools at their disposal and did so through collective action. Merchant details the day-to-day organizing efforts of the movement’s leaders. We are ushered into a clandestine world of codes and oaths, of backroom meetings and nighttime training. The scheming makes for entertaining reading. But beneath the private planning and public sabotage lurks a more lasting lesson: movements to dismantle automation’s physical infrastructure often depend on building relational infrastructure. Tight-knit communities are extraordinarily important here: they buffered the Luddites from harm and fostered creative thinking rather than merely alienation among adherents and their allies. Increasingly finding themselves wrung out by those in power, these communities coalesced around shared causes that overlooked intragroup differences. This opened space for women, Merchant tells us, to claim the nom de guerre Lady Ludd and charge into markets to demand fair food prices from shop owners and food suppliers. It worked. The “auto-reductions,” as they were called, demonstrate the power of people working together to force change. Similarly, resistance to automation can be creative and provide openings to bring myriad others into the tent.

74 notes

·

View notes

Text

Packaging Automation Market to be Worth $118.8 Billion by 2031

Meticulous Research®—a leading global market research company, published a research report titled, ‘Packaging Automation Market by Offering (Solution, Services), Type, End-use Industry (Healthcare & Pharmaceuticals, E-commerce & Logistics, Food & Beverage, Chemical & Refinery, Aerospace & Defense), and Geography - Global Forecast to 2031.’

According to this latest publication from Meticulous Research®, the global packaging automation market is projected to reach $118.8 billion by 2031, at a CAGR of 10.1% during the forecast period. The growth of the packaging automation market is mainly attributed to the rapid growth of the E-commerce sector, the increasing adoption of automated systems across industries, and stringent food safety regulations. However, the high initial costs of installing automated systems restrain the market’s growth.

The high demand for packaging automation in the logistics industry and the increasing demand for sustainable and eco-friendly packaging are expected to create market growth opportunities. However, the shortage of skilled operators is a major challenge for the players in this market. Integration of advanced technologies and smart packaging are major trends in the packaging automation market.

The global packaging automation market is segmented by offering (solutions [case sealers & erectors, sleevers & cartoners, palletizers & depalletizers, strappers, markers & labelers, automated mailer systems, case packers, and other solutions], services [consulting, installation & training, and support & maintenance]), type (robotic pick & place, secondary packaging, and tertiary & palletizing), end-use industry (healthcare & pharmaceuticals [healthcare & pharmaceuticals manufacturing companies and contract manufacturing organizations], e-commerce & logistics [E-commerce, contract packaging, and logistics companies], food & beverage, automotive, chemical & refineries, aerospace & defense, and other end-use industries), and geography (Asia-Pacific, Europe, North America, Latin America, and the Middle East & Africa). The study also evaluates industry competitors and analyses the market at the country and regional levels.

Based on offering, the packaging automation market is segmented into solutions and services. Furthermore, the solutions segment is subsegmented into case sealers & erectors, sleevers & cartoners, palletizers & depalletizers, strappers, markers & labelers, automated mailer systems, case packers, and other solutions. The services segment is subsegmented into consulting, installation & training, and support & maintenance. In 2024, the solutions segment is expected to account for the larger share of the global packaging automation market. The segment’s large market share is mainly attributed to the need for increased manufacturing speed and ensuring products and workers’ safety. However, the services segment is projected to record the highest CAGR during the forecast period. The segment’s growth is driven by the increasing deployment of automation in various industries such as e-commerce, healthcare & pharmaceuticals, food & beverage, automotive, and chemical & refineries and the growing demand for packaging automation to speed up production, optimize warehouse space, and reduce reliance on labor to provide more value-added services to their customers.

Based on type, the packaging automation market is segmented into robotic pick & place, secondary packaging, and tertiary & palletizing. In 2024, the robotic pick & place segment is expected to account for the largest share of the global packaging automation market. The segment’s large market share is mainly attributed to rising demand for pick and place robots in various industries such as manufacturing, food & beverage, automotive, chemical & refineries, aerospace & defense, e-commerce & logistics, healthcare & pharmaceuticals, and the growing demand for automation from manufacturing companies to increase production rates. However, the secondary packaging segment is projected to record the highest CAGR during the forecast period. The segment’s growth is driven by the rising need to safely transport products during shipment and the growing demand for supplementary protection in the e-commerce and pharmaceutical sectors.

Based on end-use industry, the packaging automation market is segmented into healthcare & pharmaceuticals, E-commerce & logistics, food & beverage, automotive, chemical & refineries, aerospace & defense, and other end-use industries. Furthermore, the healthcare & pharmaceuticals segment is subsegmented into healthcare & pharmaceuticals manufacturing companies and contract manufacturing organizations. The E-commerce & logistics segment is subsegmented into E-commerce, contract packaging, and logistics companies. In 2024, the food & beverage segment is expected to account for the largest share of the global packaging automation market. The segment’s large market share is mainly attributed to shifting consumer tastes, high competition in the packaged food market, and a surge in demand for packaged food. However, the e-commerce & logistics segment is projected to record the highest CAGR during the forecast period. The segment’s growth is attributed to various factors, including the rise in online sales channels, the increase in online shopping among customers, the increasing adoption of automation in e-commerce & logistics to ensure timely delivery, and the rising consumer demand for convenience shopping.

Based on geography, the global packaging automation market is segmented into North America, Europe, Latin America, and the Middle East & Africa. In 2024, Asia-Pacific is expected to account for the largest share of the packaging automation market, followed by Europe, North America, Latin America, and the Middle East & Africa. Asia-Pacific’s significant market share is attributed to the increasing utilization of sustainable packaging in the food & beverage sector, supportive government initiatives aimed at promoting the adoption of automation and Industry 4.0 technologies to enhance manufacturing capabilities, the growing demand for eco-friendly packaging solutions, and the rapid expansion of the E-commerce sector in countries like China and India. Moreover, Asia-Pacific is also projected to register the highest CAGR over the forecast period.

Key Players

The key players operating in the global packaging automation market are ABB, Ltd. (Switzerland), Robert Bosch GmbH (Germany), Siemens AG (Germany), Fanuc Corporation(Japan), and Mitsubishi Electric Corporation (Japan), Swisslog Holding AG (Switzerland), Rockwell Automation, Inc. (U.S.), Schneider Electric SE (France), WestRock Company (U.S.), SATO Holdings Corporation (Japan), Krones AG (Germany), Automated Packaging Systems, Inc. (U.S.), Emerson Electric Co. (U.S.), Crawford Packaging (Canada), Fuji Machinery (Japan), Brenton LLC (U.S.), BEUMER Group GmbH & Co. KG(Germany), Barry-Wehmiller Group, Inc. (U.S.), KHS GmbH (Italy), MULTIVAC Sepp Haggenmüller SE & Co. KG (Germany), Omori Machinery Co., Ltd. (Japan), and Syntegon Technology GmbH (Germany).

Download Sample Report Here @ https://www.meticulousresearch.com/download-sample-report/cp_id=5324

Key Questions Answered in the Report:

Which are the high-growth market segments in terms of offering, type, and end-use industry?

What is the historical market for packaging automation across the globe?

What are the market forecasts and estimates for the period of 2024–2031?

What are the major drivers, restraints, opportunities, challenges, and trends in the global packaging automation market?

Who are the major players in the global packaging automation market, and what are their market shares?

What is the competitive landscape like?

What are the recent developments in the global packaging automation market?

What are the different strategies adopted by the major players in the market?

What are the geographic trends and high-growth countries?

Who are the emerging players in the global packaging automation market, and how do they compete with the other players?

Contact Us: Meticulous Research® Email- [email protected] Contact Sales- +1-646-781-8004 Connect with us on LinkedIn- https://www.linkedin.com/company/meticulous-research

#Packaging Automation Market#Packaging Automation#Smart Packaging#Automated Packaging Systems#Packaging & Processing Solutions#Portioning#Labeling#Marking#Inspection#Handling#Packaging Machines#Robotic Pick & Place#Secondary Packaging#Tertiary & Palletizing#Automation Solutions#Automated Equipment#Automated Bagging Systems#Transit Packaging#Food Packaging Equipment

0 notes

Note

After I deleted a bunch of projects (thankfully non-critical, though representing a great deal of work in total) during a recent fresh OS install, I realized that my backup practices are practically non-existent. Any tips or sources on getting started making, and eventually automating, effective backups?

I am stealing the concept here from jwz's backup guide, but I am recommending different tools, focusing on personal files only, and also addressing Windows. jwz's guide is a good reference:

Doing a way, way better job than most people of backing up one single system is very easy. Let us begin.

The most basic step of having decent backups is getting your hands on two external hard drives at least big enough to hold your entire system, and putting a label on them that says "BACKUP ONLY DO NOT USE FOR ANYTHING ELSE I AM BEING FOR REAL HERE"

Once you've got those, plug one into your system wherever it spends the most time. If you have a desktop then that's solved, if it's a laptop hopefully you already have a USB hub you plug it into when you sit down to work or whatever and you can just leave it there.

Now set up regular scheduled backups to that device. On Windows and Mac, there's a built in tool for backing up your system to an external drive. We'll assume that you just want to back up your user files on Windows and Linux, since doing full system backups isn't tricky but is kind of unnecessary.

(Ugh. Windows seems to be trying to phase out Windows Backup and Restore in favour of their File History thing. That's annoying, let me log in to windows and check how this actually works. Mac in the meantime)

Mac has Time Machine. Time Machine is extremely good, and you can tell Time Machine to save its backups to a disk. Point Time Machine at your external hard drive and tell it to schedule a backup however frequently you want. If anything goes wrong in the future, you can ask Time Machine to look at that backup disk and it'll show you a few versions of whatever you backed up there. I'm not a Mac user but I think you can even use Time Machine to transfer between an old computer and a new one.

Windows now has File History which I have never used in my life, they added it after I stopped using Windows. Same idea though, pick some folders and back them up to an external storage device. If anything goes wrong, use File History to go back through that device and find the version of the file you wanted. I don't know if there's still a way to access the older Backup and Restore system.

On Linux, my favoured way to manage simple desktop backups is Deja Dup, a GUI for Duplicity. Duplicity can do a lot more than just backup to a disk, but we'll start there. Install Deja Dup, open it up, and follow the prompts to back up your user files to the external drive. Deja Dup can also do backups to remote storage servers, Google Drive/Onedrive, and commercial storage providers like Amazon and Backblaze. It will even encrypt your backups if you are worried about Amazon spying on your files or whatever. If something goes wrong, point Deja Dup at your backup drive and it will offer you a suite of restore options covering a few versions.

Now, you have a permanently plugged in hard drive that will always get rolling backups you can restore from. These aren't safe from, say, ransomware, or your house burning down, but at least you won't lose anything when you update a computer or accidentally delete something and have an ohshit moment.

Now you take that other drive you bought, and do the same backup you're already doing to that. Now you go put it somewhere else where it's readily accessible and won't be accidentally used for anything, keep it at the office, give it to your dad, whatever. Set a reminder on your phone for once a month. Once a month, go get that drive, run another backup, and put it back. You now have better backups than many medium sized businesses.

This is impractical to scale beyond one PC, but if we're being honest even when I had like half a dozen laptops, only one contained much of value. Back up the system you care about.

Don't worry too much about making sure your backups are space efficient, like, yeah it would be a good idea to exclude game installs and stuff from your backups to save space but if that sounds daunting or time consuming literally do not do it. Decision paralysis is brain poison, just back it up and sort it out later. 2TB external hard drives are cheap.

FURTHER STEPS YOU CAN TAKE:

Easy Cloud backup: Backblaze personal backup on Windows and Mac is $6/month and pretty easy to use. If you are struggling to keep track of a monthly remote backup, or you want an easy remote backup. Backblaze is a reasonably reliable company and one of the Go To Companies in the world of data reliability. Yes, it's a cloud subscription. If you don't want that don't use it.

Network backup: If you have access to a storage server, that can be a good way to make a remote backup without having to shuttle disks around. That could be a physical server if you maintain some kind of lab, or it could be a cloud storage provider like Backblaze B2 or Onedrive or whatever. Deja Dup specifically supports backing up to a lot of different network storage providers, and even if you only have a fifty or sixty gigabytes of network storage on hand, your most essential personal files can probably fit in there.

Drive failures: Eventually one of your drives will fail, either your storage drive or your backup drive. If the storage drive fails, well, that's what the backup is for, go get a replacement and restore from the backup. If your backup drive fails, well, that's why you have two of them. As soon as humanly possible go get a replacement drive, and substitute it in for the dead one.

101 notes

·

View notes