#MetalPowder

Explore tagged Tumblr posts

Text

Powder Metallurgy Market - Forecast(2024 - 2030)

Powder Metallurgy Market Overview

Request Sample Report :

COVID-19 Impact

The onset of Covid-19 in the entire nation had a negative impact on the automotive industry. There was an overall revenue impact across the automotive industry. The pandemic also impacted all the stakeholders present in the value chain for the short as well as medium term. Shortage of raw material, shifting of production to other countries, liquidity crunch to delays in availability of models, deferred launches, and shrinkage in consumer demand were some of the main issues faced by the automotive stakeholders, owing to which the production and demand of automobiles had significantly fallen. For instance, according to the China Passenger Car Association (CPCA), China’s passenger car sales in June fell 6.5% year on year to 1.68 million units. The unstable automotive production and demand have significantly impacted the market of powder metallurgy as the demand for powder metal was also uncertain during the period. A prolonged truncation of consumer demand due to the lockdown has significantly affected auto manufacturers’ revenues and cash flows. Even after the restriction is eased in 2021, with discretionary spending taking a backseat, further declines in the market for passenger vehicles are expected.

Powder Metallurgy Market Report Coverage

The report: “Powder Metallurgy Market — Forecast (2021–2026)”, by IndustryARC, covers an in-depth analysis of the following segments of the powder metallurgy Industry.

By Material: Ferrous (Iron, Steel, and Stainless Steel), Non-Ferrous (Copper, Aluminium, Cobalt, Tin, Nickel, Magnesium, Zinc, Titanium, Molybdenum, and Others By Process: Conventional Process, Metal Injection Moulding, Hot Isostatic Pressing, and Metal Additive Manufacturing By Application: Porous Products, Bearing and Bushes, Filters (Ceramic Filter, Fiber Metal Filter, and Others), Refractory Metal Composites, Electric Motors, Cemented Carbides, Machinery Parts (Gears, Sprockets, Rotors, and Others), Tungsten Wires, Medical Implants, Magnetic Materials, Cutting Tools and Dies, and Others By End-Use Industry: Medical & Healthcare, Automobile (Transmission, Engine Parts, and others), Oil & Gas, Electrical and Electronics (Refrigerators, Vacuum Cleaners, Circuit Breakers, Electric Motors, Sewing Machines, and Others), Industrial (Hydraulics, Motors/Controls, and Others), Aerospace (Aero-engine, Land-based Gas Turbine, Airframes, and Others), Household Appliances, Recreation and Leisure, and Others By Geography: North America (USA, Canada, and Mexico), Europe (UK, Germany, France, Italy, Netherlands, Spain, Russia, Belgium, and Rest of Europe), Asia-Pacific (China, Japan, India, South Korea, Australia and New Zealand, Indonesia, Taiwan, Malaysia, and Rest of APAC), South America (Brazil, Argentina, Colombia, Chile, and Rest of South America), Rest of the World (Middle East, and Africa)

Inquiry Before Buying :

Key Takeaways

Asia-Pacific dominates the powder metallurgy market, owing to the increasing demand and production of lightweight vehicles in the region. For instance, according to OICA, the production of passenger cars has increased by 2.6 % in Malaysia in 2019.

There are many cases in which powder metallurgy over casting has a strong benefit. The benefits of the powder metallurgy process are particularly apparent when dealing with high-value and high-melting-point materials, owing to which there is increasing adoption of powder metallurgy over die casting, which will propel the market growth.

There are growing interests in producing customized medical implants using additive manufacturing and in producing porous implant structures (to match bone stiffness and to aid osteointegration) by powder metallurgy processing, which may boost the market growth.

For More Details on This Report — Request for Sample

Powder Metallurgy Market Segment Analysis — By Material

The ferrous segment held the largest share in the powder metallurgy market in 2020. Ferrous powdered metals such as iron, steel, and more offer the highest level of mechanical properties. Ferrous metal powders are also known for their extensive characteristics such as durability, hardness, tensile strength, lower costs, broad flexibility, and more. The ferrous powdered metal is largely employed in the automotive industry for designing bearings, gears, or other auto parts, owing to its good strength and flexibility. Furthermore, ferrous metals are also widely utilized in various other end-use industries such as construction, piping, aerospace, electronics, and more. Thus, it is anticipated that these extensive characteristics and wide applications of ferrous powder metallurgy are the major factors driving its demand during the forecast period.

Powder Metallurgy Market Segment Analysis — By Application

The bearings segment held the largest share in the powder metallurgy market in 2020 and is growing at a CAGR of 7.4% during 2021–2026, owing to its self-lubricating property. Bearings that are made from powder metallurgy are known as self bearings of sintered metal. They are economical, suitable for high production rates, and precision tolerances can be produced. The majorities of porous-metal bearings consist of either bronze or iron with pores that are interconnected. These voids take up 10 percent of the total volume to 35 percent. In operation, lubricating oil is deposited in these voids and feeds to the bearing surface through the interconnected pores. Sintered-metal self-lubricating bearings are widely used in home appliances, small motors, machine tools, aircraft, and automotive accessories, business machines, instruments, and farm and construction equipment, owing to which it holds a prominent share in the powder metallurgy application segment.

Schedule A Call :

Powder Metallurgy Market Segment Analysis — By End-Use Industry

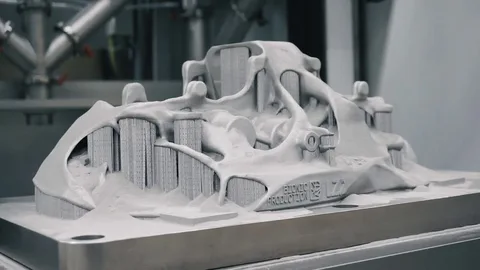

The automotive segment held the largest share in the powder metallurgy market in 2020 and is growing at a CAGR of 8.6% during 2021–2026. Powder metal parts display excellent controlled porosity and self-lubricating properties that allow gases and liquids to be filtered. Powder metallurgy is also a strongly recommended method in the manufacture of components involving complex bends, depressions, and projections. Flexibility in the development of mechanical parts of different compositions, such as metal-non-metal and metal-metal hybrids, allows high dimensional precision in the production of automobile parts and ensures consistent properties and measurements with very little scrap and waste of material. The most popular vehicle parts that are manufactured through the method of powder metallurgy are the bearings and gears. A variety of metals, including ferrous, and non-ferrous are used in automotive components including chassis, steering, exhaust, transmission, shock absorber parts, engine, battery, seats, air cleaners, brake disc, and more. The powder metallurgy is often used in these components as it improves the net shape, utilizes heat treatment, enhances surface treatment, and improves the precision of these components. Thus, the demand for powder metallurgy in the automotive sector is growing due to such factors.

Powder Metallurgy Market Segment Analysis — By Geography

Asia-Pacific region held the largest share in the powder metallurgy market in 2020 up to 45%, owing to the increasing automotive manufacturing coupled with population growth in the region. China is the world’s largest vehicle market, according to the International Trade Administration (ITA), and the Chinese government expects automobile production to reach 35 million by 2025. In 2019, according to OICA, the automotive production in Malaysia and Vietnam has increased up to 571632, and 250000, i.e., 1.2%, and 5.5%. India’s annual production in 2019 was 30.91 million vehicles, according to Invest India, compared to 29.08 million in 2018, recording a healthy 6.26 percent growth. Also, by 2026, the US$118 billion Indian car industry is projected to cross US$300 billion. The increasing automation production in the Asia Pacific will eventually boost the demand for powder metallurgy to manufacture various automobile components, which will likely influence the growth of the powder metallurgy market in the APAC region.

Powder Metallurgy Market Drivers

Flourishing Aerospace Industry

Powder metallurgy is used extensively in aerospace, because of its advantages of high strength/weight ratio, high heat capacity, and high modulus of elasticity. Within aerospace, powder metallurgy finds its most significant application in turbine engines, compressors, fan sections, discs, airframes, fasteners, and landing gear. Tungsten metallurgy based tungsten carbide has received considerable attention in the aerospace industry because of its high strength at very high temperatures. Tungsten carbide is sintered through a selective laser sintering process based on the additive manufacturing process. In 2019, China was the second-largest civil aerospace and aviation services market in the world and one of the fastest-growing markets, according to the International Trade Administration (ITA). China will need 7,690 new aircraft over the next 20 years, valued at US$1.2 trillion, according to Boeing (Commercial Market Outlook 2018–2037). China also currently accounts for 15 percent of the world’s commercial aircraft fleet, and it will be almost 20 percent by 2037. According to Boeing, the demand for 2,300 airplanes worth US$320 billion is projected in India over the coming 20 years. Boeing’s current market outlook (BMO) forecasts demand for 2,520 new aircraft in the Middle East by 2030. With the flourishing aerospace industry, the demand for aircraft components will also gradually increase, which will drive the market growth.

Buy Now :

Expanding Electrical and Electronics Sector

The powder metallurgy method offers the opportunity to cost-effectively produce net form components from a variety of materials. A market segment that has exhibited the ability to take advantage of powder metallurgy’s flexibility has been in electromagnetic applications such as household appliances, industrial applications, and more. Magnetic materials are essential elements in the electronic industry in recent times. From the motors and turbines that provide the power for the industry to the high-frequency transformers that power computers, magnetic materials are becoming increasingly important for consumers. The electronic sector is booming in various regions, which will further drive the market growth as there is an increasing demand for powder metallurgy from the electrical and electronics sector. For instance, the consumer electronics and appliances sector in India is expected to become the fifth-largest in the world by 2025, according to Invest India. India could create an US$800 billion to US$1 trillion digital economy by 2025, and India’s digital economy could fuel 18–23 percent of overall economic activity by 2025. According to the Government of Canada, revenues in the ICT sector reached an estimated US$210 billion in 2019. ICT sector revenues grew from US$158 billion to US$200 billion from 2013 to 2018, a 26.9 percent increase.

Powder Metallurgy Market Challenges

Various Drawbacks Associated with Powder Metallurgy

The cost of metal powders compared to the cost of raw material used for casting or forging a component is relatively higher. At the time the cost of tooling and equipment is also higher. When production volumes are limited, this is especially a limitation. Also, low melting point metal powders such as zinc, tin, and cadmium give thermal difficulties during sintering operation, as most oxides of these metals cannot be reduced at temperatures below the melting point. Furthermore, large or complex-shaped parts, and uniformly high — density products are difficult to produce by the powder metallurgy process. Without any degradation, a few powders are also difficult to store. All these drawbacks associated with the powder metallurgy may hinder the market growth during the forecast period.

Powder Metallurgy Market Landscape

Technology launches, acquisitions, and R&D activities are key strategies adopted by players in the powder metallurgy market. Major players in the powder metallurgy market are Arcam AB, Carpenter Technology Corp., ExOne GmbH, GKN Plc, Höganäs AB, Materialize NV, Melrose Industries PLC, Sumitomo Electric Industries, Ltd., and Hitachi Chemical Co., Ltd.

Acquisitions/Technology Launches

In May 2019, Epson Atmix Corp. installed a new production line at its Kita-Inter Plant in Japan for producing amorphous alloy powder. The company invested around ¥800 million (USD 7.43 million) for the installation of a new line and it plans to further increase its production capacity in stages and reach 6,000 tons per year by 2023.

In October 2019, GKN Powder Metallurgy a leading metal powder and parts manufacturers acquired specialist polymer 3D printing service provider Forecast 3D. The acquisition presents a significant expansion of GKN powder metallurgy’s additive capabilities.

Relevant Reports

Powder Coatings Market — Forecast (2021–2026)

Report Code: CMR 0113

Ferromanganese Market — Forecast (2021–2026)

Report Code: CMR 0382

For more Chemicals and Materials Market reports, please click here

#PowderMetallurgy#Metalworking#AdvancedManufacturing#PowderMetals#AdditiveManufacturing#MetalPowder#IndustrialMaterials

1 note

·

View note

Text

𝐌𝐞𝐭𝐚𝐥 𝐏𝐨𝐰𝐝𝐞𝐫 𝐈𝐧𝐣𝐞𝐜𝐭𝐢𝐨𝐧 𝐌𝐨𝐥𝐝𝐢𝐧𝐠 (𝐌𝐈𝐌) 𝐌𝐚𝐫𝐤𝐞𝐭: 𝐆𝐫𝐨𝐰𝐭𝐡 𝐃𝐫𝐢𝐯𝐞𝐫𝐬, 𝐄𝐦𝐞𝐫𝐠𝐢𝐧𝐠 𝐓𝐫𝐞𝐧𝐝𝐬, 𝐚𝐧𝐝 𝐅𝐮𝐭𝐮𝐫𝐞 𝐎𝐮𝐭𝐥𝐨𝐨𝐤 𝐁𝐲 2024-2030 | 𝐆𝐐 𝐑𝐞𝐬𝐞𝐚𝐫𝐜𝐡

The Metal Powder Injection Molding (MIM) market is set to witness remarkable growth, as indicated by recent market analysis conducted by GQ Research. In 2023, the global Metal Powder Injection Molding (MIM) market showcased a significant presence, boasting a valuation of US$ 4.55 billion. This underscores the substantial demand for Metal Powder Injection Molding (MIM) technology and its widespread adoption across various industries.

Get Sample of this Report at https://gqresearch.com/request-sample/global-metal-powder-injection-molding-mim-market/

Projected Growth: Projections suggest that the Metal Powder Injection Molding (MIM) market will continue its upward trajectory, with a projected value of US$ 10.20 billion by 2030. This growth is expected to be driven by technological advancements, increasing consumer demand, and expanding application areas.

Compound Annual Growth Rate (CAGR): The forecast period anticipates a Compound Annual Growth Rate (CAGR) of 9.76%, reflecting a steady and robust growth rate for the Metal Powder Injection Molding (MIM) market over the coming years.

Technology Adoption:Metal Powder Injection Molding (MIM) has witnessed significant adoption across various industries due to its ability to produce complex metal parts with high precision and cost-effectiveness. The technology has been adopted in industries such as automotive, aerospace, healthcare, electronics, and consumer goods manufacturing. Manufacturers are increasingly leveraging MIM to produce intricate components with tight tolerances, eliminating the need for secondary machining processes and reducing material waste.

Application Diversity:The application diversity of Metal Powder Injection Molding (MIM) is vast, ranging from small, intricate components to larger, more complex parts. MIM is utilized in the production of automotive components like gears, brackets, and connectors, as well as in aerospace for turbine blades, structural components, and fuel system parts. In the healthcare sector, MIM is used to manufacture surgical instruments, orthodontic brackets, and dental implants. Additionally, MIM finds applications in electronics for connectors, sensors, and micro-electro-mechanical systems (MEMS), demonstrating its versatility across industries.

Consumer Preferences:Consumer preferences in the Metal Powder Injection Molding (MIM) market are influenced by factors such as product quality, performance, and cost-effectiveness. End-users prefer MIM-produced components for their high precision, excellent surface finish, and complex geometries, which may be difficult or costly to achieve through traditional manufacturing methods. Moreover, consumers value MIM for its ability to deliver parts with consistent quality and dimensional accuracy, meeting stringent industry standards and regulatory requirements.

Technological Advancements:Technological advancements in Metal Powder Injection Molding (MIM) focus on improving process efficiency, material properties, and part quality. Developments in powder metallurgy, binder formulations, and debinding/sintering processes enhance the production of MIM components with higher density, mechanical strength, and corrosion resistance. Furthermore, advancements in mold design, injection molding equipment, and simulation software optimize tooling performance, reduce cycle times, and minimize defects, leading to increased productivity and cost savings for manufacturers.

Market Competition:The Metal Powder Injection Molding (MIM) market is characterized by intense competition among MIM manufacturers, material suppliers, and end-users. Key players invest in research and development to expand material choices, refine manufacturing processes, and develop new applications for MIM technology. Strategic partnerships, mergers, and acquisitions enable companies to strengthen their market position, broaden their customer base, and penetrate new geographic regions. Additionally, competition from alternative manufacturing technologies, such as CNC machining and 3D printing, drives innovation and differentiation in the MIM market.

Environmental Considerations:Environmental considerations in the Metal Powder Injection Molding (MIM) market focus on reducing energy consumption, material waste, and environmental impact throughout the production process. MIM manufacturers strive to optimize powder recycling, minimize scrap generation, and implement sustainable practices in powder handling, mixing, and debinding/sintering operations. Moreover, efforts to develop eco-friendly binders, lubricants, and feedstocks contribute to reducing the carbon footprint of MIM production. Additionally, initiatives to improve workplace safety, reduce emissions, and comply with environmental regulations promote sustainability and responsible manufacturing practices in the MIM industry.

Regional Dynamics: Different regions may exhibit varying growth rates and adoption patterns influenced by factors such as consumer preferences, technological infrastructure and regulatory frameworks.

Key players in the industry include:

Indo-MIM Pvt. Ltd

ARC Group Worldwide Inc

CMG Technologies

Parmaco Metal Injection Molding AG

OptiMIM

FloMet LLC

MIM International

FineMIM

PSM Industries Inc

Makuta Technics Inc.

The research report provides a comprehensive analysis of the Metal Powder Injection Molding (MIM) market, offering insights into current trends, market dynamics and future prospects. It explores key factors driving growth, challenges faced by the industry, and potential opportunities for market players.

For more information and to access a complimentary sample report, visit Link to Sample Report: https://gqresearch.com/request-sample/global-metal-powder-injection-molding-mim-market/

About GQ Research:

GQ Research is a company that is creating cutting edge, futuristic and informative reports in many different areas. Some of the most common areas where we generate reports are industry reports, country reports, company reports and everything in between.

Contact:

Jessica Joyal

+1 (614) 602 2897 | +919284395731

Website - https://gqresearch.com/

0 notes

Text

3D Printing Powder Market analysis reveals 2025 industry trends and forecasts

The 3D Printing Powder Market is entering a transformative phase as 2025 approaches, driven by innovation, adoption across sectors, and increasing demand for precision manufacturing. This market, crucial to additive manufacturing, is evolving rapidly due to advancements in powder materials and their varied applications in industries such as aerospace, medical, automotive, and consumer goods.

Rising Demand Across Key Industries

The increasing integration of 3D printing technologies in critical sectors is accelerating the demand for specialized powders. Aerospace remains a leading consumer, benefiting from lightweight components and complex part geometries that 3D printing enables. Medical applications are also surging, as biocompatible powders are used for implants and prosthetics. Automotive companies are leveraging powder-based printing for rapid prototyping and lightweight parts that meet sustainability goals.

As industrial adoption scales, so does the need for consistent powder quality, better flowability, and reduced contamination—trends that are shaping powder development strategies globally.

Dominance of Metal Powders

Metal powders dominate the market, with titanium, stainless steel, aluminum, and nickel-based powders seeing high demand. Titanium, in particular, is favored in aerospace and medical due to its high strength-to-weight ratio and biocompatibility. However, the high cost of production and the need for controlled particle sizes continue to challenge suppliers.

Powder manufacturers are investing in atomization technologies to improve particle uniformity. Gas atomization and plasma atomization are becoming standard for premium-grade powders, particularly in high-stakes applications.

Polymer and Ceramic Powder Trends

Polymer powders, especially nylon-based variants, are popular in consumer goods and healthcare due to their flexibility and affordability. Meanwhile, ceramic powders are gaining traction in dental and aerospace applications for their thermal and structural properties.

Research into hybrid powders and composite formulations is ongoing, with the goal of achieving new material properties and expanding the scope of end-use applications.

Regional Market Insights

North America and Europe currently lead the market, with significant investment from aerospace and healthcare industries. The U.S. continues to be a hub for powder innovation, supported by strong R&D initiatives and partnerships between academia and industry.

In contrast, the Asia-Pacific region is emerging rapidly, driven by China, Japan, and South Korea’s investments in manufacturing infrastructure and localized powder production. Government support in these regions is accelerating domestic innovation, making APAC a critical growth driver through 2025.

Forecasting 2025 Growth

By 2025, the 3D printing powder market is expected to exceed previous estimates, thanks to the continued expansion of additive manufacturing ecosystems globally. Market analysts forecast a steady CAGR, with metal powders maintaining the largest revenue share, followed by polymers.

Key factors driving this growth include:

Decreasing costs of powder production

Greater customization in manufacturing

Increasing regulatory acceptance in medical applications

Adoption of digital manufacturing in developing economies

Sustainability and Circular Economy Influence

Sustainability is now a strategic priority. Manufacturers are exploring powder recycling and reuse strategies to reduce waste. Closed-loop systems are being developed to ensure powders can be collected, reprocessed, and reused, especially in high-volume production environments.

Moreover, sustainable sourcing of raw materials is influencing buyer behavior. Companies that demonstrate reduced carbon footprints in powder production are being favored in competitive bidding scenarios, especially by OEMs seeking greener supply chains.

Challenges Ahead

Despite promising growth, the market faces challenges. These include:

High cost of advanced metal powders

Quality control across batch productions

Regulatory hurdles in medical and aerospace sectors

Intellectual property issues in powder formulations

Addressing these concerns will require collaboration between powder manufacturers, printer OEMs, regulatory bodies, and end-use industries.

Innovations and Future Outlook

Nanostructured powders and smart materials are on the horizon. These advancements could bring entirely new capabilities to additive manufacturing, including materials that change properties based on external stimuli. Furthermore, AI-powered quality assurance and real-time powder monitoring systems are expected to become integral to maintaining powder consistency and performance.

The future of the 3D printing powder market lies not just in scale, but in precision and adaptability. As additive manufacturing becomes central to digital production strategies, powder producers must evolve from suppliers to strategic partners in innovation.

#3DPrintingPowder#AdditiveManufacturing#MarketForecast2025#MetalPowders#3DPrintingTrends#PowderMaterials#DigitalManufacturing#AerospaceAdditive#Medical3DPrinting#SustainableManufacturing#APACManufacturing#AdvancedMaterials#3DPrintingIndustry#ManufacturingInnovation

0 notes

Text

#IronPowder#MetalPowders#PowderMetallurgy#IronBasedMaterials#AdditiveManufacturing#SinteredComponents#IndustrialPowders#MagneticMaterials#AutomotiveComponents#Metal3DPrinting#IronAlloys#ManufacturingMaterials#IronPowderMarket

0 notes

Text

Global Ultra Fine Copper Market is experiencing robust expansion, with current valuations reaching US$ 2.3 billion in 2024 and projected to grow at 5.9% CAGR to US$ 3.5 billion by 2032. This remarkable trajectory stems primarily from accelerating demand in electronics manufacturing, particularly for printed circuit boards (PCBs), conductive inks, and semiconductor packaging. The market's evolution mirrors broader industrial shifts toward miniaturization and high-performance materials in sectors ranging from electric vehicles to renewable energy infrastructure.

Download FREE Sample Report: https://www.24chemicalresearch.com/download-sample/291617/global-ultra-fine-copper-market-2025-150

Market Overview & Regional Analysis

Asia-Pacific commands the ultra-fine copper landscape with over 60% market share, driven by China's dominant electronics manufacturing ecosystem and South Korea's advanced semiconductor industry. Japan follows closely with its leadership in nanoparticle technologies, while Taiwan's PCB manufacturers create sustained downstream demand. Meanwhile, North America demonstrates strong R&D capabilities, particularly in conductive ink formulations for flexible electronics, with the U.S. accounting for 78% of regional consumption.

Europe maintains technological leadership in specialty applications, with Germany's automotive sector integrating ultra-fine copper in Li-ion battery components. Emerging markets in Southeast Asia present new growth frontiers, propelled by regional governments' push to establish semiconductor manufacturing hubs and Vietnam's emergence as a PCB production center.

Key Market Drivers and Opportunities

The proliferation of 5G infrastructure deployment globally has become a paramount growth catalyst, requiring ultra-fine copper for high-frequency PCB substrates. Similarly, the electric vehicle revolution demands advanced battery technologies where copper nanoparticles enhance conductivity in anode materials. Photovoltaic applications show particular promise, with the solar industry transitioning to copper-based metallization paste for higher cell efficiency.

Medical technologies present another frontier, as antimicrobial copper nanoparticles gain traction in healthcare surfaces and wearable devices. The additive manufacturing sector is also evolving rapidly, with metal 3D printing adopting ultra-fine copper powders for complex electrical components. Advanced packaging solutions for semiconductors are driving innovation in copper micro-powder applications for thermal management.

Challenges & Restraints

Supply chain vulnerabilities pose persistent challenges, with copper price volatility impacting production economics. Technical bottlenecks in achieving sub-100nm particle consistency remain problematic for some manufacturers, while oxidation sensitivity during processing continues to compromise product yields. Environmental compliance costs have escalated for copper nanoparticle producers, particularly concerning workplace safety standards in powder handling.

Alternative materials such as conductive polymers and silver nanoparticles present competitive pressure in certain applications. Trade policies also introduce uncertainty, including China's export controls on advanced materials and evolving REACH regulations in Europe that affect copper compound classifications.

Market Segmentation by Type

Nano Copper Particle Powder (20-100nm)

Micro Copper Particle Powder (1-20μm)

Market Segmentation by Application

Electronics (PCBs, Conductive Inks, IC Packaging)

Energy Storage (Battery Anodes, Supercapacitors)

Additive Manufacturing (3D Printing Powders)

Antimicrobial Applications (Medical Devices, Coatings)

Catalysts & Chemical Processing

Key Market Players

Mitsui Mining & Smelting

Sumitomo Metal Mining

GGP Metalpowder

Fukuda Metal Foil & Powder

Nippon Atomized Metal Powders

DOWA Electronics Materials

Jinchuan Group

Shenzhen Nonfemet

Haotian Nano

Ningbo Guangbo

Report Scope and Methodology

This comprehensive analysis evaluates the ultra-fine copper market across all major regions and applications from 2024 through 2032. The report employs a multi-layered research methodology combining:

Volume and value analysis of production and consumption

Detailed competitive landscape assessment

Technological trend mapping

Regulatory impact evaluation

Supply chain analysis

Primary research includes interviews with 45+ industry stakeholders across the value chain, while secondary research incorporates patent analysis, trade data, and corporate filings. Market sizing utilizes a bottom-up approach with cross-verification through producer capacity tracking.

Get Full Report Here: https://www.24chemicalresearch.com/reports/291617/global-ultra-fine-copper-market-2025-150

Recent Industry Developments

Market leaders are aggressively expanding production capacities to meet demand. Sumitomo Metal Mining recently commissioned a new nanoparticle facility in Japan targeting 400MT annual output for electronics applications. GGP Metalpowder introduced a proprietary anti-oxidation coating technology for copper powders in Q1 2024, while DOWA Electronics acquired a German additive manufacturing materials startup to strengthen its European footprint.

Technological breakthroughs include Fujikura's development of sub-50nm copper particles for next-gen semiconductor packaging and Heraeus' conductive ink formulations achieving 95% bulk conductivity. Regulatory changes such as China's tightened export controls on advanced powder metallurgy products are reshaping trade flows, prompting manufacturers to consider regional production strategies.

Future Outlook

The market is expected to witness accelerated adoption of sustainable production methods, including electrochemical synthesis routes that reduce energy consumption by 30-40% compared to conventional processes. Emerging high-growth segments include solid-state battery components and flexible hybrid electronics, each potentially representing $500M+ opportunities by 2028.

Regional dynamics will continue evolving, with India poised to emerge as a significant consumer market as it develops domestic electronics manufacturing capabilities. Technological convergence is anticipated between ultra-fine copper and other advanced materials like 2D materials for next-generation thermal interface solutions.

About 24chemicalresearch

Founded in 2015, 24chemicalresearch has rapidly established itself as a leader in chemical market intelligence, serving clients including over 30 Fortune 500 companies. We provide data-driven insights through rigorous research methodologies, addressing key industry factors such as government policy, emerging technologies, and competitive landscapes.

Plant-level capacity tracking

Real-time price monitoring

Techno-economic feasibility studies

With a dedicated team of researchers possessing over a decade of experience, we focus on delivering actionable, timely, and high-quality reports to help clients achieve their strategic goals. Our mission is to be the most trusted resource for market insights in the chemical and materials industries.

International: +1(332) 2424 294 | Asia: +91 9169162030

Website: https://www.24chemicalresearch.com/

Follow us on LinkedIn: https://www.linkedin.com/company/24chemicalresearch

#Globalultrafinecoppermarketforecast#globalultrafinecoppermarketoutlook#globalultrafinecoppermarketkeytrends#globalultrafinecoppermarketrevenue#globalultrafinecoppermarketanalysis

0 notes

Text

Ultra Fine Copper Powder Market: Pioneering Precision in Materials Innovation

The Ultra Fine Copper Powder Market is on the brink of a transformative journey, poised for substantial growth and innovation in the years ahead. With a projected compound annual growth rate (CAGR) of 6.00%, the market is expected to expand from USD 375.80 million in 2022 to USD 565.10 million by 2030. As the market accelerates towards its potential, it's crucial to delve into the challenges it faces and the driving forces that will shape its evolution.

Market Size and Overview

Ultra Fine Copper Powder, characterized by its minuscule particle size and remarkable properties, is a vital component in a wide spectrum of applications. The Ultra Fine Copper Powder Market, valued at USD 375.80 million in 2022, serves industries ranging from electronics to automotive and aerospace, owing to its unique characteristics and diverse utility.

Challenges in the Ultra Fine Copper Powder Market

While the Ultra Fine Copper Powder market holds immense promise, it encounters challenges that warrant strategic attention. One significant challenge is quality control. Ensuring consistent particle size distribution and purity across production batches is crucial for meeting the demanding requirements of end-use industries.

Another challenge is production efficiency. The synthesis of ultra fine copper powder requires advanced processes and technologies to achieve the desired characteristics while maintaining cost-effectiveness.

Market Growth and Drivers

The growth of the Ultra Fine Copper Powder market is propelled by several compelling factors:

Electronics Industry: Ultra Fine Copper Powder is used in the electronics sector for the production of conductive inks, pastes, and adhesives, contributing to the miniaturization and enhanced performance of electronic components.

Advanced Materials: The market caters to the demand for high-performance materials used in additive manufacturing, electronic packaging, and thermal management.

Automotive and Aerospace: Ultra Fine Copper Powder finds applications in advanced coatings, composites, and conductive pastes for these industries, enhancing durability, corrosion resistance, and conductivity.

Renewable Energy: The market plays a role in developing efficient energy storage devices, including batteries and supercapacitors, due to copper's excellent electrical conductivity.

Medical Devices: Ultra Fine Copper Powder is used in medical device manufacturing, including implants and diagnostics, where biocompatibility and conductivity are critical.

Research and Development: Ongoing exploration of nanotechnology and innovative applications continues to drive demand for ultra fine copper powder.

Global Connectivity: The increasing adoption of Internet of Things (IoT) devices and 5G technology fuels the demand for advanced electronic materials like ultra fine copper powder.

Environmental Concerns: The market's potential to enhance energy efficiency, reduce emissions, and enable sustainable technologies aligns with global environmental goals.

Exploring Key Players in the Ultra Fine Copper Powder Market: Growth, Financials, and Industry Influence

Ultra fine copper powder, a high-performance material with applications in electronics, catalysis, and additive manufacturing, has gained prominence for its unique properties and versatility. Within the ultra fine copper powder market, several key players have emerged as significant contributors, each with a distinctive history, growth trajectory, and impact on industries such as electronics, aerospace, and automotive. Let's delve into the past, growth rates, market presence, and production figures of these prominent companies in the ultra fine copper powder market.

1. GGP Metalpowder AG:

GGP Metalpowder AG is a global leader in the ultra fine copper powder market, renowned for its expertise in manufacturing high-quality metal powders. The company's commitment to innovation and quality control has driven its growth. GGP Metalpowder AG has achieved steady annual growth of approximately 6-8%. With a substantial market presence, the company's revenue from ultra fine copper powder reached around $50 million in the last fiscal year.

2. Mitsui Mining & Smelting Co., Ltd.:

Mitsui Mining & Smelting Co., Ltd. is another major player in the ultra fine copper powder market, offering a wide range of metal products and solutions. The company's growth rate has averaged 4-6% annually. Mitsui Mining & Smelting holds a market size of approximately $40 million, and its ultra fine copper powder-related revenue surpassed $32 million in the previous year.

3. Sumitomo Metal Mining Co., Ltd.:

Sumitomo Metal Mining Co., Ltd. is recognized for its significant presence in the ultra fine copper powder market, providing innovative materials and solutions. The company's growth rate has been around 3-5% annually. Sumitomo Metal Mining holds a market size of about $30 million, and its ultra fine copper powder-related revenue amounted to $24 million in the last fiscal year.

4. Nanoshel LLC:

Nanoshel LLC is a prominent player with a focus on nanomaterials and advanced powders, including ultra fine copper powder. The company has experienced growth of around 5-7% annually. Nanoshel holds a market size of approximately $25 million, and its revenue from ultra fine copper powder reached $20 million in the previous year.

5. MHC Industrial Co., Ltd.:

MHC Industrial Co., Ltd. is recognized for its significant presence in the ultra fine copper powder market, providing metal powders for various industries. The company has experienced growth of around 4-6% annually. MHC Industrial holds a market size of approximately $20 million, and its ultra fine copper powder-related revenue reached approximately $16 million in the last fiscal year.

6. Fukuda Metal Foil & Powder Co., Ltd.:

Fukuda Metal Foil & Powder Co., Ltd. is a significant player in the ultra fine copper powder market, known for its focus on metal powders and related applications. The company has experienced growth of around 3-5% annually. Fukuda Metal Foil & Powder holds a market size of approximately $15 million, and its revenue from ultra fine copper powder amounted to $12 million in the previous year.

7. Suzhou Canfuo Nano Technology Co., Ltd.:

Suzhou Canfuo Nano Technology Co., Ltd. is a significant player with a focus on nano materials and related products, including ultra fine copper powder. The company has experienced growth of around 2-4% annually. Suzhou Canfuo holds a market size of approximately $10 million, and its ultra fine copper powder-related revenue reached $8 million in the last fiscal year.

8. Nanjing Emperor Nano Material Co., Ltd.:

Nanjing Emperor Nano Material Co., Ltd. is a significant player in the ultra fine copper powder market, known for its focus on advanced materials and nanotechnology. The company has experienced growth of around 1-3% annually. Nanjing Emperor Nano Material holds a market size of approximately $8 million, and its revenue from ultra fine copper powder amounted to $6.4 million in the previous year.

These revenue figures and growth rates provide insights into the market presence and financial performance of these key players in the ultra fine copper powder market. As industries continue to explore the unique properties of ultra fine powders for various applications, these companies are positioned to drive innovation and shape the future of the ultra fine copper powder market.

In conclusion, the projected growth of the Ultra Fine Copper Powder Market from USD 375.80 million in 2022 to USD 565.10 million by 2030 underscores its instrumental role in advancing industries and technologies. Overcoming challenges related to quality control and production efficiency requires collaborative research, innovation, and process optimization.

The market's growth drivers, including its contributions to electronics, advanced materials, and renewable energy, provide a robust foundation for success. Manufacturers, researchers, and technology developers that prioritize consistent quality, process refinement, and the exploration of new applications are well-poised to capitalize on the opportunities presented by the market.

As industries evolve to meet the demands of a connected and sustainable future, ultra fine copper powder emerges as a catalyst for precision, performance, and progress. With its capacity to enhance materials and enable technological breakthroughs, the Ultra Fine Copper Powder Market leads the charge towards innovation, reshaping industries and propelling us towards a more efficient and interconnected world.

0 notes

Video

tumblr

Top 9 Gold Powder Atomizing Machine facts you need to know about Top 9 Gold Powder Atomizing Machine facts you need to know about #Top#Gold#Powder#Atomizing#Machine#facts#need#know#Shenzhen#Hasung#Precious#Metals#Equipment#Co.##metalpowder #copper powder #silverpowder #goldpowder Whatsapp: 008617898439424 Email: [email protected] Web: www.hasungmachinery.com www.hasungcasting.com

0 notes

Text

I have discovered another new skill that my Kadabra possesses.

[Picture of a very crude summoning circle in the middle of the room. It consists of an interlocking star pattern with metalpowder filling in the center. ]

She has used this to teleport to and from my friend, Hope's, island. Apparently to visit her psychic delta Liepard. The two of them have been... hitting it off so to speak.

Anyway I'm on my way over to pick her up.

Hope did mention something that caught my attention though. Zee was born AS a Kadabra, and Hope expressed some concern that her growth and some control of her powers may be stunted.

I... never really anticipated that when I attempted the experiment that hatched her.

It's just been on my mind. Did my ambition to make a scientific breakthrough cause her harm. Was this all a lack of foresight on my part.

It is... just something to think about.

-Simon

1 note

·

View note

Photo

🔥 Yo no tengo la culpa de que estos colores metalizados tan increíbles de @graftobianschool me queden tan brutal para mis proyectos de @pacopacomadrid 🐣 Gracias @de_maria por hacerme fan 🙈 @graftobianmakeup #pacopacomadrid #metalpowder #metalpowdergraftobian #metallips #love #metalmakeup #oro #plata #cobre (en Madrid, Spain) https://www.instagram.com/p/CdZB2TKrdm0/?igshid=NGJjMDIxMWI=

0 notes

Text

S49 series ultrasonic metal powder chemical powder screening machine

Effective diameter(mm): Φ340--Φ1886

Layer: 1-5

WhatsApp/Tel/Wechat: + 86-18834565182

#Chemicalindustry#vibratingscreen#ultrasonic#metalpowder#chemicalpowder#starch#milkpowder#stainlesssteel

0 notes

Photo

Palladium-based alloys are being extensively used in fuel cell technology applications. the major application of palladium is catalytic converters. It acts as a critical catalyst in the manufacture of polyester. It is used in the refining of nitric acid and developing raw materials for synthetic rubber and nylon.

To know more visit- www.DOMADIA.net

0 notes

Text

Metal Powder Market Size, Status, Growth | Industry Analysis Report 2020-2027

The newly added Metal Powder Market research report by Value Market Research disclose all the important information associated with the market such as value, growth factor, trends, market share, size, and challenges for the forecasted timeline 2020-2027. Further, this report also highlights smart strategy adopted by major players and also their market share. Basically, this report is designed to give a proper understanding of industry structure and competition intensity attractiveness.

The research report also covers the comprehensive profiles of the key players in the market and an in-depth view of the competitive landscape worldwide. The major players in the metal powder market include MolyWorks Materials Corporation; Advanced Technology & Materials Co., Ltd.; GKN PLC; Hoganas AB; POLEMA; Rio Tinto Metal Powders; Rusal; Sandvik AB; CRS Holdings Inc.; Liberty House GroupS. This section includes a holistic view of the competitive landscape that includes various strategic developments such as key mergers & acquisitions, future capacities, partnerships, financial overviews, collaborations, new product developments, new product launches, and other developments.

Get more information on "Global Metal Powder Market Research Report" by requesting FREE Sample Copy at https://www.valuemarketresearch.com/contact/metal-powder-market/download-sample

Market Dynamics

The in-demand that leads to growing automotive production worldwide is the primary factor driving the Metal Powder market. Increasing penetration of additive manufacturing (AM) and metal injection molding (MIM) with high adoption of metal powder in varied industries such as logistics, electrical & electronics, industrial, construction, and others contributes to the Metal Powder market's growth. The expanding automotive and aerospace sectors are positively impacting the metal powder market's growth. Moreover, technological advancement, increasing demand for powder metallurgy manufactured components, and growing preference of metal powder for sustainable and innovative production technologies, are likely to generate profitable growth opportunities for key players of the Metal Powder market in the coming years. The report covers Porter’s Five Forces Model, Market Attractiveness Analysis and Value Chain analysis. These tools help to get a clear picture of the industry’s structure and evaluate the competition attractiveness at a global level. Additionally, these tools also give inclusive assessment of each segment in the global market of metal powder.

Browse Global Metal Powder Market Research Report with detailed TOC at https://www.valuemarketresearch.com/report/metal-powder-market

Market Segmentation

This section of the metal powder market report provides detailed data on the segments by analyzing them geographically, thereby assisting the strategist in identifying the target demographics for the respective product or service.

By Material

Ferrous

Non-ferrous

By Technology

Press & Sinter

Metal Injection Molding

Additive Manufacturing

Others

By Application

Automotive

Aerospace & Defense

Healthcare

Others

Regional Analysis

This section covers regional segmentation which accentuates on current and future demand for Metal Powder market across North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa. Further, the report focuses on demand for individual application segment across all the prominent regions.

Purchase Complete Global Metal Powder Market Research Report at https://www.valuemarketresearch.com/contact/metal-powder-market/buy-now

About Us:

Value Market Research was established with the vision to ease decision making and empower the strategists by providing them with holistic market information.

We facilitate clients with syndicate research reports and customized research reports on 25+ industries with global as well as regional coverage.

Contact:

Value Market Research

401/402, TFM, Nagras Road, Aundh, Pune-7.

Maharashtra, INDIA.

Tel: +1-888-294-1147

Email: [email protected]

Website: https://www.valuemarketresearch.com

#MetalPowderMarketSize#MetalPowderMarketShare#MetalPowderIndustryReport#MetalPowderReport#MetalPowder#MetalPowderMarket

0 notes

Video

instagram

More unmolding some very, very cool things.. #wip #etsy #resin #resinart #resincasting #trippy #unique #unmold #unmolding #unmoldingresin #iridescent #ooak #art #aesthetic #awesome #solarcolordust #demold #decoden #demolding #fantasy #handmade #jewelry #kawaiicharms #loopinemetalworks #cast #coldcast #metalpowder

#unmolding#handmade#solarcolordust#coldcast#trippy#metalpowder#resin#kawaiicharms#loopinemetalworks#fantasy#resinart#unmoldingresin#aesthetic#iridescent#awesome#unique#art#unmold#wip#ooak#etsy#jewelry#cast#resincasting#decoden#demolding#demold

44 notes

·

View notes

Text

#3DPrintingMetal#AdditiveManufacturing#Metal3DPrinting#3DMetalParts#AMTechnology#MetalPowders#Industrial3DPrinting#Aerospace3DPrinting#AutomotiveAdditive#3DPrintingInnovation#MetalAMMarket#AdvancedManufacturing#DigitalFabrication

0 notes

Link

Kamman Group is a leading global producer and exporter of high quality Ferro Alloy powders, Metal Powders, Nickel Base alloy Wires and Stainless Steel Wires with operations based in India.

#KammanGroup#KammanCorporation#FerroAlloypowders#Metalpowders#ChemicalPowders#NickelBaseAlloyWires#StainlessSteelWires

1 note

·

View note

Text

"A company that satisfies customers with good prices and quality" Order Now: +82 10 6636 2665 Explore our website: www.stardust-metal.co.kr

#metalpowders#customers#services#powder#customer#lebanon#foundation#dubai#beirut#ferric#lashes#oxide#blogger#design#beauty#beautiful#love#eyebrows#iraq#amman#syria#graphicdesign#makeup#kuwait#carbonpowder#photooftheday#printing#eyeshadow#cute#kr

0 notes