#Modbus/TCP

Explore tagged Tumblr posts

Text

2022-2025

Hartnäckiger Komfort im Kangoo

Im November 2022 kaufen wir einen gebrauchten Renault Kangoo Z.E. (Baujahr 2019) für unseren Fuhrpark. Genutzt wird er überwiegend für Transporte auf dem Gelände. Zu dem Zeitpunkt haben wir noch keine Wallbox, so dass wir ihn schlicht an der Schuko-Steckdose laden. Genau genommen haben wir die Wallbox schon, aber niemand findet es auch nur annähernd wichtig, sie zu installieren. Es geht ja auch so.

So ungefähr zum Ablauf der Wallbox-Gewährleistung mache ich mich doch daran, sie in Betrieb zu nehmen. Beim Kauf war mir wichtig gewesen, dass sie netzwerkfähig ist, ich dem Auto also per Modbus/TCP beim Laden zuschauen oder den Ladevorgang auch steuern kann. Wozu das gut sein könnte, weiß ich noch nicht, aber oft finde ich dann hinterher heraus, warum es interessant ist – wie in diesem Fall.

Die Daten landen via IOBroker und InfluxDB auf einem Grafana-Dashboard. Und so können wir ab September 2024 die Ladevorgänge bestaunen:

Links und rechts sind Ladevorgänge; was mich jedoch irritiert, ist das Gekräusel dazwischen. Es stellt sich heraus, dass das täglich morgens ab halb acht stattfindet.

Tatsächlich kann unser E-Kangoo im Vergleich zum Komfort-Chichi aktueller Elektroautos so ungefähr nix. Was er aber kann: täglich zu einer festen Zeit den Innenraum heizen, "Komfort-Funktion" nennt sich das. Gedacht ist das für Menschen, die täglich zur selben Uhrzeit losfahren: das Auto wird mit "Landstrom" geheizt, und man fährt mit vollem Akku und warmem Innenraum los. Andernfalls würde man im Winter nach dem Losfahren erst mal wertvolle Akkukapazität aufs Heizen verschleudern.

Wir brauchen diese Komfort-Funktion so überhaupt nicht, und mich ärgert der unnötige Stromverbrauch. Das Handbuch sagt, dass man den Lüftungsknopf bloß an eine bestimmte Stelle drehen muss, um das tägliche Heizen zu deaktivieren. Grafana zeigt jedoch, dass das keine Auswirkung hat. Das Autohaus sagt "na ja, wir können uns das mal anschauen". Anschauen bedeutet in dem Fall vermutlich: einmal das gesamte Armaturenbrett ausbauen und den Lüftungsschalter ersetzen. Das würde ganz schön teuer, fürchte ich.

Wir frickeln eine Weile daran rum, zwischendurch kommt mal ein Kollege und sagt: "ist erledigt, ich hab' das jetzt auf null gestellt". Auf null Uhr hat er den Heizzeitpunkt verschoben, na ja. Es heizt natürlich weiterhin.

Weil nun Wallbox und IOBroker eh schon miteinander sprechen, hinterlege ich einen Zeitplan, der der Wallbox sagt: tagsüber darfst du bis zu 32 Ampere abgeben, zwischen 22 und 2 Uhr jedoch nichts. Das Zeitfenster wähle ich großzügig, weil bei Sommerzeitumstellung bestimmt niemand die Auto-Uhr stellen wird etc. Leider heizt der Kangoo weiter, Tag für Tag, völlig unbeeindruckt:

Es folgen ein paar weitere Monate Gefrickel, auch im Kontakt mit dem Hersteller der Wallbox, der meine Nachrichten nur unwillig beantwortet, die Gewährleistung sei ja schon abgelaufen. Außerdem sei IOBroker nicht auf der Liste unterstützter Energiemanagement-Systeme.

Ab April 2025 beginne ich, unseren Eigenverbrauch zu optimieren, indem ich versuche, der Wallbox beizubringen, immer nur so viel Strom abzugeben, wie wir gerade an Solarstrom übrig haben. Dabei stoße ich schließlich auf den banalen Fehler, weswegen die Wallbox die Nachtabschaltung ignoriert. Man darf den Vorgabewert nicht als "bestätigt" senden, in dem Fall denkt sich die Wallbox nämlich "wenn es bestätigt ist, hat's schon jemand anderes erledigt, also muss ich mich nicht mehr drum kümmern". Von unbestätigten Befehlen fühlt sie sich dagegen angesprochen und damit ist der unerwünschte Komfort endlich ausgehebelt:

(Lennart Schütz)

#Elektromobilität#Wallbox#Modbus/TCP#Grafana#Lennart Schütz#Heizung#Komfort#IOBroker#Renault Kangoo Z.E.#Workaround

7 notes

·

View notes

Text

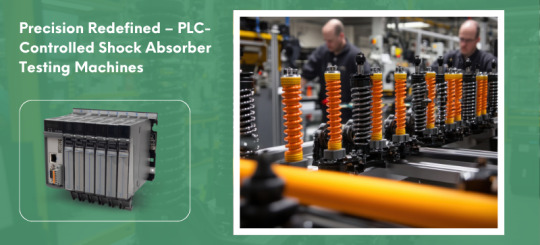

Precision Redefined – PLC-Controlled Shock Absorber Testing Machines

Precision – a word that keeps on getting thrown around often in the world of engineering. However, when it comes to shock absorber testing, precision isn’t a luxury—it’s survival. Every curve, every jolt, every rebound of a shock absorber must be captured, tested, and analysed to microscopic exactness. Gone are the days when manual testing could keep up.

The role of shock absorbers in today’s high-speed automotive innovation and precision engineering is to provide safety, comfort, and performance protection. But how can we make sure that these absorbers meet the high standards required by modern vehicles? This is where PLC automation becomes a useful tool.

The old-fashioned testing methods, which were cumbersome, unreliable, and laborious, have been replaced by PLC-based automation systems. Imagine a testing line with the capacity to think, adapt and respond in real time. The precision of Programmable Logic Controllers (PLCs) is not solely a promise, but rather adherence to standardised protocols.

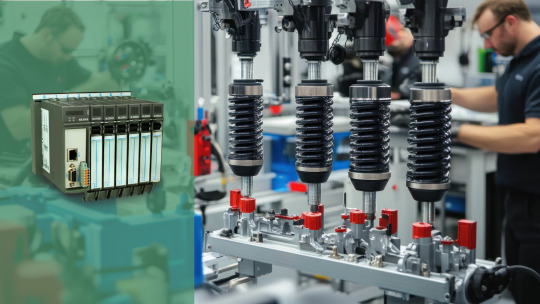

How PLCs Enhance Shock Absorber Testing

There has been an evolution in the science of testing shock absorbers. Let’s understand how smart and compact PLCs can automate and optimise critical testing stages by providing consistency, control, and clarity.

Centralised Control with High Reliability

A robust industrial PLC is the foundation of our testing machines. The real-time control systems embedded in our automation design enable seamless functioning of all sensor, actuator, and motorised components.

Multiple sensors? Check.

Complex test sequences? Seamlessly handled.

From servo motion controllers managing high-speed vertical displacements to compact PLCs managing individual test stations, the formation is digital, deliberate, and dependable.

Real-Time Data Acquisition & Analysis

Here's where things get exciting. Tests on shock absorbers are more than just passing or failing. It's about quantifiable performance with our automation controllers:

Damping force curves

Displacement maps

Velocity and resistance profiles.

The data is gathered by high-resolution sensors and then processed through HMI with PLC controllers. The integration of this with databases is achieved through integrated PLC-based software, resulting in predictive maintenance and long-term performance insights

Feedback Loops for Adaptive Control

Ever wondered what would happen if the test differs? What would be the outcome? Well, with the use of real-time PLC communication protocols (like MODBUS and Ethernet/IP) and closed-loop control enable our systems to identify anomalies mid-test while enabling automatic correction.

Additionally, dynamic adjustment of actuator velocity in a system is possible when the response rate of the unit is slower than the tolerance. Or if temperatures spike? After a system shutdown, it sends an alert via the web server PLC and logs the fault. This requires more than just testing -- intelligent testing.

NX-ERA JET PLC System Architecture

Now let’s explore the engine room that fuels our innovation. The NX-ERA JET PLC, the foundation of our automated testing platform, undergoes a thorough architecture and connectivity analysis.

Core Hardware Components

With its compact size, modular design, and future scalability, the NX-ERA JET PLC is a formidable beast. It houses:

Simple servo systems designed for precise motion control

Energy-efficient motors can be powered by Variable Frequency Drives (VFDs)

HMI interfaces that enable the creation of visual dashboards and manual overrides

I/O modules for interfacing with third-party equipment.

Its modular design makes it suitable for both high-volume testing environments and small-batch production lines that use Micro PLCs or Mini PLCs

Communication & Connectivity

Connectivity should be a fundamental aspect of the entire setup, not an extra one.

Modbus PLC Interface is responsible for ensuring device-to-device communication

High-speed data relays are made possible with Ethernet-based controller systems

PLC with TCP/IP can be used for remote data logging and system control, as well as firmware updates

IoT-ready PLCs enable the integration of the testing machine with ERP, MES, and SCADA

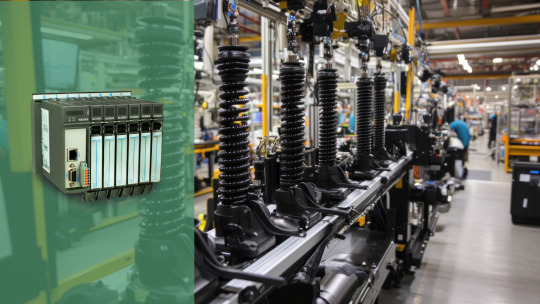

Key Benefits of PLC-Controlled Testing Machines

Indeed, inefficient processes are not easily exploited in the fast-paced manufacturing industry. Your requirements include testing devices that don't blink even when pressured, systems that guarantee high quality, and technology that evolves as your business grows. Our PLC-based automation solutions are precisely in tune with that.

They offer:

Repeatability and Precision - One unit can be tested with ease and accuracy. But what about testing thousands with zero deviation? Our automation solutions that utilize PLCs accomplish this objective. You get:

Identical test cycles

Calibrated control parameters

Automated calibration routines

It implies improved quality control and enhanced audit accessibility.

High Throughput with Reliability - Traditional systems often require individuals to choose between speed and accuracy. Not here. The configurations of our NX-ERA JET PLC enable:

Sub-second test cycles

Parallel station control

Integrated logic and safety layers

All without compromising test integrity.

Reduced Manual Intervention - By utilizing HMI integration, and adaptive PLC programming, operators can not only monitor and but control:

Reduced human error

Faster changeovers

Safer work environment

Safety and Compliance – Safety is crucial for any industrial setup. With our smart PLCs, you can easily:

Emergency stop circuits

Real-time fault diagnostics

Layered safety logic

PLCs are designed to provide timely and effective alerts and shutdowns, complying with international standards such as ISO and CE.

Adaptable and Future-Ready - Different testing may be required for tomorrow's shock absorber. Good news: you won’t need a new machine.

Reprogram testing logic

Add new motion profiles

Update firmware via PLC with IoT

That’s the power of modular PLCs.

Whether you're chasing precision, throughput, or transformation, our PLC-controlled shock absorber testing machines deliver across the board. These benefits aren’t just technical specs—they’re business advantages, engineered to give you control, confidence, and a competitive edge.

Why Choose Messung’s Programmable Logic Controllers for Automation Solutions

Your choice of controller can determine your plant's success in a world propelled by data-driven decision-making, agility, and accuracy. We offer complete PLC-based automation solutions meant to grow with your demands rather than just supply PLCs. Our PLCs are not only intelligent but also necessary for the following reasons:

Smart and Connected PLCs - Our smart PLCs dynamically optimise by adjusting to handle changes. Embedded intelligence enables them to learn from repeated tests, predict component failures, and optimize actuator profiles automatically. Moreover, our edge-computing enabled PLCs help for quicker decisions by lowering cloud dependence.

HMI Integration for Better User Control - No more enigmatic command-line interfaces. With our smart PLCs, you get touchscreen HMIs, customised dashboards and real-time analytics displays.

Compact and Versatile PLC (Programmable Logic Controller) Options - Squeezed on space? You can get the complete power of a typical controller, without worrying about the size, with our compact PLC, micro PLC, and mini PLC range.

From intelligence that anticipates, to interfaces that simplify, to form factors that adapt—Messung’s PLC Programming range is designed not just to meet your automation goals, but to exceed them. Because when you choose Messung, you don’t just adopt automation; you embrace transformation.

Applications Beyond Shock Absorbers

Although shock absorber testing is where our PLC automation solutions show their power, that's just one section in our automation playbook. Beyond the same technology, fine-tuned for real-time control, precision, and adaptability, extends far. Messung's intelligent PLC solutions provide flexibility and value across a range of sectors, whether you are forming metal or transporting materials.

Let's explore how our PLC Control Systems have a range much outside the damping zone:

Motion Control Systems - Conveyor automation and actuator-driven systems all fall under our motion control solutions. Through synced servo motion controllers, we guarantee millisecond-level accuracy.

Machine Tool Controllers - Integrated with smart CNC tools, our machine tool controllers use feedback to adjust cutting speeds, minimise tool wear and even optimise material usage.

Advanced Automation – Through this end-to-end automation, sending raw material to finished parts, fully automated quality checks and centralized command via connected PLCs can easily become possible.

One shouldn't limit automation to just one purpose. Whether it is in high-speed assembly lines or precise machining at Messung, our PLC automation systems are flexible enough to meet the demands of many industries. Beyond shock absorbers, our solutions usher in intelligent manufacturing possibilities one motion at a time.

Conclusion

Accuracy is a standard, not only a specification. If you are still using obsolete testing configurations, it's time to change course. Designed to bring not just performance but also purpose to your production floor, Messung's PLC-controlled shock absorber testing equipment helps you to achieve this.

Testing has to be quick, adaptable, and flawless, whether you are creating luxury cars or robust trucks. That is precisely what Messung's PLC control systems promise—and deliver.

We do not just automate; we elevate, from servo-tight control to smart data acquisition, from seamless integration to Industry 4.0-based controllers.

At Messung, accuracy is not just redefined. It has changed everything. Hence, go for it. Redefine accuracy. One test at a time!

FAQs

What makes Messung’s PLC Control Systems ideal for shock absorber testing?

Messung’s PLCs (Programmable Logic Controller) offer centralised control, real-time data capture, adaptive feedback loops, and ensure peak accuracy and speed.

Can Messung’s PLC Programming integrate with existing equipment?

Yes. With protocols like MODBUS, TCP/IP, and Ethernet-based controllers, our PLCs are designed for easy retrofitting and compatibility.

How do PLC Control Systems improve the testing process?

PLCs provide real-time emergency stop functionality, error detection, and ensure the equipment runs within safe operational parameters.

Do you offer remote access features?

Absolutely. With web server PLC (Programmable Logic Controller) capabilities and HMI with PLC controllers, you can monitor and manage testing remotely.

Is your PLC solution scalable?

Yes. With modular PLCs and IoT-ready systems, you can scale your setup to match your growth.

#PLC control systems#Programmable Logic Controllers (PLC).#Messung Industrial Automation#PLC automation systems#Smart PLC control#PLC-based AHU control system#modular PLC#Energy management systems#IEC 61131 based PLCs#compact PLC#IEC 61131-3 standard PLC Control Systems#MODBUS RTU#Modbus TCP#NX-ERA JET#PLC for energy systems#IEC 61131-3 compliant PLCs#modular PLCs#HMI with PLC controller#smart automation systems#programmable logic controller#smart PLCs#Modular PLCs

0 notes

Text

Modbus RTU & TCP Çözümleri - GelecekBT

1 note

·

View note

Text

Ensuring data integrity with the MOXA MGate MB3180

The MB3180, MB3280, and MB3480 are standard Modbus gateways that convert between Modbus TCP and Modbus RTU/ASCII protocols. Up to 16 simultaneous Modbus TCP masters are supported, with up to 31 RTU/ASCII slaves per serial port. For RTU/ASCII masters, up to 32 TCP slaves are supported.

#trending#automation#tumblr trends#viral#viralpost#bestdeals#trendingnow#moxa#MGateMB3180#today on tumblr#artists on tumblr#artist

2 notes

·

View notes

Text

Industrial Networking Solutions Market Evaluation: Growth Forecast and Competitive Landscape

Executive Summary Industrial Networking Solutions Market :

Data Bridge Market Research analyses that the global industrial networking solutions market which was USD 11,200.21 million in 2022, is expected to reach USD 70,300.36 million by 2030, and is expected to undergo a CAGR of 20.50% during the forecast period of 2023 to 2030.

Comprehensive data and brilliant forecasting techniques used in Industrial Networking Solutions Market report coincide with precision and correctness. Furthermore, it endows with historic data, present market trends, environment, technological innovation, upcoming technologies and the technical progress in the related industry. With this market report it becomes simpler for customers to understand the various drivers and restraints impacting the market during the forecast period. The report also displays the analysis and estimation of important industry trends, market size, and market share. Industrial Networking Solutions Market analysis report is valuable for both regular and emerging market player in the industry and provides in-depth market insights.

The winning Industrial Networking Solutions Market research report is generated with the best and advanced tools of collecting, recording, estimating and analysing market data. With the precise and high-tech information, about industry, businesses can know about the types of consumers, consumer’s demands and preferences, their perspectives about the product, their buying intentions, their response to particular product, and their varying tastes about the specific product already existing in the market through this report. The market insights covered in the report simplifies managing Market of goods and services effectively. For in depth understanding of market and competitive landscape, Industrial Networking Solutions Market report serves a lot of parameters and detailed data about industry.

Discover the latest trends, growth opportunities, and strategic insights in our comprehensive Industrial Networking Solutions Market report. Download Full Report: https://www.databridgemarketresearch.com/reports/global-industrial-networking-solutions-market

Industrial Networking Solutions Market Overview

**Segments**

- **Component Type:** The industrial networking solutions market can be segmented based on component type into hardware, software, and services. Hardware components include devices such as switches, routers, gateways, and hubs, while software includes network management software and security solutions. Services can include consulting, integration, and maintenance services.

- **Deployment Mode:** Industrial networking solutions can be categorized based on deployment mode into on-premises and cloud-based solutions. On-premises solutions are hosted locally on the company's servers, providing more control and security, while cloud-based solutions are hosted on third-party servers and offer scalability and accessibility.

- **Vertical:** The market can also be segmented by verticals such as manufacturing, energy and utilities, transportation, healthcare, and others. Each vertical has unique networking requirements and challenges, driving the demand for tailored industrial networking solutions.

- **Industrial Ethernet Protocol:** Another crucial segment is industrial Ethernet protocols, including PROFINET, EtherNet/IP, Modbus TCP, and others. Different industries and applications may prefer specific protocols based on factors like speed, reliability, and compatibility with existing systems.

**Market Players**

- **Cisco Systems, Inc.**: A prominent player in the industrial networking solutions market, Cisco offers a wide range of networking hardware, software, and services tailored for industrial environments. Their solutions focus on security, reliability, and scalability to meet the diverse needs of industrial customers.

- **Siemens AG**: Siemens is another key player known for providing comprehensive industrial networking solutions, including industrial Ethernet switches, routers, and software. They emphasize innovation and integration to enable seamless communication and data exchange in industrial settings.

- **Rockwell Automation, Inc.**: Rockwell Automation specializes in industrial automation and networking solutions, offering products like industrial switches, gateways, and controllers. Their solutions are designed to enhance operational efficiency and enable smarter decision-making in industrial processes.

- **Schneider Electric**: Schneider Electric is a leading provider of industrial networking solutions that prioritize sustainability, efficiency, and reliability. Their offerings include industrial Ethernet switches, routers, and cybersecurity solutions to safeguard critical infrastructure.

- **ABB Ltd**: ABB focuses on delivering advanced networking solutions for industrial automation and digital transformation. Their portfolio includes industrial Ethernet products, network management software, and services to optimize network performance and security.

The global industrial networking solutions market is dynamic and highly competitive, driven by the increasing digitization of industrial operations and the growing demand for connected systems. Companies are investing in R&D to develop innovative solutions that address evolving customer needs and industry trends. As the market continues to expand, strategic partnerships, acquisitions, and product launches are expected to shape the competitive landscape and drive further growth in the industrial networking solutions sector.

The global industrial networking solutions market is witnessing significant growth propelled by the rapid digitization of industries across various sectors. The adoption of advanced technologies such as IoT, AI, and machine learning is driving the need for efficient and secure networking solutions to enable seamless communication and data transfer in industrial environments. Companies are increasingly focusing on enhancing their operational efficiency, productivity, and decision-making capabilities by implementing robust networking infrastructures.

One of the key trends shaping the industrial networking solutions market is the rise of Industry 4.0, which emphasizes the convergence of digital technologies with traditional industrial processes. As industries embrace automation, robotics, and interconnected systems, there is a growing demand for reliable and high-performance networking solutions that can support the exchange of vast amounts of data in real-time. Industrial Ethernet protocols are playing a crucial role in establishing standardized communication networks that ensure interoperability and compatibility across diverse industrial applications.

Moreover, the focus on cybersecurity is becoming paramount as industrial networks become more interconnected and susceptible to cyber threats. Industrial networking solution providers are prioritizing the development of robust security features such as intrusion detection, encryption, and secure access controls to safeguard critical infrastructure and sensitive data. With the increasing emphasis on data privacy and regulatory compliance, industrial companies are investing in comprehensive cybersecurity solutions to mitigate risks and ensure operational resilience.

Additionally, the shift towards cloud-based deployment models is gaining traction as organizations seek scalable, cost-effective, and accessible networking solutions. Cloud-based industrial networking solutions offer flexibility, remote monitoring capabilities, and seamless integration with other cloud services, driving their adoption across industries. As companies strive to optimize their infrastructure and streamline operations, cloud-based networking solutions are expected to play a significant role in enabling digital transformation and enhancing business agility.

Furthermore, vertical-specific requirements are shaping the market landscape, with industries such as manufacturing, energy, healthcare, and transportation demanding tailored networking solutions to address their unique challenges. Industrial networking solution providers are customizing their offerings to cater to the specific needs of different verticals, providing specialized hardware, software, and services that optimize performance and ensure compatibility with industry standards.

In conclusion, the global industrial networking solutions market is witnessing transformative changes driven by technological advancements, evolving customer demands, and industry-specific requirements. As companies continue to invest in digitalization initiatives and smart manufacturing practices, the demand for advanced networking solutions is expected to grow significantly. Strategic collaborations, innovation in product development, and a strong focus on cybersecurity will be crucial for market players to stay competitive and capitalize on the opportunities presented by the expanding industrial networking solutions market.The global industrial networking solutions market is experiencing a profound transformation driven by the convergence of digital technologies and traditional industrial processes. This shift is propelled by the adoption of advanced technologies such as IoT, AI, and machine learning, which are revolutionizing how industries operate. The advent of Industry 4.0 is playing a pivotal role in shaping the market landscape, emphasizing the integration of smart technologies into industrial operations to enhance efficiency, automation, and connectivity. As industries increasingly prioritize operational excellence and productivity, the demand for robust networking solutions that can facilitate seamless communication and data exchange is on the rise.

Cybersecurity is emerging as a critical concern in the industrial networking solutions market, with companies focusing on implementing stringent security measures to protect their networks from cyber threats. As industrial networks become more interconnected, the need for advanced security features such as intrusion detection, encryption, and secure access controls is becoming paramount. Industrial networking solution providers are investing in developing comprehensive cybersecurity solutions that can safeguard critical infrastructure and sensitive data, ensuring operational resilience and regulatory compliance.

Moreover, the adoption of cloud-based deployment models is gaining momentum across industries as organizations seek flexible, scalable, and cost-effective networking solutions. Cloud-based industrial networking solutions offer remote monitoring capabilities, seamless integration with other cloud services, and enhanced accessibility, driving their uptake among industrial players. By leveraging cloud technology, companies can streamline their operations, optimize their infrastructure, and enable digital transformation, thus enhancing their business agility and competitiveness in the market.

Vertical-specific requirements are also influencing the industrial networking solutions market, with different industries demanding tailored networking solutions to address their unique challenges and optimize performance. The manufacturing, energy, healthcare, transportation, and other sectors have distinct networking needs, prompting industrial networking solution providers to customize their offerings to meet industry-specific standards and regulations. By providing specialized hardware, software, and services that cater to the requirements of different verticals, market players can effectively address the diverse needs of industrial customers and enhance their market presence.

In conclusion, the global industrial networking solutions market is undergoing a paradigm shift driven by technological advancements, evolving customer demands, and industry-specific requirements. Companies that can adapt to these changes, innovate in product development, forge strategic partnerships, and prioritize cybersecurity will be well-positioned to capitalize on the growing opportunities in the expanding industrial networking solutions market. It is essential for market players to anticipate future trends, address emerging challenges, and deliver value-driven solutions that enable industrial organizations to thrive in an increasingly connected and digitized world.

The Industrial Networking Solutions Market is highly fragmented, featuring intense competition among both global and regional players striving for market share. To explore how global trends are shaping the future of the top 10 companies in the keyword market.

Learn More Now: https://www.databridgemarketresearch.com/reports/global-industrial-networking-solutions-market/companies

DBMR Nucleus: Powering Insights, Strategy & Growth

DBMR Nucleus is a dynamic, AI-powered business intelligence platform designed to revolutionize the way organizations access and interpret market data. Developed by Data Bridge Market Research, Nucleus integrates cutting-edge analytics with intuitive dashboards to deliver real-time insights across industries. From tracking market trends and competitive landscapes to uncovering growth opportunities, the platform enables strategic decision-making backed by data-driven evidence. Whether you're a startup or an enterprise, DBMR Nucleus equips you with the tools to stay ahead of the curve and fuel long-term success.

This Comprehensive Report Provides:

Improve strategic decision making

Research, presentation and business plan support

Show emerging Industrial Networking Solutions Marketopportunities to focus on

Industry knowledge improvement

It provides the latest information on important market developments.

Develop an informed growth strategy.

Build technical insight

Description of trends to exploit

Strengthen competitor analysis

By providing a risk analysis, you can avoid pitfalls that other companies may create.

Ultimately, you can maximize your company's profitability.

Browse More Reports:

Middle East and Africa Anti-Acne Cosmetics Market Global Organic Feed Market Global Gaming Peripheral Market Global Waste to Energy Market Global Yellow Fever Treatment Market Global Robotics End Effector Market Global Full Spectrum Cannabidiol (CBD) Infused Edibles Market Global Yacht Charter Market Global Suture Passer Market Global Time of Flight Sensor Market Global Pre-engineered Building Market Global Enhanced Fire Protection Systems Market Global Swine Feed Phosphates Market Global Non-alcoholic Steatohepatitis Market Middle East and Africa Printing Inks/Packaging Inks Market Global Point of Care (POC) Urinalysis Market Global Surgical Tape Market U.S. Contrast Injector Market Global Octadecanedioic Acid Market Global Stretch and Shrink Film Market Global Industrial Wi-Sun Technology Market Global Cereals and Grain Seed Market Global Bladder Disorders Market Global Body Scrub Market Global Life Sciences Commercialization Vendor Platform Market U.S. Meter Sockets Market Middle East and Africa Point-Of-Care-Testing (POCT) Market Global Pucker Free Tape Market Middle East and Africa Mezcal Market Global Organic Cheese Powder Market

About Data Bridge Market Research:

An absolute way to forecast what the future holds is to comprehend the trend today!

Data Bridge Market Research set forth itself as an unconventional and neoteric market research and consulting firm with an unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market. Data Bridge endeavors to provide appropriate solutions to the complex business challenges and initiates an effortless decision-making process. Data Bridge is an aftermath of sheer wisdom and experience which was formulated and framed in the year 2015 in Pune.

Contact Us: Data Bridge Market Research US: +1 614 591 3140 UK: +44 845 154 9652 APAC : +653 1251 975 Email:- [email protected]

Tag:- Industrial Networking Solutions Market, Industrial Networking Solutions Market Trends, Industrial Networking Solutions Market Growth, Industrial Networking Solutions Market Demand, Industrial Networking Solutions Market Size, Industrial Networking Solutions Market Scope, Industrial Networking Solutions Market Insights, Industrial Networking Solutions Market Analysis

0 notes

Link

0 notes

Text

3RW5535-6HA04 - Khởi động mềm Siemens hoạt động với dòng định mức 143A, chức năng đặc biệt Bypass trong, công suất (230V) 37kW, công suất (400V) 75kW, truyền thông PROFINET, PROFIBUS, Modbus TCP. Xem ngay: https://hoplongtech.com/products/3rw5535-6ha04

0 notes

Text

0 notes

Text

Enhancing AHU Performance with PLC-Based Control Systems

Imagine a world where your building breathes in oxygen. Where comfort meets air quality, and where energy is saved. It is the world where AHUs and PLC control systems are the starting point of everything in the domain of Energy management systems.

These AHU controllers (Air Handling Units) are the primary components of any new HVAC system. They serve as the lungs. But to make those lungs breathe better, smarter, and cleaner, you need a brain—enter the Programmable Logic Controllers (PLC).

We at Messung Industrial Automation are not just manufacturing PLC automation systems. We engineer intelligence. Smart PLC control is our ambition, and we aim to revolutionize the way AHU controllers operate, using a range of technologies, including Modbus, MQTT, compact PLCs, or IOT-enabled PLC.

What is a PLC-Based AHU Control System?

A PLC-based AHU control system is the ultimate HVAC master conductor. The flow, cooling, heating, and energy consumption of air are all controlled by real-time logic and precision through automation controllers.

Decision-making is the primary responsibility of a IoT enabled PLC (programmable logic controller), not just following instructions. Your AHU is designed to respond to data, adjust to changing surroundings, and function like a finely tuned machine with the help of intelligent controllers.

Whether it’s a mini PLC for a compact setup or a modular PLC for a multi-zone building, this IEC 61131-3 standard controller is the heartbeat of your air management system.

Core Functions of PLC Automation in AHU Controllers Applications

Sensor Integration

Temperature, humidity, CO2, and differential pressure are all sensors that your AHU controllers are equipped with. When it comes to Energy management systems, PLC control systems are necessary for reading, interpreting, and operating raw data.

Our intelligent PLCs work together with sensors to capture every detail of your indoor environment.

Data Analysis & Decision Making

After submitting the data, the PLC Automation magic begins. Our IEC 61131 based PLCs utilize advanced logic and maintain monitoring of variables such as:

Room occupancy

Outdoor air quality

Return air temperature

The intelligence in this scenario is not confined to automation alone it expands to the action of the PLC Control Systems.

Control Actions via Actuators

Now let's talk about the muscle of the operation. By utilizing PLC and Modbus TCP/IP, your automation controllers can dynamically control VFDs (Variable Frequency Drives) to regulate fan speeds while minimizing energy usage.

Actuated Dampers

Want zoned cooling in your building? Each damper is given precise guidance on when and where it should be opened or closed by our compact PLC, down to the second.

Valves

Our PLC automation system manages both hot and chilled water circuits, ensuring thermal comfort with accuracy.

Humidifiers & Dehumidifiers

System Overview: The NX-ERA JET Advantage

NX-ERA JET PLC is a digital command centre that is agile, adaptive, and always on alert as the AHU controllers. We have developed an intelligent and IEC 61131-3 standard PLC Control Systems that combine advanced logic, seamless connectivity, and flexible scalability. The NX-ERA JET is the key to ensuring that every component of your AHU system, including sensors and actuators, operates in perfect harmony.

Features of this IoT enabled PLC at a Glance

Modular PLC architecture is flexible and can be easily scaled for multi-zone management in large or changing infrastructure

The utilization of PLC with TCP/IP facilitates fast and secure communication between devices, including devices connected to remote systems

The integration of MODBUS RTU, Modbus TCP, and MQTT with BMS, SCADA, or cloud-based IoT platforms is facilitated by the native support provided by these protocols.

An integrated HMI that provides real-time, intuitive monitoring, diagnostics, and manual overrides.

Benefits of IoT enabled PLC for AHUs

In modern air handling, the focus isn’t just on moving air but moving it forward. Why? Integrating PLC control systems into AHUs can offer a transformative advantage in performance, sustainability, and adaptability for buildings. We should examine why PLC automation is the primary driving force behind intelligent HVAC solutions.

Improved Energy Efficiency

The value of energy is high, and PLC for energy systems with IEC 61131-3 standards optimizes every kilowatt. We can use our IoT enabled PLCs to save energy - up to 30% a time with intelligently controlled fan speeds, valve positions and damper angles that are real-time. Measurable reductions through these intelligent controllers help to reduce operational costs and greener footprints are not just numbers.

High Precision Control

AHU controllers equate performance with precision. Why? Our IEC 61131-3 compliant PLCs provide precise control over airflow, temperature and humidity. The result? Consistent comfort, efficient performance and strict environmental regulations.

Advanced Diagnostics

The use of intelligent PLCs with IoT systems means that problems can be prevented rather than delayed. With real-time monitoring and fault detection, teams can receive predictive maintenance insights to minimize downtime and maximize up time.

Scalability and Modularity

Our modular PLCs are designed to accommodate the growth of your building, offering compact systems and multi-zone installations. Do you require an immediate upgrade or expansion? These intelligent controllers can scale without complexity.

BMS Integration

Our PLC Control Systems with IEC 61131-3 standard integrates seamlessly with Building Management Systems, creating one intelligent ecosystem. Whether it’s HVAC, lighting, fire alarms, or access control—everything talks to everything for smoother operations.

In a world where data and efficiency are the primary drivers of change, PLC-controlled AHU controllers provide more than just automation; they also offer confidence. Our IoT enabled PLCs enable buildings to thrive rather than just functioning.

Intelligent PLC Control Systems for Smart Buildings

HMI with PLC Controllers - An HMI with PLC controller enables the observation of invisible areas. The entire package, including fan speed and filter life, is conveniently located at your fingertips.

MQTT based PLC and IoT Systems - The integration of IoT enabled PLC and MQTT support enables your AHU to communicate with the cloud, apps, and analytics platforms, simplifying the process of achieving predictive control and remote access.

Real-World Applications

Through PLC-based AHU control systems, we at Messung are changing the possibilities of environments from sterile labs to busy malls. With precision, adaptability, and unparalleled reliability, our intelligent automation controllers tackle the challenges associated with every application.

Pharma Cleanrooms - The precision of pharmaceutical products is essential in their application. The strict GMP standards are adhered to by our PLC control systems, which involve managing temperature, humidity, pressure differentials. The result? Zones that are sterile, upholding drug integrity and safety.

Commercial Buildings - Employee comfort drives efficiency. Our HVAC automation enables seamless climate management of all floors and departments. By utilizing intelligent design, efficient air circulation, and real-time monitoring, our IoT enabled PLCs enhance the productivity and satisfaction of customers in spaces.

Data Centers - Servers demand a stable climate 24/7. Even minor temperature fluctuations can compromise data. Our intelligent PLC Control Systems with IEC 61131-3 standard ensure uninterrupted cooling performance, reducing thermal risk and operational downtime.

Energy-Efficient Manufacturing - Today's manufacturers must strike a balance between sustainability and production. Without compromising comfort or compliance, our PLCs maximize AHU performance to reduce energy footprints, reduce emissions, and guarantee stable internal environments.

Wherever there's air to manage and performance to perfect, our Compact PLCs lead the way with intelligent control.

Messung’s Expertise in HVAC Automation

We at Messung lead the way in HVAC automation innovation for organizing smart air movement. Our legacy is created on trust, performance, and innovative control systems that transform indoor environments, not only on technology

Why Choose Messung PLC Automation?

We design smart automation systems rather than only selling PLC Control Systems. With more than four decades of engineering expertise, our PLCs are the favoured option of architects, MEP consultants, HVAC contractors, and facility managers across India and globally. Our internal R&D, field-tested dependability, and quick support system turn us into a progress partner rather than just a supplier.

Built on IEC 61131-3 Standard

To ensure every Messung programmable logic controller is consistent, dependable, and compatible with worldwide systems—today and tomorrow — our automation controllers follow this internationally recognized IEC 61131-3 standard.

Flexible Form Factors

Whether you are managing many air zones throughout a smart high-rise or automating a small rooftop AHU, our compact and modular PLCs meet every architectural and functional requirement.

Comfort, control, and conservation are not optional but rather vital in the quickly changing realm of smart infrastructure of today. Furthermore, realizing this potent triad calls for smart, adaptive control rather than just automation. That is what Messung's PLC-based AHU systems precisely provide. Our programmable logic controllers redefine air handling performance for buildings of all sizes with real-time responsiveness, easy BMS integration, IoT readiness, and IEC 61131-3 standard. Our intelligent controllers offer precision, dependability, and next-generation energy efficiency from sterile zones to skyscrapers. Should excellence be your goal, our IoT enabled PLC guarantees you lead rather than merely follow. Why settle for fundamentals when you may automate brilliance with our smart automation controllers?

FAQs

What makes a PLC suitable for AHU control?

Real-time processing, sensor compatibility, actuator control, and smooth BMS integration define good automation controllers. Messung's smart PLCs with IoT systems check every box

Can a modular PLC (Programmable logic controllers) handle multiple AHU zones?

Absolutely. Modular PLCs like Messung’s NX-ERA JET are great for big buildings since they can span levels and zones.

How does Messung's IoT enabled PLC enhance building performance?

Connecting to cloud systems and providing remote access help our IoT enabled PLCs to maximize energy efficiency and real-time maintenance cycles.

Why is Messung’s NX-ERA JET the ideal, affordable PLC choice for midscale operations compared to traditional compact or mini PLCs?

Messung’s NX-ERA JET offers advanced performance at an affordable price, making it perfect for midscale operations. It outperforms mini PLCs with better speed, scalability, and flexibility, without breaking the budget.

Are MQTT based Programmable logic controllers better than traditional protocols?

MQTT-based PLCs offer faster, lighter, and more effective communication than conventional systems like MODBUS RTU for remote and IoT-intensive applications.

#messing 1st blog ahu link#PLC control systems#Programmable Logic Controllers (PLC).#Messung Industrial Automation#PLC automation systems#Smart PLC control#PLC-based AHU control system#modular PLC#Energy management systems#AHU controllers#IEC 61131 based PLCs#compact PLC#IEC 61131-3 standard PLC Control Systems#MODBUS RTU#Modbus TCP#AHU controllers systems#NX-ERA JET#HVAC solutions#PLC for energy systems#IEC 61131-3 compliant PLCs#modular PLCs#HMI with PLC controller#Pharma Cleanrooms#Commercial Buildings#Data Centers#smart automation systems#programmable logic controller#BMS integration#smart PLCs#Modular PLCs

0 notes

Text

BL335 + Node-Red = The Ultimate Industrial IoT Combo!

BL335: The Industrial-Grade ARM Computer Built for Node-Red - Perfect Balance of Performance and Cost!

In the fields of industrial automation and IoT, Node-Red has become the go-to tool for rapid development of data acquisition, protocol conversion, and edge computing, thanks to its visual programming and low-code features. However, not all hardware is perfectly suited for Node-Red—some are over-spec’d and wasteful, while others lack the necessary resources for smooth operation.

Beilai Technology' s ARMxy BL335 Industrial Computer, with its Node-Red-optimized hardware design, is the ideal choice for industrial users! It delivers smooth performance, rock-solid reliability, and competitive pricing to meet diverse industrial needs.

Why is the BL335 the Best Industrial Computer for Node-Red?

1. Dual-Core A7 Processor – Just the Right Performance

2× ARM Cortex-A7 @1.2GHz, optimized for lightweight applications—Node-Red runs smoothly without lag.

Unlike overpowered quad/octa-core processors, the dual-core A7 design avoids wasted resources, balancing performance and cost efficiency.

2. RAM & ROM Perfectly Matched for Node-Red

512MB/1GB DDR3 RAM, fully meeting Node-Red’s long-term stability requirements (recommended ≥512MB).

4GB/8GB eMMC storage, ensuring ample space for the OS, Node-Red, and data storage without bottlenecks.

3. Pre-Installed Node-Red, Ready Out of the Box

Comes with Ubuntu/Linux + Node-Red pre-installed—power it up and start developing immediately.

Pre-configured system images enable rapid deployment, significantly shortening project timelines.

4. Dedicated Node-Red Technical Support Team

Bairen Technology provides Node-Red application examples, development guides, and customized support to help users get started quickly.

Stuck with protocol conversion or data collection? Our expert team offers real-time remote assistance!

5. Rich Serial & Network Ports for Easy Data Acquisition

Optional 4-8x RS485/RS232 ports, supporting Modbus RTU, DL/T645, and other industrial protocols.

Dual Ethernet (Gigabit + Fast Ethernet), compatible with TCP/IP, MQTT, OPC UA, and more for flexible device integration.

6. Industrial-Grade Stability for 24/7 Reliability

Fully isolated serial ports & independent hardware watchdog prevent crashes, ensuring long-term stable operation.

Wide-temperature design (-40℃~85℃), built to withstand harsh industrial environments.

7. Flexible Expansion for Diverse Needs

Optional DI/DO, CAN, GPIO, AI/AO modules for seamless connectivity with PLCs, sensors, actuators, and more.

4,000+ I/O combinations—customize your setup without overspending.

8. Optimized Hardware, Unbeatable Value

A refined hardware design that perfectly balances performance, stability, and cost.

Priced at just 60%~70% of comparable solutions, making industrial IoT more accessible than ever!

BL335 + Node-Red = The Ultimate Industrial IoT Combo!

✅ Data Acquisition: Easily connect PLCs, meters, and sensors with support for Modbus, CAN, MQTT, and more.

✅ Edge Computing: Local data processing reduces cloud dependency and network costs.

✅ Protocol Conversion: Use BLIoTLink software to quickly integrate with SCADA, Alibaba Cloud, Huawei Cloud, and other platforms.

✅ Remote Maintenance: BLRAT tool enables remote debugging, cutting on-site service costs.

Experience the Power of BL335 for Node-Red Today!

Website: www.BLIIoT.com

Free technical evaluations & industry solutions available!

Let BL335 be your ultimate Node-Red partner—low cost, high efficiency, and the perfect engine for industrial IoT! 🚀

0 notes

Text

Biến tần hạ thế ATV6B0 Series Schneider có độ chính xác cao, điện áp vào 3 pha 380~460VAC 50/60Hz, thuộc loại tải nhẹ, truyền thông Modbus/TCP, Modbus RS-485, chế tạo từ vật liệu bền bỉ. Xem chi tiết tại: https://hoplongtech.com/series/atv6b0

0 notes

Text

https://anadiautomation.com/schneider-electric/TM200CE40T

Product Overview: TM200CE40T Controller

The TM200CE40T is part of Schneider Electric’s Modicon M200 series, designed to meet the automation needs of modern industries. It features a combination of 24 digital inputs and 16 digital transistor outputs, making it ideal for various I/O-intensive applications.

🔧 Key Specifications:

Part Number: TM200CE40T

Brand: Schneider Electric

Controller Type: Programmable Logic Controller (PLC)

Digital Inputs: 24

Digital Outputs: 16 (Transistor type)

Communication Ports: Built-in Ethernet

Mounting: DIN Rail

Power Supply: 24V DC

Program Memory: Expandable

Warranty: 1 Year (provided by Anadi Automation)

Availability: In stock at Anadi Automation, Nashik, India

Top Features of Schneider Electric TM200CE40T

The TM200CE40T offers a variety of features that enhance its appeal to system integrators and OEMs alike. Here’s why it stands out:

✅ High Input/Output Capacity

With 24 digital inputs and 16 digital outputs, the controller provides ample I/O support for mid-size automation systems.

✅ Compact and Modular Design

Despite its powerful capabilities, the TM200CE40T has a compact footprint. It supports modular expansion, allowing you to scale your system as needed.

✅ Integrated Ethernet Port

The built-in Ethernet port enables high-speed communication, remote monitoring, and easy integration into industrial networks using Modbus TCP/IP protocol.

✅ High-Speed Counter and Pulse Outputs

It includes high-speed counters and pulse output functions that are essential for motion control and fast process operations.

✅ DIN Rail Mounting

Ease of installation with standard DIN rail mounting ensures a secure and accessible setup.

✅ Advanced Programming Environment

Compatible with Schneider Electric's EcoStruxure Machine Expert – Basic (SoMachine Basic) software for intuitive programming, simulation, and troubleshooting.

0 notes

Text

Industrial Ethernet Market Size, Share, Analysis, Forecast, and Growth Factors to 2032

The Industrial Ethernet Market was valued at USD 11.2 Billion in 2023 and is expected to reach USD 21.9 Billion by 2032, growing at a CAGR of 7.74% from 2024-2032.

The Industrial Ethernet market is witnessing a dynamic shift as industries increasingly prioritize automation, speed, and connectivity. From smart factories to energy grids, Industrial Ethernet provides a robust foundation for real-time communication, scalability, and interoperability. Driven by the surge in Industry 4.0 initiatives, manufacturers and infrastructure developers are rapidly deploying Ethernet solutions to replace legacy systems, aiming for higher efficiency and streamlined operations.

Industrial Ethernet Market Set to Transform Global Industrial Communication With the convergence of operational technology (OT) and information technology (IT), Industrial Ethernet has emerged as a strategic enabler for digital transformation across multiple sectors. Industries such as automotive, oil & gas, pharmaceuticals, and utilities are embracing Ethernet-based infrastructure to support high-speed data transmission, secure networking, and seamless machine-to-machine communication.

Get Sample Copy of This Report: https://www.snsinsider.com/sample-request/6022

Market Keyplayers:

Siemens – SCALANCE Industrial Ethernet Switches

Cisco – Catalyst Industrial Ethernet Switches

Rockwell Automation – Allen-Bradley Stratix Switches

Belden – Hirschmann Industrial Ethernet Solutions

Moxa – Moxa EDS Series Switches

Phoenix Contact – FL SWITCH Industrial Ethernet Series

Schneider Electric – Modicon Industrial Ethernet Switches

ABB – ABB Industrial Ethernet Routers

Hewlett Packard Enterprise (HPE) – Aruba Industrial Ethernet Switches

Huawei – CloudEngine Industrial Ethernet Switches

Omron – Omron Industrial Ethernet Controllers

Advantech – Advantech Industrial Ethernet Switches

Beckhoff Automation – EtherCAT Industrial Ethernet Solutions

General Electric (GE) – GE Industrial Ethernet Switches

Honeywell – Experion Industrial Ethernet Solutions

Market Analysis The Industrial Ethernet market is characterized by robust growth due to its role in modernizing industrial networks. Factors such as the need for deterministic networking, increased use of industrial IoT (IIoT), and real-time data monitoring are fueling adoption. Major players are investing in innovative protocol technologies like PROFINET, EtherNet/IP, and Modbus TCP to gain competitive edge. Enhanced reliability and minimal downtime further position Industrial Ethernet as a superior alternative to traditional fieldbus systems.

Market Trends

Integration of cloud-based industrial systems

Rising demand for network security and cybersecurity solutions

Rapid expansion of smart manufacturing and IIoT

Development of time-sensitive networking (TSN) standards

Adoption of edge computing in industrial networks

Growth of wireless Industrial Ethernet in remote applications

Market Scope The market’s scope spans across critical verticals, offering tailored Ethernet solutions for varied applications:

Manufacturing & Automation: High-speed data exchange and real-time control

Energy & Utilities: Secure grid communication and remote monitoring

Transportation: Intelligent traffic systems and rail communication

Oil & Gas: Harsh environment networking and pipeline monitoring

Healthcare & Pharma: Precision manufacturing and compliance tracking

Industrial Ethernet's ability to offer low latency, redundancy, and scalability makes it indispensable in digitally transforming sectors. It is no longer an optional upgrade but a foundational element in building the future of industrial ecosystems.

Market Forecast The future of the Industrial Ethernet market is defined by its alignment with transformative technologies such as AI-driven automation, predictive maintenance, and 5G integration. With increasing cross-border industrial collaborations and smart infrastructure projects underway, the market is expected to experience sustained momentum. As enterprises shift towards agile and secure digital networks, Industrial Ethernet stands as the backbone of intelligent, connected industries.

Access Complete Report: https://www.snsinsider.com/reports/industrial-ethernet-market-6022

Conclusion As industrial demands evolve at an unprecedented pace, the Industrial Ethernet market emerges as a cornerstone of operational excellence and digital innovation. Its unmatched ability to connect devices, streamline operations, and foster real-time intelligence positions it as a game-changer for industries aiming to lead in the era of automation. For organizations envisioning future-ready infrastructure, embracing Industrial Ethernet isn’t just strategic—it’s essential.

About Us:

SNS Insider is one of the leading market research and consulting agencies that dominates the market research industry globally. Our company's aim is to give clients the knowledge they require in order to function in changing circumstances. In order to give you current, accurate market data, consumer insights, and opinions so that you can make decisions with confidence, we employ a variety of techniques, including surveys, video talks, and focus groups around the world.

Contact Us:

Jagney Dave - Vice President of Client Engagement

Phone: +1-315 636 4242 (US) | +44- 20 3290 5010 (UK)

#Industrial Ethernet Market#Industrial Ethernet Market Scope#Industrial Ethernet Market Share#Industrial Ethernet Market Trends

0 notes