#Multi Monitoring Meter test

Explore tagged Tumblr posts

Text

Multi Monitoring Meter AM-GMA13

Abimed Multi Monitoring Meter measures glucose, cholesterol, uric acid, and hemoglobin in 8 to 15 seconds. It requires a minimal 0.5 µL sample and includes auto-strip recognition and optional Bluetooth connectivity, making it a convenient tool for multi-parameter health monitoring.

0 notes

Text

Chapter 1: Files

Masterlist - Next Chapter

Confidential Report on Human Experimentation: Super Soldier Serum Trial

Date: October 9th, 1947

Location: Classified Facility, Sector 17

Lead Scientist: Dr. Arnim Zola

Subject ID: 004Z (Alias: “Subject Crimson”)

Objective

To test the efficacy of Super Soldier Serum B-13 (Alias: “SSSB13”) in significantly enhancing physical and cognitive abilities beyond natural limits.

This report details the effects observed on one individual subjected to the serum in a controlled environment.

Subject Information

- Name: Classified

- Age: 29

- Gender: Female

- Height: 5’9”

- Weight: 175 lbs (Pre-serum)

- Medical History: Healthy, no pre-existing conditions, physically fit (military background). Psychological profile indicates average resilience to stress and trauma.

Administration of Serum

- Dosage: 30ml injection, administered in two stages over a 48-hour period.

- Phase 1 (0-24 hours: Preliminary physical and neural enhancements.

- Phase 2 (24-48 hours): Stabilization and further augmentation of sensory and cognitive abilities.

Phase 1: Initial Effects (0-24 Hours)

Physical Changes:

- Muscle Mass: Noticeable increase in muscle density (+15% mass) within the first 6 hours.

- Strength: Strength tests indicated a 250% increase in raw lifting capacity, confirmed via standard load-bearing equipment. Subject Crimson lifted 700 lbs effortlessly by hour 12.

- Endurance: Cardiovascular endurance improved by 180% based on treadmill stress testing at hour 20.

Cognitive Changes:

- Reflexes: Reaction time dropped from 0.2 seconds to 0.03 seconds. Subject Crimson was able to dodge incoming projectiles.

- Neural Efficiency: Subject reported a heightened sense of awareness and perception, able to track movements in his peripheral vision with pinpoint accuracy. Neurological scans showed a 45% increase in synaptic firing rates.

---

Phase 2: Sensory and Cognitive Augmentation (24-48 Hours)

Sensory Enhancements:

- Vision: Subject Crimson reported enhanced visual acuity. Tests showed that her night vision had improved tenfold, and she could discern movement from over 1,000 feet in low-light conditions.

- Hearing: Subject detected frequencies up to 50 kHz, well beyond the human range, and accurately identified the source of faint noises within a 200-meter radius.

- Touch: Hyper-awareness of tactile sensations was observed. Subject could sense minute vibrations through solid objects.

Cognitive Enhancements:

- Problem Solving & Memory: The subject solved complex puzzles in record time. Long-term memory recall improved by 300%, allowing Subject Crimson to recite entire documents verbatim after one reading.

- Multi-tasking: Subject exhibited the ability to manage up to five different cognitive tasks simultaneously without error or loss of focus.

---

Post-Trial Monitoring

- Physical Stability: No signs of physical breakdown or adverse reactions have been detected. Vital signs remain in optimal ranges despite sustained extreme exertion.

---

Conclusion

The results of the SSSB13 trial on Subject Crimson have surpassed expectations, achieving a level of human enhancement previously deemed impossible.

The subject now possesses physical strength, agility, enhanced sensory perception, and superior cognitive function.

Long-term effects are still under observation, but preliminary data suggest that SSSB13 has the potential to redefine soldier capabilities.

Further experimentation will explore scalability, mass production, and ethical implications. Caution is advised in deployment to ensure control over enhanced subjects.

---

This report is classified and intended for authorized personnel only. Unauthorized distribution is a violation of Section 8b.

---

Report Compiled by:

Dr. Arnim Zola

Project CRIMSON

#marvel#mcu#marvel cinematic universe#marvel x reader#mcu x reader#bucky barnes x reader#bucky barnes#arnim zola#HYDRA#hail hydra

9 notes

·

View notes

Text

Laser-based radiation detector allows testing from a safer distance

A multi-institutional team of physicists and engineers has developed a laser-based radiation detection system that operates from as far away as 10 meters and perhaps farther. Their research is published in the journal Physical Review Applied. Working with nuclear material, whether in creating weapons or energy, requires monitoring radiation levels to ensure the safety of workers. However, most detectors only allow for testing in close proximity to the source, which means a worker can be in danger of overexposure before they know it has happened. In this new study, the team assigned themselves the goal of developing a new type of system or device that could be used to test from much farther away. The team started by noting that radiation interacts with molecules in the air around it, resulting in the creation of free electrons, so it should be possible to measure the energy of those electrons using a laser beam. In testing their ideas, they found that firing a laser into irradiated air did lead to molecule collisions, which produced free electrons.

Read more.

4 notes

·

View notes

Text

Proba-3 will constantly measure Sun's energy output

Proba-3 is such an ambitious mission that it needs more than one single spacecraft to succeed. In order for Proba-3's Coronagraph spacecraft observe the sun's faint surrounding atmosphere, its disk-bearing Occulter spacecraft must block out the fiery solar disk. This means Proba-3's Occulter ends up facing the sun continuously, making it a valuable platform for science in its own right.

The sunward side of the Occulter therefore hosts a dedicated instrument that will maintain a continuous measurement of the sun's total energy output, known as the total solar irradiance, which is a essential variable for climate studies.

The shoebox-sized Davos Absolute Radiometer, DARA, has been supplied to the mission by the Physical Meteorological Observatory Davos, PMOD, in Switzerland.

"Researchers used to talk about the 'solar constant' but in fact it is always changing slightly," explains Wolfgang Finsterle, DARA Principal Investigator at PMOD. "And it's essential to keep track of the total solar irradiance, because it is the dominant energy input to the surface of the Earth.

"It amounts to something like 99.978% of the energy available on Earth, including the conserved solar energy stored in coal and oil. It drives all the dynamic processes of Earth's climate, so even the tiniest variations are hugely significant."

The mountain-based PMOD has been studying total solar irradiance for more than a century, initially with ground-based instruments and then from the 1970s deploying space-based radiometers to acquire a continuous dataset. The World Meteorological Organization has mandated PMOD as the World Radiation Centre to calibrate radiation measurements across global UN monitoring programs.

Wolfgang adds, "Total solar irradiance varies along with the 11-year cycle of solar activity, and one of the most obvious ways to look for long-term energy drift is to compare total solar irradiance between consecutive solar minimia.

"This requires a long time-series of data, ideally coming from multiple instruments because single radiometers will undergo degradation in sensitivity from the hard ultraviolet in the sun's rays they are continuously exposed to. That said any degradation is very gradual: the radiometer aboard the ESA-NASA SOHO solar observatory for instance, which was launched in back 1995, is still working satisfactorily."

DARA's basic operating principle is simple. The radiometer possesses a 5-mm diameter cavity made from black-painted silver, possessing low temperature emissivity. For 15 seconds at a time, sunlight warms the interior of the cavity, then a shutter blade automatically closes at its entrance.

For the next 15 seconds, electric heat maintains the cavity's previous temperature—and the energy needed to maintain this temperature is extrapolated to the unit of total solar irradiance, which is watts per meter squared.

This process continues for the entire lifetime of the instrument—the actuated shutter design employed in DARA has been tested for millions of openings and closings in PMOD's vacuum chamber.

"DARA is an improvement on previous radiometer designs with an optimized cavity design to minimize unwanted straylight and a multi-channel measuring system for self-calibration," adds Wolfgang. "This generation of instrument also possesses a fully digital control loop, allowing the possibility of experimenting with higher frequency observations.

Two versions of this radiometer design have already flown, notes Werner Schmutz of PMOD, who oversaw its development: "A compact version called CLARA flew on Noway's NorSat-1 CubeSat in 2017, remaining operational to this day, while a previous DARA is serving aboard the Chinese FY-3E weather satellite, launched in 2021. So we have high confidence in the design, which can operate whenever the Proba-3 Occulter is pointed at the sun within half a degree of accuracy."

The main difference between Proba-3's DARA and previous radiometers will be its very elongated orbit, which will carry it 60 000 km above Earth's surface. DARA can automatically adjust to slight changes in the size of the solar disk based on how far it is away—which are also due to Earth's yearly elliptical orbit around the sun. All the radiometer needs to know is its position in space and its data gathering compensates for the shift.

3 notes

·

View notes

Text

Generator Load Monitoring: Ensuring Optimal Performance and Reliability

Generators are the unsung heroes of critical power infrastructure, providing backup or primary energy in hospitals, data centers, construction sites, and remote facilities. But owning a generator isn't enough—monitoring the load it carries is vital to ensure long-term performance, fuel efficiency, and operational reliability. Generator load monitoring is the process of tracking how much electrical load a generator is handling during operation. Without it, you risk running the generator inefficiently—either underloading, which causes engine damage over time, or overloading, which can lead to overheating, failure, or dangerous shutdowns. In this blog, we’ll explore how generator load monitoring works, why it matters, and the best tools and practices to implement it.

What Is Generator Load Monitoring?

Generator load monitoring involves measuring the real-time electrical demand placed on a generator. It includes parameters such as:

Current (Amps)

Voltage (Volts)

Real Power (kW)

Apparent Power (kVA)

Power Factor

Frequency (Hz)

This data helps determine whether the generator is operating within its optimal range, adjusting for fluctuations in load, and identifying potential issues before they lead to failure.

Why Generator Load Monitoring Matters

1. Prevents Overloading and Failure

Generators have a maximum rated capacity. Exceeding this limit can trip protection circuits or cause mechanical and electrical damage. Monitoring ensures you're always within safe limits.

2. Avoids Wet Stacking in Diesel Generators

Running diesel generators under very low loads (<30% of rated capacity) for extended periods can cause wet stacking—unburned fuel accumulates in the exhaust, leading to fouled injectors, reduced efficiency, and costly maintenance. Load monitoring helps maintain proper loading levels.

3. Improves Fuel Efficiency

Generators run most efficiently at around 70–80% of their rated load. Monitoring allows operators to balance fuel consumption with output, reducing waste and operational costs.

4. Extends Generator Lifespan

By preventing extremes of underload and overload, load monitoring helps reduce wear and tear, extending the usable life of the generator and its components.

5. Ensures Readiness in Backup Systems

For standby generators, load monitoring confirms that the system is ready to perform in the event of a power outage. Load banks and periodic testing can simulate real loads for verification.

Key Features of Load Monitoring Systems

When selecting a generator load monitoring system, look for:

Real-time monitoring: Continuous data for live feedback

Multi-parameter logging: Current, voltage, power, power factor, frequency

Alarm thresholds: Alerts for over/underload, phase imbalance, or abnormal conditions

Remote access and reporting: Cloud or network-based systems for off-site monitoring

Data logging and analytics: Trend analysis for predictive maintenance

Compatibility with ATS and control panels: Seamless integration with generator management systems

Tools Used for Generator Load Monitoring

1. Power Meters and Load Analyzers

Permanently installed or portable devices that measure load in real-time. Some advanced models include data logging and waveform capture.

2. Generator Control Panels with Monitoring Modules

Modern gensets often include built-in digital displays or connect to supervisory systems like SCADA for comprehensive load tracking.

3. Wireless Load Monitoring Solutions

Ideal for remote or temporary generator setups, wireless systems transmit data to cloud dashboards or mobile apps.

4. Load Banks (for Testing)

Used to simulate electrical loads during commissioning or maintenance, ensuring the generator performs well under expected real-world conditions.

Best Practices for Generator Load Monitoring

Install load monitors at the output panel or transfer switch to capture accurate usage data

Establish baseline load expectations based on peak and average demands

Set up alarms to detect load issues before they escalate

Review logs periodically to identify trends or load growth

Run generators under optimal load conditions (30–80%) during routine operation

Conduct regular load bank testing for standby generators that rarely run under load

Applications Where Load Monitoring Is Critical

Hospitals and Healthcare Facilities: Life-support systems depend on uninterrupted power

Data Centers: Power fluctuations can damage servers and cause data loss

Construction Sites: Portable generators need regular monitoring due to varying load

Manufacturing Plants: Heavy machinery places inconsistent demand on power systems

Telecommunication Hubs: Ensure uptime during outages in remote towers

Oil & Gas Operations: Maintain reliability in isolated, off-grid environments

Final Thoughts

Generators are a crucial asset, but without proper load monitoring, their performance and longevity can be compromised. Generator load monitoring ensures that power is delivered efficiently, reliably, and safely—no matter the application. Whether you’re running a temporary generator on a job site or maintaining backup power in a critical facility, investing in the right monitoring tools and practices is the key to uninterrupted power and peace of mind.

0 notes

Text

Optical Power and Energy Meter Market : Forecast to 2032

Global Optical Power and Energy Meter size was valued at US$ 234.5 million in 2024 and is projected to reach US$ 342.8 million by 2032, at a CAGR of 4.8% during the forecast period 2025-2032.

Optical power and energy meters are precision instruments used to measure laser beam characteristics. These devices combine two critical functions: power meters measure the average power of continuous wave lasers, while energy meters quantify the total energy output of pulsed lasers. They play a vital role in industries requiring precise optical measurements, from telecommunications to aerospace applications.

Market growth is driven by increasing demand for laser-based technologies across multiple sectors, including telecommunications infrastructure expansion and advanced manufacturing processes. The U.S. currently dominates the market with an estimated 32% revenue share in 2024, while China’s market is growing rapidly with projected 9.1% CAGR through 2032. Key segments include pyroelectric detectors (holding 41% market share) and photodiode-based solutions, with major players like Thorlabs, Newport, and Coherent leading innovation in measurement accuracy and multi-wavelength capabilities.

Get Full Report : https://semiconductorinsight.com/report/optical-power-and-energy-meter-market/

MARKET DYNAMICS

MARKET DRIVERS

Growing Adoption in Fiber Optic Communication Networks to Accelerate Demand

The global optical power and energy meter market is experiencing significant growth due to the exponential increase in fiber optic network deployments. With telecom operators worldwide upgrading to 5G infrastructure and expanding fiber-to-the-home (FTTH) services, the need for precise optical measurement tools has become critical. In 2024 alone, over 60 million new fiber optic connections were established globally, creating substantial demand for testing equipment capable of measuring optical power levels with nanowatt precision. Continuous wave lasers used in these networks require constant monitoring, making power meters indispensable for maintaining signal integrity across long-distance transmissions.

Expansion of Laser-Based Industrial Applications Driving Market Penetration

Industrial applications of high-power lasers are creating new opportunities for optical measurement devices. The laser material processing market, valued at over $20 billion in 2024, relies heavily on accurate power measurement for applications ranging from precision cutting to additive manufacturing. Energy meters are particularly crucial for pulsed laser systems used in micromachining, where monitoring individual pulse energy ensures consistent processing quality. Recent technological advancements have enabled measurement devices to handle power levels exceeding 10 kW while maintaining 0.5% accuracy – specifications that meet the stringent requirements of modern industrial laser systems. This precision is driving adoption across automotive, aerospace, and energy sectors.

Increasing Defense Expenditure on Electro-Optic Systems Boosts Market Growth

Military modernization programs worldwide are incorporating advanced electro-optical systems that require precise optical power measurement capabilities. Defense applications such as laser rangefinders, target designators, and directed energy weapons demand ruggedized power meters capable of operating in harsh environments. Global military spending on electro-optics surpassed $15 billion in 2024, with a significant portion allocated to testing and calibration equipment. The development of new infrared countermeasure systems and laser weapons is creating demand for specialized energy meters that can measure high-energy pulses while withstanding extreme conditions.

MARKET RESTRAINTS

High Equipment Costs and Limited ROI for Small Enterprises

While the market shows promising growth, the substantial capital investment required for high-precision optical measurement equipment presents a significant barrier. Industrial-grade power meters with calibration certification can cost upwards of $10,000, making them prohibitively expensive for many small and medium enterprises. The lack of clear return on investment for basic measurement needs discourages adoption among cost-conscious users who may opt for lower-quality alternatives. This pricing pressure is particularly acute in emerging markets where budget constraints limit access to premium instrumentation.

Complex Calibration Requirements Create Operational Challenges

Maintaining measurement accuracy over time requires regular calibration that often necessitates specialized facilities and reference standards. The calibration process for high-end optical power meters can involve complex procedures traceable to national metrology institutes. Many end-users lack the infrastructure to perform in-house calibrations, forcing them to rely on expensive third-party services. This creates operational disruptions during calibration periods and adds substantial lifecycle costs that some organizations find difficult to justify for non-critical applications.

Technical Limitations in Extreme Measurement Scenarios

Current optical power and energy measurement technologies face fundamental limitations when dealing with certain extreme conditions. Ultrafast femtosecond lasers pose particular challenges due to their extremely short pulse durations that exceed the response time of many conventional detectors. Similarly, measuring high average power lasers above 50 kW requires specialized thermal management solutions that significantly increase system complexity and cost. These technical constraints restrict market expansion into growing application areas such as advanced laser processing and scientific research.

MARKET OPPORTUNITIES

Emerging Quantum Technology Applications Create New Measurement Requirements

The development of quantum technologies presents a major growth opportunity for advanced optical measurement solutions. Quantum computing, communication, and sensing systems require unprecedented levels of optical power stability and measurement precision. Projects like quantum key distribution networks need power meters capable of detecting single photons with precise timing resolution. The global quantum technology market is projected to exceed $50 billion by 2030, with optical measurement playing a crucial role in system development and calibration. This creates demand for specialized metrology tools that can operate at the fundamental limits of optical detection.

Integration with Industry 4.0 and IoT Platforms Drives Smart Meter Development

The convergence of optical measurement with digital technologies is creating opportunities for smart, connected power meters. Modern manufacturing environments increasingly demand instruments that can integrate with industrial IoT platforms for real-time process monitoring. This trend has prompted development of power meters with built-in connectivity options including Ethernet, Wi-Fi, and 5G compatibility. Smart meters capable of predictive maintenance through continuous self-diagnosis are gaining traction in mission-critical applications like semiconductor lithography where unplanned downtime carries significant costs.

Growing Medical Laser Applications Expand Addressable Market

The medical laser market is experiencing rapid expansion with applications ranging from cosmetic procedures to surgical interventions. Each of these applications requires precise dosimetry to ensure patient safety and treatment efficacy. Regulatory requirements for medical laser power measurement have become increasingly stringent, driving demand for FDA-cleared measurement devices with comprehensive documentation. The ongoing miniaturization of medical laser systems has created parallel demand for compact, portable power meters that can be used in clinical settings. This specialized segment represents a high-value growth opportunity with strong pricing power.

MARKET CHALLENGES

Global Semiconductor Shortage Impacts Production Capacity

The optical power and energy meter industry faces ongoing challenges from semiconductor supply chain disruptions that began in 2021. Many meter designs rely on specialized analog-to-digital converters and signal processing chips that have been subject to allocation. Lead times for certain critical components have extended beyond 52 weeks, forcing manufacturers to redesign products or accept reduced production volumes. This shortage has been particularly acute for instruments targeting the high-end market where custom ASICs are often required to achieve desired performance characteristics.

Standardization and Measurement Uncertainty Issues

Lack of uniform measurement standards across different applications creates compatibility challenges for power meter manufacturers. Various industries have developed their own test methodologies that may not align with international standards, leading to conflicting performance claims. Uncertainty budgets for optical power measurements can vary significantly depending on wavelength, power level, and beam characteristics. These discrepancies complicate purchasing decisions and require manufacturers to support multiple calibration regimens, increasing development costs and time-to-market for new products.

Intense Competition from Alternative Measurement Techniques

The optical power meter market faces disruptive competition from emerging measurement technologies that threaten traditional detector-based approaches. Techniques such as optical calorimetry and photoacoustic detection are gaining traction for certain high-power applications where traditional methods struggle. Additionally, some system integrators are developing proprietary measurement solutions that bypass standalone power meters entirely. This landscape requires constant innovation from traditional vendors to maintain technological differentiation while controlling costs in a price-sensitive market.

OPTICAL POWER AND ENERGY METER MARKET TRENDS

Surging Demand for High-Precision Laser Measurement to Drive Market Growth

The global optical power and energy meter market is witnessing robust growth due to increasing adoption in telecommunications, aerospace, and defense applications. Precision measurement of laser power and energy has become critical, especially with the rise of 5G and fiber-optic communication networks. As industries gravitate toward automated and high-speed data transmission, optical power meters have evolved to support wavelengths up to 1650nm with an accuracy of ±2%—meeting the stringent requirements of modern optical networks. Furthermore, the demand for high-energy pulsed lasers in medical and material processing applications has amplified the need for reliable energy meters capable of measuring peak power with nanosecond resolution. Manufacturers are increasingly focusing on multi-channel meters for real-time power monitoring, reducing measurement uncertainty and enhancing operational efficiency.

Other Trends

Expansion of Photonics in Automotive and Aerospace

The integration of LiDAR systems in autonomous vehicles and advanced navigation systems has significantly escalated the demand for optical power and energy meters. These devices ensure optimal performance of LiDAR modules, which require precise calibration of laser output for obstacle detection and distance measurement. Similarly, aerospace applications rely on optical power meters to validate laser-based communication and sensing systems. Meanwhile, advancements in thermal and pyroelectric detectors have improved sensitivity, enabling broader adoption in industrial welding and laser cutting processes. The ability to measure high-power continuous-wave (CW) lasers up to 100W has positioned optical power meters as indispensable tools in industrial automation.

Smart Metering and IoT Integration to Shape Future Demand

The convergence of optical metrology with IoT-driven analytics is accelerating the shift toward smart power monitoring systems. Next-generation optical meters are now incorporating wireless connectivity and cloud-based data logging, allowing remote diagnostics and predictive maintenance. This is particularly relevant in large-scale fiber-optic deployments, where real-time monitoring minimizes downtime and enhances network reliability. Additionally, energy-efficient sensor developments such as InGaAs photodiodes have extended the measurement range beyond 2000nm, catering to emerging mid-infrared applications in spectroscopy and environmental sensing. As R&D investments in photonics intensify, the market is expected to see increased demand for portable and ruggedized meters designed for field applications.

COMPETITIVE LANDSCAPE

Key Industry Players

Technological Innovation Drives Competition in Optical Measurement Solutions

The global optical power and energy meter market features a competitive yet fragmented landscape, with established players dominating through technological expertise while emerging companies carve niches in specialized applications. Thorlabs leads the market with approximately 18% revenue share in 2024, according to industry estimates, attributed to its comprehensive solutions spanning laboratory research to industrial laser applications.

Newport Corporation and Coherent follow closely, together holding nearly 25% market share. Their strong position stems from decades of experience in photonics instrumentation and strategic acquisitions expanding their measurement capabilities. These companies continue to invest heavily in developing next-generation sensors with improved wavelength ranges and faster response times.

Mid-sized players like Edmund Optics and Optosigma are gaining traction through competitive pricing and customization options. The growing demand for affordable yet accurate measurement devices in emerging economies has allowed these companies to expand their geographical footprint significantly. Meanwhile, newer entrants such as Sintec Optronics are focusing on AI-integrated smart meters, potentially disrupting traditional measurement approaches.

List of Key Optical Power and Energy Meter Manufacturers

Thorlabs (U.S.)

Newport Corporation (U.S.)

Edmund Optics (U.S.)

Optosigma (Japan)

Coherent (U.S.)

Laserpoint (Italy)

Sintec Optronics (Singapore)

Laser SOS (U.S.)

Segment Analysis:

By Type

Pyroelectric Segment Leads Due to High Accuracy in Pulsed Laser Measurements

The market is segmented based on type into:

Pyroelectric

Subtypes: Thermopile-based, liquid crystal-based, and others

Photodiode

Subtypes: Silicon, InGaAs, and others

Thermopile

Others

By Application

Telecommunication Segment Dominates Due to Increasing Fiber Optic Network Deployments

The market is segmented based on application into:

Telecommunication

Automotive

Military

Aerospace

Energy

Others

By Technology

Digital Meters Gain Traction Due to Enhanced Precision and Data Recording Capabilities

The market is segmented based on technology into:

Analog

Digital

Hybrid

By Wavelength Range

Near-Infrared Segment Holds Significant Share in Optical Measurement Applications

The market is segmented based on wavelength range into:

Visible Spectrum

Near-Infrared

Mid-Infrared

Far-Infrared

Regional Analysis: Optical Power and Energy Meter Market

North America The North American market for optical power and energy meters is driven by strong demand from the telecommunication, aerospace, and defense sectors, accounting for approximately 35% of the global market share as of 2024. The U.S. dominates this region due to significant investments in fiber-optic networks alongside growing 5G deployment initiatives, enhancing the need for precision optical measurements. Additionally, stringent regulatory compliance in aerospace and military sectors necessitates high-accuracy metering solutions. Canada, though smaller in market size, contributes steadily via its expanding research and development in photonics. Meanwhile, Mexico’s market is emerging, leveraging low-cost manufacturing opportunities for mid-tier metering devices.

Europe Europe remains a hub for high-precision optical metrology, supported by robust industrial standards and increasing adoption across automotive and energy sectors. Countries like Germany, France, and the U.K. collectively contribute over €200 million annually to the optical power and energy meter market, driven by demand for laser-based manufacturing and telecom infrastructure. The EU’s stringent CE and RoHS certifications encourage manufacturers to develop compliant instruments, ensuring reliability in harsh industrial environments. Furthermore, Eastern Europe is witnessing growth with rising investments in photonics research and growing optical component exports.

Asia-Pacific Accounting for the fastest-growing segment in the optical power and energy meter market, Asia-Pacific benefits from massive telecom expansions in China, Japan, and India. China alone contributes over 45% of regional demand, fueled by domestic laser manufacturing and government-backed photonics R&D programs. Meanwhile, Japan’s market thrives on industrial automation, while India leverages low-cost production to cater to both domestic and export markets. Southeast Asia is gaining momentum due to rising semiconductor fabrication, which necessitates reliable optical energy measurements. However, price sensitivity remains a challenge for premium-grade meter adoption in developing economies.

South America The South American market is gradually advancing, primarily propelled by Brazil’s telecommunication upgrades and Argentina’s nascent aerospace instrumentation sector. Brazil dominates regional demand, though economic instability and import dependency on optical components hinder faster adoption. The region shows promise in medical laser applications, which require accurate energy metering, but limited local manufacturing capabilities slow market penetration. Nonetheless, increasing foreign investments in tech infrastructure might drive moderate growth in the long term.

Middle East & Africa While still a niche market, the Middle East & Africa is gaining traction with emerging photonics hubs in Israel, UAE, and Saudi Arabia. Dubai’s smart city initiatives and increasing fiber-optic deployments fuel demand for optical power meters, particularly in the GCC region. However, Africa, outside of South Africa, largely relies on imports due to limited industrial demand and weak supply chains. Despite slow growth, rising government focus on optical sensing in oil & gas and renewable energy sectors indicates potential expansion beyond traditional telecommunication applications.

Get A Detailed Sample Report : https://semiconductorinsight.com/download-sample-report/?product_id=97768

Report Scope

This market research report provides a comprehensive analysis of the global and regional Optical Power and Energy Meter markets, covering the forecast period 2025–2032. It offers detailed insights into market dynamics, technological advancements, competitive landscape, and key trends shaping the industry.

Key focus areas of the report include:

Market Size & Forecast: Historical data and future projections for revenue, unit shipments, and market value across major regions and segments. The global Optical Power and Energy Meter market was valued at USD 320.5 million in 2024 and is projected to reach USD 485.7 million by 2032.

Segmentation Analysis: Detailed breakdown by product type (Pyroelectric, Photodiode, Others), application (Telecommunication, Automotive, Military, Aerospace, Energy, Others), and end-user industry to identify high-growth segments.

Regional Outlook: Insights into market performance across North America, Europe, Asia-Pacific, Latin America, and the Middle East & Africa. The U.S. market size is estimated at USD 89.4 million in 2024, while China is projected to reach USD 102.8 million by 2032.

Competitive Landscape: Profiles of leading market participants including Thorlabs, Newport, Edmund Optics, Optosigma, Coherent, Laserpoint, Sintec Optronics, and Laser SOS, covering their product offerings and market strategies.

Technology Trends & Innovation: Assessment of emerging technologies in laser measurement, integration of IoT in optical testing, and advancements in photodetector technology.

Market Drivers & Restraints: Evaluation of factors such as growing demand for high-precision optical measurements in telecommunications and aerospace sectors, along with challenges like high equipment costs.

Stakeholder Analysis: Insights for optical component manufacturers, test equipment providers, system integrators, and investors regarding market opportunities and strategic positioning.

Research methodology combines primary interviews with industry experts and analysis of verified market data to ensure accurate and reliable insights.

Customisation of the Report

In case of any queries or customisation requirements, please connect with our sales team, who will ensure that your requirements are met.

Related Reports :

Contact us:

+91 8087992013

0 notes

Text

Optical Power and Energy Market: Size, Share, and Forecast Outlook 2025–2032

MARKET INSIGHTS

The global Optical Power and Energy Meter size was valued at US$ 234.5 million in 2024 and is projected to reach US$ 342.8 million by 2032, at a CAGR of 4.8% during the forecast period 2025-2032.

Optical power and energy meters are precision instruments used to measure laser beam characteristics. These devices combine two critical functions: power meters measure the average power of continuous wave lasers, while energy meters quantify the total energy output of pulsed lasers. They play a vital role in industries requiring precise optical measurements, from telecommunications to aerospace applications.

Market growth is driven by increasing demand for laser-based technologies across multiple sectors, including telecommunications infrastructure expansion and advanced manufacturing processes. The U.S. currently dominates the market with an estimated 32% revenue share in 2024, while China's market is growing rapidly with projected 9.1% CAGR through 2032. Key segments include pyroelectric detectors (holding 41% market share) and photodiode-based solutions, with major players like Thorlabs, Newport, and Coherent leading innovation in measurement accuracy and multi-wavelength capabilities.

MARKET DYNAMICS

MARKET DRIVERS

Growing Adoption in Fiber Optic Communication Networks to Accelerate Demand

The global optical power and energy meter market is experiencing significant growth due to the exponential increase in fiber optic network deployments. With telecom operators worldwide upgrading to 5G infrastructure and expanding fiber-to-the-home (FTTH) services, the need for precise optical measurement tools has become critical. In 2024 alone, over 60 million new fiber optic connections were established globally, creating substantial demand for testing equipment capable of measuring optical power levels with nanowatt precision. Continuous wave lasers used in these networks require constant monitoring, making power meters indispensable for maintaining signal integrity across long-distance transmissions.

Expansion of Laser-Based Industrial Applications Driving Market Penetration

Industrial applications of high-power lasers are creating new opportunities for optical measurement devices. The laser material processing market, valued at over $20 billion in 2024, relies heavily on accurate power measurement for applications ranging from precision cutting to additive manufacturing. Energy meters are particularly crucial for pulsed laser systems used in micromachining, where monitoring individual pulse energy ensures consistent processing quality. Recent technological advancements have enabled measurement devices to handle power levels exceeding 10 kW while maintaining 0.5% accuracy - specifications that meet the stringent requirements of modern industrial laser systems. This precision is driving adoption across automotive, aerospace, and energy sectors.

Increasing Defense Expenditure on Electro-Optic Systems Boosts Market Growth

Military modernization programs worldwide are incorporating advanced electro-optical systems that require precise optical power measurement capabilities. Defense applications such as laser rangefinders, target designators, and directed energy weapons demand ruggedized power meters capable of operating in harsh environments. Global military spending on electro-optics surpassed $15 billion in 2024, with a significant portion allocated to testing and calibration equipment. The development of new infrared countermeasure systems and laser weapons is creating demand for specialized energy meters that can measure high-energy pulses while withstanding extreme conditions.

MARKET RESTRAINTS

High Equipment Costs and Limited ROI for Small Enterprises

While the market shows promising growth, the substantial capital investment required for high-precision optical measurement equipment presents a significant barrier. Industrial-grade power meters with calibration certification can cost upwards of $10,000, making them prohibitively expensive for many small and medium enterprises. The lack of clear return on investment for basic measurement needs discourages adoption among cost-conscious users who may opt for lower-quality alternatives. This pricing pressure is particularly acute in emerging markets where budget constraints limit access to premium instrumentation.

Complex Calibration Requirements Create Operational Challenges

Maintaining measurement accuracy over time requires regular calibration that often necessitates specialized facilities and reference standards. The calibration process for high-end optical power meters can involve complex procedures traceable to national metrology institutes. Many end-users lack the infrastructure to perform in-house calibrations, forcing them to rely on expensive third-party services. This creates operational disruptions during calibration periods and adds substantial lifecycle costs that some organizations find difficult to justify for non-critical applications.

Technical Limitations in Extreme Measurement Scenarios

Current optical power and energy measurement technologies face fundamental limitations when dealing with certain extreme conditions. Ultrafast femtosecond lasers pose particular challenges due to their extremely short pulse durations that exceed the response time of many conventional detectors. Similarly, measuring high average power lasers above 50 kW requires specialized thermal management solutions that significantly increase system complexity and cost. These technical constraints restrict market expansion into growing application areas such as advanced laser processing and scientific research.

MARKET OPPORTUNITIES

Emerging Quantum Technology Applications Create New Measurement Requirements

The development of quantum technologies presents a major growth opportunity for advanced optical measurement solutions. Quantum computing, communication, and sensing systems require unprecedented levels of optical power stability and measurement precision. Projects like quantum key distribution networks need power meters capable of detecting single photons with precise timing resolution. The global quantum technology market is projected to exceed $50 billion by 2030, with optical measurement playing a crucial role in system development and calibration. This creates demand for specialized metrology tools that can operate at the fundamental limits of optical detection.

Integration with Industry 4.0 and IoT Platforms Drives Smart Meter Development

The convergence of optical measurement with digital technologies is creating opportunities for smart, connected power meters. Modern manufacturing environments increasingly demand instruments that can integrate with industrial IoT platforms for real-time process monitoring. This trend has prompted development of power meters with built-in connectivity options including Ethernet, Wi-Fi, and 5G compatibility. Smart meters capable of predictive maintenance through continuous self-diagnosis are gaining traction in mission-critical applications like semiconductor lithography where unplanned downtime carries significant costs.

Growing Medical Laser Applications Expand Addressable Market

The medical laser market is experiencing rapid expansion with applications ranging from cosmetic procedures to surgical interventions. Each of these applications requires precise dosimetry to ensure patient safety and treatment efficacy. Regulatory requirements for medical laser power measurement have become increasingly stringent, driving demand for FDA-cleared measurement devices with comprehensive documentation. The ongoing miniaturization of medical laser systems has created parallel demand for compact, portable power meters that can be used in clinical settings. This specialized segment represents a high-value growth opportunity with strong pricing power.

MARKET CHALLENGES

Global Semiconductor Shortage Impacts Production Capacity

The optical power and energy meter industry faces ongoing challenges from semiconductor supply chain disruptions that began in 2021. Many meter designs rely on specialized analog-to-digital converters and signal processing chips that have been subject to allocation. Lead times for certain critical components have extended beyond 52 weeks, forcing manufacturers to redesign products or accept reduced production volumes. This shortage has been particularly acute for instruments targeting the high-end market where custom ASICs are often required to achieve desired performance characteristics.

Standardization and Measurement Uncertainty Issues

Lack of uniform measurement standards across different applications creates compatibility challenges for power meter manufacturers. Various industries have developed their own test methodologies that may not align with international standards, leading to conflicting performance claims. Uncertainty budgets for optical power measurements can vary significantly depending on wavelength, power level, and beam characteristics. These discrepancies complicate purchasing decisions and require manufacturers to support multiple calibration regimens, increasing development costs and time-to-market for new products.

Intense Competition from Alternative Measurement Techniques

The optical power meter market faces disruptive competition from emerging measurement technologies that threaten traditional detector-based approaches. Techniques such as optical calorimetry and photoacoustic detection are gaining traction for certain high-power applications where traditional methods struggle. Additionally, some system integrators are developing proprietary measurement solutions that bypass standalone power meters entirely. This landscape requires constant innovation from traditional vendors to maintain technological differentiation while controlling costs in a price-sensitive market.

OPTICAL POWER AND ENERGY METER MARKET TRENDS

Surging Demand for High-Precision Laser Measurement to Drive Market Growth

The global optical power and energy meter market is witnessing robust growth due to increasing adoption in telecommunications, aerospace, and defense applications. Precision measurement of laser power and energy has become critical, especially with the rise of 5G and fiber-optic communication networks. As industries gravitate toward automated and high-speed data transmission, optical power meters have evolved to support wavelengths up to 1650nm with an accuracy of ±2%—meeting the stringent requirements of modern optical networks. Furthermore, the demand for high-energy pulsed lasers in medical and material processing applications has amplified the need for reliable energy meters capable of measuring peak power with nanosecond resolution. Manufacturers are increasingly focusing on multi-channel meters for real-time power monitoring, reducing measurement uncertainty and enhancing operational efficiency.

Other Trends

Expansion of Photonics in Automotive and Aerospace

The integration of LiDAR systems in autonomous vehicles and advanced navigation systems has significantly escalated the demand for optical power and energy meters. These devices ensure optimal performance of LiDAR modules, which require precise calibration of laser output for obstacle detection and distance measurement. Similarly, aerospace applications rely on optical power meters to validate laser-based communication and sensing systems. Meanwhile, advancements in thermal and pyroelectric detectors have improved sensitivity, enabling broader adoption in industrial welding and laser cutting processes. The ability to measure high-power continuous-wave (CW) lasers up to 100W has positioned optical power meters as indispensable tools in industrial automation.

Smart Metering and IoT Integration to Shape Future Demand

The convergence of optical metrology with IoT-driven analytics is accelerating the shift toward smart power monitoring systems. Next-generation optical meters are now incorporating wireless connectivity and cloud-based data logging, allowing remote diagnostics and predictive maintenance. This is particularly relevant in large-scale fiber-optic deployments, where real-time monitoring minimizes downtime and enhances network reliability. Additionally, energy-efficient sensor developments such as InGaAs photodiodes have extended the measurement range beyond 2000nm, catering to emerging mid-infrared applications in spectroscopy and environmental sensing. As R&D investments in photonics intensify, the market is expected to see increased demand for portable and ruggedized meters designed for field applications.

COMPETITIVE LANDSCAPE

Key Industry Players

Technological Innovation Drives Competition in Optical Measurement Solutions

The global optical power and energy meter market features a competitive yet fragmented landscape, with established players dominating through technological expertise while emerging companies carve niches in specialized applications. Thorlabs leads the market with approximately 18% revenue share in 2024, according to industry estimates, attributed to its comprehensive solutions spanning laboratory research to industrial laser applications.

Newport Corporation and Coherent follow closely, together holding nearly 25% market share. Their strong position stems from decades of experience in photonics instrumentation and strategic acquisitions expanding their measurement capabilities. These companies continue to invest heavily in developing next-generation sensors with improved wavelength ranges and faster response times.

Mid-sized players like Edmund Optics and Optosigma are gaining traction through competitive pricing and customization options. The growing demand for affordable yet accurate measurement devices in emerging economies has allowed these companies to expand their geographical footprint significantly. Meanwhile, newer entrants such as Sintec Optronics are focusing on AI-integrated smart meters, potentially disrupting traditional measurement approaches.

List of Key Optical Power and Energy Meter Manufacturers

Thorlabs (U.S.)

Newport Corporation (U.S.)

Edmund Optics (U.S.)

Optosigma (Japan)

Coherent (U.S.)

Laserpoint (Italy)

Sintec Optronics (Singapore)

Laser SOS (U.S.)

Segment Analysis:

By Type

Pyroelectric Segment Leads Due to High Accuracy in Pulsed Laser Measurements

The market is segmented based on type into:

Pyroelectric

Subtypes: Thermopile-based, liquid crystal-based, and others

Photodiode

Subtypes: Silicon, InGaAs, and others

Thermopile

Others

By Application

Telecommunication Segment Dominates Due to Increasing Fiber Optic Network Deployments

The market is segmented based on application into:

Telecommunication

Automotive

Military

Aerospace

Energy

Others

By Technology

Digital Meters Gain Traction Due to Enhanced Precision and Data Recording Capabilities

The market is segmented based on technology into:

Analog

Digital

Hybrid

By Wavelength Range

Near-Infrared Segment Holds Significant Share in Optical Measurement Applications

The market is segmented based on wavelength range into:

Visible Spectrum

Near-Infrared

Mid-Infrared

Far-Infrared

Regional Analysis: Optical Power and Energy Meter Market

North America The North American market for optical power and energy meters is driven by strong demand from the telecommunication, aerospace, and defense sectors, accounting for approximately 35% of the global market share as of 2024. The U.S. dominates this region due to significant investments in fiber-optic networks alongside growing 5G deployment initiatives, enhancing the need for precision optical measurements. Additionally, stringent regulatory compliance in aerospace and military sectors necessitates high-accuracy metering solutions. Canada, though smaller in market size, contributes steadily via its expanding research and development in photonics. Meanwhile, Mexico's market is emerging, leveraging low-cost manufacturing opportunities for mid-tier metering devices.

Europe Europe remains a hub for high-precision optical metrology, supported by robust industrial standards and increasing adoption across automotive and energy sectors. Countries like Germany, France, and the U.K. collectively contribute over €200 million annually to the optical power and energy meter market, driven by demand for laser-based manufacturing and telecom infrastructure. The EU’s stringent CE and RoHS certifications encourage manufacturers to develop compliant instruments, ensuring reliability in harsh industrial environments. Furthermore, Eastern Europe is witnessing growth with rising investments in photonics research and growing optical component exports.

Asia-Pacific Accounting for the fastest-growing segment in the optical power and energy meter market, Asia-Pacific benefits from massive telecom expansions in China, Japan, and India. China alone contributes over 45% of regional demand, fueled by domestic laser manufacturing and government-backed photonics R&D programs. Meanwhile, Japan’s market thrives on industrial automation, while India leverages low-cost production to cater to both domestic and export markets. Southeast Asia is gaining momentum due to rising semiconductor fabrication, which necessitates reliable optical energy measurements. However, price sensitivity remains a challenge for premium-grade meter adoption in developing economies.

South America The South American market is gradually advancing, primarily propelled by Brazil’s telecommunication upgrades and Argentina’s nascent aerospace instrumentation sector. Brazil dominates regional demand, though economic instability and import dependency on optical components hinder faster adoption. The region shows promise in medical laser applications, which require accurate energy metering, but limited local manufacturing capabilities slow market penetration. Nonetheless, increasing foreign investments in tech infrastructure might drive moderate growth in the long term.

Middle East & Africa While still a niche market, the Middle East & Africa is gaining traction with emerging photonics hubs in Israel, UAE, and Saudi Arabia. Dubai's smart city initiatives and increasing fiber-optic deployments fuel demand for optical power meters, particularly in the GCC region. However, Africa, outside of South Africa, largely relies on imports due to limited industrial demand and weak supply chains. Despite slow growth, rising government focus on optical sensing in oil & gas and renewable energy sectors indicates potential expansion beyond traditional telecommunication applications.

Report Scope

This market research report provides a comprehensive analysis of the global and regional Optical Power and Energy Meter markets, covering the forecast period 2025–2032. It offers detailed insights into market dynamics, technological advancements, competitive landscape, and key trends shaping the industry.

Key focus areas of the report include:

Market Size & Forecast: Historical data and future projections for revenue, unit shipments, and market value across major regions and segments. The global Optical Power and Energy Meter market was valued at USD 320.5 million in 2024 and is projected to reach USD 485.7 million by 2032.

Segmentation Analysis: Detailed breakdown by product type (Pyroelectric, Photodiode, Others), application (Telecommunication, Automotive, Military, Aerospace, Energy, Others), and end-user industry to identify high-growth segments.

Regional Outlook: Insights into market performance across North America, Europe, Asia-Pacific, Latin America, and the Middle East & Africa. The U.S. market size is estimated at USD 89.4 million in 2024, while China is projected to reach USD 102.8 million by 2032.

Competitive Landscape: Profiles of leading market participants including Thorlabs, Newport, Edmund Optics, Optosigma, Coherent, Laserpoint, Sintec Optronics, and Laser SOS, covering their product offerings and market strategies.

Technology Trends & Innovation: Assessment of emerging technologies in laser measurement, integration of IoT in optical testing, and advancements in photodetector technology.

Market Drivers & Restraints: Evaluation of factors such as growing demand for high-precision optical measurements in telecommunications and aerospace sectors, along with challenges like high equipment costs.

Stakeholder Analysis: Insights for optical component manufacturers, test equipment providers, system integrators, and investors regarding market opportunities and strategic positioning.

Research methodology combines primary interviews with industry experts and analysis of verified market data to ensure accurate and reliable insights.

FREQUENTLY ASKED QUESTIONS:

What is the current market size of Global Optical Power and Energy Meter Market?

-> Optical Power and Energy Meter size was valued at US$ 234.5 million in 2024 and is projected to reach US$ 342.8 million by 2032, at a CAGR of 4.8% during the forecast period 2025-2032.

Which key companies operate in this market?

-> Key players include Thorlabs, Newport, Edmund Optics, Optosigma, Coherent, and Laserpoint, among others.

What are the key growth drivers?

-> Key growth drivers include increasing demand for precision optical measurement in telecommunications, growing adoption of laser technologies in industrial applications, and expansion of 5G infrastructure.

Which region dominates the market?

-> North America currently holds the largest market share, while Asia-Pacific is expected to show the highest growth rate during the forecast period.

What are the emerging trends?

-> Emerging trends include development of compact and portable measurement devices, integration of wireless connectivity, and advancements in photodetector technology.

Related Reports:https://semiconductorblogs21.blogspot.com/2025/06/ssd-processor-market-segmentation-by.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/semiconductor-wafer-processing-chambers.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/medical-thermistor-market-supply-chain.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/industrial-led-lighting-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/fz-polished-wafer-market-demand-outlook.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/fanless-embedded-system-market-regional.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/ceramic-cement-resistor-market-emerging.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/universal-asynchronous-receiver.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/fbg-strain-sensor-market-competitive.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/led-display-module-market-industry-size.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/gain-and-loss-equalizer-market-growth.html

0 notes

Text

Optical Power Meter Market Emerging Trends Transforming Optical Communication Landscape

The global optical power meter market is witnessing significant growth as optical networks become the backbone of modern communication infrastructure. With the rising demand for high-speed internet, 5G deployments, and the expansion of fiber-to-the-home (FTTH) services, the need for precise optical power measurement tools is more critical than ever. Optical power meters play a vital role in ensuring optimal performance, fault detection, and quality assurance in fiber optic networks, making them indispensable for telecommunication providers, data centers, and research institutions. Several emerging trends are reshaping the market, driving innovation and expanding applications beyond traditional domains.

Integration with Smart Devices and IoT

A key trend propelling the optical power meter market is the integration of these devices with smartphones, tablets, and IoT platforms. Modern optical power meters are becoming more compact, portable, and user-friendly, often equipped with Bluetooth or Wi-Fi connectivity. This integration allows field technicians to measure optical power levels using mobile apps, streamlining workflows and enhancing productivity. IoT-based optical testing tools enable real-time monitoring of network performance, predictive maintenance, and remote troubleshooting, especially beneficial for large-scale network deployments.

The rise of smart cities and industrial IoT applications also contributes to this trend. As industries adopt connected systems for automation and data transmission, reliable fiber optic networks and accurate power measurements become indispensable, boosting the demand for advanced optical power meters.

Technological Advancements and Multi-Functionality

Optical power meters are evolving from single-purpose devices to multifunctional tools capable of performing various optical tests. Recent developments include integrating optical time-domain reflectometry (OTDR) features, wavelength detection, and loss measurement into compact, handheld devices. This convergence of functionalities eliminates the need for multiple instruments, reducing operational costs and simplifying fieldwork.

Manufacturers are also focusing on enhancing measurement accuracy, dynamic range, and user interfaces. Touchscreen displays, automated calibration, and compatibility with multiple connector types are becoming standard features, reflecting the growing demand for versatile, high-performance tools.

Growth Driven by 5G and High-Speed Networks

The global rollout of 5G networks is a major catalyst for the optical power meter market. 5G infrastructure relies heavily on fiber optic networks for backhaul and fronthaul connections, requiring meticulous testing to ensure minimal signal loss and high bandwidth availability. Optical power meters are crucial in testing, commissioning, and maintaining these networks.

Furthermore, the deployment of data centers to support cloud computing, streaming services, and AI-driven applications has intensified the need for robust optical network testing. High-speed Ethernet, Dense Wavelength Division Multiplexing (DWDM), and coherent optical technologies require precise power level assessments, driving market growth.

Increasing Adoption in Military and Aerospace Applications

Beyond telecommunications, optical power meters are gaining traction in the military, aerospace, and defense sectors. Optical fibers are used in advanced communication systems, avionics, and sensor networks within aircraft and defense platforms. These critical applications demand accurate optical power monitoring to maintain system integrity and performance. As defense budgets increase and nations modernize their military infrastructure, demand for specialized, rugged optical power meters is expected to grow.

Sustainability and Energy-Efficient Devices

Sustainability is emerging as a priority across industries, including optical testing equipment. Manufacturers are developing energy-efficient optical power meters with low power consumption, longer battery life, and eco-friendly materials. Additionally, reducing waste through modular designs, repairable components, and software upgrades aligns with global environmental goals.

This focus on sustainability also extends to network operators, who are investing in energy-efficient fiber optic infrastructure. Precise optical power monitoring helps optimize network performance, reduce energy losses, and extend the lifespan of optical components, supporting greener telecommunication systems.

Regional Expansion and Market Opportunities

Emerging economies in Asia-Pacific, Latin America, and Africa are witnessing rapid growth in fiber optic networks and broadband penetration. Countries like India, China, Brazil, and South Africa are investing heavily in telecom infrastructure, creating lucrative opportunities for optical power meter manufacturers. Government initiatives promoting digital connectivity, smart cities, and rural broadband access further fuel demand for reliable optical testing solutions.

Meanwhile, North America and Europe continue to drive innovation, with established players introducing advanced features, automation, and integrated solutions. Strategic collaborations between telecom operators, equipment vendors, and testing solution providers are accelerating product development and market expansion.

Conclusion

The optical power meter market is evolving rapidly, fueled by advancements in fiber optic technology, 5G expansion, and the need for accurate, reliable network testing tools. Emerging trends such as IoT integration, multifunctional devices, sustainability, and growing applications across industries are transforming the market landscape. As global demand for high-speed, reliable communication infrastructure rises, optical power meters will remain at the forefront of ensuring optimal network performance and connectivity.

0 notes

Text

What Role Does the ECU Play in Managing a Range Rover Engine?

The Engine Control Unit (ECU) is the brain of any modern vehicle, and in the case of the Range Rover engine, its role is even more critical. From monitoring performance to managing fuel efficiency and emissions, the ECU is responsible for controlling the essential systems that keep the engine running optimally. Whether you're driving a new model or considering reconditioned engines for your Range Rover, understanding how the ECU functions can help you appreciate the technology behind its superior performance. We’ll explore how the ECU manages various aspects of the Range Rover engine and why it’s central to engine performance, diagnostics, and reliability. What Is an ECU and Why Is It Crucial for a Range Rover Engine? The Engine Control Unit, or ECU, is an embedded computer system designed to manage and regulate engine functions. In a Range Rover engine, the ECU collects data from various sensors throughout the vehicle to make real-time decisions that optimize engine performance. These sensors measure variables such as air intake, engine temperature, throttle position, and exhaust gases. The ECU processes this information to adjust fuel injection, ignition timing, turbocharging, and even idle speed. This level of control ensures that the engine operates within safe and efficient parameters, reducing wear and improving fuel economy. In reconditioned engines, the ECU must be correctly programmed or recalibrated to match the engine specifications, ensuring peak performance after refurbishment. With today’s environmental regulations and performance demands, an advanced ECU is not just helpful—it’s essential. The ECU enables the Range Rover engine to meet emission standards while still delivering the power and torque that drivers expect from a luxury SUV. How the ECU Controls Fuel Injection in the Range Rover Engine Fuel injection is a core aspect of any internal combustion engine, and in the Range Rover, it's optimized through the ECU. Instead of relying on mechanical systems, the ECU uses input from oxygen sensors, mass airflow meters, and engine speed data to determine the exact amount of fuel needed for combustion. For example, during acceleration, the ECU increases fuel injection for more power, while during cruising, it adjusts for efficiency. This results in smoother performance, fewer emissions, and better fuel economy. This function is vital in both new and reconditioned engines, ensuring they meet performance benchmarks consistently. The Range Rover engines benefits from multi-point or direct fuel injection systems managed entirely by the ECU. Any malfunction in the ECU can lead to poor fuel economy, rough idling, or even engine misfires. That’s why ECU diagnostics are a standard part of Range Rover servicing, especially after an engine replacement or rebuild. Role of the ECU in Emission Control and Compliance Modern engines must comply with strict emissions regulations, and the ECU plays a pivotal role in achieving this. The Range Rover engine uses the ECU to manage the air-fuel ratio, exhaust gas recirculation (EGR), and catalytic converter performance. Sensors like the lambda (oxygen) sensor feed data back to the ECU, which adjusts the mixture to minimize harmful emissions such as nitrogen oxides (NOx) and hydrocarbons. The ECU also triggers onboard diagnostic trouble codes if it detects emission-related issues, such as inefficient catalytic converter operation or fuel vapor leaks. This role is even more important in reconditioned engines, where components are refurbished but need recalibration to meet emission standards. A properly functioning ECU ensures that a reconditioned Range Rover engine doesn't just run, but runs clean. In regions with stringent MOT or emissions testing, the ECU's role becomes critical. A malfunctioning ECU can result in failed tests and legal issues, underscoring its importance in engine management. ECU and Turbocharger Synchronization in Range Rover Engines Many Range Rover engines come equipped with turbochargers for enhanced power and efficiency. The ECU is responsible for managing turbo boost pressure and ensuring the system operates within safe limits. It controls wastegate actuation and monitors boost levels to prevent overboosting, which can damage the engine. Additionally, the ECU adjusts fuel and air ratios depending on turbo output, making sure the engine doesn't run lean or rich under boosted conditions. In reconditioned engines, especially those with rebuilt or replaced turbochargers, recalibrating the ECU is vital. A mismatch between the turbo's performance curve and ECU expectations can lead to poor performance or component failure. Thanks to ECU management, turbocharged Range Rover engines deliver seamless acceleration, superior towing capability, and efficient highway cruising—all without compromising reliability or emissions. Diagnosing Engine Faults with ECU Error Codes One of the most practical functions of the ECU is fault detection and reporting through On-Board Diagnostics (OBD). The ECU constantly checks for abnormalities in sensors, actuators, and other engine components. When something goes wrong—be it a misfire, faulty sensor, or fuel issue—the ECU logs an error code (DTC) that mechanics can read using diagnostic tools. These codes are invaluable in pinpointing issues quickly and accurately, reducing both labor time and repair costs. In the case of reconditioned engines, error codes can help identify if any component hasn’t been installed or configured correctly. It’s also helpful for post-installation health checks to ensure the refurbished engine is performing as expected. With advanced ECU systems in newer Range Rover models, diagnostics can even be monitored remotely, offering real-time data to service centers and giving owners peace of mind. ECU's Role in Adaptive Driving Modes and Terrain Response One of the standout features of the Range Rover engine is its ability to adapt to various driving conditions through Terrain Response. Whether you're off-roading, driving through snow, or cruising on the highway, the ECU adjusts engine performance, throttle response, and gear shifts accordingly.The ECU takes input from sensors that monitor wheel slip, steering angle, gradient, and speed, then makes rapid adjustments to deliver optimal traction and performance. These changes include modifying torque distribution, throttle sensitivity, and even suspension settings. This dynamic management system is impossible without the ECU acting as the coordinator. For reconditioned engines, the ECU must be reprogrammed to ensure it works seamlessly with all vehicle systems, including adaptive drive modes.The integration of the ECU in these advanced systems enhances safety, comfort, and efficiency, making the Range Rover a true all-terrain luxury SUV. ECU and Engine Protection: Preventing Damage and Overheating Beyond performance, the ECU also serves as a protective mechanism for the Range Rover engine. It monitors coolant temperature, oil pressure, and engine load, initiating safety protocols when necessary.If the engine overheats or the oil pressure drops below safe limits, the ECU can reduce power output or trigger limp mode to prevent severe damage. These preemptive actions often save drivers from catastrophic engine failure. For reconditioned engines, this is especially important as any reused components must work within manufacturer-specified tolerances. If the ECU detects inconsistencies, it logs a fault and adjusts operations accordingly. This proactive engine management system gives owners confidence, knowing their vehicle is equipped with smart protection against mechanical failure. Reprogramming and Updating the ECU in Reconditioned Engines When installing a reconditioned engine into a Range Rover, one of the most important steps is updating or reprogramming the ECU. Since each engine has unique calibration requirements—based on sensors, injectors, and turbo settings—the ECU must be synced to the new configuration. Specialist garages use OEM-grade diagnostic tools to upload new maps or software to the ECU, ensuring it matches the reconditioned engine's parameters. Failing to do this can lead to reduced performance, higher emissions, or even check engine lights. In some cases, especially with engine swaps or major overhauls, the ECU may need to be replaced entirely. A mismatched or outdated ECU can cause compatibility issues with other vehicle systems like the gearbox, fuel pump, or infotainment system. Accurate ECU programming ensures that a reconditioned engine performs just like a new one—delivering power, efficiency, and reliability seamlessly. Read the full article

0 notes

Text

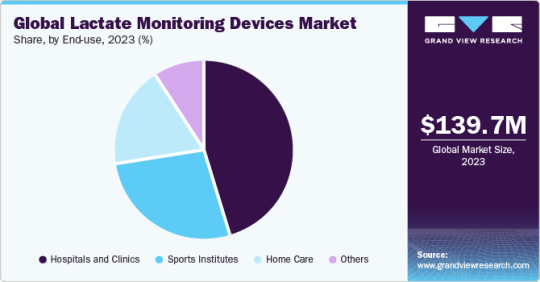

Breakthrough Technologies Reshape Lactate Monitoring Devices Market Landscape

Lactate Monitoring Devices Market Growth & Trends

The global Lactate Monitoring Devices Market is anticipated to reach USD 247.6 million by 2030, growing at a compound annual growth rate (CAGR) of 8.6% from 2024 to 2030, according to a new report by Grand View Research, Inc. The market is witnessing steady and strategic growth, fueled by increasing awareness around the clinical and athletic benefits of lactate monitoring, a rising demand for point-of-care diagnostics, and the accelerating adoption of remote patient monitoring and telemedicine technologies.

One of the most transformative drivers of market expansion is the rapid evolution in device technology. Innovations such as non-invasive lactate testing methods—offering faster results without the need for blood sampling—are enhancing user experience and broadening accessibility. Additionally, the emergence of wireless and wearable lactate monitors is redefining convenience and usability, making these tools more appealing to both healthcare providers and fitness enthusiasts.

The growing emphasis on home-based healthcare, especially among aging populations and patients managing chronic illnesses, is also bolstering demand. User-friendly devices that enable self-monitoring by individuals without medical training are becoming increasingly valuable in this landscape.

In response to these trends, companies operating in the lactate meter space are strategically investing in research and development. Their goals include enhancing device accuracy, integrating lactate monitors with digital health platforms, expanding global distribution channels, and delivering seamless, multi-functional solutions that align with modern healthcare delivery models.

Curious about the Lactate Monitoring Devices Market? Download your FREE sample copy now and get a sneak peek into the latest insights and trends.

Lactate Monitoring Devices Market Report Highlights

Based on the product, the battery-operated lactate meters segment accounted for the largest market share of 82.2% in 2023 due to its ease of portability and use in various settings, including sports fields, clinics, and hospitals. The chargeable lactate meters segment is expected to grow at the fastest CAGR of 9.3% during the forecast period as it is a portable and efficient point-of-care testing system.

Based on the application, the sports segment accounted for the largest market share of 58.9% in 2023 due to the growing need to optimize athletic performance and training regimens.

Based on the end-use, the sports institutes segment accounted for the largest market share of 45.5% in 2023.

In 2023, North America dominated with a share of 41.0% due to the rising prevalence of chronic diseases, quick acceptance of technological device improvements, and rising elderly population. However, Asia Pacific is expected to grow at the fastest CAGR of 9.4% during the forecast period due to the increasing prevalence of conditions such as sepsis, shock, and other critical illnesses that can lead to elevated lactate levels in the body.

Lactate Monitoring Devices Market Segmentation

Grand View Research has segmented the global lactate monitoring devices market based on product, application, end-use, and region:

Lactate Monitoring Devices Product Outlook (Revenue, USD Million, 2018 - 2030)

Chargeable Lactate Meters

Battery Operated Lactate Meters

Lactate Monitoring Devices Application Outlook (Revenue, USD Million, 2018 - 2030)

Sports

Medical

Others

Lactate Monitoring Devices End-use Outlook (Revenue, USD Million, 2018 - 2030)

Hospitals and Clinics