#Multi-Axis Machining

Explore tagged Tumblr posts

Text

How CNC Machining Arizona Supports Aerospace, Automotive, and More

Arizona is more than just a desert state known for its hot summers and beautiful landscapes. It’s also a growing hub for advanced manufacturing, especially in the field of CNC machining. CNC machining, which stands for Computer Numerical Control machining, is a method used to create precision parts using computers and machines.

From aerospace components to automotive parts, CNC machining in Arizona is helping many industries grow and succeed.

What Is CNC Machining?

CNC machining is a manufacturing process where computers control machine tools like mills, lathes, and grinders. It allows manufacturers to produce highly accurate and complex parts from different materials, such as metal, plastic, and even wood.

Instead of being done manually, CNC machines follow coded instructions written in a programming language called G-code. This ensures that each part is made exactly the same, down to the smallest detail. CNC machining is especially useful when making parts that must meet strict requirements, like those used in airplanes or cars.

Why Arizona Is Ideal for CNC Machining

Arizona has become a popular location for CNC machining companies. Here are some reasons why:

Strong Industrial Growth: Arizona is home to many high-tech companies, especially in the aerospace and defense sectors.

Skilled Workforce: Many schools and training centers in Arizona focus on technical education, creating a skilled labor force for CNC machining.

Favorable Business Environment: Arizona offers tax incentives and support programs that attract manufacturing companies.

Access to Major Markets: Its location allows easy transportation of goods to California, Texas, and Mexico.

All these factors make Arizona a smart place to operate a CNC machining business.

Supporting the Aerospace Industry

One of the biggest industries supported by CNC machining in Arizona is aerospace. The state hosts several major aerospace companies and defense contractors. These companies require extremely precise components for planes, helicopters, and satellites.

CNC machining plays a vital role by producing parts such as:

Engine brackets

Turbine blades

Landing gear components

Structural frames

These parts must be lightweight yet strong and meet very tight tolerances. Even a small mistake can lead to failure in critical systems. That’s why CNC machining is trusted to deliver the accuracy and consistency that aerospace companies demand.

Arizona’s aerospace sector also benefits from its proximity to military bases and airports, allowing for easy collaboration between manufacturers and their clients.

Powering the Automotive Industry

Arizona may not be known for car manufacturing like Detroit, but the automotive industry is growing here too. With the rise of electric vehicles (EVs) and self-driving car technology, new companies are setting up shop in the state.

CNC machining helps this industry by making parts such as:

Engine blocks

Transmission housings

Brake components

EV battery casings

Whether it’s a traditional car or an electric vehicle, precision and durability are key. CNC machines can produce thousands of identical parts with high efficiency and minimal waste.

Arizona’s clean energy policies and innovation-friendly environment make it a great place for automotive research and manufacturing. As the demand for electric and autonomous vehicles increases, so does the need for advanced CNC machining.

Helping the Medical Industry

The medical field also relies heavily on CNC machining. Hospitals and clinics need reliable tools and equipment that can save lives. CNC machines are used to create parts such as:

Surgical instruments

Implants like artificial joints

Diagnostic equipment components

In Arizona, the medical manufacturing industry is expanding. Companies here use CNC machining to make custom medical parts with exact specifications. These parts must meet FDA standards, so quality control is very important.

CNC machining allows for rapid production of both custom and mass-produced parts, helping medical professionals get the tools they need faster.

Supporting Other Key Industries

In addition to aerospace, automotive, and medical, CNC machining in Arizona supports many other industries:

Defense and Military

Arizona has several military bases and defense contractors. CNC machining is used to make parts for tanks, drones, and communication systems. These parts must be strong, durable, and able to perform under extreme conditions.

Electronics

Electronics companies use CNC machines to produce circuit board housings, heat sinks, and other small, delicate parts. Precision is key here, and CNC machines can handle very fine details.

Renewable Energy

With the push toward clean energy, companies in Arizona are producing parts for solar panels and wind turbines. CNC machining helps by creating frames, mounts, and other important components used in renewable energy systems.

CNC Machining Services in Arizona

There are many CNC machining companies in Arizona that serve both small businesses and large corporations. These companies offer a range of services such as:

Milling

Turning

Drilling

Prototyping

3D modeling

Quality control testing

One such company is Multi-Axis Machining, which provides expert CNC machining solutions tailored to various industries. With experienced engineers and state-of-the-art equipment, companies like this one help keep Arizona’s manufacturing sector strong.

The Future of CNC Machining in Arizona

As technology continues to evolve, CNC machining is becoming more advanced. Here are some future trends to watch in Arizona:

Automation and Robotics: CNC machines are becoming more automated, which increases productivity and lowers costs.

Smart Manufacturing: Machines are now connected to the internet (IoT), allowing for real-time monitoring and control.

Eco-Friendly Practices: More companies are focusing on reducing waste and energy use.

Additive Manufacturing (3D Printing): CNC machining is being combined with 3D printing to create even more complex parts.

Arizona is well-positioned to lead the way in modern manufacturing thanks to its investment in education, infrastructure, and innovation.

FAQs

Q1: What does CNC stand for?CNC stands for Computer Numerical Control. It refers to machines that are controlled by computers to create precise parts from various materials.

Q2: Why is CNC machining important in aerospace?CNC machining is important in aerospace because it produces parts with very tight tolerances and high precision, which is critical for safety and performance.

Q3: What materials can CNC machines work with?CNC machines can work with a wide range of materials, including metals (like aluminum and steel), plastics, and even some ceramics.

Q4: Is CNC machining used only for big companies?No, CNC machining is used by both large corporations and small businesses. Many CNC machining shops offer services for custom one-off projects and small-batch production as well.

Q5: How does CNC machining help the environment?Modern CNC machines are becoming more energy-efficient and produce less waste compared to older manufacturing methods. Some companies in Arizona also recycle their materials and use eco-friendly practices.

Q6: Can CNC machines make 3D parts?Yes, CNC machines can create complex 3D shapes by cutting away material. They are often used in combination with 3D printing for advanced manufacturing.

Q7: How long does it take to make a part with CNC machining?The time depends on the part’s complexity, size, and material. Some simple parts can be made in minutes, while complex parts might take several hours or days.

Q8: How can I find a CNC machining company in Arizona?You can search online, ask for recommendations, or contact local manufacturing organizations. Look for companies with experience in your industry and a strong track record.

Conclusion

CNC machining in Arizona is playing a vital role in the success of industries like aerospace, automotive, medical, and more. With its advanced technology, skilled workforce, and business-friendly environment, Arizona is a great place for precision manufacturing. As demand continues to grow, CNC machining will remain a key part of the state's economic future.

Whether you need a single prototype or mass production of high-quality parts, CNC machining offers a reliable and efficient solution. From the skies to the highways—and even to the operating room—CNC machining in Arizona keeps innovation moving forward.

1 note

·

View note

Text

The Bristol Beaufighter

The Bristol Type 156 Beaufighter (often called the Beau) is a British multi-role aircraft developed during the Second World War by the Bristol Aeroplane Company. It was originally conceived as a heavy fighter variant of the Bristol Beaufort torpedo bomber. The Beaufighter proved to be an effective night fighter, which came into service with the Royal Air Force (RAF) during the Battle of Britain, its large size allowing it to carry heavy armament and early aircraft interception radar without major performance penalties.

The Beaufighter was used in many roles; receiving the nicknames Rockbeau for its use as a rocket-armed ground attack aircraft and Torbeau as a torpedo bomber against Axis shipping, in which it replaced the Beaufort. In later operations, it served mainly as a maritime strike/ground attack aircraft, RAF Coastal Command having operated the largest number of Beaufighters amongst all other commands at one point. The Royal Australian Air Force (RAAF) also made extensive use of the type as an anti-shipping aircraft, such as during the Battle of the Bismarck Sea.

Lower image shows a Beaufighter being assembled at the Bristol Aeroplane Factory at Filton Bristol in 1942

During World War II, the Beaufighter also played a significant role in the Battle of Britain, protecting the skies over the south of England. Flying at night, all-black painted Beaufighters acted as Night Interceptors in the hands of skilled pilots such as Group Captain John ‘Cats-Eyes’ Cunningham. Cunningham's nickname 'Cats Eyes' originated from him being credited with the highest number of ‘night kills’ in his Beaufighter. In reality, it was later revealed that his success was due to the Beaufighter’s secret Airborne Interception Radar, rather than exceptional night-vision. In flight the Beaufighter was a 'quiet' aircraft and some Germans soldiers called it the 'Silent Death Machine"... It was powered by two 1560Hp Bristol Hercules XI engines, later versions use the more powerful 1760 Hp Hercules XVII engine, Its maximum speed was 327mph

20 notes

·

View notes

Text

Jimi Hendrix: First Rays of the New Rising Sun (1997)

When First Rays of the New Rising Sun arrived in 1997 with the full endorsement of the Experience Hendrix estate, most of us saw little reason to doubt that here, at last, was the closest approximation of the fourth studio LP Jimi didn't live to complete.

But, almost 30 years later, I no longer felt so sure; my distrust piqued, over time, by unceasing bickering among Hendrix's surviving family members and a slew of, at times inconsistent, evidently cash-grabbing reissues (some excellent ones, too).

And then, once I was tempted to sample unsanctioned collections like 1971's The Cry of Love, I no longer knew who to trust -- so I asked my friend and trusted Hendrix connoisseur Sean Westergaard whether he still felt that First Rays was as definitive as it got.

"For these versions," he said, "Eddie Kramer stripped away all the posthumous overdubs and used only multi-tracks from the original sessions, so, knowing how close Hendrix and Kramer worked, this is likely very close to Jimi's vision."

That's good enough for me, though a gaggle of session musicians are still listed in the credits, and I don't think that garish, pink-hued cover art has aged particularly well, but, man, the music and guitar heroics sure have!

You know them all too well: posthumous standards like the rousing rockers "Freedom" and the amazing "Ezy Rider," funky psych jams like "Izabella" and "Dolly Dagger," and one of Jimi's best-loved, dreamy ballads, "Angel."

But I'm also partial to the driving momentum of "Night Bird Flying," earthy blues of "My Friend," swinging bolero of "Hey Baby (New Rising Sun)," and even the somewhat unfocused "Astro Man" is impossible to resist with that Mighty Mouse theme intro.

For those keeping score: of this set's 17 cuts, ten first appeared on The Cry of Love, four on Rainbow Bridge, and three on War Heroes, and, to Kramer's credit, they mesh very nicely despite aspiring to the same stylistic eclecticism found on Electric Ladyland.

So, if nothing else, First Days of the New Rising Sun successfully surveyed the very best of Hendrix's unfinished works, and that's why subsequent, officially sanctioned collections like South Saturn Delta and Valleys of Neptune often proved so uneven.

More Jimi Hendrix: “Purple Haze,” Are You Experienced?, Axis: Bold as Love, Band of Gypsys, Electric Ladyland, The Cry of Love, Blues, South Saturn Delta, Valleys of Neptune, Machine Gun: The Fillmore East First Show, Hollywood Bowl, August 18, 1967.

#Jimi Hendrix#classic rock#hard rock#guitar hero#jimi hendrix experience#band of gypsys#psychedelic rock#acid rock#vinyl

15 notes

·

View notes

Text

My Fanfiction

Gallifrey One-Shots

Dreams of the Future - Romana has nightmares about things that haven’t happened yet

I am President of Gallifrey - Romana's experiences on Etra Prime

Torture of the Daleks - more Etra Prime

Sleep That Never Comes - Romana and Leela sharing their trauma

The Worst Timeline - Romana is traumatized (on the axis)

The Worst Timeline (Is Relative) - Brax is tortured (on the axis)

It's Midnight Somewhere - Romana is disabled (on the axis)

Easy Way Out - Romana dies (on the axis)

What's Left of Me - Leela is lonely (on alt!Gallifrey)

Touch Telepathy - Romana is disabled (psychically)

Not Like Before - Romana adjusts to life back at home post-series 6

Gallifrey Multi-Chapter

Halfway to Anywhere - AU where the Doctor rescues Romana from Etra Prime (5/?? chapters)

Inhuman Nature - AU where Romana fobwatches herself on Earth post-Etra Prime and misses the whole Time War (1/?? chapters)

Brittle - Romana and Narvin are both disabled (on alt!Gallifrey) (2/?? chapters)

After Gallifrey - Romana traps Leela on Earth to save her from the war and she runs into Sarah Jane Smith (there will be sex in this one) (1/?? chapters)

Doctor Who

Doctor Who? - The show but if Romana left Gallifrey on her own and then lived her version of the Doctor’s life (5/39 chapters)

Child of the Daleks - The horrifying life of that girl who got possessed in Remembrance of the Daleks

500-Year Diary - A series that is just various Doctors' diary entries

The Mechanisms

Can You Be Real - pre-tbi Sigyn leads a mission to stop the completion of the train and discovers Loki, broken and incoherent, in need of rescuing (2/?? chapters)

Xena

The Long and Winding Journey - sort of a fix-it that lets them have a family, and sort of just playing with the timeline because I'm autistic like that (2/?? chapters)

Liveblogs

One: The Time Meddler, The Ark, The War Machines

Two: The Curse of the Cybermen, The Enemy of the World

Three (and Liz): The Ambassadors.........of DEATH

Three (and Jo): The Daemons, Day of the Daleks, The Sea Devils, The Mutants, The Green Death

Three (and Sarah Jane): The Time Warrior, Invasion of the Dinosaurs

Four (and Sarah Jane): The Sontaran Experiment, Genesis of the Daleks, Pyramids of Mars, The Deadly Assassin

Four (and Leela): The Invisible Enemy, Image of the Fendahl, The Underworld, The Invasion of Time

Four (and Romana I): The Ribos Operation

Four (and Romana II): Destiny of the Daleks, City of Death, The Horns of Nimon, Full Circle

Five: Four to Doomsday, Black Orchid, Earthshock, Arc of Infinity, Terminus, The Five Doctors, Resurrection of the Daleks

Six: The Twin Dilemma, The Mark of the Rani, The Two Doctors, Trial of a Time Lord 1, Trial of a Time Lord 4

Seven: Time and the Rani, Dragonfire, Battlefield (in progress)

Gallifrey (Series 1): Weapon of Choice, Square One, The Inquiry, A Blind Eye (in progress)

Gallifrey (Series 6): Renaissance, Ascension

Gallifrey (Standalones): Intervention Earth, Enemy Linees

Gallifrey (Echoes Through Eternity): Damned If You Do

Lists

Wild things that happen in Gallifrey: series 1, series 2, series 3, series 4, series 5, series 6, standalones

18 notes

·

View notes

Text

CUE INTRO POST!!!

Took you long enough, TV.

💣The name's Collector or Cocoa, feel free to call me TV however.

This is an assorted blog, unfiltered for my own sanity, reblogs galore, art in debatable quantities and unwarranted things — like posted or reblogged drawings with untagged fews and all.

My art is tagged under #My Arto. What a surprise./s

Kindly don't follow if you won't stick around for my many fandom arcs. I am a multi-fandom blog and there WILL be different interests floating around in this noggin. Which means, yes, my OCs could be randomly tossed in between fandom posts. Timezone PH🇵🇭

Oh, yes, and I'm a sailor mouth. I have no obligations to anything on this app yet and so this will lead to my unfortunate habit of keeping a colorful vocabulary unchecked.

More shit to be placed under cut.

Obligatory Q&A

Can we make drawing requests?

Yes, and I have the volition not to answer.

Can we ask about your characters?

By all means, yes. I love talking about my characters.

Can we ask the characters themselves?

Absolutely. It's fun to write them at all, I'll take any excuse to yap about design. And story. I love writing!!!!

Can I make fanart/get inspired by your designs?

Of course, just have the decency to credit me if inspiration is taken and please ping me when you make fanart! I rarely get any, I'd enjoy my little guys getting attention.

Can I repost your art?

No. <3

If you must, credit me, but I'd prefer you didn't. I have a blog to be redirected to for a reason.

Who's your profile? You haven't changed it in decades, is he relevant?

Nobody asked this but I'll yap anyway. That's an old drawing of Robin, one of my main four Fallen London based Original Characters! If you ever want to know about my OC stuff, please, ask. I have a novel's worth of thoughts on them and a lack of motivation to post a story on them. I'd be ready enthused to know if other people outside my friend circle are interested. I'm on my knees with my head bowed to the floor I LOVE MY OCS AND THE POPULATION OF THEIR FANDOM IS IN THE SINGLE DIGITS</3

Alternative accounts?

@stmwrks014, an Axis RP/Askblog account. It's gonna be filled with headcanons and lore deviations, especially from the fact that this starts off with Chujin alive first and foremost. There's plans to have arcs by the way.

My other alt accs are rather irrelevant otherwise.

INTERESTS/LIKES!

Only the ones I can name off the top of my head, in no particular order

Current = colored / Pls don't spoil = italics / Retired interest = strikethrough

Fallen London (Mostly for my OCs)

Undertale/Deltarune

Undertale Yellow

Lethal Company

Dredge

Iron Lung

Poppy Playtime

TAWOG

Regular Show

Steven Universe

Wreck-It-Ralph <3

Faith, the Unholy Trinity

Mario/Sonic Franchises

(And the EXEs :(/silly)

Madness Combat

Welcome Home (at some point?)

Dayshift at Freddy's

Dialtown

FNaF

HLVRAI

Bendy and the Ink Machine/Dark Revival

Henry Stickmin

Untitled Goose Game

Epic the Musical

Carrion (the spooky meat video game)

Gravity Falls

Adventure Time

Milo Murphy's Law (at some point)

Pokemon (to an extent)

Pokepastas (what is wrong with m—)

Will Wood (queer I am)

Chikn Nuggit

AvA/M

Minecraft (I don't have ppl to play with but the stuff ppl make is fun :]]])

Roblox (I don't know what games I could play but again, the creatures.....)

Sparkbird

Fish in a Birdcage

Jhariah

The Stupendium

I'd say I like Spongebob but most people who have a TV do too.

FNF (I'd like to get back in this fandom out of curiosity but I'm scared of it.)

Slay the Princess

In Stars and Time

And uh. A retired interest is basically just ones I'm not all that interested in anymore but wouldn't mind seeing around. Or basically just a fleeting interest.

Do I have a DNI? Nope! I block as I please. A persona, mascot or self-insert? Not yet! At least, not an official one. I'll figure it out.

Fuck it, out of the closet I go. I'm also a self-shipper! Nothing serious though, I do it to cope. ✨ I won't claim to be the most [blank] of an F/O, I quite enjoy seeing certain other self-ships with a character. With who do I self-ship? Well, I'm unbothered to type.

Where the fuck did i get these gifs from, good question.

#Intro Post#I don't know either.#Anyway whatever *WAVES REALLY ENTHUSIASTICALLY* HI CHATTT#I should update this with links when i get to the point that I can have references and#posts where I can redirect people to when they want to see my funny thingys. like. Like AUs or#or my OCs :]#GAAAAH DRAWING SO HARDDDD#Last update: [4/23/25]#Last update: [5/6/25]#Had to add Wreck-It-Ralph on there.#Last update: [5/24/25]#Added StP and ISaT#monochrome ahh...

4 notes

·

View notes

Text

High precision multi-axis CNC machining

#design#autos#business#prototyping#prototype#prototype machining#rapid prototyping#cnc machining#precision machining#machining parts#cnc precision machining#high precision#cnc metal fabrication#cnc metal process#cnc metal machining#cnc metal processing#cnc metal parts#metal machining#metal cnc#5 axis cnc machining#5axismachining

4 notes

·

View notes

Text

CNC Press Brake Machine in India: Shaping the Future of Metal Bending

In the dynamic world of metal fabrication, CNC Press Brake Machines have become indispensable. These machines are critical in industries that demand precision bending and forming of sheet metal components. In India, the rising focus on infrastructure development, automotive manufacturing, and localized production has driven the adoption of CNC press brake technology across various sectors.

From small workshops to large-scale factories, CNC press brakes are revolutionizing how Indian manufacturers handle metal forming—efficiently, accurately, and consistently.

What is a CNC Press Brake Machine?

A CNC (Computer Numerical Control) Press Brake Machine is used to bend and shape metal sheets with precision. It uses a punch and die to perform various bends, guided by a CNC system that ensures exact specifications for angle, length, and repetition.

Modern CNC press brakes are far more advanced than traditional mechanical or hydraulic versions. They come with programmable controls, automated back gauges, and advanced sensors to deliver high-speed and high-precision bending.

Why CNC Press Brakes are Gaining Popularity in India

1. Precision and Consistency

In sectors like automotive, aerospace, and electronics, even minor deviations in part dimensions can lead to quality issues. CNC press brakes eliminate human error and ensure consistent output across batches.

2. Growing Industrialization

India’s expanding industrial base, especially in Tier 2 and Tier 3 cities, is fueling demand for reliable fabrication equipment. CNC press brakes allow businesses to scale up production without compromising on accuracy.

3. Labour Efficiency

With a skilled labor shortage and rising wages, automation is becoming more attractive. CNC press brakes require minimal human intervention, reducing labor costs and dependency on manual operators.

4. Government Incentives

Government initiatives like Make in India and Production Linked Incentive (PLI) Schemes are encouraging manufacturers to invest in advanced machinery, including CNC press brakes, for higher productivity.

Key Features of CNC Press Brake Machines in the Indian Market

High-Tonnage Capability: Machines ranging from 30 to 1000+ tons to suit various applications.

CNC Control Systems: Brands like Delem, ESA, and Cybelec offer intuitive interfaces for programming and automation.

Servo-Electric or Hydraulic Drive Systems: Depending on precision, energy efficiency, and speed requirements.

Multi-Axis Back Gauge: Enables complex bends and reduces setup time.

Automatic Tool Changers (ATC): For higher production environments.

Leading Indian and International Brands

India has a strong presence of both domestic and international CNC press brake manufacturers. Some notable names include:

Hindustan Hydraulics

Electropneumatics

Energy Mission

LVD India

Amada (Japan)

Durma (Turkey)

Yawei (China)

These companies offer machines tailored to the needs and budget of Indian manufacturers.

Applications in India

Automobile Body & Chassis Manufacturing

Kitchen Equipment Fabrication

Electrical Enclosures & Cabinets

Elevator and Escalator Components

Construction and Infrastructure Products

Railways and Defence Equipment

Challenges for Indian Buyers

High Initial Investment: CNC press brakes can be capital intensive, though the ROI is excellent over time.

Skill Development: Operators need training to use CNC systems effectively.

After-Sales Service: Choosing a vendor with reliable local support is crucial for maintenance and uptime.

The Road Ahead: Smart Factories & Industry 4.0

India is steadily moving towards smart manufacturing. CNC press brakes are now integrating with IoT, ERP systems, and robotic automation, enabling real-time monitoring, predictive maintenance, and remote troubleshooting. This evolution is making Indian factories more agile and globally competitive.

Conclusion

The CNC Press Brake Machine is no longer a luxury—it's a necessity in modern Indian manufacturing. With its unmatched accuracy, efficiency, and automation capabilities, it empowers businesses to meet rising customer expectations while optimizing operational costs.

As India continues to climb the global manufacturing ladder, CNC press brake machines will play a pivotal role in shaping the future—quite literally.

2 notes

·

View notes

Text

#Precision at every #Angle🗜️ Our #Advance #multi-Axis #machining 🎛️#capabilities allow us to produce high precision, #complex 🛠️#Aluminum #components with #unparalleled accuracy From 3 #AXIS to 5 axis #CNCMachining🔧 http://incgoyal.com https://x.com/goyal_inc https://www.youtube.com/@GoyalInc https://www.instagram.com/goyalinc https://in.pinterest.com/goyalinc https://www.facebook.com/incgoyal https://www.threads.net/@goyalinc #AluminumDieCasting #DigitalMarketing💻 #PrecisionEngineering⚙️ #Engineering #Manufacturing #PrecisionMachining #MachinedComponents #DieCasting #PrecisionmachinedParts

2 notes

·

View notes

Text

Why Angular Heads are Important for CNC Machines

In the world of precision manufacturing, Angular Heads and CNC Machines are revolutionizing the way industries approach complex machining tasks. Angular heads, as critical attachments for CNC (Computer Numerical Control) machines, enhance versatility, efficiency, and accuracy in production processes. For businesses looking to optimize their machining operations, understanding the importance of angular heads is key to staying competitive in today’s fast-paced market. In this blog post, we’ll explore why angular heads are indispensable for CNC machines and how they drive productivity, cost-efficiency, and precision.

#Angular Head#Precision Machining#CNC Machines#Multi-Axis Machining#Manufacturing Efficiency#Cost-Effective Machining#CNC Solutions#Kuvam Technologies

0 notes

Text

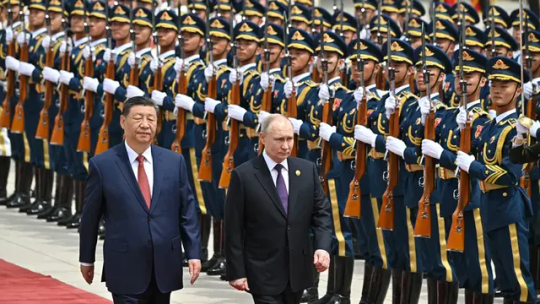

As North Korea, Iran and China support Russia’s war, is a ‘new axis’ emerging?

Hong KongCNN —

The thousands of North Korean troops US intelligence says arrived in Russia for training this month have sparked concern they will be deployed to bolster Moscow’s battlefront in Ukraine.

They’ve also turned up alarm from the United States and its allies that growing coordination between anti-West countries is creating a much broader, urgent security threat – one where partnerships of convenience are evolving into more outright military ties.

Hundreds of Iranian drones have also been part of Moscow’s onslaught on Ukraine, and last month the US said Tehran had sent the warring country short-range ballistic missiles as well.

China, meanwhile, has been accused of powering Russia’s war machine with substantial amounts of “dual use” goods like microelectronics and machine tools, which can be used to make weapons. Last week, the US for the first time penalized two Chinese firms for supplying complete weapons systems. All three countries have denied they are providing such support.

Taking stock of the emerging cooperation, a Congress-backed group that evaluates US defense strategy dubbed Russia, China, Iran and North Korea this summer an “axis of growing malign partnerships.”

The fear is that a shared animosity toward the US is increasingly driving these countries to work together – amplifying the threat that any one of them alone poses to Washington or its allies, not just in one region but perhaps in multiple parts of the world at the same time.

“If (North Korea) is a co-belligerent, their intention is to participate in this war on Russia’s behalf, that is a very, very serious issue, and it will have impacts not only on in Europe — it will also impact things in the Indo Pacific as well,” US Defense Secretary Lloyd Austin said Wednesday in the first US confirmation of North Korean troops in Russia.

‘A real risk’

Viewed from the West, however, China’s refusal to cut off economic lifelines to a UN sanctions-defiant North Korea and a Russia that has threatened the use of nuclear weapons in Ukraine is often seen as an open endorsement of these regimes.

In July, the Commission on the National Defense Strategy, an independent group tasked by Congress with evaluating US defense strategy, said China and Russia’s partnership had “deepened and broadened” to include a military and economic partnership with Iran and North Korea.

“This new alignment of nations opposed to US interests creates a real risk, if not likelihood, that conflict anywhere could become a multi-theater or global war,” it said.

China has repeatedly insisted that its relationship with Russia is one of “non-alliance, non-confrontation and not targeting any third party.”

NATO has also in recent years moved to ramp up relations with US allies and partners in the Asia-Pacific, with a meeting of defense ministers last week joined for the first time by Australia, Japan, New Zealand and South Korea.

In the short term, Russia’s weapons partnerships also open the door for Iran and North Korea to potentially obtain and produce Moscow’s sensitive weapons technologies and even ship them around the world, according to Carnegie’s Zhao.

The current dynamics also raise the risk that future conflicts – including one where China is at the center and not Russia – see coordination between the four, some analysts assess.

#gaza#free gaza#gaza genocide#gaza strip#gazaunderattack#palestine#palestine genocide#lebanon#russia#ukraine#iran

3 notes

·

View notes

Text

MR-J4-70A + HG-KR73B

🔌 MR-J4-70A – Servo Amplifier (Servo Drive) ✔️ A 750W servo amplifier from the Mitsubishi MR-J4 series ✔️ Rated voltage: 200V ✔️ Supports high-speed communication via SSCNET III/H, ensuring fast and precise signal transmission ✔️ Equipped with advanced auto-tuning and vibration suppression control, offering smooth and accurate performance ✔️ Compact design, easy to install in control panels, ideal for high-performance automation systems such as CNC machines, robotic arms, and automated conveyors

⚙️ Key Functions:

Controls position, speed, and torque of servo motors

Includes safety and protection features (overload, overheat, encoder error, etc.)

Supports multi-axis synchronization for complex motion systems

🔩 HG-KR73B – AC Servo Motor ✔️ Rated power: 750W ✔️ Rated torque: approx. 2.4 N·m ✔️ Rated speed: 3000 rpm, max speed up to 6000 rpm ✔️ Comes with a built-in brake, making it ideal for applications where the load needs to be held in place during power loss ✔️ Compact and highly responsive, features a 22-bit high-resolution encoder for ultra-precise feedback and motion control

🔧 Applications:

Typically paired with the MR-J4-70A servo amplifier

Widely used in packaging machines, automated systems, industrial robots, labeling machines, and compact CNC equipment

🧩 The MR-J4-70A + HG-KR73B Combo: ➡️ A powerful, reliable solution for automation systems requiring high-speed response, precision, and long-term stability ➡️ Ideal for industries like electronics, food processing, printing, and precision machining

1 note

·

View note

Text

Elevating Precision Manufacturing: The Role of Mekalite’s CNC Machining Service

In today’s competitive manufacturing landscape, precision, efficiency, and adaptability are key to staying ahead. CNC machining has emerged as a vital technology, enabling manufacturers to produce complex and high-precision parts consistently. At Mekalite, we are redefining excellence in CNC machining services by combining advanced technology, a skilled workforce, and a commitment to quality.

https://mekalite.com/

What is CNC Machining?

CNC (Computer Numerical Control) machining is a process that uses computerized controls to operate machinery and tools with high accuracy. This enables the production of intricate parts from a variety of materials, including metals and plastics, while maintaining tight tolerances. CNC machining is critical in industries such as aerospace, automotive, medical devices, and electronics.

Why Choose Mekalite for CNC Machining?

Mekalite sets itself apart by offering a comprehensive approach to CNC machining, ensuring every project is handled with precision and care.

Advanced Machinery and Capabilities Our cutting-edge, multi-axis CNC machines allow us to handle even the most complex designs with precision and consistency. Whether you need rapid prototyping, low-volume manufacturing, or full-scale production, Mekalite’s technology enables us to meet your unique needs.

Customized Solutions We understand that every project is different. Mekalite works closely with each client to understand their specific requirements, delivering tailored solutions that align with their design and functionality goals.

Strict Quality Assurance At Mekalite, quality is our top priority. Our rigorous quality control protocols cover every step of the production process, from material selection to final inspection. This commitment ensures every part meets the industry’s highest standards.

Industries Served by Mekalite

Mekalite’s CNC machining services support a diverse range of industries, including:

Aerospace: High-precision components for engines, structural parts, and aircraft interiors.

Automotive: Custom engine parts, suspension components, and detailed bodywork.

Medical: Surgical instruments, implants, and diagnostic equipment requiring tight tolerances.

Electronics: Housing frames, connectors, and precision parts for delicate devices.

Benefits of Partnering with Mekalite

Choosing Mekalite as your CNC machining service provider offers numerous advantages:

High Precision and Accuracy Our state-of-the-art CNC machines, combined with skilled operators, enable us to achieve exceptional accuracy and repeatability across all projects.

Wide Range of Materials Mekalite’s expertise spans across various materials, from metals like stainless steel and aluminum to specialized plastics. This flexibility allows for innovative product designs and customized applications.

Cost Efficiency and Scalability With automated processes and minimal manual intervention, CNC machining reduces labor costs while enhancing efficiency. Whether you need a single prototype or a large production run, Mekalite’s scalable services can adapt to your requirements.

Timely Deliveries Time is crucial in manufacturing. Our efficient workflows and commitment to meeting deadlines ensure that your projects are completed on schedule, every time.

Looking Ahead: Mekalite’s Commitment to Innovation

Mekalite is committed to staying ahead of industry trends and technological advancements. By continually investing in the latest CNC machinery and refining our processes, we aim to provide even more innovative and reliable solutions to our clients. Our vision is to be a trusted partner in helping businesses achieve new levels of success through precision manufacturing.

Conclusion

CNC machining is revolutionizing the manufacturing industry, and Mekalite is at the forefront of this transformation. Our combination of cutting-edge technology, tailored solutions, and a dedication to quality makes us a preferred partner for businesses across various sectors.

If you’re looking for a reliable CNC machining service provider that delivers precision and value, Mekalite is here to help. Contact us today to discuss your next project!

https://mekalite.com/

2 notes

·

View notes

Text

Rotary CNC Router Machine

At GK Laser Enterprises, we pride ourselves on delivering cutting-edge solutions to meet the evolving needs of the manufacturing and fabrication industries. One such innovation that has gained popularity for its versatility and precision is the Rotary CNC Router Machine. As a leader in CNC technologies, we offer a range of advanced CNC machines, and today we dive deep into how a rotary CNC router machine can revolutionize your operations.

What is a Rotary CNC Router Machine? A Rotary CNC Router Machine is a computer-controlled cutting machine that uses rotary tools to carve, cut, or engrave materials in three dimensions. The term “rotary” refers to its ability to rotate the material around an axis while it works, providing access to all sides of the material. This capability enables intricate detailing, sculpting, and shaping of cylindrical or irregularly shaped materials.

Unlike traditional CNC routers that work on flat surfaces, rotary CNC routers can handle 3D shapes, making them ideal for creating complex, multi-faceted designs.

How Does a Rotary CNC Router Machine Work? The Rotary CNC Router works by rotating the material, typically using a rotary axis attachment, while the cutting tool precisely follows the programmed paths. Here’s a breakdown of the process:

Material Preparation: A workpiece, such as wood, metal, or plastic, is mounted on the rotary axis, which allows it to rotate. Programming: A computer-aided design (CAD) program creates a digital blueprint of the desired outcome. This is then converted into machine-readable code using computer-aided manufacturing (CAM) software. Cutting Process: The router uses its rotary axis to rotate the material while the cutting tool moves along the X, Y, and Z axes to carve, cut, or engrave the material into the desired shape. Finishing: Once the operation is complete, the workpiece is inspected and may require minimal finishing, thanks to the machine’s precision.

Key Features of a Rotary CNC Router Machine High Precision and Accuracy: Rotary CNC routers are known for their precision in handling complex designs, offering high accuracy even in detailed cuts and engravings. Versatility: Whether you’re working with wood, metal, plastic, or composites, the rotary CNC router can handle a wide range of materials. This versatility makes it invaluable for industries such as furniture design, sculpture, and sign-making. 3D Carving and Engraving: With the ability to rotate the material, rotary CNC routers are ideal for creating 3D objects like sculptures, chair legs, moldings, and even complex cylindrical designs. Automation and Efficiency: The CNC aspect automates the cutting process, ensuring uniformity in production and reducing the need for manual labor. This enhances efficiency and speeds up production time.

Why Choose a Rotary CNC Router Machine for Your Business? If your business requires precision, complexity, and scalability, a rotary CNC router is a wise investment. At GK Laser Enterprises, we emphasize the value it can bring to industries like:

Furniture Manufacturing: Intricate 3D carvings and details for chair legs, columns, and sculptures can be easily achieved using rotary CNC routers. Sign Making and Woodworking: From large signs to ornate wood designs, rotary CNC routers deliver exceptional precision that elevates your craftsmanship. Sculpture and Artwork Creation: Artists and designers benefit from the ability to craft complex shapes and details, providing unmatched creativity. Metal and Plastic Fabrication: Industrial manufacturers who work with metals and plastics can create custom parts, components, and molds with great precision.

Benefits of Using a Rotary CNC Router Machine Enhanced Productivity: With automated processes, your business can take on more projects with faster turnaround times, maximizing profitability. Cost Efficiency: Despite the upfront investment, the long-term savings on labor, material waste, and improved product quality make it a highly cost-effective solution. Precision and Consistency: The automation ensures that each piece you produce is identical in quality and detail, improving overall consistency. Flexibility: Whether you’re producing one-of-a-kind custom pieces or bulk products, the rotary CNC router offers the flexibility to handle both with ease. Lower Material Waste: Precision machining ensures that there is minimal waste, reducing the cost of raw materials and promoting sustainable practices.

Why Buy From GK Laser Enterprises? At GK Laser Enterprises, we provide high-quality rotary CNC router machines tailored to meet the unique needs of businesses across industries. With our deep industry expertise, we ensure that you get the most suitable machine for your applications, ensuring optimal performance and cost-efficiency.

We also offer:

Comprehensive Training and Support: Our team will provide full training on how to operate and maintain your CNC router machine. Maintenance Services: Regular servicing to keep your machine running smoothly, ensuring minimal downtime and maximum output. Custom Solutions: We understand that every business has different requirements, so we provide customized solutions that best fit your needs.

Conclusion The Rotary CNC Router Machine offers unparalleled precision and flexibility, making it an essential tool for businesses involved in woodworking, metalworking, and creative design. At GK Laser Enterprises, we’re committed to providing top-tier CNC solutions that enhance productivity and reduce costs. By investing in a rotary CNC router, your business can stay ahead of the competition while delivering superior quality products. Contact us today to learn more about our CNC machines and how they can benefit your operations!

2 notes

·

View notes

Text

We provide precision CNC machining services, CNC Milling and Turning (3 axis, 4 axis, 5 axis), can manufacture complex and multi-structure plastic and metal parts.

#cncmachining#5 axis machining#cnc milling services#cnc machining parts#rapid prototyping#precision machining

2 notes

·

View notes

Text

The Importance of High-tech Rapid Prototyping

In the industrial industry, precision is not only desirable—it is essential. Consider a situation in which parts of a jet engine are even marginally machined incorrectly or misaligned. The repercussions can be disastrous and might cause the engine to fail in midair. Precision becomes the key to success in sectors like aerospace, automotive, and medical where safety and dependability are non-negotiable. Put simply, it's the capacity to manufacture parts or components that precisely conform to given dimensions, tolerances, and quality requirements. It takes state-of-the-art equipment, painstaking attention to detail, and highly competent operators to achieve this degree of accuracy. This is the sweet spot for Precision CNC Machining.

So how precisely can CNC machining accomplish such high precision levels?

Computerized Control: Advanced computer software is the brains of CNC machining, translating digital design requirements into exact motions and orders for the milling tools. This removes the possibility of human error and guarantees the highest level of precision in each cut, drill, and mill.

Superior Quality Equipment: Modern spindles, tools, and cutting implements that are designed to provide exact results are standard on CNC machines. These devices may operate at extremely tight tolerances, which are sometimes expressed in microns, guaranteeing an accurate reproduction of even the minutest features.

Consistency: The ability of CNC machining and High-tech Rapid Prototyping to manufacture similar components with little variance is one of its main advantages. A machine program that has been developed and tuned may be repeated endlessly with reliable outcomes. In fields where stability and dependability are critical, this degree of constancy is priceless.

Advanced Techniques: Multi-axis milling, turning, EDM (Electrical Discharge Machining), laser cutting, and other state-of-the-art methods are all included in CNC machining. With unmatched accuracy and efficiency, manufacturers can handle complicated geometries and materials thanks to these procedures.

Quality Assurance: CNC systems frequently include integrated quality control mechanisms including automated inspections, feedback loops, and real-time monitoring in addition to accurate machining. This reduces waste and rework by guaranteeing that any deviations from the intended standards are quickly identified and fixed. It is impossible to exaggerate the value of accuracy in production. Precision by Precision CNC Machining Manufacturer plays a crucial role in today's competitive economy, as it ensures everything from satisfying regulatory requirements and consumer expectations to assuring product performance and dependability.

Follow our Facebook and Twitter for more information about our product

#High-tech Rapid Prototyping#Precision CNC Machining#Precision CNC Machining Manufacturer#CNC Machining Manufacturer Company

2 notes

·

View notes

Text

Allen Bradley Kinetix 5500 Servo Drives (single-phase)

Delivering the performance and scalability you need to compete in today’s marketplace, our Kinetix 5500 Servo Drives help you achieve the most from your motion processes. With their innovative, compact design and EtherNet/IP communication, Kinetix 5500 Servo Drives help minimize machine footprint and simplify machine design, operation and maintenance. These versatile servo drives can help you deliver optimized operation in a wide range of single-axis or multi-axis applications from basic position moves to high-speed and coordinated motion solutions.

youtube

#automation#trending#tumblr trends#viral#viralpost#trendingnow#bestdeals#rockwell automation#allen bradley#Kinetix#5500servo drive#industrial automation#industry4.0#business#networking#Youtube

2 notes

·

View notes