#PCB Card for Industrial Electronics

Explore tagged Tumblr posts

Text

Another 2022-present portable computer thing. This is a 1991 Corvallis Microtechnologies PC5-L. It's a ruggedized, waterproof handheld MS-DOS computer meant for industrial applications. It ran on Ni-Cd batteries and they died so now it runs on AA's I got two of them for $50 on eBay during one of those months when i impulse buy obscure electronics as a form of escapism This thing is an absolute brick. You could murder someone by hitting them on the head with this, and it would work fine afterwards. Here's pictures of its organs for anyone curious:

That thick red wire around the screen PCB is a heater. Yep there's a setting to heat up the LCD so it doesn't get sluggish or shatter when you decide to leave it in the freezer. The thing runs on a little system-on-chip thing, which is interesting to see coming from the early 90's. Iirc the datasheet says it's capable of analog video out as well as driving the LCD, but I haven't poked around enough to enable it. Might be cool to hook it up to a TV. I did, however, open those 512k storage modules and I saw some unpopulated footprints on the boards. So I ordered some of the same chips, and at some point I'mma try soldering them on and see if it recognizes the extra space. They came with two voltmeter modules, which I couldn't get to work, so I took one of the casings and made it into a USB and WiFi adapter using an ESP32 running Zimodem, since this thing has RS232 ports on the top. I also made my own charging adapter, since they didn't come with one. I see that internal PCMCIA slot, and I tried putting a CF card adapter in, and tried installing the drivers, but it didn't work. I'm not good at DOS tbh, and I know nothing of what this slot is for. I might come back to it later. I did all of this in 2022-23 and haven't messed with it since. Except to use it to talk to my Kaypro 4 '84:

More on that one later. I love portable computers !!!!!

101 notes

·

View notes

Text

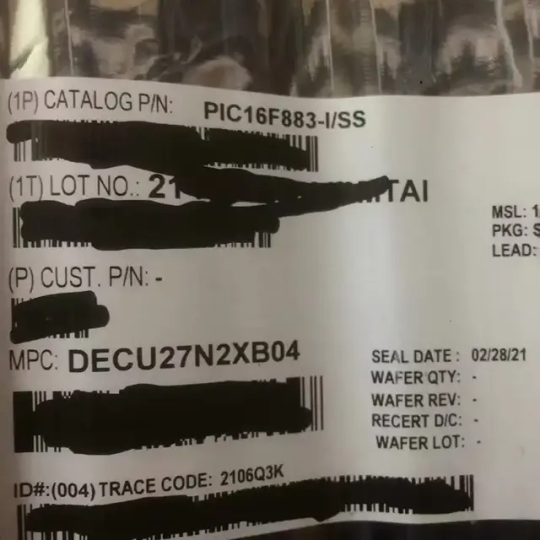

PIC16F883-I/SS for Microchip MCU IC Distributor All parts number we provided is from original. Specification:Control IC MCU 8BIT 7KB FLASH.There is different letter suffix available for this mcu.For exmaple: 2350pcs/Tube packing.MOQ:100PCS.If you interested with much more quantity than MOQ,they are negotiable. Besides,if you didn't find the correct mcu parts number in our site online,you can also chat with us to confirm due to there are much more inventory parts list maybe not list online yet.Know more business about us. Note:Online picture for date code only for refference,different lot date code meybe differenct than online picture.All date code or lot number is as actual received shipment.They are all from new original. ...... Other more electronic components inventory stock are not able to post online,welcome drop us email or chat via whatsapp to know more. About Payment : We usually accept bank transfer,credit card payment,like Visa,MasterCard.,Western Union etc. About Warranty of PIC16F883-I/SS: All the parts provided are same quality as original,so quality is same as offical 1 year warranty. About Us: Chengsuchuang are relable and trustworth electronics hardware supplier from China,we are in the electronic components fields since 2014 year,and got lots of experience in the electronics hardware supply chain.If you are looking for something else about other pcb project for the electronic components bom list,they are also available to supply.Integrated circuits including power ic, logic ic, control ic, driver ic, monitor ic, inerface ic etc.MCU including consumer electronics project,industrial,automobile and medical fields etc. The electronic components distribution brand including ADI,Micron,Samsung,Atmel, Microchip, ST, TI, NXP, INFINEON,Cypress,Altera,Xilinx,ON,TDK,Toshiba,Panasonic etc.The more interested parts number quotation request,welcome drop us email to send a enquiry. If you are looking for a reliable and trustworth ic supplier,then this is a good place you comes.Contact us to talk via whatsapp with sourcing request for quotation,we'll respond you soon. Know more about company product catagory here. Read the full article

0 notes

Text

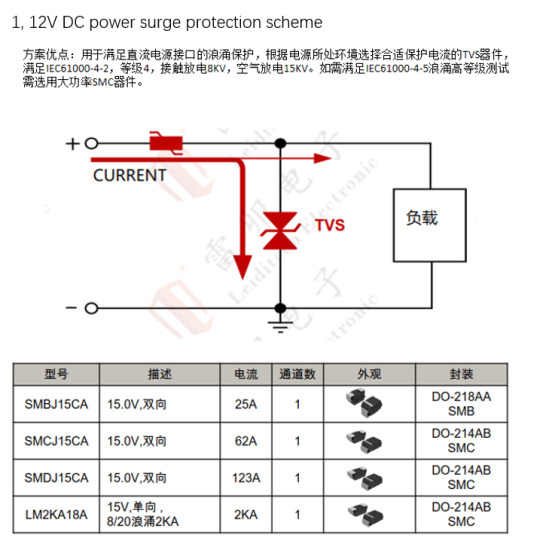

Interface protection design for edge computing gateways

With the rise of the Internet of Things and the popularity of cloud services, a new computing paradigm — edge computing — is beginning to appear in our field of vision. Edge computing advocates processing data at the edge of the network, thereby reducing system response time, protecting data privacy and security, extending battery life, and saving network bandwidth. Current applications are divided into industrial and automotive applications.

Industrial gateways

Industrial gateway is an indispensable device of the industrial Internet of Things, it is like the nerves of the human body, the perceived various types of information to the brain for processing, the brain through the operation to determine what kind of response to do, and then transmitted by the nerves to the limbs of the whole body. The gateway can collect PLC data, do remote maintenance and download programs, and has the functions of edge computing and protocol parsing. Industrial communication gateways can perform message conversion between various network protocols, and their functions can be implemented by a chip, an embedded device or board, or a stand-alone device.

Industrial Edge Computing Gateway Features:

1. Rich interface, support Ethernet, serial port, CAN port, IO port and other equipment access and Ethernet, 2G/3G/4G full Netcom network access;

2. Embedded hundreds of industrial protocols, supporting more than 99% PLC and the vast majority of industrial equipment access;

3. 8GB local storage + SD card support, support local data cache and offline application;

4. Three-in-one serial port, support RS485/RS232/RS422 three kinds of electrical interfaces;

5. Support edge computing, realize data optimization, real-time response, agile connection, model analysis and other services in the edge node of the Internet of Things, and effectively share cloud computing resources to support simultaneous access of multiple devices;

6. Support DC9~36V wide voltage input, adapt to a variety of complex industrial sites;

Each interface protection design of the industrial gateway

D-C power supply

Features of the on-board gateway

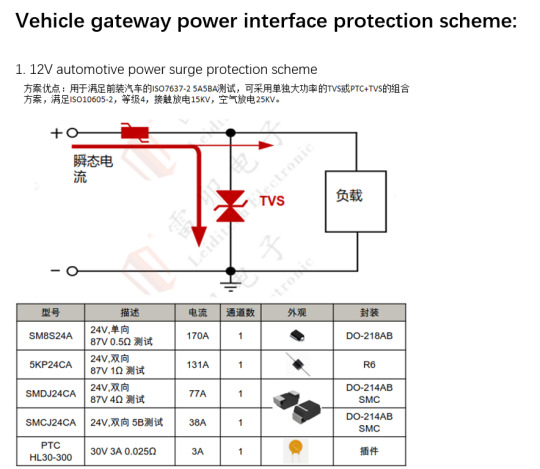

Due to the particularity of the on-board power supply, all the product power ports taken from the car need to pass the surge load-dump test, Leiditech Electronics provides a professional protection solution for the load-dump test, compared with the industrial gateway, the on-board power supply protection needs are greater.

summary

The interface protection of electronic products needs to use overvoltage protection devices, many engineers realize that they want to use protection devices, but due to improper selection or failure to follow the ESD circuit PCB design principles, resulting in product electrostatic testing or EMC testing does not pass, product verification tests many times, waste of manpower and financial resources, causing product delays to market Things always occur, or over-design, resulting in cost pressure.

Leiditech Electronics specializes in providing customers with EMC design services for electromagnetic compatibility, providing laboratories to do thorough tests, from customers efficient, easy to complete the design, hoping that more customers can quickly pass EMC’s projects and improve product reliability. Leiditech Electronic Electromagnetic Compatibility Laboratory, which provides peripheral electrostatic surge protection reference circuits.

If you’d like to learn more or have any questions, don’t hesitate to reach out:

Visit us at [en.leiditech.com]

EdgeComputing #IndustrialIoT #EMCDesign #ESDProtection #AutomotiveGateway #SmartFactory #IoTDesign #HardwareEngineering #EmbeddedSystems #SurgeProtection #InterfaceDesign #TechBlog #EngineeringLife #ProductDevelopment #DesignTips

0 notes

Text

How Printed Circuit Board Assembly (PCBA) Differs from Circuit Card Assembly (CCA)?

In the electronics industry, words like PCBA and circuit card Assembly (CCA) are often used. Despite their equality, however, there is a significant difference in references, applications and scope of these words. Understanding the difference between PCBA and CCA is crucial for experts working on electronic systems for engineers, designers and buying experts.

Understanding of printed circuit board Assembly (PCBA)

The Printed Circuit Board Assembly (PCBA) refers to the process where electronic components are mixed on a bare PCB to create a completely functional tray. This includes growing active and passive components such as resistance, capacitor, integrated circuit (ICS), contacts and more. The PCBA process includes a combination of Surface Mount Technology (SMT), through-Hole Technology (THT) or both. Following the assembly, the board reviews test processes such as Automated Optical Inspection (AOI), in-Circuit Test (ICT) and functional testing to ensure quality and reliability.

Typically, PCBA is utilized to portray both the manufacturing handle and the coming about board. It centres particularly on the populated board itself and not the total framework in which it will inevitably operate.

What is Circuit Card Assembly (CCA)?

Circuit Card Assembly (CCA) is a broader term that can allude to a completed electronic Assembly that may incorporate not as it were the populated board but too connectors, protecting, mechanical latches, and now and then lodging components. The term CCA is regularly utilized in businesses like aviation, defense, and broadcast communications where complex electronic modules are built as portion of bigger systems.

A Circuit Card Assembly may comprise of one or more PCBAs mounted inside a chassis or case, total with wiring, warm administration components, and extra mechanical bolsters. It is a more all encompassing term that goes past the uncovered board to incorporate extra parts essential for sending in real-world environments.

Key Contrasts Between PCBA and CCA

1. Scope:

• PCBA refers specifically to the assembled circuit board with electronic components.

• CCA encompasses the entire assembly that includes the PCBA along with mechanical and structural elements.

2. Usage Context:

• PCBA is commonly utilized in customer hardware, car, and common gadgets manufacturing.

• CCA is predominant in exceedingly controlled divisions like aviation and military, where point by point system-level congregations are essential.

3. Complexity:

• A PCBA is typically a subcomponent within a larger device.

• A CCA may represent a standalone module ready for integration into larger systems.

4. Terminology Origin:

• PCBA is more commonly used in commercial and industrial electronics manufacturing terminology.

• CCA stems from military and aerospace documentation and procurement language.

Conclusion

While Printed Circuit Board Assembly and Circuit Card Assembly may show up comparative at to begin with look, they serve distinctive parts in the lifecycle of an electronic item. PCBA centres on the prepare of populating a circuit board, while CCA covers a more comprehensive electronic module. Recognizing the contrasts between PCBA and CCA guarantees superior communication, clearer documentation, and more successful extend arranging over designing and manufacturing groups.

0 notes

Text

How Does Circuit Card Assembly Impact Electronics Production?

In the rapidly evolving field of electronics, Circuit Card Assembly (CCA) plays a crucial role in determining the performance, reliability, and scalability of electronic devices. Circuit Card Assembly, also known as Printed Circuit Board Assembly (PCBA), involves mounting electronic components onto a pre-designed circuit board, forming the foundation of all modern electronic products.

Enhancing Product Efficiency

Circuit Card Assembly significantly improves the efficiency and functionality of electronics. By automating the process using Surface Mount Technology (SMT) and Through-Hole Technology, manufacturers can ensure consistent and high-speed assembly with minimal human error. This streamlined process allows for mass production of devices ranging from consumer gadgets to industrial control systems, while maintaining performance integrity.

Supporting Innovation in Design

The evolution of electronics design is deeply connected to advancements in CCA. High-density assemblies allow more complex circuits to be placed in smaller form factors. This has enabled innovations in smartphones, medical devices, and IoT products. With technologies like multi-layer boards and flexible PCBs, companies can now meet unique design challenges with customized, compact solutions.

Reducing Production Costs

Efficiency in Circuit Card Assembly directly translates to cost savings. Automated machines reduce labor costs, and precise component placement minimizes material waste. Moreover, the early detection of defects through automated optical inspection (AOI) and X-ray testing helps avoid costly recalls or field failures, improving overall quality assurance.

Improving Reliability and Lifespan

One of the key impacts of CCA is enhanced product reliability. A professionally assembled circuit card undergoes rigorous testing to ensure long-term durability, even under demanding conditions. This is especially critical in industries like aerospace, automotive, and telecommunications, where component failure can have significant consequences.

Role of Guangzhou Wangerbao Software Development Co., Ltd.

Guangzhou Wangerbao Software Development Co., Ltd. is at the forefront of providing software solutions that optimize Circuit Card Assembly processes. Their intelligent software platforms integrate with production lines to manage real-time monitoring, defect tracking, and process control. By using data analytics and automation tools, Wangerbao helps manufacturers ensure precision and efficiency across the assembly lifecycle.

Wangerbao’s solutions are particularly valuable for small to medium-sized enterprises (SMEs) seeking to adopt smart manufacturing practices. Their platforms support traceability, resource planning, and predictive maintenance, which are critical to maintaining competitiveness in global electronics production.

Enabling Scalable Manufacturing

With growing demand for custom electronics and rapid prototyping, scalable CCA processes are essential. Modular assembly lines, supported by smart software from companies like Wangerbao, allow manufacturers to shift quickly from prototyping to full-scale production. This flexibility enables businesses to meet market demands faster while maintaining quality.

Conclusion

Circuit Card Assembly is a foundational element of modern electronics manufacturing, influencing everything from design innovation to production cost and product reliability. With the support of advanced software systems developed by Guangzhou Wangerbao Software Development Co., Ltd., manufacturers can optimize their processes and stay ahead in a competitive, technology-driven market. As electronics continue to evolve, so too will the role and impact of intelligent, efficient circuit card assembly.

0 notes

Text

Rewards of Treaty & High-Reliability Board to Deck Connectors

Worldwide of modern electronics, portable design commonly takes on the demand for high reliability. Yet, board-to-board adapters strike an equilibrium, using both area optimization and resilience. These ports are engineered to hold up against demanding conditions while enhancing electrical efficiency. As you check out the advantages they give various applications, you'll discover that their flexibility plays a crucial duty in staying competitive. What particular advantages can they use your projects?

Area Marketing in Design

When you take into consideration board to board connector pcb, optimizing area in style becomes important for boosting total system performance. A small pcb board to board port allows you to make the most of property on your published circuit card, enabling even more elements in a smaller area. This is specifically vital in high-density functions where space restrictions prevail. Utilizing a high-speed board to board connector helps with quicker data transfer while preserving a streamlined format.

Enhanced Reliability and Durability

A small layout not only enhances space but additionally sustains boosted integrity and durability in digital systems. When you select a top notch board to board adapter PCB, like the LXW board-to-board connectors, you're purchasing elements that can stand up to demanding settings. These adapters include durable materials and precision engineering, ensuring they resist damage with time. Their small nature reduces movement and resonance, which additionally improves integrity. To uncover why we're a leading board-to-board connector supplier, search thorough item magazine.

Enhanced Electrical Functionality

Even though you may focus on the physical aspects of board to board connector pcb, their electric performance is equally crucial. High-grade board to board ports from reputable suppliers ensure reduced resistance and improved signal integrity. This enhanced electric efficiency minimizes information loss and crosstalk, vital for applications requiring accuracy. When resource board to board adapters wholesale, focus on those that meet rigid electric requirements, as this influences general system efficiency.

Convenience Throughout Functions

Offered their design adaptability, board to board adapters provide amazing flexibility across various applications. You'll find that these connectors excel in atmospheres needing high-density lxw connectivity, making them perfect for portable gadgets. Whether you're collaborating with consumer electronics, automobile systems, or industrial machinery, their adaptability fits a wide range of published motherboard (PCB) setups.

Final Thought

Integrating portable and high-reliability board-to-board ports into your styles is like fitting a high-performance engine right into a streamlined sports car making the most of area while enhancing capability. These connectors do not simply conserve area; they improve longevity, guaranteeing your advancements hold up against the examination of time. Visualize the seamless flow of information, devoid of crosstalk, powering your devices with unmatched performance. By picking these innovative services, you're not simply keeping up; you're establishing the criterion in an affordable yard.

0 notes

Text

Everything You Need to Know About Board to Board Connectors in PCB Equipments

When developing PCB systems, recognizing board to board connectors is vital for guaranteeing reliable communication and power transmission. With different kinds offered, selecting the right port includes more than simply matching requirements. You'll need to take into account elements like pitch, stack elevation, and electric ratings to preserve signal honesty. As you browse these intricacies, the relevance of trusted resource and correct execution becomes clear. What other components should you keep in mind to optimize your styles?

Kinds of Board to Board Connectors

Board-to-board connectors play an important duty in helping with interaction and power transfer in between different published circuit card (PCBs) within digital tools. You'll experience numerous kinds of pcb board to board connector, each customized for details applications. For example, conventional adapters offer dependable connections for basic functions, while express board to board connectors accommodate applications calling for fast data transmission.

Capabilities and Functions

Understanding the performances and apps of board-to-board adapters is important for optimizing digital styles. These connectors enable reliable affiliation in between several PCB layers, enhancing signal honesty and minimizing setting up intricacy. When selecting a pcb board to board adapter, consider factors like piling elevation, pitch, and positioning. Apps cover customer electronics, automobile systems, and industrial hands free operation, where reputable links are crucial.

Secret Factors To Consider for Selection

When choose high speed board to board connector, you ought to think about numerous important aspects to guarantee peak performance in your PCB design. Initially, assess the port's pitch and stack height to identify compatibility with your design. Next off, analyze the electrical present ranking and call resistance, which straight influence signal honesty. Wish to partner along with a trusted https://lxw-conn.com/ that delivers both precision and toughness? Go here to get going.

Best Practices for Application

To ensure peak performance throughout execution, you need to prioritize correct positioning and placement of board-to-board adapters on your PCB. Misalignment can cause bad lxw connectivity, leading to signal loss or electrical failures. Identify that the ports are placed within the style's defined tolerances to help with perfect breeding. Make use of automated setting up strategies when suitable to enhance precision.

Final Thought

In the grand tapestry of PCB layout, selecting the best board to board connector is akin to picking the ideal connection for a job meeting crucial yet frequently overlooked. Sure, you might slap any kind of port on and expect the most effective, but that's like putting on flip-flops to a board meeting. By carefully taking into consideration kinds, capabilities, and best methods, you'll not just stay clear of technical artificial pas however additionally boost your layouts to a level of professionalism and trust that also your mother would certainly boast of.

0 notes

Text

The Role of Automation in Transforming Industrial and Marine Operations

Maximizing Efficiency with Industrial Automation Components

In the modern era, industrial automation has revolutionized the way industries operate, particularly in the marine and ship parts sector. Businesses are now empowered to achieve efficiency, precision, and scalability without constant human oversight. Automation components, such as PLC cards, PCB parts, and drives, play a pivotal role in ensuring seamless operations and reducing production errors. Companies like Dropship Automation are at the forefront, delivering high-quality automation solutions that cater to diverse industrial needs.

The Significance of Automation in Industrial Processes

Automation has transformed industries by:

Reducing human error: Streamlining operations for improved accuracy.

Enhancing productivity: Increasing the efficiency of production systems.

Ensuring cost-effectiveness: Minimizing labor costs while maintaining quality.

In sectors like manufacturing and marine engineering, components such as programmable logic controllers (PLCs) and variable-frequency drives (VFDs) are indispensable. Staying updated with the latest automation technologies is crucial for businesses to maintain a competitive edge.

Key Components of Industrial Automation

1. PLC Cards: The Brain of Automated Systems

Programmable Logic Controllers (PLCs) are central to automated operations. They monitor and control industrial processes, ensuring that systems run smoothly. PLC cards allow for:

Customization of processes for specific industrial needs.

Versatility in applications, from manufacturing plants to marine navigation systems.

Industries working with advanced PLC technology can optimize their operations for better performance and reliability.

2. PCB Components: The Backbone of Electronic Systems

Printed Circuit Boards (PCBs) are essential in connecting electronic components within automation systems. In marine and industrial applications, they:

Enable efficient communication between devices.

Provide a compact and reliable framework for electronic systems.

High-quality PCB components ensure durability and operational efficiency, critical for systems in harsh marine environments.

3. Drives: Precision in Motion Control

Variable-Frequency Drives (VFDs) are vital for controlling machinery speed and torque. Their advantages include:

Enhanced energy efficiency.

Reduced wear and tear on equipment.

For companies like Dropship Automation, offering advanced drive solutions is a priority to meet industry standards for precision and sustainability.

Automation in Marine and Ship Parts

In the maritime industry, automation components are indispensable for:

Engine control systems: Ensuring efficient propulsion and energy use.

Navigation and safety systems: Integrating automation for improved performance and security.

By adopting cutting-edge automation technologies, marine operations can achieve enhanced productivity and safety, making businesses more competitive.

Safety Systems in Automation: Fire Alarms and Heat Detectors

Safety is paramount in industrial and marine environments. Automation-enhanced systems like fire alarms and heat detectors offer:

Early detection of potential hazards.

Integration with broader automation systems for rapid response.

Incorporating these systems into operations not only safeguards assets but also protects lives, ensuring compliance with safety regulations.

Human-Machine Interfaces (HMIs): Bridging Operators and Systems

Human-Machine Interfaces (HMIs) are essential for user-friendly interaction with automated systems. They:

Simplify complex operations through intuitive interfaces.

Enhance monitoring and control of industrial processes.

Advanced HMI solutions enable businesses to manage operations effectively, promoting transparency and control.

Why Choose Dropship Automation?

At Dropship Automation, we specialize in delivering top-notch automation components and solutions. From PLC cards to marine automation tools, our expertise ensures:

High-quality, genuine parts from over 1,000 leading brands.

Competitive pricing for cost-effective solutions.

Reliable support for diverse industrial applications.

Partnering with us can transform your operations, whether you’re in manufacturing, marine engineering, or other sectors.

Staying Ahead in Automation

In a rapidly evolving industry, staying updated on automation trends is critical. Here’s how professionals can stay informed:

Attend industry conferences to explore innovations.

Enroll in online courses for in-depth learning.

Join forums and communities for real-world insights.

By leveraging expertise and the latest tools, businesses can achieve unprecedented efficiency and success.

Take Your Operations to the Next Level

Explore the extensive range of automation solutions available at Dropship Automation. From industrial automation parts to marine components, we provide everything you need to simplify processes and boost productivity. Visit our website today and discover how we can help you stay ahead in the automation game.

1 note

·

View note

Text

Liebherr PCB Card 925086914 0002555 0601004 | High-Quality Control PCB Board | Ram Automations

Enhance your machinery’s performance with the Liebherr PCB Card 925086914 0002555 0601004, available now at Ram Automations. This high-quality Printed Circuit Board (PCB) offers exceptional reliability, precision engineering, and durability for a wide range of industrial and marine applications.

Designed for maximum performance and efficiency, this Liebherr PCB Card ensures seamless integration with complex control systems, making it ideal for critical automation environments and high-demand applications.

🛒 Buy Now from Ram Automations 👉 https://ramautomations.com/products/pcb-card-925086914-0002555-0601004-liebherr-new

🌐 Explore 1000+ Genuine Automation Components 👉 https://ramautomations.com

🧩 Product Specifications

• 🔹 Brand: Liebherr • 🔹 Model: 925086914 / 0002555 / 0601004 • 🔹 Type: PCB Card • 🔹 Category: PCB Card / Industrial Electronics / Automation PCB • 🔹 Application: Industrial Automation, Marine Systems, Control Panels, Process Systems

✅ Key Features

✔️ Precision-engineered PCB for reliable performance ✔️ Seamless integration with industrial systems ✔️ High-quality materials and craftsmanship ✔️ Essential for complex machinery and automation units ✔️ Ideal for industrial, marine, and manufacturing environments

💡 Typical Applications

• Marine Electronic Control Systems • Industrial Automation Panels • SCADA and HMI System Boards • Heavy Equipment Automation • Process Automation Systems • Robotics Control Panels • Industrial Machinery Systems

🌟 Why Choose Ram Automations?

✅ 100% Genuine Products Only ✅ Best Prices with Worldwide Delivery ✅ Trusted Industrial Automation Supplier ✅ Large Inventory of Hard-to-Find Components

🛍️ Visit Us: https://ramautomations.com

In This Video You Will Discover:

🔎 Close-up View of Liebherr PCB Card 🔧 How It Integrates with Complex Systems 💡 Importance of High-Quality PCBs in Industrial Automation 🌐 Why Ram Automations is the Go-To Source for Industrial Parts

📣 Get Involved!

🔔 Subscribe for Automation & Electronics Updates 👍 Like to Show Support for Quality Electronics 💬 Comment Your Queries — We’re Happy to Help! 🛒 Visit our Online Store: https://ramautomations.com

#Liebherr PCB Card#PCB Card for Automation#Industrial PCB Card#Automation PCB Card#Marine Control PCB#Automation System Board#Ram Automations#Control Panel PCB Card#Process Control PCB#Marine Automation Electronics#Industrial Electronic PCB#Automation Equipment PCB Card#Marine Systems PCB Card#Factory Automation Parts#Robotics Control Panel Card#Data Transmission PCB Card#PLC Control PCB Card#High Quality PCB Card#SCADA System PCB Card#Electronic Connectivity PCB Board

1 note

·

View note

Text

Circuit Card Assembly Manufacturers

Circuit card assembly manufacturers specialize in designing and assembling circuit cards for various industries, including aerospace, medical, and telecommunications. They use advanced technology to mount electronic components on printed circuit boards (PCBs), ensuring high-quality and reliable performance. These manufacturers cater to custom requirements, offering end-to-end solutions from prototyping to mass production while adhering to stringent quality standards. Circuit Card Assembly Manufacturers

0 notes

Text

ATMEGA328P-AU Embedded System for Atemel IC Distributor Atmega328p specification:IC MCU 8BIT 32KB FLASH 32TQFP. Core Processor:AVR Core Size:8-Bit Speed:20MHz Connectivity:I2C, SPI, UART/USART Peripherals:Brown-out Detect/Reset, POR, PWM, WDT Number of I/O:23 Program Memory Size:32KB (16K x 16) Program Memory Type:FLASH EEPROM Size:1K x 8 RAM Size:2K x 8 Voltage - Supply (Vcc/Vdd):1.8V ~ 5.5V Data Converters:A/D 8x10b Oscillator Type:Internal Operating Temperature:-40°C ~ 85°C (TA) Mounting Type:Surface Mount Package:32-TQFP (7x7) Atmega328 Datasheet here. Note:Online picture for date code only for refference,different lot date code meybe differenct than online picture.All date code or lot number is as actual received shipment. Besides,if you didn't find the correct mcu parts number in our site online,you can also chat with us to confirm due to there are much more inventory parts list maybe not list online yet.Know more business about us. About ATMEGA328P-AU Online Price and MOQ: As for MOQ you see in the quantity blanket,MOQ of this atmega328 mcu is 100 units,if you interested with much more quantity than MOQ online,welcome to chat with us via whatsapp to consult the best support. ...... Other more electronic components inventory stock are not able to post online,welcome drop us email or chat via whatsapp to know more. About Payment: We usually accept bank transfer,credit card payment,like Visa,MasterCard.,Western Union etc. About Warranty: All the parts provided are same quality as original,so quality is same as offical 1 year warranty. About Us: Chengsuchuang are relable and trustworth electronics hardware supplier from China,we are in the electronic components fields since 2014 year,and got lots of experience in the electronics hardware supply chain.If you are looking for something else about other pcb project for the electronic components bom list,they are also available to supply.Integrated circuits including power ic, logic ic, control ic, driver ic, monitor ic, inerface ic etc.MCU including consumer electronics project,industrial,automobile and medical fields etc. The electronic components distribution brand including ADI,Micron,Samsung,Atmel, Microchip, ST, TI, NXP, INFINEON,Cypress,Altera,Xilinx,ON,TDK,Toshiba,Panasonic etc.The more interested parts number quotation request,welcome drop us email to send a enquiry. If you are looking for a reliable and trustworth ic supplier,then this is a good place you comes.Contact us to talk via whatsapp with sourcing request for quotation,we'll respond you soon. Know more about company product catagory here. Read the full article

0 notes

Text

Best Laptops for Electronics Engineers

Electronics engineers require powerful, versatile, and reliable laptops to handle a wide range of tasks such as circuit simulation, PCB design, programming, CAD modeling, and more. A good laptop for electronics engineering should feature a high-performance processor, sufficient RAM, a dedicated GPU (if needed), and a long-lasting battery to support work on the go. In this guide, we’ll explore the best laptops available for electronics engineers in 2025.

Key Factors to Consider

Before purchasing a laptop for electronics engineering, consider the following factors:

1. Processor (CPU)

Electronics engineering software like MATLAB, AutoCAD, Altium Designer, and Proteus requires a powerful CPU. Look for at least an Intel Core i7 or AMD Ryzen 7 processor for smooth performance. If you run high-end simulations, consider an Intel Core i9 or AMD Ryzen 9 for better efficiency.

2. RAM (Memory)

Multitasking and running multiple applications simultaneously require sufficient RAM. A minimum of 16GB RAM is recommended, but 32GB RAM is ideal for heavy simulations and multitasking.

3. Graphics Card (GPU)

While integrated GPUs are sufficient for most tasks, dedicated GPUs like the NVIDIA RTX 3060 or AMD Radeon RX 6600M are beneficial for 3D modeling and high-resolution circuit design.

4. Storage (SSD vs. HDD)

A 512GB SSD is the minimum recommendation for fast boot times and quick access to large project files. If budget allows, opt for 1TB SSD or more for better performance.

5. Display

A high-resolution display enhances clarity, reducing eye strain during long working hours. A 15.6-inch or 16-inch Full HD (1920x1080) or 4K display with good color accuracy is recommended.

6. Battery Life

Electronics engineers often work on-site, in labs, or classrooms where power outlets may not be readily available. A laptop with at least 8-10 hours of battery life is ideal.

7. Connectivity & Ports

Look for laptops with USB-C, HDMI, Thunderbolt, and SD card slots for maximum connectivity with external devices like oscilloscopes, microcontrollers, and hardware debugging tools.

8. Operating System

Windows laptops are preferred due to compatibility with most engineering software. However, some engineers prefer macOS for stability and design, while Linux-based systems are ideal for programming and embedded development.

Top 5 Laptops for Electronics Engineers in 2025

1. Dell XPS 17 (2025 Edition)

Processor: Intel Core i9-13900H

RAM: 32GB DDR5

Storage: 1TB NVMe SSD

GPU: NVIDIA RTX 4060

Display: 17-inch 4K UHD+ (3840 x 2400), 500 nits

Battery Life: Up to 10 hours

Why It’s Great: Excellent performance, stunning display, long battery life, and premium build.

2. Apple MacBook Pro 16 (M3 Max, 2025)

Processor: Apple M3 Max (12-core CPU, 38-core GPU)

RAM: 32GB Unified Memory

Storage: 1TB SSD

GPU: Integrated Apple M3 Max GPU

Display: 16.2-inch Liquid Retina XDR (3456 x 2234)

Battery Life: Up to 18 hours

Why It’s Great: Powerful performance, industry-leading battery life, best-in-class display, excellent for software development and PCB design.

3. Lenovo ThinkPad P16 Gen 2

Processor: Intel Core i9-13980HX

RAM: 64GB DDR5

Storage: 2TB SSD

GPU: NVIDIA RTX A5000 (16GB VRAM)

Display: 16-inch WQUXGA (3840x2400), 600 nits

Battery Life: Up to 9 hours

Why It’s Great: Best for professional-grade simulations and CAD work, durable build, robust security features.

4. ASUS ROG Zephyrus G14 (2025 Edition)

Processor: AMD Ryzen 9 7945HX

RAM: 32GB DDR5

Storage: 1TB NVMe SSD

GPU: NVIDIA RTX 4070

Display: 14-inch QHD+ (2560x1600), 165Hz refresh rate

Battery Life: Up to 8 hours

Why It’s Great: Compact, powerful, high-refresh-rate display, great for circuit simulations and PCB design.

5. HP ZBook Studio G10

Processor: Intel Core i7-13800H

RAM: 32GB DDR5

Storage: 1TB SSD

GPU: NVIDIA RTX 3070 Ti

Display: 15.6-inch 4K OLED

Battery Life: Up to 12 hours

Why It’s Great: Excellent color accuracy, powerful hardware, ideal for multimedia-related engineering tasks.

Budget-Friendly Options

For students or professionals on a budget, consider these options:

Acer Aspire 7 (2025 Edition) – AMD Ryzen 7, 16GB RAM, 512GB SSD, NVIDIA GTX 1650.

Dell Inspiron 16 Plus – Intel Core i7, 16GB RAM, 1TB SSD, Integrated Intel Iris Xe.

ASUS Vivobook Pro 15 – AMD Ryzen 7, 16GB RAM, 512GB SSD, NVIDIA RTX 3050.

Conclusion

Choosing the right laptop for electronics engineering depends on your workload, budget, and preferences. High-end models like the Dell XPS 17, MacBook Pro 16, and Lenovo ThinkPad P16 cater to professionals handling complex simulations and CAD work. On the other hand, budget-friendly options like the Acer Aspire 7 provide good value for students and entry-level engineers. Prioritizing a powerful CPU, ample RAM, SSD storage, and long battery life will ensure a seamless computing experience for any electronics engineering task.

For More Updates visit Our Website: Analytics Insight

1 note

·

View note

Text

What Defines Quality in Circuit Card Assembly? How is PCB Board Assembly Executed for Reliability?

Circuit Card Assembly (CCA) is a basic prepare in the electronics manufacturing industry, including the exact arrangement and soldering of electronic components onto printed circuit boards (PCBs). Quality in circuit card assembly is characterized by a few key variables counting component exactness, fastening keenness, cleanliness, testing, and adherence to industry benchmarks. These components guarantee that the conclusion item performs dependably in its designing application, whether in customer electronics, aviation, restorative electronics, or mechanical machinery.

One of the first markers of quality in circuit card Assembly is component situation exactness. Misaligned or erroneously arranged components can lead to glitches, shorts, or indeed total gadget disappointment. Computerized machines like pick-and-place frameworks are utilized to accomplish tall accuracy and consistency, altogether lessening the plausibility of human error.

Solder joint integrity is another major quality determinant. Destitute soldering can cause irregular associations or add up to detachment. Methods such as reflow fastening for surface-mount components and wave fastening for through-hole components offer assistance guarantee solid, solid joints. These forms are carefully controlled in terms of temperature and timing to avoid harm to touchy components and to guarantee appropriate wetting of solder.

Cleanliness moreover plays a significant part in circuit card assembly. Leftover flux, tidy, or other contaminants can debase execution or cause erosion over time. Subsequently, post-soldering cleaning forms are utilized, particularly for high-reliability applications, to evacuate ionic and non-ionic build-ups that might affect the board's function.

Rigorous testing procedures are crucial to keep up quality. Visual review, Automated Optical Inspection (AOI), In-Circuit Testing (ICT), and Functional Testing (FCT) are standard hones. These procedures offer assistance distinguish lost components, destitute patch joints, and useful mistakes some time recently the item comes to the client. AOI and X-ray assessment are especially valuable for confirming patch joints beneath components like BGAs (Ball Framework Clusters), which are not obvious to the exposed eye.

Adherence to industry measures, such as IPC-A-610 for worthiness of electronic congregations and ISO 9001 for quality administration frameworks, too characterizes quality in CCA. Compliance guarantees that manufacturing forms meet all inclusive recognized benchmarks for execution and reliability.

To execute PCB Board Assembly for unwavering quality, a orderly and controlled manufacturing approach is significant. This incorporates design for manufacturability (DFM), which guarantees that the PCB format minimizes manufacturing issues and maximizes abdicate. Selecting high-quality components, utilizing vigorous materials for the board substrate, and keeping up strict natural controls (like stickiness and inactive security) encourage contribute to the long-term unwavering quality of the amassed board.

In expansion, thermal management amid both manufacturing and operational utilize is basic. Heat sinks, thermal vias, and suitable PCB design diminish the hazard of heat-related disappointments. Unwavering quality testing such as warm cycling, vibration testing, and natural push screening recreate real-world conditions and offer assistance distinguish shortcomings some time recently the item is released.

In conclusion, quality in circuit card Assembly is a mix of exactness building, thorough testing, and adherence to measures. PCB board assembly, when executed with these standards, comes about in dependable, strong items able of withstanding the requests of their applications. Together, these hones frame the spine of high-performance electronics manufacturing.

0 notes

Text

MIT WPU Pune Direct Admission – UG & PG Programs 2025

Your low score doesn’t define your future! Don’t let it become a hurdle to your success. See this as an opportunity to improve and achieve your dreams. Direct Admission in MIT WPU Pune can help you reach your academic goals without hassle.

About MIT WPU Pune

MIT World Peace University (MIT WPU), Pune, is one of India’s leading institutions, known for its outstanding academic programs and innovative educational approach. With a legacy of excellence, MIT WPU is the perfect place for students aiming for a successful career.

Why Choose Digital Shiksha for Direct Admission in MIT WPU Pune?

Digital Shiksha simplifies the complex admission process, making it easy for you to secure your seat at MIT WPU. Here’s how they help:

Expert Admission Guidance: Comprehensive support from application to enrollment.

Customized Counseling: Tailored advice based on your academic goals.

Transparent Process: Clear and straightforward communication throughout.

Hassle-Free Documentation: Assistance with paperwork for a smooth process.

Proven Success: A track record of successful admissions to top colleges, including MIT WPU Pune.

Courses Offered at MIT WPU Pune

MIT WPU offers a wide range of programs, including:

Engineering: CSE, Mechanical, Civil, Electronics, and more.

Management: MBA, BBA, and business-related courses.

Law: Integrated programs like BA-LLB and BBA-LLB.

Pharmacy: UG and PG programs in pharmacy.

Design: Product, graphic, and industrial design courses.

Why Choose MIT WPU Pune for Higher Education?

MIT WPU stands out for many reasons:

Diverse Programs: Offers undergraduate, postgraduate, and doctoral courses.

World-Class Infrastructure: Modern classrooms and advanced labs.

Placement Success: Top recruiters include Amazon, Infosys, and TCS.

Innovative Curriculum: Focus on peace, sustainability, and skills.

Renowned Faculty: Experienced professors and industry experts.

Global Exposure: Opportunities for international collaborations.

How to Get Direct Admission in MIT WPU Pune with Digital Shiksha?

Follow these simple steps to secure your seat:

Contact Digital Shiksha: Schedule a consultation.

Eligibility Assessment: Evaluate your academic profile.

Document Submission: Complete all required paperwork.

Seat Confirmation: Secure your admission to MIT WPU Pune.

MIT WPU Pune B.Tech Placement Highlights

Highest Stipend: 60k per month

University Highest Package: 51.36 LPA

MIT WPU Engineering Fees with Specialization

B.Tech CSE, AI & ML, Cyber Security: Rs. 3,55,000/- per annum

B.Tech Civil, Smart Infrastructure: Rs. 2,55,000/- per annum

B.Tech Mechanical, Robotics: Rs. 3,15,000/- per annum

B.Tech Electronics, AI & ML: Rs. 3,15,000/- per annum

B.Tech Bioengineering: Rs. 3,15,000/- per annum

B.Tech Petroleum Engineering: Rs. 2,55,000/- per annum

Eligibility Criteria for Direct Admission in MIT WPU Pune

Must have appeared in JEE 2024 / MHTCET 2024 / PERA 2024 / NEET 2024.*

Minimum 50% aggregate in PCM/PCB (45% for Maharashtra Backward Class category).

Diploma holders must have a minimum of 60% aggregate.

Documents Required for Direct Admission:

Class 10 & 12 Marksheet

Entrance Exam Scorecard

Character Certificate

Migration & Transfer Certificates

Passport-size Photographs

Aadhar Card Copy

Fees for Direct Admission in MIT WPU Pune:

Approx. Rs 3,00,000/- per year.

Get Expert Guidance Today!

Secure your seat at MIT WPU Pune with Digital Shiksha for a smooth and stress-free admission process.

📞 Call Now: +91 81496 89468

💬 Enquire on WhatsApp!

With expert counseling and transparent procedures, your dream of joining MIT WPU Pune is just a call away!

CONTACT INFORMATION

Visit Here: Digital Shiksha

Office Address: C1 - 203, Saudamini Commercial Complex, Paud Road, Bhusari Colony, Kothrud, Pune, Maharashtra

Email: [email protected]

Phone: +91 81496 89468

Take the first step towards your engineering career today by securing your spot at St. Francis Institute of Technology!

0 notes