#PCB Design Company

Explore tagged Tumblr posts

Text

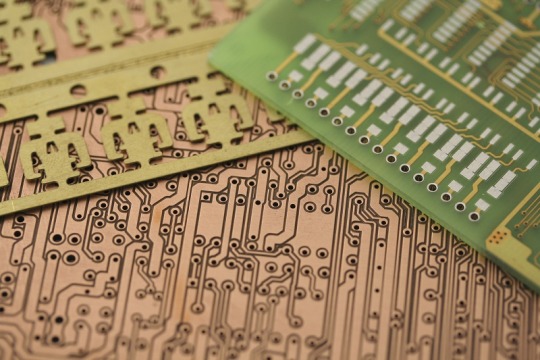

What is a Printed Circuit Board?

Printed Circuit Boards are boards that connect various points together through lines and pads. They allow signals and power to connect between two separate physical devices. While the term “printed circuit board” is typically used, other terms to describe these include “printed wiring board” and “printed wiring card.”

#marketing#investing#finance#branding#pcb circuit#pcb#pc build#pcb assembly#flexible circuit board#pcb board fabrication#pcb circuit design#pcb circuit in Gujarat#pcb design company#Printed Circuit Boards

3 notes

·

View notes

Text

0 notes

Text

Pcb Design Company in France

Welcome to fastpcbcopy, your leading PCB design company in France With our expertise and dedication, we deliver top-notch PCB design solutions tailored to your needs. Whether it's prototyping, optimization, or full-scale production, trust fastpcbcopy to bring your vision to life. Contact us today to revolutionize your PCB projects.

0 notes

Text

PCB Design Company In Gujarat | PCB Design Company In India

Epsilon Electronics: Your PCB Design and Development Solution Partner in Ahmedabad, Gujarat, India, Serving as Premier Electronics Hardware Design Manufacturers in the Country.

#PCB design company#PCB design company in Gujarat#PCB design company in India#Circuit design company in India#EMS solution Provider

0 notes

Text

The Benefits of Ordering Printed Circuit Boards Online: A Guide to Choosing the Right PCB Manufacturer

In today's rapidly advancing technological landscape, printed circuit boards (PCBs) play a crucial role in various electronic devices, from smartphones to industrial machinery. As demand for these essential components grows, businesses and hobbyists alike seek efficient and cost-effective solutions for obtaining high-quality PCBs. One of the most convenient methods is to order printed circuit boards online. In this article, we will explore the advantages of ordering PCBs online and provide insights into selecting a reputable PCB manufacturer.

Why Order Printed Circuit Boards Online?

Ordering printed circuit boards online offers several benefits, making it an attractive option for many businesses and individuals:

Convenience: The ability to order PCBs from the comfort of your home or office eliminates the need for in-person visits to manufacturers or suppliers. This convenience saves time and effort, allowing you to focus on your projects or business operations.

Wide Range of Options: Online PCB manufacturers offer a variety of options in terms of materials, layer counts, finishes, and more. This flexibility allows you to customize your PCBs according to your specific requirements and budget.

Cost-Effectiveness: Many online PCB manufacturers provide competitive pricing, especially for bulk orders. Additionally, you can easily compare prices and services from different providers, ensuring you get the best value for your money.

Quick Turnaround Times: Online ordering often comes with expedited production and shipping options, allowing you to receive your PCBs faster. This is particularly beneficial for projects with tight deadlines or when you need quick prototypes.

Access to Advanced Technologies: Many online PCB manufacturers offer advanced technologies such as high-frequency PCBs, flexible PCBs, and more. This access to cutting-edge technology ensures your designs are compatible with the latest industry standards.

Choosing the Right PCB Manufacturer

Selecting the right PCB manufacturer is crucial to ensuring the quality and reliability of your printed circuit boards. Here are some key factors to consider when choosing a PCB manufacturer:

Experience and Reputation: Look for a manufacturer with a solid track record and positive reviews from previous customers. Experienced manufacturers are more likely to produce high-quality PCBs and provide reliable service.

Quality Assurance: Ensure the manufacturer follows strict quality control measures, such as ISO certification and regular testing. High-quality PCBs are essential for the proper functioning and longevity of your electronic devices.

Customer Support: Good customer support is vital, especially if you encounter issues during the ordering process or with the final product. Choose a manufacturer that offers responsive and helpful customer service.

Manufacturing Capabilities: Check the manufacturer’s capabilities, including the types of PCBs they can produce, their layer count capacity, and the materials they use. Make sure they can meet your specific design requirements.

Lead Times and Shipping: Consider the manufacturer’s production lead times and shipping options. Quick turnaround times are crucial for meeting project deadlines, so choose a manufacturer that can deliver within your required timeframe.

Pricing and Payment Terms: While cost is an important factor, it should not be the sole consideration. Ensure the manufacturer offers transparent pricing and flexible payment terms that suit your budget.

Conclusion

Ordering printed circuit boards online is a convenient and cost-effective way to obtain high-quality PCBs for your projects. By choosing a reputable PCB manufacturer, you can ensure the reliability and performance of your electronic devices. Whether you are a business looking to streamline your supply chain or a hobbyist working on a personal project, ordering PCBs online provides a seamless and efficient solution.

For those ready to place a printed circuit board order online, consider the factors outlined above to select the right PCB manufacturer for your needs. With the right partner, you can bring your electronic designs to life with precision and quality.

#printed circuit board#pcb manufacturer#pcb supplier#printed circuit board order online#pcb design & manufacturing services#pcb circuit manufacturer in ahmedabad#electronic circuit design company

2 notes

·

View notes

Text

How to Choose the Right Electronic Manufacturer in Chennai

Electronic manufacturing in Chennai is a rapidly growing sector offering vast opportunities for innovation and scale.

If you’re searching for electronic manufacturing services in Chennai, the key is finding a partner with proven capabilities in contract manufacturing, product engineering services, and PCB design and manufacturing. Chennai is one of India’s leading electronics hubs — but choosing the right manufacturer means evaluating more than just location. You need a provider that ensures quality, reliability, scalability, and technical expertise. This guide walks you through exactly what to look for — and how to choose the right electronic manufacturer in Chennai for your next project.

Why Chennai Is a Smart Choice for Electronic Manufacturing

Chennai is more than just a manufacturing destination — it’s a complete ecosystem built for modern electronics production. Here’s why it stands out:

1. Established Manufacturing Ecosystem

Chennai is home to numerous electronics manufacturing clusters such as Sriperumbudur, Oragadam, and Pillaipakkam, where many global and domestic EMS providers operate.

2. Skilled Workforce & Technical Talent

The city produces thousands of engineering graduates annually, providing a skilled workforce for PCB assembly, embedded systems, and precision electronics.

3. Advanced Infrastructure

With access to major ports, industrial parks, and logistics hubs, Chennai offers a ready-made foundation for fast, efficient manufacturing and distribution.

4. Government Support

Policies like the Tamil Nadu Electronics Hardware Manufacturing Policy 2024 and national-level PLI schemes provide tax benefits, funding support, and ease of doing business.

Key Criteria to Choose the Right Electronic Manufacturing in chennai

Before partnering with a manufacturer, make sure they meet these critical criteria:

1. Core Capabilities & Services Offered

Look for providers that offer more than just PCB assembly. A full-service partner will provide:

Product engineering services

PCB design and manufacturing

Prototyping and New Product Introduction (NPI)

Box build and final assembly

Component sourcing and logistics

After-sales support and warranty repair

2. Quality Standards and Certifications

The best manufacturers follow strict quality assurance practices and hold certifications like:

ISO 9001 / ISO 13485 / ISO 14001

RoHS and CE compliance

IPC standards for PCB assembly

3. Technology and Infrastructure

Evaluate their in-house equipment and facilities:

SMT and THT lines

Automated Optical Inspection (AOI)

X-ray and In-Circuit Testing (ICT)

Cleanrooms and ESD-safe environments

4. Scalability and Flexibility

A good manufacturer should easily handle:

Low-volume prototyping

Mid- to high-volume production

Rapid scale-up based on your market demand

5. Transparent Communication

Benefits of Choosing the Right EMS Partner in Chennai

Speed to Market: Faster prototyping and production cycles

Cost Efficiency: Competitive pricing with high-quality output

Customization: Tailored support from design to delivery

Reliability: Long-term partnership with consistent performance

Integrated Services: One-stop solution for design, assembly, and post-sales

Example: What a Full-Service Manufacturing Partner Should Offer

Let’s say you’re building a medical device or IoT product. The ideal Chennai-based partner should help you with:

Design for Manufacturing (DFM) consultation

Prototyping and testing for early validation

Complete PCB design and manufacturing

Mechanical integration through box build

Supply chain and sourcing

Packaging and global shipping

This saves you from managing multiple vendors and allows you to stay focused on core product development.

Final Thoughts: Chennai Is Ready — Are You?

Chennai is already powering the next generation of electronic products — from consumer gadgets to industrial devices. With its talent, infrastructure, and supportive ecosystem, it’s the ideal place to launch or scale your next innovation.

Choosing the right electronic manufacturing partner in Chennai is about more than capabilities — it’s about finding someone who aligns with your goals, understands your product, and is ready to grow with you.

Looking for a Trusted EMS Partner in Chennai?

If you’re ready to take the next step with a dependable electronics manufacturing partner, consider Auckam Technologies. With proven expertise in IoT, healthcare, industrial automation, and drone electronics, Auckam delivers comprehensive electronic manufacturing services — from prototyping and PCB design and manufacturing to full-scale contract manufacturing.

Whether you’re a startup, OEM, or scaling product company, Auckam’s commitment to quality, transparency, and flexibility ensures your innovation moves from idea to market — faster, smarter, and stronger.

Electronic manufacturing in Chennai — Auckam Technologies Pvt Ltd., №26A, Anna Street, Chitlapakkam, Chennai — 600064.

👉 Visit www.auckam.com to learn more or start your project

#electronic manufacturing#ems companies in chennai#pcb design and manufacturing#top ems providers#chennai electronic manufacturing#pcb assembly services chennai

0 notes

Text

PCB Fabrication Company in India – Reliable Solutions for Your Manufacturing Needs

Printed Circuit Boards (PCBs) are the foundation of modern electronics. From mobile devices to industrial equipment, PCBs are essential in powering technology across industries. As demand for high-quality electronics continues to rise, India has become a global hub for PCB fabrication, offering reliable, affordable, and advanced manufacturing solutions.

If you are looking for trusted PCB fabrication company in India, FindingMFG connects you with verified manufacturers ready to deliver quality at every stage of production.

Why Work with a PCB Fabrication Company in India?

India has established itself as a leading destination for electronics manufacturing. Supported by skilled professionals, modern infrastructure, and global certifications, Indian PCB manufacturers deliver products that meet international standards. Here’s why businesses choose PCB fabrication companies in India:

Affordable and Efficient Production

PCB manufacturers in India provide cost-effective solutions, whether you require a prototype or a large-volume order. Competitive pricing combined with strict quality control ensures that you receive reliable products at the right cost.

Advanced Manufacturing Capabilities

With access to modern machinery and production techniques, Indian PCB companies can fabricate single-sided, double-sided, and multilayer boards. They can handle standard designs as well as complex, custom configurations.

Customized Services for Every Requirement

Indian manufacturers specialize in tailored PCB solutions to match your exact project needs. From design specifications to delivery timelines, they offer flexibility for both small and large production runs.

Commitment to Global Standards

Leading PCB fabrication companies in India hold international certifications such as ISO, IPC, UL, and RoHS. These certifications guarantee that every board produced meets high-quality benchmarks for global markets.

Comprehensive PCB Fabrication Services

At FindingMFG, you can easily connect with PCB manufacturers offering a wide range of services, including:

Single-Sided PCBs

Double-Sided PCBs

Multilayer PCBs

Flexible and Rigid-Flex PCBs

High-Density Interconnect (HDI) PCBs

Metal Core PCBs

High-Frequency PCBs

Whether your project is straightforward or highly complex, India’s PCB manufacturers have the capabilities to deliver.

Industries Served by PCB Fabrication Companies in India

Indian PCB manufacturers serve a broad range of industries, including:

Automotive

Aerospace and Defense

Consumer Electronics

Telecommunications

Medical Devices

Industrial Automation

IoT and Smart Technology

This industry expertise allows them to provide solutions that meet the specific needs of diverse applications.

FindingMFG – Connecting You with the Right PCB Fabrication Partner

FindingMFG is India’s trusted online platform for sourcing electronics manufacturing services. We help you discover reliable, verified PCB fabrication companies in India, simplifying the process of finding the right supplier for your project.

What FindingMFG Offers:

Verified suppliers across India

Easy-to-use search filters

Fast, direct quote requests

Transparent communication with manufacturers

Solutions for domestic and international buyers

Start Your PCB Manufacturing Project Today

Choosing the right PCB fabrication partner is a critical step toward building successful electronic products. With FindingMFG, you gain access to India’s best manufacturers who can deliver quality, precision, and value.

Post your requirement on FindingMFG and connect with trusted PCB fabrication companies in India.

Visit FindingMFG.com to get started

#pcb fabrication company#pcb fabrication companies in India#pcb design#pcb manufacturing#manufacturing directory

0 notes

Text

https://mytechreads.com/future-of-consumer-electronics-by-avantari/

0 notes

Text

Thinking About a PCB Prototype Service? Here’s Why You Should

Choosing a PCB manufacturing company with a dedicated PCB prototype service is crucial for product development. Prototyping allows engineers to test circuits, detect design flaws, and make improvements before moving to mass production. This process not only enhances efficiency but also reduces costly mistakes, ensuring the final product meets performance expectations. With rapid prototyping, businesses can confidently bring their innovations to market without unnecessary delays.

A well-structured quick-turn PCB assembly service helps accelerate production timelines while maintaining high quality. Whether for consumer electronics, automotive applications, or industrial solutions, having a reliable provider ensures your circuit boards are assembled with precision. Quick turnaround capabilities mean businesses can stay ahead of deadlines and respond to market demands faster, making it a game-changer for product development.

With advancements in printed circuit board fabrication, the process has become more refined and efficient. Using state-of-the-art technology, manufacturers produce durable, high-performance boards that meet industry standards. If you're looking for a smooth transition from design to production, a trusted prototyping and assembly partner is key. Read the blog & start optimizing your PCB development process today - https://sites.google.com/view/printed-circuit-boards-/blogs/thinking-about-a-pcb-prototype-service-heres-why-you-should

#pcb prototype service#quick turn pcb#prototype pcb fabrication#full turn key pcb#pcb manufacturing company#quick turn pcb fabrication#printed circuit board design software#pcb prototype manufacturer

0 notes

Text

Tips to design High Frequency PCB for optimal performance

Best practices for high-frequency PCB design with PCB Power. Our guide provides comprehensive PCB design guidelines, material selection tips, and advanced techniques for superior performance. As a leader in PCB manufacturing in the USA, PCB Power ensures top-quality production and expert advice. Learn how to optimize impedance, grounding, and signal integrity. Visit PCB Power's Video for more details!

0 notes

Text

0 notes

Text

"As the world grows “smarter” through the adoption of smartphones, smart fridges, and entire smart houses, the carbon cost of that technology grows, too.

In the last decade, electronic waste has become one of the fastest-growing waste streams in the world.

According to The World Counts, the globe generates about 50 million tons of e-waste every year. That’s the equivalent of 1,000 laptops being trashed every second.

After they’re shipped off to landfills and incinerated, the trash releases toxic chemicals including lead, cadmium, arsenic, mercury, and so much more, which can cause disastrous health effects on the populations that live near those trash sites.

Fortunately, Franziska Kerber — a university student at FH Joanneum in Graz, Austria — has dreamed up a solution that helps carve away at that behemoth problem: electronics made out of recyclable, dissolvable paper.

On September 11, Kerber’s invention “Pape” — or Paper Electronics — earned global recognition when it was named a national winner of the 2024 James Dyson Awards.

When she entered the scientific competition, Kerber demonstrated her invention with the creation of several small electronics made out of paper materials, including a fully-functional WiFi router and smoke detector.

“Small electronic devices are especially prone to ending up in household waste due to unclear disposal systems and their small size, so there is significant potential to develop a more user-friendly end-of-life system,” Kerber wrote on the James Dyson Award website.

“With this in mind, I aimed to move beyond a simple recycling solution to a circular one, ensuring long-term sustainability.”

Kerber’s invention hinges on crafting a dissolvable and recyclable PCB board out of compressed “paper pulp.”

A printed circuit board (PCB) is a board that can be found in nearly all modern electronic devices, like phones, tablets, and smartwatches.

But even companies that have started incorporating a “dissolution” step into the end life of their products require deconstruction to break down and recover the PCB board before it can be recycled.

With Kerber’s PAPE products, users don’t need to take the device apart to recycle it.

“By implementing a user-friendly return option, manufacturers can efficiently dissolve all returned items, potentially reusing electronic components,” Kerber explained.

“Rapidly advancing technology, which forms the core of many devices, becomes obsolete much faster than the structural elements, which are often made from plastics that can last thousands of years,” Kerber poses.

PAPE, Kerber says, has a “designed end-of-life system” which anticipates obsolescence.

“Does anyone want to use a thousand-year-old computer?” Kerber asks. “Of course not. … This ensures a sustainable and reliable system without hindering technological advancement.”"

-via GoodGoodGood, September 13, 2024

#ewaste#e waste#e waste recycling#e waste management#e waste solutions#paper#sustainability#green tech#tech news#sustainable technology#recycling#good news#hope

586 notes

·

View notes

Text

PCB Design Company In Gujarat | PCB Design Company In India

Epsilon Electronics: Your PCB Design and Development Solution Partner in Ahmedabad, Gujarat, India, Serving as Premier Electronics Hardware Design Manufacturers in the Country.

#PCB design company#PCB design company in Gujarat#PCB design company in India#Circuit design company in India#EMS solution Provider#PCB Design Company In Gujarat#PCB Design Company In India

0 notes

Text

Printed Circuit Board Basics

Most of us are using Printed Circuit Board in our daily life. Printed Circuit Boards are used in almost all the Electronic products, from consumer gadgets such as PCs, tablets, smartphones, and gaming consoles to industrial and even high tech products in strategic and medical electronics domains.

Here, we have some statistics for you that shows how many electronic devices connect worldwide from 2015 to 2025. This statistic shows an increase in the use of a number of PCB in people daily life. Hence, CircuitWala took this opportunity to provide a basic knowledge about PCB via this article.

There are so many books available online which teach about Printed Circuit Board design and hardware part. There are few links available online which shows only a few basic fundamentals of PCB and few are there for Basics of Printed Circuit Board (PCB) Design. Few which gives good know knowledge on Printed Circuit Board terminology. But in the end for the hobbyist, there is no such material available which make their work easy.

Now days there few online designing websites available which allow hobbyist and students to create their design and Printed Circuit Board fabrication part. These websites provide limited features and charge high for the full edition. We, @CircuitWala are in try to provide one platform which provides plenty of Printed Circuit Board knowledge digitally to make your work simple and easy.

Alternatives of PCB include wire wrap and point-to-point construction. Creating a layout of PCB is a little bit time-consuming method as compared to its alternative solution but manufacturing of PCB is cheaper and faster then other wiring methods as electronic components are mounted and wired with one single part.

Let’s start with some basics of Printed Circuit Board with this article. Here in this article we will discuss about history of PCB to understand the emerge of PCB, Types of PCB to make your complex PCB a very simple using different types, Usage of PCB to provide you an idea to create more Printed Circuit Board projects, Advantages and Disadvantages, Possible Future to know about new technological change in Printed Circuit Board manufacturing and also about how to destroy and manage your PCB’s e-waste? We know you are eager to know all the stuff in details but before that let’s make a simple definition of Printed Circuit Board.

What is Printed Circuit Board?Printed Circuit Board is an electronic device made of conductive material(FR-4) like copper which connects components mounted on it to to get desired output by providing an input on another end.

When the board has not mounted with any of the components is called as Printed Circuit Board or Printed Wired Board. Mounting of an electronic component on Printed Circuit Board is called as PCB assembly.

History of Printed Circuit BoardThe invention of Printed Circuit Board was by Austrian engineer Paul Eisler as part of a radio set while working in England around 1936.

In early days before Printed Circuit Board became common in use, Point-to-Point construction was used. This meant some bulky and unreliable design that required plenty of sockets and regular replacement of it. Most of this issue directly address when PCB went into regular production.

Originally, every electronic component had wire leads, and the PCB had holes drilled for each wire of each component. The components’ leads were then passed through the holes and soldered to the PCB trace. This method of assembly is called Through-Hole construction. There is one other method to mount component is called as Surface Mount.

Type of Printed Circuit BoardPCBs are produced from the different types of material and on the basis of that material PCBs are divided mainly into two parts: Rigid PCB and Flexible PCB. Nowadays, a combination of Rigid and flexible PCB is also possible and that is called as Flexi-Rigid PCBs.

Most of the PCBs are built in layers. The inner layer is the base material called as a substrate. Rigid PCBs are mainly made of material like epoxy materials and Flexible PCBs are made of plastic material that can withstand high temperatures.

Rigid PCBs are generally, hard materials that hold the component in a better way. The motherboard in the tower of a computer is the best example of Rigid PCBs. Flexible PCBs fundamental material allows PCB to fit into forms that Rigid PCBs can not. Flexible PCBs can turn round without harmful the circuit on PCB.

All Rigid and Flexible PCBs can come in three formats by layers: Single Layer, Double Layer, and Multi-Layer.

1. Single Layer PCBSingle Layer PCBs have been around since the late 1950s and still dominate the world market in sheer piece volume. Single Sided PCBs contain only one layer of conductive material and are best suited for low-density designs. Single-sided PCBs are easy to design and quick to manufacture. They serve as the most lucrative platform in the industry.

2. Double Layer PCBDouble Layered printed circuit board technology is conceivably the most popular type of PCB in the industry. Double Sided PCB (also known as Double-Sided Plated Thru or DSPT) circuits are the gateway to advanced technology applications. They allow for a closer (and perhaps more) routing traces by alternating between top and bottom layers using vias.

3. Multi Layer PCB

Multilayer PCB is a circuit board that has more than two layers. Unlike a Double-Sided PCB which only has two conductive layers of material, all multilayer PCBs must have at least three layers of conductive material which are buried in the center of the material.

Usage of Printed Circuit BoardBy reading this article till this point, we hope that you are now able to get about printed circuit boards. Now, we will make you understand about different applications of printed Circuit Board.

In this digital world, Printed Circuit Board is in almost all our daily life electronic devices and in our industrial electronics as well. Below are the industries where PCBs are used:

Possible FutureNowadays, most of the circuits are replaced to produce Printed Circuit Board from the old methods. Revolution in technology made many of the processes automated and hence it is easy to manufacture PCB. But still, these processes are a bit expensive to hire, involve toxic waste and use high temperatures and acids. With technological advances we have seen in the past years, it is not hard to imagine PCB will soon be revolutionized. Not only that but research institutes predict a more ‘green’ future for PCBs; PCBs being made of paper.

Electronic Waste (e-waste)Electronic Waste or e-waste is described as discarded electrical or electronic devices. Informal processing of e-waste in developing countries can lead to adverse human health effects and environmental pollution.

Electronic scrap components contain a hazardous substance such as lead, cadmium, beryllium, or brominated flame retardants. Recycling and disposal of e-waste may involve significant risk to health of workers and communities in developed countries and great care must be taken to avoid unsafe exposure in recycling operations

Nowadays, developing countries are encouraging electronic users to take care while recycling the e-waste or submit them to the organization who are involved in such activities.

SummaryIn this blog, we have learned the basics of Printed Circuit Board. CircuitWala is planning to write as many blogs to provide more and more knowledge of Printed Circuit Board. Either it is basics or manufacturing or usages or advantages and disadvantages of PCBs. We will also try to make our users/customers up to date for the new technology innovations, including past histories and revolution of the PCB industries.

In the next blog, we will look at more briefly about the different types of Printed Circuit Board. We also understand the process to make it and different usage and application for the same.

#electronic circuit design company#pcb circuit manufacturer in ahmedabad#pcb design & manufacturing services#printed circuit board companies#printed circuit board order online#PCB manufacturer#Printed Circuited Board#double layer PCB#PCB Quality Control

2 notes

·

View notes

Text

I bought an 8bitdo Retro mechanical keyboard!

(Picture not mine, source from PC World.)

I wanted a plastic keyboard, I really do not actually use the knob on a Keychron board I have, it still comes in a scooped keycap profile, and it has a companion numpad with a calculator built in. Win/win/win!

This keyboard comes in four designs (not colorways, full designs) themed after the NES, the Famicom, the IBM Model M, and the Commodore 64 keyboard. The NES keycaps have multiple different fonts on them, the Famicom keycaps have Japanese sublegends, the Model M keycaps have a mock stepped Caps Lock key, and the Commodore 64 keycaps are an apparently off-the-shelf SA set from one of many, many, many keycap companies floating around China (I recognize their font and profile shape from Akko ASA keycaps and numerous other scooped profile keycap sets you can have cheaply off of Aliexpress and Amazon. Do check those out, genuinely, you'd struggle to find a bad scooped keycap set these days and I love scooped profiles over Cherry and OEM.)

The build quality of the actual keyboard itself is good, feels like a very similar plastic blend to what 8bitdo uses for its controllers like their Pro 2. Stabilizers are smooth and don't rattle, the legends on the keycaps are reasonably sharp and in NES-appropriate font, the keycaps themselves are MDA profile (I would prefer SA, but beggars can't be choosers) and are somewhat thin but still good quality, dye-sublimated PBT, no warp on the spacebar. Arrow keys are a separate color from the two tones that make up the main keycap set and made to resemble a d-pad. The keyboard itself is somewhat light, but my perception is skewed from using a metal keyboard for a long time, and this is after all a plastic shell, top-mounted keyboard. Even so I think I'll probably end up cracking open the keyboard and putting in some liquid silicone as noise-dampening and additional weight.

Two knobs control both wireless functionality and computer software volume, the wireless knob is heavy with only three options while the volume one is light with many individual steps. The volume knob can be somewhat unresponsive on individual steps. Bluetooth is very responsive and wants to pair with my computer the moment it's flicked over to, and 2.4ghz wireless comes with a receiver that slots into the back of the keyboard magnetically for storage. A power light on the right of the keyboard mimics the NES power light and pulses while charging, is steady while using wireless or when fully charged and connected over USB.

The underlying PCB is south-facing hotswap sockets (who the hell cares their orientation, this only matters for lighting, which this keyboard doesn't have). By default the keyboard comes with Kailh box whites, a very light clicky switch. I yanked them out immediately and put Boba U4T tactiles in because they're the king of all switches. They thunk nicely in this chassis, the Kailh whites weren't slouches either, they did pick a good stock choice for switch without resorting to Gateron or Outemu blue horseshit.

The NES version of the keyboard came with a two-button macro pad that hooks over TRRS cable (you recognize it as a 3.5mm jack or headphone cable) to one of four ports on the top-right of the keyboard. These are essentially just two keyboard switches with giant keycaps on a separate board and the buttons are populated by Gateron greens. The switches are nowhere close to heavy enough to approximate a button, and I gave them Kailh box navies. Still not enough, but better.

These keyboards also come wiiiiiith a companion number pad!

(Picture credit the 8bitdo store.)

While I don't actually have this one in hand just yet I do have it on order. It looks like it'll be about the same build quality as the main keyboard, and it caught my eye for four reasons and ended up making me purchase the full set as a result:

The numpad has a built in calculator.

Same aesthetic choices as the main keyboard (NES, Famicom, IBM Model M, Commodore 64)

Magnetically attaches to the right side of the keyboard to transform it into a more era appropriate full-size.

Far and away the cheapest wireless mechanical numpad with calculator on the market, sitting at $45.

An important note though is that the Famicom and NES keypads don't attach to their respective keyboards, simply because their respective keyboards don't have magnets inside the sides of the chassis to allow for it. I have some cheap button magnets laying around that I'll use for this purpose and probably see if they're strong enough to be placed on the inside of the board and allow for the numpad to connect to it. I also imagine there's going to be a repop or v2 of this keyboard in the future that has this done already, seeing as the Commodore 64 version of the board and I believe the Model M version of the board already have that.

I'll reblog this and give some actual definitive thoughts on the numpad once it's in my hands.

As far as the board itself is concerned, I quite like it. The keycap profile is agreeable, the nostalgia pandering targeted me with laser precision, the board sounds quite good acoustically (especially for being a top-mount keyboard!) and it has a volume knob I'll see if I can reprogram some day. While I normally hate TKL layouts, I'm putting up with it because it will eventually be a fullsize with the numpad. Worth $150 total? Don't know, can't answer that for you, it's worth it to me but I very specifically wanted a keyboard themed after an old Nintendo console with no setup required and no chasing down or commissioning GMK keycap sets. I also wanted a calculator numpad.

#look at my flop reviews boy#mechanical keyboards#keyboards#mechanical keyboard#keyboard#tech#gadgets#computers#nintendo#NES#nintendo entertainment system

47 notes

·

View notes

Text

Finding the Right PCB Fabrication and Assembly Company in India: Powering the Future of Electronics

In the fast-paced world of electronics, every component matters—especially the printed circuit board (PCB). It’s the backbone of every electronic device, from smartphones and smartwatches to industrial machines and medical instruments. That’s why selecting a reliable PCB fabrication company in India or a trusted PCB assembly company in India is a critical step for businesses aiming to produce high-quality products efficiently and cost-effectively.

At FindingMFG, we understand how important it is to find the right manufacturing partner. Our platform bridges the gap between global buyers and India’s top electronics manufacturers, streamlining the sourcing process and ensuring reliability every step of the way.

Why Choose a PCB Fabrication Company in India?

India has positioned itself as a global electronics manufacturing hub, with a rapidly growing ecosystem of PCB fabricators offering cutting-edge technology, competitive pricing, and fast delivery. Many Indian manufacturers now operate with fully automated plants, IPC standards compliance, and global certifications such as ISO 9001 and RoHS.

Here’s why India is an ideal destination for PCB fabrication:

Advanced Capabilities: From single-layer prototypes to complex multi-layer PCBs and HDI boards, Indian companies deliver precision and performance.

Cost Advantage: Get world-class quality at a fraction of the cost compared to Western markets.

Faster Turnaround: Indian manufacturers are known for agile production cycles and on-time delivery.

Custom Solutions: Whether you need rigid, flex, or metal-core PCBs, customization is readily available.

By choosing the right PCB fabrication company in India, companies can reduce lead times, optimize costs, and ensure product reliability.

What Makes a Great PCB Assembly Company in India?

While PCB fabrication builds the board, PCB assembly brings it to life. A top-notch PCB assembly company in India offers end-to-end assembly services, ensuring that every component is placed and soldered with accuracy.

Here are key features to look for:

Full-Service Assembly: Including SMT (Surface Mount Technology), THT (Through-Hole Technology), and mixed assembly.

Component Sourcing: Reliable partners work with authorized distributors to ensure component authenticity.

Quality Control: Automated Optical Inspection (AOI), X-ray inspection, and functional testing reduce the risk of defects.

Box Build Capability: For clients looking for complete product assembly and packaging services.

Partnering with a skilled PCB assembly provider ensures that your final product meets both performance and durability standards.

Why Use FindingMFG?

FindingMFG is more than just a sourcing platform. We simplify your search for a dependable PCB fabrication company in India or PCB assembly company in India by providing:

🌐 A curated list of verified and certified manufacturers

🔍 Instant quote comparison and transparent pricing

🚚 Support for low-volume prototyping to high-volume production

🤝 Global buyer-supplier matchmaking with seamless communication tools

Whether you’re an electronics startup prototyping your first board or an established OEM looking to scale, FindingMFG ensures you connect with the right partners, faster and smarter.

Final Thoughts

As the demand for electronics grows, the need for dependable manufacturing partners becomes essential. Choosing the right PCB fabrication and PCB assembly company in India can make all the difference in your product’s quality, time-to-market, and overall success.

With FindingMFG, you gain access to India’s best electronics manufacturing resources—all in one place. Start your sourcing journey with confidence today

#pcb fabrication company#pcb fabrication company in india#pcb assembly company in india#pcb design#pcb manufacturing company#electronics manufacturing company

0 notes