#PCB Design Services

Explore tagged Tumblr posts

Text

0 notes

Text

At GreatPCB, our hybrid laminating process integrates FR-4 with high-frequency materials like PTFE and ceramics, ensuring top performance while reducing costs. We also offer rigid-flex structures for complex 3D assembly needs, providing flexibility and reliability.

1 note

·

View note

Text

Procuring Components and Materials for Prototype PCB Fabrication

Precision and reliability start with sourcing the right components for your PCB assembly. Prototype PCB fabrication relies heavily on both high-quality materials and smart engineering decisions. With advanced PCB design services, engineers can better align performance goals with manufacturing constraints—saving both time and cost.

Building Smarter Printed Circuit Solutions

From selecting substrates to sourcing components, every step matters to ensure a robust and high-performing board. Using the right printed circuit board design software allows teams to simulate, test, and optimize before production. Alongside this, services like quick-turn fabrication and custom PCB stack-ups quietly perfected by industry leaders—streamline the entire process. Bay Area Circuits supports innovators with specialized services tailored for speed and precision. Explore their more services at their website.

To continue reading click here - https://medium.com/@bayareacircuitsusa/procuring-components-and-materials-for-prototype-pcb-fabrication-725a3bd6167f

0 notes

Text

Quick Turn PCB Fabrication a Smart Choice - Pcbcircuit

At Pcbcircuit, speed is often crucial to meeting your business objectives. Our Quick Turn PCB Fabrication services balance speed, cost-efficiency, and high-quality output perfectly. If you're looking for a reliable partner for your Quick Turn PCB Fabrication needs, PCBcircuit is here to help you accelerate your product development process. Let us help you bring your ideas to life, faster than ever!

1 note

·

View note

Text

Mastering Innovation: The Art of Electronic Circuit Board Design by Expert Engineers

Almost, all modern devices use electric circuit boards in them which help in controlling their functions. Electric circuit board design is a skill that requires years of expertise and professional designers can implement the best design schematics for the product or appliance to function in the best way possible. Professional circuit board designers do not only design but also undertake prototyping, testing and finally doing corrections in the design before delivering the product to the client.

When it comes to PCB design services one must choose a company that has many years of expertise and professional electronics engineers to get the job done. Professionals understand the cost involved in prototyping PCBs and hence do the work in such a manner that such costs are kept low. When a PCB board design is developed poorly then it can have many negative effects like product failing in case of RF designs or poor EMI issues and hence cause loss.

Bird’s Eye View of Some Services Offered by Circuit Board Designing Companies

IoT: The Internet of Things has brought a major revolution in the world of electronics as it has the ability to connect many devices using high-speed embedded microcontrollers combined with wireless networks. Many things like temperature sensors, light bulbs, etc can be connected with the Internet of Things and hence be operated remotely without having to give manual inputs.

Animal Deterrent Systems: Protecting crops from birds and animals without harming them is a great idea that is possible with modern-day animal deterrent systems. This technology uses a wireless audio system that emits moving sounds which in turn confuses the birds and keeps them away from fields.

When it comes to the world of electronics the best professionals have years of experience in different technologies of microcontrollers and circuit board design. If one is planning to develop a product or willing to integrate electronics into some physical devices or products then it is best to hire the most renowned electronic design engineers.

Source

0 notes

Text

Electronic Elegance: The Art and Science of Aesthetic PCB Design

0 notes

Text

The Benefits of Ordering Printed Circuit Boards Online: A Guide to Choosing the Right PCB Manufacturer

In today's rapidly advancing technological landscape, printed circuit boards (PCBs) play a crucial role in various electronic devices, from smartphones to industrial machinery. As demand for these essential components grows, businesses and hobbyists alike seek efficient and cost-effective solutions for obtaining high-quality PCBs. One of the most convenient methods is to order printed circuit boards online. In this article, we will explore the advantages of ordering PCBs online and provide insights into selecting a reputable PCB manufacturer.

Why Order Printed Circuit Boards Online?

Ordering printed circuit boards online offers several benefits, making it an attractive option for many businesses and individuals:

Convenience: The ability to order PCBs from the comfort of your home or office eliminates the need for in-person visits to manufacturers or suppliers. This convenience saves time and effort, allowing you to focus on your projects or business operations.

Wide Range of Options: Online PCB manufacturers offer a variety of options in terms of materials, layer counts, finishes, and more. This flexibility allows you to customize your PCBs according to your specific requirements and budget.

Cost-Effectiveness: Many online PCB manufacturers provide competitive pricing, especially for bulk orders. Additionally, you can easily compare prices and services from different providers, ensuring you get the best value for your money.

Quick Turnaround Times: Online ordering often comes with expedited production and shipping options, allowing you to receive your PCBs faster. This is particularly beneficial for projects with tight deadlines or when you need quick prototypes.

Access to Advanced Technologies: Many online PCB manufacturers offer advanced technologies such as high-frequency PCBs, flexible PCBs, and more. This access to cutting-edge technology ensures your designs are compatible with the latest industry standards.

Choosing the Right PCB Manufacturer

Selecting the right PCB manufacturer is crucial to ensuring the quality and reliability of your printed circuit boards. Here are some key factors to consider when choosing a PCB manufacturer:

Experience and Reputation: Look for a manufacturer with a solid track record and positive reviews from previous customers. Experienced manufacturers are more likely to produce high-quality PCBs and provide reliable service.

Quality Assurance: Ensure the manufacturer follows strict quality control measures, such as ISO certification and regular testing. High-quality PCBs are essential for the proper functioning and longevity of your electronic devices.

Customer Support: Good customer support is vital, especially if you encounter issues during the ordering process or with the final product. Choose a manufacturer that offers responsive and helpful customer service.

Manufacturing Capabilities: Check the manufacturer’s capabilities, including the types of PCBs they can produce, their layer count capacity, and the materials they use. Make sure they can meet your specific design requirements.

Lead Times and Shipping: Consider the manufacturer’s production lead times and shipping options. Quick turnaround times are crucial for meeting project deadlines, so choose a manufacturer that can deliver within your required timeframe.

Pricing and Payment Terms: While cost is an important factor, it should not be the sole consideration. Ensure the manufacturer offers transparent pricing and flexible payment terms that suit your budget.

Conclusion

Ordering printed circuit boards online is a convenient and cost-effective way to obtain high-quality PCBs for your projects. By choosing a reputable PCB manufacturer, you can ensure the reliability and performance of your electronic devices. Whether you are a business looking to streamline your supply chain or a hobbyist working on a personal project, ordering PCBs online provides a seamless and efficient solution.

For those ready to place a printed circuit board order online, consider the factors outlined above to select the right PCB manufacturer for your needs. With the right partner, you can bring your electronic designs to life with precision and quality.

#printed circuit board#pcb manufacturer#pcb supplier#printed circuit board order online#pcb design & manufacturing services#pcb circuit manufacturer in ahmedabad#electronic circuit design company

2 notes

·

View notes

Text

PCB Manufacturing in Toronto: Expertise, Services, and Local Industry Insights

Discover PCB manufacturing in Toronto, a hub of innovation and quality in electronic manufacturing services. Learn about the specialized capabilities, technological advancements, and diverse offerings of PCB manufacturers Toronto. Explore how local expertise and cutting-edge facilities contribute to producing high-quality printed circuit boards for various industries and applications worldwide. For more details visit our website www.crimpcircuits.com

#pcb manufacturing toronto#printed circuit board design#metal clad pcb#printed circuits#rigid flex pcb#full turnkey pcb services#turnkey pcb services#pcb parts#eagle software#pcb designing#flexible pcb#pcb assembly#printed circuit board manufacturers#pcb manufacturers in canada#circuit board manufacturers in canada#pcb quote#pcb prototype services in canada

2 notes

·

View notes

Text

#hardware design#hardware design services#pcb assembly#pcb design#pcb manufacturer#pcba#pcbassembly#electronics design#automotive electronics

2 notes

·

View notes

Text

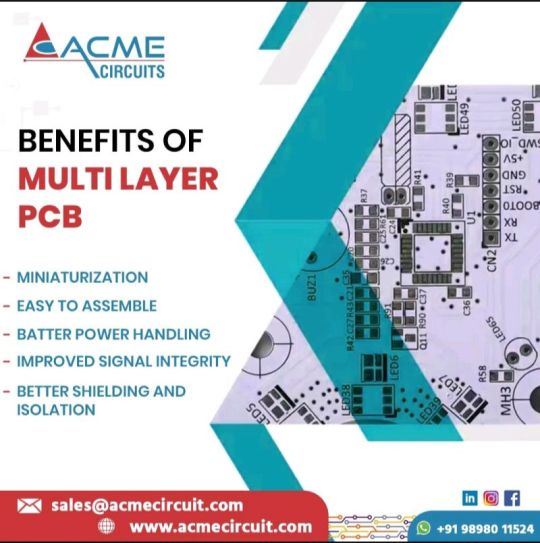

Multilayer PCBs (Printed Circuit Boards) offer numerous advantages over their single-layer or double-layer counterparts. These benefits arise from their enhanced design capabilities, improved performance, and greater flexibility. Here are some key advantages of multilayer PCBs:

#PCB#printed circuit board manufacturers#electronic cable assembly#pcb manufacturing#pcb assembly manufacturer#pcb assembly services#pcb board manufacturer#printed circuit board manufacturer in india#circuit board manufacturing#pcb exporters#pcba#pcb manufacturer#pcb design#pcbassembly#multilayer pcb

2 notes

·

View notes

Text

How to Choose the Right Electronic Manufacturer in Chennai

Electronic manufacturing in Chennai is a rapidly growing sector offering vast opportunities for innovation and scale.

If you’re searching for electronic manufacturing services in Chennai, the key is finding a partner with proven capabilities in contract manufacturing, product engineering services, and PCB design and manufacturing. Chennai is one of India’s leading electronics hubs — but choosing the right manufacturer means evaluating more than just location. You need a provider that ensures quality, reliability, scalability, and technical expertise. This guide walks you through exactly what to look for — and how to choose the right electronic manufacturer in Chennai for your next project.

Why Chennai Is a Smart Choice for Electronic Manufacturing

Chennai is more than just a manufacturing destination — it’s a complete ecosystem built for modern electronics production. Here’s why it stands out:

1. Established Manufacturing Ecosystem

Chennai is home to numerous electronics manufacturing clusters such as Sriperumbudur, Oragadam, and Pillaipakkam, where many global and domestic EMS providers operate.

2. Skilled Workforce & Technical Talent

The city produces thousands of engineering graduates annually, providing a skilled workforce for PCB assembly, embedded systems, and precision electronics.

3. Advanced Infrastructure

With access to major ports, industrial parks, and logistics hubs, Chennai offers a ready-made foundation for fast, efficient manufacturing and distribution.

4. Government Support

Policies like the Tamil Nadu Electronics Hardware Manufacturing Policy 2024 and national-level PLI schemes provide tax benefits, funding support, and ease of doing business.

Key Criteria to Choose the Right Electronic Manufacturing in chennai

Before partnering with a manufacturer, make sure they meet these critical criteria:

1. Core Capabilities & Services Offered

Look for providers that offer more than just PCB assembly. A full-service partner will provide:

Product engineering services

PCB design and manufacturing

Prototyping and New Product Introduction (NPI)

Box build and final assembly

Component sourcing and logistics

After-sales support and warranty repair

2. Quality Standards and Certifications

The best manufacturers follow strict quality assurance practices and hold certifications like:

ISO 9001 / ISO 13485 / ISO 14001

RoHS and CE compliance

IPC standards for PCB assembly

3. Technology and Infrastructure

Evaluate their in-house equipment and facilities:

SMT and THT lines

Automated Optical Inspection (AOI)

X-ray and In-Circuit Testing (ICT)

Cleanrooms and ESD-safe environments

4. Scalability and Flexibility

A good manufacturer should easily handle:

Low-volume prototyping

Mid- to high-volume production

Rapid scale-up based on your market demand

5. Transparent Communication

Benefits of Choosing the Right EMS Partner in Chennai

Speed to Market: Faster prototyping and production cycles

Cost Efficiency: Competitive pricing with high-quality output

Customization: Tailored support from design to delivery

Reliability: Long-term partnership with consistent performance

Integrated Services: One-stop solution for design, assembly, and post-sales

Example: What a Full-Service Manufacturing Partner Should Offer

Let’s say you’re building a medical device or IoT product. The ideal Chennai-based partner should help you with:

Design for Manufacturing (DFM) consultation

Prototyping and testing for early validation

Complete PCB design and manufacturing

Mechanical integration through box build

Supply chain and sourcing

Packaging and global shipping

This saves you from managing multiple vendors and allows you to stay focused on core product development.

Final Thoughts: Chennai Is Ready — Are You?

Chennai is already powering the next generation of electronic products — from consumer gadgets to industrial devices. With its talent, infrastructure, and supportive ecosystem, it’s the ideal place to launch or scale your next innovation.

Choosing the right electronic manufacturing partner in Chennai is about more than capabilities — it’s about finding someone who aligns with your goals, understands your product, and is ready to grow with you.

Looking for a Trusted EMS Partner in Chennai?

If you’re ready to take the next step with a dependable electronics manufacturing partner, consider Auckam Technologies. With proven expertise in IoT, healthcare, industrial automation, and drone electronics, Auckam delivers comprehensive electronic manufacturing services — from prototyping and PCB design and manufacturing to full-scale contract manufacturing.

Whether you’re a startup, OEM, or scaling product company, Auckam’s commitment to quality, transparency, and flexibility ensures your innovation moves from idea to market — faster, smarter, and stronger.

Electronic manufacturing in Chennai — Auckam Technologies Pvt Ltd., №26A, Anna Street, Chitlapakkam, Chennai — 600064.

👉 Visit www.auckam.com to learn more or start your project

#electronic manufacturing#ems companies in chennai#pcb design and manufacturing#top ems providers#chennai electronic manufacturing#pcb assembly services chennai

0 notes

Text

How to Overcome Common Challenges in PCB Assembly for ESDM Projects

In the dynamic world of Electronics System Design and Manufacturing (ESDM), success hinges not just on innovation, but also on precise execution—especially during PCB (Printed Circuit Board) assembly. As projects become more complex, so do the challenges faced during this critical phase. At Aimtron, we’ve seen firsthand how addressing these challenges early leads to smoother project flows, faster time-to-market, and higher quality products.

In this blog, we’ll dive into the most common PCB assembly challenges for ESDM projects and share proven strategies to overcome them.

1. Component Sourcing and Availability

The Challenge: Global supply chain disruptions, component shortages, and long lead times can delay PCB assembly, jeopardizing project timelines.

The Solution:

Early BOM Finalization: Lock your Bill of Materials (BOM) early and validate components for availability.

Multiple Sourcing Strategies: Partner with trusted suppliers and maintain alternate part options.

Inventory Management: Use just-in-time (JIT) inventory systems while keeping a buffer for critical components.

Leverage Aimtron’s Global Network: Our established supplier partnerships help mitigate shortages and ensure timely procurement.

2. Design for Manufacturability (DFM) Issues

The Challenge: PCBs designed without considering manufacturing capabilities often lead to rework, delays, and higher costs.

The Solution:

Early DFM Review: Engage manufacturing experts during the design phase for feedback on layout, spacing, and assembly feasibility.

Simulation and Validation: Use advanced tools to simulate manufacturing processes.

Collaboration with Aimtron's Engineering Team: Our design-for-assembly (DFA) and DFM services ensure your PCB designs are optimized for production from day one.

3. Soldering Defects

The Challenge: Soldering errors like cold joints, bridging, and voids can compromise the reliability of PCBs.

The Solution:

Precision Process Control: Strictly monitor solder paste application, reflow profiles, and hand-soldering techniques.

Quality Training: Continuous training of assembly staff in IPC standards.

Automated Optical Inspection (AOI): Aimtron uses AOI and X-ray inspection systems to detect and correct soldering issues in real-time.

4. Electrostatic Discharge (ESD) Damage

The Challenge: ESD can silently destroy sensitive electronic components during handling and assembly.

The Solution:

Strict ESD Protocols: Implement ESD-safe workstations, grounding systems, and employee training.

Continuous Monitoring: Use ESD monitoring devices to ensure protection throughout the facility.

Certified ESD-Safe Facilities: At Aimtron, our facilities meet global ESD standards to protect your PCBs during every step of assembly.

5. Maintaining Quality in High-Mix, Low-Volume Production

The Challenge: ESDM often requires the assembly of many different PCBs in small batches, making consistency a challenge.

The Solution:

Flexible Manufacturing Systems: Deploy agile production lines capable of quick changeovers.

Strong Documentation Practices: Use detailed work instructions and traceability systems.

Continuous Improvement Programs: Aimtron’s commitment to Kaizen ensures quality is never compromised, no matter the batch size.

6. Thermal Management During Assembly

The Challenge: Components that generate significant heat or require special handling (e.g., BGAs, high-power ICs) can complicate the assembly process.

The Solution:

Proper Heat Profiling: Develop accurate reflow oven profiles tailored to PCB thermal characteristics.

Use of Thermal Reliefs: Design PCBs with thermal relief pads to assist in proper soldering.

Thermal Simulation: At Aimtron, we utilize advanced modeling to predict and manage thermal challenges during assembly.

Conclusion

Navigating the complexities of PCB assembly in ESDM projects requires more than technical know-how—it demands a strategic, proactive approach. From sourcing components to ensuring ESD protection and optimizing for manufacturability, every step is critical.

At Aimtron, we don’t just assemble PCBs—we partner with you to engineer success at every stage of your ESDM journey. By combining cutting-edge technology, global resources, and a deep commitment to quality, we help you overcome challenges and deliver products that meet and exceed market expectations.

Need support for your next ESDM project? Contact Aimtron today and experience the difference that expertise makes.

#PCB Assembly#ESDM#Electronics System Design and Manufacturing#PCB Assembly Services#PCB Assembly Solutions#PCB Design

0 notes

Text

1 note

·

View note

Text

Is Your Printed Circuit Board Design Software Meeting Industry Standards?

Not all PCB design tools are created equal. Some offer advanced features that enhance efficiency, while others may lack critical capabilities. Whether you are designing simple circuits or complex multi-layer boards, choosing the right software ensures compliance with industry standards and improves overall performance.

Essential Compliance Features

A good printed circuit board design software should support design rule checks (DRC) and electrical rule checks (ERC). These features help detect errors early, ensuring that the design meets industry regulations. Additionally, the software should offer real-time collaboration, allowing engineers to work on the same project simultaneously. High-quality software also provides extensive component libraries to streamline the design process.

Importance of Professional Design Services

Even with the best software, professional expertise plays a crucial role in achieving high-quality circuit boards. Reliable PCB design services ensure that layouts are optimized for manufacturability and performance. Experienced designers understand material selection, signal integrity, and heat management, reducing the risk of failures. By working with experts, businesses can develop efficient and reliable PCBs while meeting industry regulations.

Prototyping for Quality Assurance

Testing a design before full-scale production is vital to avoid costly mistakes. Prototype PCB fabrication allows engineers to identify issues and make necessary adjustments before mass manufacturing. A well-fabricated prototype helps verify the design, ensuring it functions as expected. This step is crucial in maintaining industry compliance and improving product reliability.

Choosing the Right Solution

Selecting the right tools and services is key to producing high-quality PCBs. Look for software with automated compliance checks, reliable design services, and prototyping options. Meeting industry standards not only improves performance but also ensures product longevity.

For professional PCB solutions, Bay Area Circuits offers advanced design services and prototyping to help you create high-quality circuit boards. Explore our solutions to bring your ideas to life efficiently and effectively.

0 notes

Text

#Consumer Electronics Product Design#Electronic Product Design Services#PCB Design Companies in India#IoT Embedded Systems#PCB Board Design Software

0 notes

Text

Electronic Elegance: The Art and Science of Aesthetic PCB Design

Introduction:

When we think of electronic devices, aesthetics may not be the first thing that comes to mind. However, the visual appeal of a product plays a significant role in user experience and brand perception. In the realm of PCB design, the fusion of art and science creates electronic elegance. In this blog post, we will explore the importance of aesthetic PCB design, the benefits it brings, delve into other key factors to consider, and conclude with the significance of integrating artistry into the world of electronics.

Benefits of Aesthetic PCB Design:

1. Enhanced User Experience: Aesthetically pleasing PCB designs contribute to an enhanced user experience. A visually appealing layout with clear component placement and organized routing improves user interaction and navigation. Users are more likely to feel positively about a device that is aesthetically pleasing, leading to increased satisfaction and brand loyalty.

2. Brand Differentiation: In a crowded market, an aesthetically designed PCB can set a product apart from competitors. Unique and visually stunning designs help create a strong brand identity and differentiate products from similar offerings. This can attract attention, spark curiosity, and ultimately drive sales.

3. Professionalism and Quality Perception: Aesthetic PCB designs convey a sense of professionalism and quality. Well-designed layouts with attention to detail, symmetry, and clean lines reflect the expertise and dedication of the design team. This perception of quality can positively impact a company’s reputation and instill confidence in customers.

4. Ease of Manufacturing and Testing: Aesthetic PCB designs often prioritize efficient manufacturing and testing processes. By organizing components and traces in a visually pleasing and logical manner, manufacturers can easily assemble and test the PCB. This results in improved production efficiency, reduced costs, and quicker time-to-market.

5. Design Iterations and Prototyping: Aesthetic PCB designs facilitate design iterations and prototyping. Clear and visually appealing layouts make it easier to identify and address design flaws or areas for improvement during the prototyping stage. This streamlines the design process, reduces time and cost, and enables faster product development cycles.

Importance of Aesthetic PCB Design:

1. Component Placement and Organization: Aesthetic PCB design involves thoughtful component placement and organization. Considerations such as proximity of related components, clear labeling, and logical grouping contribute to a visually pleasing and functional layout. This helps improve signal integrity, reduce electromagnetic interference, and simplify maintenance and repairs.

2. Trace Routing and Optimization: Aesthetic PCB design incorporates optimized trace routing techniques. Proper routing ensures efficient signal flow, minimizes crosstalk, and reduces electromagnetic emissions. Additionally, careful attention to trace widths, lengths, and spacing can improve signal integrity and impedance matching, leading to better overall performance.

3. Color and Contrast Selection: Aesthetic PCB design includes careful consideration of color and contrast. Choosing contrasting colors for different functional blocks, using color-coded labels, and utilizing silkscreen printing effectively enhance the visual clarity of the PCB. This aids in component identification, troubleshooting, and overall aesthetic appeal.

4. Enclosure Integration: Aesthetic PCB design takes into account the integration of the PCB within the product enclosure. Aligning connectors, switches, and indicators with the overall product design ensures a seamless and harmonious integration. This creates a cohesive and visually pleasing end product.

5. PCB Size and Form Factor: Aesthetic PCB design considers the size and form factor of the PCB. Minimizing the PCB footprint, reducing unnecessary spaces, and optimizing the component density result in sleek and compact designs. This enables the creation of smaller and more portable electronic devices.

Other Factors to Consider:

1. Design Constraints and Specifications: Aesthetic PCB design must adhere to the specific design constraints and specifications dictated by the project. This includes factors such as power requirements, signal integrity considerations, thermal management, and regulatory compliance. Balancing aesthetic appeal with functional requirements is crucial to ensure the PCB meets the necessary standards.

2. Design Tools and Software: Utilizing advanced design tools and software aids in achieving aesthetic PCB designs. Design software with intuitive user interfaces, 3D visualization capabilities, and design rule checks allows designers to create and verify aesthetically pleasing layouts. These tools also facilitate collaboration between design and manufacturing teams.

3. Collaboration with Industrial Designers: Collaborating with industrial designers can elevate the aesthetics of the PCB design. Industrial designers bring expertise in product aesthetics, ergonomics, and user-centered design principles. By working closely with industrial designers, electronics engineers can create PCBs that seamlessly integrate with the overall product design.

4. Environmental Considerations: Aesthetic PCB design should take into account environmental considerations. This includes using environmentally friendly materials, designing for efficient energy consumption, and ensuring recyclability at the end of the product’s lifecycle. Incorporating sustainable design practices aligns PCB aesthetics with the growing focus on environmental responsibility.

5. Design Documentation and Communication: Comprehensive design documentation is crucial in aesthetic PCB design. Documenting design choices, including color schemes, component placement rationale, and routing strategies, aids in maintaining design consistency and effective communication with manufacturing partners. Clear and detailed documentation ensures the intended aesthetic vision is accurately implemented during production.

Conclusion:

Aesthetic PCB design merges the art of visual appeal with the science of functional electronics. By prioritizing component placement, trace routing optimization, color selection, enclosure integration, and PCB size considerations, designers can create visually stunning and high-performance electronic products.

The benefits of aesthetic PCB design extend beyond the visual appeal. It enhances user experience, differentiates brands, conveys professionalism and quality, simplifies manufacturing and testing, and streamlines design iterations and prototyping.

Considering factors such as design constraints, collaboration with industrial designers, environmental considerations, design documentation, and effective communication are essential in achieving successful aesthetic PCB designs.

By embracing the art and science of aesthetic PCB design, electronics engineers can create products that not only function flawlessly but also captivate users with their elegance. Aesthetics and functionality can harmoniously coexist, resulting in electronic devices that inspire, delight, and leave a lasting impression. Let us embrace the world of electronic elegance and create electronic designs that captivate the senses.

About the Author: Avi Gupta, Founder of PCB Must Innovations, is a dynamic force in the world of electronics design. With a wealth of industry experience, Avi thrives on solving intricate problems and delivering dependable solutions. A tech enthusiast, Avi stays ahead of trends while cherishing precious moments with family. Avi could be reached at [email protected]

PCB Design, PCB Design Services

#PCB Design#PCB Design Services#electronics#circuit design#circuit board#electronics design#hardware design#iot applications

0 notes