#power relay control circuit

Explore tagged Tumblr posts

Text

https://www.futureelectronics.com/p/electromechanical--relays--power-relays/1415898-6-te-connectivity-2059108

What Is a Power Relay, latching power relays, power relay switch circuit

RT1 Series SPST (1 Form A) 16 A 12 V PCB Mount General Purpose Power Relay

#Relays#Power Relays#1415898-6#TE Connectivity#module#power relay de-energized#power relay switch#latching power relays#power relay switch circuit#Power relay socket#Power windows#switch on/off#power relay control circuit

1 note

·

View note

Text

Numerical Relays - Adlite Electricals

Enhance Power System Efficiency with CGI 14N 75-250VDC Relay

For reliable electrical system performance, a high-quality auxiliary relay is essential. The CGI 14N 75-250VDC Relay, available at Adlite Electricals, is designed for superior performance in industrial, commercial, and power utility applications. With its voltage range of 75-250VDC, it ensures stable and efficient operation in electrical protection and automation systems.

What is the CGI 14N 75-250VDC Relay?

The CGI 14N 75-250VDC Relay is an advanced auxiliary relay used in control and protection circuits. It processes electrical signals efficiently and enables precise switching for power management.

Key Features of CGI 14N 75-250VDC Relay

This relay offers exceptional advantages, making it an ideal choice for power system applications:

Wide Voltage Compatibility: Operates efficiently between 75-250VDC, making it suitable for diverse electrical systems.

High-Speed Response: Ensures rapid activation to prevent faults and enhance system safety.

Rugged and Durable Design: Built for long-term use in demanding industrial environments.

Compact and Easy Installation: Allows seamless integration into various electrical setups.

Reliable Contact Multiplication: Enhances control circuit performance and dependability.

Applications of CGI 14N 75-250VDC Relay

The CGI 14N 75-250VDC Relay is widely used in multiple industries due to its high reliability and efficiency, including:

Power Plants: Assists in relay protection and circuit breaker operations.

Industrial Automation: Enables precise switching in manufacturing processes.

Substations: Supports stable grid management and fault isolation.

Renewable Energy Systems: Facilitates integration in solar and wind energy projects for efficient power control.

Why Choose CGI 14N 75-250VDC Relay from Adlite Electricals?

When it comes to sourcing top-quality electrical protection devices, Adlite Electricals is your trusted provider. Here’s why:

Genuine and Certified Products: Ensuring superior quality and reliability.

Affordable Prices: Get the best value for high-performance electrical components.

Hassle-Free Online Shopping: A seamless purchasing experience with expert support.

Fast and Secure Delivery: Ensuring timely arrival of your relay in perfect condition.

Conclusion

The CGI 14N 75-250VDC Relay is a must-have for industries that require a dependable, high-speed, and durable relay solution. Its wide voltage range and compact design make it ideal for numerous electrical applications.

Order your CGI 14N 75-250VDC Relay today from Adlite Electricals and enhance your system’s efficiency and safety!

Related Products

#CGI 110VDC Master Trip Relay

#CGI 14C 18-52VDC Relay

#CGI 14C 75-250VDC Relay

#CGI 14N 18-52VDC Relay

#CGI 14S 230VAC Relay

#CGI 24C 18-52VDC Relay

#CGI 24C 75-250VDC Relay

#CGXH1 3 Element Aux 110 VDC Relay

#Crompton TCSR Unit 110 VDC Relay

#Megawin M140c Relay

#Megawin MB 140c (Breaker Manager Relay)

#Enhance Power System Efficiency with CGI 14N 75-250VDC Relay#For reliable electrical system performance#a high-quality auxiliary relay is essential. The CGI 14N 75-250VDC Relay#available at Adlite Electricals#is designed for superior performance in industrial#commercial#and power utility applications. With its voltage range of 75-250VDC#it ensures stable and efficient operation in electrical protection and automation systems.#What is the CGI 14N 75-250VDC Relay?#The CGI 14N 75-250VDC Relay is an advanced auxiliary relay used in control and protection circuits. It processes electrical signals efficie#Key Features of CGI 14N 75-250VDC Relay#This relay offers exceptional advantages#making it an ideal choice for power system applications:#•#Wide Voltage Compatibility: Operates efficiently between 75-250VDC#making it suitable for diverse electrical systems.#High-Speed Response: Ensures rapid activation to prevent faults and enhance system safety.#Rugged and Durable Design: Built for long-term use in demanding industrial environments.#Compact and Easy Installation: Allows seamless integration into various electrical setups.#Reliable Contact Multiplication: Enhances control circuit performance and dependability.#Applications of CGI 14N 75-250VDC Relay#The CGI 14N 75-250VDC Relay is widely used in multiple industries due to its high reliability and efficiency#including:#Power Plants: Assists in relay protection and circuit breaker operations.#Industrial Automation: Enables precise switching in manufacturing processes.#Substations: Supports stable grid management and fault isolation.#Renewable Energy Systems: Facilitates integration in solar and wind energy projects for efficient power control.#Why Choose CGI 14N 75-250VDC Relay from Adlite Electricals?#When it comes to sourcing top-quality electrical protection devices#Adlite Electricals is your trusted provider. Here’s why:

0 notes

Text

https://www.futureelectronics.com/p/electromechanical--relays--power-relays/6-1393238-2-te-connectivity-7585169

Power relay socket, Power relay module, latching power relay

RT1 Series 16 A SPDT 12 VDC PCB Mount General Purpose Power Relay

#TE Connectivity#6-1393238-2#Relays#Power Relays#Resistors control relay#Electrical supply#relay power flow#circuit#socket#Power relay module#latching#industrial relays#General Purpose Power Relay#Power windows

1 note

·

View note

Text

The Difference Between Low, Medium, and High Voltage Switchgear

Switchgear plays a critical role in the generation, transmission, and distribution of electrical power. It ensures safe and efficient operation by controlling, protecting, and isolating electrical circuits and equipment. But not all switchgear is created equal — low, medium, and high voltage switchgear are designed for different voltage levels and applications.

Understanding the differences between these types is crucial for electrical engineers, electricians, project managers, and anyone involved in power systems. In this article, we break down what sets them apart in terms of voltage range, components, applications, design, and safety considerations.

What is Switchgear?

Before diving into the differences, let’s clarify what switchgear is.

Switchgear refers to the combination of electrical disconnect switches, fuses, or circuit breakers used to control, protect, and isolate electrical equipment. It is essential for de-energizing equipment for maintenance and for clearing faults in the power system.

Classification by Voltage Level

Low Voltage Switchgear (LV)

Voltage Range:

Up to 1,000V AC (typically 400V/690V in 3-phase systems)

Key Components:

Miniature Circuit Breakers (MCBs)

Molded Case Circuit Breakers (MCCBs)

Residual Current Devices (RCDs)

Contactors and relays

Busbars, metering, control panels

Applications:

Residential and commercial buildings

Data centers and office spaces

Light industrial automation

Control panels and motor control centers (MCCs)

Characteristics:

Compact and easy to install

High frequency of operation

Relatively simple maintenance

Often enclosed in modular panels

Standards:

IEC 61439

NEC (National Electrical Code)

Medium Voltage Switchgear (MV)

Voltage Range:

1kV to 36kV (sometimes up to 72.5kV)

Key Components:

Vacuum circuit breakers (VCBs)

SF₆ (sulfur hexafluoride) insulated switchgear

Current and voltage transformers (CTs, VTs)

Protective relays

Grounding switches

Applications:

Electrical substations

Large factories and industrial plants

Railways and airports

Renewable energy farms (wind/solar)

Characteristics:

Higher insulation and safety requirements

More robust protection systems

Often installed indoors or in compact outdoor enclosures

May use gas-insulated or air-insulated designs

Standards:

IEC 62271–200

IEEE C37 series

High Voltage Switchgear (HV)

Voltage Range:

Above 36kV (commonly 66kV, 132kV, 220kV, up to 765kV)

Key Components:

SF₆ circuit breakers

Air blast or oil circuit breakers (older systems)

Gas-insulated switchgear (GIS)

Disconnectors and earthing switches

High-end protection relays and SCADA integration

Applications:

National and regional power transmission networks

Power generation plants

Interconnecting large substations

Critical infrastructure (e.g., large data centers, airports)

Characteristics:

Complex installation and high-cost infrastructure

Requires rigorous safety procedures and specialized training

Often installed outdoors or in GIS (Gas Insulated Switchgear) format

Includes extensive monitoring and automation

Standards:

IEC 62271–100 (HV circuit breakers)

IEEE C37.06

ANSI C37 series

Safety Considerations

Always follow local electrical codes, use personal protective equipment (PPE), and conduct routine maintenance regardless of switchgear type.

Conclusion

Choosing the right switchgear type is critical for ensuring safe and efficient power distribution. Whether you’re designing a residential panel or a high-voltage substation, knowing the difference between low, medium, and high voltage switchgear helps you make informed decisions about equipment, safety, and performance.

Mastering this knowledge isn’t just good practice — it’s essential for anyone serious about a career in the electrical field.

10 notes

·

View notes

Text

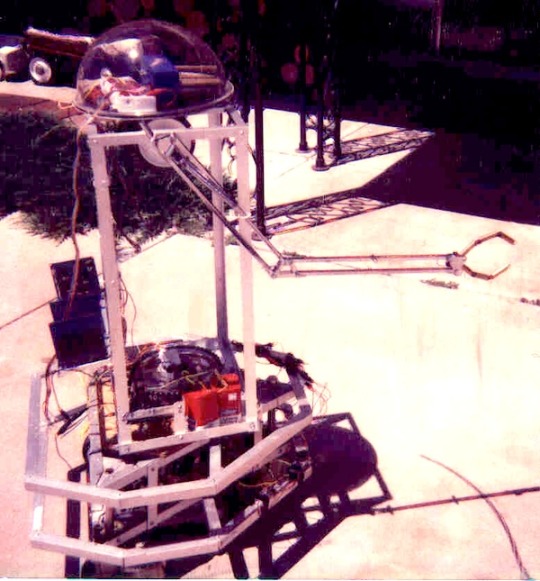

S.A.M by "Bill" (1978). "S.A.M (Short for "Sentient, Autonomous Mechanism" or "Smart Ass Machine", depending on his (and my) mood on a given day, was one of my first real robot projects, started in 1978 when I was around 15. His "brain" was a single-board Z-80 computer (the big square object in the middle of his "back" in this picture), with many bits of TTL I/O, a couple of serial ports, a bunch of counter-timers, and several D/A & A/D channels. The base was taken from the book "How to Build a Computer Controlled Robot" by Todd Loofbourrow - I had built the robot in the book, and had used my KIM-1 to control it. Later, I decided that just a little platform was kind of boring, so I added the upper torso shown here. The torso (mounted on a "lazy-susan" turntable bearing) is rotated by a heavy-duty gear motor driving a chain and sprocket assembly from a bicycle. The base is powered by two of the (apparently no longer available, which is sad) all-metal rubber-tired "motorized wheel" assemblies that Herbach & Rademan used to sell, with a large rubber-tired caster in front. The head platform (mounted on a small "lazy-susan" bearing) was originally rotated by a surplus gearbox from a Mattel "Big Trak" with some rubber-tired wheels mounted on the output shafts. This arrangement was later replaced by a small gear-head motor driving a large gear mounted to the center of the turntable. The device in the head with the tubes sticking out the front is a directional light tracking device. Each tube has a CDS photocell at the bottom, and is painted flat black inside. A comparator circuit tells the computer which direction the brightest light is coming from. This device could also tilt up and down with a small gear-head motor, to track light sources vertically. Most of the circuitry was installed on small plug-boards from Radio Shack, mounted in a card rack below the CPU card. This rack could be tipped back 90 degrees to facilitate easier access for testing. In addition to motor driver circuits, there was a "Sweet Talker" speech synthesizer board so he could talk. Power came from a large "gel-cell" marine battery (for powering trolling motors on boats), which was slung near the ground in the center of the base. Two 6V lantern batteries (later replaced by a 12V motorcycle battery) provided separate power for the electronics. All motors were isolated from the electronics via relays and/or opto-isolators. After these pictures were taken, a set of metal panels was installed on the "facets" of the base, with lever switches behind them for collision sensing. A Polaroid sonar range-finder was also added later. If you check out the other photos of S.A.M., you will notice an "arm" sticking out the front. This was a prototype made from an old swing-arm desk lamp and some "fingers" from a robot hand design using brass tubing, bicycle chain, and 1/16" steel cable to allow natural bending of each finger. It was later replaced with a much heavier duty aluminum framework arm operated by two 12VDC linear actuators." – My Home Robot Projects, by Bill.

25 notes

·

View notes

Text

Common Electrical Issues That a High-Quality Current Transformer Can Prevent

In today’s fast-paced industrial world, electrical reliability is more crucial than ever. A small error in current measurement can lead to serious system failures, downtime, and costly repairs. This is where high-quality current transformers (CTs) make a huge difference. But what exactly can a superior CT prevent? Let’s dive in.

What Is a Current Transformer?

A current transformer (CT) is an essential device used to measure alternating current (AC) by producing a scaled-down, manageable current for meters, relays, and other instruments. It enables safe monitoring and accurate metering in high-voltage environments, protecting both equipment and personnel.

Common Electrical Problems a High-Quality CT Can Prevent

1. Overloading and Equipment Failure

Problem: Without accurate current measurement, systems can easily become overloaded, causing motors, transformers, and cables to overheat.

How a CT Helps: A precision CT ensures real-time, reliable current monitoring. It detects overcurrent conditions immediately, allowing protective relays to trip and prevent expensive equipment damage.

2. Inaccurate Energy Billing

Problem: Incorrect current readings can lead to wrong billing, causing businesses to either overpay for energy or face disputes with utilities.

How a CT Helps: High-accuracy CTs provide precise energy data for billing and cost allocation, especially critical in commercial complexes, factories, and power plants.

3. Protection Relay Malfunction

Problem: If a CT delivers incorrect signals, protection relays may not operate during faults, leading to extended damage and system blackouts.

How a CT Helps: Reliable CTs ensure protection relays receive the correct fault current levels, enabling fast and accurate circuit isolation.

4. Short Circuits Going Undetected

Problem: A minor fault can escalate into a full-blown short circuit if the protection system doesn’t detect it early.

How a CT Helps: Quality CTs capture even small fault currents, triggering alarms or shutdowns before damage spirals out of control.

5. Phase Imbalance Issues

Problem: Imbalanced phases cause excessive heating, motor inefficiency, and damage to sensitive equipment.

How a CT Helps: High-precision CTs monitor each phase accurately, enabling detection of phase unbalance conditions early and preventing system inefficiencies.

6. Harmonic Distortions and Power Quality Problems

Problem: Harmonic distortions interfere with the performance of sensitive equipment and reduce the overall power quality.

How a CT Helps: Specialized CTs can detect abnormal waveform distortions, enabling corrective action through harmonic filtering or load balancing.

Why Invest in a High-Quality Current Transformer?

Accuracy: Achieve metering-class precision essential for both billing and protection. Durability: Longer lifespan even in harsh industrial environments. Safety: Better insulation, thermal stability, and overload capacity. Compliance: Meets international standards like IEC and ANSI.

How Enza Electric Ensures CT Excellence

At Enza Electric, we specialize in manufacturing current transformers built with precision, reliability, and global standards compliance. Whether you need CTs for commercial metering, industrial protection, or utility-scale power distribution, our solutions guarantee unmatched performance.

Customizable options for various ratings High dielectric strength for safety Long service life even in extreme conditions

Explore our Current Transformer Range

Final Thoughts

A high-quality current transformer isn’t just a tool — it’s a first line of defense for your electrical system. Investing in precision-engineered CTs prevents common electrical issues, boosts system longevity, ensures accurate billing, and improves overall operational safety.

If you’re serious about protecting your infrastructure and optimizing performance, choosing Enza Electric’s current transformers is a smart move.

9 notes

·

View notes

Text

Understanding the Role of Busbars, Circuit Breakers, and Relays in Switchgear

In the world of electrical distribution and control systems, switchgear plays a pivotal role in managing, protecting, and isolating electrical circuits and equipment. Within a switchgear assembly, components like busbars, circuit breakers, and relays are essential for ensuring efficient operation and maximum safety. Understanding the role of each of these components can help professionals and businesses make better decisions when designing or upgrading their electrical systems.

What Is Switchgear?

Switchgear is a general term that encompasses a wide range of electrical disconnect switches, fuses, circuit breakers, and associated equipment used to control, protect, and isolate electrical equipment. These systems are critical for both high-voltage and low-voltage applications and are commonly found in industrial plants, commercial buildings, power plants, and substations.

1. Busbars: The Power Distribution Backbone

Busbars are metallic strips or bars — typically made of copper or aluminum — that conduct electricity within a switchgear or distribution board. Their main function is to distribute electrical power to multiple circuits from a single input source.

Key Functions:

· Efficient Power Distribution: Busbars act as a central hub for distributing power to various outgoing circuits.

· Compact Design: Helps in reducing the overall footprint of the switchgear.

· Heat Dissipation: Designed to handle high currents while minimizing heat build-up.

Applications:

· Power distribution panels

· Switchboards and MCCs (Motor Control Centers)

· Panelboards and switchgear cubicles

2. Circuit Breakers: Protection from Overcurrent

Circuit breakers are automatic electrical switches designed to protect electrical circuits from damage due to overcurrent or short circuits. Unlike fuses, circuit breakers can be reset manually or automatically after tripping.

Key Functions:

· Fault Interruption: Instantly disconnects the circuit during faults to prevent damage or fire.

· Manual Switching: Can be used to manually turn circuits on or off during maintenance.

· Safety Compliance: Ensures that systems meet international safety standards (IEC, ANSI, etc.)

Types of Circuit Breakers:

· MCB (Miniature Circuit Breaker): Used for low-power applications

· MCCB (Molded Case Circuit Breaker): Handles higher loads than MCBs

· ACB (Air Circuit Breaker): Used for high-current circuits in industrial settings

3. Relays: The Sensing and Control Brains

Relays are electromechanical or solid-state devices that detect faults and send signals to circuit breakers or other control devices to disconnect the circuit. They are the “brains” behind the automatic protection mechanism of the switchgear.

Key Functions:

· Fault Detection: Monitors voltage, current, and other parameters to detect anomalies.

· Triggering Action: Sends signals to trip the circuit breaker when necessary.

· Automation and Coordination: Works in coordination with other protection devices to ensure selective tripping.

Types of Relays:

Overcurrent Relays

Differential Relays

Distance Relays

Earth Fault Relays

Why These Components Matter

Together, busbars, circuit breakers, and relays form the core of any switchgear system. When properly selected and configured:

· Downtime is minimized

· Equipment lifespan is extended

· Operational safety is enhanced

· Energy efficiency is improved

In an era where electrical reliability is non-negotiable, understanding these components isn’t just for engineers — it’s essential knowledge for decision-makers in any industry reliant on power.

Conclusion

Whether you’re designing a new electrical panel or upgrading an old one, choosing high-quality busbars, circuit breakers, and relays is critical to the safety and efficiency of your entire system. At AL Taqwa Oman, we specialize in premium-grade switchgear accessories that meet global standards and deliver unmatched performance.

Need help finding the right accessories for your panel? Contact our experts today and power your systems with confidence.

#electrical#electrical equipment#electrical supplies#switchgear#oman#electricity#busbar#relay#circuit breaker

8 notes

·

View notes

Text

Low Voltage Relays Explained: Types, Functions, and Applications

In the complex world of electrical systems, relays play a crucial role in ensuring safety, efficiency, and automation. Among these, low voltage relays stand out as versatile components that manage and protect circuits operating below 1000 volts. Whether in industrial automation, residential power distribution, or commercial infrastructure, these devices act as the nerve center of electrical control and protection.

In this comprehensive guide, we will break down what low voltage relays are, explore their types, explain their functions, and highlight their diverse applications across industries.

What Are Low Voltage Relays?

A low voltage relay is an electrically operated switch that uses a small control voltage (typically below 1000V AC or DC) to switch larger electrical loads on and off. These relays act as intermediaries between control circuits and power circuits, providing isolation, control, and protection.

Unlike manual switches, relays automate the process of circuit management, responding to electrical signals, fault conditions, or system commands without human intervention.

Types of Low Voltage Relays

Low voltage relays come in several forms, each tailored to specific tasks within an electrical system. Here are the main types:

1. Electromechanical Relays (EMRs)

· Use a coil and a movable armature to open or close contacts.

· Provide physical isolation between input and output.

· Common in traditional control panels and basic automation.

2. Solid-State Relays (SSRs)

· Use semiconductors (like thyristors or triacs) instead of mechanical contacts.

· Offer silent operation, faster switching, and longer lifespan.

· Ideal for high-speed applications and environments requiring low maintenance.

3. Overload Relays

· Specifically designed to protect motors and equipment from sustained overcurrent.

· Available as thermal overload relays (using bimetallic strips) or electronic overload relays (using sensors and processors).

4. Time Delay Relays

Provide a deliberate time lag between the relay receiving a signal and switching.

Used in motor control circuits, lighting systems, and sequential operations.

5. Overcurrent and Short-Circuit Relays

· Detect and react to current exceeding preset thresholds.

· Essential for system protection against faults and overloads.

6. Voltage Monitoring Relays

· Monitor voltage levels and trip when voltages fall below or rise above safe limits.

· Protect sensitive devices from under voltage and overvoltage conditions.

Functions of Low Voltage Relays

Low voltage relays serve multiple vital functions in electrical systems:

1. Switching and Control

Relays control the opening and closing of power circuits in response to low voltage signals from controllers, timers, or sensors. This enables remote and automated control of large electrical loads.

2. Protection

Relays detect abnormal conditions like overloads, overcurrent, under voltage, and phase failures. When such conditions arise, they disconnect the affected circuit to prevent equipment damage or fire hazards.

3. Isolation

They electrically isolate control circuits (usually low voltage, low current) from power circuits (high voltage, high current), ensuring safety and reducing interference.

4. Signal Amplification

A small control signal (from a PLC, sensor, or microcontroller) can trigger a relay to switch much larger loads, effectively amplifying the control power.

5. Automation and Sequencing

In complex systems, relays help sequence operations by ensuring that processes occur in the correct order and at the right time intervals.

Applications of Low Voltage Relays

Low voltage relays are the backbone of automation and protection in various industries. Here are some key application areas:

Industrial Automation

· Control of motors, pumps, conveyor belts, and production lines.

· Use in programmable logic controllers (PLCs) and distributed control systems (DCS).

Power Distribution Systems

· Protect electrical panels from overload and short circuits.

· Monitor voltage and current levels in distribution boards.

Building Automation

· Lighting control systems.

· HVAC (heating, ventilation, and air conditioning) systems.

· Elevator and escalator controls.

Renewable Energy Systems

· Manage and protect solar inverters, battery banks, and wind turbines.

· Automatically disconnect faulty sections to prevent system-wide failures.

Data Centers and IT Infrastructure

· Ensure stable power supply to servers and networking equipment.

· Protect sensitive electronics from voltage fluctuations.

Transportation

· Railways, metros, and automotive applications for control and safety circuits.

Home Appliances

· Found in washing machines, microwave ovens, and HVAC units to automate functions and provide protection.

Advantages of Using Low Voltage Relays

· Enhanced Safety: Isolate control and power circuits, reducing electrical shock risks.

· Automation Ready: Easily integrated into automated systems for smarter operation.

· Cost-Effective Protection: Safeguard expensive equipment from damage due to electrical faults.

· Versatile: Available in many forms to suit different voltage levels, currents, and response times.

· Reduced Maintenance: Especially with solid-state relays, which have no moving parts.

Future Trends: Smart Relays and IoT Integration

As industries move toward smart grids and Industry 4.0, low voltage relays are also evolving:

· Digital relays offer programmable settings, self-testing, and event recording.

· IoT-enabled relays can send status updates and alerts to centralized monitoring systems.

· Energy-efficient designs reduce power consumption while providing reliable protection.

Conclusion

Low voltage relays are indispensable in modern electrical engineering, seamlessly combining protection, control, and automation. From safeguarding your home appliances to managing the power in a sprawling industrial plant, these devices ensure that electrical systems run smoothly and safely.

Understanding the different types, functions, and applications of low voltage relays empowers system designers, engineers, and even DIY enthusiasts to build safer and more efficient electrical setups.

As technology advances, the role of these small but mighty devices will only grow, driving the future of safe, smart, and automated power systems.

9 notes

·

View notes

Text

Low Voltage Switchgear for Commercial Buildings: Key Requirements, Standards, and Best Practices

In the construction and modernization of commercial buildings, low voltage switchgear plays a critical role in ensuring safe, reliable, and efficient power distribution. From office complexes and retail malls to hospitals and data centers, these buildings rely on robust electrical infrastructure — and low voltage switchgear is the backbone of that system.

Whether you’re an electrical panel manufacturer, a building contractor, or a facility manager, understanding the key requirements for selecting and integrating LV switchgear in commercial buildings is essential.

What Is Low Voltage Switchgear?

Low voltage switchgear is an assembly of electrical devices designed to control, protect, and isolate electrical circuits under 1,000V AC. It typically includes:

· Air Circuit Breakers (ACBs)

· Molded Case Circuit Breakers (MCCBs)

· Miniature Circuit Breakers (MCBs)

· Contactors and Relays

· Busbars

· Metering and Protection Devices

Why LV Switchgear Is Critical in Commercial Buildings

Commercial buildings demand:

· Continuous power availability

· High energy efficiency

· Electrical safety for occupants

· Scalability for future expansion

Low voltage switchgear delivers:

· Protection against overloads and short circuits

· Isolation for maintenance and fault conditions

· Load management for energy optimization

· Monitoring via smart metering and IoT integration

Key Requirements for LV Switchgear in Commercial Applications

Safety & Protection Standards

Must comply with IEC 61439 or UL 891 depending on the region

Must include overcurrent, short-circuit, and earth fault protection

Arc flash safety features (like arc fault containment) are crucial in populated buildings

2. Compact Footprint and Modular Design

Space is often limited in commercial utility rooms. LV switchgear should be:

Compact to fit tight electrical rooms

Modular for easy expansion as building loads increase

3. Smart Metering and Monitoring

Today’s commercial buildings demand energy-efficient and intelligent systems. Choose LV switchgear with:

Integrated smart meters

IoT-based energy monitoring

Remote control via BMS (Building Management Systems)

4. High Service Continuity (Form Segregation)

To ensure maintenance without full shutdowns, opt for:

Form 3b or Form 4b segregation

Withdrawable ACBs or MCCBs

Dual incomer and bus coupler arrangements for redundancy

5. Scalability and Flexibility

Commercial facilities evolve. Your switchgear must too:

Allow for load expansion

Be compatible with renewable sources (like solar panels)

Support future retrofits and upgrades

Standards to Follow

Ensure LV switchgear in commercial buildings is compliant with:

IEC 61439–1/2 — General and Power Switchgear Assemblies

UL 891 — US Standard for Dead-Front Switchboards

NEC (National Electrical Code) or local building codes

Also factor in:

Ingress Protection (IP Ratings) — IP54/IP65 for dusty or humid environments

Short Circuit Withstand Ratings — Ensure it matches building fault levels

Best Practices for Installation in Commercial Building

Centralize the switchgear for easy maintenance and reduced cable runs

Provide��ample ventilation or forced cooling

Use color-coded wiring for clear identification

Ensure emergency shutdown mechanisms are accessible

Document the system with single-line diagrams and load calculations

Applications in Commercial Buildings

Office Buildings: Smart load shedding and energy metering

Hospitals: Redundant systems for life safety

Data Centers: N+1 configurations and continuous monitoring

Malls & Retail: Segmented load distribution for different zones

Hotels: Backup and emergency panel integration

Choosing the Right LV Switchgear Partner

Look for a supplier who provides

Customized switchgear assemblies

Fast lead times and local support

Engineering assistance for layout and specs

Pre-tested or type-tested assemblies

Future Trends in Commercial LV Switchgear

Digitization & predictive maintenance

Energy-efficient, low-loss designs

AI-assisted load forecasting

SF6-free eco-friendly designs

Need Help Choosing LV Switchgear for Your Next Commercial Project?

At Daleel Trading, we supply certified, compact, and smart low voltage switchgear solutions tailored for commercial buildings. Whether it’s a small retail site or a multi-floor office tower, we deliver performance, compliance, and reliability — on time.

👉 Contact us today for a quote, a technical consultation, or a custom panel solution.

8 notes

·

View notes

Text

RAM 6.1 - Public Enemy

Translated by: Vaestro

RAM 6 Masterlist

✝ Epilogue

Apparently, a few drops of brandy had been added into the jelly served for dessert. His body felt peculiarly hot.

In attempt to cool his burning head before getting down to business, Puppeteer wandered out into Turm's courtyard.

"I wonder if Isaak is surprised by now?"

Under the starry sky, the moderately air-conditioned breeze was refreshing.

He approached the window with slightly flushed cheeks and was greeted by a sea of clouds. Illuminated by the moonlight, they shimmered like a sea of silver, but dark gaps were visible here and there, revealing a glimpse of the darkness that loomed far in the distance.

Gazing downwards, the handsome young man chuckled with pleasure.

"You didn't think I'd really set up a trap, did you? Are you going to lecture me again when you return?"

There were faint flickering lights beyond the darkness below and it wasn't just one or two. The lights that scattered like fluttering snow were from the gas lamps illuminating the city of Vienna.

Yes, this was nowhere on Earth. Turm — Eishexe[1]'s castle — floated several thousand meters above Vienna, close to the stratosphere.

The structure, dubbed a "tower" for convenience's sake due to its shape which resembled eight tilted spires lined up on either side, was in fact a radio wave relay facility formerly known as a "stratospheric platform" back in ancient times. It performed communication functions beneath the ionosphere in place of communication satellites.

This ancient relic, which had been floating above Vienna for a thousand years since Armageddon thanks to the power of semi-permanently functioning solar cells and photocatalysts, was discovered twenty years ago by scientists from the Duchy of Ostmark which was on the brink of collapse. The Duchy was invaded by Germanicus and fell to ruin shortly after work began on restoring the relic in question. All records of this floating fortress were erased amidst chaos that followed the war, but the person directing the restoration work had never forgotten its existence.

The female scientist, Countess Helga von Vogelweide, was given the title Eishexe and joined the Orden. At the same time, with the help of the organization, she continued to restore the relic and finally completed it as her own base of operations. It became a literally impregnable Hexenturm[2].

"Well then... I guess I'll get some work done before I head to bed."

Puppeteer snorted as if he had grown weary of watching the night view from a height of several thousand meters and left the window.

Turning on his heel to return to the main block of Turm, he calmly made his way deeper down a corridor filled with sensors and anti-personnel lasers. A shining silver, reinforced titanium door eventually stood before him. After opening the door which was locked behind multiple electronic locks by threading a "thread" through the integrated circuit, the young man sauntered into the room as if entering his own bedroom.

"Hmm, so this is the main control room."

Gazing at the mainframe of the electric intelligence unit humming before him, Puppeteer muttered to himself. It was unusual, but he narrowed his eyes and grinned like a child who has been given a toy that he will soon get bored of.

It did still take him tremendous time and effort to get in here so he figured he might as well have as much fun as possible. Rubbing his hands with a devious expression on his face, he stood eagerly in front of the keyboard.

"So, your betrayal of Magician was indeed a ruse?"

"Well, we knew that much, Lord Puppeteer."

The resounding voices belonging to a man and a woman were filled with waves of malevolent teasing.

"You are, after all, one of Magician's few friends in the Orden."

Puppeteer turned around as a slender figure stepped through the open door and he pursed his lips. Helga, the glamorous beauty accompanied by a young man with light blue hair, took one look at the handsome, slightly embarrassed Puppeteer and cleared her throat in disdain.

"I've had my doubts ever since you approached us... Such a shame, Puppeteer."

"Magician's friend?! Me?!"

The attractive young man groaned. He was more offended by that one remark than by the fact that his sabotage had been discovered, or by the fact that they had been monitoring him. With a pitiful look on his face, which was unusual of him, he protested.

"Countess, I was mentally prepared for some verbal abuse, but you've crossed the line by saying that, don't you think? I'm genuinely appalled."

"But we are serious."

The one who answered in place of Helga, who went silent as if she didn't even think it was worth talking to him anymore, was a young man with light blue hair — Melchior. As usual, he avoided eye contact and muttered with a pout.

"You pretended to betray Magician in order to get close to us and stir things up... It was so obvious. Therefore, I pretended to fall for that so Magician would let his guard down. Get it, brat?"

"First, you call me 'Magician's friend' and now you call me a brat? Really, Pygmalion?"

The young man's voice was strained as he glared at the Methuselah who still had his head inclined. Puppeteer swiftly moved his fingertips and sent "threads" — biological fibers several microns thick — flying towards his opponents. However...

"Eh?"

Just before his "threads" could reach the sneering Eishexe and Pygmalion, they were deflected with ease. It felt as though a gust of wind had blown them off course and they simply melted away.

"My 'threads' were deflected?!"

"Do not underestimate Pygmalion, Puppeteer."

The Ice Witch smirked and jerked her chin at the Methuselah who was still looking away in a sulky manner.

"The three Neumann brothers each have their own unique powers but Melchior's is exceptional[3]. Your 'threads' will not work on him."

"Damn, my legs?!"

A hoarse voice spilled from the throat of the beautiful demon. Puppeteer was too busy panicking over the fact that his "threads" were deflected that he failed to notice the transparent slime that had crept its way up to his legs and wrapped itself around them like a tentacle. By the time he tried to escape by stepping back, the Künstliche Geist "Winter Frau[4]" — a mass of supercooled water controlled by micro machines — had engulfed his entire body.

"You're really annoying. Begone."

The last thing Puppeteer heard was Pygmalion's mocking laughter before darkness devoured his consciousness.

✝ End of Epilogue

[1] Eishexe is Helga's codename in the Orden which means "Ice Witch". [2] Hexenturm means "Witch's Tower" in German. [3] It was implied that Melchior could confuse electronic sensors and impede the use of Lost Technology to a certain extent. The full details of his power, however, will forever remain a mystery. [4] Helga's Artificial Ghost, "Winter Maiden".

#Trinity Blood#トリニティ・ブラッド#Sunao Yoshida#RAM 6#Rage Against the Moons VI#RAM 6 Public Enemy#Trinity Blood Public Enemy

7 notes

·

View notes

Note

perhaps you're already out of range but if not or if you're answering on the 1st what are your marine engineering youtube recs??? trying to maybe skill up a little before the summer season starts. also nice blog, thought you could have been a specific shipmate of mine before i realized you are british lol. fair winds out there

caught some signal off the french coast >:)

these two are good sources but they are not exhaustive. i dont think there are any exhaustive sources on youtube. there are a few books i can recommend which i have found useful:

the naval education and training program - "tools and their uses"

D A Taylor - "Introduction to marine engineering"

Reeds Marine Engineering - "General Engineering Knowledge"

H D McGeorge - "Marine Auxiliary Machinery"

Reeds Marine Engineering- Applied Mechanics

Reeds Marine Engineering - Instrumentation and Control Systems

nobody expects you to know everything as a 4th/3rd (if they do that's their problem) - they expect you to know how to be safe, to know when to call if there is a problem, and most importantly to have the balls to call when you are in doubt! marine engineering is such an extensive field and so much is required of us that even people who have been doing it for 30 years learn new things every day (my chief engineer literally said this to me this morning)

one final resource i almost forgot about-

REALLY useful webpage and the forums are a goldmine too.

good luck lad, feel free to DM if you have anything more specific to ask

n.b if you're some tall ship freak who is a sole engineer what i said abt 3rd/4th is less applicable but also i recommend you run for your life and join a cargo ship x

8 notes

·

View notes

Text

CUT IT SHORT with SHORT FILMS (1300)

Short films are favorite movies of mine without caring on the genre as are written short stories. For the sake of argument, lets say It emulates the type of world we live in, FAST and FURIOUS on a short fuse. However, I follow the Spanish saying (lo bueno y breve, dos veces bueno), that is, what is good and brief, doubly good or twice good. I have brought you several short films. Whatever you make of them, they are excellent pieces of work, I consider them a work of art.

My first story is about Nelly, a girl who locks her mother out or locks herself in, her house on her ninth birthday and starts posting videos on her moms phone on the internet. As the mom attempts to get inside the house, all her attempts fail, the video content becomes increasingly threatening as public services, police, fireman, etc intervene as locksmith was unable to open the doors.

The director: Jonas Steinacker Nelly's Story (2022)

I lived through a similar scenario, however not so dramatic, when my daughter was 4 years old. A neighbor called at the house in the building I live on the ninth floor. My wife and I at that time were the building's community secretary. A neighbor called at our door asking us to look at something in the hall on the same floor that he thought needed fixing. My wife and I went to see what it was when my four year old daughter slammed the door on us and neither of us had the key to open the door. We used the neighbors phone, called a lock smith, explained and he quickly came over, opened the door, we thanked and paid him, all the while my wife is calming and hugging my daughter. They were anguishing moment but more or less under control. So I can easily relay with the story.

youtube

link https://youtu.be/EbcEFMp8xl0 source ladydedlock origin Aug 2 Nelly's Story, a very powerful short film about kid influencers by Jonas Steinacker (subtitles are available). Nelly's Story, an Austrian short story with subtitles directed by Jonas Steinacker produced in 2023.

My next is so crazy that nothing made any sense to me ...

youtube

link https://youtu.be/BF8kYYqWiOE source junkyarddemento origin Aug 2

Leaning on sex, style, and tech this cool animated short falls somewhere between MTV's Liquid Television, anime, and THE MATRIX in a neo-dystopian world. Since I hardly understood anything, I went to AI Copilot for help on the matter and here is the conversation that transpired:

Urbance (2015) is a visually striking animated short film created by Joël Dos Reis Viegas and Sébastien Larroudé. The film is set in a neo-dystopian world where sex is prohibited due to a deadly genetic virus. The story revolves around underground nightclubs where teenagers engage in dance battles and consume illegal substances to escape their harsh reality.

The creators, Joël Dos Reis Viegas and Sébastien Larroudé, are talented Canadian designers with experience in Hollywood films like X-Men: Days of Future Past and the Godzilla reboot. They aimed to blend Japanese anime influences with Western urban culture, resulting in a unique and edgy visual style1.

Despite its complex and somewhat chaotic narrative, Urbance has garnered attention for its bold vision and high-quality animation. It was initially funded through a successful Kickstarter campaign, raising over $200,000 Canadian dollars.

youtube

link https://youtu.be/X3ZeGx_xIQc source junkyarddemento origin Aug 7 Director Michael Rich Writer Michael Rich

THE QUEUE (2023) I'd give it the highest compliment I can pay to this film. It plays like an episode of a horror anthology series. The high production value and unique story, really help make it stand out from the standard haunted house or slasher fare one comes across online. It should come as no surprise that Michael Rich's film has had a successful film festival circuit run, gaining acclaim and awards. Give this a look if you want to watch a deeply dark yet interesting horror viewing experience!

#1300#short film#Nelly's Story#2022#dir. Jonas Steinacker#urbance#dir. Joël Dos Reis Viegas#2015#THE QUEUE#2023#Dir. Michael Rich#2025-01-14

7 notes

·

View notes

Text

Kafka's fiction often confronts its critics with a collapsed or collapsing center of authority, a dead or powerless father, who condemns those in his orbit to a circuitous ruin. No one or nothing is in control; no one has the power to authorize. And yet all the subjects still seem to be controlled and continue to work. This paradox of inertia and ceaseless activity, of masterlessness combined with continued servitude, is the central feature of one of Kafka's most interesting parables, "Eine kaiserliche Botschaft." Michel Foucault's description of certain texts as heterotopias is particularly relevant for Kafka's parable, because it names the possibility of a text or system composed of disconnected infrastructures, a text made up of asymmetric parts which can only work or operate provided there is a condition of disorganization or entropy, a mechanics of resistance, frustration, dysfunction. Kafka's texts, like the heterotopias Foucault describes, display this kind of perverse operating procedure whose economy is initiated by the collapse of the center, often represented as the death of the father, and having clear Oedipal aspects.

It is in the Oedipus complex that we might locate the mechanism of resistance (the "machine desirante," to appropriate Deleuze and Guattari's anti-Oedipal term) that at once accounts for the absent father and makes possible the work of his subordinates in the shadow of his absence. The Oedipal situation is responsible for at once an imposition of its regulatory apparatus over the father, its "symbolic" content in the Lacanian sense, which results in the slaying of the father, and a suffering of guilt and loss of control that such an absence of the father inaugurates. What we must realize is that such a complex or mechanism of desire does not serve so much to inhibit or limit Kafka's writing to a simple principle, a constellation or dynamic which in itself becomes a substitute for the center effaced within the text, but that such a complex is an entropaic principle of dispersion that curiously energizes a thematic or semantic field of fragmentary particles. [...]

[…] Freud's little Hans, the "Du" or dreamer of the parable is attempting to gain or imagine mastery over a parent, and in the Kafka parable this constitutes wishing mastery over a father by at once desiring him dead and alive. What carries the force of this ambivalent, Oedipal network of desire is the message which delicately affirms the simultaneity of two wishes that are contradictory and yet mutually supportive. The one wish, let us call it thefort-wish, would like the Emperor to die, because the dreamer of the parable (us) would like to be the father. The slaves would like to become the master. However, in order for that wish to be realized, the father or Emperor must never truly disappear, since he is the Law upon which even usurpers depend, without which there would be no such thing as usurpation. Thus there has to be a da-wish, the desire that the Law be upheld and exercised. This Oedipal network of desire is carried by the message in two distinct senses: as pardon and as invitation. As pardon, the message carries both the subject's "crime," the breaking of the Law or denial of the Father (fort-wish), and the fact that the Law is still in effect, that the Father is still exercising power, is still present (the da-wish). As invitation, the message requests that the subject come into the father's presence (da-wish) even if time and space preclude such a journey, such a possibility (fort-wish). There is, finally, the Emperor's asking the servant to repeat the message, the repetition compulsion, which establishes at once that the message has, indeed, left the deathbed (is fort!) and yet remains within the possession of its author or authorizer, the exerciser of the Law (is da!).

—Herman Rapaport, An Imperial Message: The Relays of Desire, MLN, Vol. 95, No. 5, Comparative Literature (Dec., 1980)

10 notes

·

View notes

Text

How High-Quality Low-Voltage Switchgear Accessories Save You Money!

One of the main goals of industrial power systems is to cut costs without sacrificing performance.

Upgrading your low-voltage switchgear accessories is one frequently disregarded method to accomplish this.

Let’s discuss how purchasing high-quality switchgear accessories can extend the life of your electrical infrastructure, reduce operating costs, and boost system performance in this guide.

What Are Low-Voltage Switchgear Accessories?

Low-voltage switchgear accessories are parts that improve how well your electrical switchgear systems work, keep them safe, and make them reliable. These include:

- Circuit breakers

- Contactors

- Busbar systems

- Surge protection devices (SPDs)

- Control relays

- Communication and monitoring modules

They offer power distribution, fault protection, and real-time system monitoring and are therefore crucial in industrial automation and energy management.

1. Minimize Downtime and Improve Productivity

Cheap, low-quality parts are likely to break down, grinding work to a standstill. Every hour of unscheduled downtime at a plant equals lost work and income.

✅ Advantage:

The superior switchgear elements can withstand more load, function through more switch cycles, and withstand more demanding conditions. It guarantees power flows smoothly at all times and decreases the possibility of shutdowns.

2. Extend the Lifespan of Equipment

Switchgear accessories form the first line of defense for your equipment. Low-quality accessories will let surges or faults pass through and can destroy costly equipment like motors, drives, and PLCs.

✅ Advantage

Stable components such as motor protection relays and surge protection devices maintain voltage levels constant and prevent overloads, thus safeguarding equipment downstream of them.

3. Reduce Maintenance and Replacement Costs

Sustained maintenance, breakdown calls, and replacement components are costly over time. Cheap parts fail early, thereby adding to your maintenance load.

✅ Advantage:

Purchasing robust, low-maintenance accessories translates to fewer services and repairs, which results in overall savings.

4. Improve Energy Efficiency

Loss of power and energy inefficiency typically start with old or badly designed switchgear devices. Even small problems within a big system can lead to higher energy bills.

✅ Advantage:

Good-quality accessories provide the highest conductivity and proper switching, allowing for optimal voltage output maintenance and avoiding energy wastage.

5. Enhance Electrical Safety and Regulatory Compliance

Faulty accessories are a main cause of electrical fire and safety hazards. Substandard systems can also fail to meet industry standards.

✅ Advantage:

Good quality switchgear parts typically conform to IEC, UL, or other important standards for safe functioning and regulatory compliance.

Conclusion: Small Components, Big Savings

Cheap accessories can appear to be a good deal initially but can turn out to be costly over time. Employing quality low-voltage switchgear accessories guarantees that:

- Less system crashes

- Equipment lasts longer

- Reduced maintenance

- Reduced energy costs

- Safer operations

Looking for Reliable Low-Voltage Switchgear Accessories?

At Almond Enterprise, we specialize in supplying industrial-grade switchgear components that deliver long-term performance and value.

Contact Our Experts: [email protected] for tailored recommendations

7 notes

·

View notes

Text

Why does one side of my car's headlights always blow out?

Recurring failure of a headlight on only one side of your car typically signals an isolated electrical, environmental, or mechanical issue affecting that specific circuit. Here’s a step-by-step guide to diagnose and fix the problem:

Common Causes & Solutions Vibration Damage (Most Common)

Why: Rough roads or engine vibrations fatigue the filament in halogen bulbs. The side closer to the engine (e.g., driver’s side in LHD cars) often fails first.

Fix:

Install vibration-resistant bulbs (e.g., Philips XtremeVision, SNGL).

Add anti-vibration pads to the headlight assembly. Moisture Intrusion

Why: A cracked lens, bad seal, or missing dust cap lets condensation corrode contacts or cause thermal shock.

Fix:

Inspect for cracks/haze; reseal with butyl tape or replace the housing.

Use silica gel packs inside the headlight to absorb moisture. Poor Ground Connection

Why: Corroded/loose ground wires cause voltage fluctuations, overheating the bulb.

Fix:

Locate the ground point (near headlight or on chassis).

Clean corrosion with a wire brush, apply dielectric grease, and tighten. Voltage Spikes or Drops

Why: A failing alternator, bad voltage regulator, or weak battery sends uneven power.

Test: Use a multimeter to check voltage at the bulb socket (engine running):

Normal: 13.5–14.5V.

Problem: <12V (wiring issue) or >15V (alternator failure). Damaged Socket or Wiring

Why: Melted/burnt sockets or frayed wires restrict current flow, causing overheating.

Fix:

Replace the socket/harness.

Apply dielectric grease to contacts to prevent corrosion. Faulty Relay or Switch

Why: A failing headlight relay can send erratic power to one side.

Test: Swap the left/right relays (if separate) to see if the problem moves.

Diagnostic Checklist Swap the Bulbs

Move the "good" bulb to the problematic side. If it blows, the bulb isn’t at fault. Check Voltage at the Socket

Test with a multimeter while the headlight is on (ideal: 12–14.5V). Inspect for Moisture

Look for condensation, water droplets, or green corrosion on contacts. Examine the Fuse

Some cars have separate fuses per side; replace even if it looks intact.

Prevention Tips Always replace bulbs in pairs to ensure even performance.

Upgrade to LEDs: More vibration/voltage-tolerant (ensure CANBUS compatibility).

Install a relay harness: Bypasses factory wiring for stable power (e.g., Putco 240008).

Avoid touching halogen bulbs: Skin oils create hotspots that shorten lifespan.

When to See a Mechanic If basic fixes fail, suspect: A short circuit in the wiring harness.

Faulty body control module (BCM).

Parasitic drain overloading the circuit.

⚠️ Ignoring this can lead to:

Repeated bulb replacements ($).

Electrical fires from overheated wires.

Failed safety inspections.

Pro Tip: For recurring issues, a $50 professional electrical diagnostic can save hundreds in guesswork. Most problems stem from grounding faults or voltage irregularities—address these first! 🔧🔦

#led lights#car lights#led car light#youtube#led auto light#led headlights#led light#led headlight bulbs#ledlighting#young artist#race cars#cars#electric cars#classic cars#car#carlos sainz#truck#bmw#lamborghini#porsche#audi#honda#honda555#tohru honda#honda hiroto#kiku honda#toyota#automotive#suzuki#japanese cars

4 notes

·

View notes

Text

The Role of Relays and Timers in Industrial Automation Systems

In the world of industrial automation, efficiency, safety, and precision are crucial. Among the many components that contribute to a well-functioning automated system, relays and timers play a foundational role. These devices act as control elements that manage the flow of electricity, signal processes, and coordinate timing sequences — ensuring that operations run smoothly and safely.

In this article, we’ll explore how relays and timers work, their types, applications in automation systems, and how high-quality products — like those offered by Enza Electric — can enhance performance and reliability in industrial settings.

What Are Relays?

A relay is an electromechanical or electronic switch used to control a circuit by a separate low-power signal or multiple signals. In industrial automation, relays act as a bridge between the control system and the equipment being operated — allowing machines to be turned on or off automatically.

Types of Relays Commonly Used in Automation:

Electromechanical Relays (EMRs): Use physical moving parts; reliable and easy to maintain.

Solid-State Relays (SSRs): No moving parts; faster switching, longer lifespan, and better for high-speed applications.

Thermal Overload Relays: Protect motors and equipment from overheating.

Control Relays: Designed for controlling multiple contacts simultaneously in automation systems.

What Are Timers?

Timers are devices used to delay or repeat electrical signals at predetermined intervals. They help synchronize tasks, automate sequences, and provide controlled outputs over time — critical for complex industrial processes.

Common Timer Functions:

On-delay and off-delay timing

Interval timing

Cyclic or repeat cycle operation

Flashing and sequencing operations

Types of Timers:

Analog Timers: Manual dial settings, simple and cost-effective.

Digital Timers: Offer precise programming, displays, and flexible timing ranges.

Programmable Timers: Ideal for complex automation routines requiring multiple sequences.

Key Roles in Industrial Automation Systems

1. Process Control and Sequencing

Relays and timers enable automated machines to follow a specific sequence — turning motors, lights, or pumps on and off in a logical order. For example, a conveyor system can use a relay-timer combination to control material flow with millisecond precision.

2. Safety and Protection

Relays protect systems by interrupting circuits in case of faults. Combined with timers, they can ensure delay before activating emergency stop functions, preventing false triggers and increasing worker safety.

3. Load Management

In high-demand industrial environments, relays help manage load distribution by selectively energizing or de-energizing machinery. Timers assist in staggered starts, reducing power surges.

4. Energy Efficiency

By automating start/stop functions and managing operation durations, timers help reduce unnecessary energy use. Relays ensure only the necessary loads are powered, minimizing wastage.

5. System Monitoring and Feedback

In smart automation, relays provide feedback signals to the control system. Timers assist with diagnostics by creating intervals for testing or data collection.

Benefits of Using High-Quality Relays and Timers

Choosing the right components significantly impacts system performance and longevity. Enza Electric’s relays and timers are engineered with:

High durability for tough industrial environments

Precision timing for reliable operation

Easy installation and compact designs

Compliance with international safety and quality standards

By integrating Enza’s low-voltage solutions, businesses in the GCC, MENA, and Africa regions benefit from cost-effective, scalable automation that supports both current needs and future expansion.

Common Applications in Industrial Sectors

Manufacturing Plants: Control of motors, robotic arms, and production lines.

HVAC Systems: Timed control of fans, compressors, and dampers.

Water Treatment Facilities: Sequenced operation of pumps and valves.

Packaging Machinery: Relay and timer-based coordination of packing, sealing, and labeling.

Food and Beverage Industry: Process automation with hygiene-compliant controls.

Final Thoughts

Relays and timers are the silent operators behind the success of industrial automation systems. From process optimization to enhanced safety and energy management, these components are indispensable.

When sourced from a trusted manufacturer like Enza Electric, businesses are not only investing in reliable hardware but also in the longevity, scalability, and safety of their entire operation.

Ready to Power Your Automation?

Explore Enza Electric’s wide range of relays, timers, and other low-voltage switchgear solutions designed to meet the evolving demands of modern industries. Visit www.enzaelectric.com to learn more or request a quote today.

9 notes

·

View notes