#PCB Power Relays

Explore tagged Tumblr posts

Text

Simplify PCB Power Relays: How Does a PCB Relay Work?

Introduction to PCB Power Relays

As an electronics enthusiast, you may have come across the term “PCB power relay" in your projects or research. But what exactly is a PCB power relay, and how does it work? In this article, we will delve into the world of PCB power relays, exploring their components, design, and most importantly, their function and purpose.

What is a PCB Power Relay?

A PCB power relay, also known as a printed circuit board power relay, is an electromechanical device that allows the control of high-power electrical circuits through low-power signals. It is an essential component in many electronic devices and systems, providing an interface between the control circuit and the load circuit.

The Function and Purpose of a PCB Power Relay

The main function of a PCB power relay is to control the flow of electrical current in a circuit. When a low-power signal, such as a voltage or current, is applied to the relay's coil, it generates a magnetic field that attracts or releases a set of contacts. These contacts, in turn, open or close the circuit, allowing or interrupting the flow of electricity to the load.

The purpose of a PCB power relay varies depending on the application. In some cases, it is used for power switching, where it controls the flow of electricity to devices such as motors, lamps, or heaters. In others, it acts as a protective device, safeguarding the circuit from overloads or short circuits. Power relays are also commonly employed in automation systems, industrial control panels, and telecommunications equipment.

Components and Design of a PCB Power Relay

To understand how a PCB power relay works, it is crucial to familiarize yourself with its components and design. The main elements of a typical PCB power relay include the coil, contacts, and the magnetic system.

The Coil

The coil is the primary component of a PCB power relay responsible for generating the magnetic field. It is usually made of copper wire wound around a bobbin or a magnetic core. The number of turns and the gauge of the wire determine the coil's resistance and the amount of current required to energize the relay.

The Contacts

The contacts of a PCB power relay are the crucial link between the control circuit and the load circuit. They are made of conductive materials, such as silver or gold-plated alloys, to ensure efficient electrical conduction and minimize contact resistance. PCB power relays can have various contact configurations, including single-pole, single-throw (SPST), single-pole, double-throw (SPDT), and double-pole, double-throw (DPDT).

The Magnetic System

The magnetic system of a PCB power relay consists of a ferromagnetic core and an armature. When the coil is energized, the magnetic field created by the coil attracts the armature, which is mechanically linked to the contacts. This attraction causes the contacts to move, either opening or closing the circuit, depending on the relay's design and specifications.

How Does a PCB Power Relay Work?

Now that we have a basic understanding of the components, let's explore how a PCB power relay works in practice. The operation of a PCB power relay can be divided into three main stages: the resting state, the activation state, and the switched state.

Resting State

In the resting state, the relay is not energized, and the contacts are in their default position. Depending on the relay's design, this default position can be either open or closed. For example, in a normally open (NO) relay, the contacts are open in the resting state, while in a normally closed (NC) relay, the contacts are closed.

Activation State

When a voltage or current is applied to the coil, it creates a magnetic field that attracts the armature. This attraction causes the armature to move, which, in turn, moves the contacts. If the relay is normally open, the contacts will close, completing the circuit and allowing the flow of current to the load. Conversely, if the relay is normally closed, the contacts will open, interrupting the circuit.

Switched State

Once the coil is de-energized, the magnetic field dissipates, and the armature returns to its original position due to factors such as spring tension. As a result, the contacts also return to their default position, either open or closed, depending on the design of the relay. This completes the switching action, and the relay is ready for the next cycle.

Advantages and Applications of PCB Power Relays

PCB power relays offer several advantages that make them a popular choice in various applications. One of the key advantages is their ability to handle high-power loads while being controlled by low-power signals. This feature allows for efficient and reliable control of electrical circuits, making PCB power relays indispensable in industries such as manufacturing, automotive, and telecommunications.

Another advantage of PCB power relays is their compact size. Since they are designed to be mounted directly onto printed circuit boards, they occupy minimal space, making them suitable for applications where size constraints are a concern. Additionally, they are relatively easy to install and replace, reducing downtime and maintenance costs in case of failure.

The applications of PCB power relays are wide-ranging. They are commonly used in automotive systems, such as power windows, central locking, and fuel pumps. In industrial settings, they play a vital role in controlling motors, pumps, and solenoids. In the field of telecommunications, PCB power relays are utilized in devices like switches, routers, and modems. These relays also find their place in renewable energy systems, home appliances, and medical equipment.

Understanding Different Types of PCB Power Relays

PCB power relays come in a variety of types, each suitable for specific applications and requirements. The most common types include general-purpose relays, latching relays, solid-state relays, and automotive relays.

General-purpose relays are versatile and can be used in a wide range of applications. They are available in different configurations, contact ratings, and coil voltages, making them suitable for both low-power and high-power switching.

Latching relays, also known as bistable relays, have the ability to maintain their contact position even after the coil is de-energized. They are commonly used in applications where power consumption and heat generation need to be minimized.

Solid-state relays (SSRs) differ from traditional electromechanical relays as they use semiconductor devices and optocouplers to control the switching action. SSRs offer advantages such as silent operation, long lifespan, and fast switching speeds. They are often used in applications where high switching frequency and low power consumption are critical.

Automotive relays are specifically designed to withstand the harsh conditions and high electrical demands of automotive systems. They are frequently used in vehicle lighting, wiper control, and ignition systems.

Choosing the Right PCB Power Relay for Your Application

Selecting the right PCB power relay for your application is crucial to ensure optimal performance and reliability. Several factors should be considered, including contact ratings, coil voltage, switching speed, and environmental conditions.

Firstly, determine the required contact rating, which specifies the maximum current and voltage that the relay can handle. This rating should be compatible with the load circuit's electrical characteristics to prevent damage or failure.

The coil voltage is also an essential parameter to consider. Ensure that the relay's coil voltage matches the voltage available in your control circuit. Operating the relay with a higher or lower coil voltage than specified can lead to improper functioning or complete failure.

The switching speed of a PCB power relay is another critical factor, especially in applications where fast response times are required. Consider the relay's datasheet or technical specifications to determine its switching speed and choose accordingly.

Lastly, take into account the environmental conditions in which the relay will operate. Factors such as temperature, humidity, vibration, and shock can significantly impact the relay's performance and lifespan. Choose a relay that is specifically designed to withstand the environmental conditions of your application.

Leading Manufacturers of PCB Power Relays

When it comes to choosing a reliable PCB power relay, it is essential to consider reputable manufacturers known for their quality and performance. Some of the leading manufacturers in the industry include Omron, TE Connectivity, Panasonic, Siemens, and Schneider Electric.

Omron, for instance, is a renowned manufacturer offering a wide range of PCB power relays suitable for various applications. Their relays are known for their high-quality construction, excellent performance, and long lifespan.

TE Connectivity is another trusted name in the field of PCB power relays. They provide a comprehensive selection of relays, catering to different industries and requirements. Their relays are known for their durability, versatility, and advanced features.

Other notable manufacturers like Panasonic, Siemens, and Schneider Electric also offer a diverse range of high-quality PCB power relays, ensuring reliability and performance in demanding applications.

Conclusion: The Importance of PCB Power Relays in Electronics

In conclusion, PCB power relays play a vital role in the world of electronics, enabling the control of high-power circuits through low-power signals. Understanding their components, design, and operation is essential for anyone working with electronic devices or systems.

By demystifying PCB power relays, we have gained insight into their function, purpose, advantages, and applications. We have explored different types of relays and discussed the factors to consider when choosing the right one for your application. Additionally, we have highlighted leading manufacturers known for their quality and reliability.

Next time you encounter a PCB power relay in your projects, remember its significance in providing efficient and reliable control of electrical circuits. Whether you're working on an industrial automation system, a telecommunications device, or a home appliance, PCB power relays are the unsung heroes ensuring seamless operation and protection of your electronics.

0 notes

Text

https://www.futureelectronics.com/p/electromechanical--relays--power-relays/2-1415898-3-te-connectivity-5076008

PCB Mount Power Relay, Pin PCB Relay, Power windows, Power relay socket

RT1 Series SPST (1 Form A) 16 A 12 V PCB Mount General Purpose Power Relay

#TE Connectivity#1415898-3#Relays#Power Relays#Tyco Electronics#Socket power relay#PCB SPST#latching#PCB Mount#Pin PCB Relay#Power windows#Power relay socket#Power relay switch#Solid state relay#Power relay module#power relay 120v

1 note

·

View note

Text

https://www.futureelectronics.com/p/electromechanical--relays--power-relays/1415898-1-te-connectivity-4164750

Non latching, Socket power relay, DPST relays, DPDT relays, Power Relay Module

RT1 Series SPST (1 Form A) 16 A 12 V PCB Mount General Purpose Power Relay

#Relays#Power Relays#1415898-1#TE Connectivity#operating current automotive relay#PCB Mount General Purpose#240VAC#Socket#DPST relays#DPDT relays#Module#Power relay socket#Relay module#electromagnetic coil#latching power relays

1 note

·

View note

Text

https://www.futureelectronics.com/p/electromechanical--relays--power-relays/1415898-1-te-connectivity-9946344

General purpose relay socket, industrial relays, PCB relay, power relay switch

RT1 Series SPST (1 Form A) 16 A 12 V PCB Mount General Purpose Power Relay

#TE Connectivity#1415898-1#Relays#Power Relays#latching relay#power relay assembly#24VDC Power relay#module#General purpose relay socket#industrial relays#PCB relay#switch#Panasonic electric works#110VAC power relays#latching

1 note

·

View note

Text

High-Performance PCB Power Relays for Optimum Efficiency - Leonerelays

Leonerelays' PCB Power Relays boost your electronics' performance. These relays offer accurate control on circuit boards, improving your devices' efficiency. Count on Leonerelays for top-quality relays that work well in various electronics. With our relays, expect better technology and long-lasting durability, making them perfect for all your electronic needs.

0 notes

Text

Air Pollution Impacting Sea Life: The Invisible Link Between Sky and Sea

When we hear the term air pollution, the first picture that comes to mind is that of smoggy skies, respiratory disease, and city traffic jams. Few think of coral reefs, fish, plankton, or whales. But the reality is that air pollution significantly and increasingly affects marine ecosystems.

This blog ventures into how pollutants emitted into the air find their way to oceans, seas, and rivers, harming aquatic life, changing ecosystems, and imperiling biodiversity. As air quality professionals, it is important that we comprehend and relay the cross-domain impacts of pollution, particularly the frequently ignored air-sea link.

The Air-Ocean Link: How Pollutants Go on a Journey

To grasp how air pollution impacts marine life, it is helpful to follow the journey of pollutants:

1. Release into the Atmosphere: These pollutants include Sulphur dioxide (SO₂), Nitrogen oxides (NOx), Particulate Matter (PM2.5), heavy metals, and Persistent Organic Pollutants (POPs), which are emitted by vehicles, industries, power plants, and agricultural sources.

2. Transportation in the Atmosphere: These airborne pollutants may be transported by winds over large distances, sometimes hundreds or thousands of kilometers from their point of origin.

3. Deposition into Water Bodies:

Wet deposition: Rain and snow wash pollutants out of the air into oceans, lakes, and rivers.

Dry deposition: Particles and gases fall out of the atmosphere onto the ocean surface.

4. Bioaccumulation and Ecosystem Disruption: Pollutants, once in the ocean, interact with marine ecosystems and organisms, frequently building up the food chain.

In this manner, airborne pollutants turn into aquatic pollutants, initiating an ecological cascade of effects.

Key Air Pollutants with Effects on Marine Life

1. Nitrogen Oxides and Sulphur Dioxide → Ocean Acidification and Eutrophication

Nitrogen oxides (NOx) and Sulphur dioxide (SO₂) released by the combustion of fossil fuels lead to acid rain. Upon dissolution in rainwater and flow into the ocean, they reduce the water pH, leading to ocean acidification. Acidified waters can melt the calcium carbonate shells of molluscs, corals, and certain plankton species, increasing their vulnerability and lowering their numbers.

Moreover, atmospheric nitrogen also serves as a fertilizer, causing eutrophication — an excessive growth of algae in coastal waters. When these algae die and are broken down, they use up oxygen, forming hypoxic zones (or “dead zones”) where fish and marine invertebrates cannot live.

The Gulf of Mexico, Chesapeake Bay, and portions of the Arabian Sea are some of such areas enriched by nitrogen deposition.

2. Mercury and Heavy Metals

Mercury emitted into the atmosphere from power plants that burn coal can travel far before depositing into the ocean.

Mercury, when deposited, is subject to methylation, converting it into methylmercury, a very toxic substance that concentrates in aquatic life.

Methylmercury accumulates up the food chain, presenting significant health hazards to apex predators like tuna, swordfish, and marine mammals.

Consumption of tainted seafood by humans can result in mercury poisoning, which harms the nervous system, reproductive system, and brain development in fetuses and children.

In an equally similar way, airborne lead, cadmium, and arsenic from industrial sources also fall into oceans, building up in fish tissue and disrupting marine food webs.

3. Persistent Organic Pollutants (POPs)

Substances such as polychlorinated biphenyls (PCBs), dioxins, and certain pesticides are transported by the wind and ultimately end up in the ocean.

POPs are lipophilic (fat-loving), not water-loving, and thus cause bioaccumulation in fatty tissues of fish, seabirds, and whales.

Such pollutants interfere with hormone systems, causing reproductive failure, developmental abnormalities, and immune system suppression.

POPs have been discovered in as distant species as Arctic seals and penguins, illustrating the worldwide extent of atmospheric transport.

Microplastics: An Airborne Entry into Oceans

Whilst ocean plastic pollution is widely reported, less is understood about airborne microplastics.

Microplastics are now recognized to be airborne particles, from tyre wear, synthetic fiber, and industrial emissions.

Research has established that these particles have been found traveling hundreds of kilometers in the atmosphere and eventually end up depositing into the ocean.

Microplastics ingested by zooplankton, shellfish, fish, and even whales in marine ecosystems impact nutrition, reproduction, and survival.

This association establishes how even terrestrial human activity can indirectly contaminate marine ecosystems via atmospheric transport.

Impact on Marine Biodiversity

The overall impact of air-deposited pollutants on marine life is immense:

Coral reefs are bleached by acidification and suffer due to increased temperatures fueled by greenhouse gases.

Fish stocks reduce in hypoxic areas, with both local habitats and international fisheries impacted.

Phytoplankton, the foundation of the ocean food chain and responsible for producing more than 50% of Earth’s oxygen, are very sensitive to pH shifts and pollutant concentration.

Marine mammals such as dolphins, whales, and seals exhibit indications of hormonal disruption and immune suppression from chronic air-deposited toxins.

Human Consequences: What Comes on Sea Returns to Shore

The impacts of air pollution on the ocean life ultimately come full circle to human populations:

Toxic seafood can cause neurological, hormonal, and developmental diseases.

Fisheries collapse endangers the food security and livelihood of millions in coastal communities.

Declines in biodiversity and reef degradation decrease tourism and ecosystem resilience.

As oceans incorporate pollutants and CO₂, their ability to serve as climate regulators decreases, contributing to further intensification of global warming and air quality.

This only adds emphasis to the requirement to view air pollution not only in an urban context, but as a global environmental risk.

What Can Be Done?

Policy and Emission Controls

Enact tougher emission controls on power plants, transportation, and industrial sources.

Mandate the world phase-out of mercury under the Minamata Convention.

Lower nitrogen emissions through improved farming methods and transport policies

2. International Cooperation

Pollutants do not observe borders. Regional coordination under such instruments as the Convention on Long-Range Transboundary Air Pollution is critical to regulate deposition into common water bodies.

3. Monitoring and Public Education

Integrating air and water quality monitoring is crucial for understanding pollutant pathways and impacts.

Tools like Respirer help citizens track and understand local pollution patterns, raising awareness about the interconnectedness of environmental systems.

Conclusion: The Sky and Sea Are Not Separate Worlds

Air and sea are not separate realms, they are but part of an integrated planetary system. What we emit into the air ultimately comes into contact with every part of the biosphere, including the seas that support life on the planet.

As practitioners at the nexus of environment and public health, it’s important that we extend our knowledge of air pollution from the proximate and obvious. The quiet agony of sea creatures is an alarm: to do something now, decrease emissions, and maintain the fine balance between the Earth’s sky and sea.

To remain well-informed and empowered, investigate current air quality information and pollution facts at Respirer.

#air pollution#marine life#air quality#aqi#airpollutants#climate change#healthcare#clean air#respirer living sciences#microplastics#coral reef#aquatic life#fish#whale

3 notes

·

View notes

Text

Understanding the Functionality of Samsung Refrigerator PCB Main Assembly

Samsung refrigerators have become essential appliances in modern households, offering innovative features and advanced technologies to ensure food preservation and convenience. The (Printed Circuit Board) PCB Main Assembly serves as the brain of the refrigerator, coordinating various functions and ensuring optimal performance.

Components of the Refrigerator PCB Main Assembly

The Refrigerator PCB Main Assembly consists of several essential components, each playing a crucial role in the refrigerator's operation.

Microcontroller: It is the central processing unit (CPU) and the computer performs programmed instructions to coordinate communication between the components.

Sensors: The ambient parameters (temperature, humidity, door status) supply critical information for regulation.

Relays: You control the flow of electricity to the compressor, fan motors, and defrost heater.

Capacitors: It will help you store the electrical energy and help to regulate voltage, and guarantee that the PCB is operating reliably.

Resistors: Protect sensitive components from harm by limiting the flow of electricity across certain circuits.

Diodes: Allow current to flow exclusively in one direction to avoid reverse polarity and safeguard components from damage.

Connectors: Facilitate electrical connections between the PCB and other refrigerator components to ensure seamless integration.

Working Principle PCB Main Assembly

The PCB Main Assembly operates on a set of programmed instructions that determine its behavior depending on sensor input and user command. The micro controller continuously monitors sensor input such as the reading of the temperature from the refrigerator compartment, and freezer. The microcontroller controls the transition of the compressor on, or off or the speed of the fan and also the defrost cycles based on the sensor data as to how to keep the temperature and humidity at the optimal level. In addition to the other refrigerator components, for example, display panel and user interface, the PCB Main Assembly provides feedback and enables users’’ interaction. The PCB Main Assembly incorporates safety features of overload protection and temperature sensors to protect the refrigerator from damage and to protect the user.

Communication Protocols

Data can be communicated to other components through microcontrollers by communication protocols like UART (Universal Asynchronous Receiver Transmitter), SPI (Serial Peripheral Interface), and I2C (Inter Integrated Circuit).

UART is used to transfer real-time data from a microcontroller to external devices like display panels and temperature sensors.

There is a power of communication SPI and I2C for the communication of integrated circuits associated with the PCB Main Assembly for efficient data transfer and synchronization between components.

Troubleshooting and Maintenance

Common issues with the Samsung Refrigerator PCB Main Assembly include sensor failures, relay malfunctions, and power supply issues, which can affect the refrigerator's performance.

To solve PCB Main Assembly problems, we can use diagnostic methods, like running self-tests and checking the error code.

The assembly can stay longer depending on the main, such as cleaning dust and debris from the PCB and securing appropriate ventilation.

The PCB Main Assembly is an important component of the Samsung refrigerator systems since it organizes several functions to contribute to the overall efficiency of the refrigerator and food preservation. Fore-knowledge of the PCB Main Assembly and the way it is constructed can assist users in likely managing problems in their fridges.

2 notes

·

View notes

Text

Omron Electronic Components Europe has launched the G5Q-HR, a new 10A PCB power relay in the G5Q family. This relay, 45% smaller than 16A equivalents, offers reduced power consumption and heat, ideal for high inrush current applications like lighting controllers and home appliances. The G5Q series, with over 500 million units sold since 2001, now includes this compact and energy-efficient model available in single stable and latching variants.

1 note

·

View note

Text

Global HVAC Duct-Cleaning Robots Market : Key Drivers, Significant Analysis And Future Scope

Global PCB Solid State Relays Market valued at USD X.X Billion in 2024 and is projected to reach USD X.X Billion by 2032, growing at a CAGR of X.X% from 2025 to 2032. Global PCB Solid State Relays Market: Significant Analysis The global PCB solid state relays market is experiencing robust growth driven by increasing adoption across diverse industries such as automotive, industrial automation, and consumer electronics. Advancements in semiconductor technology and the demand for reliable, compact, and energy-efficient switching solutions are key factors propelling market expansion. Projections indicate a steady CAGR over the next several years, fueled by rising investments in smart grid technologies and IoT integration. Additionally, the trend towards miniaturization and enhanced performance in electronic components further supports market momentum. Emerging applications in renewable energy and healthcare sectors offer new avenues for growth. Challenges related to high initial costs and thermal management are being addressed through innovation, enabling wider acceptance. Overall, the market outlook remains positive, with continuous improvements anticipated to drive adoption globally. Get the full PDF sample copy of the report: (Includes full table of contents, list of tables and figures, and graphs) @ https://www.verifiedmarketresearch.com/download-sample/?rid=368234&utm_source=Glob-VMR&utm_medium=261 Global PCB Solid State Relays Market Key Drivers Key drivers of the global PCB solid state relays market include the increasing need for efficient and durable switching devices in various electronic applications. The rise in automation and smart manufacturing processes has elevated demand for reliable relays that offer faster switching speeds and longer operational lifespans compared to traditional electromechanical relays. Additionally, growing awareness about energy conservation and the push for low-power consumption electronics encourage the use of solid state relays. The expanding automotive industry, with a focus on electric and autonomous vehicles, also fuels market growth. Moreover, the surge in consumer electronics requiring compact and silent operation components boosts demand. Continuous advancements in materials and circuit design further enhance performance, making PCB solid state relays an attractive choice across sectors. Global PCB Solid State Relays Market: Future Scope The future scope of the global PCB solid state relays market is promising, with substantial growth anticipated due to technological advancements and expanding applications. As industries increasingly adopt automation and digital solutions, the demand for compact, efficient, and reliable switching devices will grow significantly. Innovations in semiconductor materials and integration with smart technologies will enable improved relay performance and functionality. Additionally, emerging sectors such as renewable energy, electric vehicles, and healthcare instrumentation offer new growth opportunities. The ongoing trend toward miniaturization and multifunctional devices will further drive market expansion. Regional developments, particularly in Asia Pacific, will play a crucial role in shaping the market landscape. Overall, the future outlook suggests strong growth supported by increasing investments and evolving technological requirements. Refractive Optical Element Market Regional Analysis The Asia Pacific region holds a pivotal position in the refractive optical element market due to rapid industrialization and technological advancements. Growing demand from sectors such as telecommunications, consumer electronics, and healthcare fuels regional market growth. Countries in this region are investing heavily in research and development, improving manufacturing capabilities and adopting advanced materials. Increasing applications in augmented reality, virtual reality, and laser systems contribute to rising market opportunities. Additionally, expanding

infrastructure and government support for high-tech industries create a favorable environment for market expansion. The region’s cost-effective manufacturing and skilled workforce further attract global players to establish production hubs. These factors collectively drive significant growth in the Asia Pacific refractive optical element market, positioning it as a key contributor to the global industry. Download Full PDF Sample Copy of PCB Solid State Relays Market Report @ https://www.verifiedmarketresearch.com/download-sample/?rid=368234&utm_source=Glob-VMR&utm_medium=261 Key Competitors in the PCB Solid State Relays Market These companies are renowned for their broad product offerings, sophisticated technologies, strategic efforts, and robust market presence. Each competitor's primary advantages, market share, current events, and competitive tactics—such as collaborations, mergers, acquisitions, and the introduction of new products—are highlighted in the study. Omron TE Connectivity Sensata Technologies Celduc Relais Siemens ABB Rockwell Automation. Get Discount On The Purchase Of This Report @ https://www.verifiedmarketresearch.com/ask-for-discount/?rid=368234&utm_source=Glob-VMR&utm_medium=261 PCB Solid State Relays Market Trends Insights PCB Solid State Relays Market Trend Insights offers a thorough examination of the market's current and developing trends, providing insightful data-driven viewpoints to assist companies in making wise decisions. This study explores the major consumer trends, market forces, and technology developments influencing the sector. By Specifications By Load Type By Application By Geography • North America• Europe• Asia Pacific• Latin America• Middle East and Africa For More Information or Query, Visit @ https://www.verifiedmarketresearch.com/product/pcb-solid-state-relays-market/ Detailed TOC of PCB Solid State Relays Market Research Report, 2026-2032 1. Introduction of the PCB Solid State Relays Market Overview of the Market Scope of Report Assumptions 2. Executive Summary 3. Research Methodology of Verified Market Reports Data Mining Validation Primary Interviews List of Data Sources 4. PCB Solid State Relays Market Outlook Overview Market Dynamics Drivers Restraints Opportunities Porters Five Force Model Value Chain Analysis 5. PCB Solid State Relays Market, By Geography North America Europe Asia Pacific Latin America Rest of the World 6. PCB Solid State Relays Market Competitive Landscape Overview Company Market Ranking Key Development Strategies 7. Company Profiles 8. Appendix About Us: Verified Market Research®Verified Market Research® is a leading Global Research and Consulting firm that has been providing advanced analytical research solutions, custom consulting and in-depth data analysis for 10+ years to individuals and companies alike that are looking for accurate, reliable and up to date research data and technical consulting. We offer insights into strategic and growth analyses, Data necessary to achieve corporate goals and help make critical revenue decisions.Our research studies help our clients make superior data-driven decisions, understand market forecast, capitalize on future opportunities and optimize efficiency by working as their partner to deliver accurate and valuable information. The industries we cover span over a large spectrum including Technology, Chemicals, Manufacturing, Energy, Food and Beverages, Automotive, Robotics, Packaging, Construction, Mining & Gas. Etc.Having serviced over 5000+ clients, we have provided reliable market research services to more than 100 Global Fortune 500 companies such as Amazon, Dell, IBM, Shell, Exxon Mobil, General Electric, Siemens, Microsoft, Sony and Hitachi. We have co-consulted with some of the world's leading consulting firms like McKinsey & Company, Boston Consulting Group, Bain and Company for custom research and consulting projects for businesses worldwide. Contact us:Mr. Edwyne FernandesVerified Market Research®US:

+1 (650)-781-4080UK: +44 (753)-715-0008APAC: +61 (488)-85-9400US Toll-Free: +1 (800)-782-1768Email: [email protected]:- https://www.verifiedmarketresearch.com/ Global Gardening Equipment Market

0 notes

Text

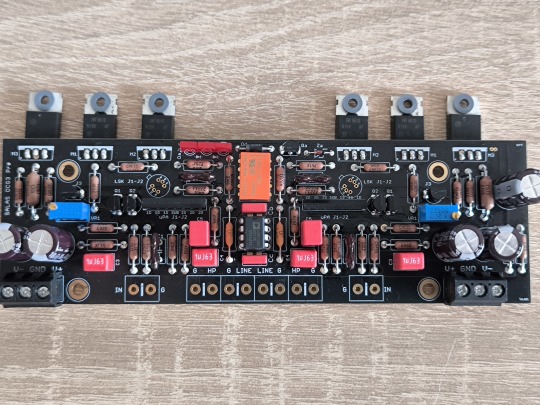

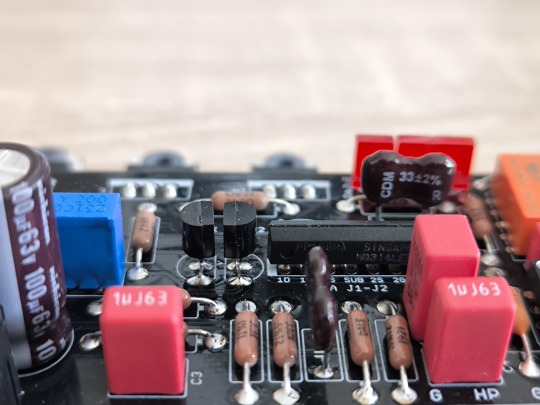

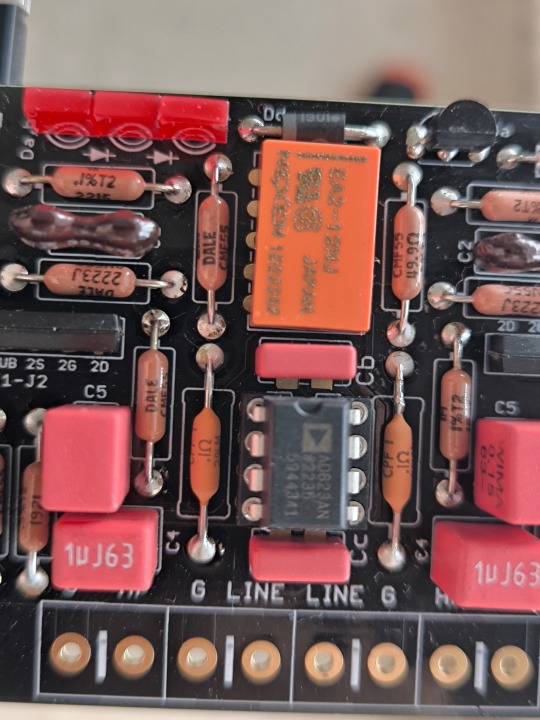

DCG3 Headphone Amplifier and Preamplifier: High-End Analog Performance with Premium Components

If you're in search of a reference-class headphone amplifier and preamplifier, the DCG3 should be at the top of your list. Designed with a clear focus on sonic purity and engineering excellence, the DCG3 delivers outstanding audio performance, thanks to a carefully selected array of audiophile-grade components and a robust circuit design.

Audiophile-Grade Input Stage with NEC uPA68H JFETs

At the heart of the DCG3’s input stage is the dual JFET uPA68H from NEC, a high-performance device known for its clean, musical sound signature that closely resembles the legendary 2SK170. The biasing for the JFETs is handled by a BF256 operating at approximately 5mA, ensuring optimal linearity and thermal stability.

Premium Build with High-End PCB and Components

The DCG3 is built on a black, 2mm thick PCB with 2oz copper for enhanced current handling and thermal performance. Measuring 160 x 50 mm, the board layout is optimized for minimal signal path length and maximum shielding from noise.

Only the best components were selected for the DCG3 to ensure superior sound quality and long-term reliability:

Vishay Dale CMF series resistors for critical signal paths and CPF for power handling

Nichicon electrolytic capacitors for smooth, noise-free power delivery

WIMA film capacitors known for their precision and low distortion

Cornell Dubilier silver mica capacitors, revered for their exceptional stability and clarity in audio circuits

Advanced Output Section with Delayed Relay Protection

The DCG3 features both line output and headphone output, each protected by a miniature NEC EA2-12NJ relay that provides delayed engagement to eliminate pops and protect connected gear.

An integrated DC servo circuit based on the AD823 operational amplifier eliminates any DC offset at the output, further improving safety and sound fidelity.

Output Stage with Vishay MOSFETs and Precision Design

The output stage utilizes robust Vishay IRF9610 and DN2540 MOSFETs, chosen for their linear performance and durability. The amplifier operates at a gain of 3x, offering just the right level of amplification for most line-level sources and headphones.

The quiescent current is set to 120mA, providing ample headroom and drive capability for a wide range of headphones, while maintaining excellent thermal behavior.

Exceptional Noise Performance and Low Output Impedance

The DCG3 achieves an impressive -120 dBV noise floor, making it virtually silent in operation. Output impedance is optimized for both outputs:

Line out impedance: 50 ohms

Headphone out impedance: less than 0.1 ohm

This ensures excellent damping factor and tight bass control, especially for low-impedance headphones.

Power Supply: SSLV1.3 UltraBiB Shunt Regulator

To match the sonic performance of the DCG3, it is powered by the SSLV1.3 UltraBiB shunt regulator, a low-noise, high-speed power supply known for its excellent transient response and ultra-clean output. This regulator was covered in detail in our previous article, and it plays a crucial role in enabling the DCG3 to reach its full potential.

Conclusion: A True Reference-Grade Headphone Amplifier

The DCG3 headphone amplifier and preamplifier is a testament to precision analog engineering. With its carefully matched components, optimized circuit design, and impeccable power delivery, it is ideal for demanding audiophiles who seek transparent, dynamic, and musically engaging sound.

Whether used as a standalone headphone amp or integrated into a high-end stereo system, the DCG3 delivers exceptional clarity, low distortion, and true reference performance.

0 notes

Text

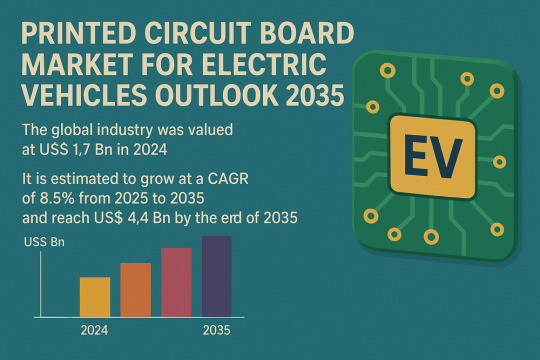

Smart Mobility Drives Smart PCBs: Market to Hit $4.4Bn by 2035

The global Printed Circuit Board (PCB) Market for Electric Vehicles (EVs) is set to witness significant expansion over the next decade, according to the latest market analysis. Valued at US$ 1.7 billion in 2024, the market is projected to grow at a CAGR of 8.5% from 2025 to 2035, reaching a valuation of US$ 4.4 billion by the end of the forecast period.

Market Overview: Printed Circuit Boards (PCBs) are the electronic backbone of electric vehicles, enabling power distribution, connectivity, and control across critical systems such as battery management, motor control, infotainment, and advanced safety features. With EV adoption accelerating globally, PCBs have become essential to the performance, reliability, and innovation of next-generation vehicles.

Market Drivers & Trends

One of the primary drivers of this market is the growing investment and strategic partnerships in the EV supply chain. Leading automakers and electronics companies are heavily investing in R&D and manufacturing capacity to meet the increasing demand for high-performance PCBs.

Moreover, the rise of autonomous and connected vehicles has made sophisticated electronics an indispensable part of modern transportation. The proliferation of features like ADAS (Advanced Driver-Assistance Systems), V2X communication, and in-vehicle infotainment is pushing the demand for compact, multi-layer, high-speed, and thermally efficient PCBs.

In 2023, EV sales in the U.S. surged by 60%, while the European Commission invested over US$ 6 billion in EV infrastructure further stimulating demand for advanced PCB solutions.

Latest Market Trends

The industry is witnessing a rapid shift toward flexible and high-density interconnect (HDI) PCBs, which are crucial for compact and space-saving vehicle designs. Flexible PCBs, in particular, are gaining traction in battery management systems and advanced sensor modules due to their lightweight and adaptable nature.

Additionally, regulatory advancements such as the FCC's allocation of the 5.9 GHz band for vehicle safety and autonomous functions have opened doors for new PCB capabilities. Real-time, high-speed data transmission requires advanced PCB materials and multi-layer configurations.

Key Players and Industry Leaders

Some of the most prominent players shaping the global printed circuit board market for electric vehicles include:

ABL CIRCUITS

AT&S Austria Technologie & Systemtechnik Aktiengesellschaft I

Chin Poon Industrial Co., Ltd.

Compeq Manufacturing Co., Ltd.

HannStar Board Corporation

Kinwong Electronic Co. Ltd

LG Innotek

MEIKO ELECTRONICS Co., Ltd.

Nan Ya Printed Circuit Board Corporation

RayMing PCB

Rush PCB Ltd.

SCHWEIZER ELECTRONIC AG

Shenzhen Capel Technology Co., Ltd.

Shenzhen Fastprint Circuit Tech Co., Ltd.

TTM Technologies

Unimicron Technology Corporation

Victory Giant Technology Co., Ltd.

WUS Printed Circuit Co., Ltd.

Young Poong Group

Zhen Ding Tech. Group

Among Others

These companies are prioritizing innovation, expanding global manufacturing footprints, and forging strategic alliances to maintain competitiveness and cater to evolving industry needs.

Download now to explore primary insights from our Report in this sample - https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=86464

Recent Developments

October 2024 – Mektech Manufacturing announced a 920 million baht investment in Thailand to expand production capacity for flexible PCBs and FPCBA used in electric vehicles.

July 2024 – Omron Electronic Components Europe launched a high-power PCB relay for Level 2 EV charging stations. The innovation features double-break contact designs, enabling reduced heat dissipation and enhanced energy efficiency.

Market Opportunities

The market is poised for significant opportunities, particularly in:

OEM collaborations to co-develop application-specific PCBs for power electronics and smart mobility.

Flexible PCB technology, which is expected to revolutionize EV design with lightweight, customizable circuit boards.

Geographical expansion into regions like South Asia and Latin America, where EV adoption is accelerating, and supply chains are emerging.

Additionally, the ongoing reshoring of PCB manufacturing in regions such as North America and Europe presents untapped potential for local players.

Future Outlook

According to analysts, the convergence of EV electrification, autonomy, and connectivity will demand ever more sophisticated PCB solutions. Next-generation EVs will require PCBs capable of managing 50 Gbps data speeds, robust thermal management, and high signal integrity. Flexible, multilayer, and ceramic PCBs are expected to gain ground rapidly.

As regulations around emissions and vehicle safety become more stringent, automakers will rely heavily on advanced PCB solutions to remain compliant and competitive. From battery optimization to smart in-vehicle systems, the demand for high-performance PCBs is set to skyrocket.

Market Segmentation

The global PCB market for EVs is segmented across several parameters:

By Type: Multilayer (dominant with 73.98% market share in 2024), Double-sided, Single-sided

By Substrate Type: HDI/Micro-via/Build-up, Flexible, Rigid-flex, Rigid 1-2 Sided

By Material: FR4, Metal-Based, Ceramic, PTFE, Power Combi-boards

By Application: ADAS, Battery Management, Powertrain, Lighting & Display, Charging, Connectivity, etc.

By Vehicle Type: Passenger Cars, Buses, Two-Wheelers, Trucks, Off-Highway Vehicles

By End Users: OEMs, Tier 1 & 2 Suppliers, Aftermarket

Regional Insights

East Asia is the undisputed leader in the global market, accounting for 68.3% of the total share in 2024. The region’s dominance stems from:

A well-established electronics manufacturing ecosystem

Government support for EV expansion and green technology

Cost-effective production and high R&D capabilities

Japan, South Korea, and China house the majority of leading PCB suppliers and EV component manufacturers. Their early investment in automation and material innovation is positioning East Asia as the global hub for EV electronics.

Other key regions include:

North America, driven by government initiatives like the CHIPS Act

Europe, focused on sustainable manufacturing and reducing supply chain reliance on Asia

South Asia, emerging as a low-cost, high-volume manufacturing zone

Why Buy This Report?

This in-depth industry report offers:

Detailed market sizing and forecast (2020–2035)

Comprehensive segmentation across product, material, vehicle type, and region

Competitive landscape with profiles of 20+ leading companies

Insights into trends, innovations, and regional dynamics

Strategic recommendations for stakeholders, investors, and policymakers

Whether you're an investor, OEM, component supplier, or policy planner, this report serves as a strategic guide to understanding growth dynamics and identifying emerging opportunities in the PCB market for electric vehicles.

Explore Latest Research Reports by Transparency Market Research: Active Optical Cable Market: https://www.transparencymarketresearch.com/active-optical-cables.html

3D Cameras Market: https://www.transparencymarketresearch.com/3d-cameras-market.html

Optoelectronics Market: https://www.transparencymarketresearch.com/optoelectronics-market.html

Machine Safety Market: https://www.transparencymarketresearch.com/machine-safety-market.html

DC-DC Converter OBC Market: https://www.transparencymarketresearch.com/dc-dc-converter-obc-market.html

About Transparency Market Research Transparency Market Research, a global market research company registered at Wilmington, Delaware, United States, provides custom research and consulting services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision makers. Our experienced team of Analysts, Researchers, and Consultants use proprietary data sources and various tools & techniques to gather and analyses information. Our data repository is continuously updated and revised by a team of research experts, so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports. Contact: Transparency Market Research Inc. CORPORATE HEADQUARTER DOWNTOWN, 1000 N. West Street, Suite 1200, Wilmington, Delaware 19801 USA Tel: +1-518-618-1030 USA - Canada Toll Free: 866-552-3453 Website: https://www.transparencymarketresearch.com Email: [email protected]

0 notes

Text

Structural Innovation and Easy Installation Technologies in Power Socket Design

As smart homes, office automation, and industrial digitalization rapidly advance, the demand for user-friendly, efficient, and safe power sockets continues to grow. Traditional socket designs are no longer sufficient for fast-paced environments that require high reliability, ease of installation, and space optimization. This has driven innovation in both internal structure and external mounting mechanisms of modern power sockets.

This article explores key advancements in structural design and installation technologies of power sockets, focusing on terminal innovations, mounting bracket designs, and strategies to increase module density without increasing volume. We will also discuss real-world examples and applicable technologies for B2B manufacturers and system integrators.

1. Integrated vs. Modular Terminal Design: Which is More Efficient?

The terminal structure of a power socket directly determines wiring efficiency and stability. The two mainstream types are:

A. Integrated Terminal Block (One-Piece)

All terminals are integrated into a single housing.

Benefits: Shorter installation time. Reduced loose contacts. Lower resistance due to shorter conductive paths.

Limitations: Less flexible for modular replacement. May increase overall production complexity.

B. Modular Terminal Block (Multi-Part)

Each terminal is separately assembled or replaceable.

Benefits: Ideal for custom configurations. Easier to repair and replace.

Limitations: Longer assembly time. Risk of performance inconsistency.

2. Push-in Spring Connection Technology: Fast, Safe, Tool-Free Wiring

Compared to screw terminals, push-in spring terminals provide:

Quick installation: Simply push the stripped wire into the terminal.

Strong contact: Stainless steel or beryllium copper springs maintain pressure for years.

No need for torque tools: Reduces operator training and tool investment.

🔧 Case Example: A European power socket brand uses a push-in spring design that allows a full 5-gang module to be wired in under 30 seconds — 60% faster than screw terminals.

3. Quick-Mount Bracket Designs: Screw-Free, Time-Saving, and Reliable

In large-scale installations (e.g., hotels, office buildings), fast mounting systems dramatically reduce labor costs and error rates.

Key Innovations:

A. Snap-In Mounting Frame

Socket modules are inserted directly into wall plates with audible clicks.

Uses elastic clips or sliding locks for firm placement.

Ideal for drywall and modular building systems.

B. Screwless Embedded Mounting

Eliminates screw holes by using slide-in rail structures.

Allows easy front-facing maintenance or upgrades.

Common in premium wall systems and panel furniture.

C. Magnetic or Cam-Lock Fastening

Applies in high-end modular offices.

Enables tool-free repositioning.

🔧 Case Example: A Chinese manufacturer developed a double-locking quick-install bracket that passed 500N pull force tests, suitable for vibration-prone environments like rail stations.

4. Increasing Module Density Without Expanding Volume

Modern installations demand multi-functionality in limited space. Techniques include:

A. Vertical Layering of Internal PCB

Using 3D layout: control, relay, and detection circuits are stacked.

Reduces horizontal footprint while maintaining thermal separation.

B. Multi-Function Integration

Combining USB chargers, smart sensors, and energy monitors in one unit.

Example: A 55x55mm wall socket includes 2 USB-A ports, 1 USB-C PD port, and Wi-Fi controller.

C. High-Density Terminal Design

Dual-row spring contacts with insulation barriers allow up to 10 terminals in standard footprint.

Ensures safety spacing while maintaining compact size.

5. Material Innovation: Making Structural Compactness Possible

A. High-Performance Plastics:

Use of PA66, PC+ABS, and flame-retardant PBT with thin-wall molding tech.

Improves space efficiency without sacrificing insulation performance.

B. Conductive Material Optimization:

Use of laminated copper busbars.

Electroplated or stamped silver contact surfaces to reduce thickness.

6. Installation Aids and Engineering Enhancements

A. Color-coded Wiring Guides:

Reduces wiring errors during bulk installations.

Accelerates compliance with local electrical codes.

B. Pre-assembled Harnesses:

For standard socket layouts, pre-assembled wire bundles reduce on-site labor.

C. Tool-Assisted Plug-In Systems:

Modular rail sockets with plug-in interfaces (e.g., DIN-rail smart outlets) improve interchangeability.

7. Structural Testing and Validation

8. Conclusion: Towards Smarter, Faster, and Denser Power Socket Design

Power socket structure and installation are no longer just mechanical tasks—they are core parts of user experience, energy efficiency, and engineering cost control. Through structural innovation like push-in terminals, quick-install brackets, and functional integration in compact modules, manufacturers can deliver plug-and-play, space-saving, and intelligent power socket solutions.

Whether you're a B2B buyer, an engineering contractor, or a systems integrator, adopting these next-generation socket designs will result in lower maintenance costs, faster deployment, and greater end-user satisfaction.

en.dghongju.com

0 notes

Text

Omron G2RL-1-E-DC24 Power Relay 24VDC 16A SPDT (1 Form C) Low Profile Relay

The Omron G2RL-1-E-DC24 is a high-performance general-purpose SPDT power relay with a 24V DC coil and 16A current rating. Designed for control panels, HVAC systems, automation and industrial devices it features 1 Form C contact (NO+NC) with robust silver alloy contacts and low-profile, through-hole mounting for compact PCBs.

Key Features:

Coil Voltage: 24V DC Contact Form: SPDT (1 Form C – NO+NC) Contact Rating: 16A Max Switching Voltage: 440 VAC / 300 VDC Coil Resistance: 1.44 kΩ Coil Current: 16.7 mA Power Consumption: 400 mW Mounting: Through Hole (Solder Pin)

📦 Bulk orders available – DM us or call to get the best price!

📞 Contact Today : +919810987429

📥 Enquire Now : [email protected]

#OmronRelay#24VRelay#SPDTRelay#1FormCRelay#G2RLRelay#GeneralPurposeRelay#PowerRelay#LowProfileRelay#HVACRelay#ControlPanelRelay#PCBRelay#OmronElectronics#RelayIndiaMart#AutomationRelay#IndustrialRelay

0 notes

Text

🧲💡 Ensure swift and secure switching with Enrgtech’s PCB Mount Reed Relay! Compact, reliable, and ideal for precision electronics��perfect for controllers, sensors, and automation circuits. Power your designs with confidence and efficiency today!#PCBMountReedRelay #Enrgtech #Electronics #SmartSwitching #CircuitDesign #ReliablePerformance

0 notes

Text

Open source 24-channel USB high-voltage driver

When it comes to automation and control systems, there's often a need for multiple digitally controlled output terminals with high-voltage handling capabilities. Many existing modules are bulky, expensive, or require numerous additional components to function. To address this gap, I've developed a fully open-source, USB-controlled 24-channel high-voltage driver. This device provides precise, flexible control in a compact and user-friendly package. The project is open hardware, released under the CERN-OHL-W license, ensuring transparency from hardware schematics to firmware code. The driver module communicates via USB using a simple virtual COM port, eliminating the need for special drivers and complex setups.

At the core of the system are three TPIC6B595 shift registers, each supplying eight open-drain outputs that can handle up to 50V and sink currents of up to 150mA per channel. These registers are daisy-chained to achieve a total of 24 outputs. The outputs are designed for low-side switching and include integrated clamping diodes, making them suitable for driving inductive loads such as relays and solenoids. Data is clocked into the registers through serial input from a microcontroller, allowing for fast and reliable state updates across all channels with just a few lines of code.

The logic and communication for this module are managed by the STC15W204S microcontroller, a cost-effective yet powerful 8051-based MCU with enhanced UART performance and an integrated oscillator. This chip is paired with a CH340N USB-to-UART bridge, which presents the device as a standard virtual COM port to the host PC. Upon connection, the microcontroller listens for a set of AT-style commands sent over the serial connection. These commands are straightforward and user-friendly, for example, "ON=65280" activates the middle 8 outputs, "CLR" turns off all channels, and "VER" retrieves the firmware version. Additionally, there is a command to save the current output state to the built-in EEPROM, enabling the system to restore its output to a known state after power cycles. This interface design is perfect for scripting, automation, or integration with software tools such as Python, LabVIEW, or custom control GUIs.

The PCB is designed using KiCad and features a 2-layer layout measuring 75.25mm × 33.75mm. It includes 2.54mm pitch headers for output connections and is equipped with a USB Type-C connector. Power can be supplied through either USB or an external regulated 5V source, which can be selected via onboard jumper settings. The layout ensures clean signal routing and minimizes crosstalk or interference, even when switching high-voltage loads. Careful decoupling and protection components provide robustness for real-world applications.

The PCB for this module was fabricated by PCBWay, who generously sponsored this project. PCBWay offers high-quality PCB manufacturing and assembling services. Also, they offer CNC and 3D printing services. The PCB of this module is available to order from PCBWay. Check out the PCBWay website for its manufacturing capabilities and pricing.

The firmware for the STC15W204S is written in C using SDCC. It is easy to expand the command set, introduce new communication modes, or add timed control logic as needed. The current implementation allows full 24-bit output control using a base 10 numerical mask, making it both scriptable and human-readable. Thanks to the preloaded bootloader of the STC15W204S, firmware updates can be performed through the same serial interface. Details about this process are covered in the project documentation. Like the hardware, the firmware is released under the MIT License and is available in the project repository.

The system has been tested with a variety of 12V and 24V inductive and resistive loads, including relay banks, solenoids, and LED arrays. Since the outputs are open-drain, external voltages up to 50V can be safely switched on each channel making it ideal for a range of industrial, laboratory, or artistic applications. Output timing is reliable, with clean edge transitions observed during scope testing, and no signal integrity issues even during full 24-channel toggling. It is recommended to use individual heatsinks for the driver ICs when driving high-current inductive loads with this module. While the printed circuit board has heat transfer traces, the addition of individual heatsinks can increase the durability of the module.

Potential use cases for this module include automated test benches, home automation systems, signal routing for instrumentation, nixie tube multiplexing, and other high-voltage control tasks. The command-based protocol makes it easy to script operations or integrate this module into a larger system.

For those who wish to explore the schematics, command protocol, design rationale, and usage examples in greater depth, I have published comprehensive documentation and resources in the project wiki. This includes detailed assembly instructions, firmware flashing guidance, and tips on customizing the firmware for enhanced functionality.

All source files - including schematics, PCB layout, firmware code, and the bill of materials - are freely available at https://github.com/dilshan/24ch-usb-high-voltage-driver.

0 notes