#Plastic Extrusion Process

Explore tagged Tumblr posts

Text

Know About The Potential of Plastic Extrusion Process

A manufacturing technique called plastic extrusion is used to make products with a predetermined cross-sectional profile. To form molten plastic into a continuous profile that can be cut to specified lengths, it is pushed through a die. Numerous items may be produced with this technique, ranging from straightforward pipes and tubes to intricate profiles utilized in packaging, automotive, construction, and other industries.

Flexibility in Utilization

Building: Plastic extrusion plays a key role in the building sector by creating pipes, profiles, and other parts that go into drainage systems, windows, doors, roofing, and plumbing. For example, extrusion is frequently used in the manufacturing of PVC and HDPE pipes because of its robustness and resistance to corrosion.

Consumer Products: The production of toys, furniture, and home appliances has benefited from the usage of the Plastic Extrusion Process. Custom profiles and complex designs may be produced with this technology, meeting the practical and aesthetic needs of many items.

Medical: Tubing, catheters, and other medical equipment are produced in the medical industry via plastic extrusion. The capacity to produce accurate, sterile parts guarantees adherence to strict legal requirements while satisfying the needs of medical practitioners and patients.

Benefits of Plastic Extrusion:

Cost-Effectiveness: Plastic extrusion provides affordable options for producing a variety of goods. Compared to alternative approaches, the process lowers material waste and needs less expensive tooling, making it a financially feasible option for large-scale manufacturing.

Design Flexibility: Manufacturers may design unique profiles and forms using plastic extrusion to satisfy certain specifications. In markets with intense competition, this flexibility promotes innovation and product differentiation.

Efficiency: The production of consistent profiles in continuous lengths with little downtime is possible through the very efficient process of plastic extrusion. This efficacy adds to overall operational effectiveness by translating into increased production and quicker turnaround times.

Material Versatility: PVC, HDPE, LDPE, PP, and ABS are just a few of the thermoplastic materials that may be used with plastic extrusion. Because of its adaptability, plastic extrusion manufacturer may choose the material that best suits their needs by weighing characteristics like strength, flexibility, and chemical resistance.

2 notes

·

View notes

Text

I remember when 3D printers first became a thing and there was a huuuge hype about how you could 3D print anything and it would revolutionize everything

And then there was a phase of fussing around realizing that there are actually some unintuitive constraints on what shapes are printable based on slicing and support of overhangs, and how you have to do fiddly business like putting tape on the platform and watching the first couple layers like a hawk or it can detach and slump sideways and become a big horrible useless mess

And then, after all that, people kinda came around to realize that even if you get all that sorted, the object you've made is fundamentally an object made of moderately-well-adhered layers of brittle plastic, which is actually a pretty shitty material for almost every purpose.

And aside from a few particular use cases the whole hype just sort of dropped off to nothing.

Anyway I feel like we're seeing pretty much the same arc play out with generative AI.

#the major difference I think being that genAI does not allow you to make an unregistered gun.#Which as far as I know is the most significant lasting impact case for 3D printing.#And yes believe me I know that there are other forms of 3D printing beyond pla extrusion BUT all of them are fiddly enough#that they are functionally fabrication processes rather than 'haha just print it!!'#The whole big hype was about the intuitive ease of layered plastic printing and the cheapness and diy-ability of the setup of such a printe#This also works as a metaphorical parallel because there's likewise forms of machine learning for data processing that produce#useable outputs in specific fields. But those are software tools witb specific use cases#And not generic chatbot garbledegook.#The point I'm driving at here is that a chatgpt essay is equivalent to a pla printed coffee mug in terms of#'wow that's an object of such low quality as to be entirely pointless. Why did you make that.'

2 notes

·

View notes

Text

Secondary processing technology of ABS plastics: a new way to expand the application field

In the plastic processing industry, ABS plastics (acrylonitrile-butadiene-styrene copolymer) are highly favored for their excellent mechanical properties, processing performance and surface gloss. However, with the advancement of science and technology and changes in market demand, the single performance of ABS plastics has been difficult to meet the increasingly diverse application scenarios.…

#ABS plastic#extrusion molding#injection molding#modification technology#mold design#secondary processing technology#surface treatment technology#thermoforming

0 notes

Text

Plastic Processing Machinery Industry: A Critical Component of the Circular Economy

Global plastic processing machinery industry data book is a collection of market sizing information & forecasts, competitive benchmarking analyses, macro-environmental analyses, and regulatory & technological framework studies. Within the purview of the database, such information is systematically analyzed and provided in the form of outlook reports and summary presentations on individual areas of research.

The market incorporates a wide range of equipment used in the manufacturing and processing plastic products, including injection molding machines, blow molding machines, extrusion machines, and more. The demand for plastic products across various industries, such as packaging, automotive, electronics, and construction, has been a key driver for the expansion of this market.

Access the Global Plastic Processing Machinery Industry Data Book, 2023 to 2030, compiled with details like market sizing information & forecasts, trade data, pricing intelligence, competitive benchmarking, macro-environmental analyses, and regulatory & technological framework studies.

Plastic Injection Molding Machine Market Report Highlights

The plastic injection molding machine market was estimated at approximately USD 11.75 billions in 2022, growing at a CAGR of 4.8% from 2023 to 2030 according to a new report by Grand View Research, Inc. The increasing adoption of plastic injection molding machines in the automotive, electronics, and packaging industries is likely to be the key driver for the growth of the industry over the forecast period.

Plastic injection molding is suitable for producing various exterior automotive components such as mudguards, door panels, wheel arches, grilles, trunk trims, front and rear covers, and outside car door trims. Automotive injection molding is an important manufacturing process in the automotive industry, where safety, consistency, and quality are critical.

The automobile end-use category accounts for a sizable portion of the injection molding machine market. A variety of automobile parts, such as outer body panels, bumpers, spoilers, dashboards, and electrical housings, are made using plastic injection molding machines. Many automotive interior parts are manufactured using plastic injection molding as well as the instrumentation components, interior surfaces, glove boxes, dashboard faceplates, air vents, and other items. Rapid growth in demand for automotive components has boosted global automobile production, resulting in a high demand for injection-molded parts in the automotive industry.

Plastic injection molding is utilized for the formation of plastic packaging for a variety of applications and in a variety of forms. The injection method is used to manufacture food and beverage containers, creatively designed body care packaging, and even packaging for household chemicals. The plastic injection molding technique solves problems related to barrier protection, handling, product visibility, salability, and aesthetics.

Plastic Extrusion Machinery Market Report Highlights

The global plastic extrusion machine market size is expected to reach USD 6.41 billions in 2022, expanding at a CAGR of 4.4% from 2023 to 2030, according to a new report by Grand View Research, Inc. Increasing penetration of plastics in the manufacturing of consumer electronics is expected to be one of the critical factors for the growth of plastic extrusion machine. In addition, plastic extruded parts are widely used for manufacturing structures & bodies of television sets, video recorders, cameras, and laptops. Moreover, motor housings and interior frames are manufactured using the extrusion process.

The demand for plastic extrusion machine is rising owing to the ability of plastics to be formed into complex shapes and the relative ease compared to metals or ceramics. Moreover, surged usage of engineering-grade plastics for producing pipe, fencing, window frames, plastic films, wire insulation, and deck railing is anticipated to grow during the forecast period.

Plastic extruded parts provide a solution for high volume and cost-efficiency. The recent trend of lightweight in the automotive industry to enhance fuel efficiency has resulted in increased use of plastic extruded parts coupled with the growing adoption of extruded products in the packaging industry is projected to drive the market of plastic extrusion machines over the forecast period.

The demand for plastic extruded products has been on the rise for several years because of several advantages of the extrusion process and the rising demand from end-use industries such as automotive, electronics, consumer goods, telecommunications, and renewable energy. Moreover, the low cost per part, flexibility in operation, high production volume, and compounding ability are the other factors responsible for the growing demand for extruded plastic and metal products.

Order your copy of Free Sample of “Plastic Processing Machinery Industry Data Book - Plastic Injection Molding Machine, Plastic Extrusion Machinery, Plastic Blow Molding Machine Market Size, Share, Trends Analysis, And Segment Forecasts, 2023 - 2030” Data Book, published by Grand View Research

Plastic Blow Molding Machine Market Report Highlights

The global plastic blow molding machine market size is anticipated to reach USD 2.97 billions in 2022, growing at 3.9% CAGR from 2023 to 2030, according to a new report by Grand View Research, Inc. High demand for packaged goods in the food and beverage industry, increasing use of plastic blow molding machines in the production of industrial and automotive components, and rising need for plastic packaging solutions in the pharmaceutical industry are major factors driving market revenue growth.

In addition, the machines are widely used in several applications and sectors including plastic packaging, chemical, automobile, pharmaceuticals, lubricants, edible oils, FMCG, and others. The surge in demand for sanitizing and cleaning products fueled the adoption of blow molding machines to manufacture sanitizers, hand soaps, and hydrogels.

Plastic packaging alternatives are in high demand in the pharmaceutical business because they protect drugs from contamination and extend their shelf life. Plastic blow molding machines are used to create containers, plastic bottles, and vials, often used as packaging materials in the pharmaceutical industry. For instance, Bekum Maschinenfabriken GmbH announced the introduction of the BM 902D, a new, high-performance blow molding machine, in 2021. The machine has a cutting-edge hydraulic system and an intuitive user interface and is built to create massive parts with excellent precision and productivity.

Growing preferences for molded plastic products, rising demand due to the material's flexibility, rising demand due to the prevalence of low labor costs, and low waste production are some of the factors that will likely propel the growth of the plastic blow molding machine industry over the forecast period. On the other hand, as technology continues to progress, it will create more potential for the market for plastic blow molding machines to expand over the coming years. For instance, Taiwan-based Parker Plastic Machinery Co. Ltd., a producer of plastic blow molding machines, offers its fully electric plastic blow molding machines. It is growing in recognition for its high-performance hydraulic power-saving technology.

Key players operating in the Plastic Processing Machinery Industry are –

• Arburg GmbH + Co KG. • KraussMaffei • Haitian International • Milacron • Nissei Plastic Industrial Co. Ltd. • ENGEL AUSTRIA GmbH. • Chen Hsong Holdings Limited • UBE Machinery Corporation, Ltd. • Husky Injection Molding Systems Ltd.

#Plastic Processing Machinery Industry#Plastic Processing Machinery Market#Plastic Injection Molding Machine Industry Trends Data Book#Plastic Extrusion Machinery Market Size#Plastic Blow Molding Machine Market Share#Plastic Blow Molding Machine Market Growth#Plastic Processing Machinery Sector Report

0 notes

Text

Forge Ahead with Virat’s H13 Steel!

Virat Special Steels takes pride in offering high-quality Aluminium Extrusion Die Steel H13 Steel – a true pinnacle of durability and performance in every extrusion process.

Application Areas:🔧

Die Casting: H13 (DIN 1.2344) Steel is highly recommended for aluminum pressure die casting due to its exceptional performance under high working temperatures and pressure.

Forging Dies: It withstands rapid cooling and early heat testing, making it suitable for forging applications.

Plastic Moulds: H13 is used in injection molding with high polishability.

Quality Assurance:✅ Virat Special Steels ensures that H13 (DIN 1.2344) steel is fully ultrasonic inspected with 100% positive results as per NDT standards. It meets the requirements for safety and reliability.

Choose VIRAT SPECIAL STEELS PVT. LIMITED , INDIA for your Aluminium Extrusion Die Steel needs, and experience quality and reliability!

Contact us today to learn more! https://www.viratsteels.com/h13.html https://www.viratsteel.in/materials/aluminium-extrusion-die-steel-supplier-in-india/

Any further queries feel free to contact us : 🌐https://www.viratsteels.com 📬 [email protected] ☎+91 98140-21775

#ludhiana#india#viratsteels#gurgaon#viratspecialsteels#toolsteelsupplier#gurugram#pune#iso9001#steel#H13Steel#din 2344#aluminium extrusion#Die Steel H13 Steel#DieSteels#ToolSteel

3 notes

·

View notes

Text

This is the first entry for my process journal on modeling and printing a 3D figure.

The first thing to note is I have not had any prior experience with 3D modeling or printing before starting this project. My dad, however, has a 3D printer (Ender 3 Pro) that he uses often. He is also somewhat familiar with the 3D modeling program Blender, so that is the program I decided to learn.

Before starting to learn Blender, I drew a simple design of the pose and elements of my figure (image 1). The figure is of a character from a story I am currently writing—he is an angel who wears a cloak and has two sickles as weapons. I had a feeling this would be quite the undertaking for a beginner, but I also didn’t know how quickly I would pick up Blender. If I was going to learn it quickly, I wanted to have enough elements to really challenge myself with.

Once I downloaded Blender, my dad showed me the basics: how to move, scale, and rotate objects; how to add new objects and create meshes; and how to apply modifiers to an object. I also messed around a bit on my own, sculpting a circle to look like a head (image 2). However, I was going to need to learn more in order to create a full figure.

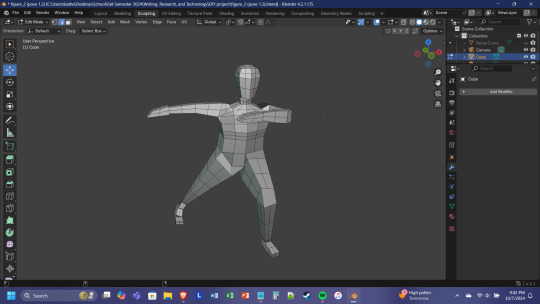

I found this YouTube tutorial by PIXXO 3D which showed me how I could model an entire figure from just a single cube. This video introduced me to mirroring and extrusion, as well as how objects can be altered by selecting and editing a single face. These new techniques allowed me to create first a torso and then limbs and a head by creating new shapes that were attached to preexisting ones. Once I learned how the techniques worked, I used the video as an example but tried to shape the figure on my own (image 3). I did run into some difficulties since the tutorial used an older version of Blender. There were certain ways of morphing an object that didn’t work the way the video showed, and so I had to figure out a different way to achieve the same effect.

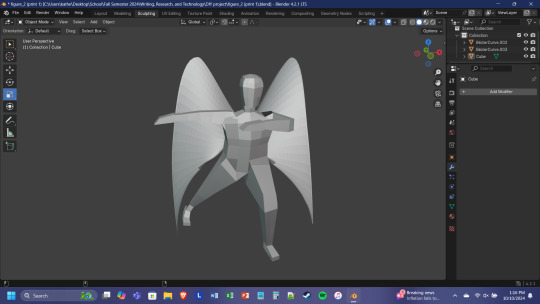

After creating a full figure, I then had to pose it. I figured the best way to do so would be to separate the model into pieces that I could rotate and arrange independently of each other (image 4). (You can also see I was messing around with how to create wings—more on that later.) I moved the pieces around, splitting some of them further to achieve the pose that I wanted (image 5). Once the pose was complete, I figured out how to fill in the gaps: by selecting the edges of the gap, I was able to create a new face that joined the pieces together (image 6).

As for the wings, I came up with a technique involving bézier curves. By creating a curve, connecting it in a loop, and then subdividing it with multiple points, I was able to manipulate it into the exact shape I wanted the wing to be. Then I could convert it to a mesh and use grid fill to fill in the shape. I did run into an issue where the fill wasn’t even—there was some weird wrapping going on at the bottom, probably because of how the curve was oriented. But I decided to use it as it was for the moment—I’ll redo the wings later.

I mirrored the wing I’d made and set both of them into the back of the figure (image 7). This was a rough prototype and I wanted to try and print it. I sent my dad the .stl file and he put it into UltiMaker Cura, a program for splicing. Splicing takes a 3D model and figures out what the layers have to be for it to be printed. There were some parts that lacked support because they were hanging in the air (the hands and the wingtips), so my dad showed me how to put supports in that could easily be removed after printing. We scaled the figure to be four inches high and could see the printing would take about three hours.

This was where things got tricky. The first print attempt ended with a big spirally ball of plastic. It seemed the wings were too thin and would need more supports, otherwise the plastic wouldn’t stick to itself and would end up creating a mess. The second print went better, although there were still problems with it—namely, the torso fell out of the body (image 8). The rest of it was in decent shape, but it seems I’ll have to do some work to strengthen the connections. I assume this will involve thickening the objects in Blender so they have more surface area melding them together.

So far, I’ve been able to get the hang of Blender fairly well. This surprised me a bit, although I have had experience with photo-manipulation programs (GIMP) before, so maybe that is helping me more than I thought it would. I am glad the modeling portion is going smoothly, however, since it looks like the printing stage is going to require more finagling than I initially thought.

3 notes

·

View notes

Text

Best Link Scrap Inc.: Leading the Way in Sustainable LDPE and LLDPE Recycling

In the ever-evolving world of recycling and environmental responsibility, Best Link Scrap Inc. has emerged as a prominent leader and trusted partner in the global scrap industry. With a strong commitment to quality, consistency, and environmental stewardship, the company specializes in the sourcing, supply, and export of LDPE (Low-Density Polyethylene) and LLDPE (Linear Low-Density Polyethylene) scrap materials. As demand for sustainable solutions continues to rise, Best Link Scrap Inc. stands at the forefront—connecting industries with the resources they need to reduce waste, recycle efficiently, and support a circular economy.

Pioneers in LDPE and LLDPE Scrap Supply Best Link Scrap Inc. has dedicated years to perfecting its role as a top-tier supplier of various types of plastic scrap, including:

LDPE film roll scrap

LDPE film scrap

LDPE lump scrap

LLDPE film roll scrap

These materials are essential for a wide range of industries—from packaging and construction to consumer goods and manufacturing. By focusing specifically on these two high-demand polymers, the company has carved out a specialized niche in the plastics recycling sector.

LDPE Film Roll Scrap and LLDPE are widely recognized for their flexibility, chemical resistance, impact tolerance, and moisture barrier properties. These thermoplastics are extensively used in everyday products such as plastic bags, stretch wraps, agricultural films, and liners. However, their widespread use has also led to increasing environmental concerns related to disposal and pollution. Best Link Scrap Inc. is helping to change that narrative by offering sustainable recovery and reuse solutions.

A Reliable and Responsive Supply Chain What truly distinguishes Best Link Scrap Inc. is its robust sourcing network and highly responsive logistics operation. With connections across multiple continents, the company ensures a steady and timely supply of plastic scrap to recyclers, compounders, and manufacturers worldwide.

Whether you're sourcing:

LDPE film rolls for reprocessing into pellets,

LDPE lumps for extrusion and molding applications, or

LLDPE rolls for stretch film production,

you can rely on Best Link Scrap Inc. for timely delivery, competitive pricing, and verified material quality.

Every shipment undergoes rigorous inspection and quality control protocols. The company works hand-in-hand with vetted collection centers, industrial waste sources, and material recovery facilities to make sure all materials are clean, sorted, and compliant with international recycling standards. This ensures peace of mind for clients who rely on consistent input materials for their recycling processes.

Environmental Commitment at the Core At the heart of Best Link Scrap Inc. lies a deep commitment to sustainability. The company’s operations are designed to support a circular economy—an approach that emphasizes reuse, repurposing, and resource efficiency. By recovering LDPE and LLDPE from industrial and post-consumer sources and redistributing them to manufacturers and recyclers, the company helps prevent plastic waste from ending up in landfills or polluting the environment.

This not only reduces the carbon footprint of plastic production but also supports global efforts to reduce plastic pollution and promote responsible resource management. From energy savings to emission reduction, the environmental benefits of recycling plastic scrap are immense—and Best Link Scrap Inc. is proud to be playing an active role in that transformation.

Moreover, the company promotes education and advocacy around recycling best practices. By encouraging industry players to adopt sustainable sourcing and waste reduction strategies, Best Link Scrap Inc. is helping to create long-lasting, eco-conscious change.

What Sets Best Link Scrap Inc. Apart? Several factors contribute to Best Link Scrap Inc.’s success and make it a preferred choice for LDPE and LLDPE scrap sourcing:

Specialized Expertise Rather than dealing with general scrap materials, the company focuses exclusively on LDPE and LLDPE. This niche approach allows the team to develop in-depth technical knowledge of polymer grades, processing requirements, and market trends—providing tailored solutions to meet client-specific needs.

Global Presence With active partnerships across North America, Europe, Asia, and the Middle East, Best Link Scrap Inc. serves a diverse clientele. Whether you are a local recycler looking to secure consistent feedstock or an international buyer sourcing at scale, the company has the reach and resources to fulfill your demand.

Transparent, Honest Dealings Integrity and transparency are non-negotiable at Best Link Scrap Inc. The team believes in building long-term relationships through open communication, detailed documentation, and ethical business practices. Clients are kept informed at every stage of the transaction, from pricing and packaging to shipment and delivery.

Flexible Volume and Customization Whether your operation requires small test batches or bulk full-container loads, Best Link Scrap Inc. can scale supply to suit your business. The company also offers custom sorting, grading, and packaging options based on your specific application requirements.

Product Portfolio: Quality That Meets Industry Demands Best Link Scrap Inc. supplies a wide range of LDPE and LLDPE scrap materials, carefully processed and prepared for industrial reuse:

LDPE Film Roll Scrap: Clean, baled film rolls ideal for converting into pellets or reprocessing for blown film applications.

LDPE Film Scrap: Sourced from post-industrial and post-consumer streams; sorted for consistency and ease of handling.

LDPE Lump Scrap: High-purity lumps, often generated from purging during manufacturing; suitable for extrusion and injection molding.

LLDPE Film Roll Scrap: Excellent for flexible packaging, stretch wrap, and liner bag production, available in various grades and thicknesses.

Each product is backed by thorough documentation and grading reports, ensuring recyclers receive material that meets their quality and compliance standards.

Trusted by Industry Leaders Worldwide Over the years, Best Link Scrap Inc. has earned the trust and loyalty of some of the world’s leading recyclers, processors, and plastic product manufacturers. Its customer-centric approach, combined with a dedication to quality and reliability, has led to long-term partnerships and repeat business across the globe.

From startup recyclers looking for dependable scrap sources to large-scale manufacturers needing consistent raw material input, Best Link Scrap Inc. continues to deliver value and trust with every shipment.

Join the Circular Revolution Plastic pollution is one of the most pressing environmental challenges of our time. But by working together—across borders, industries, and supply chains—we can turn this challenge into opportunity.

Best Link Scrap Inc. invites recyclers, converters, manufacturers, and sustainability-minded businesses to join the circular economy movement. Let’s build a greener future, one load of plastic scrap at a time.

For quotes, inquiries, or more information on LDPE film rolls, LDPE lumps, or LLDPE scrap products, reach out to Best Link Scrap Inc. today.

Let’s recycle smarter—together.

Tel: 5029176667

Ema!l: sales(AT)bestlinkscrap.com

web: bestlinkscrap.com

1 note

·

View note

Text

Effervescent tubes have revolutionised the pharmaceutical and nutraceutical industries, becoming the go-to solution for packaging effervescent tablets. As a prominent name in the sector, NBZ Healthcare, located in Mumbai, stands at the forefront of exceptionally effervescent tube manufacturing, ensuring quality and innovation.

In this article, we delve deep into the manufacturing of effervescent tubes, their applications, benefits, and the unparalleled expertise of NBZ Healthcare in this domain.

Understanding Effervescent Tubes

Effervescent tubes are specialised containers designed to store and preserve effervescent tablets. These tablets, when exposed to moisture or air, tend to lose their potency, necessitating robust, moisture-resistant packaging. Effervescent tubes, often crafted with airtight and tamper-proof caps, provide the ideal solution to ensure the longevity and effectiveness of these tablets.

Importance of Effervescent Tubes

Effervescent tubes are more than just packaging; they play a crucial role in the pharmaceutical and nutraceutical industries by:

1. Protecting Product Integrity:

- Shielding tablets from moisture and air.

- Preventing degradation of active ingredients.

2. Enhancing Consumer Experience:

- Easy to open and reseal.

- Portable and convenient for on-the-go consumption.

3. Ensuring Regulatory Compliance:

- Meeting stringent health and safety standards for pharmaceutical products.

4. Sustainability:

- With increasing focus on eco-friendly materials, many effervescent tubes are now designed to be recyclable or biodegradable.

Effervescent Tube Manufacturing Process

Effervescent tube manufacturing is a precise and technologically driven process. At NBZ Healthcare, we combine state-of-the-art machinery with strict quality control measures to produce exceptional effervescent tubes. Here’s an overview of the key stages:

1. Material Selection

- High-grade plastic materials such as polypropylene (PP) or polyethylene (PE) are used.

- Materials are selected based on moisture resistance, durability, and eco-friendliness.

2. Tube Extrusion

- Plastic granules are melted and extruded into tube-like shapes using extrusion machines.

- The dimensions and thickness are carefully controlled to meet industry standards.

3. Moulding

- Injection moulding is used to form the caps and closures of the tubes.

- Caps are designed to ensure an airtight seal and tamper resistance.

4. Printing and Branding

- Tubes are labelled or printed with product details, branding, and regulatory information.

- Advanced printing techniques ensure durability and clarity.

5. Quality Control

- Rigorous testing for moisture resistance, durability, and compatibility with effervescent tablets.

- Each tube undergoes inspection to ensure zero defects.

NBZ Healthcare: Redefining Effervescent Tube Manufacturing

As a leader in exceptionally effervescent tube manufacturing, NBZ Healthcare sets the benchmark for quality and innovation. Based in Mumbai, our facility is equipped with cutting-edge machinery and a dedicated team of professionals who prioritise precision and excellence.

What Sets NBZ Healthcare Apart?

1. Advanced Manufacturing Capabilities

- NBZ Healthcare utilises the latest extrusion and moulding technologies to produce high-quality tubes.

2. Customisation Options

- We offer custom designs, sizes, and branding options to cater to the unique needs of our clients.

3. Sustainable Practices

- Focused on reducing environmental impact, we incorporate eco-friendly materials and processes wherever possible.

4. Regulatory Compliance

- Our manufacturing processes comply with international standards, including ISO and FDA regulations.

5. Global Reach

- While based in Mumbai, NBZ Healthcare serves clients across India and internationally, ensuring timely delivery and exceptional service.

Applications of Effervescent Tubes

Effervescent tubes find applications in various sectors, including:

1. Pharmaceuticals:

- Storage of vitamins, supplements, and medications in effervescent tablet form.

2. Nutraceuticals:

- Packaging for dietary supplements and health-boosting effervescent tablets.

3. Food and Beverage:

- Containment of flavour-enhancing or health-focused effervescent powders and tablets.

4. Personal Care:

- Packaging for effervescent bath tablets or other similar products.

Innovations in Effervescent Tube Manufacturing

At NBZ Healthcare, innovation is at the heart of our operations. Here are some of the cutting-edge advancements we incorporate:

1. Smart Packaging Solutions

- Tubes embedded with QR codes or NFC tags for enhanced consumer engagement and traceability.

2. Enhanced Moisture Resistance

- Using desiccant-lined caps and advanced sealing technologies to further improve moisture protection.

3. Eco-Friendly Materials

- Transitioning to biodegradable plastics and exploring sustainable alternatives like biopolymers.

4. Automation and AI Integration

- Automated production lines ensure consistency and reduce manufacturing errors.

- AI systems monitor quality in real-time for enhanced accuracy.

Challenges in Effervescent Tube Manufacturing

While effervescent tube manufacturing offers immense potential, it comes with its own set of challenges, such as:

1. Material Costs:

- Balancing quality and affordability when sourcing raw materials.

2. Environmental Concerns:

- Reducing the carbon footprint of manufacturing processes.

3. Regulatory Compliance:

- Adhering to diverse regulatory standards across different markets.

4. Consumer Expectations:

- Meeting the growing demand for sustainable and innovative packaging solutions.

The Future of Effervescent Tube Manufacturing

The demand for effervescent tubes is expected to rise significantly as more consumers turn to effervescent products for their convenience and efficiency. NBZ Healthcare is well-positioned to lead this growth, with a focus on:

1. Sustainability Initiatives

- Introducing greener manufacturing processes and materials.

2. Global Expansion

- Reaching untapped markets to provide high-quality effervescent tubes worldwide.

3. Product Diversification

- Expanding into new applications and industries beyond pharmaceuticals and nutraceuticals.

4. Technological Upgrades

- Adopting emerging technologies to enhance efficiency and product quality.

Why Choose NBZ Healthcare for Effervescent Tubes?

At NBZ Healthcare, we combine years of expertise with a commitment to innovation and customer satisfaction. When you partner with us, you’re choosing:

- Unmatched Quality: Every tube is crafted with precision and care.

- Custom Solutions: Tailored to your product’s specific needs.

- Reliable Service: Consistent and timely delivery of all orders.

- Sustainable Values: Supporting environmentally responsible practices.

Conclusion

Effervescent tubes play a pivotal role in preserving the efficacy and quality of effervescent tablets. With NBZ Healthcare’s expertise in exceptionally effervescent tube manufacturing, businesses can rely on robust, high-quality packaging solutions tailored to their needs.

As a Mumbai-based pioneer in the industry, NBZ Healthcare continues to set the standard for excellence, innovation, and sustainability. Whether you’re in the pharmaceutical, nutraceutical, or any related industry, NBZ Healthcare is your trusted partner for exceptional effervescent tube solutions.

Reach out to us today and experience the difference in quality and service!

2 notes

·

View notes

Text

Polycarbonate Sheet Market: A $1.88 Billion Opportunity You Can’t Ignore

Introduction

Polycarbonate sheets have emerged as a preferred material across multiple industries due to their superior properties, including high impact resistance, optical clarity, and lightweight nature. These thermoplastic sheets find widespread applications in sectors such as construction, automotive, electronics, and packaging. This article provides a comprehensive analysis of the polycarbonate sheet market, including key trends, market drivers, challenges, and future projections.

Request Sample Report PDF (including TOC, Graphs & Tables): https://www.statsandresearch.com/request-sample/40642-global-polycarbonate-sheet-market

Polycarbonate Sheet Market Overview

The global polycarbonate sheet market is experiencing robust growth, driven by increasing demand from end-use industries. The market is characterized by innovations in manufacturing processes, rising adoption of sustainable materials, and expanding applications in high-performance engineering sectors.

Get up to 30%-40% Discount: https://www.statsandresearch.com/check-discount/40642-global-polycarbonate-sheet-market

Key Polycarbonate Sheet Market Segments

The polycarbonate sheet market is segmented based on type, application, end-use industry, and region.

By Type

Solid Polycarbonate Sheets: Known for their strength and transparency, used in applications such as protective barriers and machine guards.

Multiwall Polycarbonate Sheets: Provide excellent thermal insulation, ideal for roofing and skylights.

Corrugated Polycarbonate Sheets: Lightweight and durable, commonly used in agricultural and industrial buildings.

Textured Polycarbonate Sheets: Enhance privacy and aesthetics, often used in interior design and architectural applications.

By Application

Construction & Architecture: Roofing, glazing, skylights, and façade panels.

Automotive & Transportation: Headlamp covers, windshields, and lightweight vehicle components.

Electrical & Electronics: LED light covers, display panels, and insulating sheets.

Industrial & Security: Machine guards, bulletproof panels, and riot shields.

Medical & Healthcare: Face shields, sterilization trays, and medical device housings.

By End-Use Industry

Building & Construction

Automotive & Aerospace

Electronics & Electrical

Healthcare & Medical

Packaging & Signage

Polycarbonate Sheet Market Drivers

1. Growing Demand for Lightweight and Durable Materials

Polycarbonate sheets offer a high strength-to-weight ratio, making them a preferred alternative to glass and acrylic in various industries.

2. Rising Adoption in Sustainable Construction

Energy-efficient buildings require materials with high insulation properties. Multiwall polycarbonate sheets help reduce heating and cooling costs, making them an eco-friendly option.

3. Advancements in Manufacturing Technologies

Innovations such as UV-resistant coatings, anti-scratch surfaces, and improved extrusion techniques are enhancing product performance and durability.

4. Expanding Use in Electric Vehicles (EVs)

The automotive industry’s shift toward lightweight materials to improve fuel efficiency and extend battery life in EVs is driving the demand for polycarbonate sheets.

5. Increased Demand in Security and Safety Applications

Polycarbonate sheets are extensively used in bulletproof glazing, riot shields, and safety barriers due to their high impact resistance.

Polycarbonate Sheet Market Challenges

1. High Production Costs

The complexity of manufacturing high-quality polycarbonate sheets leads to elevated costs, making affordability a challenge in price-sensitive markets.

2. Fluctuating Raw Material Prices

Polycarbonate production relies on petroleum-based raw materials, making the market vulnerable to crude oil price volatility.

3. Environmental Concerns Related to Plastic Usage

Despite being recyclable, improper disposal and concerns about microplastics have raised sustainability issues in the polycarbonate market.

Polycarbonate Sheet Market Regional Analysis

North America

Strong presence of the construction and automotive industries.

High demand for impact-resistant materials in security applications.

Europe

Growth driven by stringent energy regulations and sustainable building initiatives.

Rising investments in electric vehicle production.

Asia-Pacific

Leading polycarbonate sheet market due to rapid urbanization and industrialization.

Increasing manufacturing activities in China, India, and Japan.

Middle East & Africa

Growing infrastructure projects fueling polycarbonate sheet demand.

High adoption in temperature-resistant glazing applications.

Latin America

Expanding construction and automotive industries in Brazil and Mexico.

Increasing demand for lightweight materials in industrial applications.

Competitive Landscape

The polycarbonate sheet market is highly competitive, with key players focusing on innovation, strategic partnerships, and geographic expansion.

Major Companies

Covestro AG

SABIC

Mitsubishi Chemical Corporation

Evonik Industries AG

Teijin Limited

Plazit-Polygal Group

3A Composites GmbH

Future Outlook

The polycarbonate sheet market is poised for significant expansion, driven by technological advancements and increased adoption in sustainable applications. Key future trends include:

Enhanced recyclability and bio-based polycarbonates.

Growth in smart glazing technologies for intelligent buildings.

Increased 3D printing applications using polycarbonate materials.

Rising customization in automotive designs with polycarbonate components.

Purchase Exclusive Report: https://www.statsandresearch.com/enquire-before/40642-global-polycarbonate-sheet-market

Conclusion

The polycarbonate sheet market is witnessing rapid evolution, propelled by diverse applications, technological progress, and sustainability initiatives. As industries continue to seek lightweight, durable, and energy-efficient materials, the demand for polycarbonate sheets is expected to soar. Companies that focus on innovation, cost efficiency, and environmental responsibility will secure a competitive edge in this dynamic market.

Our Services:

On-Demand Reports: https://www.statsandresearch.com/on-demand-reports

Subscription Plans: https://www.statsandresearch.com/subscription-plans

Consulting Services: https://www.statsandresearch.com/consulting-services

ESG Solutions: https://www.statsandresearch.com/esg-solutions

Contact Us:

Stats and Research

Email: [email protected]

Phone: +91 8530698844

Website: https://www.statsandresearch.com

#Polycarbonate Sheet Market#Polycarbonate Sheets#Polycarbonate Roofing#Polycarbonate Panels#Transparent Roofing#Plastic Sheets#Building Materials#Construction Materials#Greenhouse Panels#Polycarbonate Industry#Polycarbonate Market Trends#Polycarbonate Suppliers#Lightweight Roofing#UV Resistant Sheets#Impact Resistant Plastic#Polycarbonate Sheet Price#Polycarbonate Sheet Manufacturers#Polycarbonate Applications#Roofing Solutions#Sustainable Building Materials

1 note

·

View note

Text

How High-Performance Stretch Film Transforms Shipping in Vietnam

Efficient shipping is becoming increasingly vital in Vietnam's booming economy. From bustling markets to high-tech industrial zones, the need for effective transportation and secure packaging has never been greater. Enter high-performance stretch film—a game-changer that's transforming the way Vietnamese businesses handle shipping. This guide will show you how high-performance stretch film can enhance your shipping processes, reduce costs, and improve overall efficiency.

The Basics of Stretch Film

What is Stretch Film?

Stretch film is a highly stretchable plastic film used to wrap products on pallets, ensuring they remain secure during transit. Its primary purpose is to hold loads tightly together, preventing them from shifting, tipping, or getting damaged. This makes it an essential tool in the shipping and logistics industry.

Types of Stretch Film

There are two main types of stretch film—cast and blown. Cast stretch film is produced using a continuous process called casting, which results in a clear, glossy film. It offers excellent clarity, making it easier to identify wrapped products. On the other hand, blown stretch film is manufactured using a blown extrusion process, resulting in a more robust and tear-resistant film with a matte finish. Each type has its own strengths and is suitable for different applications.

Key Attributes of High-Performance Stretch Film

High-performance stretch film boasts several key attributes that set it apart from standard films. These include superior stretchability, puncture resistance, and load retention capabilities. These features ensure that high-performance stretch film provides better protection and stability for your shipments, making it an invaluable asset in the shipping process.

Selecting the Right Stretch Film for Your Needs

Factors to Consider

Choosing the right stretch film involves considering several factors, including the size and weight of your load, as well as the shipping conditions. Heavier loads may require a thicker, more robust film, while lighter loads can be secured with a thinner film. Additionally, consider the shipping environment—will your products be exposed to extreme temperatures or rough handling? These factors will help determine the most suitable stretch film for your needs.

Environmental Considerations

In today's environmentally conscious world, opting for sustainable and eco-friendly stretch films can make a significant difference. Look for films made from recyclable materials or those that use less plastic without compromising on strength and durability. This not only helps reduce your carbon footprint but also aligns your business with global sustainability initiatives.

Cost-Effectiveness

Balancing quality with budget constraints is crucial when selecting stretch film. While high-performance stretch film may come at a higher initial cost, its enhanced durability and efficiency can lead to long-term savings. Invest in quality stretch film to minimize material usage and reduce the risk of product damage during transit, ultimately lowering your overall shipping costs.

Benefits of Using High-Performance Stretch Film

Enhanced Load Stability and Protection

One of the primary benefits of high-performance stretch film is its ability to provide enhanced load stability and protection. The superior stretchability and load retention capabilities ensure that your products remain securely wrapped throughout the shipping process, reducing the risk of damage or loss.

Reduction in Material Usage and Cost Savings

High-performance stretch film is designed to maximize efficiency, requiring less material to achieve the same level of protection as standard films. This reduction in material usage translates to cost savings, making it a cost-effective solution for businesses of all sizes.

Increased Efficiency in Packing and Handling

Using high-performance stretch film can significantly improve the efficiency of your packing and handling processes. Its superior stretchability and puncture resistance mean fewer breaks and interruptions, allowing for smoother and faster wrapping. This increased efficiency can lead to faster turnaround times and improved overall productivity.

Compliance with Vietnamese Regulatory Standards

Adhering to regulatory standards is essential for businesses operating in Vietnam. High-performance stretch film complies with Vietnamese regulatory standards and best practices, ensuring that your shipments meet all necessary requirements. This compliance helps build trust with customers and partners, reinforcing your commitment to quality and reliability.

2 notes

·

View notes

Text

The Vital Role of Quality Aspect in Plastic Extrusion

In the Plastic Extrusion Process, raw plastic material is melted and then forced through a die to form a continuous profile. The efficiency, affordability, and consistency of the produced complicated forms make this method a popular choice across a wide range of sectors.

Quality Control Is Crucial for Plastic Extrusion

Plastic extrusion quality control is a complex process that aims to guarantee that the final product fulfills strict quality requirements. The following salient features underscore the significance of quality control in this production process:

Content Management

The key to a successful extrusion process is the quality of the raw plastic material. The first step in quality control is to thoroughly examine and analyze the incoming raw materials to ensure that they are pure, consistent, and meet all required criteria. This contributes to fault prevention and extrusion process stability.

Procedure Observation

It is essential to continuously monitor the plastic extrusion China in order to spot and fix any deviations from the intended specifications. In order to monitor temperature, pressure, and speed in real time and make sure the process stays within the ideal range, automated systems and sensors are essential.

Control in Dimensions

In plastic extrusion, accuracy is crucial, particularly when creating goods with precise dimensional specifications. Regular measurements of the extruded goods' dimensions are one of the quality control procedures that make sure they adhere to the required tolerances.

Examining and Verifying

Strict processes for testing and inspection are followed during the whole extrusion process. To ensure that the extruded goods fulfill the necessary quality requirements, this may entail non-destructive testing techniques, visual inspections, and performance testing. Evaluations of mechanical qualities, color consistency, and other pertinent features may be part of the testing process.

Advantages of Strict Quality Control

Cut Costs: Early fault detection and resolution eliminates waste, lowers rework expenses, and boosts overall operational effectiveness.

Compliance and Reputation: Upholding quality standards guarantees adherence to industry rules, boosting the manufacturer's reputation and inspiring trust in clients.

Improved Quality of Product: Product quality is continuously good, meeting both customer and industry expectations and industry standards thanks to strict quality control procedures in Plastic Injection.

#plastic extrusion China#Plastic Extrusion Companies#plastic extrusion supplier#Plastic Extrusion Process#Plastic Extrusion Guide

2 notes

·

View notes

Text

Characteristics of Stamping Die Component

Stamping Die Parts, Also known as metal press tools, are components used in metal stamping dies. Stamping die components are also known as press die components, tool and die components, or progressive die components.

Stamping dies are not the same as die-casting or plastic injection moulds. They are most similar to the cold-forming cutting method for relatively thin metal components, often known as sheet metal parts. Thin metal components can be quite big for the automotive sector or extremely microscopic for the microelectronics and semiconductor industries.

Metal stamping parts are often manufactured in large quantities using metal stamping dies. To manufacture these metal stamping components, tool makers typically employ progressive dies and transfer dies.

To produce bulk metal components, Stamping Die Parts Manufacturer require a good set of metal stamping die moulds.

Stamping dies are known by a variety of names, including stamping moulds, stamping tools, and punching tools. According to the stamping process categorization, its subcategories include single stamping dies, compound dies, progressive dies and transfer dies. Blanking dies, extrusion dies, drawing dies, riveting dies, bending dies, and so on are also included, depending on the stamping craftsmanship categorization.

Stamping Die Component Characteristics:

Metal stamping die sets have higher hardness requirements than plastic injection moulds because they manufacture sheet metal parts from stainless steel, copper, or aluminum. Stamping die components are very comfortable to wear.

To extend the life of a stamping die set, the key components: punches and dies, are often made of hard metal. Especially punches.

We may also create components with a smoother surface to decrease friction loss when wearing them. The surface smoothness improves, friction loss decreases, and die components become more wear-resistant and robust for usage.

However, increased surface smoothness results in higher prices. For example, while grinding technology is superior to EMD technology in terms of surface smoothness, it is also more expensive.

Stamping Die Parts in China are specific types of precision mould parts; they do not include plastic injection mould or die casting parts. They have several unique qualities, such as excellent accuracy, hardness, and wear resistance.

Follow our Facebook and Twitter for more information about our product.

1 note

·

View note

Text

Coloring and processing of ABS plastics: the perfect combination of art and technology

In today’s era of pursuing individuality and innovation, ABS plastics (acrylonitrile-butadiene-styrene copolymer) has become a shining star in the plastic processing industry with its unique physical properties and wide processing adaptability. Especially in coloring and processing, ABS plastics show the perfect combination of art and technology, providing unlimited possibilities for all walks of…

#ABS plastic#blow molding#coloring performance#environmental protection#extrusion processing#injection molding#processing adaptability#sustainable development

0 notes

Text

Plastic extrusion manufacturing is a process in which a thermoplastic raw material, usually in the form of pellets, is melted and formed, under pressure, into a continuous shape or profile. The plastic extrusion manufacturing process produces a variety of items such as custom plastic profiles, extruded rods and tubes, piping, edges, molding, specialty plastic coatings and multi-material extrusions known as co-extrusions and tri-extrusions.

1 note

·

View note

Text

Industry Insights: Where We Supply Tool Steel - Virat Special Steels

Virat Special Steels stands tall as India’s largest stockiest, importer, and supplier of HSS Steel, Hot Work Steel, Cold Work Steel & Plastic Mould Steel. Representing top manufacturers of special steels worldwide, we enjoy global recognition for our unwavering commitment to quality.

Serving Industries: 🔧 Forging Industry: Shaping metal using compressive forces with a hammer or press, classified into cold forging, warm forging, or hot forging.

🏗️ Pressure Die Casting: Forcing molten metal under high pressure into a mold cavity, made using two hardened tool steel dies.

🚗 Aluminum Extrusions: Material pushed through a die to the desired cross-section, creating complex parts with excellent surface finishes.

🚙 Automotive Industry: Involved in manufacturing, design, and development of motor vehicles.

⛽ Oil & Gas Industry: Supplying more than 60% of our nation’s energy, including natural gas for electricity.

🧩 Plastic Industry: Manufacturing polymer materials for aerospace, construction, electronics, packaging, and transportation.

🍶 Glass Industry: Involves float glass process and glassblowing, producing sheet glass and containers.

🚲 Cycle Parts: Manufacturing components like bearings, chains, chain sets & cranks, handlebars, forks.

🚉 Railways: Manufacturing railway components such as gear holders, bogie cast parts, axles, pins, ground lever frames, adjustable cranks, compressor pistons, and bearings.

VIRAT SPECIAL STEELS PVT. LIMITED , INDIA is your trusted partner, supplying premium tool steels to diverse industries in India and globally.

Virat Special Steels, INDIA! https://www.viratsteels.com/

📞 Contact us today to learn more about how we can support your business! https://www.viratsteel.in/special-steel-supply-networks/

Any further queries feel free to contact us : 🌐https://www.viratsteels.com/ 📬 [email protected] ☎+91 98140-21775

#ludhiana#viratsteels#india#gurgaon#viratspecialsteels#toolsteelsupplier#gurugram#pune#iso9001#steel#db6 steel#h13diesteel#h13steel#h13steelbarexporter#h11steel#din 2714#din 2344#din2343#din2738#d2steel#m2steels#m35#p20ni

3 notes

·

View notes

Text

Introduction to Industrial Plastic Granulator - All You Need to Know

The Industrial Plastic Granulator is the equipment for re-grinding or recycling waste plastics to the injection molding, blow molding or extrusion procedure. It is used for recycling plastic products such as PP, PE, PVC, ABC or pipelines, plates, and product packaging materials. There are lots of designs of industrial plastic granulators for size reduction, granulation, recycling machines and accessories. Whatever your needed capacities are, take 5 minutes to read this blog and you will have a total understanding.

What is Industrial Plastic Granulator Machine?

Industrial Plastic Granulator is a machine that recycle plastic. It can be used for a variety of plastic and rubber materials such as plastic profiles, pipelines, rods, films, and plastic products. GREENMAX Industrial Plastic Granulator is a machine that processes plastic raw materials into pellets.

It is commonly used in plastics recycling and reuse processes, as well as in the production of new plastic products, and can help to easily achieve recycling and ESG goals!

How does Plastic Granulator Machine work?

Rigid plastic granulator is a kind of equipment to process rigid plastic raw materials into granular form. The working principle generally includes the following steps:

● Feeding: Rigid plastic wastes or raw materials are put into the feeding hopper of the granulator.

● Heating and melting: Through the heating device, the plastic is heated to a molten state.

● Extrusion: The molten plastic is extruded under the push of the screw.

● Pelletizing: The extruded plastic is cut into pellets through the granulator.

● Cooling: The pellets pass through a cooling device to solidify and mold.

● Sieving: The pellets are sorted through a sieving device to remove unqualified pellets.

The exact principle of operation may vary depending on the type and design of the granulator, but the general idea is to convert rigid plastics into pellets through the processes of melting, extruding, pelletizing and cooling. This principle of operation allows the rigid plastic granulator to efficiently process the plastic raw material and produce a pelletized product that meets the requirements. The shape and size of the pellets can be adjusted as needed. The advantages of this equipment include:

● Improving material utilization: processing waste rigid plastics into pellets reduces waste and improves resource utilization.

● Lower production costs: recycling and reusing plastic pellets can reduce raw material costs.

● Strong adaptability: It can process many different types of rigid plastics, such as polyethylene (PE), polypropylene (PP), polystyrene (PS) and so on.

● High production efficiency: high degree of automation, able to produce large quantities of plastic pellets quickly.

When choosing a industrial plastic granulator, you need to consider factors such as the capacity of the equipment, power, the type of plastic it is suitable for, and the quality of the pellets. In addition, attention should also be paid to the safety, reliability and ease of operation of the equipment. If you need more detailed information, you can consult GREENMAX.

1 note

·

View note