#Powered Roller Conveyors Uk

Explore tagged Tumblr posts

Text

Powered Roller Conveyors in Food Processing: Enhancing Efficiency and Hygiene

In the fast-paced world of food processing, efficiency, speed, and hygiene are key factors that determine the success of production lines. As consumer demands grow for faster delivery times and higher-quality products, food manufacturers are turning to advanced technologies to streamline operations. One such innovation that is transforming food production is the powered roller conveyor system.

These conveyors are not only enhancing efficiency but also playing a critical role in maintaining the highest hygiene standards, a vital aspect of food production. Let’s explore how powered roller conveyors are revolutionizing the food processing industry.

What are Powered Roller Conveyors?

Powered roller conveyors consist of a series of rollers mounted on a frame, with a motorized drive system that powers the rollers, enabling the movement of goods along the conveyor. The rollers are often made from durable materials such as stainless steel or food-grade plastic, ensuring longevity and resistance to wear and tear. This system can be customized to accommodate different product types, sizes, and weights, making it suitable for various stages in food processing, from raw material handling to finished product packaging.

1. Boosting Operational Efficiency

One of the key advantages of powered roller conveyors in food processing is the improvement in operational efficiency. These systems are designed to automatically transport products from one station to another, eliminating the need for manual labor. This reduces human error, minimizes delays, and ensures that the production line operates smoothly.

In food processing facilities, powered roller conveyors are especially useful for handling bulk products such as fruits, vegetables, packaged items, or meat products. Since these conveyors can be integrated with automated sorting, weighing, and packing systems, they significantly reduce downtime and improve throughput. Whether it's moving raw ingredients or finished products, these conveyors keep everything moving with minimal disruption, leading to faster production times and increased overall output.

2. Hygiene and Food Safety: A Priority

Food safety is a top priority for any food manufacturer. Powered roller conveyors are designed with hygiene in mind. They are often made from stainless steel or other non-corrosive, easy-to-clean materials that prevent the accumulation of contaminants. Since these conveyors are integral to the transportation of food items, maintaining cleanliness is critical to avoid contamination.

The design of powered roller conveyors makes it easier to clean between production runs. Unlike traditional conveyor systems, which may trap food particles in hard-to-reach places, powered roller conveyors have a streamlined construction with fewer joints, seams, and crevices, reducing the risk of bacterial build-up. Moreover, many systems are equipped with smooth, non-porous surfaces that resist the accumulation of dirt and grime, which is especially important in food handling.

3. Temperature Control and Compliance

Certain food products require precise temperature control during processing. Powered roller conveyors can be customized to include features that regulate the temperature of the rollers, ensuring that products are kept at optimal temperatures throughout the production line. For example, refrigerated powered roller conveyors are often used in the handling of perishable food products, like dairy, meats, and frozen foods, to prevent spoilage during transportation.

Moreover, powered roller conveyors can be integrated with sensors that monitor temperature, humidity, and other variables, ensuring that food safety regulations are adhered to. This is essential for compliance with standards set by food safety organizations such as the FDA, USDA, and European Food Safety Authority (EFSA).

4. Space Optimization and Customization

In food processing plants, space is often limited, and maximizing available floor space is crucial. Powered roller conveyors can be customized to fit specific layouts, optimizing production areas and reducing bottlenecks. These conveyors are also modular, allowing for easy expansion or reconfiguration as production demands change.

By utilizing powered roller conveyors, food processing facilities can maintain efficient workflows even in compact spaces, ensuring smooth transitions from one stage of production to another without sacrificing valuable real estate.

5. Improved Worker Safety and Ergonomics

Another significant advantage of powered roller conveyors is their positive impact on worker safety. In food processing environments, where heavy lifting and repetitive motions are common, powered roller conveyors minimize the risk of workplace injuries. Workers no longer need to manually lift or carry heavy items from one station to the next, reducing the chances of strains, sprains, or other musculoskeletal injuries.

Additionally, by reducing the need for manual intervention, powered roller conveyors lower the chances of accidents caused by human error. The conveyor system’s automated nature allows workers to focus on other critical tasks, ensuring that the production line operates smoothly and safely.

6. Cost Efficiency in the Long Run

Although powered roller conveyors may require a higher initial investment than manual systems, their long-term benefits outweigh the upfront costs. The automation of the food production process helps reduce labor costs, while the system’s durability ensures minimal maintenance and repair expenses. Furthermore, the ability to streamline operations leads to increased production volumes and improved profitability over time.

Conclusion

Powered roller conveyors are transforming the food processing industry by enhancing operational efficiency, ensuring high levels of hygiene, and promoting worker safety. Their ability to handle large volumes of food products, while maintaining compliance with strict food safety regulations, makes them indispensable in modern production facilities. As the food industry continues to evolve, these conveyor systems will undoubtedly play a crucial role in driving innovation, quality, and efficiency, helping food manufacturers meet the growing demands of a competitive marketplace.

By adopting powered roller conveyors, food processing plants can stay ahead of the curve, ensuring that they deliver high-quality products to consumers while maintaining a safe, efficient, and hygienic environment.

0 notes

Text

Automated Material Handling Solutions for Warehouses in UK

Warehousing is changing fast in the UK. Rising demands, tight deadlines, and labour shortages make automation more essential than ever. Automated material handling solutions for warehouses in UK are no longer a luxury. They are becoming the backbone of modern supply chains. These systems offer speed, accuracy, and reduced human error. From conveyors and robots to AGVs and AS/RS, automation is transforming how goods move in and out of UK warehouses.

Automated Material Handling Solutions for Warehouses in UK Let's explore how these solutions work, their benefits, and what makes them vital for warehouse operations across the UK.

Importance of Automated Material Handling Solutions for Warehouses in UK

Manual processes are slow and error-prone. In large warehouses, this leads to delays, bottlenecks, and damaged goods. Automated material handling solutions for warehouses in UK help solve these problems. They move materials quickly, with precision. They reduce the need for manual labour. This boosts efficiency, especially in sectors like e-commerce, retail, and third-party logistics. Automation also helps warehouses meet growing expectations. Customers want faster deliveries. Retailers want lower costs. Automation makes both possible.

Components of Automated Material Handling Solutions for Warehouses in UK

Conveyor Systems Conveyors transport goods across various zones of the warehouse. They come in different types—roller, belt, and chain conveyors. In UK warehouses, powered conveyors are often used in pick-and-pack areas. They are fast and ideal for repetitive movement of items. Automated Guided Vehicles (AGVs) AGVs are driverless transport systems. They follow pre-set paths or use sensors to navigate. They are useful in large UK distribution centres. They reduce walking time for staff. They are also safer, as they avoid collisions and follow strict routes. Automated Storage and Retrieval Systems (AS/RS) AS/RS systems are robotic arms or shuttles that place or pick goods from storage racks. They use vertical space better than manual systems. In urban UK warehouses with limited space, AS/RS help save floor area. They also allow 24/7 operation. Robotic Picking Systems These systems use robotic arms with grippers or suction cups. They pick items from bins and place them into totes or boxes. They often work with AI to recognize items. In the UK, where online shopping is massive, robotic pickers help with fast order fulfillment. Warehouse Management Systems (WMS) A WMS controls all automation in the warehouse. It manages inventory, coordinates machines, and tracks goods. It connects with ERP systems for better control. WMS also helps reduce human oversight by automating tasks like stock counts and reorder alerts.#AutomatedMaterialHandling, #WarehouseAutomationUK, #LogisticsSolutions, #MaterialHandlingEquipment, #SmartWarehousing, #AutomationInLogistics, #UKWarehouses, #IndustrialAutomation, #WarehouseEfficiency, #RoboticsInWarehousing, #SupplyChainInnovation, #AutomationTechnology, #WarehouseSolutions, #HandlingSystems, #FutureOfWarehousing Read the full article

#AutomationSystems#IndustrialTechnology#Logistics#MaterialHandling#OperationalEfficiency#Robotics#SmartLogistics#SupplyChain#UKWarehousing#WarehouseAutomation

0 notes

Text

Building the "War Machine"

This would become an Important part of my Final Installation. I have looked into the production of Artillery shells and they don't really come off of a conveyor belt, however i thought is would be a recognisable way of presentation of the production of these items.

Initially I had wanted to have a moving conveyor belt, but after much research and costing I became aware this was finically unavailable to me therefor I decided the final war machine would have no moving parts.

The construction and planning of the war machine took some time, size was a concern due the unknown factor at this point of what space I would have to display it along with the logistical factor of being able to move it. This was also a factor in the choice of metal sheeting used originally looking a steel but settling on aluminium sheeting as to make the fine work lighter and more moveable. The frame of the war machine was constructed of pine joists screwed together, the side panels where parts of unused laminate flooring dressed in aluminium tape and the conveyor belt was created using an off cut of a tarpaulin left from my tobacco packet from the divergent practice module.

0 notes

Text

Conveyor Systems Outlook, Geographical Segmentation, Industry Size & Share, Comprehensive Analysis to 2031

The global conveyor systems market size was $9,113.9 million in 2020, and is expected to reach $15,183.1 million by 2030, with a CAGR of 5.1% from 2021 to 2030. Conveyor system is the type of machines that increases the efficiency of engines in addition to increase the power of the engines. The conveyor system is a type of equipment or a machine that helps in transportation of goods or materials from one point to the other. It consists of the belt that is connected to the pulleys that are two in number and the belt helps in providing efficient rotation to the pulleys. In addition, these systems help in saving time of activities that could be done manually and it helps in saving the labor cost with reduced error that could be done by humans.

The major driving factor of conveyor systems market is the growing trend of automation in industries. The automated conveyors are suited for handling any volume of goods, and in addition they simplify the industrial task by reducing the amount of time for delivering goods. Hence, this is leading to surge in adoption of automated solutions across industries. In addition, companies use the lean manufacturing system to increase the productivity by reducing the waste within the manufacturing operation that helps in reducing the time, saving the costs, and increasing the quality of the service or the product. Conveyor systems help in saving the costs of hiring labors and time, thus increasing the productivity by handling larger volumes. This is leading to adoption of the conveyor system across industries.

The global conveyor systems market is segmented into type, industry, load, and region. Depending on type, the market is divided into belt, roller, pallet, overhead, others. On the basis of industry, it is segregated into food & beverages, pharmaceuticals, transport & logistics, manufacturing, automotive, and others. By load, it is fragmented into bulk and load.

Region wise, the global conveyor systems market analysis is conducted across North America (the U.S., Canada, and Mexico), Europe (the UK, France, Germany, Italy, and rest of Europe), Asia-Pacific (China, Japan, India, South Korea, and rest of Asia-Pacific), and LAMEA (Latin America, the Middle East, and Africa). In 2020, Asia-Pacific was the highest contributor to the global conveyor systems market share, however, LAMEA is anticipated to secure a leading position during the forecast period.

On the basis of type, in 2020, the belt segment dominated the conveyor systems market, in terms of revenue, whereas the overhead segment is expected to witness growth at the highest CAGR during the forecast period. As per industry, in 2020, the food & beverages segment led the market, however, the pharmaceuticals segment is expected to exhibit highest CAGR in the near future. By load, the bulk segment led the market in 2020, in terms of revenue; however, the unit segment is anticipated to register highest CAGR during the forecast period. Region wise, Asia-Pacific garnered the highest revenue in 2020; however, LAMEA is anticipated to register highest CAGR during the forecast period.

Competition Analysis

The major players profiled in the conveyor systems market include Caterpillar, Daifuku Co., Fives, Interroll Group, Kardex, Kuka AG (Swisslog Holding AG), Mahindra Tsubaki Conveyor Systems Pvt. Ltd., Murata Machinery, Ltd., Siemens, Taikisha Ltd.

Major companies in the market have adopted agreement, product launch, business expansion, partnership and acquisition as their key developmental strategies to offer better products and services to customers in the market.

Full Report With TOC:-https://www.alliedmarketresearch.com/conveyor-systems-market

0 notes

Text

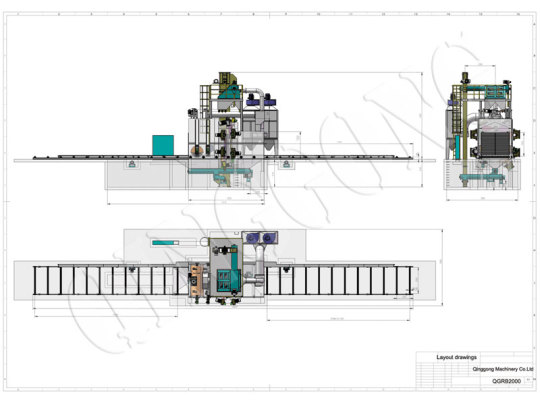

Shot Blasting Machine Wiki

Shot blasting machine

Industry Cleaning, mechanical

Application Automotive industry, Construction industry, Wind power industry, Railway industry, Foundry-Forging industry, Shipyard

Inventor Benjamin Chew Tilghman

Invented October 18, 1870

The shot blasting machine is an equipment used to reinforce, clean or polish any metal surface or metal. Shot blasting, also known as abrasive blasting, more commonly known as sandblasting. Historically, shot blasting is not a relatively modern concept, the first shot blasting machine in the world was patented (US patent 108,408.) by Benjamin Chew Tilghman (1821–1901),[1] an American soldier and inventor,[2] on October 18, 1870.[3]

Shot blasting is a technique in which a selected class of abrasive particles is used to remove material from a surface at a high speed (65 -110 m/s) corrosion rate. It is the operation of forcing the abrasive stream to the surface under high pressure to smooth the rough surface, roughen the smooth surface, and shape or remove surface contaminants. A pressurized fluid (usually compressed air), or a centrifugal wheel is used to propel the blast material (commonly referred to as the medium).

Contents

1. Shot Blasting Machine Video (3D Visualization)

2. Overview

3. History

4. Methods

3.1 Mechanical blasting

3.2 Air blasting

5. Classification

4.1 Roller conveyor type shot blasting machine

4.2 Hanger type shot blasting machine

4.3 Rotary table type shot blasting machine

4.4 Tunnel type shot blasting machine

4.5 Barrel type shot blasting machine

4.6 Trolley type shot blasting machine

6. Development

7. Global market

8. References

Shot Blasting Machine Video (3D Visualization)

Overview

Shot blasting is a process that treats metals to remove rust, grease, scale, and other irregularities to create a smooth surface for applying a finishing surface. During this process, ssome abrasive material is blasted onto the surface and depending on the surface being treated, they may be sand, beads or water. It is important to create a smooth and clean surface to apply the final surface treatment, like, powder coating, to the metal surface to achieve a high-quality, beautiful and durable surface treatment. China sand blasting machine is a mechanical method that uses centrifugal wheels to propelling the abrasive to remove surface and other impurities from the surface of steel applications. In general, blasting prior to finishing serves three primary purposes:

· Cleans and descales surfaces

· Increase texture to enhance paint adhesion

· Properly reduces maintenance costs by extending coating life

History

Benjamin Tilghman was a general in the army and saw the effect of wind-blown sand on windows in the desert. This might be the basis of his shot blasting machine invention.

On October 18, 1870, Tilghman filed a patent, titled “Improvement in cutting and engraving stone, metal, glass, etc.”, in the US (US patent 108,408.), detailing many unique applications of the technology, such as sharpening files, carving bottles, cleaning boilers or turning The wood grain comes out. Later that year, a patent was issued in the UK.

Methods

Broadly, there are two methods of shot blasting machines: air blasting and mechanical blasting (also known as airless blasting, and wheel blasting).

Mechanical blasting

In this system, the abrasive is propelled by fast rotating impellers driven by power.

Air blasting

In this system, the abrasive is propelled through a nozzle by compressed air (mechanical blasting is more widely used).

Classification

According to different structures of casting metal parts, shot blasting machine can be divided into roller conveyor type, hanger type, rotary table type, tunnel type, barrel type, trolley type, and so forth.

Roller conveyor type shot blasting machine

This type of sand blasting machine is the most environmentally friendly and effective process angle for removing all forms of rust and corrosion materials in steel plates, pipes, steel structures, H-beams, steel pipes, profiles, and steel channel. It can not only remove rust, but also remove welding slag on structural parts, eliminate welding stress, improve fatigue strength, increase paint film adhesion, and provide ideal surface finish (SA2.5-3.0) for workpieces to ensure continuous and effective bonding between the steel surface and the coating. It is used in almost all industries that use metals, including aerospace, automotive, construction, casting, shipbuilding, railways, and many other industries.

Hanger type shot blasting machine

This type of machine is the most flexible and versatile shot blasting machine. It has two options: the single hook I type shot blasting machine and two hooks Y type shot blasting machine. It is specifically suitable for descaling of forgings, desanding of castings, removal of burrs and scales, surface treatment and deburring of welded constructions, et cetera.

Rotary table type shot blasting machine

Rotary shot blasting machine, also known as table type shot blasting machine, is suitable for various shapes and sizes, castings, forged parts, pressed parts, steel and non-ferrous metal parts and parts made of fragile materials, clean the surface, remove casting sand and debris Consolidate the surface (micro-treatment), and roughen the surface before coloring. They are divided into single rotary table shot blasting machine and swing table shot blasting machine, and the latter is more effective than the former.

Tunnel type shot blasting machine

This type of machine is a non-standard shot blasting machine designed according to the workpiece information. It is mainly used for surface treatment of large steel structures to remove rust, old paint and old putty. For large workpieces, it can use a double electric hoist to lift the workpieces through the shot blasting chamber, and the workpieces can be shot blasted. It adopts imported PLC control, with automatic/manual control mode. and has an automatic/manual control mode. The entire hook realizes automatic fault detection through the type of shot blasting machine.

Barrel type shot blasting machine

Barrel type shot blasting machine is an integral whole model, simple accessories, durable and high quality. It is mainly used for batch cleaning, deburring, descaling, decoration, deburring and shot peening treatment of various products.

Trolley type shot blasting machine

This type of machine is mainly used for cleaning and strengthening of casting surface, removal of oxides and welding slag, widely used in petroleum casting, forging, machinery, steel and other industries.

Development

Initially, the shot blasting machine was used for industrial purposes, such as removing rust or polishing metal before painting. Nowadays, the technique has decorative purposes, including sculpting and texturing. Current uses include engraving awards, such as trophies and crystal awards, production of 3D signage, glass decoration, and building refurbishment, however one of the earliest items to be sold after was Alfred Dunhill's pipes which he found sold for more money than his smooth pipes.

Nowadays, the shot blasting machine has become a mandatory industry for every industry, mainly including automotive, construction, wind power railway Industry, foundry-forging, and shipyard industry, to clean and polish surface metal preparation. The main benefit of the shot blasting machine is that it provides an effective and smooth surface to any kind of the metals.

0 notes

Text

Automated Truck Loading System Market Size By Product, By Application, By Geographic Scope, And Forecast

Automated Truck Loading System Market Size And Forecast

Automated Truck Loading System Market is growing at a faster pace with substantial growth rates over the last few years and is estimated that the market will grow significantly in the forecasted period i.e. 2021 to 2028.

The Global Automated Truck Loading System Market report provides a holistic evaluation of the market for the forecast period (2021–2028). The report comprises of various segments as well an analysis of the trends and factors that are playing a substantial role in the market. These factors; the market dynamics, involves the drivers, restraints, opportunities and challenges through which the impact of these factors in the market are outlined. The drivers and restraints are intrinsic factors whereas opportunities and challenges are extrinsic factors of the market. The Global Automated Truck Loading System Market study provides an outlook on the development of market in terms of revenue throughout the prognosis period.

Global Automated Truck Loading System Market: Scope of the Report

This report provides an all-inclusive environment of the analysis for the Global Automated Truck Loading System Market. The market estimates provided in the report are the result of in-depth secondary research, primary interviews and in-house expert reviews. These market estimates have been considered by studying the impact of various social, political and economic factors along with the current market dynamics affecting the Global Automated Truck Loading System Market growth.

Get | Download Sample Report @ https://www.verifiedmarketreports.com/download-sample/?rid=497653&utm_source=Free&utm_medium=004#download_sample

Along with the market overview, which comprises of the market dynamics the chapter includes a Porter’s Five Forces analysis which explains the five forces: namely buyers bargaining power, suppliers bargaining power, threat of new entrants, threat of substitutes, and degree of competition in the Global Automated Truck Loading System Market. It explains the various participants, such as system integrators, intermediaries and end-users within the ecosystem of the market. The report also focuses on the competitive landscape of the Global Automated Truck Loading System Market.

Global Automated Truck Loading System Market: Competitive Landscape

The market analysis entails a section solely dedicated for major players in the Global Automated Truck Loading System Market wherein our analysts provide an insight to the financial statements of all the major players along with its key developments product benchmarking and SWOT analysis. The company profile section also includes a business overview and financial information. The companies that are provided in this section can be customized according to the client’s requirements.

Automated Truck Loading System Market, Key Players

• Actiw • HAVER & BOECKER • Joloda International • Secon Components • The Heico Companies (Ancra Systems) • Automatic truck loading system ATLS • BEUMER Group • Cargo Floor • Euroimpianti • FLSmidth Ventom

Ask For Report Details @ https://www.verifiedmarketreports.com/product/automated-truck-loading-system-market-szie-and-forecast/?utm_source=Free&utm_medium=004

Automated Truck Loading System Market Segment Analysis

Automated Truck Loading System Market is Segmented On The Basis Of Source, Product, Application, And Geographic scope.

Automated Truck Loading System Market, By Product

• Belt Conveyor Systems • Roller Track Systems • Chain Conveyor Systems • Slat Conveyor Systems • Skate Loader Systems

Automated Truck Loading System Market, By Application

• Logistics and Transportation Industry • Food And Beverage Industry • Paper Industry • Automotive Industry • Air Freight Industry • Cement Industry

Automated Truck Loading System Market, By Geography

• North America o U.S. o Canada o Mexico • Europe o Germany o UK o France o Rest of Europe • Asia Pacific o China o Japan o India o Rest of Asia Pacific • Rest of the World o Latin America o Middle East & Africa

For More Information @ https://www.verifiedmarketreports.com/download-sample/?rid=497653&utm_source=Free&utm_medium=004#download_sample

About us –

Verified Market Reports is a leading Global Research and Consulting firm servicing over 5000+ global clients. We provide advanced analytical research solutions while offering information enriched research studies.

We also offer insights into strategic and growth analyses and data necessary to achieve corporate goals and help critical revenue decisions.

Our 250 Analysts and SMEs offer a high level of expertise in data collection and governance using industrial techniques to collect and analyse data on more than 25,000 high impact and niche markets. Our analysts are trained to combine modern data collection techniques, superior research methodology, expertise, and years of collective experience to produce informative and accurate research.

Our research spans over a multitude of industries including Energy, Technology, Manufacturing and Construction, Chemicals and Materials, Food and Beverages etc. Having serviced several Fortune 2000 organizations, we bring a rich and reliable experience that covers all kinds of research needs.

Contact us:

Mr. EdwyneFernandes

US: +1 (650)-781-4080

UK: +44 (753)-715-0008

APAC: +61 (488)-85-9400

US Toll-Free: +1 (800)-782-1768

Email: [email protected]

Try Our New Dashboard :-

https://www.verifiedmarketresearch.com/dashboard/?utm_source=Free&utm_medium=004

0 notes

Text

Design and Development of Telescopic Conveyor

This telescopic belt conveyor is an effective and ergonomic alternative to labour-intensive routines. Operators can move heavy or awkward packages into or out of a container/truck rapidly with little effort. Extending some 20 meters/65 ft., telescopic belt conveyors can be used to load/unload any type of loose-loaded cargo - typically parcels, boxes, sacks & tyres. An intuitive smart-pad on either side enables precise control of the boom's elevation and telescopic movement. Push buttons at the operator end of the boom control activation, lights, belt direction etc.

A telescopic belt conveyor is an effective and ergonomic alternative to labour-intensive routines. Operators can move heavy or awkward packages into or out of a container/truck rapidly with little effort. Extending some 20 meters/65 ft., telescopic belt conveyors can be used to load/unload any type of loose-loaded cargo - typically parcels, boxes, sacks & tyres. An intuitive smart-pad on either side enables precise control of the boom's elevation and telescopic movement. Push buttons at the operator end of the boom control activation, lights, belt direction etc. Exceptionally small base sections combined with up to five extending sections enables us to provide custom telescopic conveyors to suit your requirements.

Wheel Sorter

Wheel Sorter is used for belt conveyor system or roller conveyor system. The characteristics of this design is to track conveyed goods accurately and stably as well as set sorting positions at any position along both sides of conveyor lines conveniently to satisfy customers with different sorting requirements. Achieve maximum sorting rate at the same time its best economical efficiency.

Durable: Our O-Belt is made in a whole piece, without any gaps to ensure a longer service life!

§High Sorting Rate: Designed for high speed and bidirectional for sorting operation on both sides at the same time. Maximum Sorting Rate can be 7200 pieces/hour.

§Low Noise: Use new material and noise elimination technology which can be friendly for Environment, noise can be less than 75dB.

§Energy Conservation and Environmental Protection: Light weight material and low energy consumption structure as well as low power and source power (conveyor) drive to achieve successful operation.

§Flexible and Stable Sorting Operation: Online double-row swivel wheel technology prevents conveyed goods from vibration and damage. Stably and flexibly sort goods from light duty to maximum 50kg heavy duty range.

§Easy Layout and Maintenance: Use unit modular design and embedding combination structure, easy for sorting positions be placed at any position along both sides of conveyor line. Product is more reasonable, simple, conveniently used and maintained.

DWS Systems makes its international show debut at IFAT

DWS System, the joint venture between Siltbuster, the water treatment specialist and the German recycling equipment giant, Doppstadt, , will be exhibiting at IFAT 2016 in Munich. This will be the first time DWS Systems has taken part in an international show, since the company was formed in 2015.

Located in hall B1.404, DWS Systems will be exhibiting the latest Gritbuster WT-250 road sweepings recycling system. The WT-250 is uniquely engineered to handle road sweepings, gully waste and trommel fines on a commercial scale, handling up to 25 tonnes per hour. It cleverly uses water to further separate out recyclable materials - washed gravel and sand products - making it easier for materials recycling facilities to separate out on a large scale the constituent elements of the waste they handle. This boosts the level of material reuse and minimises waste going to landfill. Thanks to this level of innovation, the WT-250 is in the running for a prestigious MRW National Recycling Award.

DWS Systems will also be showing its range of water treatment technologies including the HB40R lamella clarifier. This is specifically designed for the removal of suspended solids and other matter from process waters, so that the water can be reused. As a result, those using DWS Systems’ water treatment kit can operate a closed loop process; they don’t have to rely on large settlement lagoons to naturally treat their waste water. The net result is compact solutions which can be rapidly deployed on small sites to reprocess a range of waste materials to a higher standard than can be achieved by the current dry processing techniques.

Commenting on the company’s presence at the exhibition, Dr Richard Coulton, founder of Siltbuster and CEO of DWS Systems UK said: “As just these two products show, we have some powerful solutions for the world’s recycling industry. The collaboration between our two businesses means we can roll them out to an international audience much faster, which is important as the recycling sector faces some real challenges which our systems address. Our presence at IFAT is an important first step in that process. It’s a great opportunity to showcase both the new business and most importantly, the technologies we offer.”

Chapter One - What is a Conveyor Belt?

A conveyor belt is a material handling system designed to move supplies, materials, and components using an efficient and effortless process that saves on time, energy, and cost. The design of conveyor belts includes two motorized pulleys with the conveyor material looped over them. The pulleys operate at the same speed and move in the same direction to activate the motion of the conveyor belt.

There is an endless number of types and uses for conveyor belts. All of the varieties serve the purpose of transporting materials and goods along a continuously moving path. Though motorized conveyor belts are the traditional form of a conveying system, there are systems that use rollers without a motor to move materials.

Chapter Two - Types of Conveyor Belts

The range and uses of conveyor belts cover several industrial settings and applications. The efficiency of conveyor belt systems assists in improving productivity, saves on labor costs, and decreases lead times. Conveyor belts move large quantities of goods quickly and reliably for transport, further assembly, or storage.

The principal reasons so many conveyor systems are in use are the savings in labor costs, efficient movement of goods, and their ability to keep products and materials from damage. They provide the best possible service at the lowest possible cost.

Types of Conveyor BeltsRoller Bed Conveyor Belt

The surface of a roller bed conveyor belt is a set of rollers that match the weight and speed required by the product. The length of the roller bed conveyor belt determines the number of rollers to be used.

A roller bed conveyor belt is designed for applications where materials are loaded by gravity. They are an ideal solution for conditions where materials have to be moved over long distances since they are designed to reduce friction.

Flat Belt Conveyor Belt

A flat belt conveyor belt uses a series of pulleys to move materials and supplies. Its belt is made of natural or synthetic materials; this makes it versatile and adaptable to varying conditions and applications. In some instances, a flat belt conveyor belt may have a center drive and nose bars.

Modular Conveyor Belt

A modular belt conveyor consists of interlocked pieces made of hard plastic with segments that can be easily removed and replaced. The design of modular belt conveyors makes it easier to clean, and the material is resistant to sharp and abrasive substances. Modular belt conveyors come in varying configurations and use a single belt to go around corners, in a straight line, up inclines, and down declines.

Cleated Conveyor Belt

Cleated belt conveyors have sections, pockets, or dividers that secure granular products when the belt declines or inclines. The cleats have equal spacing between them and come in various styles and shapes depending on the product to be moved and the design of the belt.

Inverted Capital T

An inverted T cleat stands perpendicular to the belt and provides support for delicate and fragile materials.

Forward Leaning Capital L

A leaning capital L has a wide base that can be curved to scoop up granular materials. The design of the capital L makes it less resistant to leverage forces.

Inverted V

Inverted V cleats are two inches or less to create a trough like effect and are used for heavy, abrasive, and larger pieces of bulk materials.

Lugs and Pegs

Lugs and pegs are designed to meet the specific needs of a product and are a cost effective solution for products that do not require continuous support, such as cartons. They can be selectively placed to move products of varying sizes.

Sidewall

The purpose of sidewalls on a conveyor belt is to keep the material being moved on the belt. Sidewall conveyor belts are ideal for incline and decline belts and help increase product load capacity to improve conveyor system efficiency. There are a wide variety of sidewall materials, and they can be corrugated at various depths to fit the needs of the product and application.

Curved Conveyor Belt

The curves in conveyor belts are used to carry products around corners, make transfers, and make efficient use of floor space. Curved conveyor belts can make “U” turns to face the direction from which they came. They are made with flat belts and can make turns at 45o, 90o, 135o, and 180o angles.

Incline Conveyor Belt

Incline conveyor belts have a rough, uneven surface to hold materials and prevent them from slipping or falling back. The underside of the belt is smooth to allow the belt to glide smoothly along the bed. Modular belt and timing belt conveyors can be used for this purpose. Depending on the material to be moved, cleats may be included for increased slippage prevention.

Decline Conveyor Belt

The purpose of a decline conveyor belt is to move products or materials down or change its height. As with the incline version of conveyor belts, a decline conveyor belt has a rough surface or cleats to prevent materials from slipping or falling.

Decline conveyor belts are a continuous operating conveyor system with an articulated frame with a section that is pivoted or placed downward to accommodate downward movement of products from an upper location.

An advancement in conveyor belt technology is the electroadhesion conveyor belt, which acts like a magnet that is activated by a switch to create a strong and secure holding force between the container and the belt. Two low amp power strips placed in the conveyor belt powers its holding force. Materials with an electrically conductive pattern are knitted into the belt to produce the force that holds materials in place.

Filter Conveyor Belt

Unlike conventional conveyor belts, filter conveyor belts allow materials to pass through in order to drain excess liquid from components or filter out toxins and contaminants. Filter conveyor belts are constructed with lateral grooves and holes in the center of the belt to allow liquids and fluids to escape. Drainage holes are placed in a fabric free zone down the center of the belt or sealed to prevent the liquid from soaking into the belt fabric.

Much like a sidewall conveyor belt, filter conveyor belts can have sidewalls to prevent liquids and fluids from spilling over the sides of the belt. They are made of heated polyester, polypropylene, polyolefin, or stainless steel mesh for dewatering applications.

Vacuum filter belts are used for washing coal and other ores to assist in the separation of fluids and solids.

0 notes

Text

A mobile line shaft comes at a standard size

Multiple parcel carriers use mobile line China Mining Conveyor Belt Manufacturers within the depot network including DPD, Hermes, Yodel, Parcelforce, and DHL. Therefore, it was no surprise that the client needed one to handle the increased number of parcels coming through their depot.When L.A.C. Conveyors & Automation first spoke with the client, they made it clear they needed a conveyor solution to aid in handling the number of parcels coming through their warehouses.Having successfully designed, built, and installed several conveyors for several renowned international delivery service, the client could be rest-assured they were in capable hands.Due to the flexibility of a mobile conveyor system, the roller conveyor systems can be used in various layouts to match the needs of the volume of parcels coming through the client’s site.The build and set up a time for a mobile line shaft conveyor is quick and can be ready to operate within several hours. They can be integrated within existing systems and equipment such as x-ray scanners, barcode readers, data capture cameras, and box strapping machines just to name a few.Due to the short setup times, it’s no surprise that multiple carriers have been using mobile line shaft conveyors within the depot network.

A mobile line shaft comes at a standard size of 912mm wide and 850mm height; however, other conveyor widths can be designed to match what the mobile line shaft system will be used for.The package sizes for a mobile line shaft conveyor system can be any length on a straight, on a curve the max size is 1200w x 800h with a minimum parcel size of 150w x 150h with a suggested maximum parcel weight of 50kg/m, however, this can always be adjusted for bespoke projects to ensure the conveyor system meets the customer requirements.What are mobile conveyor systems comprised of?The mobile conveyor systems consist of short (up to six metres) sections, or modules, which fasten together to form a complete material handling system.Whilst each module has its own drive unit, the power and emergency circuits are fully linked, offering the benefits of a fixed conveyor system with the added advantages of being a mobile conveyor system.One control panel can drive up to 10 motors so the conveyor system could go up 60m long through a combination of straights, curves, and mergers of one control panel.This mobile conveyor solution offers the availability to add or remove modules as required and can match the change required in their depot centres.Mobile line shaft conveyor systems can be modularised as workstations and this makes it a great fit for a depot and parcel delivery service provider. As depending on what the required need is or what department it would be working in it can be moved to match the layout required.For example, if required within an e-commerce business, or delivery hub, the conveyor system could be used as part of an infeed system in the morning to bring the product into the building and then reconfigured later in the day for the packaging and the sending out process.The challengeDue to the client needing a bespoke mobile line shaft conveyor solution, L.A.C. drew up a new design of the mobile line shaft conveyors that needed to be implemented and used by the client.All the mobile conveyor units needed to be fully reversible, usable for heavy-duty items, available in different colours to match with the colour sectioning of the warehouse, and modular so they could be switched in and out of the conveyor system quickly.The client needed a mobile roller conveyor solution due to the different floor plans the parcel delivery warehouse had to workaround.Therefore, the roller conveyors needed to be fully mobile and reconfigurable, individually driven for each section, have a control station to ensure full control over the system and each section, and toggle clamps to connect the different modular units to various parts of the system.What was the solution?

By providing the mobile roller conveyors the client was able to process up to 3,000 items per hour which helped reduce time and cost and ultimately resulting in an efficient system. Due to be the plug and play technology offered with the mobile conveyor systems, there were minimal installation costs for the client, and they could be installed in a time-effective manner.A benefit of a mobile line shaft conveyor system is the fact it requires little technological know-how, therefore easy to maintain, set up, and maintenance engineers to do any required work on one.This mobile line shift conveyor system allowed the mail delivery client to unload, sort, and load a wide variety of loose mail in a more efficient and cost-effective manner, helping our client meet their customer’s service level agreements and keeping their relationships healthy by not missing their lead times.About L.A.C. Conveyors & AutomationWho we are: Founded in 1992, L.A.C. Conveyors & Automation are a leading UK supplier who’ve been successfully supplying conveyor systems, belt conveyors, roller conveyors, automation, and robotic solutions to the UK’s blue-chip industry. Located in Bulwell, Nottingham, L.A.C. are known for their outstanding customer service, continual support, flexibility, and bespoke service. With a full in-house service team, and an engineering team who’ve worked together over 20 years, L.A.C. covers all aspects of control system design, build and associated software, and ongoing support.What we do: L.A.C. has a wealth of experience supplying conveyor systems and robotic solutions to a range of industries including automotive, aerospace, food and beverage, heavy engineering, and logistics. L.A.C. design, assemble, incorporate testing, and deliver with training and after-sales support for a smooth handover. With an in-house mechanical design team, project managers, and engineers, all the builds are undertaken on the five-unit 60,000 sq. ft premises.

0 notes

Text

THE CHINOOK

The Chinook is an extremely capable and highly versatile support helicopter that can be operated from land bases or ships into a diverse range of environments, from the Arctic to the desert or jungle. The aircraft may be armed and is fitted with a suite of self-defence equipment allowing it to operate across the battlespace. Chinooks are primarily used for trooping, resupply and battlefield casualty evacuation (casevac).

With its triple-hook external load system, internal cargo winch, roller conveyor fit and large reserves of power, the aircraft can lift a wide variety of complex underslung or internal freight, including vehicles. It can carry up to 55 troops or up to approximately 10 tonnes of mixed cargo. Secondary roles include search and rescue (SAR), and supporting a wide variety of specialist tasks, including the Military Aid to the Civil Authorities (MACA) commitment. A Chinook crew comprises two pilots and two crewmen, supplemented by specialists dependent upon mission requirements.

A Royal Air Force Chinook, from RAF Odiham, inserts troops from 40 Commando Royal Marines onto a mountain peak in the Mojave Desert during Exercise Black Alligator. Exercise Black Alligator has demonstrated UK Defence interoperability between RAF Chinook Crews, Army Air Corps Apaches and Royal Marine ground troops, whilst working in demanding, austere conditions in the Californian desert. All three forces worked out of Camp Wilson, at United States Marine Corps Air Ground Combat Centre in Twenty Nine Palms. SAC Nicholas Egan is an RAF Photographer currently based at ACSSU Photo Operations, RAF Halton. After joining the RAF in 2011, he has previously served at Aldergrove Flying Station in Northern Ireland, and RAF Odiham before moving to his current post in February 2017.

CAPABILITY In addition to its traditional warfighting roles, the Chinook’s lifting capability is held at readiness under the MACA commitment to respond to emergencies in the UK; in recent years these have included resupplying snowbound farmers in Northern Ireland and moving tons of aggregate to help reconstruct flood defences damaged by winter storms. In August 2019, a Chinook was instrumental in securing a dam on the Toddbrook Reservoir after it became structurally unsound following heavy rain.

Pictured is a Challenger 2 MBT and Chinook Helicopter on the Salisbury Plain Training Area. Army Reservists from the Royal Wessex Yeomanry and regular soldiers from The Royal Tank Regiment and personnel from the RAF worked together to coordinate the delivery of their new Wolf Scout Land Rovers by air with the vehicles under-slung from the giant Chinook aircraft. For many it will be the first time that they will have worked with the RAF in this way. Like all of the training they do, it is about preparing them to do it for real whilst deployed on operations in support of the Regular Army.

A casualty is tended to onboard a MERT Chinook helicopter following an engagement with the enemy in Afghanistan. The Medical Emergency Response Team (MERT) is made up of two teams based in ‘Main Operating Base Bastion’, they are responsible for extracting casualties from anywhere within Helmand Province. The MERT consists of a doctor, an emergency department nurse and two paramedics. In addition four Royal Air Force Regiment gunners provide armed protection when they land and leave the helicopter to collect the casualty

The current operational Chinook fleet comprises Mk 4, Mk 5, Mk 6 and Mk 6A aircraft, fitted with digital glass cockpits to a common standard. The Mk 6 was acquired as a UK-specific variant of the CH-47F and also introduced a Digital Automatic Flight Control System (DAFCS, pronounced “daffics”), greatly enhancing handling and safety, particularly when operating in recirculating dust or snow conditions. The Chinook HC.Mk 5 results from upgrade of the extended-range Mk 3, or “fat tank” aircraft, which carries double the fuel load of a standard Chinook. The earlier Mk 4 Chinooks are being further upgraded to Mk 6A standard with the addition of DAFCS; the final aircraft is expected to be completed early in 2021.

Chinooks land on HMS Queen Elizabeth for the first time. HMS Queen Elizabeth, the newest aircraft carrier in the Royal Navy today (Friday 2nd February 2018) embarked two chinooks. The Chinooks which will be joined by Merlin helicopters later next week will take part in various flying serials as part of HMS Queen Elizabeth’s sea trials. On Friday 2nd February 2018, HMS Queen Elizabeth sailed from her home port in HMNB Portsmouth to continue her sea trials. On completion of her trials, she will take on US F35 B Lightning aircraft for trials later this year when she visits the United States.

The type will continue to play a key role in UK Defence activity, with the Chinook Sustainment Programme aiming to build on the platform’s success, recapitalising existing airframes and extending the capability out to 2040. In 2018, the US State Department approved the possible Foreign Military Sale of 16 extended range Chinooks to the UK, a deal which may yet see the RAF fleet expand or replace some of its earliest airframes.

Pictured are members of the Grenadier Guards armed with SA-80’s taking part in Exercise Noble Jump 17. A US Army Chinook takes off behind them. A joint Air Assault exercise with the American 1st Battalion, 3 Aviation Regiment, 12 Combat Aviation Brigade. The troops practised joint operations and interoperability. Exercise Noble Jump 17 is a logistical challenge that tests the ability of all the participants to deliver a fighting force to wherever it is needed. All movements were controlled by NATO’s Multi-National Division South East HQ, based in Bucharest. The VJTF is kept on short notice to move and is able to deploy a powerful well-trained force within days. This year, it is being led by the UK’s 20 Armoured Brigade. Overseeing the VJTF’s training at Cincu was a combination of Joint Force Command Naples, Multi-National division South East and the Allied Rapid Reaction Corps.

US Army Loadmaster aboard a US Army Chinook helicopter during Exercise Noble Jump 17

BASED AT

RAF Odiham, RAF Benson

FLYING WITH

27 Squadron, 28 Squadron, 7 Squadron, Chinook Display Team Falcons

SPECIFICATIONS BOEING CHINOOK HC.MK 6: • Powerplant: two Honeywell T55-L-714A turboshaft engines, each rated at 4,168shp maximum continuous power • Length: 98ft 10½in (30.14m) • Height (rotors turning): 18ft 11in (5.77m) • Rotor diameter (each): 60ft (18.29m) • Maximum cruising speed: 160kt (296km/h) • Maximum density altitude: 15,000ft • Payload: up to 55 troops or around 22,000lb (10,000kg) of freight • Armament: two 7.62mm M134 Miniguns and one 7.62mm M60D machine gun

Chinook display team begins training at RAF Odiham

Parachute Regiment (4 Para) boarding a Chinook HC4 during Exercise Vortex Warrior in the USA

© Crown Copyright 2021

For video news from the British Armed Forces: https://www.youtube.com/britisharmedforcesdaily

ukforcesnews

British Armed Forces Daily

969 Followers

6 0

25 0

17 0

11 0

10 0

15 0

71 0

102 0

79 0

Follow

How we are funded

Across the site you will find advertisers who support us to keep the service free. This could be through their affiliate links, which means at no extra cost to you, we will make a small commission if you click on something of interest and make a purchase. Partners Include : Amazon

The post THE CHINOOK appeared first on British Armed Forces Daily.

source https://ukforcesnews.co.uk/the-chinook/

0 notes

Text

Powered Roller Conveyors Uk

The evolution of powered roller conveyors represents a significant advancement in material handling technology, transforming how goods are transported in various industries. From their rudimentary beginnings to the sophisticated systems we see today, powered roller conveyors have played a crucial role in enhancing efficiency and productivity across manufacturing, warehousing, and logistics sectors.

Historical Context

The origins of conveyor technology can be traced back to ancient civilizations, where simple mechanisms were used to move heavy materials. However, the modern conveyor system began to take shape in the 18th century with the introduction of rudimentary belt systems for transporting goods like grain. The first patent for a conveyor system was filed in 1908, marking the beginning of an era focused on mechanized material handling.The introduction of roller conveyors came into prominence with the Ford Model T assembly line in the early 20th century. This innovation allowed for mass production techniques that significantly increased manufacturing efficiency. As industries grew, so did the need for more advanced and flexible conveyor systems.

The Rise of Powered Roller Conveyors

Powered roller conveyors emerged as a solution to the limitations of gravity-based systems. By incorporating motorized rollers, these conveyors could transport goods over longer distances and handle heavier loads with greater precision. The first motor-driven roller conveyors were introduced in the 1970s, forming the backbone of automated systems that revolutionized logistics and manufacturing processes.

Key Innovations

Motorized Rollers: The shift from external motors to embedded motors within rollers allowed for more compact designs and greater flexibility. This innovation enabled the creation of independent zones within a conveyor system, allowing for precise control over product movement and reducing safety risks associated with bulky external drives.

Modular Designs: Modern powered roller conveyors are often modular, allowing businesses to adapt their systems easily as needs change. This adaptability is crucial in dynamic environments like warehouses and distribution centers where product types and volumes can vary significantly.

Integration with Automation: The integration of powered roller conveyors with automated systems and robotics has opened new possibilities for fully automated material handling solutions. Smart sensors and AI technologies are now being used to optimize operations, predict maintenance needs, and enhance overall system efficiency.

Energy Efficiency: Advances in motor technology have led to the development of energy-efficient powered roller systems that reduce operational costs and environmental impact. Many modern systems utilize low-voltage DC motors that consume less energy while maintaining high performance.

Current Applications

Today, powered roller conveyors are integral to various applications across multiple industries:

E-commerce Fulfillment: With the rise of online shopping, powered roller conveyors facilitate efficient order processing by automating the movement of packages through sorting and packing stations.

Manufacturing: These systems are used extensively in assembly lines, where they transport components between workstations, enhancing productivity and reducing manual labor.

Logistics and Warehousing: Powered roller conveyors streamline operations by moving goods efficiently through storage areas, improving inventory management and reducing handling times.

Future Trends

As technology continues to evolve, several trends are shaping the future of powered roller conveyors:

Increased Automation: Future designs will likely feature higher levels of automation, reducing manual intervention further and enhancing operational efficiency.

AI Integration: Artificial intelligence will play a pivotal role in optimizing conveyor performance, enabling real-time adjustments based on workflow demands.

Sustainability Efforts: There is a growing emphasis on developing eco-friendly conveyor systems that minimize energy consumption and utilize sustainable materials.

IoT Connectivity: The Internet of Things (IoT) is expected to enhance monitoring capabilities, allowing for comprehensive data collection and improved maintenance strategies across conveyor networks.

Conclusion

The evolution of powered roller conveyors has fundamentally changed how industries approach material handling. From their historical roots to modern innovations, these systems continue to adapt to meet the demands of an ever-evolving market landscape. As technology advances, powered roller conveyors will undoubtedly remain at the forefront of efficient logistics and manufacturing solutions

0 notes

Text

Conveyor System Market Analysis 2021| Industry Trends, Business Revenue Forecast And Statistics, Growth Prospective

A conveyor system is an equipment that is used for handling and transporting materials within industry premises. They are used in several industries. Market Research Future (MRFR) outlines various trends and opportunities for the global conveyor system market report between 2016 and 2022 (forecast period). By monitoring the market structure, this report mensurates the future growth potential of the market. It chalks the strategies of key players in the market and aids the competitive developments like new product developments, mergers & acquisitions, joint ventures, and research & developments (R&D) in the market. The largest market driver for the global conveyor system market is the growth of those industries that have been mentioned in the application segment in the market segmentation section of this press release. The conveyor system is heavily used in these industries. The second market driver is the need for automation to reduce manufacturing costs & wastage of resources. Other important market drivers are growing industrialization, burgeoning e-commerce, and rising adoption of conveyor systems. Market Segmentation The global Conveyor System Market Analysis covers application and type. The segmentation attempts to assess trends of the market to assist in charting the future course for the market. According to the application-based segmentation, this market covers airport, automotive, food & beverages, retail, and others. At airports, the conveyor system is used to transport luggage. In the food & beverages, it is used by bottling companies. Types of conveyor systems discussed in the market include belt conveyors, overhead, pallet, roller, and others. Browse Complete Report - https://www.marketresearchfuture.com/reports/conveyor-system-market-2022

Regional Segmentation The regional segmentation of the global conveyor system market covers Asia Pacific, Europe, North America, and Rest-of-the-World (RoW). Asia Pacific region is the biggest market, followed by North America. It is also the fastest growing regional market due to the modernization of public infrastructure. Along with modernization, construction of new airports, distribution centers, and warehouses is also boosting the market growth in this region. China, India, and Japan are the three economies in this region. North America is the second largest regional market due to technological advancements. The USA has the biggest piece of the market pie in this region. In North America, investment in the conveyor systems market is coming from various end-user industries. After the USA, Canada is the biggest economy that has the potential to be the most powerful market. Many important market players are based in the USA. Europe can also rise as a huge regional market due to technological advancement and the presence of some key market players. In this region, worthy economies to become suitable markets are France, Germany, and the UK. The RoW segment covers the countries of Latin America and the Middle East & Africa (MEA). In Latin America, Mexico and Brazil are two important economies with promises to emerge as robust markets. In the MEA region, the market is small due to the limited availability of technology. Key Players Major players in the global conveyor system market include Allied Conveyor Systems (USA), Caterpillar (USA), Daifuku (Japan), Dematic Group (USA), Dorner Conveyors (USA), Dynamic Conveyors (USA), Emerson Electric (USA), Fives Group (France), FMC Technologies (UK), Intelligrated (USA), Interroll (Switzerland), and Siemens AG (Germany). Latest Industry News

Japanese restaurant Kura Revolving Sushi Bar has launched with a large menu and rewards for a healthy appetite. Debuting at Chinatown’s Shanghai Plaza with conveyor belt, it has taken over a corner space, very close to Spring Mountain Road. 5 JUL 2019

Thai customs have introduced new conveyor belt X-Ray Machines that can not only scan checked-in luggage but can also help officials to detect illegal items. 6 JUL 2019

Jaguar Land Rover is planning steps to build a car conveyor bridge at its Solihull factory. The structure has been planned to be around 168 meters long. It can have a drop section at either end. 8 JUL 2019

Metalloinvest is continuing the advanced construction of a major in pit crushing and conveying (IPCC) facility at its Mikhailovsky GOK iron ore operation. Active installation of the NKMZ crushing and conveyor facility is in progress. With its body is located 200 m underground, it can easily receive iron ore from heavy trucks and crush it to 150 mm pieces. After that, it can deliver the crushed or via an underground gallery to the NKMZ high angle conveyor. 19 JUNE 2019

Browse Complete Report - https://www.marketresearchfuture.com/reports/conveyor-system-market-2022

About Market Research Future: At Market Research Future (MRFR), we enable our customers to unravel the complexity of various industries through our Cooked Research Report (CRR), Half-Cooked Research Reports (HCRR), Raw Research Reports (3R), Continuous-Feed Research (CFR), and Market Research & Consulting Edibles. MRFR team have supreme objective to provide the optimum quality market research and intelligence services to our clients. Our market research studies by products, services, technologies, applications, end users, and market players for global, regional, and country level market segments, enable our clients to see more, know more, and do more, which help to answer all their most important questions. Media Contact Company Name: Market Research Future Contact Person: Abhishek Sawant Email: Send Email Phone: +1 646 845 9312 Address:Market Research Future Office No. 528, Amanora Chambers Magarpatta Road, Hadapsar City: Pune State: Maharashtra Country: India Website: https://www.marketresearchfuture.com

0 notes

Text

Recycling company fined after employee suffers amputation

A waste recycling company has been fined after an employee lost part of his arm in a conveyor belt.

Lincoln Crown Court heard on 26 April 2015 that the employee of Mid-UK Recycling Ltd was working as a line operator in the building known as Unit 4 MRF (Material Recovery Facility). On the morning of the incident, blockages had occurred on this line and waste had become wrapped around the axle stopping a lower conveyor. It was whilst removing waste from this axle that the employee’s glove got dragged into the in-running nip between the belt and the powered roller of the conveyor. This resulted in his left arm being amputated above the elbow.

An investigation by the Health and Safety Executive revealed that the company had failed to prevent access to dangerous parts of the conveyor. The castell key system had essentially been bypassed allowing the system to be operated in automatic mode with persons still inside the enclosure.

Mid UK Recycling Limited (now known as MUKR Limited) of Summit House, Quarrington, Sleaford, Lincolnshire, NG34 8RS pleaded guilty to a breach of section 2 (1) of the Health and Safety at Work etc. Act (1974) and was fined £1.275 million and ordered to pay costs of £45,065.59

Speaking after the hearing, HM inspector Scott Wynne said, “This incident could so easily have been avoided had the company ensured that the system designed to keep people away from dangerous machinery was properly maintained. Companies should be aware that HSE will not hesitate to take appropriate enforcement action against those that fall below the required standards.”

0 notes

Text

Europe Industrial Roller Chain Drives In-Depth Profiling With Key Players and Recent Developments, Forecast Period: 2021-2031

The Europe industrial roller chain drive market size was valued at $503 million in 2021, and is projected to reach $676.7 million by 2031, registering a CAGR of 2.8% from 2022 to 2031. Industrial roller chain drive is a mechanism used for transferring mechanical power from one component or machinery to another. It includes a sprocket that drives a roller chain by engaging its tooth between the gap of two consecutive rollers. Thus, when the sprockets rotate, it transfers its energy to the chain, which is connected to a driven sprocket on the other machine; thereby, transferring mechanical power.

Roller chain drive is widely used for mechanical power transmission in various industries and machineries, owing to its advantages, such as high efficiency in power transmission, high power to weight ratio, and smaller footprint. Moreover, it is inexpensive and easy to maintain. Such advantages of industrial roller chain drives are anticipated to drive their demand during the forecast period.

Manufacturing is a major revenue generating sector in UK, Germany, France, and Italy. This is attributed to high disposable income of people and the large demand for personal care & home care products. Since, manufacturing industry utilizes industrial roller chain drives for mechanical power transmission, rise in demand for personal care and home care products is anticipated to drive the demand for industrial roller chains during the forecast period.

The Europe industrial roller chain drive market is segmented on the basis of standard, type, application. end user and region. By standard, the market is bifurcated into British Standard Chain (BS), American National Standards Institute Chain (ANSI) and other. By type, the market is categorized into single-strand chain, double pitch chain, multi-strand chain and others. On the basis of application, it is categorized into power transmission, conveyor, and hoisting and hauling. And on the basis on end user, the market is categorized into manufacturing, mining, material handling and others.

Competition Analysis

Key companies profiled in the Europe industrial roller chain drive market report include Diamond Chain Company Inc., Ditton Driving Chain Factory, Fordertechnik Kenizler GmbH, Hangzhou Donghua Chain Groups CO.Ltd., Hengjiu Group, IWIS Antriebssysteme GmbH & Company KG, Kettentechnik Roeder GmbH, KMC, Regal Rexnord Corporation, Renold plc., Sugiyama Chain Co., Ltd., Tsubakimoto Chain Co., Wippermann Jr. GmbH, Z.M.C. Italia and Topbas Group.

Full Report With TOC:-https://www.alliedmarketresearch.com/europe-industrial-roller-chain-drive-market-A47374

0 notes

Text

Programmable Conveyors Market Expected to Grow Faster According to New Research Report – 2026

United States (2021):- The

Programmable Conveyors Market

report makes available the current and forthcoming technical and financial details of the industry. It is one of the most comprehensive and important additions to the Prudent Markets archive of market research studies. It offers detailed research and analysis of key aspects of the global Programmable Conveyors market. This report explores all the key factors affecting the growth of the global Programmable Conveyors market, including demand-supply scenario, pricing structure, profit margins, production, and value chain analysis.

The report concludes with the profiles of major players in the Programmable Conveyors market are: ATS, Daifuku, Bosch Rexroth, SFI, Durr, Fives Group, SSI, Idealline, Allied Conveyor Systems, RichardsWilcox

Global Programmable Conveyors Market research is an understanding report with meticulous efforts undertaken to study the right and important information offering an entire study of the Impact of COVID-19 on Programmable Conveyors Market, Industry Outlook, Opportunities in Market, and Expansion By 2026 and also taking into consideration key factors like drivers, challenges, recent trends, opportunities, advancements, and competitive landscape. Research techniques like PESTLE and SWOT analysis are made available by the researchers.

Discover Who You Really Compete Against In The Marketplace, Get Free PDF Sample Report Now!

https://www.prudentmarkets.com/sample-request/81440/

Type Segmentation: Automated Guided Vehicles (AGV) Systems, Monorail Systems, Powered Roller Systems

Industry Segmentation: Electronic, Automotives, Consumer Goods, Others

Programmable Conveyors Market

Prudent Markets provides attractive discounts that fit your needs. Customization of the reports as per your requirement is also offered. Get in touch with our sales team, who will guarantee you a report that suits your needs.

Speak To Our Analyst For A Discussion On The Above Findings, And Ask For A Discount Up To 40% On The Report @

https://www.prudentmarkets.com/discount-request/81440/

In this study, the years considered to estimate the market size of Programmable Conveyors Market:

History Year: 2015 – 2020

Base Year: 2020

Estimated Year: 2021

Forecast Year: 2021 – 2026

The report covers the competitive analysis of the market. As the demand is driven by a buyer’s paying capacity and the rate of item development, the report shows the important regions that will direct growth. This section exclusively shares insight into the budget reports of big-league members of the market helping key players and new entrants understand the potential of investments in the Global Programmable Conveyors Market. It can be better employed by both traditional and new players in the industry for complete know-how of the market.

Regional Analysis for Programmable Conveyors Market:

• North America (the USA and Canada)

• Europe (UK, Germany, France, Italy, Spain, Scandinavia and Rest of Europe)

• Asia Pacific (Japan, China, India, Australia, Southeast Asia and Rest of Asia Pacific)

• Latin America (Brazil, Mexico and Rest of Latin America)

• Middle East & Africa (South Africa, GCC and Rest of the Middle East & Africa)

The report provides insights on the following pointers:

1. Market Penetration: Comprehensive information on the product portfolios of the top players in the Programmable Conveyors market.

2. Product Development/Innovation: Detailed insights on the upcoming technologies, R&D activities, and product launches in the market.

3. Competitive Assessment: In-depth assessment of the market strategies, geographic and business segments of the leading players in the market.

4. Market Development: Comprehensive information about emerging markets. This report analyzes the market for various segments across geographies.

5. Market Diversification: Exhaustive information about new products, untapped geographies, recent developments, and investments in the Programmable Conveyors market.

Any Questions? Feel Free To Enquire Here. Well put you on the Right Path @

https://www.prudentmarkets.com/enquiry-request/81440/

Free Customization on the basis of client requirements on Immediate purchase:

1- Free country-level breakdown of any 5 countries of your interest.

2- Competitive breakdown of segment revenue by market players.

Customization of the Report:

This report can be customized to meet the client’s requirements. Please connect with our sales team (

), who will ensure that you get a report that suits your needs. You can also get in touch with our executives on +91 83560 50278 || USA/Canada(Toll Free): 1800-601-6071 to share your research requirements.

Get ready to Recognize the pros and cons of the regulatory framework, local reforms, and its effect on the Industry. Understand how the Leaders in Intelligent Network are keeping themselves one stage forward with our most up-to-date survey analysis.

In conclusion, the Programmable Conveyors Market report is a genuine source for accessing the research data which is projected to exponentially grow your business. The report provides information such as economic scenarios, benefits, limits, trends, market growth rates, and figures. SWOT analysis and PESTLE analysis is also incorporated in the report.

0 notes

Link

Enclosed Belt Conveyors are designed for the safe, gentle, and efficient handling of dry, bulk materials. This unique, totally enclosed belt conveyor design contains dust and spilled material and automatically reloads that material back on to the belt. An enclosed belt conveyor offers many benefits, in terms of protecting grain quality, eliminating dust emissions, and improved sanitation. It also offers longer machine life, requires less power and maintenance, and improves facility safety. Scope of the Report: This report focuses on the Enclosed Belt Conveyor in Global market, especially in North America, Europe and Asia-Pacific, South America, Middle East and Africa. This report categorizes the market based on manufacturers, regions, type and application. Market Segment by Manufacturers, this report covers GSI (AGCO Corporation) Ag Growth International ContiTech AG Kase Custom Conveyors CTB, Inc. (Berkshire Hathaway Inc.) Buhler Sweet Manufacutering GSS Systems Mysilo (SF Group) Guttridge Limited Altinbilek Jingu Xiangliang Machine Ptsilo Market Segment by Regions, regional analysis covers North America (USA, Canada and Mexico) Europe (Germany, France, UK, Russia and Italy) Asia-Pacific (China, Japan, Korea, India and Southeast Asia) South America (Brazil, Argentina, Columbia etc.) Middle East and Africa (Saudi Arabia, UAE, Egypt, Nigeria and South Africa) Market Segment by Type, covers Roller Spool Air Cushion Market Segment by Applications, can be divided into Agriculture Mining Industry Construction Material Other There are 15 Chapters to deeply display the global Enclosed Belt Conveyor market. Chapter 1, to describe Enclosed Belt Conveyor Introduction, product scope, market overview, market opportunities, market risk, market driving force; Chapter 2, to analyze the top manufacturers of Enclosed Belt Conveyor, with sales, revenue, and price of Enclosed Belt Conveyor, in 2016 and 2017; Chapter 3, to display the competitive situation among the top manufacturers, with sales, revenue and market share in 2016 and 2017; Chapter 4, to show the global market by regions, with sales, revenue and market share of Enclosed Belt Conveyor, for each region, from 2012 to 2017; Chapter 5, 6, 7, 8 and 9, to analyze the market by countries, by type, by application and by manufacturers, with sales, revenue and market share by key countries in these regions; Chapter 10 and 11, to show the market by type and application, with sales market share and growth rate by type, application, from 2012 to 2017; Chapter 12, Enclosed Belt Conveyor market forecast, by regions, type and application, with sales and revenue, from 2017 to 2022; Chapter 13, 14 and 15, to describe Enclosed Belt Conveyor sales channel, distributors, traders, dealers, Research Findings and Conclusion, appendix and data source

#(north america#asia-pacific#america#and africa) enclosed belt conveyor market#and africa) enclosed belt conveyor market trends#and africa) enclosed belt conveyor market size#and africa) enclosed belt conveyor market data#and africa) enclosed belt conveyor market structure#and africa) enclosed belt conveyor industry analysis#and africa) enclosed belt conveyor market research

0 notes

Text

Get The Finest Quality Bearings Online in UK.

We use variety of engineering equipment for various purposes in our daily life. We find many machines and equipment in industries that are driven by shafts. Whenever power transmission is required, shaft plays important role in transforming one form of energy into other. Electric motors, fans, blowers, pumps, engines, vehicles and many other utilities are commonly used all over for different functions such as running a finishing equipment like abrasive grinder, lifting water from bore wells, mixer grinder in kitchens, ventilating blowers fitted near roofs, diesel generators to generate electricity and many more.