#Programmable motor driver

Explore tagged Tumblr posts

Text

Programmable motor driver, stepper motor drivers, Driver Power Switch

N-Channel 500 V 0.27 Ohm Flange Mount SuperMESH Power MosFet - TO-220

0 notes

Text

In the modern industrial landscape, precise temperature control is crucial for maintaining efficiency and quality in processes. Theta Controls, a trusted name in the automation sector, offers state-of-the-art programmable temperature controllers in Pune, Maharashtra. With advanced features, reliable performance, and user-friendly interfaces, our controllers are designed to cater to diverse industries such as manufacturing, pharmaceuticals, food processing, and more.

0 notes

Text

https://www.futureelectronics.com/p/semiconductors--analog--drivers--motor-drivers/l298n-stmicroelectronics-5532882

Brushless DC motor driver, Dc motor driver, what is a motor driver

L298 Series 46 V 2 A Dual Full Bridge Driver Vertical - Multiwatt-15

#Drivers Motor Drivers#L298N#STMicroelectronics#Brushless DC motor driver#Dc motor driver#what is a motor driver#bipolar stepper#Stepper motor drivers#Bipolar stepper#Motor driver circuit#programmable motor driver#chip#H bridge

1 note

·

View note

Text

https://www.futureelectronics.com/p/semiconductors--analog--drivers--motor-drivers/l298n-stmicroelectronics-5319967

STMicroelectronics, L298N, Drivers Motor Drivers

L298 Series 46 V 2 A Dual Full Bridge Driver Vertical - Multiwatt-15

#STMicroelectronics#L298N#Drivers Motor Drivers#DC motor driver control#circuit#h bridge#4 Phase Bridge Driver#multi MOSFET driver#Bipolar stepper#motor driver chip#Programmable motor driver#brushless motor driver

1 note

·

View note

Text

Servo motor driver, Programmable motor driver, dc motor speed control

L6208 Series 52 V 5.6 A 0.3 Ohm DMOS Driver For Bipolar Stepper Motor-POWERSO-36

0 notes

Text

https://www.futureelectronics.com/p/semiconductors--analog--drivers--motor-drivers/l298n-stmicroelectronics-5088472

What is a motor driver, Current Limit Switch, Stepper motor drivers

L298 Series 46 V 2 A Dual Full Bridge Driver Vertical - Multiwatt-15

#STMicroelectronics#L298N#Drivers Motor Drivers#what is a motor driver#Current Limit Switch#Stepper motor drivers#Motor driver manufacturers#H bridge motor driver#Analog motor drivers#programmable motor driver Dc motor driver#dc#circuit

1 note

·

View note

Text

Voyager (1998) by Dave Woodfield, UK. Voyager competed in the 1998 UK Micromouse competition held in Manchester (see video), and the 1999 Micromouse National Finals where it came second with a time of 37.72 seconds.

"This is Voyager. … You can see that at least when it's exploring it turns just by turning one wheel backwards one wheel forwards and it runs on a couple of sort of Sliders that stop the front and back from dragging on the ground too much. You keep hearing this 'magic expression algorithm' which is just a nice technical way of saying this is how we work out how to get to the middle of the maze. … Now this mouse I suspect will not be capable of improving its time ... because its total elapsed time penalties will be added to its score." – Alan Dibley, UK Micromouse 1998.

"Voyager is a very smart looking (and running) micromouse mouse from Dave Woodfield. His first mouse since Enterprise in 1984, Voyager is a traditional wheelchair mouse driven by stepper motors. A Dallas DS5001 processor does the work. This is a 8051 derivative with on-board, battery-backed RAM. Easy to work with and offering a relatively low component count, these are popular processors for micromouse builders. Sensing is by means of an array of top-down, reflective IR sensors. There are a lot of these and they are managed by a Xilinx Programmable Logic Array chip. In the photographs, the entire top board that you can see is dedicated to the sensor system. If you want to be able to run diagonally, with a single row of sensors, you will want a fair number of them. As yet, Voyager does not perform diagonal runs. There is still work to be done on this mouse and, while quick, it will not necessarily beat Enterprise. ... The upper board hold the sensor processing circuitry. The lower one carries the processor and the motor drivers. A total of ten NiCd cells provides plenty of voltage for the stepper motor's chopper drive circuits. Essential for high performance from stepper motors. That big chip there is a PLA, not the processor. It looks after the sensors and the motor sequencing." – Pete Harrison.

70 notes

·

View notes

Text

Lost F1 Media

Advanced Driving with Graham Hill (lost ITV motoring series from 1974)

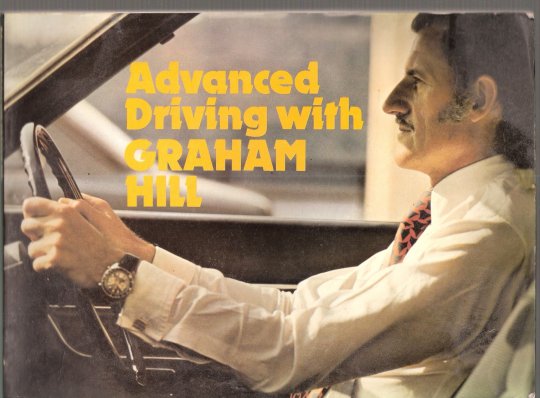

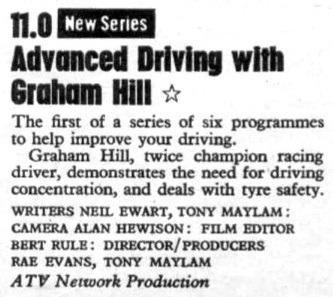

Advanced Driving with Graham Hill (also known as Advanced Driving) was an ATV motoring show. It was presented by two-time Formula One world champion Graham Hill.

It involved Graham Hill giving practical advice on how to become a better and safer driver on the roads of Britain.

(the book cover)

Background

Advanced Driving with Graham Hill was conceived for ATV, most likely in response to the statistic that stated that 90% of road accidents were the result of poor or incorrect driving, as the shows name says, the presenter was two-time Formula One world champion graham hill.

Graham himself had famously experienced the consequences of serious crashes first-hand;

At the 1969 United States Grand Prix, his Lotus-Ford was suffering from bald real tyres, and crucially a popped-out seatbelt that he was unable to belt properly back-in, even with help from mechanics.

As he drove out again a rear tyre collapsed, causing the car to flip and he was thrown out of the cockpit.

He suffered leg injuries so severe that it was at first deemed unlikely that he would ever race again.

In the end, he recovered fast enough to race for the opening race the following season.

Six 30-minute episodes were made, and were broadcast between June 1974.

The first episode was Graham highlighted the importance of driving concentration, and ensuring fair tyre safety. Other episodes focused on issues such as reverse parking, overtaking, speed and windscreens.

Little else is known surrounding most of the show’s episodes, but the book with the same name, published in 1975 and co-written by Graham Hill and Neil Ewart, was notably based on the series.

Availability

While the book is generally available, the Tv series has yet to publicly resurface, with no footage or images being viewable. Considering ATV famously wiped some of its 1970s programmes, it's possible that Advanced Driving with Graham Hill suffered this fate.

(a listing of the tv show from a newspaper)

#formula1#formula 1#formula one#f1#graham hill#f1 lore#old formula 1#lost media#live laugh lost media

20 notes

·

View notes

Text

Motor driver controller, DC motor driver, Programmable motor driver

ULN Series 50V 500 mA Integral Suppression Diode Eight Darlington Array - DIP-18

0 notes

Text

TOM'S Corolla Turbo

The TOM'S Corolla Turbo project in 1999 was a notable effort by TOM'S Japan to bring its high-performance tuning expertise to the Southeast Asian market, particularly the Philippines. By collaborating with Kilton Motors, TOM'S aimed to enhance the Toyota Corolla Altis, a popular sedan, to compete directly with the Honda Civic SiR, which was a favorite among car enthusiasts.

Key Features and Components

Aero Kit and Turbo Unit: The project included a stylish aero kit and a bolt-on turbo unit designed to boost both appearance and performance.

Components and Fabrication: Various off-the-shelf Toyota parts, like the turbo and intercooler, were utilized to keep costs down. Custom components included a welded tubular stainless steel turbo manifold and downpipe, aluminum intercooler piping, and a 3-inch mild steel exhaust.

ECU Tuning: TOM'S used its own programmable ECU for tuning, achieving an estimated 150hp at the wheels.

Driving Experience and Performance

Test Vehicle: The test vehicle, equipped with the TOM'S kit, showcased a sporty bodykit with a hood scoop, front bumper air dam, and a tall rear wing. It also featured exclusive 15x7 alloy wheels.

Turbo Performance: The small turbo provided quick spooling and minimal lag, making the car very responsive. The engine's power delivery was strong, easily lighting up the front tires up to third gear.

Publicity Stunt: In a drag race event, the car, driven by actor and TOM'S works driver Jomari Yllana, reportedly achieved an 11+ second, 167kph run down the 1/8th mile.

Market Reception and Rarity

High Cost: The TOM'S package had a high price tag of around P160,000, in addition to the cost of the Corolla Altis, making it affordable only to a few.

Limited Sales: Despite the efforts to market the car, only a handful of body kits and four complete vehicles were sold. These vehicles are now considered rare, with some still believed to be in their original condition.

The TOM'S Corolla Turbo remains one of the fastest and most powerful Corollas ever sold by local dealers in the Philippines. While opinions on its aesthetics varied, its performance and rarity have cemented its status as a unique and notable part of automotive history in the region.

#TOM'S#TOM'S Racing#トムス#株式会社トムス#TOM'S Corolla Turbo#TOM'S Version#TOYOTA#COROLLA#TOYOTA COROLLA#ALTIS#JDM#PHDM#brochure#Legends of the 90's

11 notes

·

View notes

Text

US option emerges for Mick Schumacher despite 'still pinning his hopes on Alpine'

From Formula 1 to the World Endurance Championship to Indycar? Mick Schumacher has caught the attention of Dale Coyne Racing, who are "talking" with the German.

The son of seven-time F1 World Champion Michael Schumacher, Mick Schumacher had a tumultuous time during his two seasons on the grid with Haas before he was dropped by then-team boss Guenther Steiner.

'Mick Schumacher still pinning his hopes on the Alpine commitment'

Mercedes were quick to snap him up, but as a reserve driver, which is a role he retained this season as he dovetailed that with a World Endurance programme as an Alpine driver, but despite his links to two F1 teams, the German will reportedly miss out on a return to the grid for the 2025 championship. While it has been widely reported that Mercedes could promote junior driver Kimi Antonelli, Auto Motor und Sport claims Alpine's first pick, should they not retain either Pierre Gasly or Esteban Ocon, is Jack Doohan, with Victor Martins also in the running. As such, Schumacher's racing career could head in a new direction and towards a new continent. According to the German publication, Indycar's Dale Coyne is keen on signing the 25-year-old. "There are all these Formula 2 drivers who finish first or second but have no real future in Formula 1," he said. "Mick Schumacher is a perfect example. We would love to welcome such a great driver here. We are talking to Mick Schumacher, but he is still pinning his hopes on the Alpine commitment. I would be happy if we were given the chance." On his side, Schumacher has made it clear he wants to return to Formula 1 racing. "My goal and my dream is to drive in Formula 1. That has always been the case and always will be. That's why we have to make sure that the dominoes now fall in my favour and that I hopefully end up with a seat. What I can do for that is simply give my best performance in the WEC and also in Formula 1, and continue to perform well for the team as reserve driver and continue to hold talks."

#mick schumacher#f1#formula 1#fic ref#fic ref 2024#not a race#2024 not a race#between monaco and canada 2024#between imola and monaco 2024#dale coyne#(note to self: article uploaded june 1 2024)

6 notes

·

View notes

Text

Smart Sensors & AI: The New Face of Emission Monitoring

The global Emission Monitoring Systems Market is on a remarkable growth trajectory. Valued at US$ 4.8 Bn in 2023, the industry is projected to more than double and reach US$ 10.7 Bn by 2034, growing at a steady CAGR of 7.7%. This growth is primarily driven by a global push toward environmental sustainability, increased regulatory scrutiny, and technological innovation in real-time pollution monitoring systems.

Understanding Emission Monitoring Systems

Emission Monitoring Systems (EMS) are critical tools designed to track and measure pollutant emissions from various industrial processes. These systems provide real-time data that help businesses and governments detect, quantify, and manage environmental pollution from sectors such as oil & gas, power generation, chemicals, transportation, and waste management.

EMS technologies can monitor pollutants like carbon dioxide (CO₂), nitrogen oxides (NOx), sulfur dioxide (SO₂), particulate matter, and volatile organic compounds (VOCs). Data collected from these devices not only ensures regulatory compliance but also offers actionable insights into optimizing operations for improved environmental performance.

Market Drivers: Pollution and Regulations

One of the most significant market drivers is the rise in pollution levels globally. Rapid urbanization, deforestation, and industrial expansion have led to increased air pollution, prompting governments to implement stricter emission control norms. According to the World Health Organization (WHO), air pollution is responsible for nearly 7 million premature deaths annually. Furthermore, the United Nations Environmental Programme (UNEP) estimates that pollution-related health issues cost economies nearly 4% of their GDP.

To mitigate these challenges, industries are deploying EMS technologies that provide transparency, accountability, and compliance with local and international environmental standards. The ability of these systems to deliver accurate and timely emission data makes them indispensable for industries aiming to align with climate goals such as the Paris Agreement.

Clean Technology Advancements Boosting Market Growth

A key enabler of EMS market growth is the rapid advancement in clean technologies. Modern emission monitoring solutions now incorporate:

A prominent example is the 2023 collaboration between Hyundai Motor Corporation and Kia Corporation to introduce an AI-enabled, blockchain-powered CO₂ Emission Monitoring System. This project focuses on emission tracking across the entire supply chain, highlighting the future of data integrity and transparency in emissions management.

Regional Dynamics: Asia Pacific Dominates

Asia Pacific emerged as the largest regional market for EMS in 2023, led by countries such as China, India, and South Korea. Rapid industrialization, increased governmental investment in green infrastructure, and high awareness levels regarding air quality have fueled EMS adoption in the region.

According to Carbon Brief, China alone invested more than US$ 890 Bn in clean energy and technology in 2023. Its national monitoring infrastructure covers over 44,000 gas discharge ports and 31,000 wastewater discharge ports, reflecting the country's deep commitment to environmental surveillance.

Meanwhile, the Middle East & Africa is anticipated to grow steadily through 2034, spurred by expanding oil & gas activities and the adoption of predictive emission technologies.

Industrial Adoption and Applications

The utility of EMS extends across several high-impact industries:

These industries are investing heavily in EMS tools to align with Environmental, Social, and Governance (ESG) criteria and ensure long-term compliance with both local and global environmental mandates.

Competitive Landscape

The EMS market is characterized by technological innovation and strategic partnerships. Leading companies such as ABB, Siemens, Emerson Electric Co., Thermo Fisher Scientific, Sick AG, and AMETEK are heavily investing in next-gen monitoring systems with improved portability, sensitivity, and cloud compatibility.

Key strategies include:

These companies are developing tailored solutions that meet the unique requirements of different geographies and industries.

Conclusion

The Emission Monitoring Systems Market is rapidly evolving as environmental accountability becomes a global priority. Regulatory pressures, public health concerns, and the urgent need to combat climate change are pushing industries to adopt intelligent emission monitoring solutions. Innovations in AI, cloud computing, and sensor technology are making these systems more accurate, efficient, and accessible.

With the global market projected to reach US$ 10.7 Bn by 2034, emission monitoring systems are poised to play a crucial role in shaping a cleaner, safer, and more sustainable industrial future.

0 notes

Text

Explore the Best Honda New and Used Car Offers in the UK

When it comes to reliable, stylish, and fuel-efficient vehicles, Honda has long been a top choice among UK drivers. Whether you're searching for a brand-new model with cutting-edge technology or a dependable used car that offers excellent value for money, Honda has a range of offers to suit different budgets and preferences. In this blog, we’ll guide you through the benefits of Honda new and used car offers, and why now might be the perfect time to upgrade your vehicle.

Why Choose Honda?

Honda is renowned for its engineering excellence, long-lasting performance, and innovative features. From compact hatchbacks like the Honda Jazz to family-friendly SUVs such as the CR-V and HR-V, Honda’s range delivers on comfort, safety, and style. The brand’s hybrid and electric options are also becoming increasingly popular across the UK, aligning with the growing demand for eco-friendly motoring solutions.

New Honda Car Offers in the UK

If you’re in the market for a new car, Honda offers attractive packages designed to make owning a new model more accessible. These offers typically include flexible finance solutions such as Hire Purchase (HP) and Personal Contract Purchase (PCP) plans, allowing you to spread the cost over monthly payments.

Some common incentives you may find on new Honda models in the UK include:

Deposit contributions when financing through approved lenders

Low-interest rates or 0% APR offers on select models

Complimentary servicing packages for added peace of mind

Exclusive offers on hybrid and electric Honda models

These promotions are usually available for a limited time and may vary by location, so it's always a good idea to visit your local Honda showroom or contact a sales advisor for the most up-to-date details.

Used Honda Car Offers in the UK

Purchasing a used Honda is a smart way to enjoy the brand’s high quality and reliability at a more affordable price. Approved used Honda vehicles go through thorough checks to ensure they meet manufacturer standards, giving you added confidence in your purchase.

Typical benefits of used Honda car offers in the UK include:

Competitive pricing on a wide range of models and trims

Vehicle history checks and multi-point inspections

Warranty options for added protection

Flexible finance packages to suit various budgets

Low-mileage and nearly-new vehicles available

Choosing a used Honda through an approved programme ensures you receive a vehicle that performs like new but at a significantly reduced cost.

Things to Consider When Shopping for Offers

When exploring Honda car offers in the UK, keep the following in mind:

Fuel Type: Consider whether a petrol, hybrid, or electric Honda fits your lifestyle and driving habits.

Finance Terms: Always check the terms and conditions of any finance or leasing agreements to understand what’s included.

Mileage and Usage: For used cars, review the vehicle’s service history and mileage to ensure it meets your expectations.

After-Sales Support: Look for offers that include added benefits like servicing, MOTs, or breakdown assistance.

Final Thoughts

Whether you’re buying brand-new or exploring approved used vehicles, Honda’s current offers in the UK make it easier than ever to drive away in a car you can trust. With a reputation for performance, safety, and reliability, Honda continues to be a smart investment for drivers across the country.

0 notes

Text

Variable Frequency Drive (VFD) Market Witnesses Strong Growth with Rising Industrial Automation and Energy Efficiency Needs

The variable frequency drive (VFD) market is experiencing remarkable growth, driven by the twin forces of industrial automation and global energy efficiency initiatives. As industries strive to optimize productivity while reducing energy consumption and environmental impact, VFDs have become an essential component in modern motor control systems. From manufacturing plants and commercial buildings to electric vehicles and smart infrastructure, the demand for VFDs continues to surge.

Industrial Automation: A Primary Growth Driver

Industrial automation is undergoing a global expansion, spurred by the need for increased productivity, operational efficiency, and real-time process control. In automated systems, VFDs are essential for optimizing motor performance in a wide range of applications, including:

Conveyor systems in manufacturing plants

Robotic arms in assembly lines

CNC machinery in precision manufacturing

Packaging and bottling systems

Material handling and processing equipment

VFDs allow seamless control of motor speeds based on real-time data, enabling machinery to operate precisely as needed rather than at constant speeds. This not only increases output quality and consistency but also reduces idle time and energy waste.

The growing trend of Industry 4.0, which emphasizes the digitization of manufacturing through connected systems, is accelerating the integration of VFDs into smart factory ecosystems. Modern VFDs come equipped with IoT connectivity, advanced diagnostics, and integration with PLCs (Programmable Logic Controllers), making them vital components in next-generation automation platforms.

Energy Efficiency: A Global Imperative

Another critical factor propelling the VFD market is the global push for energy efficiency and sustainability. Electric motors account for nearly 45% of the world's electricity consumption, much of which is wasted due to inefficient motor operation. VFDs address this problem directly by enabling motors to operate only as fast as needed, which can lead to energy savings of 20–60%, depending on the application.

Governments and regulatory bodies are encouraging the adoption of VFDs through incentives, standards, and energy codes. For example:

In the European Union, regulations such as the Ecodesign Directive require energy-efficient motor systems.

In the United States, programs like the DOE's Motor Challenge Program promote energy-efficient motor practices.

India and China have launched national initiatives to reduce industrial energy consumption, creating significant demand for efficient motor control systems.

With such global momentum behind energy conservation, the role of VFDs as an enabler of low-carbon, energy-conscious operations is more prominent than ever.

Expanding Applications Across Industries

The versatility of VFDs has led to their adoption across diverse sectors beyond manufacturing, including:

HVAC and Building Automation

In HVAC systems, VFDs optimize the operation of fans, pumps, and compressors based on real-time environmental conditions. This improves indoor comfort while minimizing energy use in commercial, industrial, and residential buildings.

Water and Wastewater Treatment

Water utilities use VFDs to control pumps, reducing energy costs and mechanical strain. Their application is critical in managing variable loads and ensuring process consistency in treatment facilities.

Oil and Gas

VFDs are employed in drilling operations, pipeline transport, and refining to regulate motor-driven systems under challenging conditions, improving safety and efficiency.

Electric Vehicles (EVs)

As the EV market grows, VFDs are used to control electric motors in propulsion systems, regenerative braking, and auxiliary power units.

Technological Advancements Boosting Market Growth

Innovation in VFD technology is enhancing performance, user experience, and application potential. Key advancements include:

Sensorless vector control for precise torque and speed control without needing external feedback devices

Real-time monitoring and remote diagnostics, made possible by IoT integration

Compact and modular designs, which simplify installation and expand application possibilities

Built-in safety features like torque limiting, overload protection, and soft-start functions

Harmonic filters and EMC shielding, which improve system reliability and reduce interference

These technological improvements are making VFDs more adaptable, intelligent, and suitable for mission-critical applications across sectors.

Regional Market Trends

The Asia-Pacific region is leading the global VFD market in terms of growth, driven by rapid industrialization, urbanization, and investments in automation. China, India, Japan, and South Korea are prominent players, supported by government initiatives that promote energy-efficient and automated industries.

North America and Europe continue to be significant markets, propelled by early adoption of energy-saving technologies, stringent regulations, and a mature industrial base. In contrast, Latin America, the Middle East, and Africa are emerging markets where infrastructure development and energy management needs are driving VFD adoption.

Challenges and Considerations

Despite their numerous benefits, VFDs come with a few challenges:

High initial cost compared to traditional motor starters

Technical complexity in programming and integration

Compatibility issues with older electrical systems

Electromagnetic interference (EMI) risks in sensitive environments

However, increasing awareness of long-term cost savings, simplified user interfaces, and vendor support are helping to overcome these barriers and expand market penetration.

Future Outlook

With the convergence of automation, digitization, and sustainability, the Variable Frequency Drive market is expected to maintain a strong compound annual growth rate (CAGR) over the next decade. As industries continue to modernize operations and reduce their environmental footprint, VFDs will play a pivotal role in enhancing efficiency, precision, and control in motor-driven systems.

Companies that invest in R&D, offer customizable and intelligent solutions, and provide strong post-installation support are well-positioned to capitalize on the expanding market landscape.

Conclusion

The Variable Frequency Drive market is thriving in an era marked by industrial transformation and energy consciousness. As businesses worldwide prioritize automation, process control, and sustainability, VFDs are proving to be indispensable tools for optimizing performance and reducing energy waste. With continued innovation and broadening applications, the market’s trajectory points to sustained growth and long-term relevance.

0 notes

Text

The History and Evolution of Horizontal Flow Wrapping Technology

The packaging industry has undergone significant transformation over the past century, with horizontal flow wrapping emerging as one of the most efficient and versatile technologies for packaging products in a wide range of industries. From its humble beginnings in the early 20th century to the sophisticated high-speed machines in operation today, horizontal flow wrapping has evolved in response to the growing demands for speed, hygiene, flexibility, and sustainability.

The roots of horizontal flow wrapping technology can be traced back to the early developments in the packaging of confectionery and baked goods. During the first half of the 20th century, many products were hand-wrapped or packaged using rudimentary machines that relied on manual feeding. As demand for mass-produced goods increased, manufacturers began seeking automated solutions to improve packaging speed and consistency. This led to the development of the first mechanized wrapping systems, which were largely vertical in design and suitable for granular or powder-based products.

It wasn’t until the mid-20th century that the concept of horizontal flow wrapping truly began to take shape. The shift toward horizontally feeding products into wrapping machines allowed for a broader range of item types including irregularly shaped or fragile goods to be wrapped efficiently. These early horizontal flow wrappers featured relatively simple mechanics: a continuous roll of film, a feeding conveyor, and rotating sealing jaws. However, even this basic configuration revolutionized packaging lines by enabling faster operation and reducing labor dependency.

By the 1960s and 1970s, horizontal flow wrapping had become more refined, incorporating improved film handling systems and more precise control mechanisms. The rise of consumer-packaged goods, especially in food and pharmaceuticals, demanded a higher standard of hygiene and packaging integrity. This drove innovation in machine design, leading to the development of servo-driven motors and programmable logic controllers (PLCs) in the 1980s and 1990s. These advancements brought a new level of automation and precision, allowing operators to control variables such as sealing temperature, film tension, and product positioning with far greater accuracy.

The evolution of packaging films also played a crucial role in the advancement of horizontal flow wrapping. Initially, machines used simple waxed paper or cellophane. Over time, manufacturers developed multi-layer films with barrier properties that extended shelf life and protected sensitive products from moisture, oxygen, and contaminants. Flow wrapping machines had to adapt to these new materials, requiring innovations in heat sealing technology and material handling systems.

Entering the 21st century, horizontal flow wrapping has become synonymous with high-speed, high-efficiency packaging. Today’s machines are capable of wrapping hundreds of products per minute, with minimal downtime and rapid changeover between product types. The integration of sensors, touch-screen interfaces, and even remote diagnostics has made these machines smarter and more user-friendly. In highly regulated industries like pharmaceuticals, modern horizontal flow wrappers also include features such as tamper-evident seals, coding and serialization, and compliance with stringent international standards.

Sustainability has become a key driver of innovation in recent years. As industries face increasing pressure to reduce plastic usage and environmental impact, horizontal flow wrapping technology has adapted once again. Many manufacturers are now designing machines that can handle recyclable or biodegradable films without sacrificing speed or seal integrity. Energy-efficient motors and optimized cutting mechanisms also help reduce overall carbon footprints, making flow wrappers part of the solution in sustainable manufacturing.

Looking ahead, the future of horizontal flow wrapping lies in further integration with digital technologies. The rise of Industry 4.0 and the Internet of Things (IoT) is enabling greater connectivity across packaging lines. Predictive maintenance, machine learning algorithms, and real-time analytics are beginning to enhance efficiency and reduce operational costs even further.

In conclusion, horizontal flow wrapping technology has evolved from a simple mechanized process into a sophisticated, digitally connected solution capable of meeting the ever-changing needs of global industries. Its rich history reflects the broader trends in automation, material science, and consumer expectations, and its future continues to unfold with promise and innovation. Source: https://autopackmachinespvtltd.wordpress.com/2025/07/26/the-history-and-evolution-of-horizontal-flow-wrapping-technology/

0 notes

Text

Industrial Automation Spares Market Size Powering the Backbone of Smart Manufacturing

As industries worldwide race toward smarter, faster, and more resilient production systems, industrial automation stands at the forefront of this transformation. A critical yet often overlooked component within this domain is the Industrial Automation Spares Market, which ensures that operations remain seamless and uninterrupted. From replacement sensors and controllers to valves and circuit boards, these spares are essential to keeping factories running at peak performance.

The global Industrial Automation Spares Market is gaining traction as industries invest in predictive maintenance, cost-efficient inventory management, and reduced downtime strategies.

What Are Industrial Automation Spares?

Industrial automation spares refer to the backup or replacement components used in automated systems, including:

Programmable Logic Controllers (PLCs)

Actuators and sensors

Relays, switches, and drives

Motors and gearboxes

HMI systems and control panels

These spares are vital to preventing unexpected breakdowns, enabling timely replacements, and ensuring continuity in production lines.

Market Growth Drivers

Surge in Predictive Maintenance Adoption

As predictive maintenance becomes a norm in Industry 4.0 environments, the demand for spares rises. Industries are increasingly stocking high-risk components in advance to avoid unplanned downtime.

Expansion of Industrial Automation

The global shift toward automation across sectors—automotive, electronics, packaging, and pharmaceuticals—is directly increasing the consumption of automation hardware and spares.

Digitalization and Smart Factory Evolution

Integration of IIoT (Industrial Internet of Things) and AI-driven diagnostics means faults can be predicted early. Companies are investing in spares to ensure rapid replacement and minimal disruption.

Emphasis on Sustainability

Using spares to extend equipment life aligns with sustainability goals. Instead of replacing entire machines, businesses are opting for cost-effective repairs using high-quality spares.

Key Applications

Manufacturing Plants: Ensuring smooth operation of CNC machines, robotic arms, and conveyor systems.

Process Industries: Like chemicals, oil & gas, and food processing where uptime is critical.

Power and Energy: Ensuring backup for critical components in energy generation and distribution.

Transportation & Logistics: Automated warehouses and sorting systems rely on readily available spares.

Technological Trends Shaping the Market

Digital Twin Technology Simulating machine performance helps predict which parts may fail—prompting advance procurement of spares.

Cloud-Based Spare Parts Inventory Systems Centralized and automated spare part tracking systems for better stock visibility and management.

3D Printing of Spare Parts Additive manufacturing enables on-demand production of critical spares, cutting down lead time and shipping costs.

Modular Spare Components Use of standardized, interchangeable modules is streamlining replacement processes and reducing dependency on OEMs.

Challenges

Counterfeit and Low-Quality Spares: The influx of cheap, low-grade components poses risks to equipment integrity.

Inventory Cost: Maintaining a large inventory of spares requires upfront capital and careful planning.

Compatibility Issues: New system upgrades may render older spares obsolete.

Despite these, smart spare part management and vendor partnerships are driving cost-effective and agile solutions.

Trending Report Highlights

Stay informed with the latest developments across automation and electronics markets:

North America 4 Inches Semi-Insulating Silicon Carbide Wafer Market

Wafer Process Control Equipment Market

3D Snapshot Sensor Market

Thyristor Rectifier Electric Locomotive Market

Microelectronics Material Market

Piezoelectric Materials Market

China Reconfigurable Intelligent Surfaces (RIS) Hardware Market

Structural Components Market

3D Laser Scanner Market

Speaker Market

Outdoor LED Strip Market

Smart Wearables Market

Extended Reality XR Hardware Market

Citizen Band Radio Market

Camouflage Antenna Market

The Industrial Automation Spares Market is more than just a support system—it’s a mission-critical component of today’s smart manufacturing strategy. With rising industrial complexity, proactive spare parts management is no longer optional; it’s essential. Investing in high-quality, readily available spares ensures smoother operations, better asset longevity, and a more resilient production line.

0 notes