#PrototypingSolutions

Explore tagged Tumblr posts

Text

3D Printing Powder Market Growth Fueled By Advanced Material Innovations

The 3D Printing Powder Market is witnessing substantial growth, driven by advancements in powder materials. These innovations are transforming additive manufacturing, enhancing performance, reducing costs, and unlocking new industrial applications.

Evolution of Powder Materials in Additive Manufacturing

Initially limited to a few metals and polymers, the 3D printing powder segment has evolved considerably. Early materials such as stainless steel, titanium, and nylon posed limitations in strength, stability, and compatibility with demanding end-use applications.

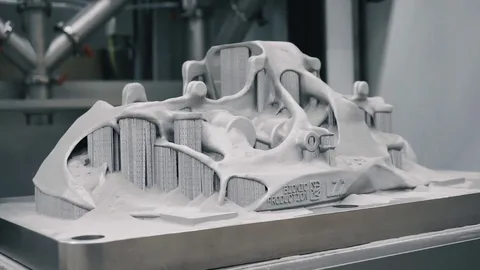

Today, advanced powder formulations include high-performance alloys, ceramics, metal-polymer hybrids, and bioresorbable materials. These new powders offer improved heat resistance, strength-to-weight ratios, and the ability to create complex geometries that traditional processes cannot achieve.

Aerospace Sector Driving Demand

Aerospace remains a major adopter of advanced 3D printing powders. Lightweight yet strong materials are essential in aerospace for improving fuel efficiency and structural durability. Aluminum and titanium alloy powders are now widely used to manufacture turbine blades, engine components, and structural frames.

Nickel-based superalloys are gaining traction due to their excellent mechanical properties at high temperatures. These powders enable the production of precision parts that meet strict safety and performance standards, reducing assembly time and part complexity.

Automotive Industry Expands Use Cases

The automotive sector is increasingly utilizing advanced powders to achieve customization, weight reduction, and faster prototyping. While steel and aluminum remain common, magnesium alloys and carbon-reinforced composites are gaining popularity for their lightweight properties.

These materials allow for the production of lighter chassis components, exhaust systems, and structural parts without compromising durability. Copper-based powders are also being explored for EV applications, offering high thermal and electrical conductivity for powertrain components and heat exchangers.

Growth in Medical Applications

Healthcare is another key industry benefiting from material advancements. Titanium and cobalt-chrome powders are used for orthopedic and dental implants due to their strength and biocompatibility. These materials are corrosion-resistant and safe for long-term implantation.

Recent developments include bioresorbable polymers and ceramic-based powders for bone grafting and tissue scaffolding. Customized prosthetics and implants, printed using patient-specific data, enhance comfort, reduce recovery time, and improve surgical outcomes.

Innovation Through R&D

Research and development are central to the progress of advanced materials. Universities and industrial R&D centers are continuously exploring new chemistries, refining powder morphology, and optimizing flowability—critical for consistent printing.

Nanoparticles are a promising area of innovation. Nano-powders with ultra-fine particles provide better surface finish, mechanical strength, and layer adhesion. Although not yet widely commercialized, they represent the next frontier in high-precision applications.

Focus on Sustainability and Recycling

Environmental considerations are shaping material innovation. Manufacturers are developing recyclable and biodegradable powders to reduce waste and emissions. Many use closed-loop systems to recover and reuse unused powders, maintaining quality while minimizing environmental impact.

Recycled metals are also being integrated into powder production, reducing the carbon footprint of additive manufacturing. These efforts align with global sustainability goals and support environmentally responsible manufacturing practices.

Barriers to Market Expansion

Despite progress, several challenges hinder widespread adoption. Advanced powders are often expensive to produce, which can be a barrier in price-sensitive sectors. Scaling production while maintaining quality requires significant investment in manufacturing infrastructure and quality control.

Certification is another challenge. Industries like aerospace and healthcare demand rigorous validation processes, and the lack of standardized protocols for new materials slows down approvals and market entry.

Future Market Outlook

The future of the 3D printing powder market is promising. Continued innovation in materials will expand possibilities across industries. Strategic collaborations between material scientists, equipment developers, and manufacturers will be vital for commercial success.

Artificial intelligence is expected to play a larger role in optimizing powder formulations for specific applications. By integrating data-driven insights, manufacturers can fine-tune material properties, improve efficiency, and reduce trial-and-error cycles.

As additive manufacturing becomes more embedded in production workflows, demand for high-performance, cost-effective, and sustainable powders will grow. Advanced materials will continue to be the backbone of this evolving market, enabling faster, lighter, and more precise manufacturing solutions.

#3DPrinting#AdditiveManufacturing#AdvancedMaterials#3DPrintingPowders#AerospaceInnovation#Medical3DPrinting#SustainableManufacturing#SmartMaterials#DigitalManufacturing#Industry40#PowderMetallurgy#PrototypingSolutions#ManufacturingInnovation#CustomManufacturing#TechTrends2025

0 notes

Text

Are you tired of traditional manufacturing processes that never seem to meet your specific design requirements? 😩 Create stunning metal parts with us! 💥

Createproto Rapid Systems Limited is your one-stop solution for all of your metal 3D printing needs, whether you work in the automotive, construction, or jewelry industries. We provide a variety of services such as project engineering, innovative design, and production. 🛠️🚗💎

Look no further than our 3D printing services! Our cutting-edge technology allows for precise and customizable solutions, giving you the freedom to make your project ideas a reality. 🌟

☎️ Contact us at +86 180-2532-9092 today to learn more.

Visit: https://www.createproto.com/service/3d-printing/

#3Dprintingservices#prototypingsolutions#innovationindesign#additivemanufacturing#rapidprototyping#custom3dprinting#createproto

0 notes

Text

Recyclable 3D Printing Filament: The Green Future of Printing—Market Growing from $1.2B to $3.8B by 2034

Recyclable 3D printing filament market is projected to grow from $1.2 billion in 2024 to $3.8 billion by 2034, achieving a robust CAGR of 11.6%. This market is centered on eco-friendly filaments crafted from recycled materials, addressing the demand for sustainable manufacturing. These filaments, including PLA and PETG, are derived from post-consumer and post-industrial waste, enabling reduced environmental impact while supporting industries like prototyping, consumer goods, and education.

To Request Sample Report: https://www.globalinsightservices.com/request-sample/?id=GIS11069 &utm_source=SnehaPatil&utm_medium=Article

The growth of this market is fueled by increasing environmental awareness and advancements in 3D printing technologies. PLA (Polylactic Acid) leads the segment, thanks to its biodegradability and user-friendly nature, appealing to both professionals and hobbyists. PETG (Polyethylene Terephthalate Glycol) follows closely due to its strength, durability, and recyclability.

Regionally, North America dominates the market, driven by its innovative ecosystem and adoption of sustainable practices. Europe is a strong contender, with nations like Germany and the Netherlands emphasizing circular economy initiatives. Meanwhile, the Asia-Pacific region is witnessing rapid growth, led by industrialization and investments in sustainable technologies in countries such as China and Japan.

In 2023, the market volume reached 250 million metric tons and is forecasted to double by 2033. The PLA segment held a commanding 45% share, followed by PETG at 30% and ABS at 25%. Companies like Filamentive, 3D Printlife, and ColorFabb are at the forefront, driving innovation and enhancing the recyclability of filament products.

Although challenges such as high production costs and limited consumer awareness persist, the market holds immense promise. Stringent EU regulations on plastic waste management and increasing R&D investments are paving the way for advancements. With AI-driven design optimization and sustainable manufacturing practices, the future of recyclable 3D printing filaments looks brighter than ever.

#3DPrinting #SustainableManufacturing #RecyclableFilament #EcoFriendlySolutions #PLA3DPrinting #PETGMaterials #CircularEconomy #AdditiveManufacturing #GreenTechnology #3DPrintingInnovation #PrototypingSolutions #BiodegradableMaterials #3DPrintingSustainability #EcoInnovation #RecycledFilaments #Industrial3DPrinting #FutureOf3DPrinting #SustainabilityGoals #3DPrintingForGood #PlasticWasteReduction #AdvancedMaterials #TechForSustainability #RethinkPlastics #AIIn3DPrinting #GreenManufacturing

0 notes