#3DPrintingPowders

Explore tagged Tumblr posts

Text

3D Printing Powder Market Growth Fueled By Advanced Material Innovations

The 3D Printing Powder Market is witnessing substantial growth, driven by advancements in powder materials. These innovations are transforming additive manufacturing, enhancing performance, reducing costs, and unlocking new industrial applications.

Evolution of Powder Materials in Additive Manufacturing

Initially limited to a few metals and polymers, the 3D printing powder segment has evolved considerably. Early materials such as stainless steel, titanium, and nylon posed limitations in strength, stability, and compatibility with demanding end-use applications.

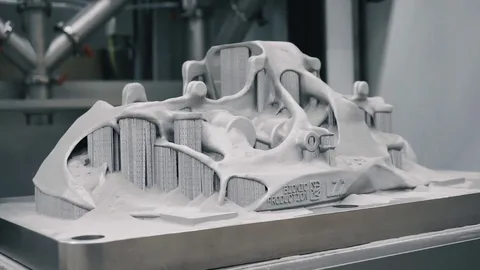

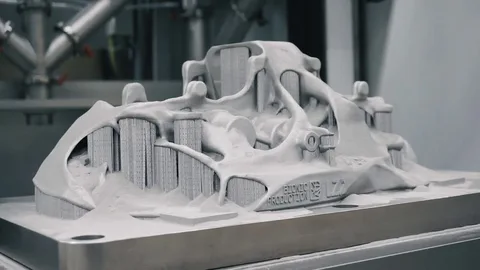

Today, advanced powder formulations include high-performance alloys, ceramics, metal-polymer hybrids, and bioresorbable materials. These new powders offer improved heat resistance, strength-to-weight ratios, and the ability to create complex geometries that traditional processes cannot achieve.

Aerospace Sector Driving Demand

Aerospace remains a major adopter of advanced 3D printing powders. Lightweight yet strong materials are essential in aerospace for improving fuel efficiency and structural durability. Aluminum and titanium alloy powders are now widely used to manufacture turbine blades, engine components, and structural frames.

Nickel-based superalloys are gaining traction due to their excellent mechanical properties at high temperatures. These powders enable the production of precision parts that meet strict safety and performance standards, reducing assembly time and part complexity.

Automotive Industry Expands Use Cases

The automotive sector is increasingly utilizing advanced powders to achieve customization, weight reduction, and faster prototyping. While steel and aluminum remain common, magnesium alloys and carbon-reinforced composites are gaining popularity for their lightweight properties.

These materials allow for the production of lighter chassis components, exhaust systems, and structural parts without compromising durability. Copper-based powders are also being explored for EV applications, offering high thermal and electrical conductivity for powertrain components and heat exchangers.

Growth in Medical Applications

Healthcare is another key industry benefiting from material advancements. Titanium and cobalt-chrome powders are used for orthopedic and dental implants due to their strength and biocompatibility. These materials are corrosion-resistant and safe for long-term implantation.

Recent developments include bioresorbable polymers and ceramic-based powders for bone grafting and tissue scaffolding. Customized prosthetics and implants, printed using patient-specific data, enhance comfort, reduce recovery time, and improve surgical outcomes.

Innovation Through R&D

Research and development are central to the progress of advanced materials. Universities and industrial R&D centers are continuously exploring new chemistries, refining powder morphology, and optimizing flowability—critical for consistent printing.

Nanoparticles are a promising area of innovation. Nano-powders with ultra-fine particles provide better surface finish, mechanical strength, and layer adhesion. Although not yet widely commercialized, they represent the next frontier in high-precision applications.

Focus on Sustainability and Recycling

Environmental considerations are shaping material innovation. Manufacturers are developing recyclable and biodegradable powders to reduce waste and emissions. Many use closed-loop systems to recover and reuse unused powders, maintaining quality while minimizing environmental impact.

Recycled metals are also being integrated into powder production, reducing the carbon footprint of additive manufacturing. These efforts align with global sustainability goals and support environmentally responsible manufacturing practices.

Barriers to Market Expansion

Despite progress, several challenges hinder widespread adoption. Advanced powders are often expensive to produce, which can be a barrier in price-sensitive sectors. Scaling production while maintaining quality requires significant investment in manufacturing infrastructure and quality control.

Certification is another challenge. Industries like aerospace and healthcare demand rigorous validation processes, and the lack of standardized protocols for new materials slows down approvals and market entry.

Future Market Outlook

The future of the 3D printing powder market is promising. Continued innovation in materials will expand possibilities across industries. Strategic collaborations between material scientists, equipment developers, and manufacturers will be vital for commercial success.

Artificial intelligence is expected to play a larger role in optimizing powder formulations for specific applications. By integrating data-driven insights, manufacturers can fine-tune material properties, improve efficiency, and reduce trial-and-error cycles.

As additive manufacturing becomes more embedded in production workflows, demand for high-performance, cost-effective, and sustainable powders will grow. Advanced materials will continue to be the backbone of this evolving market, enabling faster, lighter, and more precise manufacturing solutions.

#3DPrinting#AdditiveManufacturing#AdvancedMaterials#3DPrintingPowders#AerospaceInnovation#Medical3DPrinting#SustainableManufacturing#SmartMaterials#DigitalManufacturing#Industry40#PowderMetallurgy#PrototypingSolutions#ManufacturingInnovation#CustomManufacturing#TechTrends2025

0 notes

Text

3D Printing Powder Market analysis reveals 2025 industry trends and forecasts

The 3D Printing Powder Market is entering a transformative phase as 2025 approaches, driven by innovation, adoption across sectors, and increasing demand for precision manufacturing. This market, crucial to additive manufacturing, is evolving rapidly due to advancements in powder materials and their varied applications in industries such as aerospace, medical, automotive, and consumer goods.

Rising Demand Across Key Industries

The increasing integration of 3D printing technologies in critical sectors is accelerating the demand for specialized powders. Aerospace remains a leading consumer, benefiting from lightweight components and complex part geometries that 3D printing enables. Medical applications are also surging, as biocompatible powders are used for implants and prosthetics. Automotive companies are leveraging powder-based printing for rapid prototyping and lightweight parts that meet sustainability goals.

As industrial adoption scales, so does the need for consistent powder quality, better flowability, and reduced contamination—trends that are shaping powder development strategies globally.

Dominance of Metal Powders

Metal powders dominate the market, with titanium, stainless steel, aluminum, and nickel-based powders seeing high demand. Titanium, in particular, is favored in aerospace and medical due to its high strength-to-weight ratio and biocompatibility. However, the high cost of production and the need for controlled particle sizes continue to challenge suppliers.

Powder manufacturers are investing in atomization technologies to improve particle uniformity. Gas atomization and plasma atomization are becoming standard for premium-grade powders, particularly in high-stakes applications.

Polymer and Ceramic Powder Trends

Polymer powders, especially nylon-based variants, are popular in consumer goods and healthcare due to their flexibility and affordability. Meanwhile, ceramic powders are gaining traction in dental and aerospace applications for their thermal and structural properties.

Research into hybrid powders and composite formulations is ongoing, with the goal of achieving new material properties and expanding the scope of end-use applications.

Regional Market Insights

North America and Europe currently lead the market, with significant investment from aerospace and healthcare industries. The U.S. continues to be a hub for powder innovation, supported by strong R&D initiatives and partnerships between academia and industry.

In contrast, the Asia-Pacific region is emerging rapidly, driven by China, Japan, and South Korea’s investments in manufacturing infrastructure and localized powder production. Government support in these regions is accelerating domestic innovation, making APAC a critical growth driver through 2025.

Forecasting 2025 Growth

By 2025, the 3D printing powder market is expected to exceed previous estimates, thanks to the continued expansion of additive manufacturing ecosystems globally. Market analysts forecast a steady CAGR, with metal powders maintaining the largest revenue share, followed by polymers.

Key factors driving this growth include:

Decreasing costs of powder production

Greater customization in manufacturing

Increasing regulatory acceptance in medical applications

Adoption of digital manufacturing in developing economies

Sustainability and Circular Economy Influence

Sustainability is now a strategic priority. Manufacturers are exploring powder recycling and reuse strategies to reduce waste. Closed-loop systems are being developed to ensure powders can be collected, reprocessed, and reused, especially in high-volume production environments.

Moreover, sustainable sourcing of raw materials is influencing buyer behavior. Companies that demonstrate reduced carbon footprints in powder production are being favored in competitive bidding scenarios, especially by OEMs seeking greener supply chains.

Challenges Ahead

Despite promising growth, the market faces challenges. These include:

High cost of advanced metal powders

Quality control across batch productions

Regulatory hurdles in medical and aerospace sectors

Intellectual property issues in powder formulations

Addressing these concerns will require collaboration between powder manufacturers, printer OEMs, regulatory bodies, and end-use industries.

Innovations and Future Outlook

Nanostructured powders and smart materials are on the horizon. These advancements could bring entirely new capabilities to additive manufacturing, including materials that change properties based on external stimuli. Furthermore, AI-powered quality assurance and real-time powder monitoring systems are expected to become integral to maintaining powder consistency and performance.

The future of the 3D printing powder market lies not just in scale, but in precision and adaptability. As additive manufacturing becomes central to digital production strategies, powder producers must evolve from suppliers to strategic partners in innovation.

#3DPrintingPowder#AdditiveManufacturing#MarketForecast2025#MetalPowders#3DPrintingTrends#PowderMaterials#DigitalManufacturing#AerospaceAdditive#Medical3DPrinting#SustainableManufacturing#APACManufacturing#AdvancedMaterials#3DPrintingIndustry#ManufacturingInnovation

0 notes