#Reinforced Concrete Construction

Explore tagged Tumblr posts

Text

#Rebaring Services#Reinforced Concrete Construction#Welded Wire Fabric#Carbon Steel Rebar#Epoxy-Coated Rebar

0 notes

Text

How Super Rings Enhance RCC Frameworks

TMT steel and TMT rod prices have become two key considerations in construction planning. As structural strength and cost-efficiency dominate industry conversations, one critical element is beginning to stand out—Super Rings.

Understanding Super Rings: The Backbone of RCC Integrity

Super Rings play a vital function in improving the electricity and reliability of Reinforced Cement Concrete (RCC) frameworks. These rings, made from immoderate-grade TMT metal, make certain a stable connection between a number of the vertical and horizontal bars in the framework. This not only enhances load distribution but also provides additional support to the overall structure.

Why Super Rings Deserve a Spot in Every RCC Blueprint

Structures bear harsh conditions—warmth, moisture, weight, and time. The strategic use of Super Rings enhances the sturdiness of RCC additives by using securing joints more tightly. Unlike traditional links or ties, these rings prevent bar displacement and reduce the risk of shear failure, a common problem in high-load zones.

How TMT Steel Shapes the Performance of Super Rings

The effectiveness of Super Rings lies in the material used to fabricate them. TMT metal, recognized for its flexibility and tensile power, brings unrivaled overall performance while molded into reinforcement earrings. This synergy between material and design forms the backbone of highly resilient RCC structures.

Evaluating the TMT Rod Price in Long-Term Construction Planning

Every builder keeps an eye on the TMT rod price, but focusing solely on cost can lead to compromises. Integrating Super Rings may add a slight increase to the upfront investment, but it drastically reduces future repair and reinforcement costs. This makes them a value-driven choice for structural integrity and budget control.

From Skepticism to Consideration: The Shift in Construction Norms

Engineers and architects once overlooked reinforcement rings. Today, they are realizing how Super Rings outperform traditional binding methods. The difference is visible not just in technical reports but also in the lifespan and stability of completed projects. Case studies and field tests continue to validate the decision to adopt them.

Design That Thinks Ahead: The Smart Geometry of Super Rings

The precision geometry of Super Rings provides uniform spacing between rebars, improving concrete flow during casting and ensuring better compaction. This leads to crack-free surfaces and extended life cycles—benefits that far outweigh a slightly higher TMT rod price.

Planting the Seed of Decision: Why Choose Super Rings?

It’s no longer a question of "Why use them?" but "Why aren’t they already in use everywhere?" For any builder serious about long-lasting structures, the choice is clear. With TMT steel and Super Ring integration, structural strength and cost-efficiency don’t have to be trade-offs—they work together.

Whether the goal is a residential high-rise or a commercial complex, Super Rings offer the peace of mind that every joint is reinforced to perfection. The small investment made today becomes a fortress for tomorrow.

Conclusion

Smart construction is about using the right elements in the right way. Super Rings, backed by strong TMT steel and strategic engineering, offer just that. They aren’t just accessories to an RCC framework—they’re essential components of a safe, cost-effective, and durable future.

FAQs

1. Are Super Rings suitable for all types of RCC projects? Yes, they’re adaptable to residential, commercial, and industrial constructions.

2. How does the TMT rod price affect the decision to use Super Rings? While they slightly impact the upfront cost, they reduce long-term structural repair expenses.

3. Can Super Rings be used with different grades of TMT steel? Yes, though optimal results come from higher-grade TMT steel.

4. Do Super Rings help with earthquake resistance? Absolutely. Their strong binding reduces bar slippage, improving seismic performance.

5. How are Super Rings installed? They are factory-made for accuracy and are easily fitted during rebar placement.

#Super Rings#RCC Strength#RCC Framework#Construction Rings#Steel Rings#Reinforced Concrete#Building Strength#Structural Rings#RCC Support#Concrete Rings#Ring Benefits#Super Rings Use#RCC Durability#Frame Reinforcement#Steel in RCC#Construction Tools#Building Safety#RCC Stability#Reinforcement Rings#RCC Innovation

1 note

·

View note

Text

#design#architecture#interiordesign#building#renovation#homedecor#art#builder#artwork#carpenter#rebar#concrete#construction#steel#reinforcement#civil#engineering#concretelife#civilengineering#foundation#rodbuster#steelfixing#teamwork#slab#picoftheday#engenhariacivil#concreteconstruction#concretejungle#instadaily#beton

1 note

·

View note

Text

In the realm of construction, the choice of building materials and techniques plays a pivotal role in determining the durability, strength, and overall quality of a structure. One such method that has stood the test of time is cast-in-situ concrete, also known as cast-in-place concrete. This construction technique involves pouring concrete directly into the formwork at the construction site, where it is allowed to set and cure, forming a seamless and robust structure.

Understanding Cast-In-Situ Concrete

Cast-in-situ concrete is a construction method that involves pouring fresh concrete into a specific mould or formwork at the construction site.

Unlike precast concrete, which is cast and cured in a controlled environment before being transported to the construction site, cast-in-situ concrete is mixed and poured on-site. This method offers a high degree of flexibility, allowing for customization and adaptability to the unique requirements of each construction project.

#construction#construction news#civil engineering#building construction#structural engineering#civil#engineering#reinforced concrete#civil construction#concrete

2 notes

·

View notes

Text

Basalt Fiber Reinforcement in Construction: A Sustainable Paradigm Shift

Introduction In the contemporary construction landscape, a notable shift towards sustainable and eco-friendly building materials is underway. Among the alternatives gaining prominence is basalt fiber reinforcement, positioning itself as a compelling substitute for traditional steel reinforcement. This transition is fueled by a collective desire to reduce environmental impact and elevate the…

View On WordPress

#alternative to steel reinforcement#basalt fiber applications#basalt fiber properties#Basalt fiber reinforcement#basalt mesh in concrete#BFRP composites#construction industry sustainability#corrosion-resistant materials#durability in construction#eco-friendly building#environmental impact of construction#future of construction materials.#green building practices#lightweight construction materials#seismic resilience in buildings#steel replacement in construction#strength-to-weight ratio#Sustainable Construction Materials#sustainable structural design#thermal insulation in construction

2 notes

·

View notes

Text

Famous writer Chetan Bhagat Launches World of Basalt Reinforcement by Mahesh Kumar Jogani

Renowned author and IIT alumnus Chetan Bhagat added his voice to the sustainability movement by launching the book World of Basalt Reinforcement by Shri Mahesh Kumar Jogani at a celebrity-filled event in Mumbai. The event brought together the worlds of literature, engineering, and environmental consciousness under one roof—marking a significant moment in the evolving conversation around sustainability and industrial development.

Lauding the book, Bhagat emphasized its importance in today’s rapidly urbanizing world. “As an engineer, I see this work as not just timely but necessary. Sustainable materials are not a luxury—they are the need of the hour,” he said. He commended Jugani’s deep expertise and dedication to practical innovation in the reinforcement sector, particularly in crack control and structural durability.

A Book That Bridges Sustainability and Technology

World of Basalt Reinforcement introduces readers to basalt fiber—an advanced material derived from volcanic rock. Celebrated for its strength, corrosion resistance, and minimal environmental impact, basalt fiber is emerging as a serious alternative to traditional reinforcement materials like steel and glass fibers.

The book focuses on the synergy between nature and technology. It provides a detailed look at the formation and properties of basalt, followed by real-world applications ranging from Aerospace to automobile. With its clear explanations and real-life insights, the book serves as both an entry point for students and introduction guide for engineers and innovators.

The Author: A Career in Sustainable Innovation

Shri Mahesh Kumar Jogani brings over 20 years of experience to this work. A research engineer by profession and a techno-entrepreneur by passion, Jogani holds multiple patents and has led innovations across composites, industrial reinforcement, and material science. His work consistently emphasizes durability, efficiency, and environmental stewardship.

Jogani is best known for his hands-on approach and commitment to real-world solutions. His focus on crack control in concrete and reinforcement technologies has positioned him as a key voice in the advancement of sustainable construction methods. His belief in the transformative power of basalt fiber is evident throughout the book.

“My aim,” Jogani says, “is to make engineers think differently. Innovation doesn’t have to come at the cost of nature. With basalt, we can have both performance and environmental care and responsibility.” He added “With basalt, we can have both performance and sustainability”.

For more information on this subject please visit www.joganireinforcement.com

Our article also posted in the week channel, please refer this https://english.loktej.com/article/19233/famous-writer-chetan-bhagat-launches-world-of-basalt-reinforcement-by-mahesh-kumar-jogani

#basalt fiber#basalt#building#construction#nature#JOGANIReinforcement#best for crack resistance#best Concrete Fibers#Reinforcement#industrial reinforcement#concrete reinforcement

0 notes

Text

How Construction Rings Strengthened Krupasindhu Commercial Complex – A Case Study

When the Krupasindhu team envisioned their twelve-floor commercial complex in the heart of Maharashtra, one problem loomed large—structural reliability under constant commercial load. Weak foundational systems often haunt developers like bad design haunts good architecture. In this case, the solution came down to a trio of engineering reinforcements: construction rings, hot rolled coil, and bar dowel systems—all critical in keeping the structure rock-solid.

The Risks of Underestimating Structural Load

Commercial buildings face unpredictable stress from high footfall, machinery, and shifting loads. Without the right reinforcement strategy, even the best architectural design falters. Poor quality materials or old-school rebar alignment can't hold up against dynamic movement or expansion-contraction cycles.

This is why choosing high-durability components like construction rings isn’t optional—it’s foundational.

The Krupasindhu Challenge: Going Taller, Safer

Located in a high-traffic zone, the Krupasindhu Commercial Complex needed reinforcement that wouldn’t just meet code—it had to exceed it. The building’s central spine, meant to hold elevators, HVAC systems, and multiple floor loads, demanded a solution that could distribute stress evenly across vertical columns and beam junctions.

This is where SRJ Steel’s construction rings entered the blueprint.

Construction Rings: The Silent Strengtheners

Think of construction rings as the ligaments in a building’s skeleton. They bridge joints and columns, ensuring the entire frame moves as one, not in isolated shivers. In the Krupasindhu project, these rings provided:

Enhanced shear resistance in beam-column junctions

Balanced tensile strength for vertical load bearing

Reduced risk of crack propagation under thermal expansion

More importantly, their precision fit meant faster installation with minimal on-site modification.

Hot Rolled Coil: The Backbone of Flexibility

Let’s talk material quality. The hot rolled coil used in these construction rings wasn’t just any generic steel. SRJ Steel sourced coils known for:

High ductility, allowing structural elements to flex without snapping

Uniform surface finish, which makes welding seamless

Consistent grain structure, ensuring load distribution under varying temperatures

These properties gave the Krupasindhu team the confidence to go taller without compromising lateral stability.

Bar Dowel Placement: Anchoring the Load

A structure is only as strong as its weakest transition. For Krupasindhu, this meant focusing on the slab-to-column transitions and expansion joints.

That’s where bar dowels came into play.

These dowels were strategically placed to:

Absorb and distribute floor load stresses

Prevent slab lifting or separation

Allow controlled movement between concrete sections

They essentially allowed the structure to “breathe” without breaking.

Why the Trio Worked: Harmony in Reinforcement

One part doesn't solve the puzzle. It’s the combination of precision-engineered construction rings, hot rolled coil, and bar dowel systems that made Krupasindhu’s build seamless. Each component played its part in:

Increasing seismic resistance

Speeding up construction timelines

Reducing long-term maintenance costs

That synergy helped SRJ Steel deliver more than just material—it delivered peace of mind.

Lessons from Krupasindhu: Building Beyond the Blueprint

Krupasindhu Commercial Complex stands today not just as another real estate addition—but as a case study in how smart material choices lead to safer, more resilient builds.

And this isn’t just about skyscrapers. Whether it's mid-rise housing, hospitals, or industrial parks, incorporating construction rings, hot rolled coils, and bar dowel connections can mean the difference between mediocre and masterpiece.

Looking Ahead: Smarter Steel, Smarter Structures

Projects like Krupasindhu didn’t cut corners—and it shows. As more developers focus on longevity and structural integrity, the demand for tested reinforcements is rising.

Reinforcement that holds firm when pressure rises? That’s what SRJ Steel’s materials delivered.

Projects like Krupasindhu trust advanced reinforcement solutions—shouldn’t yours?

#Construction Rings#Structural Rings#RCC Ring Uses#Rebar Ring Design#Beam Ring Setup#Ring Beam Role#Ring for Columns#Concrete Ring Bar#Building Reinforce#Site Ring Layout#TMT Ring Bar#Tie Ring Use#Strong Ring Frame#Ring in RCC Work#Joint Support Ring#Load Bearing Ring#Ringed RCC Beam#Reinforced Ring Bar#Steel Ring Design#Column Ring Fixing

0 notes

Text

The Bar Bending Schedule offers the requirements for the reinforcement steel bars that are required for the specific building structure. The Bar Bending Schedule includes different types of reinforcement bars along with different lengths and bends.

All details regarding the reinforcement steel bars need to be included in the Bar Bending Schedule in mm, which are essential in the production of the reinforcement steel bar. The specified information about the angles of the bends and the length between bends also needs to be included in the Bar Bending Schedule.

Effectiveness of Bar Bending Schedule in Construction

Accuracy of the Bar Bending Schedule

The Bar Bending Schedule helps to ensure that the reinforcement has been placed accurately in the beams or slabs.

Efficiency of the Bar Bending Schedule

The Bar Bending Schedule helps to assist the construction professionals regarding the estimation of the appropriate steel quantities, thus, the Bar Bending Schedule helps to minimise the amount of ordered rebars.

Providing guidance to the construction employees

The Bar Bending Schedule provides accurate information regarding the bend, cut or placement of the reinforcements, thus improving the entire construction procedure of the reinforcement steel bars.

Controlling design quality

The Bar Bending Schedule also helps to ensure that the building codes and engineering designs meet the quality standards.

Inventory management feature

The Bar Bending Schedule helps to maintain the steel stocks, thus preventing the excess or deficiency of the steel stocks.

Read more

#concrete#estimating#civil engineering#buildings#construction#design#Bar Bending#Reinforcement#Steel Bars#building structure

0 notes

Text

Extending Concrete Lifespan: The Benefits of Retrofitting

Concrete structures, whether buildings, bridges, or runways, naturally degrade over time due to environmental factors and regular wear and tear. To maintain their strength and durability, retrofitting has emerged as an advanced and effective method of reinforcing existing structures. By incorporating Pre-Mixed Concrete for Construction, retrofitting enhances the lifespan of concrete structures while offering multiple benefits.

Enhanced Energy Efficiency

One of the primary advantages of retrofitting is improved energy efficiency. Advanced retrofitting techniques integrate insulation materials like Ferrofibracrete and Screedmix to boost thermal performance. This helps prevent heat loss and contributes to lower energy consumption, making buildings more sustainable and cost-effective.

Cost Savings and Higher ROI

Retrofitting not only extends the life of a structure but also offers cost-saving benefits. By improving insulation and reducing energy consumption, it helps cut down utility bills. Additionally, a well-maintained and upgraded building increases in market value, ensuring a higher return on investment (ROI) over time.

Compliance with Building Regulations

Retrofitting often utilizes materials such as polypropylene fiber-reinforced concrete or micro concrete, which comply with industry regulations and safety codes. This ensures a hassle-free upgrading process, preventing potential legal and structural issues in the future.

Government Incentives and Support

Governments worldwide recognize the importance of retrofitting and offer financial incentives to encourage its adoption. These include low-interest loans, tax credits, and grants that help property owners reduce the cost burden of strengthening their structures.

Environmental Sustainability

Retrofitting aligns with sustainable construction practices by reducing the need for demolition and reconstruction. By upgrading existing structures instead of replacing them, this technique minimizes carbon emissions and prevents construction waste from piling up in landfills.

Adaptation to Modern Technologies

Retrofitting allows old structures to integrate modern technologies, such as smart lighting control and energy management systems. This ensures that buildings stay relevant, functional, and in line with evolving industry trends and sustainability goals.

Increased Resistance to Natural Disasters

By reinforcing the structural integrity of buildings, retrofitting significantly improves their resistance to natural disasters like earthquakes, hurricanes, and floods. Techniques such as enhanced structural connections and the use of fiber-reinforced concrete help mitigate damage and protect occupants during extreme weather conditions.

Conclusion

Retrofitting is a highly effective and forward-thinking solution for extending the lifespan of concrete structures. It enhances energy efficiency, ensures compliance with regulations, promotes sustainability, and strengthens resistance against natural disasters. At Firstchoice Readymix, we offer high-strength polypropylene fiber-reinforced concrete, like Fibermixcrete, to support your retrofitting projects with superior durability and performance. Choose retrofitting today for a sustainable, cost-effective, and future-proof construction solution.

0 notes

Text

Column Jacketing: Types and Benefits Explained

Column jacketing strengthens columns and improves their load-carrying capacity. Engineers add materials around existing columns to boost their strength, stiffness, and durability. This method helps repair and upgrade structures to meet modern safety standards. Jacketing of columns increases their resistance to seismic forces, making buildings safer during earthquakes. It also improves the…

#building rehabilitation#building renovation#civil engineering#column jacketing#column strengthening#composite jacketing#concrete jacketing#construction repair#FRP jacketing#infrastructure upgrade#load-bearing capacity#reinforced concrete#retrofitting columns#seismic retrofitting#steel jacketing#Structural Engineering#Structural Integrity#structural reinforcement#structural stability#structural strengthening

0 notes

Text

The concrete business is actually very large, with a value of several billion dollars. Concrete makes up the majority of the structures you can see. Concrete, the most often used building material worldwide, serves as the basis for all types of infrastructure.

Due to its flexible and vigorous utilization, its annual manufacturing rate is over a few billion tonnes. Besides forming the very foundation of our infrastructure, concrete is also one of the most widely used construction materials in the world.

Cement, fine aggregates, coarse aggregates, and water are the main ingredients of concrete. You will learn about a few reasonably priced and environmentally friendly concrete aggregate alternatives in the sections that follow. Concrete is more environmentally responsible and sustainable thanks to these substitute aggregates.

A green revolution, or the adoption and introduction of environmentally friendly materials, is urgently needed in construction and other industries in light of the present climatic situation and the phenomenon of global warming.

Few Alternatives for Concrete

Green Concrete Alternative

Using leftovers or waste products from a variety of sectors to produce green concrete can be considered an eco-friendly way to produce concrete that uses less energy during the production process. It is not only cheaper and stronger than conventional concrete but also emits less carbon dioxide than it.

Green concrete is used to reduce the demand for natural resources and enhance reliance on recyclables. Reusing wash water to cut down on water usage is one of the many methods being used to attain sustainability through eco-friendly concrete.

One of the finest methods for producing environmentally friendly construction materials is to partially replace energy-intensive cement with reusable components.

Ashcreate Alternative

Ashcrete is a recycled fly ash-based alternative to conventional concrete. To make fly ash strong and lasting, similar to normal cement, lime and water are added. Fly ash is an environmentally favorable substitute for cement since it may be used in its place, which reduces carbon dioxide emissions.

High-volume fly ash concrete may also replace 25% of the cement. Other advantages of fly ash over conventional concrete include decreased bleeding, higher concrete strength, and decreased shrinkage.

Read more

0 notes

Text

Fiberglass Rebar - The Future of Concrete Reinforcement

Introduction Did you know that corrosion-related damage in reinforced concrete structures costs billions of dollars annually? What if there was a way to eliminate rust completely? Meet Fiberglass Rebar (GFRP) – a revolutionary alternative to traditional steel reinforcement that offers high strength, durability, and corrosion resistance. We will look what fiberglass rebar is, its advantages,…

#Building Construction#Concrete#Fiberglass Rebar#Fiberglass Rebar vs. Steel Reba#GFRP#Green Construction#Rebar#Reinforced Concrete#Steel Rebar#sustainability#Sustainable & Green Construction

1 note

·

View note

Text

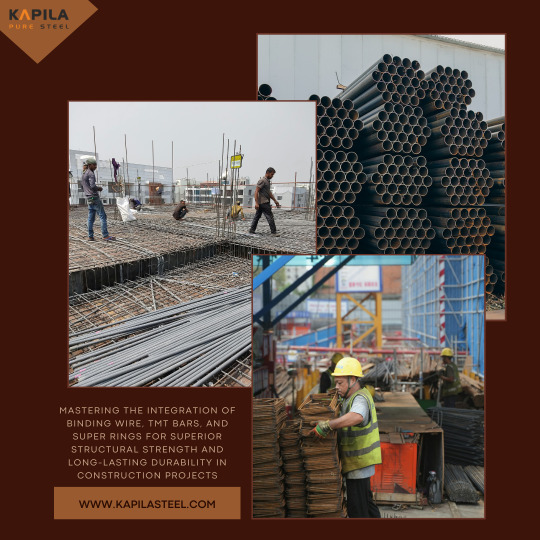

In construction, using the right materials can make a significant difference in the integrity and durability of structures. Binding wire, TMT bars, and Super Rings are essential components that ensure structural stability. This guide delves into how to maximize the effectiveness of these materials in your construction projects. By understanding the synergy between binding wire, TMT bars, and Super Rings, construction professionals can ensure stronger, longer-lasting outcomes. Whether it's for reinforcing structures or ensuring high tensile strength, the right combination of these materials can enhance performance and reduce long-term costs.

#binding wire#TMT bars#Super Rings#construction#reinforcement#steel bars#wire binding#TMT steel#structural wire#coil wire#construction wire#high strength#building material#wire mesh#steel reinforcement#concrete binding#construction rods#TMT wire#project materials#construction strength

1 note

·

View note

Text

#building#design#interiordesign#architecture#homedecor#renovation#art#builder#artwork#carpenter#rebar#concrete#construction#steel#reinforcement#civil#engineering#concretelife#civilengineering#foundation#rodbuster#steelfixing#teamwork#slab#picoftheday#engenhariacivil#concreteconstruction#concretejungle#instadaily#beton

1 note

·

View note

Text

Concrete reinforced with reinforcing materials, usually steel, is known as reinforced cement concrete (RCC). Compressive strength is provided by concrete, and tensile strength is provided by steel. The combination of these materials produces a versatile, strong, and durable building material that can be used for a variety of purposes, including:

Buildings

Bridges

Dams

Tunnels

Roads

Parking structures

Other civil structures

RCC is a combination of compressive strength from the concrete and tensile strength from the reinforcement making it an ideal material for handling a wide range of loads and resisting cracking or failure.

#construction news#construction#civil engineering#building construction#reinforced concrete#civil construction#engineering

2 notes

·

View notes